An innovative modular washing solution specifically designed for processing hydro excavated waste material that was typically a waste material. The washing process converts it into a saleable product, openign up a new revenue stream for many quarries.

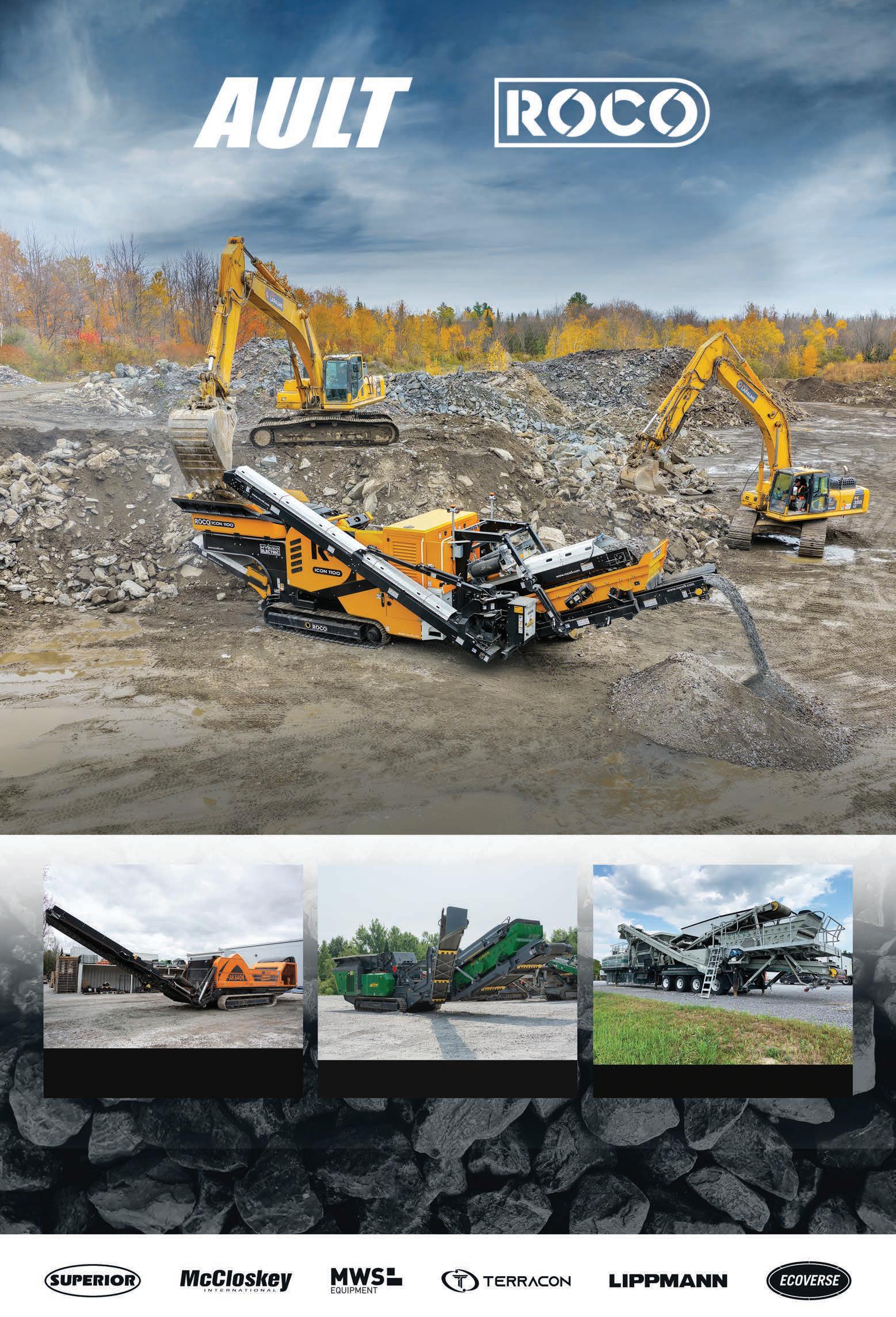

COBRA 230 IMPACT CRUSHER

3.4yd3 hopper capacity, integrated pre-screen for fines removal, 34”x24” crusher inlet, hydraulic overload protection, 36” conveyor, diesel power. Great for Construction & Demolition, Asphalt Recycling, Quarrying or Contract Crushing.

TRAKPACTOR 320SR IMPACT CRUSHER

Double deck 11’ x 5’ screen, bolt in cartridge grizzly, highly fuel efficient direct drive system. Excellent reduction and high consistency of product shape in recycling, demolition and quarry applications.

400 JAW CRUSHER

28” x 44” jaw, hyd. crusher adjust system for un-crushable materials, direct drive, diesel power. Ideal for sand & gravel, blasted rock, river rock, C&D waste, overburden, foundry waste, processed ores, processed minerals.

Highly mobile CRC1150S cone and screen plant combines a modern TC1150 300 HP Cone crusher with the highly efficient TSV 6x20 3-deck screen. 300 HP cone utilizes high efficiency roller bearings. Key features include automated cone controls and larger closed side settings and is rubber isolation mounted on a heavy-duty chassis frame.

Samantha Da Silva has found her calling operating a hydrovac truck at Miller Underground

Auctions ...............................................................A1

Jardine Auctions ..............................................................B6

Michener Allen Auctions .................................................A10

North Toronto Auctions ..............................................A1,B12

Sunrise Auctions ............................................................A20

The growing demand for reliable power in Ontario will require the province to increase its generation abilities quickly.

By 2050, demand for electricity in the province is projected to increase by 75 per cent. Emerging industries are incredibly power hungry. Data centres, for example, represent 13 per cent of new electricity requirements, while new electric vehicle and supply chain facilities will require the same amount of power as Toronto.

Small modular reactors (SMRs) are Ontario’s best bet to meet its future electricity needs, and their rollout could spark a wave of opportunity for Canada’s construction industry. Ontario has announced it will build four SMRs at Darlington Nuclear Station, the rst of their kind in the G7.

e $3 billion project will

create 18,000 jobs during construction. Construction on the first SMR began in May 2025, with the reactor coming online in 2030.

“Today’s investment to support the rst SMRs in the G7 is a down payment on Ontario’s nuclear energy future,” said Premier Doug Ford. “We’re protecting Ontario by supporting good-paying, long-term jobs for Ontario workers and building the energy infrastructure — including both SMRs and new, large-scale nuclear — needed to make Ontario an energy superpower.”

Unlike conventional nuclear plants, SMRs are compact, factory-built units designed for fast, more predictable deployment. Each SMR requires specialized civil, mechanical and electrical work, creating years of steady activity for contractors, trades and suppliers.

The technology also fits within Canada’s construction expertise. Contractors who’ve built power plants, processing facilities and large industrial projects will nd familiar challenges like demanding standards, heavy coordination and precision work, but within a new, scalable framework.

e modular nature of SMRs means projects can roll out in phases, providing continuity of employment and allowing firms to build specialized capacity over time.

The construction, operation and maintenance of the four units will add $38.5 billion to Canada’s GDP over the next 65 years. e provincial government has worked with Ontario Power Generation (OPG) to ensure 80 per cent of project spending goes to Ontario companies, including steel produced in Ontario, and construction

and operations will enhance employment by sustaining an estimated 3,700 highly skilled, good-paying jobs annually.

Ontario has the engineering know-how and construction talent to lead in the nuclear construction field. Embracing SMRs is not just about meeting future power needs, it’s about building the next generation of Canadian industry.

Excavator Company has debuted the new 145 X4S hydraulic excavator, a machine designed to improve performance, eciency and comfort. At the heart of the 145 X4S is an advanced, electronically controlled hydraulic pump system paired with the industry-renowned Spool Stroke Control (SSC) system. is combination delivers an impressive advancement in e ciency and control, ensuring maximum productivity. With an operating weight of 14,800 kg, the 145 X4S is powered by the 102-hp Isuzu

AR-4JJ1X Tier 4 Final engine, which is known for its exceptional fuel economy. As well, the 145 X4S can reduce fuel consumption without the need for a Diesel Particulate Filter (DPF), eliminating DPF-related maintenance and replacement costs. Operators can fine-tune their work with four selectable power modes, including SP, Power, Eco and Lift, allowing them to optimize for power, precision and ultimate cost-e ectiveness. The excavator features a maximum travel speed of

5.6 km per hour, a 12.5 rpm swing speed, a max digging depth of 5.5 metres and a maximum reach of 8.14 metres.

Advanced tech

e 145 X4S excavator embraces advanced technology, offering optional features such as digital level, height and depth alarm as well as payload management.

e payload management system allows the operator to see the bucket volume in real-time, prevent overloading trucks and view loading history. e payload feature also

enables the ability to store up to six unique truck capacities and 10 bucket dimensions.

e machine also comes precision grade ready, which helps to streamline the installation of precision grade kits and reduces the time and e ort required to integrate IMU sensors for essential machine guidance and control systems.

Minimal maintenance

Engineered for extended operation, the 145 X4S maximizes time on the jobsite. A 500-hour fuel lter service interval means operators

can work longer between changes.

