The word “tariff” is likely to hold a prominent spot in Canadian vocabulary for the foreseeable future.

Despite the previously negotiated Canada-United States-Mexico Agreement (CUSMA), we find ourselves caught in a trade war, which seems to escalate and deescalate and re-escalate again, sometimes within the hour.

Even if a deal is reached, it’s hard to say how long it will last or prevent new industries from being targeted.

As a result, I believe everyone will need to become vocal advocates for their own industries. For example, Ontario Premier Doug Ford suggested Alberta Premier Danielle Smith might have to use her “Trump card” (poor word choice on his part) and approve an export tax on the 4.3 million barrels of oil her province sends stateside each day. Smith is holding

her ground to protect Alberta's interests.

“There’s no circumstance under which I would agree to another tax on Alberta oil that takes $40 billion out of Alberta. You can ask me as much as you like, the answer is still no,” Smith told CTV News

In the equipment world, Canada’s first round of tariffs was considerably gentle, affecting snowplows, snowblowers and lawnmowers.

However, by the time you’re reading this, the federal government’s second round of tariffs may be in effect, targeting an additional $125 billion of products from the United States.

The second round would impose a 25 per cent tariff on nearly all heavy equipment and parts, from dozers to cranes to concrete mixers. The federal government held a 21-day consultation per-

iod to mitigate the impact of its countermeasures before implementing the new tariffs, and I’d bet the loudest industries are the most likely to see reprieve.

Heavy equipment has an incredibly strong case to be exempt from tariffs on both sides of the border.

With a federal election coming this year, many of the promises you will hear rely heavily on the use of machinery. New pipelines, transit projects or Canada’s first Arctic military base all require equipment, and a 25 per cent surcharge makes these promises much more difficult to keep.

And of course, you can’t build affordable homes with unaffordable equipment and materials. Brad Jones, Chief Development Officer for Wesgroup Properties explained on Linkedin that nearly half of the ma -

terials used are now subject to tariffs that are “stopping projects in their tracks.”

While Canada is home to world-renowned equipment manufacturers, domestic supply in many cases is dwarfed by demand. So, as governments continue to trade ideas on what to tariff next, it’s vitally important to remind them that equipment is more than heavy iron, it’s the backbone of everything extracted from or built in Canada.

Two French construction equipment groups are joining forces following the Fayat Group’s announcement that it has signed an agreement to acquire Mecalac.

The transaction is subject to regulatory approval by the relevant competition authorities and is expected to be completed by the end of the first half of 2025.

“We are pleased to announce that the Fayat and Mecalac groups have signed an agreement for the acquisition of the Mecalac Group by the Fayat Group,” Alexandre Marchetta, Chairman and CEO of the Mecalac Group, and Henri Marchetta, Founder and President of the Mecalac Group said in a joint letter.

“In the meantime, the Mecalac Group continues to operate as usual, and remains committed to supporting its customers and partners around the world.”

The letter also notes that once the transaction is finalized, both groups will work to ensure a seamless transition.

Mecalac, or “Mécanique du Lac,” was founded in 1974 in Annecy-le-Vieux, France. Marchetta acquires the Pel-

Job Group and becomes its chairman in 1990. The group includes three plants in France: Mecalac in Annecy, Pel-Job in Belley and Hydromo in Albens.

Today, Mecalac Group machines are in more than 85 countries. Its line of compact construction equipment is focused on flexibility and process innovation and designed for 3D compactness and optimized attachment and tool carrier.

Its manufacturing facilities are located in France, Germany, the United Kingdom and Turkey.

As part of the Fayat Group, Mecalac joins Bomag, Dynapac, Ermot, Marini, SAE, Secmair, Dulevo and Scarab. The company also owns the winery Château Fayat in Libourne in the Bordeaux Region of South-West France.

Founded in 1957, Fayat Group is now present in 170 countries and employs more than 23,000 people. Its companies build equipment for roadbuilding, public works, foundations, energy and services, metal work and boiler making.

In 2024, the group achieved a turnover of $5.7 billion euros.

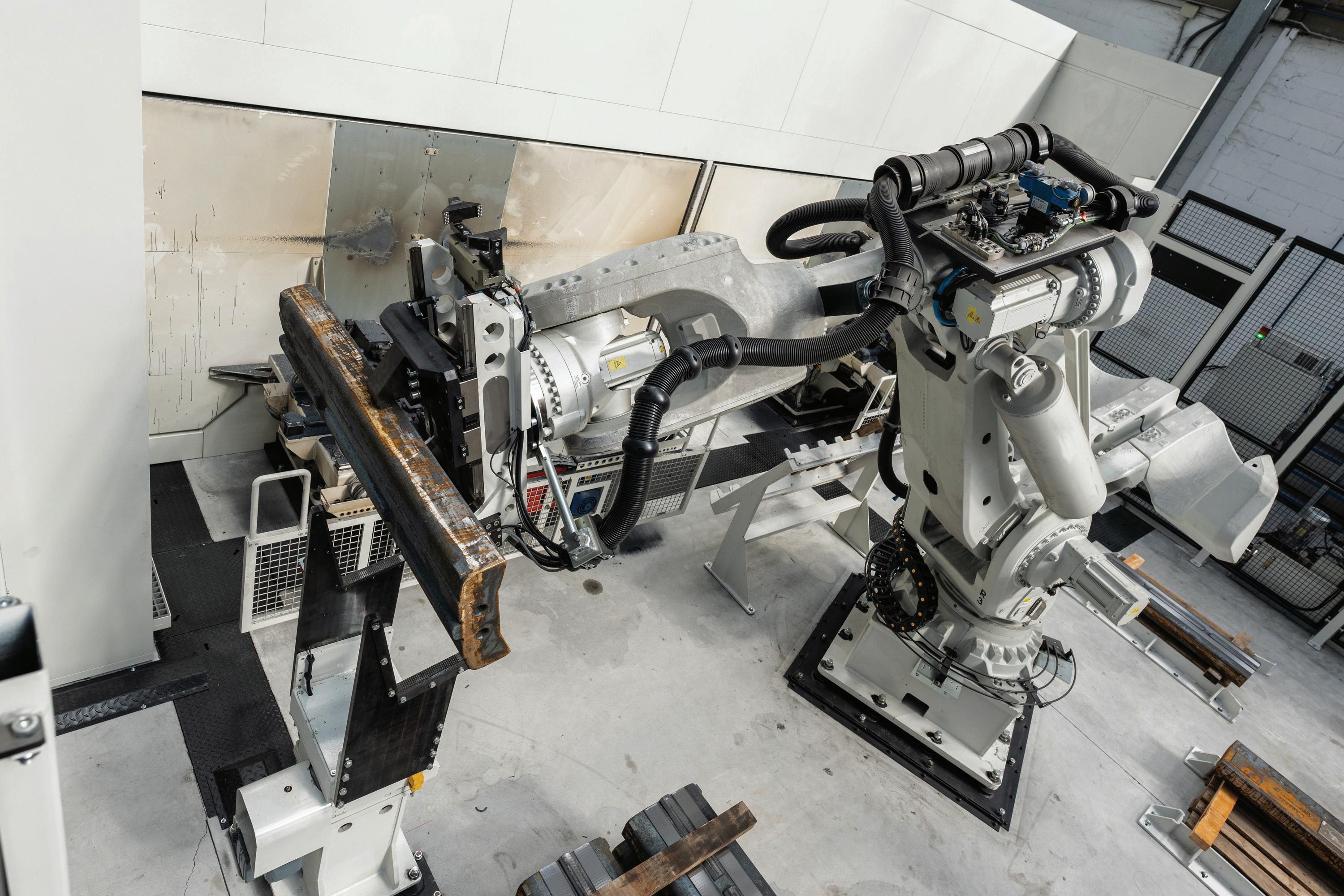

Unirope has opened a new training centre at its Mississauga, Ontario headquarters.

Unirope is a specialist in the manufacturing, distribution, testing, certification and inspection of high-performance wire rope and rigging products. The company began work on the new facility in April.

Unirope utilized an existing area previously used for manufacturing to create an 1,800-square-foot, state-ofthe-art facility designed to accommodate large groups.

"Previously, we rented a space in a neighbouring building for training. However, since 2021, we have not had a dedicated facility due to other expansion works,” said Unirope President Justin Brown. “The demand for training has grown, as customers increasingly seek to upskill their teams. This aligns with our commitment to promote safe lifting practices and ensure workers return home safely at the end of their day. The new centre allows us to better serve our industry and customers.”

Unirope trainers hold certifications with reputable organizations, such as the

National Commission for the Certification of Crane Operators (NCCCO), and the Lifting Equipment Engineers Association (LEEA), which represent the highest standards in lifting and rigging education.

Unirope’s primary training program is ‘Prevention of Rigger Mortis,’ which covers essential rigging practices and inspection. It also offers product-specific training, such as a crane rope seminar and facilitates third-party rigger certifications.

“Training is not a revenue driver for Unirope. We are a high-end supplier with deep expertise, and our goal is to share that knowledge,” Brown said. “While there are fees for courses, they are designed to sustain the program rather than generate profit. In-person training provides hands-on experience and fosters stronger engagement, which we believe is critical for effective learning.”

Several courses have already been conducted in the new Mississauga training centre, while future bookings are quickly filling up. Unirope will also host key vendors that specialize in certain product lines.

Wacker Neuson has dominated the compaction industry for over 160 years. As the inventor of the rammer and reversible plate, Wacker Neuson understands the compaction needs of contractors. From confined area trench compaction to the newest soil compactors designed for large area compaction, Wacker Neuson has all it takes to keep your job on solid ground.

