The situation in Europe is tense. There is great uncertainty both about how the electricity supply will work, and what will happen with interest rates, not to mention the high fuel costs.

Despite the uncertain times, everything is going as planned for us at ExTe. This means full speed in production, while new products are soon about to be launched on the market.

We can therefore look to the near future with some confidence and optimism. In production, we are investing in many new machines to meet our contin ued growth and expansion.

During the summer, together with our sister com pany, we established a new sales company in Poland. The aim is to develop and increase our presence in parts of Eastern Europe. We already have a strong position in these markets and now we are now even closer to all our customers when it comes to sales activities, products and service.

For ExTe, all the summer and autumn trade fairs can best be described in two words. Total success.

On the continent, there is considerable interest in our A and D timber bunks . In addition, the TU ten sioners, not least the remote-controlled ones, have achieved new top ratings.

In the Nordic region, our new high capacity bunk in the S-series has been met with an interest that actu ally exceeds our expectations. Being able to load more wood in each stack is becoming increasingly important for the profitability of hauliers. The trade fairs have once again confirmed our leading position in the market.

Late autumn will be filled with a variety of activities on the majority of the world’s continents. The needs can look very different in the different markets. That is why it is so important for us to constantly stay focused on the customers and their ideas. That is the key to our continued success.

Our competence is increasing, while at the same time we are strengthening our competitiveness for the future. It also means that the benefit for our customers increases.

Already today, we have a complete machine park for the manufacture of the sheet steel components that are found in several of our products. But now it is time to raise the bar a few more notches.

We are commissioning a brand new press brake that bends steel plate with 3 tons of pressing force. The machine, which is the very latest in design, has technical solutions that provide high precision, in

addition, an axle speed that enables higher produc tivity, to name just one of numerous improvements.

In the New Year, it will be time for the next machine, a brand new laser cutting machine. The refinements are many, for example a higher plate throughput with high detail precision. The laser power control provides, among other things, better detail quality and shorter lead times. The machine is also more operator-friendly and requires less programming work.

All in all, the investments are new steps in our ongoing development to increase customer value.

ExTe has a modern and efficient production. The investments that are currently being made in our machine park mean that we are making further upgrades.

wards in -From the left: Viktor Persson, Fredrik Tomtlund and Jimmy Spring in front of the new press brake.

On ExTe's stand, it is just as obvious to offer the local delicacy of Färi lakorv as it is to show off the market's widest range. If the yardstick for successful trade fair participation is the number of sausage rings eaten on the stand – then Elmia Lastbil was truly a success. Easy-going and happy hauliers, drivers and business partners with lots of good questions and views gave us time and time again the inspiration to push the develop ment forward. The risk that we will just sit back and rest on our laurels is non-existent. Thanks to you, we had a fantastic fair. Everyone was of course interested in our news, but it was equally important to simply just meet, socialise and hold discussions with professional colleagues and our

– There was a lot of interest in our new S-bunk with built-in ten sioner. With increased load weights, bunks that can carry larger volumes become even more important. For many, in fact, it has had more significance than the weight of the bunks.

– Another thing I hear from many visitors is that they appreciate our wide range. We actually have something for all hauliers no matter what their needs are. In addition, we are alone in offering a unique Safety Guarantee for all our products.

– It was full speed ahead on our stand on all the fair days. Not least on the Thursday when the fair had invited 3,000 young peo ple, as part of a campaign to recruit new drivers. Our caps and sunglasses went very quickly, says Per with a laugh.

– Jokes aside, they were very interested and above all there were a lot of people who thought Com 90 was very cool.