Furthermore, the DEF tank boasts a consumption rate of about 2 to 3 per cent compared to diesel fuel, extending the intervals between refills. For operator convenience, all essential service points are easily accessible at ground level.

Built for total control

Inside the cab, the work environment is designed for focus and relaxation during long shifts. e high-de nition, 25-cm LCD monitor features an anti-glare coating

for crystal-clear visibility. This user-friendly monitor can be fully customized to display vital information, including custom hydraulic work tool names, system messages and SCR auto regeneration status.

Safety and visibility are enhanced by Wide Angle Visual Enhancement System (WAVES) providing a seamless 230-degree view around the machine.

The spacious cab, with ROPS and FOPS Level 1 certi cation, features ample legroom and a high-back, tilting and heated seat.

JCB North America is making signi cant progress on its $500 million manufacturing facility in San Antonio, Texas.

The state-of-the-art facility, located on a 400-acre site, is expected to generate about 1,500 jobs and will serve as a hub for producing JCB’s telehandlers and mobile elevating work platforms.

The project is the single largest investment in the company’s 80-year history. It remains on schedule with hiring set to begin in late2025.

“We're pretty confident that we're on plan and ready

to start production next year, so we're excited about building that product to you,” said David Carver, Operations Director for JCB San Antonio.

In April, JCB announced it will expand the footprint of the facility, bringing the total footprint to 1 million square feet. is expansion re ects JCB’s continued con dence in the market and supports the company’s strategy to increase production closer to customers, which aims to improve delivery times and reduce supply chain risk.

“For the last 50 years, we've been proud to manufacture right here in the United States, first in Bal -

timore, then in Savannah and now through this major expansion in San Antonio, we're taking another bold step forward,” said Richard Fox-Marrs, CEO of JCB North America. “When complete, the site will be the largest JCB facility anywhere in the world.”

JCB selected the San Antonio site as Texas is its single largest construction equipment market in the United States. As well, the new facility will be centrally located to supply the United States with machinery.

“We are geographically diversifying our manufacturing footprint, giving greater re-

silience and exibility across all of our North American operations,” Fox-Marrs said.

Since the groundbreaking in June 2024, JCB has made rapid progress on site preparation and infrastructure. e architectural design is being led by RVK, a women-owned rm with a track record in commercial and industrial projects. R&S Excavation Ltd. completed mass grading, and Ella Contracting led utility work. More than 1 million tons of dirt and 119,000 tons of select fill were moved. As well, nearly 5,900 metres of sewer, water and storm lines have been installed.

With foundational work complete, vertical construction has now begun on the production and ofce buildings. Texas- based Joeris General Contractors is leading the next phase of development.

JCB has started hiring key roles in San Antonio and is focused on building a workforce from the local community and veteran populations.

“JCB is deeply committed to the local workforce and creating meaningful career pathways,” Carver said. “Through education partnerships and a focus on veterans, we’re building a

team that re ects our values and the community we’re joining.”

Fox-Marrs added the San Antonio site represents a long-term commitment to the North American market. e site includes a demonstration area and ranch to enhance the customer experience as well as the ability to more than triple manufacturing.

“ is new facility has been designed for exibility and growth. It will have the capability to manufacture any JCB product going forward, allowing us to meet custom demand quickly and competitively,” Fox-Marrs said.

The ORION line of high-capacity forklift trucks is designed for superior performance and reliability. Engineered with advanced technology, ORION machines o er maximum e iciency and productivity, making them ideal for a wide range of applications. Whether you need powerful lifting capabilities or precise maneuverability, ORION has the right solution for your needs.

ADVANCED PERFORMANCE

LIFTING VERSATILITY

PRECISION CONTROLS

DIESEL AND LP POWER OPTIONS

ROBUST CONSTRUCTION

SUPERIOR LIFTING CAPACITY

BUILT BY OPERATORS FOR OPERATORS

CUSTOMIZED FOR YOU

EASE OF USE

ENHANCED PRODUCTIVITY

Flourish Landscaping began in 2019 with one truck, a lawnmower and a vision. “It was just me at the start,” says owner Tristan Nagler. “Over the past seven years, we’ve grown to offer a full range of services, commercial snow removal, lawn care, decks and fences, interlock and more.”

Based in Kingston, Ont., the company serves clients from Napanee to Gananoque, predominately in the Kingston area. “The first three years we grew really fast,” Nagler says. “Since then, growth has been steady, and we’re proud of where we are today.”

Nagler says his decision to enter landscaping came after working in the restaurant industry. “I was just looking for some extra weekend work,” he recalls. “I put up a few posters, the phone started ringing, and it grew from there.”

Nagler says equipment reliability and

BARRIE

Bobcat of Barrie

705-726-2228 oakenequipment.ca

GREY BRUCE

Bobcat of Grey Bruce 519-372-9100

bobcatoftc.com

PARRY SOUND

Bobcat of Parry Sound Ltd.

705-342-1717 bobcatofparrysound.com

TORONTO WEST

Bobcat of Toronto 416-679-4172 oakenequipment.ca

BRANTFORD

Bobcat of Brantford 519-752-7900 bobcatofbrantford.com

HAMILTON

Bobcat of Hamilton 905-643-3177 bobcatofhamilton.com

PETERBOROUGH

Bobcat of Peterborough 705-748-9119 bobcatofpeterborough.com

THUNDER BAY Equipment World Inc. 807-623-9561 bobcat-tbay.com

after-sales support are key factors in choosing a dealer. “We use our machines hard, they’re running all day and really pushed to the limit,” he says. “The machines themselves are usually priced about the same, but the cost of parts and repairs has skyrocketed with the past brand we were using. When we were quoted a ridiculous price for a part, I knew it was time to look for a new dealer. For us, the support after the sale must make sense.”

So, when it came time to expand the company’s equipment lineup, Nagler turned to Bobcat®. “I’d always heard great things, it’s the original skid-steer that everyone else’s is based on, so I figured I’d go to the source and get the best,” he says.

Flourish Landscaping recently added two Bobcat machines to its fleet, a T66 compact track loader and an S64 compact skid-steer loader. “They’ll be plowing downtown this winter in tighter parking lots where maneuverability is key,” Nagler explains. “In the summer, especially the

track machine, we’ll be using for grading and new projects.”

Nagler worked with Bobcat sales specialist Terry Hayduk, from Bobcat of Kingston, who he says made the process smooth and easy. “He’s been super helpful, met me on-site, got me all kinds of quotes, and guided me through every step,” Nagler says. “We went through a few options before deciding, and he was great through it all.”

The company opted for the Bobcat Leasing three-year program on both machines, with plans to either buy them out or upgrade at the end of the term. This program allows me to have more cash flow and lower monthly payments. “The keyless start on the T66 is really slick, just punch in your code and go. It’s pretty sweet,” Nagler says. “They’re nice, smooth machines.”.

Fully insured with $2 million commercial liability coverage, Flourish Landscaping continues to grow, with quality equipment and customer service at the core of its success.

CASSELMAN

Bobcat of Ottawa Valley 613-764-2033 bobcatov.com

KITCHENER

Bobcat of Tri-Cities Ltd. 1-866-214-3939 bobcatoftc.com

STRATFORD

Bobcat of Stratford 519-393-6040 bobcatofstratford.ca

SAULT STE. MARIE

Bobcat of Sault Ste. Marie 705-949-7379 bobcat-ssm.com

LONDON

Bobcat of London 519-455-4900 bobcatoflondon.ca

Bobcat of Ottawa Valley 613-932-2034 bobcatov.com STRATTON Stratton Equipment 807-483-5505 strattonequipment.com

WINDSOR

Bobcat of Windsor 519-737-0120 oakenequipment.ca

COURTICE

Bobcat of Durham East Ltd. 905-404-9990 bobcatofdurhameast.com

MUSKOKA

Bobcat of Muskoka 249-390-7000 oakenequipment.ca

SUDBURY

McDowell B Equipment Ltd. 705-566-8190 bmcdowell.com

WYOMING

Advantage Farm Equipment Ltd. 519-845-3346 advantage-equip.com

FRANKFORD

John’s Equipment 613-398-6522 johnsequipmentsales.com

OTTAWA

Bobcat of Ottawa Valley 613-831-5166 bobcatov.com

TORONTO EAST

Bobcat of Toronto 416-679-4171 oakenequipment.ca

The new Cummins X10 will include the first-to-market application of Cummins Valvetrain Technologies’ High Power Density (HPD) engine brake.

The X10 engine, designed for heavy and medium-duty vocational, regional haul or bus vehicles, is part of Cummins’ HELM fuel-agnostic engine lineup, where it replaces both the L9 and the X12 engines.

For all your needs in construction equipment, aftermarket, used or reconditioned parts! 833-848-0745 / 418-841-7945 www.graderspro.com / info@graderspro.com

800, RUE ARDOUIN, QUÉBEC, QC G1C 7M9

“The HPD engine brake is both a unique and ideal braking solution for the wide displacement coverage of the new X10 engine, as well as the variety of duty cycles to be served,” said RaNae Isaak, Program Leader of the X10 at Cummins. “Feedback from both OEM and end-user customers who have test-driven the new X10 with the HPD engine brake attest to its ability to offer the braking power of up to a 13-litre truck, via a 10litre displacement engine. In fact, many comment that the HPD engine brake is the most powerful braking solution in a vehicle they have ever driven.”

