Manitou has launched three new large-frame skid steers as well as two large frame compact track loaders

Manitou has launched three new large-frame skid steers as well as two large frame compact track loaders

In 2007, prospector Richard Nemis discovered one of the most significant mineral deposits in Canada.

Drawing upon influence from Johnny Cash, the deposit was named the Ring of Fire, and governments have been promoting the potential the untapped trove of rare earth minerals ever since.

Located about 500 km northeast of Thunder Bay, the Ring of Fire covers about 5,000 square kilometres and contains one of the world’s most promising mineral development opportunities, including nickel, copper, platinum and chromite. These minerals are required to make modern technologies function, from mobile phones to medical devices to cars.

Despite the mining project's potential, progress on mineral extraction has been

slow, due to its remote location, a lack of supporting infrastructure and land rights issues with First Nations.

This month, the provincial government took a significant step towards harnessing the potential of the region by promising to spend $61.8 million on the Geraldton’s Main Street Rehabilitation Project, a critical roadbuilding project that will serve as the gateway to the Ring of Fire and help provide year-round access.

The project will connect Highway 11 at the south end to Highway 584 at the north, ultimately connecting the Trans-Canada, and will be the first segment on the road network leading to and from the Ring of Fire.

"Ontario has a plan to build a stronger and more self-reliant Canada. This investment is unlocking the

gateway to one of the most significant mineral development opportunities in the world.

In partnership with First Nations, we are seizing this generational opportunity to create jobs, improve quality of life, and power Ontario’s clean energy future," said Stephen Lecce, Ontario’s Minister of Energy and Mines.

The Ring of Fire failed to make the priority list for fast tracking from the federal government’s newly created Major Projects Office (MPO). However, it did earn an honourable mention.

In addition to the five projects announced, the federal government said a priority for the MPO will be to help critical minerals projects get to final investment decisions within a two-year window.

Ontario’s recent investments, as well as Canada’s

signal to move quickly, are more than a bet on mineral wealth, they are the beginning of a blueprint for lasting prosperity.

And before the first mine opens, strategic infrastructure, like roads, energy transmission and broadband, built to support the Ring of Fire, will leave their own legacy of connectivity and opportunity.

Raimondi Cranes has entered into a definitive agreement to acquire key crane businesses from United States-based Terex Corporation.

Raimondi Cranes is set to acquire Terex Tower Cranes, Terex Self-Erecting Cranes and Terex Rough Terrain Cranes, as well as its United States-based after-sales and service infrastructure.

“This transformative move, recognized as the most impactful deal in the industry over the past 20 years, marks the most significant acquisition in Raimondi’s history, representing a milestone into our journey to become a full-fledged global lifting conglomerate,” said Luigi Maggioni, Chief Executive Officer of Raimondi Group.

This transaction broadens Raimondi’s offerings in terms of luffing jib cranes and tower cranes, while expanding the company’s scope to include new business lines, such as self-erecting and rough terrain cranes.

The step also fuels Raimondi’s growth strategy and opens access to an extensive global distribution network, enhancing shareholder confidence and elevating the customer experience

through expanded capabilities.

“As market leaders in their segments, Terex Tower Cranes, Terex Self-erecting Cranes and Terex Rough Terrain Cranes, along with their US-based service hub, will enable Raimondi to take its first major step toward diversification,” Maggioni said.

“By integrating Terex’s range of tower and rough terrain cranes, we are creating synergies that enhance our ability to deliver a broader range of lifting solutions, paving the way for sustainable, accelerated growth.”

The acquisition will see around 250 Terex employees join the Raimondi Group.

The deal is part of a wider development plan aimed at capturing a larger share of the global heavy lifting sector. It combines Raimondi’s Italian engineering legacy with Terex’s applications and established market presence, offering clients a comprehensive and competitive product lineup designed to meet the evolving demands of the construction and heavy lifting sectors.

The Terex Tower Cranes and Terex Self-Erecting Cranes facilities in Fontanafredda, Italy, are included in

the transaction, as well as the Terex Rough Terrain Cranes facility in Crespellano, Italy, and the Terex North America Cranes service and support operation in Wilmington, North Carolina.

“The lifting businesses, together with their strong legacy, seamlessly align with Raimondi’s values and vision, reinforcing our shared commitment to innovation, quality and customer-centric solutions,” Maggioni said.

In addition to its expanded product portfolio, the acquisition provides Raimondi with significant operational advantages.

By leveraging enhanced manufacturing capabilities, optimizing product segmentation and streamlining procurement processes, the company aims to achieve economies of scale and further strengthen its market position.

Additionally, the integration of Terex’s established North American infrastructure accelerates Raimondi’s entry into the market, enabling the company to serve one of the largest construction sectors globally while reinforcing its leadership in Europe and the Middle East.

“We are pleased to enter into this agreement with Raimondi, a manufacturer of cranes that is widely recognized for product innovation and customer service. We believe the tower and rough terrain cranes businesses will benefit by becoming part of an Italian-based, global specialty crane company,” said Simon Meester, President and Chief Executive Officer at Terex Corporation.

In a news release, Raimondi said it is committed to ensuring a seamless integration process, prioritizing

continuity for Terex employees and customers.

The combined entity, which will bring Raimondi’s total workforce to about 400 employees, will focus on delivering solutions to the most demanding lifting requirements, further cementing its position as a trusted partner in the industry.

“During the transition to Raimondi, our team is committed to servicing and supporting our customers seamlessly,” Meester said. “Terex is working closely with Raimondi to support the team and manage the

change with transparency and respect for everyone involved. Our cranes team members in Italy have made substantial contributions throughout their years of service to the company, and we thank them and wish them continued success in the future.”

Raimondi Cranes is poised to drive long-term value and is targeting annual revenue of $500 million from its global operations by 2028.

The transaction is expected to close in the third quarter of 2025, subject to market regulatory approvals.

JCB is breaking into the 100-plus horsepower range for its compact track loader lineup with the debut of the 4TS Teleskid and 400T CTL.

As the largest models in JCB's compact track loader lineup, these machines are a step up from the 3TS, delivering more horsepower and higher torque.

JCB developed the 4TS and 400T with extensive customer feedback, incorporating updates that deliver more power, greater reach and improved productivity.

“These machines reflect our commitment to equipping operators with the tools

they need to work smarter, not harder,” said Lee Tice, Product Manager at JCB.

“Whether you’re managing construction projects, tackling forestry challenges or handling versatile applications, these machines are built to exceed expectations.”

4TS Teleskid

The 5.9-tonne, 109 hp 4TS Teleskid is a game-changer for construction contractors looking to maximize equipment usage.

The 3TS revolutionized the industry, and the 4TS raises the bar even higher – nearly 60-cm higher. Fea-

turing a 4.5 metre lift height and a nearly 1,800-kg rated operating capacity, the 4TS eliminates the need for a separate telehandler in many situations, providing a single machine that handles everything from grading and trenching to material handling and loading. As a true start-to-finish tool, the 4TS allows contractors to consolidate equipment fleets and increase jobsite efficiency.

Its compact profile enables the 4TS to navigate tight spaces with ease while excelling in heavy-duty applications.

With a 4.5 metre lift height, the 4TS is ideal for stacking, loading and accessing hardto-reach areas. Addressing feedback from 3TS owners, the 4TS is designed to run high-flow attachments even when the boom is fully extended, overcoming a key challenge and expanding its capabilities for complex jobsite operations.

The 4TS features a newly designed low-leak valve body that prevents boom drift, ensuring materials stay exactly where you need them – even when the boom is fully extended. This design delivers unmatched precision and enhanced safety on the jobsite.

“The 4TS Teleskid bridges the gap between compact and capability,” Tice said.

“It’s the ultimate all-in-one machine for contractors who need to get more done with less equipment.”

4TS Teleskid specs

· Operating weight: 5.9 tonnes

· Hinge pin height: 4.5 metres

· Engine power: 109 hp

· Lift capacity: 1,813 kg

· Travel speed: 12.5 km per hour

The 400T compact track loader is built for operators

facing demanding applications like forestry, snow removal and land clearing. With an operating weight of 5.7 tonnes, the 109-hp 400T is built to handle heavy-duty tasks while maintaining the agility expected from a compact loader.