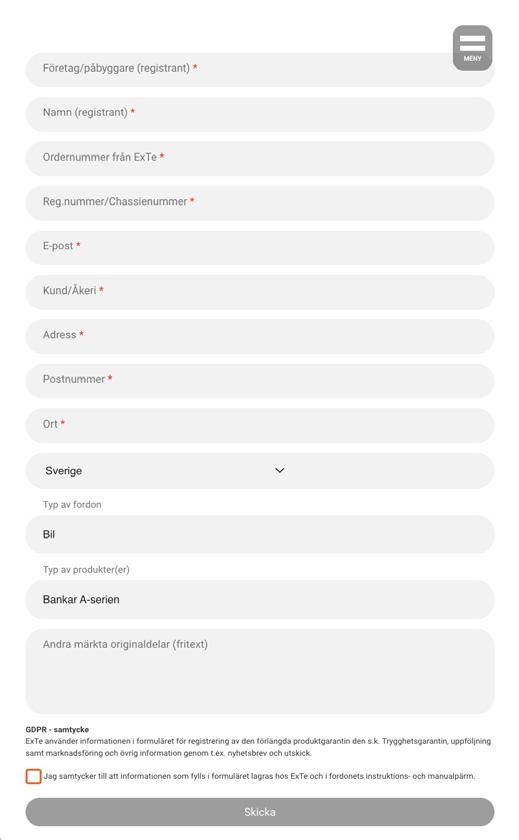

ExTe is gradually building up a network of service partners in Sweden. Andreas Landin, who owns A Landins Bromsservice in Norsjö in Västerbotten, is one of several people who are about to become ExTe Service partners.

– We work with everything to do with vehicles and trailers, including servicing, repairs and even bodywork. When it comes to timber bunks, they are exclusively from ExTe. We probably keep in stock pretty much all the spare parts one might need. In our area, ExTe commands about 90% of the market.

– We have very good contact with ExTe through Jörgen, and also Staffan Swahn from ExTe’s Technical Service and Support, who usually visit us. They are good to talk to.

We have also visited the factory in Färila. It was impressive how orderly and tidy it was and so well cleaned. I think it is good that ExTe is building up a service network. it is good for our local hauliers, says Andreas Landin.

Things are going very well, says ExTe's Mikael Deemus and Staffan Swahn. They are referring to all the people who visited the ExTes stand.

– Cheerful, positive and very interested. They agree that it would have needed to clone themselves to have had time to talk to all the visitors.

– Since we have such a wide range, there are obviously a lot of questions and feed back. Not least about our new S10i bunk, which is something many people are inter ested in.

Not a fair but the Timber King from Norway, Odd Anders Saeter, of Tretransport AS

Apart from the fact that everything is going well with regard to the tim ber transport, he is a little worried about developments in the vast country to the east.

– I am actually considering buying him out, the king says, without mentioning a name.

Öjvind Björkebakken is a timber hauler from Torpa near Lillehammer. He is about to acquire his second vehicle.

- I have ExTe bunks and TU tensioners. They are very good and work as they should. Right now I am thinking about how to tackle the changing of the load weight in Norway to 68 tons. The new S-bunk seems very interesting.

ExTe's Jenny Gustafsson talked about both the technical and functional advantages of the new S-bunk with built-in tensioner.

– Increased load weights often mean a need for more axles on vehicles and trailers. This leads to a lack of space for tensioners mounted on bunks and frames, explains Jenny. Therefore, the new S-bunk has a tensioner in the frame.

Patrik Hjertbro, also known as Olle, visited ExTe's stand together with his partner Camilla Wasseng and some col leagues, to see what was new and to update themselves on the most important things in terms of addons for timber haulage vehicles.

Patrik runs Fordon & Marinservice with a workshop in Nykvarn. Above all, they work with the repair and servicing of heavy vehicles. But also some assembly and transfer of superstructures.

We have two timber trucks, says Johan Evertsson. Together with his son Martin and driver Ted Andersson, they thought a lot about how to handle increased load weights.

– They reached the same clear consensus, that the weight of the equipment becomes less important and the volume all the more interesting. ExTe's new slimline S-bunk with built-in tension er, is definitely a good solution for getting more timber on the load.