The 1.5-stroke HPD engine brake for the X10 provides small and medium displacement engines with large engine displacement retarding power, generating up to 40 per cent higher levels of supplemental braking force than traditional compression release braking at high engine speeds, and improvements of up to 100 per cent at lower rpm cruising speeds. This supports the commercial vehicle industry’s pursuit of better fuel economy and lower total cost of ownership.

A conventional engine brake has one compression release (CR) and one brake gas recirculation (BGR) event for each of the engine’s cam rotations. With the 1.5-stroke HPD, cylinder de-activation (CDA) mechanisms are used to eliminate the main exhaust valve events, allowing two CR events per cam rotation.

e rst CR event is powered by a standard intake charge, however, for the second CR event, the power is achieved through the recirculation of exhaust manifold gases, without drawing air from the intake.

Two HPD engine brakes, a 3-cylinder and 6-cylinder version, will be o ered on the X10 to provide coverage for customers formerly specifying Cummins L9 (medium-duty) and X12 (heavy duty) engines. The advanced brake o ers up to 320 hp at 2,300 rpm for the 3-cylinder option, and up to 475 hp at 2,300 rpm for the 6-cylinder option.

HPD is part of Cummins Valvetrain Technologies’ common modular design frame, meaning other valvetrain technologies can be integrated, or removed, according to local market requirements. It is being developed in six other engine programs.

“Punching above its weight class, the HPD engine brake is an attractive, di erentiating proposition for both engine and vehicle designers. It’s a perfect match for the Cummins X10 engine because of the diverse number of applications, many that need high braking performance,” Isaak said.

With the exhaust side of Cummins’ Cylinder Deactivation (CDA) already integrated as part of HPD, future applications will

have a built-in bridge to the speci cation of full CDA for customer requirements.

“All that needs to be added are additional control solenoids and collapsing intake mechanisms to an already protected framework,” Isaak said.

Two-Stroke and 1.5-Stroke HPD engines were announced in 2016 and 2018, respectively, by Jacobs Vehicle Systems, which was acquired by Cummins in 2022.

- 6th @ 9:00am

Booth W42500, West Hall March 3-7, 2026

Meet the contractor-strong, feature-rich machine that’s ready to carry the load for your crew. The all-new Hyundai HT38 CTL delivers 115 HP, a 3,807-lb. rated operating capacity, and 10’9” of lift height. All backed by Hyundai’s 3-year / 3,000-hour warranty.

Hyundai Canada Dealers

Alberta Chinook Equipment chinookequipment.ca

•Hi-Flow Hydraulics

•Torsion Suspension

•Reversible Fan

•Lift-Arm Float

•Auto Self-Leveling

Nova Scotia

EMSCO Heavy Equipment emsco.ca

British Columbia

Handlers Equipment Ltd. handlersequipment.com

Manitoba

Mazergroup mazergroup.ca

New Brunswick

A.L.P.A. Equipment alpaequipment.com

Newfoundland and Labrador

Reefer Repair Services kenworthnl.com

•Ride Control

Mazergroup mazergroup.ca Introducing Hyundai's HT38 Large Frame CTL What

•Rearview (Backup) Camera

•Pressurized Cab with Heat & A/C•Bluetooth + 8” Smart Touch Display

Hurricane Industrial Equipment hurricanelift.com

Ontario

A.M.B. Lift Inc. amblift.com

Bob Mark New Holland bobmark.ca

CIMI Inc. excavatrice.com

Equipements Marquis equipementsnordmax.com

Hood Logging Equipment Canada hoodequipmentcanada.com

RTI Equipment Solutions rtigroup.ca

Quebec Agribiti agritibirh.com

Cimi Inc. excavatrice.com

Hydromec Inc. hydromec.ca

Nordmax, Inc. equipementsnordmax.com

Saskatchewan

EMSCO Heavy Equipment emsco.ca

wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, or na.hd-hyundaice.com.

By Matthew Strader

When opportunity knocks, it sometimes arrives in work boots. In 2020, faced with an unexpected career crossroads, Samantha Da Silva found herself trading the promise of a dream job at a oral wholesaler for the unpredictable world of construction.

What began as a quick two-week stint assisting her husband’s new business, Miller Underground, quickly spiralled into a full- edged career — one that would redefine both her ambitions and the industry itself.

rown into the deep end from day one, Da Silva took charge of operating a trailer-mounted flusher unit, towed by a Dodge 2500, with little prior experience.

“How hard could it be?” she mused. But as the days turned into weeks, and then months, it became clear that she was

forging a new path. Now, ve and a half years later, what began as a temporary gig has become a calling — one that she embraces with pride and determination.

Not long after her unexpected initiation into the trades, Da Silva obtained her DZ licence and helped Miller Underground purchase its rst combo truck. She recalls the thrill of running her “first love”—a 2006 Sterling Vactor — and the bittersweet upgrade to a 2022 Western Star. e Sterling has earned a permanent place in her heart — and in the company’s growing eet.

“ e 2006 had its issues, but with enough love, it thankfully still runs like a tank,” Da Silva said.

Mastering the cra

Today, as Miller Underground’s Assistant Operations

Manager, she operates a Vactor 2100i hydrovac usher truck on a 2022 Western Star 4700 chassis, working alongside sewer and watermain crews to clean, inspect and repair both new and existing infrastructure. Her expertise spans air pressure and de ection testing, concrete chipping and everything required to get the job done. Beyond the technical, she plays a vital role in the day-to-day operations — running crews, scheduling, training new hires and even managing the company’s social media presence.

“I chip concrete and do whatever it takes to get the job done,” she said.

Her responsibilities extend to hydrovac work for locating services, digging up utilities and placing sonotubes for footings. Each task is approached with the same unyielding work ethic and pride in craftsmanship that has come to de ne her career.

Breaking barriers

As the only woman at Miller Underground — and frequently the lone female on site — she has navigated unique challenges.

Her journey led her to connect with other hard-working women in the trades, inspiring the formation of Tradeswomen Tribe: a group dedicated to mentorship, support and solidarity among women in the construction industry. eir monthly meetings are an opportunity for conversation and guidance, helping members thrive in a traditionally male-dominated environment.

“I take a lot of pride in my work,” she said. “My plan is to always grow and do better. Any opportunity I get to learn a new skill or hop in a new piece of equipment I am all there.”

A LiUNA 183 member, Da Silva credits the union with supporting her growth and

opening doors to new experiences, including attending Tradeswomen Build Nations for two consecutive years — the world’s largest gathering of tradespeople, boasting more than 6,000 attendees this year.

Da Silva’s vision for the future is rooted in growth — expanding Miller Underground’s staff, fleet and services, while seeking out new opportunities.

Whether it’s learning a fresh skill or hopping into the operator’s seat of a new machine, she is always eager for the next challenge.

For her, the sewer and

watermain industry is more than just a workplace — it’s home. Colleagues have become family, fellow union members are extended kin and the tradeswomen she’s meets are cherished sisters in a shared journey. Her story is one of resilience, pride and trailblazing leadership, proving that with grit and determination, anyone can carve their own path beneath the surface — quite literally.

”I am proud to call the sewer and watermain industry my home, my co-workers family, my union members extended family and my fellow woman in the construction my sisters,” she said.

5-YEAR/

5,000 HOUR

Full Machine Warranty

5-YEAR/

10,000 HOUR

Machine Structure Warranty

• Advanced, electronically controlled hydraulic pump system paired with the industry-renowned Spool Stroke Control (SSC) system. This combination delivers a dramatic leap in e ciency and control, ensuring maximum productivity.

• Isuzu AR-4JJ1X Tier 4 Final engine, which is known for its exceptional fuel economy. Operators can fine-tune their work with four selectable power modes, including SP, Power, Eco, and Lift, allowing them to optimize for power, precision and ultimate cost-e ectiveness.

• Advanced Technology: Height and Depth Alarm: on screen notifications when entering hazardous areas, Digital Level:

NORTHERN ALBERTA

Equipment Sales & Service Ltd.

Edmonton (780) 440-4010 essltd.com

SOUTHERN ALBERTA

JT Equipment (587) 832-0772 or 1-888-214-5038 jtequip.ca

BRITISH COLUMBIA

Inland Truck & Equipment

Campbell River, BC 250-287-8878

Castlegar, BC 250-365-2807

Cranbrook, BC 250-426-6205

Fort St. John, BC 250-785-6105

Kamloops, BC 250-374-4406

Langley, BC 604-607-8555

Nanaimo, BC 250-758-5288

Penticton, BC 250-492-3939

Prince George, BC 250-562-8171

Quesnel, BC 250-992-7256

Terrace, BC 250-635-5122

Vernon, BC 250-545-4424

Williams Lake, BC 250-392-7101 inland-group.ca

Itec 2000

Rosslyn (888) 574-8530

Thunder Bay (888) 574-8530

Timmins (705) 267-0223 itec2000.com

McDowell B Equipment Ltd.