Huddig is expanding into Canada following a partnership with JT Equipment, its first Canadian dealer.

Based in Calgary, Alberta, JT Equipment was founded in 2011 and has grown to represent numerous equipment manufacturers, including brands like OilQuick and engcon. Owner’s Josh Arnold and Matt Cox bring decades of experience in heavy machinery and a commitment to providing efficient and cost-effective solutions.

"JT Equip is the right partner for us in Canada," said Daniel Myrgren, Market and Sales Manager at Huddig AB. "Their industry expertise, innovative mindset and extensive network of contacts are essential as we establish Huddig in the Canadian market. Canada has many similarities to the Scandinavian market, where we are very successful. We are excited to bring the versatility and profitability of Huddig machines to entrepreneurs in Canada."

Based in Sweden, Huddig develops and manufactures excavator loaders for the overhead line, railway and construction industries.

2023 LINK-BELT X300 & X350 – 207 hp, 67,000 O.W., 23’4” dig depth & 268 hp, 82,400 O.W.,

$57,500

1959, Huddig has made more than 12,000 excavator loaders.

"Adding Huddig to our lineup is the next natural step. It's about offering solutions that help our clients do more with less," Cox said. "As costs rise and skilled operators become harder to find, contractors need machines that can handle multiple tasks while reducing overall expenses. A Huddig machine can replace up to three traditional machines, making it a smart investment for any operation.”

"JT Equipment has always been about delivering value-driven solutions to businesses. Unlike conventional backhoes, Huddig machines offer superior power and versatility, providing a significant edge in the industry. We are excited to offer Huddig as part of our growing portfolio, providing innovative, outside-the-box solutions to our clients," Arnold said.

Since it was founded in

JT Equipment's journey with Huddig started with their background as an OilQuick dealer. Given the proximity of the two companies in Hudiksvall, Sweden, and JT Equipment's desire to bring a new, innovative product line to the Canadian market, expanding their portfolio with Huddig was a logical move.

“JT Equipment's commitment to providing valuable, innovative solutions aligns perfectly with Huddig's philosophy. We are confident in their ability to introduce Huddig machines to the Canadian market," said Huddig CEO Håkan Bäckström.

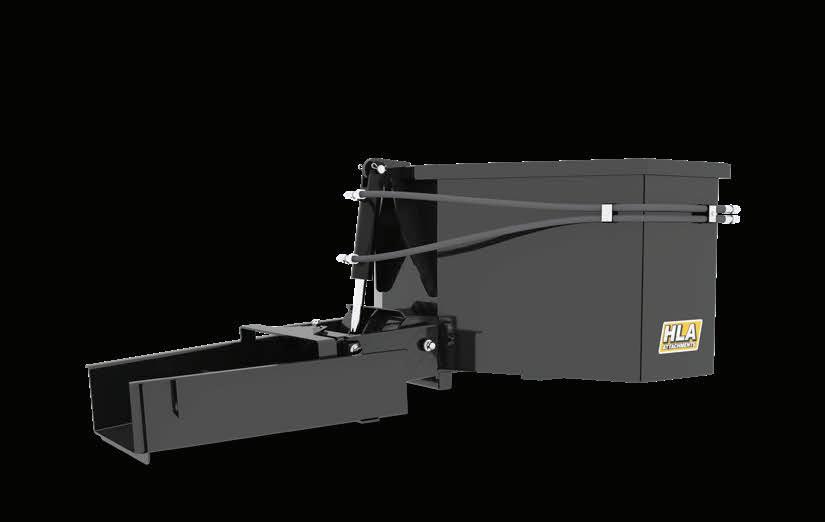

Premier Attachments has launched its latest innovation, the mini Duo-Tach.

The new mounting system offers a new method for the way attachments connect with host machines, offering a new level of performance, ease of use and versatility.

The mini Duo-Tach is designed to address the growing demands of a fleet with multiple machine styles.

The mini Duo-Tach allows for the two most common mini skid steer attachment styles (mini-skid CII and the Bobcat MT) to be utilized on a single attachment.

There is no adapter, no conversion plate and not a single tool is required to switch from one style of mount to the other. Simply unhook from the mini skid

steer or Compact track loader and hook right up to the MT and go to work.

“We are thrilled to introduce the mini Duo-Tach to the market,” said Jim Hunt, Sales and Marketing Manager for Premier Attachments.

“Our team has worked tirelessly to develop a solution that not only meets the needs of today’s consumers but anticipates the challenges of tomorrow. The mini DuoTach is a game-changer that will redefine attachments.”

The mini Duo-Tach is currently available for purchase on Premier Attachments’ power rake, power breaker, auger drive and trencher, as well as a blank mount plate allowing the user to customize each plate to meet specific needs.

MacLean Engineering has announced it will establish a surface mining vehicle division to expand its electric mining vehicle offering.

Building on its 50-year reputation as a fit-for-purpose underground OEM and a decade of battery electric vehicle design, the new MacLean division will support North America, Africa and Australia.

“As a company we turned 50 in 2023 and in 2025 we are also celebrating our 10-year anniversary of our EV Series. Now we are making another decisive move towards providing EV for the surface mining sector around the globe,” said David Jacques, MacLean Vice President of Surface Mining Vehicles.

“With a decade of EV experience in the underground

mining sector, 100-plus units sold and commissioned, and 500,000-plus operating hours logged, we are well positioned to bring our expertise and learnings around EV equipment to surface mining operations.”

The inaugural model for this new division is the GR8 EV Surface Grader. At MinExpo last year, MacLean announced its first customer, a collaboration with Fortescue in support of the company’s Real Zero 2030 decarbonization strategy for their iron ore operations in Western Australia.

MacLean plans to develop additional products to complement the GR8 and help the global surface mining sector accelerate its decarbonization timelines for ancillary equipment.

“Our message to the mining world is simple and powerful – we are here now to accelerate your fleet decarbonization requirements,” said Dan Stern, Senior Product Manager at MacLean.

“Our aspirations are much broader and longer-term than just that one surface mining vehicle model, we have a variety of planned ancillary EVs to help you realize this to meet your core business objectives of safety, productivity and cost controls. To mining companies around the globe, we want to hear about your decarbonization and operational optimization plans. We’re here to listen and provide solutions. As we like to say at MacLean, our history runs deep, and now our future is looking up.”

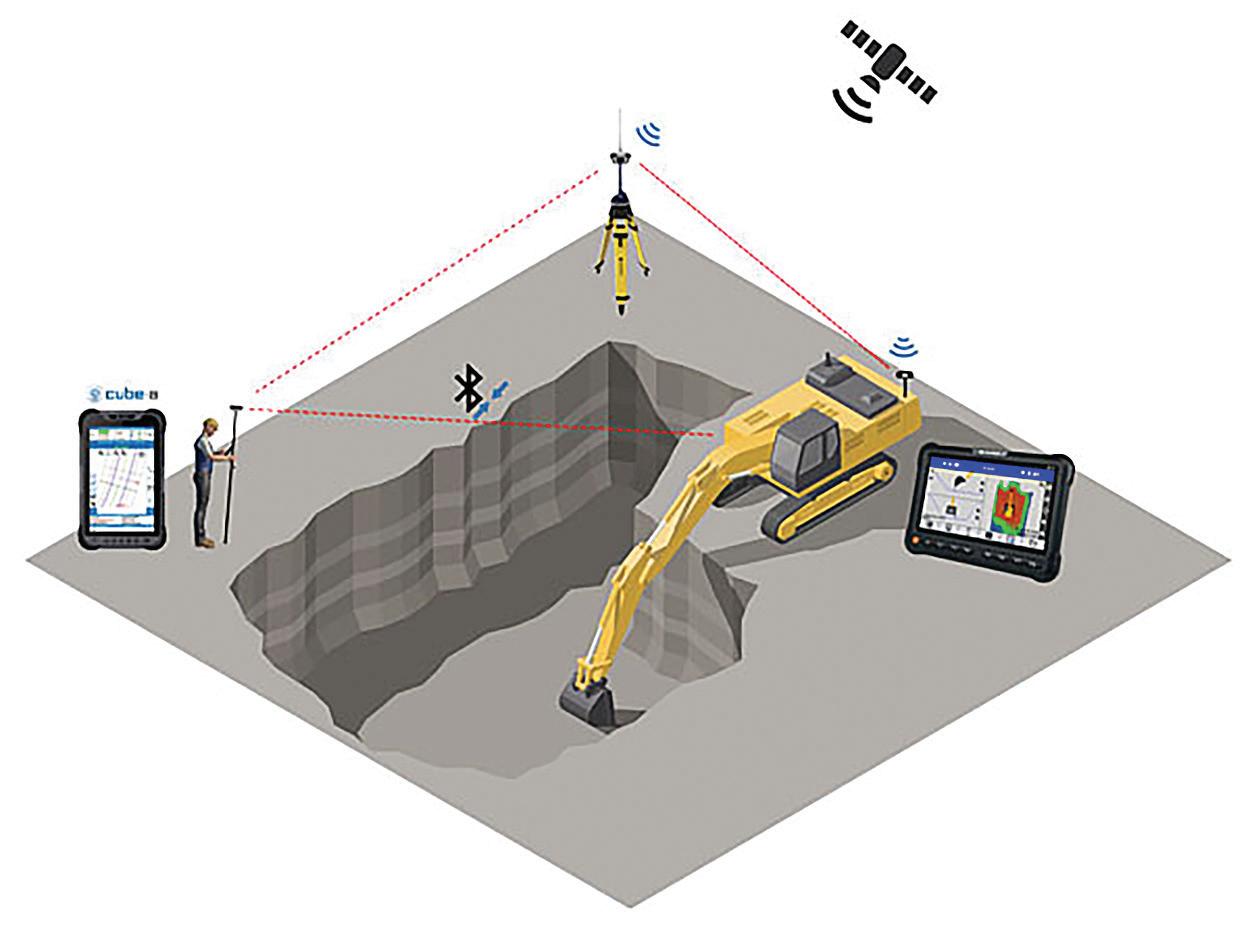

By Francisco Martins, United Rentals

For contractors, effectively managing the acquisition, operation and maintenance of a construction fleet presents significant challenges. Digital technology in the form of telematics enables companies to automate processes and make datadriven decisions in order to increase fleet productivity and maximize the value of

owned and rented equipment.

