SCALPING SCREEN Multi-purpose heavy duty incline 2-deck 9’x4’ screen, 6.15 yd3 variable speed hopper, rear wall collapsible for direct feeding, heavy duty variable speed belt feeder, hyd. folding conveyors. Capable of stockpiling, 3 way splitting or scalping before/after crushing units. Can accept bofor bars, finger screens, woven mesh and punch plate.

JAW CRUSHER A high-performance jaw crusher with 450tph capacity, featuring a fuel-efficient Scania engine, hydraulic folding hopper, and advanced screening, ideal for quarrying, mining, demolition, and recycling applications.

CONE SCREEN Combines the high production MVP380X cone and the LJ-TSV6203 screen. Unique in the industry with its High Lift Screen (HLS) and integrated flow buffering features. Operators can take advantage of the cone’s and screen’s capabilities without needing to throttle back the feed for surges.

IMPACT CRUSHER Mid-sized horizontal impact crusher. Double deck 11’ x 5’ screen, bolt in cartridge grizzly, highly fuel efficient direct drive system.

Excellent reduction and high consistency of product shape in recycling, demolition and quarry applications.

SCALPING SCREEN Mid-sized track mobile screen aimed at end users requiring high volumes of finished products in applications including topsoil, crushed stone,recycling, iron ore, sand and gravel. 5’ x 16’ screen deck, 14’ wide feed hopper, hydraulic folding conveyors, hydraulic screen angle adjustment, fast setup, double or tripple deck.

OPEN CIRCUIT CONE CRUSHER The Gladiator MT1150 is an electrically driven, wheeled open circuit cone crusher. It features the tried and tested Terex TC1150 cone chamber and is mounted on wheels which ensures ease of movement and quick set up times.

AMI Attachments recently held a tour of its manufacturing facility for construction industry veterans from southern Ontario

In the first quarter of 2025, Alberta dominated housing starts in Canada.

Alberta, the nation’s fourth largest province, accounted for 25 per cent of all housing starts coast to coast, according to the Canada Mortgage and Housing Corporation (CMHC).

Now, the province is on track to build 58,900 homes by the end of 2025 and has recorded a 30 per cent increase compared to 2024, which was a record setting year.

Meanwhile, Ontario, Canada’s largest province with more than triple the population of Alberta, is expected to build 60,200 homes this year.

Alberta is on track to meet Canada’s promise to double housing starts by 2035. In fact, Wildrose Country is propping up other provinces that are falling behind.

The federal government has pledged to double housing construction over the next decade, which would restore the cost of a home to 2019 levels. To achieve that feat, homebuilding in Canada must increase by an annual average rate of 6.5 per cent over the next decade.

By June, Alberta had increased residential construction starts by 29.7 per cent, way above the recent national average of 3.5 per cent. In contrast, Ontario housing starts dropped 24.8 per cent and British Columbia fell 8.2 per cent.

“If not for the increase in homebuilding in Alberta, national housing starts would have fallen by 2.2 per cent rather than increasing by 3.5 per cent,” the Fraser Institute noted in a recent report.

“Toronto alone saw hous -

ing starts drop by 9,954 — more than wiping out Alberta’s gains”

Obviously, there are variables in construction that may benefit Alberta, while hindering other provinces’ ability to build, such as newfound tariff pressures as well as land and labour costs. However, Alberta is clearly doing something right.

The Fraser Institute notes its success is in part due to comparatively low municipal fees on builders, faster approvals by city hall for new housing projects and more relaxed rules regarding what can be built and where.

The CMHC agrees this is the best approach to reach the target set by the federal government.

“Doubling the pace of housing construction in Canada is achievable, but not without a significant -

ly larger and modernized workforce, more private investment, less regulation, fewer delays and lower development costs,” said Aled ab Iorwerth, Deputy Chief Economist for CMHC. Outside of Alberta, there’s no shortage of ideas on how to build faster. Perhaps instead of brainstorming, we should just mimic what’s worked for Alberta.

