When the lights go out in a workshop, it doesn‘t always mean the end of the shift; quite the opposite.

At GM Diecron, located in Griffin, Georgia, the future of manufacturing shines bright precisely because the machines keep working even when no one is in the room. With the help of EROWA, this aerospace supplier has made the leap from a classic CNC operation to a cutting-edge, lights-out pioneer.

Founded in 1977 as a manual machine shop, GM Diecron has grown over the decades into a modern CNC hub for structural aircraft components, industrial parts, and high-complexity precision pieces. With just 30 employees, the company may be small – but it’s incredibly efficient, especially since it embraced EROWA automation.

«One employee per machine? That’s simply no longer viable», the management puts it plainly. The solution: an automated production system that multiplies productivity – without compromising on quality.

Like many manufacturers, GM Diecron struggled with limited manpower in a tight labor market. New projects were waiting, but new hires were hard to find. The answer was clear: automation. Thanks to the team at Morris South, GM Diecron discovered EROWA. A visit to a reference site sealed the deal.

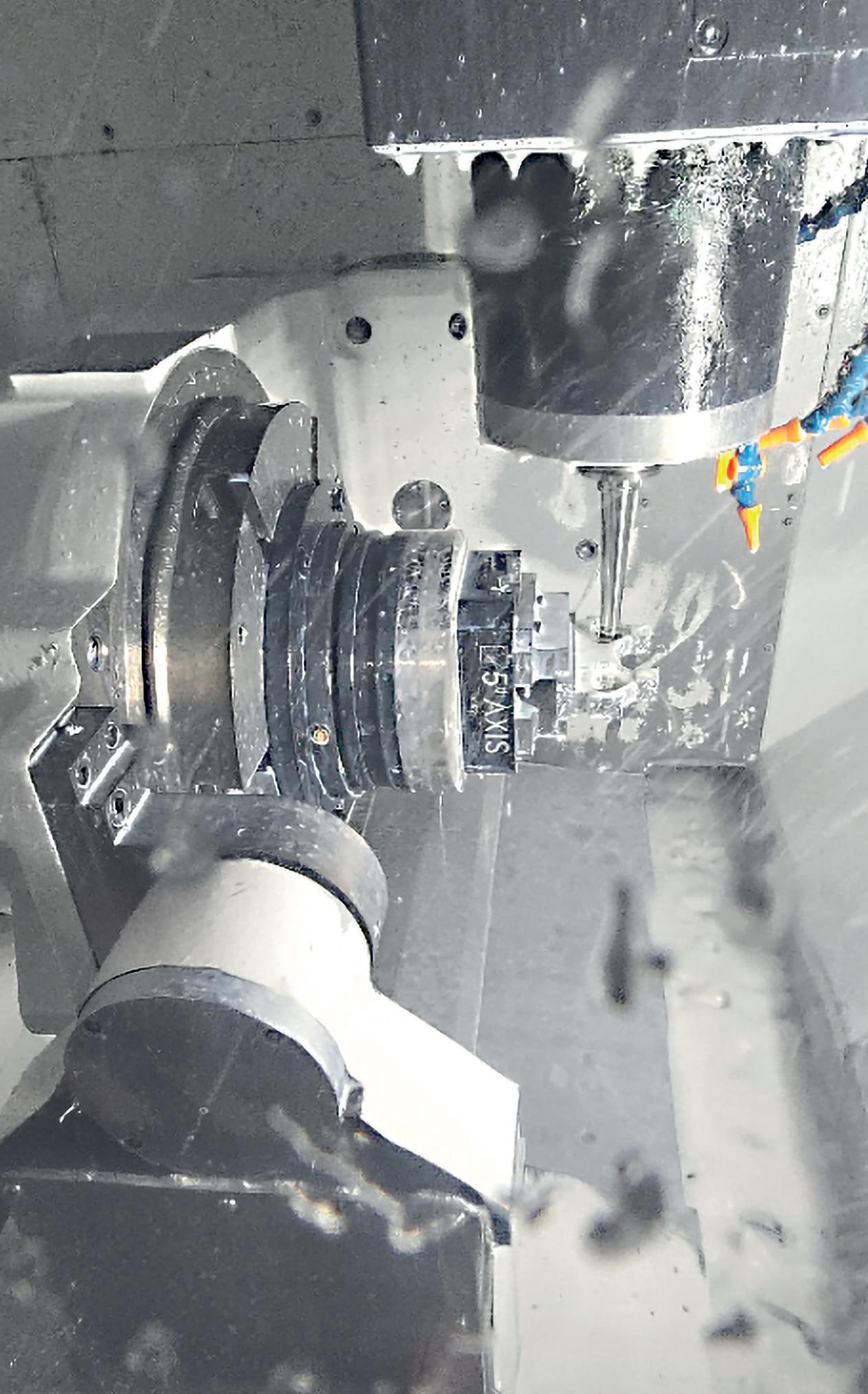

Today, the company operates an EROWA Robot Compact 80 robot with PC210 pallets and JMS process management.

Integrated with an Okuma MU4000V, the system now runs around the clock – something that used to be unimaginable: «Machines used to run 8–9 hours a day with an operator; now they run 24/7 – no breaks.»

The numbers speak for themselves: up to 100 additional machine hours each week thanks to the lights-out setup. And all while maintaining tolerances of ±0.002 inches – a level of precision made possible by EROWA’s reliable workholding technology.

«It’s comforting to know we can fully trust the system», says the production lead. Product quality remains high, and output is increased. Meanwhile, operators can oversee multiple projects simultaneously – a clear boost in flexibility.

The move to automation was more than an investment in hardware. It was a strategic shift toward the future. And it also transformed daily work life for employees. Resistance? Not here.

«We’re a company that thrives on change. If you don’t change, you stagnate. Our team was on board from day one», they say. Increased efficiency and the new roles for employees – moving from machine operators to process overseers – have improved motivation and workplace morale.

Of course, there were bumps in the road. Specifically the first steps after training took some getting used to. But GM Diecron reacted quickly by bringing the EROWA team back on site, and soon the system was running smoothly.

The journey doesn’t end here. GM Diecron plans to expand automation year after year. New spindles, new cells – all with the goal of scaling output without adding staff.

«Our goal remains the same: more output with the same team. With EROWA, we’ve found a partner that makes that possible.» The experience has proven: automation doesn’t just increase productivity, it also empowers people. When machines assume responsibility of the night shift, space opens up – for innovation, development, and for the next success story.

Conclusion: Trust in Technology Pays Off

GM Diecron is living proof that lights-out manufacturing isn’t just a vision for the future – it’s a present-day reality.

With smart automation strategies, EROWA’s cutting-edge technology, and a team that embraces change, a new kind of manufacturing is emerging: efficient, flexible, and sustainable. Or as the team at GM Diecron puts it: «Automation helps on many levels. But the best part is seeing how excited our employees are about it.»