Right now, the haulage company ExTes has A6, A9 and A10 bunks and TU tensioners with straps on their vehicles.

The choice is between ExTes A and D-bunks. Therefore, they want ed to get good information about the differences between the bunks. Per Jonasson from ExTes talked about the main differences and urged them to contact ExTe's dealers in Latvia.

– We have four vehicles and drive for Vida and Munksjö, says Niklas.

Together with his son Kim and driver Robin Weddmark, they took the opportunity to have a chat with ExTe's on site team and update themselves on the latest developments.

Jenny Gustafsson talks at ExTe about the new S10i bunks

– On our vehicles, we only have ExTe's A-bunks, says Niklas Fredriksson. The driver Robin says he really likes his job. You are very unhindered out in the forest. There are challenges every time you enter the forest.

Lucky winner of an electric scoot er. Algot Olsson gives ExTe a thumbs up.

The picture was taken in the cab of a gravel truck, which a friend drives.

Believe in a future in the industry.

– I usually never win anything, so this was great fun, says Algot Olsson about the feeling of winning an electric scooter.

At Elmia, ExTe held a competition on its stand. The first prize was an electric scooter.

– it is great when I go shopping or visit a friend's house, says Algot, who lives in Markaryd. Algot studies Vehicles and Transport at Sunnebogymnasiet in Ljungby.

– I was visiting the fair with my class, and it was very interest ing. It was cool to see everything, and what a nice stand ExTe had. I accompany an older friend sometimes when he is driving, so it was fun to look a little closer at the stuff on the stand, says Algot, who absolutely sees a future in the industry. Right now, I am a very keen on driving a tow truck, but that can change, he says.

Fröjds Åkeri in Kisa was established in 1951.

– We celebrated 70 years of trading last year, says owner Pär Fröjd, to the left in the picture. The haulage company currently has 26 timber trucks and two gravel trucks. Pär takes care of the timber trucks and his son Jonas, to the right in the picture, is responsi ble for the contracting side of the business. The company has both its own truck work shop and tyre workshop. In addition to a car repair shop.

– Lately, there has been a lot happening on the timber transport side of the business. So there has been a lot of contact with Mikael Deemus, says Per Föjd.

Edströms Åkeri in Åsele is the backbone of a company that has been active for over a hundred years.

It is now run by a fifth generation of entrepreneurs. Today, it is the brothers Tomas and Joakim Edström who manage the business. Joakim's children Amandus and Malvina both drive timber trucks. – It is great fun, says Malvina, and her brother agrees.

Of course, the new S10 i-bunk can be painted inany colour (RAL).

The S-bunks have a uniquely large loading area, which provides space for even more timber in each load.

– Our latest addition to the S-series, the new S10i, is a real stroke of luck, says Jörgen Norberg, ExTe's salesman in Norrland. Without exaggerating, I can say that the timber hauliers who have seen the new bunk are waxing lyrical about it.

The S10i is based on the new needs created by today's modern transport conditions, new regulations and possible load weights. The frame and struts are made of high-strength steel, just like the previous S-bunks.

There is a built-in tensioner in the frame, says Jörgen. A perfect bunk, not least for the new 74 ton vehicles. With higher total weights, a larger timber volume is required. To cope with this, the vehicles are built lower and more compactly, with a greater number of more closely-spaced axles This means a lack of space for bunk or frame-mounted tension ers. It will also be difficult to fit tensioners on transfer tables. Therefore, we have built a compact tensioner module into the frame. The tensioner meets international requirements and regulations, including the new Finnish requirements.

Jörgen points out that so far there has been no need for built-in ten sioners, as on vehicles with fewer axles there is plenty of space to mount the tensioners on the frame or outside the bunk.

– The advantage is that you can easily access the tensioner when it needs to be serviced, says Jörgen. it is just as easy on the new S10i bunk. You only need to loosen four bolts, lift the stake up 15 cm, lock it with a locking pin, and loosen four bolts that holds the entire tensioner module. Then just lift it out and service it.