Older legacy equipment may not have telematics devices installed, but original equipment manufacturers are now including them in most of their machines. Still, the devices are not useful if they are inactive. Some contractors don’t realize their machines are equipped with them. Others haven’t activated existing devices, perhaps because they don’t fully understand the value they can deliver.

When used in concert with a cloud-based fleet management system, telematics devices provide insight into several facets of equipment operations, including how optimally equipment is utilized, how it’s operated and its state of health. Managers can leverage this data to make more informed, more cost-effective decisions about equipment fleet size and maintenance frequency. They can also identify which operators may need additional training, with the goals of boosting safety, reducing equipment wear and tear and increasing fuel efficiency.

Equipment telematics is instrumental in optimizing the management of both owned and rented equipment, no matter the size of the fleet. Today, leading rental equipment providers are outfitting heavy equipment and other assets such as generators with telematics devices. When these devices are present across a mixed fleet, contractors can see the whole fleet on one software platform and manage it holistically.

Contractors who don’t track their equipment location with telematics may be losing money by over-fleeting and losing time by requiring crews to hunt for machines. Seeing the location of every piece of telematics-enabled equipment helps ensure that no machine goes to waste. Location tracking uncovers “misplaced” equipment and discourages hoarding.

Some fleet management platforms show not only where equipment is in real time but also how it got there, courtesy of breadcrumb mapping.

A trail of location coordinates can help answer questions around who left equipment in the wrong spot. It can also be leveraged to

increase logistical efficiency. For instance, contractors can potentially adjust the jobsite layout to reduce excavator travel distances, which helps preserve the equipment undercarriage and reduce unnecessary fuel burn.

Buy what you need, need what you buy. It sounds simple, but an optimal equipment portfolio is not always easy to achieve. Often, contractors have too much of one type of equipment and not enough of another.

Telematics data enables the generation of utilization reports, which give managers detailed utilization metrics that help them adjust fleets based on usage patterns. The ideal fleet may well be a mix of owned and rented equipment. If a certain asset is underutilized, it may be time to get it off the books and rent the equipment instead of owning it. On the other hand, if telematics indicates high usage, investing in more owned or rented units may improve productivity.

To help optimize utilization, managers can configure low-utilization alerts that notify them when equipment has been sitting for too long, possibly forgotten. These alerts may signal that it’s time to return rental equipment or sell owned equipment.

Diesel fuel typically makes up at least a third of the operating cost of construction equipment. Reducing fuel consumption cuts costs while minimizing greenhouse gas emissions. When it comes to better controlling fuel consumption, seemingly small operator behaviours such as long idling and aggressive driving make a big difference. Time-stamped idling reports pinpoint how long each machine idles and uncover discretionary idling. Other reports reveal abrupt braking, fast acceleration and unnecessary stopping and starting. Visibility into these behaviours allows managers to take appropriate corrective action. Some fleet management systems offer real-time longidling alerts. These provide the opportunity to react immediately when an operator idles a piece of equipment for an egregious amount of time.

Broderson Carry Deck Cranes are well known for their versatility and reliability. Engineered to work in tight spaces and areas with low clearance, these cranes are perfect for handling a wide range of tasks with ease. Available in multiple sizes and capacities, Broderson cranes provide the flexibility to meet all your lifting and rigging needs.

Broderson Carry Deck Cranes compact, lowprofile design allows them to navigate confined spaces and clear overhead obstacles effortlessly.

Broderson’s booms are designed for durability and precision. With exceptional reach and strength, they handle demanding lifts effortlessly, even in tight spaces and areas with vertical obstructions.

Standard 4-wheel steer, 2-wheel drive, or optional 4-wheel steer, 4-wheel drive coupled with up to four-speed powershift transmission provides industry-leading speed with a tight, turning radius.

Operating a Broderson Carry Deck Crane is straightforward, thanks to intuitive controls and user-friendly interfaces.

Choose the best diesel or dual-fuel engine to power through challenging applications— Cummins diesel (US EPA tier 4F or global) or GM dual-fuel liquefied petroleum gas (LPG).

Broderson offers a range of options to suit your specific requirements.

Broderson’s ergonomically-designed cabin provides operator comfort, safety, accessibility, and ease of entry.

Select models have integrated telematics that empower owners to access location, operating hours, utilization, engine, and maintenance information online via desktop, laptop, tablet, and mobile devices.

When you choose Broderson with us, you’re not just getting a machine—you’re gaining a trusted partner. Our dedicated support team backs every Broderson crane, offering expert advice, troubleshooting, and a vast inventory of OEM parts to keep your equipment running at peak performance.

Developing and adhering to a disciplined preventative maintenance program extends the useful life of owned equipment and mitigates the risk of unplanned downtime, but maintenance is a pain point for a lot of contractors. Typically, it’s not a core competency. Telematics can help.

Odometer and engine-hour readings captured by telematics devices enable condition-based just-in-time maintenance. This approach optimizes maintenance frequency compared to calendar-based maintenance, which can lead to under-maintenance of heavily used equipment and over-maintenance of lightly used equipment.

Over-maintenance wastes time and natural resources

such as engine oil. Undermaintenance increases the likelihood of untimely repairs and premature equipment failures, which eat into profits.

In a cloud-based fleet management system, companies can configure automatic maintenance reminders based on engine hours or odometer readings. Other telematics data points can drive equipment diagnostic alerts such as low fuel or battery level, low diesel exhaust fluid (DEF) level, high coolant temperature and, for generators, high/low frequency alerts.

Tracking tagged tools

Tools are distributed assets that can be difficult to track and manage. Telematics devices installed in generators and heavy

Superior Industries has rolled out significant upgrades to its TeleStacker Conveyor PilePro automation.

PIlePro is designed to enhance productivity, usability and durability in the most demanding environments.

The new v14.0 of the TeleStacker Conveyor PilePro Automation includes a higher resolution display to improve readability, even under direct sunlight. As well, users are now able to monitor operations from anywhere and reduce trips to the conveyor with remote viewing.

Optional instructions are integrated into each screen for seamless operation, while optimized housing withstands extreme temperatures for year-round performance.

Hydraulic and electrical schematics, along with howto videos, are integrated into the program.

“These upgrades reflect our commitment to making material handling safer, easier and more efficient,” said Lafe Grimm, Superior’s Director of Engineering.

Existing TeleStacker Conveyors with PilePro Automation can be upgraded, according to Superior.

equipment have a hidden benefit: They can read Bluetooth tags attached to tools as the tools move across the jobsite, creating an efficient, effective method of tool tracking. With greater visibility into tool inventories, asset managers can reduce tool shrinkage and overspending on replacement tools.

Affordable technology

Technology is helping construction become safer, more productive and more sustainable. Using telematics to remotely track and monitor equipment is one of the most affordable and easy-to-adopt strategies for reducing fleet costs, extending equipment life cycles, avoiding unplanned downtime, reducing fuel consumption and ultimately, turning a bigger profit.

Aftermarket telematics devices are relatively easy for experienced professionals to install. A one-stop temporary equipment provider

can install them as well as provide a subscription service plan for new or existing devices. Some rental companies give customers free access to a proprietary fleet management platform that

allows them to set up alerts, generate reports and otherwise manage mixed fleets. Francisco Martins is Marketing Campaign Manager, Customer Equipment Solutions at United Rentals.

The Customer Equipment Solutions team collaborates with equipment owners in developing service solutions to optimize their owned fleets while lowering their total cost of equipment operations.

The Port Hope, Ontariobased Revolver Screening Systems has sent its first machine to South America.

The Chilean company Arauco purchased Revolver’s model RT508 Series II trommel portable screening plant for its Quivolgo forestry operation near Constitución, Chile. This operation is the largest of three in the country.

“This is a major milestone for Revolver. We are always looking to explore new markets and having a plant in Chile provides us with our foot in the door to look at other South American countries,” said Ciarán Thompson, Revolver’s Sales and Marketing Manager.

Arauco offers a comprehensive selection of composite panels, premium plywood, millwork, lumber and wood pulp. It operates multiple production facilities in both North and South America.

The company required an effective solution to handle the vast amounts of mulch it reuses for its forestry operations, leading them to Revolver’s trommel plant.

The Revolver machine is able to produce in an hour what Arauco was typically screening in a full day, delivering an improvement in output as well as quality of material produced.

As well, Arauco is pleased with the portability of the

machine and how they can easily move it to different areas of the site to screen different sizes of material.

“We are very happy with the new equipment from Revolver. It improved the amount of material we produce at our Quivolgo site each day,” said Rodolfo Calquin, Site Manager, Vivero Quivolgo, Arauco. “The team from Revolver were very professional coming down here and taking the time to set up the machine and show our workers how to use it safely and effectively.”

Constitución is located about four hours south of Santiago. Thompson said heading to the rural area of Chile was intimidating at

first, as the Revolver team does not speak Spanish.

“We managed to show the customer how to use the plant while sometimes just relying on body language as well as putting ourselves in their shoes to anticipate questions we would ask if this technology was new to us,” Thompson said.

