Welcome to the Australian Steel Institute (ASI) 2024-2025 Year in Review

The ASI is the peak body for the Australian steel industry. We represent the entire local steel supply chain from the individual through to all businesses regardless of size.

Our vision is to influence profitable growth for the complete Australian steel value chain.

Our mission is to promote steel as the material of choice; promote the capability and capacity of the Australian steel supply chain; and provide leadership in advocacy, compliance, safety, sustainability and technical education to nearly 7,000 members and 700 companies nationwide.

Discover how we worked towards these goals this year.

Total members 6,920

Increase in fabricator members 15.2%

Total reach of database 23,714 Corporate members 700

New company members

Attendees at ASI events and seminars 1,462

The Australian Steel Institute (ASI) enjoyed strong activity and membership growth in 2024-2025 in a challenging year for the local steel industry.

ASI membership rose to a record 6,920 members (700 of those corporate members), with our certification schemes Steelwork Compliance Australia (SCA) and Steel Sustainability Australia (SSA) enjoying continued strong growth.

ASI was highly visible on ministerial bodies providing advice to federal and state governments on local content, renewables, green steel and sustainability, and in the media promoting Australian steel as the product of choice. The ramped-up activities reflect a difficult year for the local industry marked by a surge in imported fabricated steel entering Australia, the Whyalla Steelworks going into administration, and US Government’s tariffs impacting local producers.

Nationally, the ASI monitored and responded to the surge in imports by working with an Industry Advisory Group on trade measures. Our briefing paper was well received by the Department of Industry Science and Resources and the Federal Government’s Department of Foreign Affairs and Trade. We are now commissioning expert legal advice to support trade action. These next steps are critical to ensuring the viability of local fabricators in a market under pressure from very low-priced offshore supply.

ASI facilitated key discussions on renewable energy infrastructure in 2024-2025, bringing together members and project developers like ACEN Australia to showcase local capability and capacity. We were engaged by Federal Assistant Minister for Trade and Future Made in Australia Tim Ayres (now Minister for Industry and Innovation and Minister for Science) to advise on increasing local steel content in the renewable energy sector. We continue to believe renewable energy offers enormous potential for the local steel sector—provided local content is embedded in policy and project delivery.

On the compliance front, we’re proud to have promoted the release of WorkSafe Victoria’s 2024 guidance on the

dangers of imported structural steel. This publication highlights the serious risks posed by steelwork that fails to meet Australian Standards, particularly where quality assurance systems are absent. I encourage our members to reference this when tendering—it’s a strong case for choosing certified, Australian-fabricated steel.

We also worked hard to improve regulator and government understanding of how well steel is positioned to support Australia’s economic development in a lower carbon future; and debunk negative claims by competing materials. We promoted the alignment between our industry and the Future Made in Australia program in terms of sovereign capability, skills development, employment opportunities and supply chain velocity of a vibrant local industry.

In Victoria, the ASI was pleased to attend the Steel Industry Roundtable alongside eight ASI-member fabricators, representatives from BlueScope and InfraBuild and then Minister for Jobs and Industry Natalie Hutchins (now Minister for Government Services). This direct engagement followed sustained ASI advocacy and may have helped influence Laing O’Rourke’s decision to award 650 tonnes of structural steelwork for the Eastern Freeway Upgrade to local fabricators Sutcliffe Engineering and Thornton Engineering and commit the remaining steelwork packages to local fabricators. It’s a strong result and a tangible win for local content.

Across the border in South Australia, we secured support from Minister Tom Koutsantonis and the Office of the Industry Advocate for our ASI SA Fabricators Forum, which was held in February 2025.

In Queensland, we engaged with the newly elected state government to reaffirm the previous commitment to mandate SCA certification to AS/NZS 5131 as a prequalification for steel fabricators working on government building projects. Encouragingly, the new government has indicated it is likely to support the adoption of this requirement through the appropriate channels. Looking forward, the ASI will continue to advocate for fair trade, and for the commercial and societal benefits.

In Western Australia, we met with Western Australia’s Minister for Energy and Decarbonisation, Manufacturing and Skills and TAFE, Amber-Jade Sanderson, and Premier Roger Cook seeking strong local content rules.

As always, we thank you—our members—for your commitment to quality and for being champions of the Australian steel industry.

Your support and input, along with the ongoing hard work of ASI staff and the Board, is very much appreciated.

Together, we are building a stronger, safer and more sustainable future.

Mark Cain Chief executive, Australian Steel Institute

“Looking forward, the ASI will continue to advocate for fair trade, and for the commercial and societal benefits of a vibrant and competitive local steel industry.”

Membership support over the past 12 months enabled the ASI to achieve the following significant advances for the Australian steel industry.

• Lobbied government in support of trade measures to protect local fabricators from a surge in cheap imported fabricated steel. The ASI’s submission (which is backed by a survey of members and supporting ABS figures) is being reviewed by the Federal Government’s Department of Industry Science and Resources, and Department of Foreign Affairs and Trade and has resulted in ongoing consultation. A supporting media campaign highlighted the damaging impact of the surge on local fabricators. For details, see: https://www. steel.org.au/what-we-do/advocacy/asi-campaign-onimported-fabricated-steelwork/

• Prepared a pre-feasibility plan for the development of a traceability scheme for monitoring the quality, sustainability and risk-minimised outcomes of steel through its life cycle. For details, see: https://www.steel. org.au/news-and-events/news/asi-releases-traceabilitytech-note-tn017/

• Worked with then Assistant Federal Minister for Trade and Future Made in Australia Tim Ayres (now Minister for Industry and Innovation and Minister for Science) on the development of a local content policy governing renewable projects.