Sudbury (705) 566-8190

Barrie (416) 770-7706 bmcdowell.com

Stratton Equipment Sales & Service

Stratton (807) 483-7777 strattonequipment.com

Terapro Rental

Vars (613) 443-3300

Stittsville (613) 836-0654 terapro.ca

Top Lift Enterprises Inc.

Stoney Creek (905) 662-4137

Bolton (905) 857-5200 toplift.com

real-time display of attachment height, roll and pitch. Clear visuals improve accuracy and Payload: know the amount of earth you are moving and prevent overloading trucks.

• Safety and visibility are enhanced by WAVES (Wide-Angle Visual Enhancement System) with 230° view around the machine.

• Inside the cab, designed for focus and relation during long shifts. Spacious cab, ample legroom and high back, tilting and heated seat, 25-cm LCD monitor, fully customizable display with vital information.

Équipement JYL Inc.

Chicoutimi (418) 698-6656 equipementjyl.com

Micanic St-Aug-D-Desm (418) 878-2241 micanic.com

Paul Equipment (506) 826-3289 paulequipment.ca

Terapro Location Val d’Or (819) 825-4299 Plaisance (819) 718-0945 terapro.ca

Top Lift Enterprises Inc. St-Laurent (514) 335-2953 Sherbrooke (819) 612-5438 toplift.com

Paul Equipment

Balmoral (506) 826-3289 paulequipment.ca

YUKON TERRITORY

Inland Truck & Equipment

Whitehorse, YT 867-668-2127 inland-group.com

L. Walter & Sons Excavating is celebrating its 60th Liebherr machine on its 60th anniversary.

The Niagara Falls, Ontario-based company recently acquired a new Liebherr R 992 crawler excavator. The company operates a rock quarry with challenging working conditions, including the extraction of high density, large-size blocks and abrasive rock. e R 992 crawler excavator was the obvious strategic choice, thanks to

its performance tailor-made for di cult environments.

e machine’s main purpose is loading 40 tonne articulated dumper trucks, which it fills in just three passes. e R 992 delivers quick cycle times as well as impressive breakout force, which is among the best in its category. ese characteristics allow L. Walter & Sons Excavating to optimize its production ows while reducing waiting time and operating costs.

“What won us over was

the combination of power, speed, reliability and production quality. The R 992 checks all these boxes. It offers impressive power, very short cycle times and a perfect finished design,” said company Vice President Matt Walter.

Founded in 1965, L. Walter & Sons Excavating has been in business for 60 years and has acquired 60 Liebherr machines, an impressive milestone.

Designed for the most challenging environments in the extraction sector, the generation 6.2 R 992 crawler excavator features significant improvements in terms of diesel consumption and operator assistance functions.

With an operating weight of 94 tonnes, the R 992 has established itself as a stable and powerful machine. In addition to its technical capabilities, it incorporates functionalities designed with operators and their safety in mind: a spacious, comfortable and ergonomic operator’s cab, two cameras to ensure an optimal field of view, an armoured windscreen as standard and the new Bucket Fill Assist assistance system, which improves bucket lling rate and shortens work cycle times.

In line with L. Walter & Sons Excavating’s operating requirements, the machine has been configured with a 7.2 metre boom and 2.9 metre stick, o ering optimal reach and stability during loading. e bucket features a 6.2 cubic metre capacity and 2.3 metre width, allows e cient loading of large volumes of rock while ensuring good penetration into the digging material thanks to its semi-delta blade.

The bucket is equipped with Liebherr Z90 CL pro le

teeth, well known for their wear-resistance. To protect its equipment from impacts while handling blocks, the R 992 is also tted with special protective plates on the underside of both the boom and the stick.

e R 992 is part of a new range of large-capacity Liebherr crawler excavators designed for intensive applications, especially in the mining and quarrying extraction sectors and in bulk earthmoving.

Made up of the 70 to 100 tonne models, this series, which includes the R 972, R 978 SME, R 992 and R 998 SME, is designed to deliver a combination of raw power, hydraulic precision and onboard technologies, while o ering a high-quality operator experience.

Apart from their impressive size, these crawler excavators incorporate innovations that improve productivity and pro tability on site.

ey feature the Liebherr Power Efficiency – Engine Control system, which adjusts engine parameters in real time to reduce fuel consumption, while also maintaining high performance. This technological approach not only allows operating costs to be reduced but also enables businesses operating in this sector to respond to the growing environmental issues that they face.

For comfort and ergonomics, cabs are equipped with intelligent assistance systems, a layout designed for optimal eld of view and intuitive controls for easier handling.

e Modetronic function allows operators to adjust machine behaviour closely to their own driving styles and the nature of the work, thus increasing precision and exibility in use.

Hitachi Construction Machinery has announced it will change its name and brand to LANDCROS in April 2027.

The new brand will intro-

duce updated equipment and parts, while maintaining the same manufacturing and dealer support. The brand transition represents the company's next stage of

accelerating innovation to create and provide customers new forms of value as they look to the future.

LANDCROS is a symbolic word that represents the

guiding ideals the company will follow as they look towards the future. e new brand name combines the word "land,” representing their respect for the com-

pany’s history and their vision for the future, with "Customer, Reliable, Open and Solutions," (CROS) to express how they plan to provide innovative solutions to their customers.

“Hitachi Construction Machinery started as a part of Hitachi Ltd. in 1950. In 1970, they incorporated as a corporation and has since built a strong legacy of earning customer trust and contributing to society with the Hitachi brand,” said Hidehiko Matsui, CEO and Chairman of Hitachi Construction Machinery Americas.

“With this upcoming phase for our company, we are looking forward to adding to that history by providing our customers solutions beyond machines.”

e LANDCROS brand will debut with new machine decals and company logo. All other aspects like company structure, equipment manufacturing, product o erings and warranty policies will remain the same.

“ e same reliable orange we love to see on jobsites will be the same. Our customers can be assured that this brand change will not have any major impact to the way they work with our equipment or our dealers,” said Simon

Wilson, Chief Operations O cer at Hitachi Construction Machinery Americas. “Instead, this represents our renewed commitment to continue creating solutions that solve industry and job site problems. With the LANDCROS brand, we will develop products that integrate technologies like AI, augmented reality, remote operations, advanced robotics and more. Our goal is to offer our customers intelligent machines capable of operating, learning and adapting to their current and future needs, while maintaining the key functional components that they prefer us for.”

Hitachi Construction Machinery's more than 75 years of history in manufacturing equipment. eir specialty in hydraulic engineering has been advancing the heavy machinery industry since they launched the first mid-size hydraulic excavator in 1968. Since its reintroduction to the North American market in 2022, Hitachi-branded equipment has seen sustained growth and increased demand with their dealer network of more than 22 dealers across the United States and Canada.

Vermeer’s new SC402 stump cutter is delivering more power and manoeuvrability for tree care professionals.

The SC402 is equipped with a 40-hp Briggs & Stratton Vanguard engine that delivers up to 40 per cent more productivity than its predecessor, the SC382 stump cutter. Key features include standard four-wheel drive for improved traction and reduced ground disturbance, an optional remote control for operational exibility and

the SmartSweep control system to maintain consistent cutter wheel speed.

“ e SC402 stump cutter is engineered to meet the demands of tree care professionals who require robust performance and e ciency,”

said Josh Vrieze, Group Product Manager for Vermeer Environmental Equipment.

“With its increased torque and the electronic throttle control, operators can expect consistent power delivery, particularly when cutting below grade. e machine’s

design also prioritizes manoeuvrability in confined spaces and ease of operation.”

e SC402 balances torque between the drive wheels, minimizing turf disturbance while maximizing traction. For access to restricted areas, the machine’s width can be reduced to 90 cm by removing the dual wheels, allowing it to pass through standard gates.

As well, productivity is enhanced by the Vermeer SmartSweep control system,

which monitors engine load and adjusts the cutter wheel sweep rate accordingly. is feature helps provide a smooth and consistent cutting performance and can help reduce wear on the machine. Operators have the option of the Vermeer cutting system (VCS) or the Yellow Jacket cutter system to suit di erent ground conditions and operational preferences.

The SC402 includes features aimed at operator convenience and safety. An operator presence system is

standard, designed to disengage the cutter wheel if the operator’s hands leave the control station.

e optional remote control allows the operator to manoeuvrer the stump cutter and perform grinding operations from a distance,

o ering better visibility. The stump cutter is equipped with a 37.9-litre fuel tank for extended operating periods and features easily accessible panels for routine maintenance. An optional back ll blade is available to assist with site cleanup.

Caterpillar today entered into an agreement to acquire RPMGlobal, an Australian-based software company. Founded in 1977 and headquartered in Brisbane, Australia, RPMGlobal is a provider of mining software solutions. e company has deep domain expertise in mining technology enablement, providing customers worldwide with data-driven software solutions at every stage of the mining lifecycle.