“In general, we found the people we met in Chile to be welcoming and despite the language barrier, we always felt confident we could work with them and deliver a product they would be satisfied with.”

Revolver was connected to Arauco by Export Development Canada (EDC) in 2024.

EDC facilitated the calls

between Revolver and Arauco in the beginning and helped make introductions and act as translators.

Multiple meetings between Revolver and Arauco took place virtually, allowing both companies to get to know each other and develop a relationship.

After months of virtual meetings and calls, a deal was secured to ship a machine from Port Hope, Ontario, to Arauco’s nursery in Constitución.

“We are very thankful to the team at EDC for making the introduction to this new customer and being involved with the initial meetings. They were able to help us out with translating

the features and benefits of our equipment while also relaying back to us what the customer needed in terms of material being produced,” Thompson said.

“We benefited from the connection with EDC and would recommend other Canadian companies collaborating with them.”

Revolver was founded in 2013 and had grown to supply an extensive dealer network across Canada and the United States.

The company’s equipment can screen a variety of materials such as topsoil, compost, mulch, sand and gravel, construction and demolition debris and recyclables.

At World of Concrete 2025, Fehr Group introduced Artemix, an autonomous and automated concrete distributor.

The new solution is designed to streamline construction processes, increase on-site efficiency and reduce costs, providing contractors with a reliable, versatile and sustainable tool for the modern construction landscape.

With customizable mixing options, real-time quality control and instant on-demand delivery, Artemix ensures high-quality concrete is available at any time,

AUTHORIZED DISTRIBUTOR

reducing material waste, boosting productivity and shortening construction timelines.

“We developed Artemix with a clear goal: to bring unprecedented efficiency and sustainability to construction sites,” the company said in a news release.

Mobility is one of the key benefits of Artemix. Easily transportable and quickly operational, the dispenser can be moved between sites with great flexibility.

The concrete distributor is also flexible on-site.

Fresh mixes are prepared directly on-site, tailored to specific project needs up to 46 cubic yards per hour, to ensure optimal performance across various applications. This continuous production of high-quality concrete optimizes construction time and costs.

Alongside autonomous operation, Artemix features an integrated power supply and storage tanks, reducing logistical demands.

The concrete created by Artemix can be used up to 12 hours after production, depending on formulas and weather conditions.

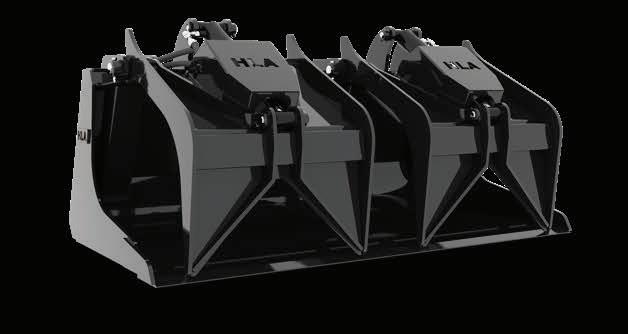

Waratah Forestry Equipment has introduced its new line of grapples designed for a wide range of forestry and non-forestry applications.

With a focus on productivity and versatility, the 15 new grapples are engineered to deliver the same durability and reliability as Waratah’s harvesting, processing and felling heads.

“Waratah’s new line of forestry grapples reflects our commitment to providing high-quality products that improve efficiency and reduce downtime,” said Brent Fisher, Product Marketing Manager for Waratah. “These grapples complement our customers’ jobsite productivity from our other products and can be utilized for a wide variety of applications.”

The grapple line includes three categories to cover all types of forestry and non-forestry applications, including C, large C and E models.

C models grapples are designed for traditional forestry needs and include the C21, C26, C30, C36, C36HD, C42, C46 and C46HD. The models are ideal for traditional forestry applications and machines, including forwarders, log loaders, shovel logging machines and bioenergy recovery.

With a symmetric frame, timing links and jaw tips designed to engage the pile at an optimal angle, these grapples ensure full loads are consistently secured.

The large C models include the C60HD, C80 and C100 and are built to tackle heavy-duty tasks. Utilizing the same successful technical design as the C series, large C-model grapples are specifically designed for larger material handlers used in wood yards, ports and other large-scale operations. The grapples offer optimized frame structure and hydraulic

features that minimize structural stresses, making them ideal for heavy-duty tasks.

Waratah’s E models are made for maximum material handling. The C21E4, C30E4, C42E5 and C46E4 are purpose-built for handling slash, logging residues, stumps and bioenergy applications. The grapples offer specialized features for use with forwarders and chippers. The E models feature unique design elements, including a choice of four or five fingers for maximum material handling flexibility.

In addition to strength, Waratah grapples are designed for ease of maintenance. Greasing the grapple is straightforward, with a single position to safely perform maintenance while the grapple is lowered. The open frame structure further facilitates maintenance by offering easy access to hydraulic hoses.

By Ontario One Call

In the bustling world of construction and landscaping in Ontario, the stakes are high, not only for the safety of workers, but for the viability of your business.

Every year, the province reports an alarming number of underground utility damages, with more than 4,222 incidents logged annually. This translates to about 19 excavation damages per day, a stark reminder of what could go wrong when ground is broken without due diligence.

Many professionals in the industry might not be fully aware that requesting locates before digging is not just a best practice, but a legal requirement. This oversight can lead to serious consequences, including hefty fines, costly delays and severe liability issues.

More importantly, failing to comply with this law puts at risk the very infrastructure that powers our homes and businesses, from gas and water lines to telecommunications and electric cables. The process of obtaining locates through Ontario One Call is a protective measure that serves more than just legal compliance — it's a strategic business decision. Ensuring that all underground utilities are accurately marked before beginning any excavation helps prevent unexpected disruptions. These disruptions can affect project timelines and budgets, potentially tarnishing the professional reputation of a business.

For contractors and landscapers new to the field or those unaware of the stringent regulations governing underground utility work,

understanding this aspect of the law is crucial. It's not merely about avoiding penalties; it's about operational success and maintaining a trustworthy business reputation.

Ignorance of the law is not a viable excuse in the eyes of regulation, and the repercussions of such ignorance can be devastating.

Educating yourself and your team about the importance of requesting locates is a critical step toward ensuring the safety and efficiency of your operations. Take advantage of the resources and support offered by Ontario One Call to integrate these practices seamlessly into your business processes. Remember, every safe dig starts with a click — a small step that can have significant implications for your business's success and longevity.

Equipment Journal will be attending some of the industry’s most relevant trade shows, and that means...

By advertising with us, your brand will reach thousands of industry professionals—both in print and online— before, during, and after the events.

Don’t miss out on this prime opportunity to maximize your reach.

advertise@equipmentjournal.com

AD SPACE DEADLINE March 28th, 2025

MATERIAL DEADLINE April 1st, 2025

AD SPACE DEADLINE May 9th, 2025

MATERIAL DEADLINE May 13th, 2025

AD SPACE DEADLINE September 12th, 2025

MATERIAL DEADLINE September 16th, 2025

John Deere is enhancing its digital experience for customers with new features in John Deere Operations Center.

The updates allow users to access comprehensive jobsite data and machine health information, empowering them to make real-time decisions.

Using feedback from John Deere customers, the added features and enhancements directly address challenges industry professionals face every day.

“Our customers voiced their needs for solutions that help provide additional jobsite monitoring and analysis to manage costs, optimize productivity and ultimately increase profits,” said Katie Voelliger, Product Marketing Manager for John Deere.

“With the introduction of new features within Oper-

ations Center, our customers can now monitor their fleet more effectively than ever before. This not only helps maximize productivity, but it also empowers operators and fleet supervisors to fully leverage their technology investments on the job.”

Custom alerts is one of the new features. Customers can be alerted when idle time, speed or fuel levels exceed limits. These alerts enable proactive planning, ensuring fuel usage and maximizing job site productivity.

As well, users are now able to monitors jobsites in near real-time with Jobsite Manager and Summary Cards. Customers can easily create, track and optimize jobsites to improve productivity and efficiency. Paired with Summary Cards, customers can monitor progress, fuel consumption and

machine locations, driving profitability and enhancing operational performance. Jobsites can also be automatically created when the automatic toggle is on.

Machine analyzer updates provide default customer reports to track operator use of grade control and its impact on productivity as well as payload weighing.

Remote display access facilitates remote monitoring and operator support, allowing control of the display and adjustment of settings to enhance productivity and maximize machine uptime.

Deere has also enhanced its Equipment Mobile app. For maintenance, there are several new solutions available to customers to help keep the jobsite running

smoothly. The maintenance plan auto assignment within Equipment Mobile allows dealers to proactively plan and provide maintenance solutions with seamless communication to ensure customers’ equipment is readily available. With this

feature, customers can add factory maintenance plans to their machines, see specific parts needed for service, streamline maintenance set up and empower customers to manage their machines efficiently.

The John Deere Equipment

Mobile app helps customers manage their equipment with less effort. With this app, customers can look up information in the operator’s manual, quickly find parts and maintenance schedules and track past or upcoming service.

A new bridge under construction over Bronte Creek in Oakville, Ontario, will be able to accommodate more than 4,000 vehicles per day once it opens in late 2026.

The bridge, which will extend Wyecroft Road between Bronte Road and Burloak Drive, will provide a new route for commuters, bicyclists, pedestrians and private vehicles while helping to reduce traffic pressure on nearby roadways. In addition, as part of this project, a new watermain will be

installed to supply Oakville in case of need or growth in the city.

This project, which is more than 30 per cent complete, will have four lanes, plus multi-use lanes on both sides of the road and bike lanes on the roadway. More than two years in the making, this project is estimated to have a budget of about $117 million, of which more than $50 million has come from the regional government.