• Welcomed a new Steelwork Compliance Australia (SCA) certification offering in 2025 that includes AS/NZS ISO 3834 certification alongside the existing AS/NZS 5131 scheme. For details, see: https://www. scacompliance.com.au

• Monitored government infrastructure projects where local content is mandated and sought enforcement where regulations/codes were not followed.

• Continued to work with the Australian Government on seeking relief from the Trump administration’s tariffs on steel. For details, see: https://www.steel.org.au/ news-and-events/media-releases/australian-steel-willcontinue-to-seek-relief-from-trump-tariffs/

• Lobbied government in support of a ban on the export of unprocessed scrap steel. The submission to a Senate inquiry highlighted the very high domestic need for unprocessed steel scrap, and the reduced CO2 emissions that result from use of the scrap in both electric arc and blast furnace steel production. The inquiry will release its findings in late 2025. For details, see: https://www.steel.org.au/news-and-events/news/ asi-calls-for-ban-on-unprocessed-scrap-steel-exports/

• Continued to work with the SA Government and administrators on helping to ensure the future of the Whyalla steelworks, which is in administration. For details, see: https://www.steel.org.au/news-and-events/ media-releases/positive-signs-for-whyalla-steelworks/

• Delivered a 15.2% increase in fabricator membership, driven by interest in taking up National Structural Steelwork Compliance Scheme (NSSCS) and Steelwork Compliance Australia (SCA) certification.

• ASI chief executive Mark Cain appointed to the Federal Government’s Green Metals Advisory Panel, a seven-member body providing strategic advice to government on opportunities for a sustainable green metals industry. For details, see: https://www.industry. gov.au/manufacturing/green-metals#meet-the-industrialdecarbonisation-and-green-metals-advisory-panel-3

• Surveyed members on diversity and inclusiveness in the steel industry and summarised the results in a report published and sent to members in late October 2024. For details, see: https://www.steel.org.au/news-andevents/news/gender-diversity-still-an-issue-for-steelindustry/

• Held a Design for Deconstruction (DfD) panel discussion at the ASI annual convention. For details, see: https://www.steel.org.au/what-we-do/focus-areas/ sustainability/design-for-deconstruction-and-reuse/

• Met with Treasury on the Federal Government’s Future Made in Australia legislation.

• Facilitated a meeting with representatives from the Australian Building Codes Board and ASI members to clarify the reasoning behind a number of changes in the National Construction Code (NCC) 2025 Public Comment Draft.

• Initiated a revision of AS/NZS 3500.3 Plumbing and Drainage-Stormwater Drainage to include improved guidance for the design of valley and eaves gutters, which has been a longstanding issue for the metal roofing industry. For details, see: https://www.steel.org. au/news-and-events/news/revision-of-as-nzs-3500-3what-you-need-to-know/

ASI provides support to members through the following focus areas.

Imported fabricated steel

2024-2025 saw a major surge in imported fabricated steelwork into Australia. ASI campaigned to minimise the damaging impact on local fabricators by:

• Exploring trade measures in consultation with the then Federal Minister for Industry and Science Ed Husic, the Anti-Dumping Commissioner, and the Department of Industry, Science and Resources.

• Surveying the local industry to accurately identify those negatively impacted by the surge, essential if trade measures are to proceed. The 2024 survey found a 50% drop in local fabricator business directly linked to very low-priced imports.

• Interrogating ABS statistics and other references to gather background data on the capacity, employment numbers, and economic contribution of the Australian steel fabrication sector to the economy, which is also essential to support trade action.

• Running a media campaign to highlight the damaging impact on local fabricators of the flood of cheap imports.

A major ASI priority in 2024-2025 was championing local content in state and federal government contracts. The work included:

• Consultation with ministers responsible for government procurement to enforce and further tighten regulations specifying local content in government contracts.

• Providing input to government as a member of a select Federal Government panel helping develop

policy on local steel content in government renewable energy projects.

• Providing AEMO Services with a detailed list of ASI members with the capability to supply products and components to NSW Renewable Energy Zone tenders.

• Monitoring government infrastructure projects to ensure contractors are complying with their local content obligations. ASI successfully took its concerns to government and contractors when breaches were identified.

On 20 September 2024, ASI participated in a Senate Inquiry hearing on an ASI proposal to ban the export of unprocessed steel scrap. The ASI submission focused on:

• The damaging environmental impacts of exporting unprocessed steel scrap to other jurisdictions.

• The very high domestic need for steel scrap.

• The reduced CO2 emissions that result from use of steel scrap in Australian electric arc and blast furnace steel production.

The Inquiry will release its findings late 2025. A number of countries have passed legislation restricting the export of steel scrap; an approach ASI is seeking for Australia.