“RPMGlobal's culture and agile approach to developing solutions aligns well with Caterpillar’s intense focus on solving customer needs,” said Denise Johnson, Group President of Caterpillar Resource Industries. “ eir software solutions complement Caterpillar’s existing technologies, especially in areas such as asset management, eet management and autonomy. Together, we have the potential to enhance minesite operations for our customers, unlocking even greater value.”

e agreement requires approval by RPMGlobal shareholders and various regulatory authorities and is subject to other customary closing conditions. The transaction is expected to close in the first quarter of 2026.

RPMGlobal has contracts in more than 125 countries and ofces in 13 locations across nine countries.

Its software suite includes advanced platforms for mine planning, scheduling, simulation

and maintenance management. Its flagship products, such as RPM MinePlanner, XECUTE and AMT (Asset Management Tools), are used by mining operators around the world to improve decision-making, reduce downtime and increase productivity.

Beyond software, RPMGlobal offers advisory services that integrate nancial modelling, equipment optimization and ESG (environmental, social and governance) strategy into mine operations.

is combination of data-driven technology and industry expertise has positioned RPMGlobal as a trusted partner to major mining firms across commodities like coal, copper, gold and iron ore. In recent years, the company has expanded its focus on automation, cloud-based analytics and digital twin technology — all aimed at helping miners modernize operations and transition toward more sustainable, e cient production.

Achieving pavement longevity isn't just about the quality and/or performance of the HMA (Hot Mix Asphalt); it's

By Brad Belvin, David Crockett and Yuki Tsukimoto, PhD of Sakai

often decided at the weakest point.

For asphalt pavement, one of the critical weak points is

the longitudinal joint: the seam connecting adjacent lanes. is point is typically weaker because of inherent

temperature di erences between the cold and hot mix connection as it is being laid and because of limitations

in unsupported edge compaction.

pecially aggressive issue in the Canadian climate.

· Ravelling: The premature dislodging of aggregate particles, a direct sign of poor aggregate interlock and low asphalt density.

For Canadian infrastructure, where extreme weather cycles demand maximum durability, mastering longitudinal joint compaction is not a best practice; it's an absolute necessity.

Achieve optimal compaction

Pavement's critical seam

A longitudinal joint is formed when a new HMA mat (a second lane) is placed against a previously paved and cooled mat ( rst lane).

e rst lane is paved without support for its edges (unsupported) while the second lane has edge support against the cooled lane.

The joint's initial shape is set by the paver screeds’ end gate positioning. While simple butt joints from the screed are common, some contractors employ specialized techniques like a notched wedge joint or use a hydraulic wheel cutter to ensure a clean linear edge for the connecting mat. However, cutting is costly and requires precision to match the second paver pass.

Regardless of the pro le, the final strength of the connection hinges entirely on compaction. In order to have enough mix to achieve density at the joint, a small overlap of the mats by the paver is necessary to provide additional material (25-mm to 38-mm for butt joints and 6-mm to 13-mm for milled edges). Do not rake the overlap!

Paving contractors use their roller trains to achieve maximum density at the joint, employing specific rolling patterns that knead the hot mix against the rst lane. Joint compaction begins with compaction of the unsupported edge (first lane) and nishes with compaction of the longitudinal joint with the second lane. Compaction of the unsupported edge is also critical and during the initial pass (forward and reverse) the drum should overhang it by about 10 cm to 15 cm. To avoid cracking and shoving of the edge, the drum edge should not be placed inside or directly on the unsupported edge. Then, two approaches to final joint compaction are commonly used:

1. Method 1 - recommended: The first (forward) and second (reverse) passes hang over the rst lane 10 cm to 15 cm, directly kneading the hot mat to the rst cooled lane. Following passes then shift fully to the hot side, focusing on maintaining a 10-cm to 15-cm overlap with each adjacent pass.

Properly compacted longitudinal joints are the first line of defence for a road's sub-structure. A strong, highdensity seam prevents the ingress of water penetration, which is the primary catalyst for almost all pavement failure.

When joints are under-compacted, they remain porous which can lead to failure under stress (cracking). The voids and subsequent cracking allow water to infiltrate leading to the rapid onset of severe pavement distress, including:

· Erosion of mix: Depressions, potholes and failures caused by the freeze-thaw cycle, an es-

2. Method 2 – pinch the joint: The initial breakdown pass of the roller is performed entirely on the second (hot) lane, typically 10-cm to 15-cm away from the edge of the rst lane. is forms a ridge of extra material at the joint. Subsequent passes then overlap the rst lane by 10 cm to 15 cm and compact that ridge into the joint.

e ultimate objective for either method is to achieve the specified optimum density and a tight, cohesive bond along the length of the seam. Due to inherent temperature and density differences at the joint, density speci ca-

tions are often 2 percentage points lower compared to the centre of the mat although allowed differences can be tighter than this depending on the specific application or municipality.

The role of compaction equipment

The performance of the compaction equipment dictates the nal quality of the joint:

· Tandem asphalt rollers: ese versatile workhorses are the most common roller used for joint compaction on road projects. ey o er reliability and are a staple of the roller train. Rollers with user-selectable vibration and oscillation (such as the Sakai ND series) enables vibrating the joint tightly before finishing smooth with oscillation.

· Pneumatic tire rollers (PTRs): PTRs are excellent for kneading HMA mixes along joints due to the exibility of their tires. eir tires conform to the slight elevation di erences between the mats, creat-

ing superb con nement and a tight seal. However, their high ground contact pressure can sometimes push material out during the first lane pass so it is recommended to run the outer tires 10-cm inside the edge and then overhang the edge with a double drum roller. ese are also available in a hybrid with a vibratory front drum, known as combination rollers.

· Vibratory pneumatic tire rollers: ese machines represent the leading edge of compaction technologies. ey combine the static kneading action of the PTR with gyratory vibration forces. This dual action dramatically increases the achievable joint densities, producing a more robust and longer-lasting longitudinal joint than a static load alone can deliver and without the risk of aggregate crushing from a vibratory steel drum. Sakai is currently the only manufacturer o ering this technology.

· Static three-wheel rollers: Unlike tandem rollers, these static rollers provide greater concentrated linear pressure (measured in pounds per linear inch) that is highly e ective for joint compaction. With the highest linear pressure among all rollers, they densify the joint without shoving mixes.

Canadian considerations

For the Canadian market, the single most critical factor is freeze-thaw resilience.

e dramatic temperature swings, heavy precipitation and sustained use of road salt (de-icing chemicals) in Canada place extreme stress on pavement. Water in ltration into under-compacted joints immediately initiates damage that is accelerated by the freeze-thaw cycle, rapidly leading to potholes and pavement failure.

A perfectly sealed longitudinal joint is an e ective way to weatherproof the road. e incremental cost of achieving high joint density is a minimal investment when compared to the

major costs associated with premature joint deterioration and subsequent full-depth repairs necessitated by the harsh Canadian winter. Investing in technology that can deliver superior, verifiable joint density (like oscillatory/vibratory tandem rollers, vibratory pneumatic tire rollers and static threewheel rollers) is an essential strategy for extending the service life of Canadian road networks.

Note: e information and techniques presented herein are general guidelines for asphalt joint compaction. Contractors are advised to adapt their compaction strat-

egies based on the applicable governmental speci cations, site condition and material characteristics of every project to ensure the highest quality and durability.

1.866.488.0878

Following in-depth customer consultations to improve performance and operator satisfaction, John Deere has unveiled its redesigned 17 P-tier and 26 P-tier compact excavators.

Stemming from customer feedback and testing insights, both models have been fully manufactured to John Deere specifications, offering a distinctive experience. The compact machines are designed to

CENTER, JACKMAN EXCAVATING,

DEALERS, AND MANY FARMER CONSIGNMENTS. Consisting of

&

MEEK

tractors, antique tractors, construction equipment, hundreds of pieces of farm equipment, side by sides, irrigation & more. All equipment located at SUNRISE EQUIPMENT AUCTIONS at 593249 Oxford Road 13, Norwich, ON. Viewing Monday to Friday 9:00am to 4:00pm. PARTIAL LISTING ONLY.

JACKMAN EXCAVATING EQUIPMENT: 2022 Cat 336 excavator (selling on last high bid confirmation); Next 4 items selling UNRESERVED. 2015 Cat 352F excavator; 2021 Western Star 4700 tri-axle dump truck; 2020 Western Star 4700 tri-axle dump truck; 2022 Ford F550, 4wd, dump & service box.

CONSTRUCTION: JD244K-II wheel ldr; 2 (two) Gehl AL750 wheel ldrs; NH C232 skid steer; Lift King LK6M22 forklift; JD 410J TLB; NH C227 track skid steer; JD 35G mini-ex; Case SV250 skid steer; JD 332G skid steer; JD 33d skid steer; JD 317 skid steer; Kubota SSV75 skid steer; Bobcat S650 skid steer; Merlo P32.6 telehandler; Hyundai 733-7 wheel ldr; JD 750 crawler dozer; Fermac 640 tractor/ldr; Vermeer BC1000 chipper.