Sarens has worked on be-

half of Niagara Rigging in the transport and subsequent placement of the eight support girders of the new West Tributary Bridge, weighing between 163 and 175 tons.

Its engineering team carried out a thorough preliminary study to define the appropriate machinery and setup to be used, taking into account the terrain conditions and the distance to be overcome to place the girders in their final location, which is more than 75 metres.

Once the girders were loaded at the beam manufacturer's facilities using Kamag K2400S SPMTs (self-propelled modular transports) in configurations of 2 files x 6 axle lines and 4 files x 12 axle lines, the Sarens team transported each unit to the west side piers for their placement. From the opposite side, a Liebherr LR1600/2 crane unit configured in SDB setup at 66 metres, working in conjunction with an LTM1500-8.1 unit in TY3 configuration, lifted each girder for later placement in their final lo-

cation while the SPMTs were moved away.

To ensure the operation was carried out to the highest safety standards, the Sarens team placed crane pads under the LR1600/2 unit to increase the stability of the crane and the correct weight distribution on the ground. In addition, it was necessary to ensure the rigging and cable always operated vertically to prevent any possible oscillations in the load from posing a safety risk to both the operators and the infrastructure itself.

The construction project for the new West Tributary bridge and Wyecroft Road extension began in 2019 with the approval of the corresponding budget.

Although construction began in October 2023, tree clearing in the area took place in March of that year. However, as part of its environmental commitment, the municipal corporation will plant three trees for every one felled in the development of this important project.

Tesab TS1550 5’x16’

Intelligent assistance systems for bottom-slewing cranes are no longer a distant promise; they are now available for all four current K series cranes.

Liebherr’s K series cranes have been in action on construction sites around the world for years. Since their introduction, the cranes have continually improved and adapted to the changing requirements of construction sites.

The latest cranes in the Liebherr series, the 43 K, 61 K and 91 K, are available now as well as the new version of the 125 K.

As part of the facelift given to the K series cranes, the machines are available with Liebherr’s 5 intelligent assistance systems. Smart functions, such as sway-free load lifting without diagonal pull, increase safety for crews and sensitive components, while semi-automated lifts maximize ease of use.

Liebherr has also retained its established features on the updated K series, including variable hook heights and manoeuvrability in tight spaces, Speed2Lift, LoadPlus and Micromove for

maximum lifting speeds, increased jib head lifting capacity and precise positioning of loads. The crane names now reflect the lifting capacities according to Load-Plus.

All new K series cranes are equipped with the new Liebherr Control 5 crane control system. This consists of the control system, the Liebherr Display 5 and I/O modules. The control system is already installed in the current L series of fast-erecting cranes and is

Hilltip’s new IceStriker 8000 CM Combi Spreader is ideal for contractors servicing large worksites and long routes, as well as municipal customers.

Designed for Class 6 medium-duty and larger trucks, the 8000 CM is a fully electric-powered spreader with an integrated liquid tank for pre-wetting material or spraying brine directly on driving surfaces. The 226-litre capacity hopper is made of polyethylene for superior corrosion resistance and has a 1,400litre integrated liquid tank for pre-wetting material. A spray bar can be added for de-icing applications, as well as a 12-metre hose reel for spraying hard-to-reach areas. The high capacities

are well suited for applications such as warehouses, retail centres, industrial facilities, county road departments and airports.

The 8000 CM is now available with Hilltip’s innovative StrikeSmart PLUS controller. The controller works in conjunction with a TempStriker sensor, which continually monitors variables like temperature, humidity and surface conditions.

It also assesses up-to-theminute weather forecasts tailored to the driver’s location. The system analyzes the combined data and recommends the appropriate material and application rate for the job according to current and forecasted conditions. Then, it automates equipment settings

used in a variety of construction machines within the Liebherr Group.

The update also sees the K cranes equipped with the new Tower Crane Operating System 2 (TC OS 2). It features standardized and intuitive menu navigation, with self-explanatory symbols and icons. A standardized radio control for all cranes in the current K and L series is another new addition.

K series cranes

The 43 K is the smallest crane in the series. It has

11 hook heights to adapt flexibly to construction site requirements. It achieves a maximum hook height of 30.2 metres and a radius of up to 35 metres. The 43 K follows on from the 34 K.

The 61 K is successor to the 53 K. It reaches a hook height of up to 33.4 metres and a maximum radius of 43 metres. Another new feature is a luffed position of up to 30 degrees, which offers more flexibility on site.

The 91 K brings with it all the proven operational possibilities of the K series and can be used for the

construction of multi-occupancy buildings as well as industrial projects. It follows the successful 81 K.1 and makes the well-established bottom-slewing crane fit for future challenges.

The 125 K, which is the largest crane in the series, combines the performance of a top-slewing crane with the mobility and flexibility of a fast-erecting crane. The machine’s performance data has remained the same. It achieves a maximum hook height of 41.5 metres, a radius of up to 55 metres and can lift 8,000 kg.

to ensure the proper material rates are applied. Furthermore, the controller is compatible with Hilltip’s exclusive HTrack tracking software, which utilizes the industry’s only two-way GPRS tracking software for real-time remote equipment monitoring and control.

The IceStriker 8000 CM can be powered by 12- or 24volt dual motors, which are mounted inside a sealed, weather-resistant enclosure. Other features include an inverted V with a vibrator to help prevent bridging, as well as a pintle chain, or an optional stainless steel chain. A stainless-steel flipup chute is designed for spreading salt in environments with high humidity.

At bauma, Caterpillar will celebrate its 100th anniversary, while previewing what the future holds for the construction equipment manufacturer.

Cat’s 9,000 square metre exhibit space is themed “The Next 100 Years,” and highlights its commitment to innovation and sustainability.

The exhibit will feature 48 machines, including 17 new introductions or upgrades. The machines include enhancements to the battery electric line-up, expansions to the next generation line-up and additions to the demolition, waste handling and recycling portfolios.

“What we will show will be a fitting tribute to our heritage while demonstrating our commitment to building a safer, smarter and more

sustainable world with our customers and dealers for the next 100 years,” said Tony Fassino, Caterpillar Construction Industries Group President.

“Alternative power sources, reduced carbon options and integrated technologies are the future, and Caterpillar is ready to deliver this in collaboration with our global dealer network.”

Cat Performance Centre

The Cat Performance Centre will take centre-stage, showcasing machinery, technology and autonomy. The display will focus on a range of solutions designed to support success on the jobsite. Visitors will have the chance to simulate how upgrading their fleet with Caterpillar's latest machine technologies can lead to significant reduc-

tions in fuel consumption and associated greenhouse gas emissions.

The Cat Performance Centre will also feature the latest 301.9 mini hydraulic excavator and 906 compact wheel loader from the battery electric product offerings, both are available through select Cat dealer rental fleets.

The newest updates to the 320 and 950 GC prototypes will also be showcased, along with associated charging options and services. Attendees can experience an electrified jobsite simulation, showing data insights and energy flows that real-world customers are already benefiting from, thanks to Caterpillar’s ecosystem of electric innovations.

At bauma, Cat will showcase three recently introduced next gen com -

pact track loaders that feature upgrades in engine power and torque, lift and tilt breakout forces, stability, operator comfort and technology.

The new D8 dozer will also be featured, based on the next generation platform. It includes a new high-end operator station that is common with the D5 to D7 platforms and comes with a 15-degree angled seat for enhanced comfort. Additionally, it introduces a full suite of Assist features and is Cat Grade 3D ready ex-factory, with the option to upgrade to Cat Command Remote Control.

Making its first appearance at bauma is the 140 AWD next generation grader.

Currently in its prototype stage, the 20-tonne operating weight prototype grader consolidates two existing

platforms into a common next generation platform for motor graders, providing customers with more features, technologies and configurations.

The launch of the new MH3032 expands the material handler line-up. Ideally suited to serve the scrap segment with a near 15 metre reach and up to 1 cubic metre grapple, this machine is equipped with 2D E-fence with cab avoidance, Cat Payload and Swing Assist for enhanced safety, production and efficiency.

Further introductions for demolition, waste handling and recycling include the new 330 UHD ultra-high demolition hydraulic excavator. Standard features include the Stability Monitoring System with light and sound indicators in the cab on the ultra-high front, Cat Payload and Cat Grade Control with 2D for the retrofit front parts. Also joining the line-up is the introduction of the variable angle boom option on the 340 VAB designed for demanding demolition

Cat will display two M323 next generation wheeled excavators, configured for the railroad industry. The new M323 railroad excavator offers hydrostatic, friction or hybrid transmission options, providing maximum versatility for customers. It features both long and short radius options addressing specific application needs, while maintaining consistent lifting capacities across both configurations.

shovel features a Cat C18B engine, improved durability and extended service intervals.

Engines and jobsite power

A range of Cat industrial engines that are compatible with renewable fuels such as 100 per cent hydrotreated vegetable oils (HVO) will be on display at bauma, including the new C13D and a new high power C3.6 delivering 142 hp. The stand features the first showing of a series electric drivetrain, part of a growing electrification ecosystem of solutions from Caterpillar; a hydrogen engine testing exhibit highlighting the ongoing fuels development work and a remanufactured C7.1. The C13D, C9.3B and C2.8 engines will also be featured. Providing reliable onsite power, the Cat range of EUV certified mobile XQP generator sets have been specifically designed to withstand the harsh conditions across many construction sites. The XQP115 genset, also compatible with HVO, will be on display outside Hall B6. The XES60 mobile battery energy storage solution (BESS) will be on display inside Hall B6 within the power hub area.