2024-2025 saw a pre-feasibility plan drawn up for the development of a ‘cradle-to-the grave’ traceability scheme for locally made steel. Backed by the ASI Board, the plan will explore a range of tools for checking and auditing the quality, sustainability and risk-minimised outcomes of steel production through its life cycle.

ASI led the steel industry’s drive to achieve sustainable steel over the last 12 months. Key sustainability initiatives undertaken by the ASI in 2024-2025 included:

• Following several submissions to the Federal Senate Inquiry into Waste Reduction and Recycling, ASI called for regulatory controls on the export of unprocessed steel scrap. The ASI position was adopted by the Australian Chamber of Commerce and Industry (ACCI) in its submission to the Federal Government green metals consultation process.

• ASI co-signed a coordinated statement with Ai Group to the Federal Government on the need for climate and energy policy certainty.

• ASI chief executive Mark Cain appointed to the Federal Government’s Green Metals Advisory Panel, a seven-member body providing strategic advice to government on opportunities for a sustainable green metals industry. The panel is a commitment under the government’s Future Made in Australia agenda to support investment in green metals and help the industry decarbonise iron, steel, and aluminium.

• ASI lodged a submission to the Federal Government’s Green Metals consultation process.

• ASI contributed with BlueScope, Liberty GFG, the Organisation for Economic Co-operation and Development (OECD) team, and 70 others to the OECD Green Iron Project: Australia Case Study project. The OECD team visited Australia on 25 November 2024.

• ASI presented to international forum the Climate Club on Inhibitors and Opportunities to Standardisation of GHGe Intensity Measurement. The ASI was the only one of the 39 represented nations invited to speak on the issue.

• ASI met with the Federal Government’s Department

of Industry, Science and Resources, and Treasury, in July 2024 to discuss the major inhibitors, barriers and opportunities for Australia in low emissions steel.

• ASI lodged a second submission to the Climate Change Authority’s carbon leakage review.

• ASI responded to questions raised by the Climate Change Authority on energy use in downstream steelmaking processes.

• ASI welcomed sustainability targets on the Victorian Northeast Link Eastern Freeway Extension and M80 Ring Road completion projects. As presented at a Steel Industry Forum in October 2024, these targets required 40% to 60% of steel volume to be sourced from accredited suppliers with Steel Sustainability Australia (SSA) certification to L1/SSA verified mills.

• ASI committed to common international approaches, practices and aligned standards for measuring GHGe under the World Steel Association Steel Standards Principles for Common International Practices in Measuring GHGe

• ASI continued its role in chairing the Australian Steel Stewardship Forum (ASSF), which includes representatives from BlueScope, InfraBuild, SRIA, NASH and GAA. ASSF achieved good wins on developing policy for embodied carbon in structures.

• ASI has been working on educational tools, seminars and references for total life cycle assessment of steel in structures, including Module D elements.

• ASI invited to the Australian Sustainable Built Environment Council (ASBEC) working group to develop policy for embodied carbon in buildings.

• ASI invited to a panel to discuss decarbonisation at the Australian Chamber of Commerce and Industry’s business summit in Canberra.

The ASI welcomed a new Steelwork Compliance Australia (SCA) certification offering in 2025 that includes AS/NZS ISO 3834 certification alongside the existing AS/NZS 5131 scheme. The expanded scheme:

• Optimises efficiency in the auditing process.

• Improves cost effectiveness.

• Reduces administrative workload.

• Provides the pathway to meet specifications requiring both standards.

The certification under the National Structural Steelwork Compliance Scheme (NSSCS) is JAS-ANZ accredited for both standards. The expansion enables fabricators to better meet quality and safety requirements specified by government departments and the private sector as a prerequisite for tendering for projects.

SCA has 155 companies currently certified, with numbers expected to increase with the new offering to clients.

For details, see: https://www.scacompliance.com.au

ShedSafe is the ASI’s third party accreditation and training program for shed manufacturers, buyers and builders. Buyers purchasing a ShedSafe-accredited shed can be confident in the engineering, steel products and site specifications of the steel shed. ShedSafe activities in the past 12 months included:

• Reviewing working at heights requirements for sheds.

• Upgrading the ShedSafe site check program to provide improved topography calculations and engineers report.

• Developing an ‘AS 4055 wind loads for housing’ option for site check

• Working with members to enable supply of habitable buildings to meet strong demand for a robust class 1a structure (a ‘Shome’).

For details, see: https://www.shedsafe.com.au

The Steel Sustainability Australia (SSA) certification program remains at the forefront of promoting sustainable practices within the steel supply chain. The program continues to assess and certify downstream steel suppliers including fabricators, roll formers and reinforcing processors, while also verifying upstream steel producers against best practice environmental, social and governance indicators.

Now in its third year, the program has achieved a notable 20% increase in registrations compared to last year, with a total of 86 companies and 109 sites now registered. Of these, 78 sites (representing 72%) have successfully attained certification, demonstrating continued commitment to sustainability across the sector. Fabricators continue to represent the largest proportion of registrations, accounting for 57% of total participants, followed by reinforcing processors who make up 24% of registrations.

Additionally, SSA worked closely with the New Zealand Sustainable Steel Council (SSC) to support their application as an approved initiative under the Green Star rating tool, which was successfully awarded to SSC in early 2025.

