STRENGTH IN AHRENS’ STEEL AHRENS’ SOLID INVESTMENT DECISIONS HAVE LED THE NATIONALLY RECOGNISED BUSINESS TO CEMENT ITS FUTURE AND POSITION AS A LEADER IN STEEL FABRICATION IN THE GLOBAL MARKET. THE FIFTH-GENERATION FAMILY-OWNED SOUTH AUSTRALIAN COMPANY, WITH FOOTPRINTS ACROSS THE NATION AND OVERSEAS, ATTRIBUTES ITS VERTICALLYINTEGRATED BUSINESS, COMPLETE IN-HOUSE CAPABILITIES AND WORLD-LEADING TECHNOLOGY AS ITS CORE STRENGTHS. COMPETITIVE ADVANTAGE

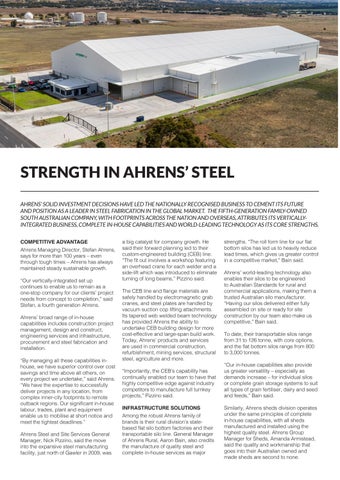

Ahrens Managing Director, Stefan Ahrens, says for more than 100 years – even through tough times – Ahrens has always maintained steady sustainable growth. “Our vertically-integrated set up continues to enable us to remain as a one-stop company for our clients’ project needs from concept to completion,” said Stefan, a fourth generation Ahrens. Ahrens’ broad range of in-house capabilities includes construction project management, design and construct, engineering services and infrastructure, procurement and steel fabrication and installation. “By managing all these capabilities inhouse, we have superior control over cost savings and time above all others, on every project we undertake,” said Ahrens. “We have the expertise to successfully deliver projects in any location, from complex inner-city footprints to remote outback regions. Our significant in-house labour, trades, plant and equipment enable us to mobilise at short notice and meet the tightest deadlines.” Ahrens Steel and Site Services General Manager, Nick Pizzino, said the move into the expansive steel manufacturing facility, just north of Gawler in 2009, was

a big catalyst for company growth. He said their forward planning led to their custom-engineered building (CEB) line. “The fit out involves a workshop featuring an overhead crane for each welder and a side-lift which was introduced to eliminate turning of long beams,” Pizzino said. The CEB line and flange materials are safely handled by electromagnetic grab cranes, and steel plates are handled by vacuum suction cop lifting attachments. Its tapered web welded beam technology has provided Ahrens the ability to undertake CEB building design for more cost-effective and large-span build work. Today, Ahrens’ products and services are used in commercial construction, refurbishment, mining services, structural steel, agriculture and more. “Importantly, the CEB’s capability has continually enabled our team to have that highly competitive edge against industry competitors to manufacture full turnkey projects,” Pizzino said. INFRASTRUCTURE SOLUTIONS

Among the robust Ahrens family of brands is their rural division’s statebased flat silo bottom factories and their transportable silo line. General Manager of Ahrens Rural, Aaron Bain, also credits the manufacture of quality steel and complete in-house services as major

strengths. “The roll form line for our flat bottom silos has led us to heavily reduce lead times, which gives us greater control in a competitive market,” Bain said. Ahrens’ world-leading technology also enables their silos to be engineered to Australian Standards for rural and commercial applications, making them a trusted Australian silo manufacturer. “Having our silos delivered either fully assembled on site or ready for site construction by our team also make us competitive,” Bain said. To date, their transportable silos range from 31 to 126 tonne, with core options, and the flat bottom silos range from 800 to 3,000 tonnes. “Our in-house capabilities also provide us greater versatility – especially as demands increase – for individual silos or complete grain storage systems to suit all types of grain fertiliser, dairy and seed and feeds,” Bain said. Similarly, Ahrens sheds division operates under the same principles of complete in-house capabilities, with all sheds manufactured and installed using the highest quality steel. Ahrens Group Manager for Sheds, Amanda Armistead, said the quality and workmanship that goes into their Australian owned and made sheds are second to none.