5 minute read

Precise Steel Detailing is Critical for Complex Projects

STEEL DETAILERS PLAY AN ESSENTIAL ROLE IN THE CONSTRUCTION CYCLE, FACILITATING COLLABORATION, COMMUNICATION, AND COOPERATION BETWEEN ALL PROJECT STAKEHOLDERS, PARTICULARLY ENGINEERS, ARCHITECTS AND FABRICATORS. QUALITY STEEL DETAILERS CAN CREATE 3D MODELS THAT PRODUCE DETAILED ERECTION PLANS, SHOP DRAWINGS, NC EXPORTS, REPORTS, AND OTHER DOCUMENTATION FOR USE BY STEEL FABRICATORS AND ERECTORS DURING MANUFACTURING AND INSTALLATION.

Precise structural steel detailing confirms that a structure is not only geometrically correct, but that it is constructible and erectable, and that fabrication is practical. Precise steel detailing also helps to avoid project delays and costly rework or replacement. All these benefits are particularly pertinent for complex projects in which miscalculations or human error can compromise its viability, safety, and structural integrity.

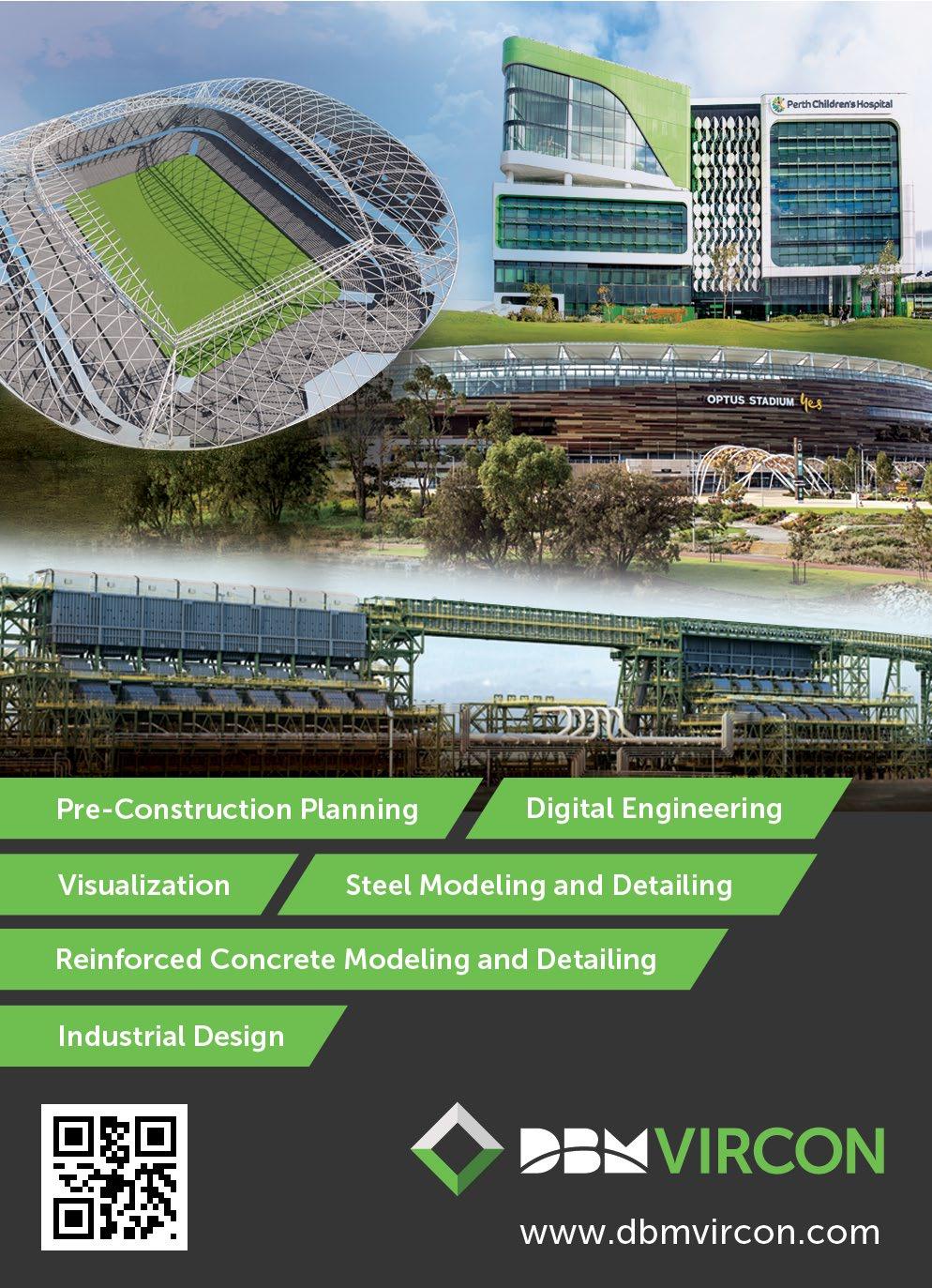

Advertisement

AVOID PROJECT DELAYS, REWORK AND REPLACEMENT

Prefabricated steelwork might be transported to a construction site hundreds or thousands of miles away. If this steelwork arrives on-site and is found to be incorrect, expensive rework may be required. Or, in the worst-case scenario, complete replacement might be the only course of action.