Equipped with a 4.4 litre engine, JCB redesigned the machine’s redesigned chassis and expanded the cooling pack to eliminate the need for auxiliary coolers, ensuring optimal performance during extended high-flow operations. Delivering over 151 litres per minute of hydraulic flow at 4,000 psi, the vertical lift 400T powers demanding attachments like drum mulchers, making it a reliable workhorse for tough applications.

“When you need equipment that works as hard as you do, the 400T is the answer,” Tice said. “With its increased engine and hydraulic performance, it’s a true workhorse built for operators tackling the most challenging applications.”

400T CTL specs

· Operating weight: 5.7 tonnes

· Max dump height: 2.9 metres

· Engine power: 109 hp

· Lift capacity: 3,091 kg

· Travel speed: 12.5 km per hour

Designed for operators

Developed at JCB’s North American headquarters in Savannah, Georgia, the 4TS and 400T reflect years of customer feedback and industry expertise. From enhanced operator comfort to increased safety and performance, these machines are designed to deliver what compact equipment owners need to succeed in today’s demanding environments. Both models are now available at JCB dealerships across North America.

We

We’re

Test

Manitou approached the design of its new large frame skid steers and compact track loaders (CTLs) as an opportunity to go toe-totoe with other large-frame machines in the construction industry.

The company recently introduced three large-frame skids steers and two large frame CTLs ranging in operating capacity from 1,475 kg to 1,635 kg.

“At the high end of this range, we are going headto-head with the largest, most powerful machines in the industry,” said Nathan Ryan, Global Product Manager — skid steers and CTLs at Manitou.

Ryan explained the large frame skid steers and CTLs meets the need for more power and capacity while maintaining a compact machine footprint. Stepping into a larger type of machine can create challenges in terms of transportation and access.

“That's why we look at making skid steer and compact track loaders bigger and better, because the operators are familiar with them. The transportation is easier, and you have better machine access, plus, obviously, you have a wider variety of attachment capabilities,” he said.

The new large frame lineup includes the 72-hp 3250 V,

100-hp 3350 V and 114-hp 3600 V skid steers and the 100-hp 3350 VT and 3600 VT compact track loaders.

“These five new models represent the best of Manitou global innovation matched with North American craftsmanship — from an engineering and design team that has built skid steers and CTLs in South Dakota for more than 50 years,” said Ilmars Nartish, Vice President — North America, Manitou. “We now offer even more of an end-to-end solution for rental businesses, large fleets and national accounts, and other businesses that prefer working with a single supplier as much as possible.”

Each new machine is built with a vertical lift design that is optimized for truck loading, as well as lifting and placing palletized materials. Strong cast links, built standard into each model, also make the new compact loaders ideal for ground engaging applications and ensuring they work well as a strong attachment platform.

Hinge pin heights range up to 3.5 metres to make these machines ideal for loading and reaching into high trucks and lifting or placing materials to higher points.

Rated operating capacities are further increased up to 1,723 kg with the addition of optional counterweights that serve as protective guarding for the rear of the machine. As well, load sensing hydraulics help the machine determine the amount of hydraulic load required for each job, which improves performance and fuel economy.

Each machine excels in auxiliary attachment use and performance, with both standard flow rates (up to 95 litres per minute and 3,450 psi) and high flow rates (151 litres per minute up to 3,450 psi).

Variable rate flow controls that allow operators to set the flow going to each attachment are standard. This dictates optimal performance of the attachment and ensures only the necessary amount of energy is consumed to operate it. Hydraulic horsepower on each machine — 50.3 hp standard and 82 hp with the optional boost —ensures overall machine performance and attachment performance.

The Manitou design and engineering team worked to incorporate existing Manitou exclusive technologies such as the IdealTrax track-tensioning system and IdealAccess foldable door with all-new design features that deliver practical benefits to machine operation and performance.

IdealTrax, which auto -

matically tensions the track to its desired tension upon startup and relieves that tension when the machine is turned off, now engages directly through the in-cab display, instead of the back of the machine in previous models.

A unique and ultra-modern lift-arm design slopes away from the operator at the top of the arm and allows for hydraulic lines to run inside of the arm or underneath it for greater protection. The unique contouring of the arms also prevents material from building up on the machine and improves visibility for the operator down to the side of the machine. Comfort ride control (boom suspension) is now standard and incorporated into the design, which reduces spillage and improves operator comfort.

The new skid steer models feature an adjustable arm downstop to accommodate different tire sizes depending on the application.

Each arm is designed with strong cast steel timing links that improve everything from attachment carrying and operation to ground engaging bucket work while reducing stress on the machine.

“These innovative patent pending lift arms are designed to slope away from the machine where the operator sits inside the cab,” said Tyler Handel, Research and Development Director at Manitou. “This reduces the amount of material that can get stuck on the lift arm, and, most importantly, it improves the visibility, both above and below the lift arm.”

Greaseable pins are also located along the lift arm for easy access and improved service.

Each machine comes standard with a sloped roof and large skylight that minimizes the front upper cross section for better visibility when loading trucks, feed mixers or placing materials at height. An optional Level 2 FOPS improves the protection of the cab and provides a robust protective bracket

for the machine’s front LED work lights.

360-degree illumination

Lighting plays an important role in the new design, with 360-degree illumination available, along with the option to add a beacon on top of the machine for greater jobsite awareness. This includes the standard rear LED position lights, turn signals and front work lights, as well as optional road lights, hazard lights and optional side lights tucked under the lift arm. The front worklights even feature an egress time delay to ensure safety around the machine in lowlight conditions.

“These machines work 24 hours a day, on the side of the road, on busy and congested jobsites — the ability to be seen is almost as important as the ability to see for overall jobsite awareness and safety,” Ryan said.

The undercarriage of each tracked model has also undergone over a major redesign for improved performance and durability. This includes steel forged hardened sprockets with a corrosion inhibitor for longer sprocket life; dual flange idlers in both the front and rear to prevent de-tracking, reduce vibration and reduce service over time; and triple flange rollers to reduce vibration, prevent de-tracking and limit spills.

Feature standardization

A central focus of the introduction of the new large-frame lineup was the addition of a considerably more robust set of standard features, aimed at simplifying the ordering process and delivering a more premium owning and operating experience.

Standard features include a foot pedal for both throttle and deceleration, cabin dome lights, 12V and USB charging ports with device storage areas and removable rubber floor mats that include a drain that goes

“I’ve used other brands before, but the feel and controls on the BOBCAT are far superior and make me more efficient.”

HARDSCAPE DREAMS BUILT WITH BOBCAT MACHINES: Bennett Lawn & Landscape, a growing hardscape business in West Ottawa.

“We’re a relatively new company, we started in 2020, and over the last few years have been getting more into hardscaping. We’re growing quickly, which means we’ve had to invest in more equipment. We cover most of West Ottawa, from Dunrobin up to Carleton Place, and down through North Gower and Kemptville. Our focus is on interlock driveways, walkways, retaining walls, and other hardscape outdoor living spaces, as well as landscaping.

I used to work as a carpenter framing

BARRIE

Bobcat of Barrie

705-726-2228 oakenequipment.ca

GREY BRUCE

Bobcat of Grey Bruce 519-372-9100 bobcatoftc.com

PARRY SOUND

Bobcat of Parry Sound Ltd. 705-342-1717 bobcatofparrysound.com

TORONTO WEST

Bobcat of Toronto 416-679-4172 oakenequipment.ca

BRANTFORD

Bobcat of Brantford 519-752-7900 bobcatofbrantford.com

HAMILTON

Bobcat of Hamilton 905-643-3177 bobcatofhamilton.com

PETERBOROUGH

Bobcat of Peterborough 705-748-9119 bobcatofpeterborough.com

THUNDER BAY

Equipment World Inc. 807-623-9561 bobcat-tbay.com

houses, but during COVID, I wanted to try something new. That’s when I started this business. Initially, I was renting machines, but I soon realized I was spending way too much time and money on rentals. I knew it was time to make the jump and invest in my own equipment.

A friend in the industry recommended Bobcat, and he spoke highly of the team at Bobcat Ottawa Valley. I met Zach Wiggins, a sales specialist for Bobcat of Ottawa Valley, and had an instant great experience. Both Zach and Pier-Olivier Castonguay have been excellent. They really went to bat for me with financing, which isn’t always easy for a younger business owner. Honestly, I’m not sure anyone else would have cared as much as they did.