– We have received very positive reviews about this new bunk. Several hauliers have already placed orders for when they will change vehicles or trailers, says Jörgen.

One of our most important goals in the business is to develop products that contribute to better profitability for the timber haulers. Our S-series is a shining example of that.

PCM Transport has two vehi cles. One with the older S-bunks and one with the new S10i bunks.

Youngest son Henric on the left is looking forward to becoming a timber lorry driver, cheered on by father

– I worked for 30 years at Junttis Åkeri, says Patrick Mäkitaavola in Kuivakangas, north of Övertorneå. In 2019, I retired thinking it was time to take it easy. But not to put it bluntly, that plan went down the drain. So I bought a timber truck. And now I have two.

– Last spring, I had the opportunity to be a test driver for ExTe's new S10i bunk, i.e. the new S-bunk with built-in tensioner. Both car and trailer were equipped with the new bunks. Patrick also has S-bunks on his second vehicle, although not with the built in tensioner.

– I have to say that I am really happy. The S10i is a prop er high capacity bunk that fits 74-ton vehicles incredibly well. We have many roads with a 74 ton weigh limit here in Norrbotten, so it works very well. it is important to be able to load as many cubic metres as possible, says Patrick. The volume is more important than the weight of, for example, the bunks. With our conditions, the S10i is by far the best you can have. Plus, ExTe are great. There is never any fuss and their safety guarantee is good reas surance. If there is any issue, I just call Jörgen Norberg or Jenny Gustafsson at ExTe. They solve most things.

– Now it is me and three employees including my old est child. The youngest is also on his way into the compa ny.

– We are busy driving. I function a bit like a transport manager for 16 shifts, i.e. eight vehicles on two shifts. All vehicles have cranes, which we can use when transport ing timber. And the wood timber goes to Billerud,

– I have to say that I am completely satisfied with the S-bunks, says Robert Rensbo. Robert runs Rensbo Åkeri on Frösön in Jämtland.

– On one of my two timber vehicles, I have S10 bunks with a stake height of 3.10 on the vehicles and A10bunks on the trailer. The car has a 10-ton front axle and total weight of 34 tons. This is before it is even loaded.

There is a big difference in how much I can load on the truck compared to the trailer, explains Robert. When I unload, the truck can handle a stack on the trailer with two lifts.

The truck takes more. It is estimated that there is one to one and a half tons more in a stack on the truck than on the trailer. There will definitely be a big differ ence,. And that affects profitability for me.

A number of years ago, there was a lot of discussion

about the weight of bunks. – It is not as important anymore. Now the volume you can load is more important, and this is where the S-bunks are superb, says Robert.

ExTe's TU tensioners with straps are on both the truck and trailer.

- I am very happy with them as well. It is easy when you connect the straps in pairs and lift them with the grapple in the middle of the stack. Then you don't have to keep mess ing around with the stakes as you have to, when you lift one strap at a time.

Robert is clearly interested in the new S10i bunk.

– it is great that ExTe came up with it. A perfect and simple solution. Just connect the bunks and the air, then you are ready.

Finnmetko is an important trade fair for forestry machines and timber trucks. In Jämsö, Finland, no less than 28,000 visitors attended the fair on 1-3 September. ExTe was represented by its dealer Alucar.

Julius Närvä is ExTe's ambassador in Finland. Here in con versation with two interested and poten tial customers.

Simpanen’s new vehicle with ExTes A-series timberbunks

At the turn of the month August-September, it was time for the fair in Klagenfurt. ExTe was of course present through its dealers and partners.

ExTe’s D-bunks are a major product on the European mar ket. Many hauliers drive both round timber and sawn tim ber. To avoid damage to the sawn timber, several people choose a welding solution when installing the frames.

On

On Schwarzmüller's stand there was a great example of the use of 144 stakes.