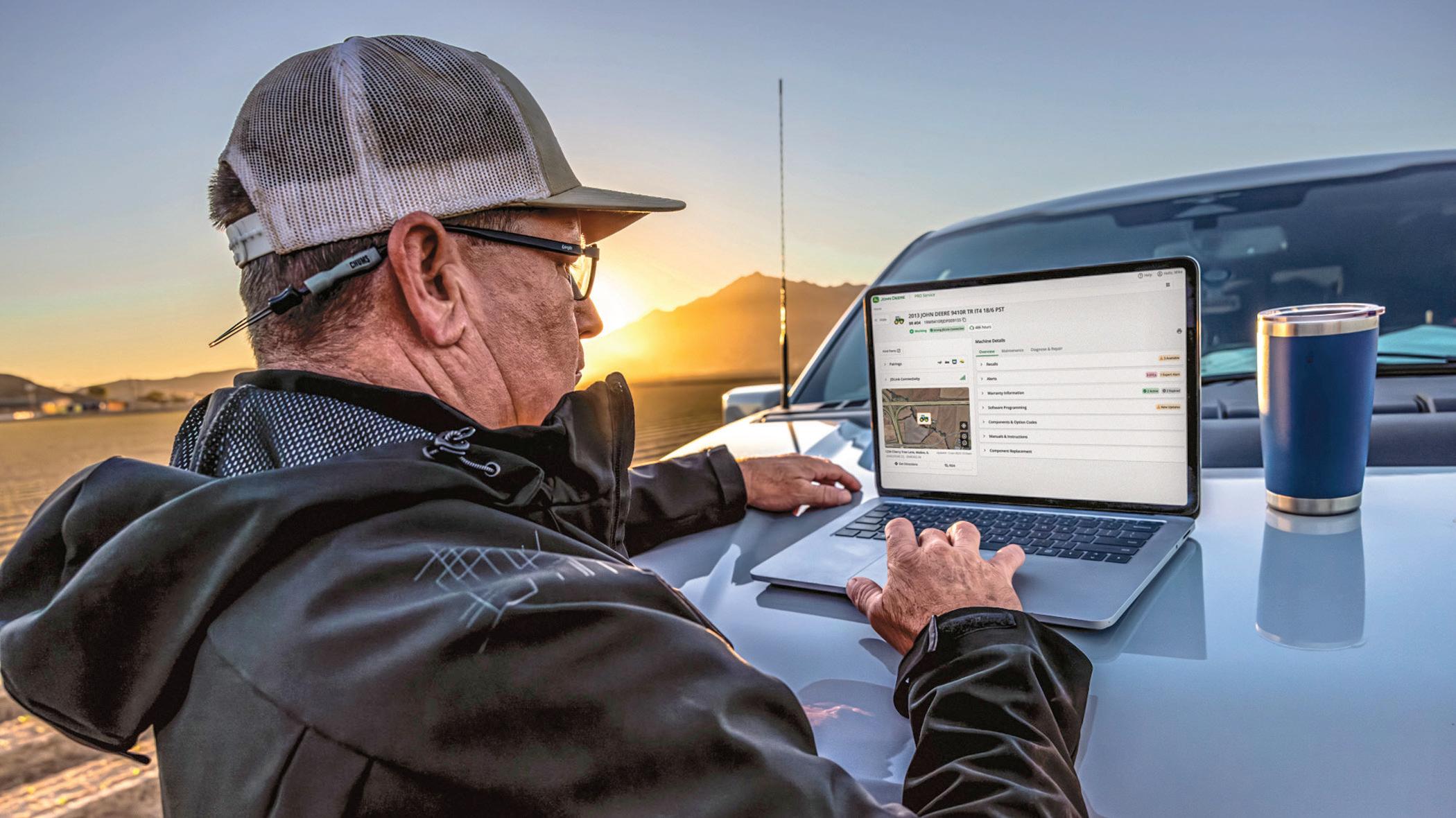

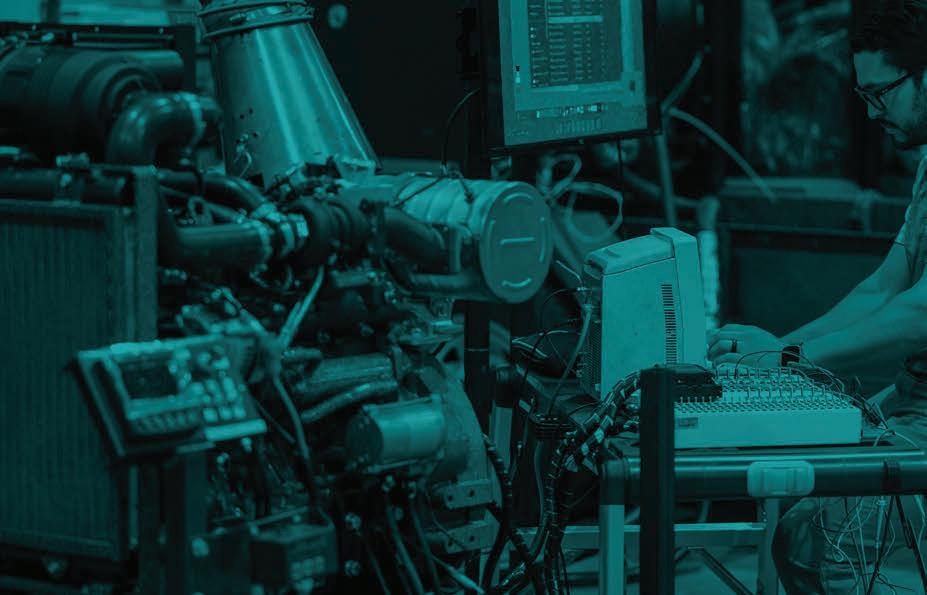

Operations Center PRO Service offers the manufacturer’s most expansive and innovative self-repair capabilities yet

John Deere has created a new digital tool to help equipment owners use, maintain, diagnose, repair and protect their equipment.

Operations Center PRO Service delivers new support capabilities for both connected and non-connected machines across John Deere’s equipment portfolio. New and enhanced features include the ability to install software when replacing electronic components or controllers, also known as reprogramming.

Operations Center PRO Service expands upon the suite of existing digital support tools available to John Deere equipment owners — including the John Deere Operations Center, Equipment Mobile and Shop. Deere.com — providing customers with even more control over how they use, maintain, diagnose, repair and protect their machines.

The increased functionality of Operations Center PRO Service also replaces John Deere Customer Service Advisor, which will be phased out over the next year.

“The launch of Operations Center PRO Service is a significant milestone that adds to John Deere’s existing tools, and it reaffirms our longstanding commitment to empowering customers to choose how they repair their equipment,” said Denver Caldwell, Vice President of Aftermarket and Customer Support.

“Importantly, our development of these tools reaffirms John Deere’s support of customer self-repair. We view continuously enhancing self-repair as consistent with our mission to ensure John Deere customers have the best machine ownership experience possible.”

Local service providers are also able to use Operations Center PRO Service. With the equipment owner’s permission, independent providers can gain access to diagnostic and repair information to support the equipment owner’s needs.

“Our message to our customers is clear,” Caldwell said. “Whether you want the support of your professionally trained and trusted John Deere dealer, to work with another local service provider, or to fix your machine yourself, we’ve created additional capabilities for you to choose the option that