In 2025 SSA further strengthened its partnerships by working with the Infrastructure Sustainability Council (ISC) and in May was awarded recognition as a Type 1 ISC Approved Environmental Label - the highest rating within the ISC’s Design and As Built Rating tool. This leads the way for SSA clients to supply sustainable steel to a wide range of government and private sector infrastructure projects, including rail, roads, freeways, bridges, tunnels, airports and train stations, seeking IS ratings.

The SSA certification enables ASI members and steel suppliers within the value chain to:

• Demonstrate and provide assurance that their operations meet best practice sustainability standards.

• Enhance operational efficiency while reducing business costs.

• More effectively meet sustainability requirements set by government as part of its drive towards Net Zero carbon emissions.

• Deliver sustainable steel to Green Star and Infrastructure Sustainability Council projects, helping both government and private sector projects achieve their sustainability targets.

With government increasingly specifying IS and Green Star ratings, as well as private sector infrastructure projects and Tier 1 and 2 contractors setting their own sustainability targets, the demand for SSA certification continues to grow. In addition, the introduction of mandatory sustainability reporting and climate-related disclosures further amplifies the need for sustainability credentials.

SSA will continue to work closely with the steel industry, government organisations and private sector stakeholders within the built environment to advocate for a sustainable and responsible steel supply chain in Australia.

For details, see: https://www.steelsustainability.com.au

ASI now has 6,920 total members, with 700 corporate members and 23,714 contacts in the broader ASI community.

This represents a significant increase on last year’s figures, which were 6,370, 611 and 21,865 respectively. 2024-2025 saw the greatest number of new accounts approved in one year, with 121 new company accounts. Our membership retention rate was an outstanding 91%.

Fabricators led the way, making up 59% of all new members. ASI’s compliance solutions Steelwork Compliance Australia (SCA) and Steel Sustainability Australia (SSA) continued to be among the biggest attractions for membership.

With state government departments now specifying AS/NZS 5131 and/or mandating certified fabricators to be used, demand for certification continues to be strong.

ASI fabricator membership increased by 15.2% over the year. Overall, ASI has seen a 252% increase in fabricator members over the past six years.

The ASI marketing and communications team crafted and delivered communication strategies, created content, and managed campaigns across various channels to drive ASI initiatives in 2024-2025. Key initiatives included:

• Designing and promoting a campaign to combat the surge in imported fabricated steel through media releases, news stories and a website landing page. For details, see: https://www.steel.org.au/what-we-do/ advocacy/asi-campaign-on-imported-fabricatedsteelwork/

• Running media campaigns on a range of steel-related issues including calls for a ban on the export of unprocessed steel, and ASI efforts to ensure provisions for local steel content in government and private industry tenders and projects.

• Developing messaging and marketing support for both the Steelwork Compliance Australia (SCA) scheme and ASI to communicate that SCA is now JAS-ANZ accredited to provide certification to both AS/NZS 5131 and AS/NZS ISO 3834.

• Delivering a communications plan and a suite of material to promote awareness of and participation in the Steel Sustainability Awards, the Australian Steel Convention, and the Steel Excellence Awards.

• Designing and publishing a new-look Steel Australia magazine, including a new online version for members and the public with additional news and advertising. For details, see https://www.steelaustralia.com.au/

• Designing and implementing a campaign to raise money for the Dry July campaign for people affected by cancer. ASI and members BlueScope, Orrcon Steel, Southern Steel Group, Liberty Primary, and Ahrens Group participated in the campaign - the first by an industry association. The ASI team and its member teams raised more than $28,000.

Work started in 2024 on an ASI-proposed revision of AS 4100 Steel structures. Various working groups are providing input. AS 4100 sets out minimum requirements for the design, fabrication, erection, and modification of steelwork in structures. ASI’s Dr Peter Key is the drafting leader for the project.

2024-2025 saw development work near testing stage on an ASI-supported AS 4055 Wind loads for housing option for site checks.

A revised version of AS/NZS 3500.3 Plumbing and drainage - Stormwater drainage was published in April 2025. The revisions of this important standard include much-needed clarification on the design of roof valley and eaves gutters, which has been widely welcomed by the metal roofing industry. The project proposal was initiated and funded by ASI roll former members.

ASI is working with roll forming members to progress a long overdue revision of HB 39 Installation code for metal roof and wall cladding. The draft project proposal has been released for public comment.

ASI attended the Steel Research Hub in 2024-2025 to discuss content for a new round of research starting in 2027. ASI continues to chair the Steel Research Hub Advisory Committee.

ASI published Technical Note 018 Ascertaining Compliance of Structural Steel. For details, see: https://www.steel.org. au/resources/tech-notes/

ASI revised the ASI Steel Industry Capability document, which was published as version 3.0. Almost every section has been updated and revised, including new case studies. For details, see: https://www.steel.org.au/about-us/ourindustry/australian-steel-industry-capability-and-capacity/

ASI continued to represent the industry on a wide range of Australian Standards committees in 2024-2025. For details, see: https://www.steel.org.au/what-we-do/representationand-memberships/

2024-2025 saw the ASI provide input to government and receive advice on a range of issues including:

• welding fumes,

• regulation of hexavalent chromium,

• building collapses and

• crane licencing.

