2 minute read

Multi-Functional and Versatile: The Ficep Drilling and Coping Line

MULTI-FUNCTIONAL & VERSATILE: THE FICEP DRILLING & COPING LINE

Modern steel constructions are built with profiles (beams, U sections, angles, tubes and so on) which are welded or bolted to shape the final structure. In addition to drilling and milling, straight, mitered and shaped tilted cuts are required on the profiles web or along the flanges to ensure the necessary geometries.

Advertisement

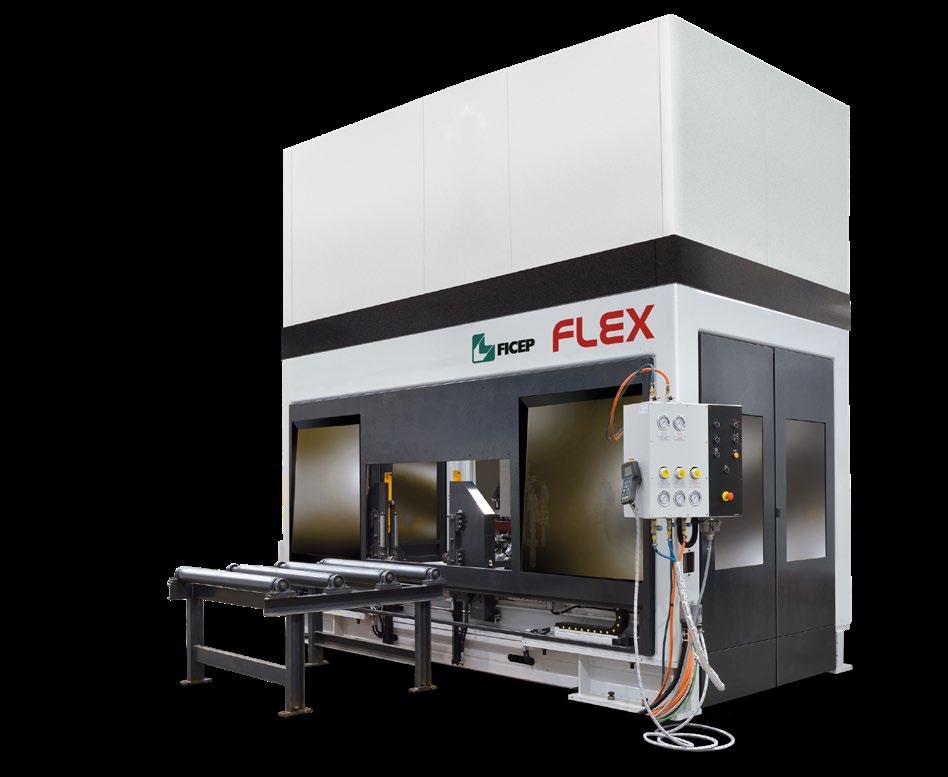

Scribing and layout marking are automatically generated to facilitate the assembly process and to avoid human errors. All these operations are efficiently performed by the FICEP drilling line VALIANT combined with the coping robot FLEX.

Multi-functionality and versatility are the most appreciated features of VALIANT, FICEP latest technological evolution for drilling operations of profiles for the steel construction industry. VALIANT is a drilling, milling and scribing system for the processing of profiles up to 1,200mm that is able to cover the entire required series of operations for the steel construction industry.

VALIANT has a robust structure and has been designed to support intensive manufacturing cycles. In terms of productivity, the new FICEP Direct Drive spindles have a crucial role as the 100% of the 31kW motor power is automatically transferred to At the machine infeed, the geometry of the piece is detected by a laser system. The real geometry of the piece is then compared to the virtual geometry included in the machine's CNC library. If differences are detected, the torch cycle is automatically corrected in order to compensate for any discrepancies. This ensures precise torch positioning at the beginning of the cycle, and throughout the enstire cutting process.

The shape to be processed is selected from the library but only the real dimension detected by the laser is loaded in the machine program.

the tool allowing even more elevated performances, and matching the highest expectations in terms of resistance and torque.

As for other FICEP lines, in addition to the longitudinal movement of the beam, a 300mm auxiliary stroke can be added to each head. This allows the spindle to process numerous operations, such as special millings and rat holes on the fixed beam, without having to move the material.

Thanks to the integration between the VALIANT line and the coping robot FLEX, FICEP is able to provide turnkey, fully integrated drilling and coping lines. These lines ensure that high quality processing can occur, without any kind of action from the operator.

The FICEP coping robot allows the torch to be moved and orientated around the profile. An automatic torch tool changer affords rapid selection of the type of torch required for cutting operations (oxy or plasma torch) so that the operator can easily proceed with the most efficient cut, based on the profile to be processed.

The FLEX robot is controlled by dedicated software that optimises its movements, ensuring the best possible cutting sequence. Both VALIANT and FLEX benefit from FICEP's internally developed CNC: Pegaso. This ensures the best possible performance and a relevant time cycle reduction. Pegaso is designed with a powerful processor, enhanced data storage, up to 15 controlled axes and more communication protocols (Canbus, Profinet, Ethercat) and comes complete with innovative offline programming software Office Technology Central, which is very user friendly.

This article was supplied as part of a paid advertising package.