A new prototype Cat 775 off-highway truck and the reintroduced 395 front shovel will be on display. The 775 transitions to the next generation platform with increased truck body volume. The truck was designed to deliver superior performance and efficiency. The 395 front

Since its launch, the XES BESS products have been a key piece of equipment on many construction sites with its rapid plug and play installation. It supports onsite battery electric machine charging. It can be used with a combination of grid connection, generator sets using a variety of liquid and gaseous fuels, and renewable energy sources, such as solar, to store surplus energy and dispatch from these reserves as needed. With automatic monitoring of load levels, it can easily combine power sources and stored energy as necessary increasing jobsite energy efficiency, resulting in decreased fossil fuel usage.

The JCB mini excavator makes navigating confined areas so easy and efficient, you’ll forget what it felt like to be limited on space. Experience the kind of maneuverability only JCB can deliver. Experience better. Learn more at JCB.com

ALBERTA

Liftboss JCB

Calgary: 403-301-0041

Edmonton: 780-474-9900 liftboss.ca

BRITISH COLUMBIA

Williams JCB

Surrey: 604-930-3316 williamsjcb.com

A.L.P.A. Equipment

Edmundston : 506-735-4144

Balmoral : 506-826-2717 Fredericton : 506-452-9818

Moncton, N.B. : 506-861-2572 alpaequipment.com

NOVA SCOTIA

A.L.P.A. Equipment

Truro : (902) 897-2717 alpaequipment.com

Harvey JCB

Corner Brook: 709-639-2960

St. Johns: 709-738-8911 harveyco.ca

ONTARIO

Advance Construction Equipment (Division of Equipment Ontario)

Harriston: 519-510-5878 Waterloo: 519-742-5878 advanceequipment.net

D&W Group Inc.

Doughty & Williamson Jarvis: 519-587-2273

Brant Tractor Burford: 519-449-2500

Redtrac International Vineland: 905-562-4136 dwgroup.ca

Delta JCB

Dunvegan: 613-527-1501

Renfrew: 613-432-4133 Winchester: 613-774-2273 deltapower.ca

Equipment Ontario

Alliston:705-320-0506

Lindsay: 705-324-6136 Port Perry: 905-982-1500 equipmentontario.com

Fulline JCB

Glencoe: 519-287-2840 fullinefarm.com

John’s Equipment Sales

Frankford: 613-398-6522 johnsequipmentsales.com

Moore JCB Toronto, York & Peel Region: 416-747-1212 moorejcb.com

ONTARIO

North Rock JCB

North Bay, Sault Ste. Marie, and Sudbury: 705-897-7369 northrockrentals.com

ReadyQuip Sales & Service Ltd. Timmins: 705-268-7600 readyquip.com

WPE Landscape

Equipment - JCB Hamilton/Halton: 905-628-3055 wpeequipment.ca

PEI

A.L.P.A. Equipment (506) 861-2572 alpaequipment.com

A.L.P.A. Equipment

Bas-Saint-Laurent : (506) 735-4144

Gaspésie : (506) 826-2717 alpaequipment.com

Bossé Quebec Inc.

Desmaures: 418-878-2241 Saint-Augustin-debosse-frere.com

Moore JCB

Montreal: 514-333-1212 moorejcb.com

SASKATCHEWAN & MANITOBA

Westcon JCB

Regina: 306-359-7273

Saskatoon: 306-934-3646 Winnipeg: 204-694-5364 westconequip.ca

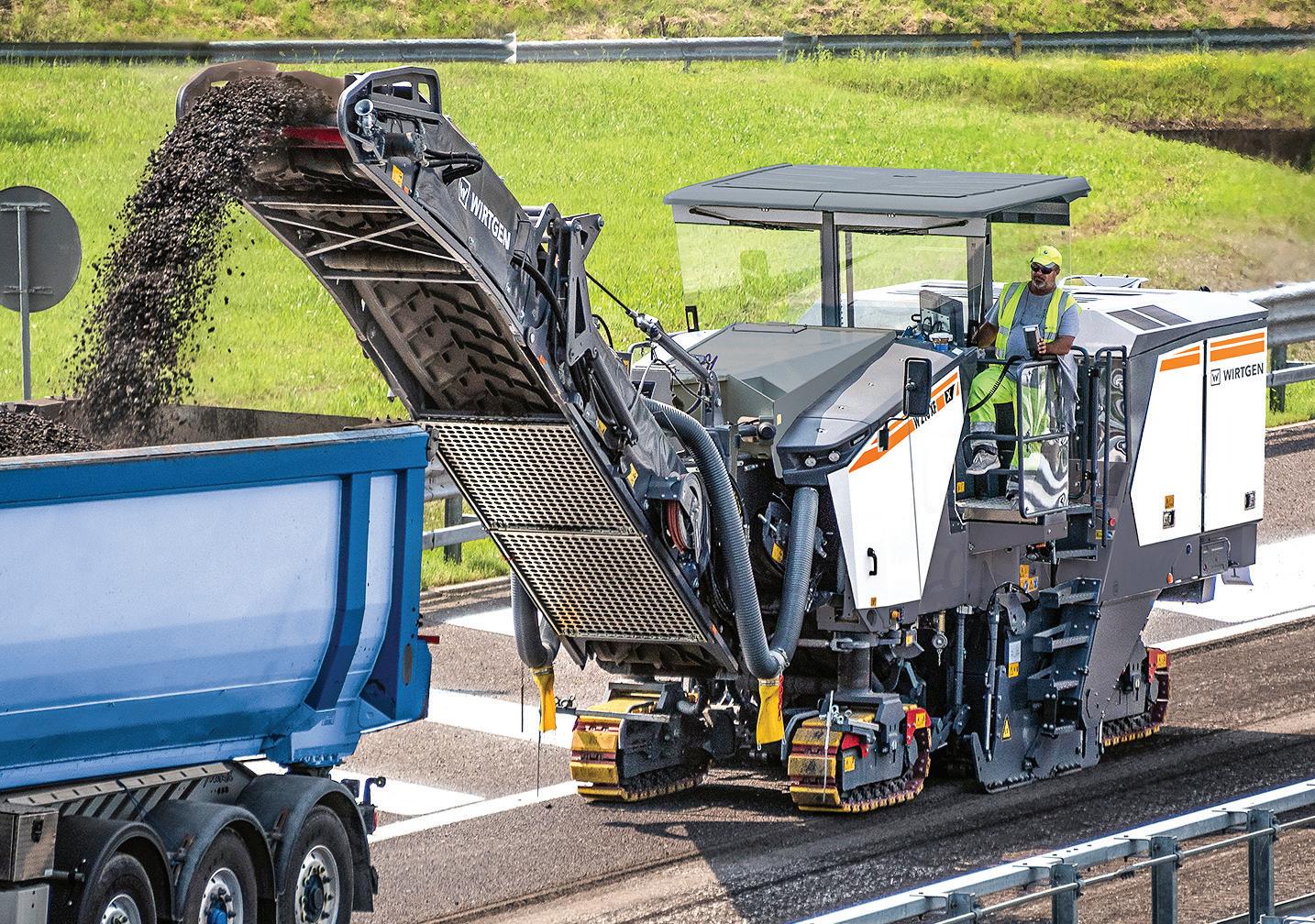

Wirtgen will unveil five world premieres in the cold milling and recycling segments, in addition to several innovations in the slipform paving and surface mining, at bauma 2025.

The new machines from the manufacturer include the new W 250 XF large milling machine and the new generation of WR series machines.

Cold milling machines

With a total of 12 cold milling machines, Wirtgen will present a broad cross-section of its overall product portfolio. Highlights include the world premieres of the battery-electric small milling machine W 50 Re (a technology project) and the large milling machine W 250 XF. The company will also present the world’s most powerful milling machine with a version featuring an optional operator’s cab.

During the development of the W 250 XF, Wirtgen focused on the realization of maximum productivity and reduced emissions.

The dual engine concept with two 18-litre John Deere engines delivers a maximum power output of 1,207 hp. Wirtgen and John Deere tuned the engine torque to meet the specific requirements of the cold milling process.

The Mill Assist machine control system regulates the power output of the two engines according to demand, to ensure the most efficient use of the machine. Automatic mode ensures a favourable working balance between performance and cost. It also enables selection of three different working strategies that optimize the process for cost, performance or quality. The machine at Wirtgen’s bauma booth is also fitted with a cab that offers the operator a comfortable, low-fatigue workplace and provides effective protection against the weather and noise.

W 210 XF

Also new in Wirtgen’s product portfolio is the large milling machine W 210 XF. With an engine power output of 778 hp and milling widths between 2 metres and 2.5 metres, the machine is ideally equipped for a wide range of applications and high daily productivity. The Dual Shift powershift transmission enables a wide range

of selectable milling drum speeds. The lower range of milling drum speeds enables significant reductions of fuel consumption, pick wear and noise emissions. The upper range of milling drum speeds makes it possible to achieve high area performance with a high-quality milling pattern, even at the maximum milling depth of 33 cm.

For the cold recycling and soil stabilization sectors, Wirtgen will present a range of machines including the three new WR 200|240|250 X models.

The focus in the development of these machines was set on ensuring easy and ergonomic operating, high performance and outstanding mixing quality. To achieve its goal, Wirtgen embarked on a comprehensive revision of both the operating concept and the design of the operator’s cab itself.

A new multi-function joystick, fingertip control and height adjustment with the multi-function armrest contribute to the improved ergonomics of the operating concept. In addition to digital process monitoring, the large machine control panel display offers a variety of automated functions, application-relevant displays and CoPilot.