Of key interest to ASI fabricator members and circulated to them for use as collateral when tendering for work was a WorkSafe Victoria safety alert warning of the need to have proper quality assurance systems in place to determine reliability of imported steelwork. Not ensuring the imported steelwork meets Australian Standards may result in catastrophic structural collapse, the safety alert warns. For details, see: https://www.worksafe.vic.gov.au/importedstructural-steelwork

ASI also played a key role in crane safety after accepting an invitation by the Australian Chamber of Commerce and Industry to represent it on the Safe Work Australia Crane Licence Review Working Group. As part of that project, ASI distributed and collated a survey on improving crane licensing under the model work health and safety laws to the ASI Distribution Council and ASI manufacturing and fabricator members.

ASI was integral in providing technical assistance to the Victorian Building Authority (VBA) in its ongoing investigation into the collapse of the Kew Recreation Centre. For details, see: https://www.steel.org.au/news-andevents/news/vba-charges-building-company-adco-groupover-kew-roof-collapse/

ASI has a strong focus on promoting steel as a career path. In 2024-20225, this included:

• Developing online resources to attract and educate young people regarding career pathways, qualifications and emerging roles in the steel industry.

• Partnering with members attending school careers expos to educate careers advisers, parents and students.

• Interviewing five Icon Metal employees about their careers in steel for educational videos on the ASI website. The videos built awareness for school students interested in a career in steel.

• Meeting with Illawarra and Shoalhaven Workplace Learning (ISWLP) to explore work experience for high school students. Twelve local businesses were approached by the ASI to host students, with two taking up the offer.

• Meeting with the Department of Education NSW (Regional Industry Education Partnerships Programs) and other relevant bodies (Manufacturing Skills Queensland, Manufacturing Industry Skills Alliance) to discuss issues like barriers to apprenticeships and future workforce planning.

• Meeting with the Australian Construction Modellers Association (ACMA) secretary to discuss the career paths for steel detailers and construction modellers.

• Becoming a member of the People Committee of worldsteel (PeopleCO).

• Continuing to offer job placement opportunities in steel through the ASI’s jobs website.

• Recognising Ashish Tiwari’s amazing academic journey from Butan to Australia with an ASI undergraduate steel design award at Western Sydney University. For details, see: https://www.steel.org.au/news-and-events/news/ winner-of-asi-western-sydney-uni-steel-design-award/

ASI welcomed 1,462 attendees at ASI events, webinars and seminars throughout the year. A total of 524 people downloaded eLearning courses. Activities included: Webinars

• Forensic Engineering Failure Investigations of Steel Structures for Legal Proceedings by forensic engineer Dr David Tawfik. More than 200 people tuned in to hear common non-compliances encountered for fabricated structural steelwork and the resulting legal obligations for builders, engineers and fabricators.

• Slabs, Footings and Tiedowns for Sheds. Jointly presented by Scott Munter and Eric Lume from the Steel Reinforcement Institute of Australia and Dr Jessey Lee from the Australian Engineered Fasteners and Anchors Council. It attracted more than 100 registrants.

• Ascertaining the Compliance of Structural Steel and Fabricated Steelwork presented by Dr Peter Key. The seminar attracted more than 50 registrants and covered the content in the current Technote TN015 on structural steel and the new Technote TN018 on structural steelwork.

• Life-cycle driven design of steel structures delivered over two days by Alper Kanyilmaz, the Associate Professor Department of Architecture, Built Environment and Construction Engineering, Milano University, Italy.

• Optimising the specification and use of protective coatings to save time, cost and the environment (sponsored and funded by AkzoNobel).

• ASI’s Dr Peter Key’s presentation on Bolting of Steel Structures (Hobson Engineering the technical partner).

• A nine-week course on Structural Steel Fabrication and

Welding for Engineers featuring guest presenters, a visit to SRG Global and hands-on welding delivered by TAFE.

Professionals continue to seek access to ASI’s world class extensive list of over 20,000+ steel related resources. 20242025 saw more than 900 books sold (eBooks and hard copies) and 700 library enquiries The website had 637,000 page views, with the industry directory the most viewed page (engagement rate on the directory is up by 74.7% after a restructure). The new-look Steel Australia magazine had 16,000 views in its revised online form.

Five online eLearning courses were added to the ASI eLearning program, bringing the total to 74. A total of 524 people downloaded courses since 1 July 2024. The most popular was the free welding safety course followed by the site inspection courses. There are a further six courses in the pipeline: Induction to Basics course revamp, two sustainability courses, two webinar to eCourse conversions and a course on Bolting Standards for Supervisors

The ASI annual convention brings ASI members together each year to share stories and explore latest development and innovations in the steel industry. Planning is underway for the ASI’s 2025 annual convention, to be held at the Manly Pacific Hotel in Sydney on September 15-17. Key sessions will focus on:

• Green steel and the path to decarbonisation.

• The smart steel revolution: harnessing technology for a competitive edge.

• Navigating global markets: resilience and adaptation in a changing trade landscape.

• Building Australia: infrastructure, innovation, and steel’s role in national development (case studies).

• Powering the future: energy, efficiency, and the steel industry’s energy transition.