PLEASE NOTE: This is a partial listing. Lots of items not listed, including tractors, farm equipment & miscellaneous. Thanks to all of our consignors! Everything sells UNRESERVED except for a few items listed which are selling on last high bid confirmation. VIEWING: Monday to Friday 9-4 now until Sale date. LOADING: Wednesday November 26th to Friday November 28th from 9:00am to 3:30pm, Saturday November 29th from 9:00am to 12:00pm & Monday December 1st to December 5th from 9:00am to 3:30pm. NO SUNDAY LOADING.

TERMS: A 5% Fee applies to all items to a maximum $2,000 (Buyer’s Premium & Internet Fees) per item. Payments will be received by cash, cheque, debit, credit, certified cheque or bank draft, E-Transfer & Wire Transfer (a three percent charge will apply to all credit card payments $2000 and above). Payments are due by 3:30pm on November 27th. Invoices will be emailed out after the auction closes! If needed, financing MUST be prearranged prior to bidding. Items to be removed by Friday December 5th, with paid invoices only. Auctioneer has described all items to the best of their ability with information provided by consigners. Owners and Auctioneers are not responsible for accidents during viewings or loading. Auctioneers are not responsible for items not picked up after final loading day. A storage fee will be applied to items if not picked up by December 5th.

excel in a variety of construction and landscaping applications.

The 1,720 kg, 14.5 hp 17 P-tier and 2,770 kg, 20-hp 26 P-tier are built to withstand tough working conditions, while still providing optimal performance in tight spaces.

“Each construction and landscaping jobsite is different, and some require more versatile equipment options. The redesigned 17 P-Tier and 26 P-Tier compact excavators meet the growing demand for powerful machines that perform in tight job sites,” said Justin Steger, Product Marketing Manager for John Deere.

“Backed by countless hours of customer testing and feedback, we are proud to offer these newly updated compact solutions that deliver power and productivity in the dirt, as well as standard features to improve the operator experience.”

The machines are designed to maximize attachment versatility for landscapers and underground customers.

For jobsites that require multiple attachments, the mini excavators are equipped with single or dual auxiliary options, which enable the use of various attachments including augers, compactors and other hydraulic attachments.

While a thumb-ready bracket is standard, both models can be equipped

from the factory with a new mechanical fixed pin coupler for fast and easy attachment changes.

Wedge style adapters are available to maximize attachment compatibility with previous John Deere compact excavators, keeping their cost down rather than converting to all new attachments.

As well, the new long arm option provides additional dig depth and added reach compared to the standard arm option. This added length helps tackle complex jobs while maintaining excellent dig power and lift capacity.

Standout features have also been incorporated to help manage and maintain the equipment.

Aiming to help prolong battery life and new for John Deere compact machines, the 17 P-Tier and 26 P-Tier models have standard and easily accessible battery disconnects.

A 500-hour maintenance tracker is easily accessible in the monitor and alerts the operator when the machine is within 10hours of a required service. Factory-installed JDLink telematics provides critical machine data to the John Deere Operations Center, where customers can easily monitor the location and health of their equipment fleets, helping with uptime, theft prevention and asset management.

By Cory Maker, Manager of Product Marketing at Ditch Witch

Data centres are rapidly becoming the backbone of the digital economy, powering everything from artificial intelligence to cloud computing to everyday online transactions. Entering this year, nearly 50 million square feet of new data centre space was under development. For underground construction professionals, this surge represents not just a wave of projects, but a chance to play a critical role in building the infrastructure that keeps the digital world running. The opportunity is significant, but so are the demands, as these facilities require complex, largescale utility ecosystems.

For those prepared to meet the demands, the sector promises steady, large-scale work. But data centres are not typical builds. Data centres need a signi cant amount of energy to power their high-performance computing racks and often large amounts of water to cool those assets. e facilities also require extensive high-strand bre bundles into and out of each site. And the utility scope only gets more complex as data centre owners and operators consider on-site energy generation options to ease demands on local power grids.

The size and scope alone of data centres signi cantly increase the workload for contractors, requiring vast amounts of power, bre and water, which leads to a surge in underground utility work.

Accelerated timelines further intensify these demands. To succeed, contractors must combine well-coordinated planning with the right equipment and expertise to deliver safe, e cient and resilient underground utility systems.

Big utilities, big demands

Fast deployment of data centres requires having all hands — and machines — on deck. To meet aggressive time targets, contractors often need to run multiple machines simultaneously on site. is makes upfront logistics planning critical to account for all the moving parts, manage parallel work and avoid equipment and workforce shortages. As data centres emerge as key drivers in underground construc-

tion, contractors must adapt to meet signi cant utility demands. Understanding the primary utility needs of these large-scale projects is essential.

Unlike smaller utility extensions or bre-to-the-home projects, data centres demand infrastructure on an entirely different scale. They require:

Electricity

Essential for cooling, make-up water systems may use reclaimed or industrial sources where permitted. Data centres also incorporate process or reverse osmosis (RO) lines, alongside comprehensive re-protection loops equipped with isolation and metering.

Fibre

To support robust data transmission, data centres need geodiverse carrier entrances and extensive longhaul laterals. High-strand trunks and diverse path con gurations are critical to ensuring reliability.

Continued on Page A22

Data centres require multiple high-capacity feeders from utility interconnects, often ranging from 115 to 230 kV, integrated into campus substations. These projects necessitate concrete-encased multi-cell duct banks, thermal back ll or precise spacing to meet ampacity models, and extensive vault and manhole networks for e cient cable pulls and maintenance.

SNOW

is combination of scale and resilience makes data centre work far more complex than typical underground projects.

WIDTHS 4½ - 20' SLIM DOUBLE SIDE WALL

Utility installation

Eliminates bulky brace for reduced material build-up

Powered by Patented Rotary Actuators ANGLE BLADES WIDTHS 4 - 20'

Form

Establishing reliable, high-capacity connections for these utilities requires precise and e cient utility installation. Using underground installation methods will help protect infrastructure, maintain surface integrity and maximize the data centre’s long-term operational stability.

Most underground installations can be open cut at a depth of 1 metre to 1.5 metres. Horizontal directional drilling (HDD) at anywhere from 3-to-18 metres deep can be reserved for installations in hard-to-access areas and when surface disruption must be avoided, like underneath roads.

Underground utility lengths can range from 150 metres to 4,500 metres depending on if a data centre has on-site utility connections. Contractors can expect to run bre in 25-mm to 15-cm conduit and power in 10 to 15-cm multi-cell duct banks.

Every project should begin with soil and site analysis, identifying underground obstacles and depth requirements. These ndings inform machine selection, tooling and installation method, ensuring safe and e cient execution.

Essential equipment

Precision and productivity are crucial in data centre construction, underscoring the importance of selecting the right equipment. Common equipment for data centre construction includes:

· Horizontal directional drills (HDD) are indispensable for burying conduits beneath roads and buildings without disrupting the surface. Equipped with all-terrain technology, HDD rigs navigate challenging terrains with precision, allowing access to hard-to-reach areas while minimizing environmental impact.

· Mixing and recycling systems play a critical role in uid control during lengthy or rocky bores, ensuring smooth and e cient operations.

· Vacuum excavators, essential for potholing and con ict checks, manage excavation uids e ectively, further enhancing site safety and e ciency.

· Trenchers and microtrenchers cut narrow trenches for conduits, cables and ducts, making them ideal for on-campus bre installations and shorter runs. eir versatility allows them to operate across various soil types, from compacted ground to rocky

terrains, making them perfect for projects that require branching or dual ducts.

· Vibratory plows o er quick, minimally invasive installation for conduits and cables in soft soils, providing rapid results with minimal surface disruption. ese machines excel in environments where speed and minimal restoration are priorities.

· Guidance and locating tools, like Subsite systems with wireline or gyro capabilities, are essential for navigating long, deep or EMI-heavy bores, ensuring accuracy and e ciency throughout the project. To optimize e ciency and minimize disruption, a hybrid approach is often best. Use vibratory plows for long stretches in soft soil, trenchers for deeper or more complex installations and HDD in areas where surface disruption is a concern, such as under roads.

Successful data centre construction requires more than just the right equipment, and technology alone doesn’t guarantee success. Contractors should also consider:

· Rock tooling: Use PDC and TC bits and hole openers for rocky conditions.

· Purpose-built pull heads: Essential for handling multi-duct bundles.

· Drilling fluid management: Prevent losses and protect geological formations.

· QA/QC and documentation: Maintain strict quality assurance and clear documentation.

· Safety and logistics planning: Critical for managing large crews and multiple moving parts.

e outlook for data centre construction is one of sustained expansion and escalating complexity. Rising demand for bre mileage, larger duct bank systems and advanced water infrastructure will keep utility contractors at the forefront of this work.

At the same time, rising power constraints are likely to accelerate on-site generation solutions, further broadening the scope of underground utility packages. Yet, success will not hinge on opportunity alone.

It will depend on a contractor’s ability to secure skilled labour, deploy the right equipment and execute with precision under fast-track schedules.