A fine example of the use of ExTe’s 310 stake. System 310 is also part of Autonordic's product range. In short, the system means that sockets are mounted in flatbeds. Stakes are inserted into the ssockets, which can be repo sitioned depending on the type of load to be transport

several of the vehicles there were TU tensioners. Riedler also showed off a truck and trailer with TU remote. Considerable interest from the visitors.In the latter part of September, the IAA was held in Hanover. The fair is gigantic and you can find pretty much everything to do with transport there. And that, of course, includes timber transport. A reason as good as any for ExTe to participate along with their dealer.

Father and son Richard and Tobias Morath are responsible for Germany, Austria and Switzerland. The fair as a whole had fewer visitors than pre viously, but our stand was well attended by both hauliers and drivers. In other words, the right tar get group.

Above all, it was the D-series and the TU ten sioner that were the focus of interest. But even our new S10i bunk attracted attention.

– The German-speaking countries are a very large and important market for ExTe and have been for decades. Germany is by far the largest market for our road products. A market that generates power and potential for new products and also gives us the opportunity to maintain our leading position in the industry, explains ExTe's Sales Manager Per Olsson.

In Warwickshire, a county near Birmingham, a combined arboriculture and forestry fair, APF, was held in September. The forestry vehicles that participated were exclusively equipped with bunks from the Extendo group, which includes

ExTe's representatives at APF. Ingemar Larsson on the left and Staffan Swahn.

ExTe's market share throughout the UK about 50%. In particular, ExTe's A5 bunks are popu lar, and ExTe counts as a premium brand.

– The interest in the TU tensioners was great, and there we got some help from Charlie, who is a driver with James Jones from Scotland, says Ingemar Larsson. Together with Staffan Swahn from ExTe’s Technical Service and Support, they represented ExTe at the fair.

– Charlie had a video with timekeeping that he showed to interested colleagues. In 2 minutes and 11 seconds, he had lashed the load.

Everyone was impressed with the time sav ings he made. This corresponds to one more load per shift, says Ingemar.

Ordinary strap tensioners are inherently cheap, but very time-consuming. It takes about 15 minutes to lash the load. In addition, you have to throw the straps over the stacks and also stop further along the road to tighten up, when the load settles.

– It was a successful fair for us, Ingemar says . One haulier ordered a new build with both D5 bunks and TU tensioners. In addition, more requests are coming in.

Interested hauliers and drivers together with Charlie, on the right in a cap.

– Maybe a bit of a

is of course a lot to ask about. The greatest interest was, of course, in the new S10i high capacity bunk.

– Many people had come just to see the new S-bunk with built-in tensioner. Many drivers spontaneously said that with the S10i we have come up with exactly the right solution, says Jörgen.

– Both the frame and the stakes are made from steel, and north of the Dalälven river, steel construction is the most popular. If you do not have S-bunks, then you often have D10 bunks where the stakes are made from alu minium.

– it is important to be able to transport as much tim ber as possible, and this requires stable structures. Especially if you have vehicles that can handle higher load weights, said several hauliers.

Tobias Dahlberg in Åsele has the usual S-bunks on his vehicle.

– The accounts show that on very occasion it is more profitable than with traditional vehicles.

In summary, both Staffan and Jörgen say that it was a very successful truck gathering in Ramsele.

In Åsele, Tobias Dahlberg runs his haulage company. He has an timber vehicle and drives for SCA and Norra skog, among others, through Timmerkörarna.

– When I come home with a full load in the evenings, my father takes over and drives it the rest of the way, in par ticular to Sävar. It can be said that the vehicle does one and a half shifts.

- For me, there was no doubt what bunks I wanted on both the vehicle and trailer. They have to take a lot of timber, and then there is no other solution than ExTe’s S-bunks. I am very happy with the bunks. They are good — probably the best, Tobias said.

– A smart detail is the construction of the wedge that locks the stake into the frame. This makes it very easy if you need to change stakes.