For details, see: https://www.steel.org.au/news-and-events/ steel-convention-2025/.

The ASI takes pride in recognising the achievements of its members. Initiatives undertaken in 2024-2025 to recognise such achievement include:

• The ASI Steel Excellence Awards. Held in 2024, the awards showcased Australia’s best and brightest steel designs. State and territory winners competed in six categories for awards presented at a gala end-of-year dinner at Doltone House in Sydney. For details, see: https://www.steel.org.au/asi-awards-portal/

• The ASI Steel Sustainability Awards. Entries are currently being taken for the 2025 awards in three broad focus areas: projects, companies and people. For details, see: https://www.steel.org.au/asi-steelsustainability-awards-2025/.

• ASI-sponsored academic awards presented to students at state and territory universities.

• ASI-nominating projects for international awards. In 2024, an ASI-nominated project was named best project at the World Steel Association’s 2024 constructsteel Awards in Charlotte, North Carolina. The Sydney Modern project – a winner of the large projects over $10m category in the ASI 2023 Steel Sustainability Awards - was recognised for its innovative efficiency and design practices, most notably its 54% reduction in whole of life carbon emissions by harnessing renewable energy sources. For details, see: https://constructsteel.org/news/constructsteel-awards/

• Sponsorship of the annual WorldSkills competition, which sees apprentices in steel and other professions compete in local and world competitions.

• Membership of the World Steel Association (worldsteel).

The ASI represents the whole of the Australian steel chain.

Its members include founding and sustaining members that provide substantial financial support, and 7,000 members and 700 companies that:

• Manufacture raw steel or are engaged in Australia in steel product manufacturing or roll-forming steel finished products (manufacturers)

• Warehouse, process, sell and/or distribute steel products and are appointed distributors for one or more ASI manufacturer members (distributors)

• Fabricate steel structures, vessels, pipelines or any other form of steel fabrication (fabricators)

• Engage in architecture, structural engineering, steel detailing, quantity surveying and/or project management (professionals)

• Supply equipment, consumables and/or services to manufacturer, service centre or fabricator members (associates)

To find out more about ASI members, see: https://www.steel.org.au/become-a-member/

AustralianSuper has renewed its corporate partnership for a further three years. The superannuation fund is a valued partner, with the offering to members now in its 12th year. Meetings in December reviewed all the agreed activities, with a further meeting this year confirming a program for the next three years. AustralianSuper is a major supplier of superannuation products for the steel supply chain. The ASI welcomes the continued relationship, providing ASI members important updates on superannuation legal requirements and products to meet industry and individual’s needs. For details, see: https://www.steel.org.au/about-us/corporate-partners/

ASI has recently worked with Choice Energy to improve the offering to ASI members, which provides discounted energy plans and solar installations for members. These services have not only provided many members with huge savings to date but can also assist in meeting sustainability targets. For details, see: https://www.steel.org.au/about-us/corporatepartners/

Membership support over the past 12 months enabled the ASI to achieve the following significant advances for the Australian steel industry.

• Compiled a list of local steel producers, fabricators, and manufacturers capable of supplying wind, solar, transmission, and pumped hydro componentry and infrastructure to use as a checklist when evaluating the tenders for energy supply projects under the NSW Renewable Energy Sector Board Plan. For details, see: https://www.steel.org.au/Membership/media/ Australian-Steel-Institute/PDFs/NSW-Steel-SupplyChain-Capability-Reference-List-160425.pdf

• Delivered the annual steel construction lecture to the civil engineering class at the Australian Defence Force Academy on 12 August, 2024. The lecture included additional special content on architecturally exposed structural steel and façade systems relating to this year’s student project, which is a brownfield redevelopment of the Officers Mess facilities.

• Presented to an inquiry into the procurement practices of government agencies in NSW and its impact on the social development of the people of NSW. Six of the eight members of the upper house Standing Committee on Social Issues were present and asked questions.

• Explored opportunities with homebuilding businesses for steel-intensive affordable first homes.

• Upgraded the architecture of the Designing to NCC 2022 ASI webpage to improve the navigation features and ease of finding information. For details, see: https://www.steel.org.au/what-we-do/focus-areas/ designing-to-ncc-2022/

• Carried out a review of NSW State Government agencies that specify either AS/NZS 5131 or AS/NZS ISO 3834.

• Engaged with the Victorian Department of Energy, Environment and Climate Action (DEECA) to gain better visibility of government-funded renewable energy projects and gain an understanding of the Victorian Energy Policy and Investment Overview.

• Participated in a Steel Industry Forum organised by the Office of the Local Jobs First Commissioner on the Suburban Rail Loop (SRL) Project which highlighted 92% local content requirements and identified steel tonnage requirements for the initial SRL East Main Works package.

• After disappointingly discovering that 11,000 tonnes of fabricated steel bridge girders were being sourced from overseas by the main contractor Laing O’Rourke for the Bullen flyover, persistently raised concerns initially from April 2024 to September 2024, and then at a steel industry forum on the project hosted by Laing O’Rourke in October 2024, and again in November 2024 at a Steel Industry Roundtable with the Victoria Government.

• Coordinated a steel industry roundtable with the Victorian Minister for Jobs and Industry, eight ASI Victorian fabricators, and steel producing mill representatives from BlueScope and InfraBuild/Liberty GFG.