Now I have a Bobcat® E20 compact excavator and a T66 compact track loader. The E20 is perfect for our excavation work. It’s smooth, fast, and super precise with the 39-inch bucket; it makes my life so much easier. I can reach right into the pile and backfill; I don’t have to load a wheelbarrow. I’ve used other brands before, but the feel and controls on the Bobcat are far superior and make me more efficient.

The T66 has been a game-changer for bigger jobs, from grading and loading trucks

CASSELMAN

Bobcat of Ottawa Valley 613-764-2033 bobcatov.com

KITCHENER

Bobcat of Tri-Cities Ltd. 1-866-214-3939 bobcatoftc.com

STRATFORD

Bobcat of Stratford 519-393-6040 bobcatofstratford.ca

SAULT STE. MARIE

Bobcat of Sault Ste. Marie 705-949-7379 bobcat-ssm.com

CORNWALL

Bobcat of Ottawa Valley 613-932-2034 bobcatov.com

LONDON

Bobcat of London

519-455-4900 bobcatoflondon.ca

STRATTON

Stratton Equipment 807-483-5505 strattonequipment.com

WINDSOR

Bobcat of Windsor 519-737-0120 oakenequipment.ca

to moving pallets of material. It was also friendlier in cost but didn’t sacrifice any performance. The foot controls are smooth, visibility is excellent, and the rearview camera gives me and my crew peace of mind. The machines don’t call in sick, and they’ve become essential to keeping our projects on track, especially with a small team.

I’ve already recommended Bobcat of Ottawa Valley to friends in the industry. In fact, one of my buddies recently bought an E20 compact excavator based on my experience. For me, it’s simple, I couldn’t be happier with the machines or the support I’ve received.”

— Isaac Bennett, Owner, Bennett Lawn & Landscape

COURTICE

Bobcat of Durham East Ltd. 905-404-9990 bobcatofdurhameast.com

MUSKOKA

Bobcat of Muskoka 249-390-7000 oakenequipment.ca

SUDBURY

McDowell B Equipment Ltd. 705-566-8190 bmcdowell.com

WYOMING

Advantage Farm Equipment Ltd. 519-845-3346 advantage-equip.com

FRANKFORD

John’s Equipment 613-398-6522 johnsequipmentsales.com

OTTAWA

Bobcat of Ottawa Valley 613-831-5166 bobcatov.com

TORONTO EAST

Bobcat of Toronto 416-679-4171 oakenequipment.ca

through to the bottom of the machine for easy clean out.

The cab is large and spacious with an adjustable workstation that allows each operator to adjust their orientation in the cab to their preference. This includes pilot joysticks attached to the seat to move with the operator, a seat and armrests that adjust independently based on operator preference, and a removable footrest for comfort and bracing. Options include a fully enclosed cab with full environmental controls, multiple seat options including heating, Bluetooth radio, a sound reduction package and Manitou’s

Hydraulic Power-A-Tach system that allows for the quick and easy swapping of attachments from inside the cab.

“Each of these machines features patented pilot controls that are mounted to the seat assembly to provide ergonomic access to the controls, no matter where you sit in the cab,” Handel said. “We know these machines operate in a lot of difficult and tough terrains and environments, so we wanted to ensure that we provided the operator with a comfortable operating experience. A lot of these creature comforts and things may otherwise be

considered bells and whistles, but we felt these were critical to these machines.”

The new large-frame skid machines also feature a new 18-cm colour display that intuitively displays critical machine settings, engine information, service intervals and other machine information critical to daily use. An all-new backlit ergonomic keypad on the right-hand side of the cab delivers new features such as a coded keyless start, lights and HVAC controls. It also includes Manitou’s smart throttle that senses the input speed and adjusts the acceleration rate — and it always starts at low idle for safety and fuel effi-

ciency. Optional creep mode is additionally controlled through this keypad and the monitor, which allows the operator to independently set machine travel speeds from the engine throttle.

Service is made simple through intelligent engine compartment design and easy access to daily service checks and fill points. The tilt-up hydraulic cooler serves a double purpose of enabling a low profile to improve visibility to the rear of the machine and allowing for improved access to service points in the engine compartment while discour-

aging the build-up of jobsite dust and debris. That cooling fan comes with optional reversing capabilities – either at scheduled intervals or on-demand – to improve cooling performance and to keep the engine compartment clear of debris.

These new large-frame loaders are Manitou Connected machines that provide instant remote access to recent activity, operation codes, CAN data and service alerts. Owners/ operators stay connected on-the-go with the myManitou mobile app, where they can monitor machine location, fuel levels, operating hours and set geofences for

added control and security. For fleet and business management, EasyManager tracks service intervals, pinpoint machine locations and quickly identify diagnostic codes, all from one centralized platform.

“We look at a total cost of ownership as a compounding benefit,” said Josè Carlos Braga Vasquez, Manitou’s Technical Training Specialist.

“There are numerous things that you can do to get most of each machine, but when you combine those many things together, you can significantly lower your operating costs and increase your revenue.”

Bid-Well has announced the MT Series, a new line of material transport systems.

Expanding Bid-Well’s portfolio beyond paving, the MT Series offers purpose-built systems that support material movement at every stage of bridge construction.

Since 1961, Bid-Well has worked with contractors on complex bridge paving projects around the world. This experience has shaped the development of the MT Series, a solution born directly from the challenges and insights gathered on jobsites.

“Bridge construction is more than paving, so Bid-

Well is more than a paver. The MT Series is our answer to the evolving needs of contractors who demand smarter, safer and more adaptable material movement solutions,” said Mark Rhead, Sales Manager at Bid-Well.

“Whether navigating overhead power lines or transporting deck pans, rebar and forms, the MT Series delivers an efficient and cost-effective solution for material movement, with features that simplify even the most complex of lifts.”

MT Behemoth

The first model in the

MT Series is the MT Behemoth, engineered to deliver powerful and precise material movement for bridge construction.

The MT Behemoth features a stationary power unit that serves as the central source of energy and operational control. This unit drives the machine’s travel, trolley movement, elevation adjustments and any powered accessories, whether hydraulic or electric. The machine frame is constructed from ultra-high strength weathering steel, offering durability and longevity. Supporting this system is a

generator that supplies power to up to three contiguous material transport trollies and their hoists. These trollies, housed within the material transport hanger frame, are the primary carrying apparatus of the machine. Each trolley is connected to the Bid-Well’s standard chain power transmission system, providing smooth and consistent movement across the span.

To maintain stability and distribute weight effectively, the MT Behemoth features an 8-wheel bogie system. This design minimizes stress on rails or overhang brackets,

while the ultra-powered leg system controls the machine’s elevation via a hydraulic motor-driven Acme screw.

The MT Behemoth Lifting heights range from 6 metres to 30 metres, with lifting speeds reaching up to 6.4 metres per minute.

The system supports a maximum load of 7.5 tons across three trollies and, in certain engineered configurations can span up to 36 metres, with longer configurations available through factory consultation.

The MT Series has been designed to integrate with Bid-Well bridge pavers and truss configurations, making it the only configurable material movement system on the market.

“The MT Series is a direct result of decades of experience working alongside contractors on complex bridge paving projects,” Rhead said. “We’ve listened, learned and engineered a solution that addresses real challenges in material movement with the reliability and adaptability Bid-Well is known for.”

Operators can select either remote and pendant control options, and tandem lifting is supported for complex lift scenarios.

Powerful and fuel-efficient performance

THE POWER. MASTER THE VERSATILITY! Advanced hydraulics for smooth, responsive control Compact swing radius for easy maneuvering

5-year / 5,000-hour warranty

Caterpillar has enhanced its PM600 and PM800 cold planer series with improved operator comfort, efficiency and equipment management upgrades compared to its previous models.

Offering milling widths from 2 metres to 2.5 metres, the latest PM620, PM622, PM820, PM822 and PM825 models deliver high-production and efficient performance with the milling precision contractors need to stay competitive.

“These most recent updates to our PM600 and PM800 cold planers are a result of direct feedback provided from our customers,” said Jameson Smieja, Senior Sales Support Consultant for Cat cold planers.