Rework and replacement of structural steelwork can be incredibly expensive, cause severe project delays and shut down a construction site altogether. Multi-discipline 3D model coordination, incorporating all construction services, delivers fully integrated clash detection capabilities to resolve delays and rework. Interactive development streamlines the design process by checking fit-up and resolves design discrepancies and intent before the final phase of the geometry lockdown.

CONFIRM ERECTABILITY AND CONSTRUCTIBILITY

Structural steelwork must fit together perfectly. However, it must also be erectable; once on-site, there must be enough space to erect or swing the steelwork into place. For example, if a beam needs to be installed between two members, but the ends are tucked in between the two flanges and it runs close to the web of those two beams, it will not be easy to erect the beam—unless it can be dropped between the two flanges and then swung around.

VERIFY DESIGN INTENT

Preconstruction modeling and planning can allow stakeholders to visualize a design concept, which improves communication and cooperation between all project stakeholders.

Precise structural steel drawings can help verify that design intent has been accurately interpreted, and that fabrication deliverables have been created in accordance with the design intent.

PROVIDE COST AND SCHEDULE CERTAINTY

On large-scale projects, cost and scheduling requirements are integral. Accurate steel detailing is essential to meet these benchmarks and ensure costly mistakes are detected early on. This means that the potential for rework delays, or even complete site shutdowns, can be avoided altogether.

Integrated design processes help ensure cost and schedule certainty by removing unnecessary design and shop detailing duplication and offer real-time project updates that allow all project stakeholders to be proactive throughout all stages of the project and accelerates the transition from conceptual design to fabrication level modeling.

HELP TO CREATE A DIGITAL TWIN

When this level of steel detailing precision is combined with early project involvement, it allows for the creation of a digital twin: a dynamic, 3D model of an asset. DBM Vircon can utilize the BIM models created during construction to build a single consolidated model—a digital twin—for use in long-term facility management.

Image: The $830 million Sydney Football Stadium is a modern, world-class venue. DBM Vircon supplied shop detailing services for the stadium roof structure and site temporary works steelwork. There are many moving parts in assets such as power stations, mine sites, stadiums, and buildings, all of which require constant maintenance. Having a live model that reflects the real world helps simplify and streamline the ongoing management and maintenance processes of these assets. A virtual walk-through of assets can be used for training purposes, as well as rapid problem resolution. Shutdowns are safer due to pre-planning and animated rehearsals facilitated by the digital twin.

CONCLUSION

Quality structural steel detailing services are vital in complex projects. They help ensure that the fabrication process flows seamlessly. While it only makes up 2-4% of the total steel package costs on a project, poor steel detailing could cost millions of dollars in fabrication rework and schedule delays. Precise steel detailing means there is no need to halt fabrication to confirm missing details or dimensions, the construction timeline is expedited, and costs can be reduced.

By investing in quality detailing undertaken by a partner like DBM Vircon, the enhanced constructibility of a project pays for itself many times over. DBM Vircon provides precise and accurate modeling and detailing to verify all elements of a steel structure, and avoid any unnecessary expenditure on additional labor and materials.

This article was supplied as part of a paid advertising package.

MAKING RENEWABLE ENERGY MORE SUSTAINABLE

Allthread’s Australian-made windturbine anchor cages have numerous advantages over imported alternatives. They’re quicker, safer and easier to install, and cheaper when the entire cost is included. Their environmental performance is also significantly better, with a recent independent Life Cycle Assessment finding the carbon footprint of Allthread’s cages to be around half that of their overseasmanufactured counterparts.

Pangolin Associates’ Life Cycle Assessment compared the environmental impacts of Allthread’s innovative, locally made and assembled anchor cages to that of similar cages manufactured in China and flat-packed to the site. Allthread’s cages had many significant benefits, including a 48% lower carbon footprint, and reductions of 133% and 89% in ozone layer depletion and minerals resources consumption, respectively.

"We are thrilled to receive these results," said Simon Preston (Group General Manager, Allthread Industries). "This expert report shows there are huge environmental advantages to using locally-manufactured wind farm components, on top of the compelling construction and financial benefits."

The exceptional environmental performance of Allthread’s anchor cages is due to several factors. The cages are made in Western Sydney using predominantly Australian materials, dramatically reducing emissions from shipping and other transport. Half of the factory’s electricity comes from solar power, further reducing greenhouse gas emissions. Allthread prioritises the use of both Australian and recycled material, reducing the environmental impact of transporting and manufacturing components.

Allthread pioneered the approach of preassembling anchor cages and delivering them to site, reducing the cages’ environmental impact and making them faster, easier, safer and more reliable to assemble. Allthread’s method dramatically reduces on-site assembly time, with the average cage taking less than four hours. In contrast, imported cages are shipped as flat packs from overseas and assembled on site from scratch, taking around 100 hours.