• In January 2025, as recommended by the Local Jobs First Commissioner, re-engaged Laing O’Rourke, who advised ASI that they will work to procure all remaining steel work packages for the Eastern Freeway Upgrade from local fabricators.

• Distributed to ASI Victoria fabricators a formal ASI letter regarding WorkSafe Victoria’s guidelines on imported structural steelwork so that it can be used by local ASI fabricators as an attachment with their tender bid for projects to the builders/main contractors and clients when competing against imported fabricated steelwork.

• Attended the 2024 Monash University Civil Engineering Annual Awards and presented the Steel Excellence Awards and eLearning voucher to the winner of the ASI Undergraduate Award.

• Discussed with Queensland Government representatives the commitment by the previous government to require SCA certification of steel fabricators to AS/NZS 5131 as a prequalification to work on government building projects. It was confirmed that the new government will likely support the progress of the commitment through the normal government protocols.

• Communicated with Manufacturing Skills Queensland (MSQ) regarding sharing of information on training, with the intention of gaining MSQ support for ASI initiatives. Joined the Engineering Skills and Training Industry Reference Group (IRG) at MSQ.

• Presented lectures on economical structural steelwork to third year engineering students at James Cook University, the Queensland University of Technology and the University of Southern Queensland.

• Held the ASI Steel Scholarship for 4th year University Students with support from Professor Mahen Mahendran and his team at the Queensland University of Technology. The successful scholarship winner Julian Alber received a $10,000 scholarship. With the support of the scholarship sponsor Orrcon Steel, Julian undertook a thesis on Screw in Steel Piles (SiSP) for residential and light commercial applications.

• Coordinated visits by Aaron Johnstone, Queensland Renewable Energy Jobs Advocate to local steel fabrication workshops to discuss support for local fabrication jobs. ASI’s focus to support local jobs is for the Queensland Government to put in place a local content scheme that specifies a minimum percentage of Australian milled and fabricated steel for renewable energy projects where government has control or influence of the procurement process.

• Prepared a submission to the Queensland Productivity Commission calling for the Queensland Government to introduce a Queensland Local Steel Procurement Framework tied to public works projects that mandates a minimum percentage of locally milled and fabricated steelwork in government-funded construction.

• Attended a Meet the Buyer event organised by the South Australia Office of Industry Advocate and engaged the Office of Northern Water Delivery, Office of Industry Advocate, Office of Hydrogen Power and Housing Authority to promote the local Australian steel supply chain.