“We’ve made numerous upgrades to lower operator fatigue and made the machines easier to use.

We’ve also added remote diagnostics and software update capabilities to help improve machine uptime. Plus, we’re excited to release VisionLink to this series of cold planers, which helps customers better manage their fleet and improve machine utilization.”

The operator’s workstation is designed for day-long comfort with adjustable consoles, large, cushioned arm rests, hip rests and optional anti-fatigue floor mats.

that enables the ground crew to change mounting locations and store the displays without removing any clamps or electrical connectors. Two rear keypads include controls for leg height, water spray, side plates, moldboard, rear door and steering, while the flushmount front keypads offer controls for the conveyor, side plates, anti-slab, high pressure washdown, water spray, inboard ski and fuel fill pump.

Available as part of the optional enhanced lighting package, the addition of high-visibility, colour LED lightbars replace traditional water level tubes and floats, helping crews identify water tank levels day or night and from much farther distances. The touchscreen displays automatically change to night mode when working lights are activated to help improve visibility.

The centre console displays now telescope to bring the touchscreens within easy reach of the operator. As well, the displays fold for secure and convenient storage. Available as an option, an adjustable operator control console slides sideways and rotates to further help boost efficiency and reduce fatigue.

The PM600 and PM800 cold planers series now come standard with Cat Remote Services technology to help improve machine diagnostics and operating efficiency when within cell range coverage.

A new pedestal seat option allows operators to rest their legs and feet while running the machine. It is designed to quickly and easily retract out of the way when not in use.

The updated machines feature a ladder and gate design that offers unimpeded access to and from the operator platform, and the updated retractable right-side handrail helps to further simplify manoeuvrability around obstacles.

Remote Troubleshoot allows the Cat dealer to perform diagnostic testing on the connected machine, enabling the technician to pinpoint issues while the mill is operating, so they arrive with the correct parts and tools the first time. Remote Flash enables contractors to update onboard software without the need for a technician, so updates can be initiated at a convenient time without interrupting production.

To enhance the operator’s sight lines to the front tracks, the new design incorporates flush-mounted front ground control panels.

To maximize torque transfer, the PM600 and PM800 series rotor drive system features a heavy-duty dry clutch, automatic belt tensioning system and two high-tensile belts to drive the rotor.

A redesigned anti-slab plow delivers improved operation and reduced wear compared to the previous design. Cat also upgraded the anti-slab-to-conveyor sealing to help contain more material to improve milling efficiency and reduce cleanup.

As well, the cold planers’ ground displays now feature a robust mounting system

Optional productivity features of VisionLink, now available with a VisionLink PerformancePro subscription, help contractors measure, monitor and manage the cold planers to maximize productivity on or off the jobsite. Critical, actionable machine operating data, such as wait time for trucks, time spent cutting and manoeuvring around the jobsite, as well as distances cut, fuel burned and detailed cycle location mapping, is transmitted from the jobsite to the VisionLink web platform for users to access anywhere an Internet connection is available.

The Cat Inspect mobile application tool enables operators and technicians to quickly perform digital preventative maintenance checks, inspections and

• The 370 has advanced technology, including Digital Level, Dynamic Stability Assist, Height and Depth Alarm, and Payload.

• The heart of these machines lies in their electronically controlled hydraulic pump system and the industry-recognized SSC (Spool Stroke Control) system.

• This innovative combination enhances efficiency and control, while the Isuzu AQ-6HK1X Final T4 engine, known for its exceptional fuel economy, powers the machine.

Equipment Sales & Service Ltd.

Edmonton (780) 440-4010 essltd.com

JT Equipment (587) 832-0772 or 1-888-214-5038 www.jtequip.ca

Inland Truck & Equipment

Campbell River, BC 250-287-8878

Castlegar, BC 250-365-2807

Cranbrook, BC 250-426-6205

Fort St. John, BC 250-785-6105

Kamloops, BC 250-374-4406

Langley, BC 604-607-8555

Nanaimo, BC 250-758-5288

Penticton, BC 250-492-3939

Prince George, BC 250-562-8171

Quesnel, BC 250-992-7256

Terrace, BC 250-635-5122

Vernon, BC 250-545-4424

Williams Lake, BC 250-392-7101 inland-group.ca

Itec 2000

Rosslyn (888) 574-8530 Thunder Bay (888) 574-8530 Timmins (705) 267-0223 itec2000.com

McDowell B Equipment Ltd.

Sudbury (705) 566-8190

Barrie (416) 770-7706 bmcdowell.com

Stratton Equipment Sales & Service Stratton (807) 483-7777 strattonequipment.com

Terapro Rental

Vars (613) 443-3300

Stittsville (613) 836-0654 terapro.ca

Top Lift Enterprises Inc.

Stoney Creek (905) 662-4137 Bolton (905) 857-5200 toplift.com

• Notably, the 370 achieves up to 7% improved fuel consumption without requiring a Diesel Particulate Filter (DPF), eliminating the need for maintenance or replacement.

• Operators can select four power modes- Speed Priority, Power, Eco, and Lift, allowing them to optimize power, precision, and fuel savings for each task, resulting in enhanced cost-effectiveness.

• Did we mention comfy, best-in-class interior cab spacing!

Équipement JYL Inc. Chicoutimi (418) 698-6656 equipementjyl.com

Micanic St-Aug-D-Desm (418) 878-2241 micanic.com

Paul Equipment (506) 826-3289 paulequipment.ca

Terapro Location Val d’Or (819) 825-4299 Plaisance (819) 718-0945 terapro.ca

Top Lift Enterprises Inc.

St-Laurent (514) 335-2953 Sherbrooke (819) 612-5438 toplift.com

Paul Equipment

Balmoral (506) 826-3289 paulequipment.ca

Inland Truck & Equipment

Whitehorse, YT 867-668-2127 inland-group.com

Blue Diamond Attachments has introduced a 12-model line of hydraulic breakers, designed for demolition and quarry applications, including underwater jobs.

The breaker line is compatible with excavators, mini-skid, skid steer and compact track loaders.

Blue Diamond’s line enables contractors to select specialized breakers engineered specifically for their machines, with models available for equipment ranging from 680-kg mini track loaders to 55-ton class excavators, providing the ideal match for any application.

Blue Diamond breakers feature a solid mono-block design milled from a single piece of steel rather than assembled sections held together with tie rods, eliminating most common maintenance issues.

As well, the breakers feature a unique vibration dampening system consisting of a polyurethane shell that wraps around the mono-block and sits inside the Hardox steel outer casing. The design reduces noise and significantly re -

duces vibration transfer to the host machine, protecting hydraulic components, pins and bushings from excessive wear while improving operator comfort.

For versatility, many of the breaker models feature interchangeable mounting brackets, allowing a single breaker to be moved between different host machines including excavator to skid steer, by simply transferring the unit to a compatible mount. This flexibility increases utilization rates and return on investment.

The breakers are also built with a self-regulating valve that protects them from over pressurization, excessive flow and back pressure. This increases productivity when switching between host machines or in rental applications, eliminating the need to test the machine’s hydraulic pressure and flow before operation.

As well, anti-blank firing means Blue Diamond Breakers will not operate unless pressure is applied to the tool. This feature prevents internal damage from dry firing while the attachment

Multiquip has announced its new battery-powered MQ Whiteman buggy.

The MQ Whiteman model WBH-16BAT buggy is a step forward in zero-emission construction equipment. Developed to meet the requirements of construction sites while meeting eco-friendly standards, this buggy is efficient, easy to use and environmentally friendly.

“At the heart of the MQ Whiteman buggy lies its powerhouse, a rechargeable 48V 7 kWh Vanguard lithium-ion battery,” said Joseph Jeong, Associate Product Manager for Buggies at Multiquip. “With its impressive runtime of 8 hours when fully charged and fully loaded, this battery ensures sustained operation without having to worry about power outlets and gasoline,”

Engineered for challenging environments, the buggy features dual drive

is not engaged with material. The hydraulic breakers feature four tool configurations: a moil point, a chisel tool, a pyramid tool and a blunt tool. Each tool type is manufactured from highgrade, heat-treated steel with precision machining to en-

sure proper fit and maximum energy transfer from the piston to the material being broken. Tools are easily interchangeable with minimal downtime, allowing operators to select and change the tool in the field without additional wrenches or keys.

motors that deliver exceptional torque. For improved traction, the buggy features a set of wide, foam filled tires to tackle muddy, rocky and uneven jobsite terrain.