For those willing to adapt, the data centre boom is more than a market trend. It is a transformative chance to lead and shape the future of underground construction. Continued from Page A21 - How contractors

W: M OB I SC R EEN M SS 502i EVO

MSS 502i EVO

Compact, powerful and versatile: Intro ducingthe MOB ISCR EEN M SS 502 i EVO mobile co ars e screen ing plant. Its com pact size , l ow t ransp ort weight and i mpressivefee d capacity of up t o 350to nnesper h our ens ure t hat t his vers ati le m achine c an be use d fl exibly andqui ckly for eve n the m ost h eavy- duty applications in natural stone a nd recyc ling. The c ompact MSS 502i EVO, withits adva nce d e rgon omics , w as des ignedfor exceptio nal o perability. It can also be operate d electrica ll y than k s t o its o ptiona l dua l -power d rive . Th e MOBISCREEN MS S 502i EVO: the (sma ll) multi-talente d p owerho use

www.wirtgen-group.com/mss-502-evo-kleemann

ALBERTA

Liftboss JCB

Calgary: 403-301-0041 Edmonton: 780-474-9900 liftboss.ca

BRITISH COLUMBIA

Williams JCB

Surrey: 604-930-3316 williamsjcb.com

NEW BRUNSWICK

A.L.P.A. Equipment

Edmundston : 506-735-4144

Balmoral : 506-826-2717

Fredericton : 506-452-9818 Moncton, N.B. : 506-861-2572 alpaequipment.com

NOVA SCOTIA

A.L.P.A. Equipment

Truro : (902) 897-2717 alpaequipment.com

ONTARIO

For 80 years, JCB has stood for more than machinery – we’ve stood for engineering excellence, relentless innovation and a commitment to reshaping what’s possible on every jobsite. To celebrate 80 years of challenging the status quo, we’re offering this amazing deal, because building better never stops, so neither should you.

Advance Construction Equipment (Division of Equipment Ontario)

Harriston: 519-510-5878

Waterloo: 519-742-5878 advanceequipment.net

D&W Group Inc.

Doughty & Williamson Jarvis: 519-587-2273

Brant Tractor Burford: 519-449-2500

Redtrac International Vineland: 905-562-4136 dwgroup.ca

Delta JCB

Dunvegan: 613-527-1501

Renfrew: 613-432-4133 Winchester: 613-774-2273 deltapower.ca

ONTARIO

Equipment Ontario

Alliston:705-320-0506 Lindsay: 705-324-6136 Port Perry: 905-982-1500 equipmentontario.com

Fulline JCB

Glencoe: 519-287-2840 fullinefarm.com

John’s Equipment Sales Frankford: 613-398-6522 johnsequipmentsales.com

Moore JCB Toronto, York & Peel Region: 416-747-1212 moorejcb.com

ONTARIO

North Rock JCB North Bay, Sault Ste. Marie, and Sudbury: 705-897-7369 northrockrentals.com

ReadyQuip Sales & Service Ltd. Timmins: 705-268-7600 readyquip.com

WPE Landscape Equipment - JCB

Hamilton/Halton: 905-628-3055 wpeequipment.ca

PEI

A.L.P.A. Equipment (506) 861-2572 alpaequipment.com

QUEBEC

A.L.P.A. Equipment

Bas-Saint-Laurent : (506) 735-4144

Gaspésie : (506) 826-2717 alpaequipment.com

Bossé Quebec Inc.

Desmaures: 418-878-2241 Saint-Augustin-debosse-frere.com

Moore JCB

Montreal: 514-333-1212 moorejcb.com

SASKATCHEWAN & MANITOBA

Westcon JCB

Regina: 306-359-7273

Saskatoon: 306-934-3646

Winnipeg: 204-694-5364 westconequip.ca

•

The latest Rototilt Control system is delivering improvements in ergonomics, ease of use and a new level of agility.

In October, Rototilt hosted the rst Canadian demo of the system, in partnership with Clearlite Excavating, in Blue Mountains, Ontario. Rototilt Control is an upgraded system designed to give operators more precision, safety and e ciency. Built with the future of excavation in mind, Rototilt Control integrates advanced technology, intuitive user

interfaces and smarter functionality into every project.

The RC tiltrotators are a next generation tiltrotator series for excavators weighing between 1.5 tonnes to 43 tonnes. ey are equipped with pressure-compensated hydraulics for smoother, more precise control of tilt and rotation — independent of each other.

“It is pressure compensated hydraulics now. When you get to the end of the stroke on your tilt, the rotate doesn't speed up like the old one,” said John Buitenhuis, Product Support for Rototilt.

“Now everything is flow compensated, so it just sends the right amount of ow to each function, and whatever doesn't get used just goes to tank, rather than taking the path of least resistance.”

The tiltrotators are now equipped with combined high ow from the factory, which allows the combination of hydraulic ow from the grapple and extra circuits.

“Standard, it's 100 litres a minute per function, but if

you have the high ow combining, you can get 200 litres a minute without having the extra high ow lines or the extra high ow circuit on the machine,” Buitenhuis said.

“So, you get 200 litres a minute out of your auxiliaries, which is pretty good for a tiltrotator.”

A completely redesigned control system features a larger, 11-cm touchscreen display and a more user-friendly interface to streamline machine operation. All functions for the coupler are now right on the screen, including return to zero and return to home.

“ e new touchscreen is quite smooth and very rened,” Buitenhuis said. “It's not clunky and bulky. It's just a nice screen o to the side with a very high-quality readout.”

In the cab, Rototilt has worked to improve ergonomics on its joysticks. e award-winning controls are ergonomically designed with input from professional

machine operators.

e RC joysticks feature up to eight buttons, four rollers, a forward/reverse selector (FNR) and customizable angle and palm rest for optimal comfort and adaptability.

“You can actually adjust the joysticks right on the y as well. So, if you like them cranked back, you can pull them completely back,” Buitenhuis said.

To improve safety, the RC system tiltrotators now come equipped with SecureLock, which ensures the correct coupling of tools and continuously monitors the connection.

“This safety feature will tell you whether your wedge is closed or not. If you don't fully grab onto your bucket, it'll stop right there, and it will throw a code for that,” Buitenhuis said.

The Rototilt Control system also includes RC Connect, a mobile app that provides remote assistance, over-the-air software updates and in- eld troubleshooting capabilities.

Epiroc is rolling out InSite, a new telematics solution engineered to transform fleet management of hydraulic attachment tools.

By combining asset tracking with real-time data insights, InSite enables its users with unprecedented control and visibility across their eet.

InSite offers comprehensive monitoring of location, usage and maintenance needs for attachment tools, regardless of the manufacturer.

Whether deployed through factory-installed units or retro t-ready modules, the system utilizes Epiroc's large mesh network, enabling connectivity across more than 1.3 million devices worldwide, the world's largest

Bluetooth network in construction.

Smart features

With real-time tracking, users can pinpoint exact asset locations, monitor equipment utilization and receive automated service alerts. Geofencing capabilities allow virtual boundaries to be established around jobsites or yards, helping to detect unauthorized movements and mitigate theft risks.

Maintenance planning also becomes proactive through predictive tools that minimize downtime and help service teams with equipment status visibility. Ensuring your equipment provides the best productivity, uptime and highest safety standards

for your next job together with advanced modules with cellular and GPS location via Epiroc’s HATCON (Hydraulic Attachment Tools Connectivity). HATCON monitors operating hours, location and service intervals of your tools. e GPS-function also enhances theft prevention measures onsite.

Seamless integration

Epiroc InSite supports exible system integration with most existing eet management platforms, enabling smooth data exchange via the standardized AEMP API. Teams on the ground bene t from real-time reporting through the mobile app, allowing

immediate response to operational issues.

For dependable performance, the battery life of InSite devices is three to ve years under typical eld conditions. All transmitted data is secured using enterprise-grade cloud encryption protocols, safeguarding sensitive operational information.

Setting up InSite is as simple as mounting the device, pairing it with the relevant asset and activating the platform. From day one, eet operators can begin optimizing operations and enhancing equipment oversight. Epiroc InSite is now available through Epiroc Business Partners globally.

Shearex has launched its new mini bite limiter mulcher, a compact powerhouse for land clearing and maintenance.

Part of the VL (Vertical Light-duty) Series, the new attachment is designed to bring exceptional mulching performance into a more compact, cost - effective package. Engineered for excavators in the 2-ton to 7-ton class, the mini bite limiter mulcher gives land clearing, invasive species removal, roadside maintenance and underbrush management a high degree of precision

without sacri cing durability. e new VL Series mulcher attaches easily with a quick coupling system and includes a complimentary startup kit with spare blades, a tube of grease, a Shearex cap, user manual and sharpening guide.

The mulcher includes a poly - chain carbon transmission belt to efficiently transmit torque as well as an internal shell and wear plate built with Hardox 500 steel for enhanced abrasion resistance.

Another feature is a drainless piston motor rated for up

to 5,800 psi in pressure and 360 psi return pressure, while oversized axles and bearings mitigate strain and extend component life.

A bolted counter blade system helps simplify maintenance. To reduce wear on the blade holders, the patented Convex DX Protection System guides material toward the centre of the cutting zone.