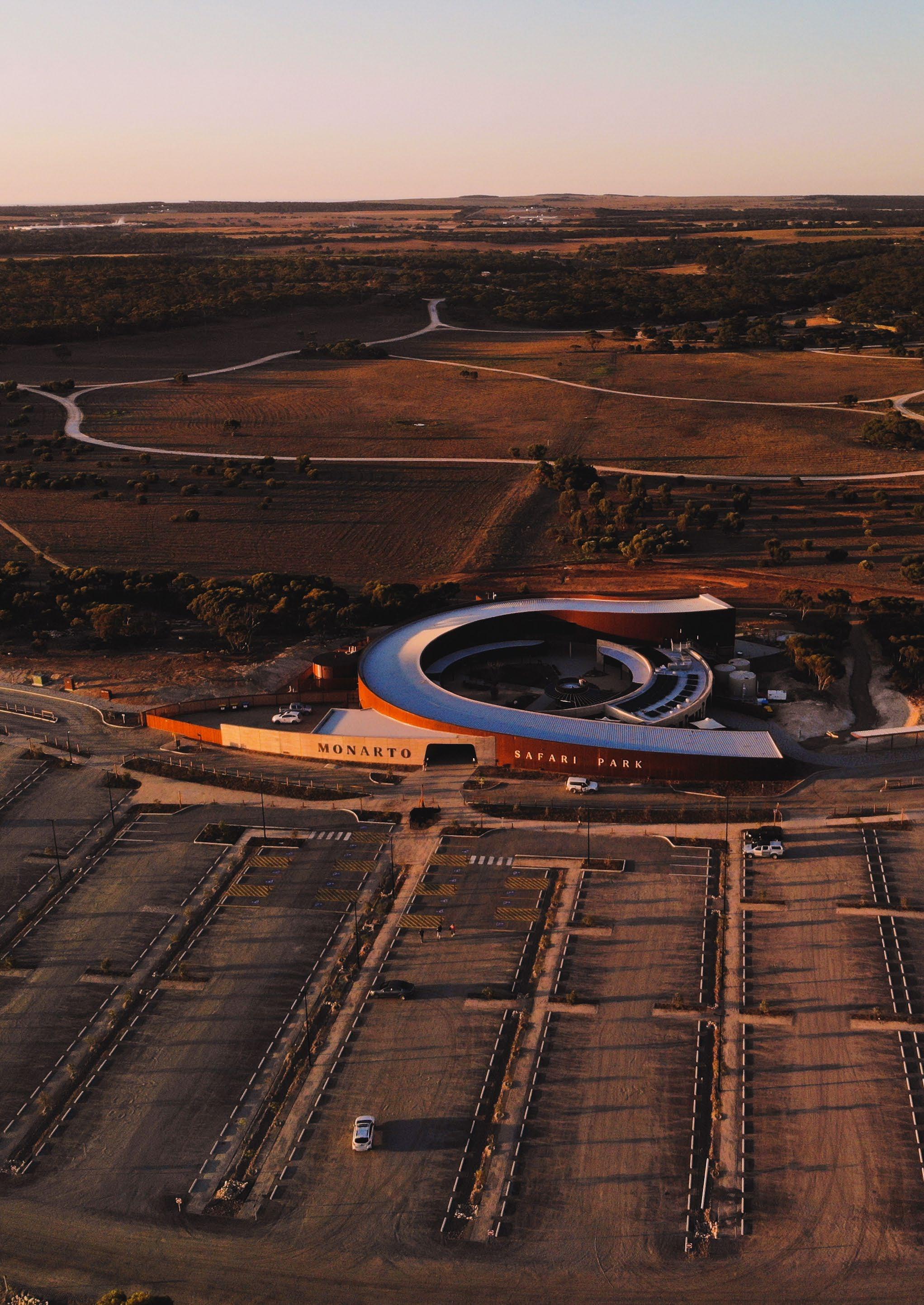

• Held a successful ASI South Australia Fabricators Forum with Minister for Infrastructure and Transport and Minister for Energy and Mining Tom Koutsantonis together with Industry Advocate John Chapman and Deputy Industry Advocate Phillip Dowsett. There were 52 attendees representing 25 local businesses (ASI South Australia members) and the South Australia Government (Minister’s Office, Department for Energy and Mining, Office of the Industry Advocate, Department for Education).

• Continued to lobby the Office of the Industry Advocate for stronger local steel and fabrication content for South Australia Government-funded projects via a Tailored Industry Participation Plan for steel.

• In conjunction with the Department for Education, ASI connected Findon Technical College with ASI South Australia fabricator members, some of whom provided work experience to the Year 10 and 11 Findon Technical College students. As a result of this initiative, ASI fabricator members have taken up new apprentices from Findon Technical College.

• Successfully set up an exhibitor stall as part of the Department of Education’s Student Pathways and Careers Hub at the Adelaide Careers and Employment Expo. The ASI was supported by several South Australia members at the stall, engaging with the student attendees to promote career pathways in the local steel industry and any potential recruitment opportunity for their respective businesses.

• Met with Western Australia’s Minister for Energy and Decarbonisation, Manufacturing and Skills, and TAFE Amber-Jade Sanderson, and the Premier Roger Cook seeking strong procurement rules that ensure subcontractors use local supply chains. Talking points included Made in WA policy, WA Jobs Act (2017), WA Industry Participation Strategy and WA Local Manufacturing Investment Fund.

• Ongoing consultation continues with the Western Australia State Government regarding traceability and the Federal Government’s guidelines document. The state is investigating the role of traceability in decarbonisation and the circular economy.

• Western Australia’s wind farm development is at a crossroads with onshore and offshore both facing protests and urgent demand from new industrial developments such as the Murchison Green Hydrogen Project. ASI has advised the government that steel supply is critical for the state’s ambitions and original equipment manufacturers should be encouraged to engage with the industry.

• Met with government to discuss local content in infrastructure projects.

• A site visit was organised by the ASI to the Boorloo Bridge (Causeway Pedestrian and Cyclist Bridges Project) project for 10 engineers. The bridge is designed in REDCOR® weathering steel supplied by BlueScope, with design by WSP and fabrication by Civmec.

• Addressed issues with project specifications and promoted certification through the Steelwork Compliance Australia and Steel Sustainability Australia schemes.

• Supported decarbonisation through renewable energy projects for steelmaking.

2025-2026 is shaping as an exciting but challenging year for the ASI and the steel industry.

Key priorities for the ASI in the coming 12 months will be:

• Protecting local fabricators from the surge in very lowpriced imported fabricated steelwork through trade measures.

• Supporting a new AS/NZS ISO 3834 certification process to join AS/NZS 5131 certification under an expanded Steelwork Compliance Australia (SCA) scheme.

• Implementing a new traceability system for steel products.

• Engaging with governments on renewable energy projects.

• Advocating for local steel content in government and private industry contracts, and monitoring contracts to ensure local content regulations are enforced.

• Promoting the Steel Sustainability Australia (SSA) scheme to provide pathways for members to meet sustainability requirements in their projects.

• Representing on Australian Standards committees.

• Protecting and growing Australian steel by supporting the Australian Resources Recovery Council initiative to restrict the export of unprocessed scrap.

• Promoting steel as the preferred building material.

• Engaging with government and industry to discuss specific industry matters.

Are you taking advantage of your ASI member benefits?

Advocacy at all levels of government to advance the cause of Australian steel

Member discounts on publications, eLearning, seminars, events and more

Superior technical advisory services, delivered by experienced industry experts

Opportunities to participate in committees and groups to address industry issues

Regular industry news and steelAustralia magazine and Steel Construction Journal

For corporate members, promotion in the ASI Directory, steelAustralia magazine and use of the ASI logo

Countless other benefits from joining and networking with a community of like-minded companies and people

steel.org.au 02 8748 0180 enquiries@steel.org.au