An 11-cm digital display provides at-a-glance information on battery charge level along with operational indicators for dump and travel speed. It also provides the operator with easy-tounderstand diagnostic alerts that can be used for troubleshooting to reduce downtime.

With a top travel speed of 10 km per hour, the MQ Whiteman buggy cuts down transport time across the job site. Its 453 litre polyethylene tub handles up to 1,135-kg of material with ease, while the hydraulic dump system ensures rapid unloading with a 7.42 second dump and retract cycle and an 88 degree dump angle that delivers material clearing and reduces manual cleanup.

John Deere has introduced new user capabilities within John Deere Operations Center. Customers using Operations Center can now benefit from streamlined parts ordering through the newly integrated shop. Deere.com feature. Customers with factory maintenance plans can add parts for scheduled services directly to their cart and complete purchases with confidence and ease.

“We are continuously evolving John Deere Operations Center to simplify and enhance our customers’ digital experience,” said Katie Voelliger, Product Marketing Manager, John Deere.

“Customers can review, create and save factory-recommended or customized maintenance plans within Operations Center and manage all equipment maintenance in one convenient location.”

The fleet maintenance management process enables users to plan maintenance intervals, order parts online and monitor machine health efficiently, in near real time, through one interface. This helps customers increase uptime through better management of preventative maintenance for their equipment fleets.

Within Operations Center, fleet managers can also

log completed maintenance tasks with details such as costs, photos, documents, repair notes and service history to support machine lifecycle management. Customers and their approved John Deere dealers or preferred service providers can jointly monitor and manage maintenance plans, helping to streamline communications for more productive operations.

As well, customers utilizing the John Deere Equipment Mobile application can benefit from the new shop.Deere. com feature as well, enabling simplified parts ordering from a variety of customer platforms.

Power Curbers Companies has announced the acquisition of Miller Formless Systems, an established producer of mid-sized slipform machines.

Power Curbers completed the acquisition on August 29, 2025, marking a significant milestone in the continued growth of both organizations.

Based in McHenry, Illinois, Miller Formless was founded in 1970, and has a long history of manufacturing easy-to-operate and reliable slipform machines for customers worldwide.

“This acquisition represents more than just growth — it’s about uniting two businesses that share a deep commitment to quality and

customer success,” said Stephen Bullock, President of Power Curbers Companies.

“Miller Formless has been a trusted name in the industry for over five decades, and we are honoured to carry that legacy forward while offering an even greater range of solutions to contractors.”

By joining Power Curbers Companies, home to the

Power Curbers, Power Pavers and Anvil American brands, this acquisition strengthens the combined company’s market leadership, expands product offerings and enhances service and support for customers worldwide.

“We are building a stronger, more innovative company with this acquisition,” Bullock said. “By joining our

resources and expertise, we can deliver better service, more product choices, and long-term benefits for our customers.”

Miller Formless will continue to operate under its brand name. Power Curbers Companies remains committed to preserving the company’s legacy while introducing operational ef-

ficiencies that will benefit customers in the areas of machine delivery, parts availability and after-sales support.

Together, the four companies will now provide contractors with a comprehensive lineup of concrete paving solutions, from extruded curb machines to mainline highway pavers.

Develon’s new wheel material handler, the DX270WMH-7, is configured to conquer tough recycling jobs.

With about 1-metre longer reach and elevated cab, the DX270WMH-7 helps position operators for better productivity when loading trucks, containers and railcars at busy sites.

The machine’s reach is 9.5-metres and it achieves a 7.1-metre loading height.

The 28-tonne material handler, powered by a 171-hp engine, is designed to boost operator productivity, enhance safety and optimize material movement at recycling and solid waste facilities.

“A wheel material handler needs to be more than powerful — it should be smart, adaptable and a true partner to the operator,” said Brian Kim, Heavy Excavator Product Manager for Develon.

“The DX270WMH-7 delivers on all fronts. Its exceptional versatility allows operators to complete a range of recycling tasks. And it features our -7 Series cab design and safety technologies, allowing operators to work longer, more comfortably and with greater peace of mind.”

The DX270WMH-7 wheel material handler makes light work of heavy loads, such as car bodies and

other bulky materials.

Utilizing a grapple or magnet attachment, the machine effortlessly moves and positions materials across recycling yards and solid waste facilities. The machine’s chassis design provides better lifting and a more durable undercarriage to minimize downtime.

Operators can work with full visibility of the site from the standard hydraulic cab riser. This feature allows an operator to safely enter the material handler’s cab at ground level. Once inside the cab, the operator can raise the cab hydraulically to the preferred height and then begin working.

The DX270WMH-7 material handler is equipped with a new virtual wall setting. The feature stops the machine’s boom and arm from hitting surrounding objects, helping the operator work confidently in tighter spaces and minimizing machine downtime.

In-cab comfort

The new DX270WMH-7 features a fully adjustable heated air-suspension seat and heat and air conditioning, allowing operators to customize their level of comfort. It also features joystick steering in addition to the standard steering wheel, giving the operator the op-

tion of steering the machine without taking their hands off the joystick.

The machine comes with an easy-to-read 82-cm LCD monitor that displays machine diagnostics and controls to improve performance. Bluetooth hands-free radio and MP3 audio allow operators to listen to their favourite content while keeping their hands free to work the controls.

Safety features

Wider front and rear outriggers on the DX270WMH-7 create a larger base that improves stability, especially when operators are working with higher lifting capacities.

The machine’s outriggers extend the footprint of the machine by creating a larger, wider area of contact with the ground.

As well, the DX270WMH-7 is outfitted with an around view monitor (AVM) camera system that provides up to 360 degrees of visibility for a bird’s-eye view of the equipment and its surroundings.

Operators can choose to only have a rearview camera to improve visibility all around.

Other key safety features include front and rear LED

working lights for enhanced visibility in low-light settings, seatbelt warning for operator safety and an alarm to identify the machine on the site.

The DX270WMH-7 wheel material handler provides operators with easy access to maintenance points and service procedures. It has an engine aftertreatment system with no diesel particulate filter (DPF) to minimize maintenance. This means the machine does not require a regeneration process to burn off accumulated soot.

The machine also features an air inlet mesh to keep fresh air flowing to the engine and a reversible fan to keep the machine cooler and keep debris out for less maintenance.

My Develon fleet management, a digital telematics platform for managing equipment, comes standard on the new machine. The diagnostic tool is available on all -7 Series machines and monitors the health, location and productivity of Develon equipment from a user-friendly mobile app and website.

Designed for contractors on the move, it delivers industrial-level performance with unmatched mobility. With its unique design, it’s the only 5’x10’ trommel screener towable by a pickup on the market. No special trailers. No permits. No downtime. Just hook it up and get to work.

High-performance screening, zero transport hassle.

Whether you’re in excavation, aggregates, landscaping, or nurseries, the R394 is built to follow your work, wherever it takes you. It packs the punch of a full-sized machine in a compact and agile frame.

Proudly built in Québec with premium North American components, the R394 is engineered to perform — and built to last.

We’re expanding and looking for o�cial dealers across various provinces and states. Seize this opportunity to grow with us!

ALBERTA

Liftboss JCB

Calgary: 403-301-0041 Edmonton: 780-474-9900 liftboss.ca

BRITISH COLUMBIA

Williams JCB

Surrey: 604-930-3316 williamsjcb.com

NEW BRUNSWICK

A.L.P.A. Equipment

Edmundston : 506-735-4144

Balmoral : 506-826-2717

Fredericton : 506-452-9818 Moncton, N.B. : 506-861-2572 alpaequipment.com

NOVA SCOTIA

A.L.P.A. Equipment

Truro : (902) 897-2717 alpaequipment.com

For 80 years, JCB has stood for more than machinery – we’ve stood for engineering excellence, relentless innovation and a commitment to reshaping what’s possible on every jobsite. To celebrate 80 years of challenging the status quo, we’re offering this amazing deal, because building better never stops, so neither should you.