The Wirtgen Group’s CoPilot provides suggested courses of action during the work process, offers interactive tutorials and a self-training function for familiarization with the machine, and its functions, with animations displayed directly on the machine’s control panel.

The field-proven Duraforce milling and mixing rotor guarantees consistently high milling and mixing performance.

The Rock Crusher WRC 240(i) will be on display alongside the new WR series machines. It crushes coarse rocks and stones, as found in hand packed stone layers and stony ground, in-situ and homogeneously mixes the resulting material in a single pass. With a working width of 2.3 metres and a depth of up to 51 cm, it can achieve cutting, crushing and mixing rates of up to 600 tons per hour.

The SP 33 slipform paver

Also, at bauma, Wirtgen is showing the compact SP 33,

its newest slipform paver for the construction of monolithic concrete profiles.

Thanks to its modular construction concept and a wide range of setting options, the machine can be configured for use in almost all situations encountered on construction sites. In offset configuration, it can pave curb and gutter profiles, rectangular profiles and concrete barriers up to 1.3 metres in height as well as sewer and gutter profiles.

Concrete slabs with a paving width of up to 2.2 metres can also be achieved without issue, and a width of 2.4 metres in combination with a trimmer.

In Crosspave configuration, the track units are turned by 90 degrees and the machine then paves transverse to the direction of travel. The slipform mould is centrally mounted under the machine, enabling the paving of concrete slabs with widths of up to 3 metres.

The quick and easy conversion from one paving mode to the other makes the machine extremely versatile. The new

operating concept with an event-driven graphic display assists operators in their work with both paving options.

The eco mode detects the current paving situation without the need for manual intervention by the operator and ensures automatic, load-optimized regulation of engine output for low fuel consumption and low emissions.

The AutoPilot 2.0 stringless machine control system is also usable with the SP 33. This eliminates the need for con-

trol by a physical stringline, which results in considerable savings in terms of time and effort and increases the safety of the personnel employed on the construction site.

At the same time, the system precisely controls both the height adjustment and steering of the machine. AutoPilot 2.0 also enables fast and precise paving of tight radii and complex geometries.

In the inset paving segment, Wirtgen will be showing an SP 94i paver with an integrated dowel bar inserter (DBI)

and a texture curing machine TCM 180i. The placement of reinforcement with a DBI increases the degree of automation, improving the efficiency of the overall paving process and the paving quality.

The placer/spreader WPS 102i is a useful addition to a paving train when paving concrete with pre-placed steel rebar reinforcement. It is deployed ahead of the slipform paver and enables feeding of material from trucks from the side.

Ammann has launched an upgraded version of ACEpro, its advanced Intelligent compaction system, to make it easier for operators to access the built-in technology.

The enhanced system is being integrated into Ammann ARP 75 and ARP 75 C pivot-steer tandem rollers.

Ammann Compaction Expert (ACE), the company’s proprietary automatic measurement, control and documentation system, was launched in 1998. Several options have been introduced since then for both soil and asphalt applications. The latest version of ACEpro automatically controls and adjusts amplitude and frequency.

It is available for pivotsteered tandem rollers used in asphalt compaction, and single-drum rollers utilized on soil and aggregates.

“All the built-in technology works quietly in the background,” said Josef Dementev, Global Product Specialist Machines at Ammann.

“To operators, it appears as a simple system. Yet the technology that seemingly ‘simple’ system brings is

a difference-maker on the jobsite.”

The revised version of ACEpro ensures operators can effortlessly access all the system’s technologies.

It is fully integrated into the machine’s new 25-cm touchscreen, which is attached to the rotating seat, ensuring it is always located directly in front of the operator.

The operator’s seat on the ARP 75 is fully adjustable, with a 270-degree rotation to optimize visibility from the cab. The machine is equipped with fingertip steering (FTS), making it more operator-friendly and comfortable.

The touchscreen helps operators control all machine functions simply, safely and quickly, including machine settings, vibratory parameters, lights and the ACE systems.

Several operating modes are available to make the system even more comfortable for all operators, from beginner to advanced levels.

From the display, the operator can choose between:

Automatic mode: Vibratory parameters (amplitude and frequency) are automatically controlled and

adjusted by the machine. The mode is set based on the compaction target, or selected by the type of materials and layers, to reach the target as effectively as possible.

Manual mode: The operator pre-selects parameters (amplitude and frequency) based on their experience or the needs on the jobsite.

User mode: The operator pre-selects the automatic regulation based on prior applications and defined material profiles.

ACEpro is integrated into the main machine display. This means no dedicated displays are needed, which reduces clutter in the cab and ensures clear sight lines for convenience and safety.

The touchscreen on the display is intuitive and highly visible. It presents a clear, simple dialogue that efficiently leads the operator through the compaction process. Straightforward graphics enable effortless monitoring of compaction progress.

Compaction parameters are highly variable for machines equipped with ACEpro. The system fluently regulates the frequency

between 38 Hz and 55 Hz, and amplitude from 0 to 0.87 mm. Automatic frequency and amplitude control is even faster and more pre -

cise with this latest version of ACEpro. The technology assesses the actual stiffness of the compacted material. It then delivers the optimal compaction force to the

ground for efficiency. This eliminates unnecessary passes and drum jumping and minimizes the risk of over-compaction or material destruction.

1.99%

• The 370 has advanced technology, including Digital Level, Dynamic Stability Assist, Height and Depth Alarm, and Payload.

• The heart of these machines lies in their electronically controlled hydraulic pump system and the industryrecognized SSC (Spool Stroke Control) system.

• This innovative combination enhances efficiency and control, while the Isuzu AQ-6HK1X Final T4 engine, known for its exceptional fuel economy, powers the machine.

Equipment Sales & Service Ltd.

Edmonton (780) 440-4010 essltd.com

Inland Truck & Equipment

Campbell River, BC 250-287-8878

Castlegar, BC 250-365-2807

Cranbrook, BC 250-426-6205

Fort St. John, BC 250-785-6105

Kamloops, BC 250-374-4406

Langley, BC 604-607-8555

Nanaimo, BC 250-758-5288

Penticton, BC 250-492-3939

Prince George, BC 250-562-8171

Quesnel, BC 250-992-7256

Terrace, BC 250-635-5122

Vernon, BC 250-545-4424

Williams Lake, BC 250-392-7101 inland-group.ca

Itec 2000

Rosslyn (888) 574-8530

Thunder Bay (888) 574-8530

Timmins (705) 267-0223 itec2000.com

McDowell B Equipment Ltd.

Sudbury (705) 566-8190

Barrie (416) 770-7706 bmcdowell.com

Stratton Equipment Sales & Service

Stratton (807) 483-7777 strattonequipment.com

Vars (613) 443-3300

• Notably, the 370 achieves up to 7% improved fuel consumption without requiring a Diesel Particulate Filter (DPF), eliminating the need for maintenance or replacement.

• Operators can select four power modes- Speed Priority, Power, Eco, and Lift, allowing them to optimize power, precision, and fuel savings for each task, resulting in enhanced cost-effectiveness.

• Did we mention comfy, best-in-class interior cab spacing!

Équipement JYL Inc.

Chicoutimi (418) 698-6656 equipementjyl.com

(418) 878-2241 micanic.com

Stittsville (613) 836-0654 terapro.ca Terapro

Top Lift Enterprises Inc.

Stoney Creek (905) 662-4137

Bolton (905) 857-5200 toplift.com

Top Lift Enterprises Inc.

St-Laurent

Paul Equipment

Balmoral (506) 826-3289 paulequipment.ca

YUKON TERRITORY

Inland Truck & Equipment

Whitehorse, YT 867-668-2127 inland-group.com

d’Or (819) 825-4299 Plaisance (819) 718-0945 terapro.ca www.lbxco.com/X4S

JCB’s lineup of vibratory tandem rollers has expanded to four machines with the introduction of the CT380 and CT430.

The two new rollers were introduced at Pave-X 2025 and join the compact CT160 and mid-size CT260 vibratory tandem rollers in the manufacturer’s lineup.

“Our new rollers underscore JCB’s long-term investment in North America,” said James Gill, JCB Product Manager.

“From our new manufacturing facility going up in

San Antonio to the launch of products like the CT380 and CT430, we are laser-focused on meeting the needs of U.S. contractors with machines that are reliable, easy to operate and built to perform.”

The CT380 is designed for jobsites with limited space. The machine is compact in design without compromising on performance.

The CT380 is ideal for road construction, asphalt reconstruction, road repairs and patching, as well as parking lots and driveways.

JCB designed the CT430

for optimal performance with minimal machine damage to deliver smooth operation that enhances onsite productivity.

The CT430 is the ideal roller for compacting tarmac, stone and asphalt; road construction; tarmacking drives and recreation areas; work on sports courts and pitches; and road repairs and patching.

Powered by efficient 48.9hp, 3-cylinder engines, the CT380 and CT430 are built to handle daily use.

With an operating weight of 4,100 kg for the CT380 and

4,500 kg for the CT430, the rollers are the largest vibratory tandem rollers offered by JCB. Their operating weights strike a balance between easy transport and heavy-duty performance.

The CT380 and CT430 are equipped with features to tackle the toughest jobs, offering reliable compaction and operator-focused design.

For example, the machines deliver versatile compaction power, with dual-drum widths of 1.3 metres for the CT380 and 1.4 metres on the CT430. This delivers centri-

fugal forces of up to 6,260-kg and 6,623-kg per drum, ensuring superior compaction.

Both models feature maximum travel speeds of 10 km per hour, enabling swift, efficient movement across worksites.

With a 34-degree steering angle and a 13-degree oscillation angle, the rollers navigate tight turns and uneven terrain with ease. Both rollers also deliver 40 per cent gradeability.