The VL Series mulcher combines toughness and agility, making it ideal for clients who need to transition between tight job sites, overgrown areas and roadside clearing zones.

Alain Baril of Enterprises Paysagers Baril Inc. in Que-

bec is using the VL Series mulcher to tackle dense brush.

“ is is the rst time I’ve had a tool like this. I’m really impressed by the power and how well it performs in tough conditions. It exceeds my expectations,” Baril said.

e VL Series mulcher is available in two con gurations, the VL-20SC (for 2-ton to 4-ton excavators) and the VL-30SC (for 3-ton to 7-ton excavators). The mini bite limiter mulcher delivers cutting widths of about 54 cm and 78cm respectively, and is optimized for material diameters of up to about 3 cm to 4cm (7.5 to 10 cm target).

CRD Creighton has launched a new rotary brush cutter speci cally designed for 3.5-ton mini excavators.

Developed by Virnig Manufacturing, the X20 rotary brush cutter is engineered to help contractors clear overgrowth, maintain trails or managing roadside vegetation.

e rotary brush cutter is able to cut through trees and brush up to 76 mm in diameter with ease.

e 1 metre cutting width covers more ground, improves e ciency and reduce time spent on the job.

is designed to enhance the power of compact equipment without compromising on weight or manoeuvrability.

e deck is built to minimize ying debris, promoting a safe work environment. Optional side extensions are available for maximum debris containment, while the rounded ywheel with three double-sided blades helps the cutter bounce o stumps, ensuring a smoother nish. Add optional carbide teeth for a ner nish or upgrade with bolt-on mounting interfaces for quick and easy hanger bracket changes, making it adaptable to most mini-excavators.

Featuring a direct drive Eaton motor with built-in relief valve protection, the X20 simplifies your setup, eliminating the need for a case drain.

Optimized for mini excavators ranging from 2,950 kg to 6,800 kg, this brush cutter

e X20 comes equipped with standard 2.2-metre hoses, couplers, motor guard and spindle guard to ensure reliable operation and protection from the elements.

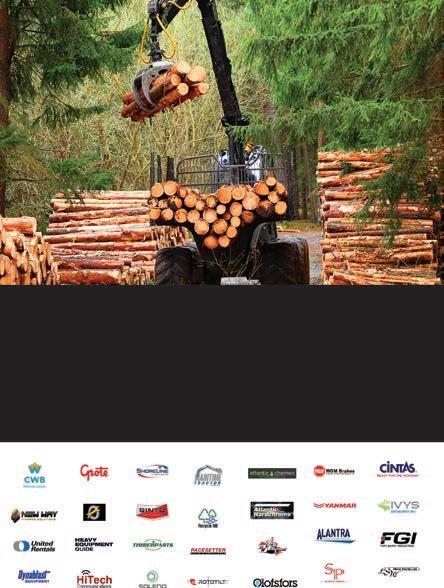

Waratah Forestry Equipment has developed two new harvester heads, the H427 and the H427X, to deliver powerful, durable and reliable solutions for tough forestry applications.

e H427 is built to handle large timber and o ers high productivity and precision.

e H427X extends that performance with heavy-duty features, purpose-built for tracked machine applications.

“As the largest heads in our 400 Series lineup, the H427 and H427X are built

to give loggers the con dence they need in the forest,” said Brent Fisher, Product Marketing Manager for Waratah. “Whether it’s the versatility of the H427 or the heavy-duty capabilities of the H427X, both models are designed to enhance performance, durability, productivity and reliability in demanding environments.”

Big-timber harvesting

The H427 is built for big timber and demanding applications from late thinning

to the final cut. Featuring a strong frame, 760 mm maximum cut capacity and high-performance saws including an optional top saw and HD tilt frame, it delivers durability, feed force and cut capacity needed for reliable productivity. Its saws are a standout feature, providing fast, precise cutting even in the toughest conditions.

“ e H427 is purpose-built to meet the demands of high-production harvesting in larger timber conditions,” Fisher said.

“Its design enhances operational efficiency, ensures long-term durability and simpli es maintenance, supporting reliable performance in the forest.”

With an operating weight of 1,655 kg, the H427 balances strength and stability in rugged forestry conditions.

Waratah’s updated measuring system design improves length and diameter accuracy, while an e cient control valve and optimized fourroller feed arm geometry ensure consistent performance on wheeled and tracked carriers.

A four-knife delimbing system and streamlined service access further enhance uptime, making the H427 a high-output solution for loggers.

The Waratah H427 will be available to customers in the United States, Canada, Europe, Australia, New Zealand, Africa, Brazil and Latin America starting in early 2026.

Extreme harvesting

Weighing in at 1,853 kg, the H427X delivers the same performance bene ts as the H427 but is purpose-built for heavy-duty tracked machine applications.

e H427X features a standard, heavy-duty tilt frame and heavy-duty feed motor covers for added durability and protection. This helps provide operators with the toughness and responsiveness required with tracked applications, hardwood and large timber.

FAE is expanding its range of MTL multitask heads for the construction sector, making them compatible with tractors up to 300 hp.

The FAE MTL multitask head has been designed for the maintenance and upgrading of dirt, gravel and asphalt roads.

The new MTL-250 width enables soil stabilization, asphalt and rock slab shredding and stone crushing, down to a maximum operating depth of 28 cm.

The variable-geometry grinding chamber, adjustable grill on the hood and adjustable Hardox counter blade deliver optimal crushing results.

Internal protection plates on the frame, bolted both centrally and laterally, en -

sure the head is robust and reliable while also guaranteeing excellent resistance to wear. The handy depth indicator allows the operator to check the operating level directly from the cab, and the central gearbox with universal-joint alignment system is designed to be compatible with a wide range of tractors on the market.

e head comes standard with G/3 teeth, with the option of G/3/HD teeth and R/65 or R/65/HD picks on a dedicated rotor.

New wheel saw FAE has also developed the new RWL/SSL wheel saw for skid steers, ideal for trenching to lay electric, water, gas and bre optic lines.

e RWL/SSL is compat-

ible with skid steers from 50 to 75 hp and can create channels up to 35 cm deep with modular widths of 2.5, 3 or 5 cm.

e depth indicator allows for precise management of working depth, while the self-levelling skids and optimized side output maintain that depth and ensures the trench is free of waste materials at all times.

The RWL/SSL can be equipped with the basic water spray system to reduce dust and cool teeth. Its hydraulic and electrical setups and equipment make it ideal for plug-and-play pairing with the leading skid steers on the market, and it features teeth speci cally designed for asphalt and concrete surfaces.

Newfoundland and Labrador

NORS

Mount Pearl, NL(709) 747-4026

www.nors.com

Nova Scotia

NORS

Dartmouth, NS(902) 468-5010

www.nors.com

New Brunswick

NORS Moncton, NB(506) 857-8425

www.nors.com

Quebec

NORS

Baie-Comeau, QC 1-866-996-3091

Chicoutimi, QC 1-800-323-1724

St-Augustin, QC 1-800-463-2662

Trois-Rivieres, QC 1-855-840-0828

Val d’Or, QC 1-800-561-4192

www.nors.com

Top Lift Enterprises, Inc.

Sherbrooke, QC(819) 612-5438

St-Laurent, QC(514) 335-2953

www.toplift.com

Ontario NORS

Stittsville, ON (613) 836-6633

Sudbury, ON(705) 692-0552

Thunder Bay, ON (807) 475-3052

www.nors.com

Top Lift Enterprises, Inc.

Bolton, ON(905) 857-5200

Stoney Creek, ON (905) 662-4137

www.toplift.com

Manitoba

NORS

Winnipeg, MB (204) 633-5800

www.westconequip.ca

Saskatchewan Redhead Equipment

Estevan, SK (306) 634-4788

Lloydminster, SK (306) 825-3434

Melfort, SK (306) 752-2273

North Battleford, SK (306) 445-8128

Prince Albert, SK (306) 763-6454

Regina, SK (306) 721-2666

Saskatoon, SK (306) 934-3555

Swift Current, SK(306) 773-2951

www.redheadequipment.ca

Alberta NORS

Acheson, AB 1-877-948-3515

Calgary, AB 1-800-342-6523

Fort McMurray, AB 1-855-799-4201

Grande Prairie, AB 1-888-513-9919

Red Deer, AB 1-866-950-3473

www.nors.com

By Tony den Hoed, Director, Key Accounts — Demolition Equipment, Volvo Construction Equipment

When it comes to excavators used for demolition cleanup, many contractors think of them simply as commodities — machines that are interchangeable with other machines and used for the same purpose, with no real value of one over the other.

As a result, they opt for less-expensive models or even low-hour used machines knowing they’ll probably be beaten up in the process, then traded in for whatever they can get instead of investing in the proper specialized demolition excavators they need to get the job done.

That way of thinking, though, can cost you money. e machines used to process demolition debris are typically conventional excavators as opposed to purpose-built demolition excavators, like a high reach.

But these demolition cleanup excavators can and should have durable features and be out tted to withstand the demands of demolition work.

at may cost a little more up front, but the savings on operating costs over time — not to mention safety and potentially higher resale values — are well worth the investment.