Harvey JCB

Corner Brook: 709-639-2960

St. Johns: 709-738-8911 harveyco.ca

ONTARIO

Advance Construction Equipment (Division of Equipment Ontario)

Harriston: 519-510-5878 Waterloo: 519-742-5878 advanceequipment.net

D&W Group Inc.

Doughty & Williamson Jarvis: 519-587-2273

Brant Tractor Burford: 519-449-2500

Redtrac International Vineland: 905-562-4136 dwgroup.ca

ONTARIO

Delta JCB

Dunvegan: 613-527-1501 Renfrew: 613-432-4133 Winchester: 613-774-2273 deltapower.ca

Equipment Ontario

Alliston:705-320-0506 Lindsay: 705-324-6136 Port Perry: 905-982-1500 equipmentontario.com

Fulline JCB

Glencoe: 519-287-2840 fullinefarm.com

John’s Equipment Sales Frankford: 613-398-6522 johnsequipmentsales.com

Moore JCB Toronto, York & Peel Region: 416-747-1212 moorejcb.com

ONTARIO

North Rock JCB North Bay, Sault Ste. Marie, and Sudbury: 705-897-7369 northrockrentals.com

ReadyQuip Sales & Service Ltd. Timmins: 705-268-7600 readyquip.com

WPE Landscape Equipment - JCB Hamilton/Halton: 905-628-3055 wpeequipment.ca

PEI

A.L.P.A. Equipment (506) 861-2572 alpaequipment.com

QUEBEC

A.L.P.A. Equipment

Bas-Saint-Laurent : (506) 735-4144

Gaspésie : (506) 826-2717 alpaequipment.com

Bossé Quebec Inc.

Desmaures: 418-878-2241 Saint-Augustin-debosse-frere.com

Moore JCB

Montreal: 514-333-1212 moorejcb.com

SASKATCHEWAN & MANITOBA

Westcon JCB

Regina: 306-359-7273

Saskatoon: 306-934-3646

Winnipeg: 204-694-5364 westconequip.ca

•

Here's how to select the right tool for feeding your crusher

By Eric Yeomans, Product Manager for Large Wheel Loaders at Volvo Construction Equipment

Quarry and aggregates operations rely on a series of coordinated steps to transform raw rock into valuable materials. The crusher is a central part of this process, and how you feed it matters significantly to your success.

For this critical task, you should think carefully about whether to use a wheel loader or an excavator — or perhaps both. There’s no one-size-fits-all solution; the right tool depends on the material, the site and your production goals.

This loading machine selection is important because an inconsistent feed can lead to slowdowns or even shutdowns. A steady feed ensures consistent particle size, which is essential for meeting strict specifications for applications like road construction and concrete production. Plus, you need to feed your crusher according to its capacity to reduce uneven wear on components and prevent issues like bridging, where material blocks the inlet and can cause damage.

Three key factors

When selecting the right machine for your operation, be sure to consider:

1. Material type: The properties of the material — rock versus sand, large versus small, hard versus soft and so on — will affect machine performance. Large, abrasive or hard materials require a heavy-duty machine like a large wheel loader or hydraulic excavator, whereas softer, more varied materials might suit a smaller-class wheel loader.

2. S ite layout and mobility: Your crusher’s location, haul distances, stockpile setup and available turning space are all important considerations. For instance, static crushers are often paired with larger, more robust loading equipment like excavators to handle continuous high-volume feeding. On the other hand, mobile crushers need smaller, more agile loaders for quick relocation.

3. P roduction targets: These targets, which can range from high-volume continuous feeding to smaller, variable output requirements, should steer your decision. High-volume sites with large material piles and fast cycles favour a wheel loader, while deep digging and accurate placement require the power and speed of an excavator.

Wheel loader benefits

Wheel loaders are known for their mobility and versatility, helping them excel at tasks like stockpiling and load-and-carry operations. They offer faster cycle times for short distances and can easily handle multiple tasks on a jobsite.

However, wheel loaders have some limitations. When it comes to placing material precisely into hoppers, they have shorter reach and less control than an excavator. They can also be less effective for continuous feeding and may burn more fuel. Wheel loaders are best designed to scoop and move large, loose volumes quickly from a pile to the crusher. The productivity of a wheel loader hinges on its large bucket capacity and its ability to handle bulky materials in fewer cycles than an excavator.

Excavator benefits

Excavators provide superior reach and control for precisely placing material into a hopper. They’re also a better choice for sites with limited manoeuvring space and are well-suited for continuous feeding to maintain steady crusher operation. While wheel loaders are made for moving large, loose volumes, excavators offer more precision and reach for digging from a specific source. The cycle time of an excavator is also superior for digging tasks.

The primary limitations of excavators are mobility and flexibility. They aren’t as ambulatory as loaders and may require a dedicated support machine (like a truck or loader) for stockpiling and hauling materials.

Tech and operator skill

Today’s technology plays a significant role in optimizing

crusher loading. Telematics is a great example, providing real-time data for remote monitoring of machine health, utilization and operational parameters. This data allows you to better manage production, track operator performance, improve maintenance scheduling and make smarter decisions about equipment deployment. Matching a machine’s size and bucket capacity to the crusher is a common challenge. Oversizing equipment can lead to excessive wear and downtime, while undersizing equipment can increase cycle times and costs. It’s also crucial to consider your operator’s skill level. A skilled operator can monitor material conditions and machine performance in real time, adjusting feed rates and minimizing downtime. A less-experienced operator may need more training or assistive tech to achieve similar results.

Before material is fed into a crusher, it should be prepared by removing oversized pieces, fines (or quarry dust) and foreign objects like metal and wood. To maintain a consistent and controlled feed rate, the operator should feed material directly into the centre and ensure that the crushing chamber is kept full. Surge piles or bins also help regulate material flow.

It’s not uncommon to use both excavators and wheel loaders to feed crushers because they can complement each other for different tasks on the same site. For example, the visibility from an excavator’s high-rise cab is helpful for primary loading from stockpiles or demolition debris. Meanwhile, a wheel loader can handle the load-and-carry functions, moving material from stock or surge piles directly into the crusher.

In the end, the right choice is about testing and tracking performance to make decisions that align with your specific material, site and production goals. When you take the time to get this right, you can expect to see increased productivity and lower costs per ton across your entire operation.

Known for its ability to produce high-quality, precisely sized rip rap material, the M515 from MDS is playing a key role in helping customers meet demand, driven by an increased focus on infrastructure development, flood protection and environmental conservation.

In the quarry industry, rip rap is produced by extract-

ing and processing rocks of varying sizes, often as a byproduct of other mining operations.

Rip rap is categorized into five classes, ranging in sizes from 30-cm to 86-cm rock. Each class is designed with a low percentage of fines, making it suitable for various erosion control and structural applications. Smaller classes are ideal

for foundational support in submerged structures such as piers, while mid-range sizes are commonly used for erosion control along rivers, lakes and embankments.

The largest classes offer protection in high-impact areas, including steep slopes, shorelines and windmill bases.

Whether it's protecting shorelines, stabilizing

riverbanks, or reinforcing structures against erosion, the need for high-quality, precisely sized rip rap material means that it is becoming an attractive market.

innovative rotating drum design that allows for the efficient cleaning of rocks, breaking down impurities and enabling quarries to make use of material that would otherwise be wasted.

"As demand for rip rap continues to rise, especially in infrastructure projects, the M515 will be crucial in helping quarries meet those demands," said Liam Óg Murray, Regional Sales Manager for MDS. "By enabling quarries to make better use of their raw materials, improve operational efficiency, and provide higher-quality products to customers, the M515 not only sets the standard for what’s possible in rip rap processing; it is a catalyst for growth in the North American rip rap market.”

In the southeast United States, Powerscreen Crushing and Screening has seen the M515 heavy duty trommel become a cornerstone in rip rap processing for their customers' quarry operations.

The M515 trommel is available in Ontario through Powerscreen of Canada.

Areas that have seen a particular growth include Chattanooga, Tennessee, where Class A rip rap is being used for the building of a pier, and Kentucky, where quarries process rip rap for shoreline projects.

As the flagship model in the MDS portfolio, the M515 can handle large, sticky materials.