At the truck meeting in Ramsele, ExTe had a competition on its stand. The person who won was “she who never wins” , to use Therese Nytröm's own words.

– So funny, the husband might be even more happy now.

The husband, Pär in this case, runs Bröderna Nyströms Åkeri with his brother Tommy, in Solberg, midway between Örnsköldsvik and Åsele. The prize was a gift card for ExTe.

pent-up need after the pandemic. But regardless of that, there were an incredible amount of people. It almost felt like the whole of Norrland was there, and sooner or later they ended up on our stand. Jörgen Norberg, who is ExTe's salesman in Norrland, was almost lyrical in his description. – Ramsele was a real hit for both us and all visitors, he says.Jörgen together with Staffan Swahn from ExTe’s Technical Service and Support were busy answering all questions. With the uniquely wide range ExTe has, there

“I want bunks that take a lot of timber.”

ExTe's leading position in the development and sale of products for securing timber loads is well known. The major products for timber hauliers are A, D and S bunks as well as Com 90, which is in a class of its own. In addition, ExTe's automatic tensioners, TU and TL, with up to an unlimited span length. No matter how much the timber settles during transportation, the tension remains safe and secure. In fact, ExTe’s TU tensioners work equally well when transporting gener al cargo, suchas lumber.

The tensioner with a strap magazine is made of steel, and has a spring-loaded locking function. The strap magazine holds about 10 m of strap, width 50 mm. The tensioner is designed for a breaking strength of 6 tons.

A low-profile tensioner with strap magazine made of steel. It also has a spring-loaded locking function. The strap magazine holds about 10 m strap, width 50 mm. The tensioner is designed for a breaking force of 6 tons.

The tensioner has a built-in strap maga zine and is made of steel. It has a spring-loaded locking function and inter changeable bearings. The strap maga zine holds about 10 m of strap, width 50 mm.

Not as well known are ExTe's Autonordic products. They are a product group with safe and functional solutions for securing cargo for all types of transportation, whether it be sawn timber, wood chips or general cargo.

The product group includes tensioners of various designs with magazines. The tensioners are robust and manual and thus lack auto matic post-tensioning. Therefore, above all, they are well suited for securing goods that do not settle.

Also included are several types of drop forged hooks, rings and lashing mounts with a breaking strength of six tons.

Recessed

Hook

Durable and impregnated.

Both systems are special and unique products. They are designed for the transport of sta ble general cargo, primarily loaded on pallets. Cargo Flexi is available in two versions, one in normal and one in XL format. Sleeves are mounted in the truck bed, so that the round and light aluminium stakes can be easily rearranged according to load needs. The stakes are available in full or part lengths and meet current requirements for securing loads.

With System 310, the concept is the same as for Cargo Flexi. Here, the sleeves and stakes are square. The stakes are made from aluminium. Solutions are available both with and without quick locks. Telescopic stakes are also included in the system.

The idea is that several sleeves are placed along the length of the vehicle to fit different load lengths. The sleeves are made of high-strength steel and are well suited for welding applications without the need for preheating. Conventional mounting with bolted wedges is also an option when the stakes do not need to be rearranged frequently.

Quick Lock is an ingeniously simple locking system for stakes. It provides unique flexibility for hauliers with flatbed trucks and wagons transporting both round timber and other goods. Quickly and easily, stakes can be removed or repositioned, all depending on the type of transport.

In the quick lock solution, the stake is easily placed in the specially designed sleeve together with ExTe's spring-loaded self-locking wedge. No bolting or use of tools is needed. No loose inserts or vibrations while driving.

To loosen the stake, the driver simply steps on the QL wedge tool. The insert is released and the stake can be lifted from the sleeve.

Whether it be round timber, sawn timber, pulp bales or other bulky general cargo that needs to be secured, there is a TU solution.