Adjustable seats, intuitive controls and exceptional visibility reduce fatigue and

enhance operator productivity.

As well, simplified service points and reduced maintenance intervals keep machines on the job longer.

JCB LiveLink telematics provides advanced tracking and monitoring for added peace of mind.

“Our philosophy is robust simplicity,” Gill said. “These machines are easy to operate, easy to maintain and ready to work whenever you are. That’s what makes the CT380 and CT430 invaluable on American jobsites.”

U.S. EPA PHASE III / EU STAGE V

The ARX10.1 offers cutting-edge “Side-Free Drums” technology that allows you to experience compaction like never before. The uniquely designed drum consoles installed from a single side provide unmatched precision, control, and performance.

Not only that, but you will:

• The safe design = focus on productivity

= reducing the time and effort spent on a task Save on fuel costs

• Reduce engine maintenance spending

By Justin Zupanc, Compaction Product Manager, Volvo Construction Equipment

Anyone involved in roadbuilding or site preparation should understand the critical role compaction plays in a project's overall success. For roads, proper soil compaction is critical to the strength and stability of everything under the pavement and helps prevent water from accumulating beneath the road. Similarly, accurate compaction of asphalt during the paving process makes it denser and more durable by eliminating air voids. These factors

ultimately determine things like the smoothness and lifespan of the road.

When it comes to road and general site prep, soil compaction affects the stability and load-bearing capacity of the soil. This can prevent or prolong any settling or shifting and support proper water drainage to avoid erosion.

As compaction is such an important part of a project, selecting the right equipment to do it is a big decision. It should be obvious whether you need a soil or asphalt compactor, but deciding on the right machine from there takes a bit more consideration. Here are some tips to help you select the right machine for the job. For this article, we’re talking about larger compaction projects like those mentioned above — not smaller ones that can be done with a tamper, rammer or plate compactor. The word “roller” is also used interchangeably with “compactor.”

If we’re talking soil

There are multiple kinds of soil compactors, and the first deciding factor is the makeup of the soil itself. Vibratory compactors excel in granular soils like sand and gravel but can also work for cohesive soils like clay and silt. Cohesive soils, however,

may require the “kneading” action of a padfoot roller (also known as a sheepsfoot roller) to achieve higher density and stability.

With vibratory rollers, there are several configurations to choose from.

A single-drum vibratory compactor has one smooth drum at the front and two tires at the back for the best combination of traction and compaction — but you may need to make several passes to get the soil as compressed as you’d like.

A double-drum model, just like it sounds, has drums at the front and back for maximum productivity. These are also called tandem rollers. A double-drum compactor can be used for some soil applications, but it’s more commonly used for asphalt.

There are static single- and double-drum compactors too, which means they do not apply vibration and won’t compress deeper soil layers like a vibratory model can. A vibratory roller can be operated in static mode simply by not turning on the

vibration function.

A pneumatic tire roller features multiple tires (typically four or five) across each axle and is best for thin, granular soils. Heavier models can work for fine silt or gravel, too. Some OEMs offer combination rollers, which have a drum at the front and pneumatic tires across the back axle.

A padfoot or sheepsfoot roller is essentially a single-drum model with lugs or feet protruding from the drum to knead more cohesive soils. The dimensions, weight and number of lugs will impact the quality of compaction. A single-drum roller can be equipped with a dedicated padfoot drum or have an optional bolt-on shell kit that can be added or removed per job requirements.

If we’re talking asphalt

In paving, the material being compacted is a human-made mixture, so you have more control over the consistency and particle size range. An asphalt-only top layer provides a smooth driving surface, better durability for high-traffic zones and a more aesthetically pleasing finish.

A chip seal application provides more traction and is usually more cost-effective but is not typically suited for higher traffic or speed rated roads. For this technique, the road is sprayed with a thin, even layer of heated liquid asphalt and then a crushed rock layer is sprinkled on top and compressed into the mix.

Power Curbers has launched the four-track version of its popular 5700 series, the Power Curber 5704-D Max.

The 5704-D Max is the latest generation of the company’s top selling slipform machine that pours curb and gutter, sidewalk, barrier, ditches, paving, tunnels, agricultural and specialized applications. It features a compact size, simple design, easy operation and high productivity.

Weighing about 14 tonnes, the 5704-D Max is available with several conveyor options, including a 3.7 metre

auger, 6 metre belt and 8.5 metre belt.

The newly designed conveyor options allow for quick transitions from right to left, thanks to a dual-swinging mount. The 8.5-metre belt option folds for easy transportation.

The new additional fourth post allows for enhanced stability during large-scale applications.

As well, a dual-swing conveyor mount allows the operator to easily switch from left to right pouring.

At the end of the day, the hydraulic barrier allows the

user to raise the mold off the steel cage. With 1.2 metres of stroke in the mold lift and 90-cm of post extension, the 5704-D Max can clear tall steel cages, allowing the operator to quickly move the machine out of traffic for the next day’s pour.

As well, the 5704-D Max is designed to provide the operator with an excellent view of the concrete as it exits the mold, enabling immediate adjustment to minimize work behind the machine. The operator is also able to see all activity around the machine.

The 5704-D Max is powered by a 130-hp Tier 4 Final Cummins engine. Power Curbers was founded in 1953 in Salisbury, North Carolina, after manufacturing the world’s first automatic curb machine.

The company produces concrete slipform machines used for paving, curbs, sidewalks, barrier walls, ditches and a variety of special applications under the brands Power Curbers and Power Pavers.

The company now has machines in more than 100 countries.

Blue Diamond Attachments has unveiled its new line of self-levelling Extreme Duty Series 2 Cold Planers.

The new cold planer line is designed to tackle road surface milling, concrete scarification and asphalt removal applications.

The comprehensive line includes eight models ranging from 35 cm to 122 cm in milling width, compatible with skid steer and compact track loaders. The attachments are available in both low and high flow.

"Our Extreme Duty Series 2 cold planer line represents a significant advancement in road maintenance and construction capabilities for contractors and municipalities," said Drew Truan, Chief Operating Officer at Blue Diamond Attachments.

"By combining precise depth control with exceptional stability and versatility, we're enabling operators to achieve superior results across a wide range of applications, from pothole repair to complete surface removal."

The new cold planer line features several innovative design elements that

enhance performance and precision. A patented self-levelling system ensures constant milling depth regardless of ground contour or machine position

As well, the planers feature independent right and left depth adjustment capability, available in both mechanical and hydraulic configurations, to enable precise surface matching and perfect sideby-side passes.

Standard hydraulic side shift functionality allows flush milling against walls and other obstacles. Multiple drum options with different widths and teeth layouts accommodate various applications from asphalt to concrete milling.

The cold planers feature milling depths from 11 cm to 17 cm, depending on model, and working speeds of up to 5 metres per minute.

All models have an optional dust suppression spray system and clear depth indicators for precise control.

The line's robust construction and direct-drive hydraulic motors ensure reliable performance while minimizing maintenance requirements.

For a smooth asphalt finish, you’ll need doubledrum vibratory compaction because it will remove air voids better and make the pavement last longer.

A pneumatic tire roller is more common for a chip seal application because the tires provide more of a kneading action to press the “chip” layer into the asphalt without fracturing the stones.

Once you know the kind of compactor you need, it’s time to find the proper machine size. For the most part, this comes down to the requirements of the job.

Road work typically involves strict specifications on density, smoothness and thickness, which are greatly affected by the number of passes done during compaction. A roller’s drum width is the top machine spec to consider here because it dictates how many passes it will take to sufficiently compress your material.

It’s possible to use drums that are too narrow or too wide for the lane being paved, but the objective is to achieve density in as few passes as possible. With a drum that is too narrow, additional passes will be required and that will lead to inconsistent densities across the lane. A drum that is too wide may create too much overlap in the centre, thus creating a significantly higher density in the centre of the lane.

Most manufacturers of highway-class compactors offer three common drum widths: 1675, 1980 and 2135 mm. These widths allow you to compact the average lane of traffic in two passes (including an appropriate overlap of a few inches) without the machine being too wide for transportation regulations.

If you’re doing something other than road work, models with drums in the 711-mm to 1422-mm range may be just fine. These are great for parking lots, driveways, bike paths and sidewalks and in residential zones where a giant machine is impractical and probably unwelcome. In addition to the drum’s width, its diam eter can make a difference in your productivity as well.

A larger drum has less tendency to displace ma terial and cause ripples in the mat. It also has a greater area of contact, which re duces drum edge markings and material displacement.

As you can imagine, lar ger roller models are much heavier, which increases the level of compaction they provide. Some models allow you to add water or sand

to sealed compartments to increase a machine’s weight if needed.

Other specs that matter

A few other machine specs that play into your machine choice are amplitude, frequency and the drum’s eccentrics.

Amplitude is the total distance that the vibrating drum is vertically displaced from its neutral position when vibration is on.

Higher amplitude is required for thicker layers or difficult-to-compact mixes, while lower amplitude is needed to compact thinner layers or mixes with softer aggregates.

Frequency is the number of cycles the vibrating mechanism makes per minute (VPM) or second (Hz). Higher frequencies allow faster rolling speeds without compromising compaction quality but will provide less force per impact.

Some manufacturers offer wider ranges of amplitudes and more frequency settings than others, all of which will affect what kind of compaction work you can take on and how fast you can complete your projects.

Tandem rollers use rotating eccentrics to create vibration. Models with auto-reversing eccentrics, however, will also reduce the bow wave in front of the drums, which minimizes material displacement and ensures more consistent compaction results. This feature helps deliver superior smoothness to the finished mat.

Don’t forget the support