One of the most significant challenges in the rip rap market is the need to clean and process materials that are often contaminated with clay, dirt or other sticky elements. Usually, the waste is discarded or processed via costly secondary processes. However, the M515 has an

With a large 12.6 cubic metre hopper that can handle up to 20 tonnes of feed material, the M515 trommel can process rocks as large as 800 mm, making it ideal for quarries producing irregular or oversized material.

The trommel has a 4 metre fines section and 1.5metre mid-product section equipped with interchangeable screens or fully welded drums that are tailored to meet the specific needs of each application. These versatile drum configurations enable customers to receive the optimal setup for their unique requirements.

The M515 is also designed for ease of use and reduced operational costs. The model features a swing-out engine for quick and hassle-free maintenance. The addition of a convenient access platform allows operators to perform service checks with minimal downtime.

For transportation, the M515 engine side placement enables it to fit on smaller bed trailers, making it more cost-effective to transport.

“One of the biggest advantages of the M515 is its loader feeder, which works wonders for sticky materials,” said Alan Coalter, President of Powerscreen Crushing and Screening. “In our territories, we often deal with dirty shot rock, and the trommel makes it easy to clean and reuse material that would otherwise be wasted. It helps quarries keep their operations running longer and more efficiently, which ultimately benefits our customers."

Before adopting the M515, Powerscreen Crushing and Screening relied on scalpers, which were limited by the size of the materials they could process, as well as their stockpile clearance. Additionally, quarries were often relying on labour and machines to manually pick through shot rock, a time-consuming and inefficient process. The M515, however, can handle larger feed sizes, and offers higher stockpile clearance, improving both material handling and efficiency.

"The trommel allows us to process bigger rock more effectively, eliminate the need for manual sorting, and make better use of resources. It provides more options and significantly improves the quality of the rip rap," Coalter said.

The feedback from Powerscreen Crushing and Screening customers has been positive, with many appreciating the machine’s ability to utilize previously wasted materials. Looking ahead, Powerscreen Crushing and Screening sees continued growth in the rip rap market, with the M515 playing a pivotal role in shaping that future.

"By offering the M515, we've been able to differentiate ourselves from competitors. It’s the best option on the market for sticky applications and large rock processing,” Coalter said.

“Replacing the scalper with the M515 has proven to be more cost-effective in the long run, thanks to the reduced need for screen media and other maintenance costs. In our opinion, the M515 has become the main player in the rip rap sector, helping us improve our competitiveness and better meet customer needs."

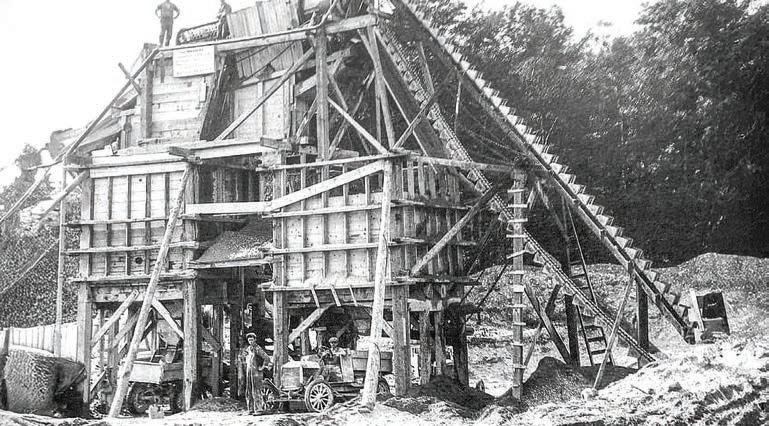

Pictured here in 1915 is a 'Champion' gravel plant in operation in Huron County, Ontario. Colborne Township had contracted Boss & Brazier Ltd. to crush pit run gravel for use in road building and maintenance.

Built in nearby Goderich by the Dominion Road Machinery Co., the plant consisted of a jaw crusher, elevating bucket line and a rotary screen to produce two sizes of aggregate. The crushing plant output was rated as 50 cubic yards per hour.

The plant structure supporting the rotary screen also provided the aggregate

bins. The drivers of the small dump trucks of the day could self-load from the hopper, eliminating the need for a shovel to load. As early as 1898, the parent company based in Pennsylvania had patented a line of portable Champion crushers.

Originally located in Hamilton, the Canadian version of the parent Good Roads Machinery Co. produced dump wagons, plows, rollers and horse drawn graders. By 1915, the renamed firm had relocated to Goderich, Ontario to be known as the Dominion Road Machinery Company. In the mid-1950s

they focused on building Champion road graders and in the 1970s appropriately changed the name to Champion Road Machinery Ltd.

To see more than 60 restored pieces of vintage construction equipment in action, be sure to attend the Historical Construction Equipment Association (HCEA) Canada's events, including the Last Blast show on Saturday, October 18 at the Simcoe County Museum near Barrie, Ont.

HCEA Canada is a Proud Community Heritage Partner of the Simcoe County Museum.

The HS300 wheel loader salt spreader features a 3 cubic yard capacity for increased efficiency, making it ideal for demanding winter maintenance tasks.

For Tommy Moore, Aftermarket Training Manager at Rokbak, a PowerPoint presentation doesn’t cut it for an articulated dump truck lesson. Instead, it happens on the workshop floor, tools in hand, surrounded by the components that keep a job site productive. It’s a handson, practical approach that perfectly mirrors his own journey through the company and embodies the brand’s commitment to its customers and dealers.

Moore’s career with the Scottish manufacturer didn’t

begin in a classroom, but on the assembly line, physically building the company’s ADTs. This foundational experience, moving from the line to mechanical engineering, where he rewrote the standard operating procedures (SOPs) for building the trucks, gave him a detailed understanding of every nut, bolt and system. It’s this practical knowledge that forms the core of Rokbak’s training philosophy.

“You can talk all day pointing to a picture, but it’s not the same as walking a group

Finlay’s J-1280 jaw crusher features a wide gape and robust throughput capabilities while weighing less than its J-1480 model.

The new 75,940-kg J-1280 boats a 1,200 mm x 820 mm jaw chamber for hard rock applications. Despite its size, the machine is engineered for easier transport.

With a transport width of 17.1 metres long by 3 metres, the jaw crusher is an ideal solution for medium-sized quarries and larger contractors seeking high capacity without the logistical challenges associated with heavier equipment.

“This balance of size and mobility has been a direct response to strong feedback from the Finlay distribution network, who emphasized the need for a lighter, more transportable model yet with the same jaw dimensions of our highest-selling units in several key regions,” said Martin Conway, Global Sales &

Marketing Director for Finlay.

The J-1280 jaw crusher is equipped with a hydrostatic drive system. Unlike direct drive alternatives, the hydrostatic setup allows the crusher to continuously operate in reverse. The reverse function is critical for clearing blockages quickly and safely, without the need to manually lift material from the chamber.

The ability to clear blockages improves safety by reducing the need for working at height and minimizes downtime by eliminating the need for lock-out/tag-out procedures during unblocking.

The J-1280 is available in three feed-in configurations, including:

· A standard vibrating grizzly feeder (VGF)

· A pre-screen option

· Extended pan feeder with pre-screen

This flexibility allows operators to tailor the machine

of technicians over to a machine, showing them the component and demonstrating how it works right there in front of them,” Moore said.

“When we discuss a part of the truck, we work on that part. We have a full workshop here at our headquarters in Motherwell, Scotland, where we can strip a machine down and rebuild it. That’s how people truly learn.”

This philosophy is about more than just effective teaching; it’s about delivering tangible value. The training, which is provided to dealers and end-users, directly im-

pacts a machine’s total cost of ownership and uptime.

Driving performance

A key focus is educating operators — or teach technicians how to educate operators — on how to use the trucks to their full potential, which takes pressure off consumable parts.

“A big part of our training is showing field engineers and operators how to use the truck’s technology properly, like the retarder and gear-changing techniques,” Moore said.

“If an operator isn’t using

to their specific application needs, whether prioritizing throughput, fines removal or feed consistency.

“This latest addition to the jaw crusher lineup reflects our commitment to engineering excellence, customer feedback and operational efficiency,” Conway said.

“With a focus on safety, transport efficiency and

high-performance crushing, the Finlay J-1280 is a machine built not only to meet the demands of today’s quarrying and contracting environments but to exceed them.”