The TU tensioner (TU stands for Tension Unlimited) has automatic post-tensioning and an unlimited span length. The TU tensioner has a pulling force of up to 1000 kg, which is adapted based on the requirements of each market. The tensioner is mounted on the bunk or frame. The symmetrical design (right/left) allows you to mount both the strap drum and the uncoupling lever on either side depending on what suits you best. Air-controlled uncoupling of the mechanism in the tensioner is available as an accessory. With it, uncoupling can take place at the touch of a button in the truck cab. It widens the area of use, e.g. when the tensioner is under a flatbed/body where the accessibility is not the best. In this situation it is optimal to control the TU tensioner with a remote control.

Gladsax Flak in Simrishamn devel ops, designs and assembles custom ised truck bodies. Among other things, sleeves are mounted on the flatbeds of vehicles that transport dif ferent types of goods. ExTe's Cargo Flexi concept is interesting in that respect. At Elmia Lastbil, Mikael Deemus from ExTe explained about the cargo system.

From the left, Lage Winberg, co-owner of the company, as well as Fredrik Lundholm, Lars Andersson

You are welcome to talk to one of our sales representatives. The best way to reach them is by phone on 0651-175 00 or by e-mail at sales@exte.se.

– Successful days, says Staffan Swahn, from ExTe’s Technical Support. This is the third year that I have had the privilege of meeting hauliers and drivers. There are always interesting questions and reflec tions.

It may also be the case that someone comes up with a technical problem. That is what happened on one of the days. A haulier needed help with our products on his trail er. Then it was just a matter of pulling on the overalls and solving the problem. Fun with variety, says Staffan.

Others who probably also liked the crane days were all the school students Studying Transportation at

Parkgymnasiet who were invited. Young, and enthusiastic, they tried their hand at running a crane. Both girls and boys at the sharp end. You had to bite your tongue and stifle some laughs.

– The fact that so many schoolchildren came was something that pleased us, says Fredrik Söderlund from Björnavagnar.

We got to learn what it is like to inform those unfamiliar with the industry, and the young people thought it was fun. The suppliers also made a good impression on the young people. Maybe we will attract some of them to the industry.

For a couple of days in early September, there was an open house at Björnavagnar in connection with their Crane Days. Both industry professionals and the general public were invited. From Extendo, both

Teknikcollege Hälsingland and Ljusdals Mekanföretag have a unique collaboration for the students on the Industrial Technology programme at Slottegymnasiet. ExTe is part of this collaboration.

– We are proud to be part of this important collabo ration between the companies and the school, says Lina Bylund, ExTe's site manager. It is an excellent way to secure the supply of skills for the future.

To emphasise the seriousness of the collaboration, stu dents met together with representatives of Slottegymnasiet, Teknikcollege and Ljudals

Mekanföretag at ExTe one evening to sign contracts.

There was a somewhat solemn atmosphere when the contracts were signed! Since the students are not of legal age, the guardian (parent) also signed.

Among other things, the students commit to keeping appointments, completing their studies with at least a pass grade and demon strating good order and behaviour. In return, the companies offer internships during all three years of high school, offer summer jobs, and offer employment if needed.

– The companies and the students get to know each other, and the students get a total of 42 weeks real industry experience. They use modern machines at the companies during their training period, which brings great benefits to them when it is time to look for a job. We, at the participating companies, then know that they are well trained, explains Lina Bylund