The J-1280 jaw crusher is equipped with T-Link telematics hardware and software along with a free seven year data subscription.

the retarder correctly, for example, they can burn through a set of brakes three times quicker than they should. By teaching them certain driving techniques, we save the customer money and keep their truck running.”

With a target to train 70 per cent of dealer technicians globally, Rokbak’s program is the core of its customer support strategy.

The four-day courses held at the Motherwell facility — complete with a test track — are comprehensive and tailored. Moore and his colleagues often contact participants in advance to understand any specific issues they are facing, allowing them to stage practical demonstrations to solve real-world problems.

“Being able to physically strip down an axle or transmission and have technicians get their hands on it is something we are very fortunate to be able to do,”

Moore said.

“We want them to leave here 100 per cent comfort-

able with the truck.”

Whether travelling to Ghana, Australia or Indonesia, the rule is the same: training must happen with a truck on-site.

“You can’t keep a group of 15 technicians interested with a presentation in a meeting room, especially when there might be some language barriers,” Moore said. “But get them out on the iron, doing tests, checking pressures and diagnosing issues together that’s a language everyone understands. They get hands-on with it.”

At the end of each course, attendees leave with new knowledge and appreciation for the Scottish culture and, just as importantly, Moore’s phone number. It’s a symbol of an ongoing partnership.

“We want our customers and dealers and their technicians to know we’re always just a phone call away,” he said.

“Our goal is to give them the knowledge and support they need to get the job done. Their success is our success."

Asphalt is one of the world’s most recycled materials. However, its potential remains untapped due to

inefficient processing methods.

Allu aims to change that with the introduction of its asphalt bucket that turns milled material into a high-quality resource onsite, supporting greener, leaner infrastructure development.

The Allu Asphalt Bucket is a hybrid screening solution engineered specifically for processing cold-milled asphalt and reclaimed asphalt pavement (RAP) in a faster, cleaner, and more cost-effective way.

“Globally, there’s a clear shift toward sustainable infrastructure in construction business. Asphalt recycling plays a major role in this movement, and our new Allu Asphalt Bucket empowers contractors to turn reclaimed and cold-milled asphalt into high-quality, reusable material — directly on site,” said Peter Grönholm, CEO of Allu Finland Oy.

“It’s a smarter, more profitable way to work, and we’re proud to help drive this transformation across the industry.”

According to Allu, the Asphalt Bucket delivers a transformative advantage for contractors looking for smarter ways to reuse milled asphalt. This purpose-built attachment crushes clumps, screens fines and separates oversized particles, all in a single pass.

“At a time when efficiency, sustainability and profitability are key, the Allu Asphalt Bucket ticks all the boxes,” said Tom Chapman, Managing Director at MRD Plant, UK. “It does the job of a mo-

bile impact crusher – but at a fraction of the cost and with far less complexity on-site.”

The asphalt bucket utilizes a hybrid blade configuration, a mix of screening and crushing blades, to fine-tune performance and achieve consistently high-quality end products. This combination allows operators to process cold-milled asphalt directly at the source without additional crushing equipment.

“The hybrid blade setup is what makes this bucket so effective — it delivers just the right mix of crushing force and fine screening to process asphalt efficiently in a single step,” Grönholm said. With nominal screen sizes of 12 mm, 16 mm and 25 mm, the bucket can produce more than 95 per cent of finished material below target size, drastically reducing reprocessing needs.

As the attachment crushes and screens simultaneously, it eliminates the need for separate pre-crushing or secondary equipment. This, according to Allu, reduces reliance on mobile impact crushers, cutting fuel consumption, wear part expenses and overall tonper-cost rates.

Asphalt Bucket models can deliver up to 250 tons per hour, with rapid drum change-outs thanks to the variable drum technology.

The Allu Asphalt Bucket is available in several sizes for 25-ton to 45-ton excavators and 15- ton to 30-ton wheel loaders. Its design includes a serrated cutting edge and reinforced frame, tailored for aggressive asphalt processing.

The construction industry is increasingly adopting a circular economy approach on a global scale, prioritizing energy efficiency, alternative fuels and sustainable raw materials.

The production of industrial sand and the separation of usable construction materials for concrete production present significant business opportunities while addressing the rising demand for sustainable practices.

The Metso HRC 8 high pressure grinding rolls (HPGR) crusher not only supports sustainable operations, but it also offers

process flexibility and higher capacity and low energy and wear part consumption, making it an attractive option for aggregate producers and contractors.

Metso showcased the capabilities of its HRC 8 crusher at bauma. With declining sand extraction sites in Europe and reduced permitting for new ones, supply is challenging, and transporting sand from distant locations is often not economically viable.

At the same time, the cement industry creates 8 per cent of global carbon dioxide emissions. The target is

to reduce these emissions by 25 to 55 per cent by 2030 and achieve zero-emission cement production by 2050. Currently, up to 20 to 30 per cent of recycled materials are used in cement and concrete production.

“The construction industry is moving towards a circular economy, and urbanization is expected to drive demand for raw materials to meet the growing global needs.

Metso's HRC 8 offers a proven solution for aggregate producers and contractors, delivering high quality output with excellent gradation and particle shape,” said Oldemar

Meneses, Product Manager Impactors and Sand solutions, Aggregates at Metso.

“It fully meets the specifications for recycled concrete and cement applications. With more than 160 units currently sold worldwide, the HRC 8 has received consistently positive feedback from customers, supporting sustainable and efficient production.”

Metso HRC 8 for Aggregates is available as a stationary crusher or as a part of Nordplant's pre-designed crushing modules and plants. As a portable model on Nordwheeler, the crusher provides flexibility for relocation based on material location. Due to its energy efficiency, it is included in the Metso Plus offering.

The HRC 8 crusher generates low dust emissions and noise levels, saves up to 50 per cent energy compared to other technologies and can convert quarry waste and demolition waste into high-quality, high-value sellable products.

It can release recycled cement from CDW, produce high-quality manufactured sand and improve poor-quality sand, thereby avoiding the use of virgin resources and upcycling quarry waste materials.

In 2020, the City of Toronto embarked on the largest and most significant water quality improvement project in its history.

The Ashbridges Bay Treatment Plant Outfall project, part of the largest and most significant stormwater management program in the city’s history, sought to create a new fallout and watertight shaft to replace the existing 80-year-old system.

The project was designed to address shortcomings in the Ashbridges Bay Treatment Plant. Its outfall was where treated water from the city’s sewer system was released and dispersed into

Lake Ontario. However, a shared pipe system carried both raw sewage and stormwater. The combined sewers occasionally released untreated wastewater into the waterways, increasing pollution. The outfall also had insufficient capacity and no longer met regulatory standards.

The contract for the tunnelling and concrete work was awarded to Southland Mole of Canada and Astaldi Canada Design and Construction Joint Venture. Southland Mole of Canada, an excavation company specializing in trenchless technologies and tunnelling

configurations, joined the project to create the tunnel and break through the lakebed to the risers above. For such a complex project, they needed machines that didn’t require operators to stand in the danger zone.

A new outfall was constructed as part of the project and required creating a new 16-metre onshore shaft that’s 85 metres deep and 3.5 km long with an internal diameter of 14 metres.

The project also involved excavating through the floor of the lake to locate 50 preinstalled risers, which convey treated and disinfected effluent from the Ashbridges Bay

Treatment Plant into Lake Ontario.

Once the new outfall is constructed, all effluent flows from the plant will be directed to the new outfall up to the wet weather design capacity of 3,923 megalitres per day. With only 1 metre of hydraulic head available at peak design flows under the highest recorded lake water level conditions, the outfall components were designed to minimize head losses and allow the outfall to operate by gravity.

Southland Mole used a tunnel boring machine to mine the shaft. At the same time, another team on a barge positioned the risers and inserted them into the lakebed of Lake Ontario.

“The point of the project is to convey the treated wastewater, which has been processed through the wastewater treatment plant, back into the lake,” said Kevin Collins, Equipment Manager with Southland Mole. “Barges prepositioned the risers, so we just had to locate them by drilling up into the rock. Although the project is straightforward, it is not simple.”

The Southland Mole crew had to excavate upward through the new tunnel into the lakebed above to link the