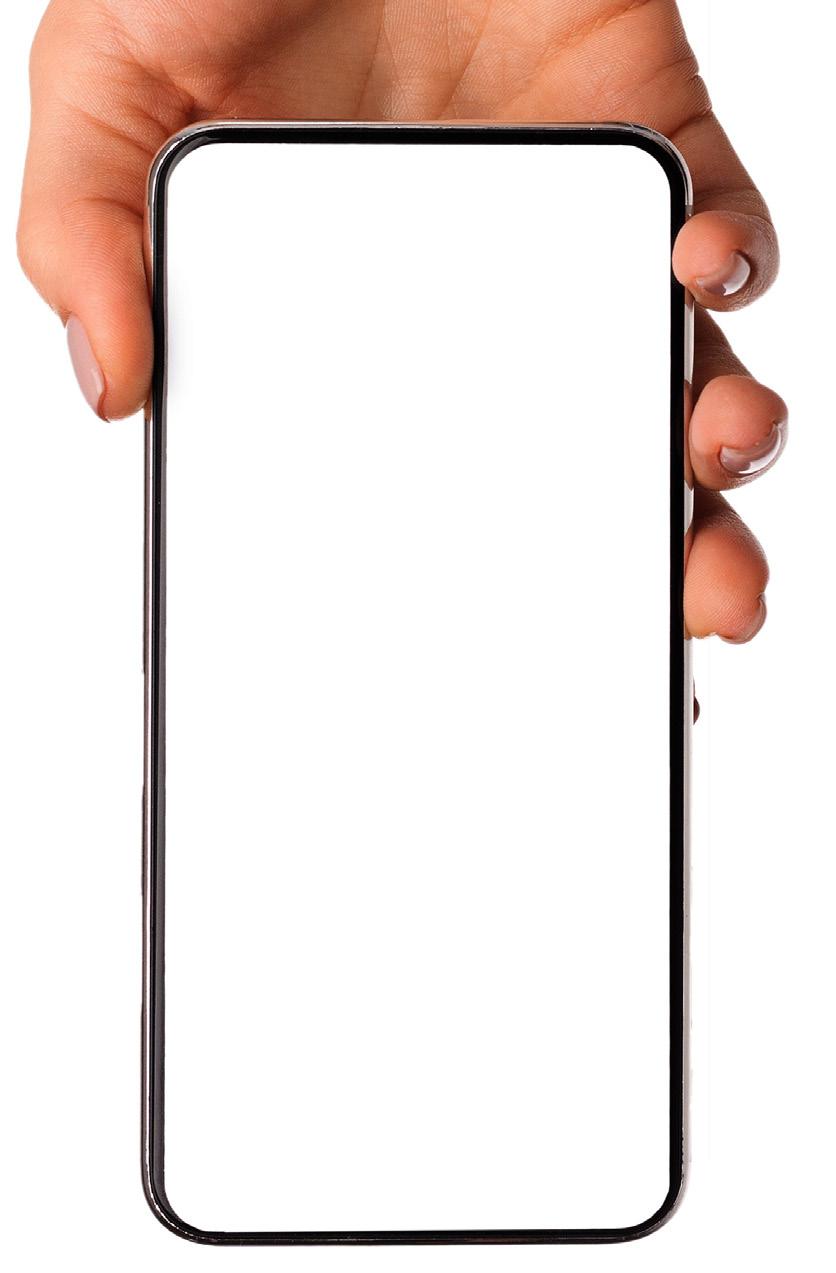

On 01/01/2023 we will switch

For several decades, ExTe's blue colour has been part of our brand. We will now move on to a new and more modern shade - but still blue.

An advantage of the new blue colour is that it is included in the RAL sys tem. This simplifies its management. For customers, it will also be easier in the event of any repairs to the paintwork. Another advantage is that the new paint is more UV resistant.

The company's choice of colour is part of the design of the products. In this respect, we feel that, after many years, it is time for a modernisa tion. ExTe's most important core value is that our products are of high quality and safe. But it is also important how the eye perceives the design and colour scheme. The difference between the old and new blue colour is relatively small and the shades are excellent to combine.

to a new shade of blue.

Minimising downtime and getting help quickly if problems arise may never have been as important as they are now. We not only want to offer the world's most secure load securing solution – we also want to offer the safest. Therefore, our generous Safety Guarantee is included for our branded products delivered within Sweden. The guarantee is unique in the industry and means a safe and comfortable own ership of ExTe products for four full years. Read about current guarantee terms on exte.se

If you want to quickly know what is happening in ExTe's (and your) world, you will always find the latest news on Facebook or at www.exte.se