best fits your needs.”

How it works

Operations Center

PRO Service is based on capabilities that are available at no additional cost upon purchase of John Deere equipment through Operations Center Service Overview and Equipment Mobile, including:

· Operator’s manuals

· Active and stored diagnostic trouble codes

· Secure software updates

· JDLink information

· Warranty information

The new Operations Center PRO Service delivers digital repair content filtered by year and model number, providing users with additional relevant machine information to help efficiently and accurately troubleshoot, diagnose and repair their equipment. It’s designed to be intuitive and deliver actionable support in real-time.

The service capabilities of Operations Center PRO Service are available through an annual license per machine for customers. Specific features now brought together in a single customer interface include:

· Machine health insights and diagnostic trouble codes

· PIN-specific machine content, including manuals

· Software reprogramming for John Deere controllers

· Diagnostic readings

· Diagnostic recordings

· Interactive diagnostic tests

· Calibrations

Equipment owners can access Operations Center PRO Service through the John Deere Operations Center. Once connected to the platform, owners will add their equipment into their account using the machine’s serial number.

Use of an electronic data link may be required for more advanced features within Operations Center PRO Service, including software reprogramming. Certain interactive tests, calibrations and reprogramming limitations will exist at initial release. John Deere will deliver additional capabilities in future updates.

Operations Center PRO Service is available to John Deere customers in Canada and the United States.

Marketplace Events (MPE) and the Canadian Rental Association (CRA) have announced a strategic partnership for the 2026 trade show season.

The partnership will focus on educational initiatives, increased member visibility and stronger industry engagement. With a shared vision of

strengthening the heavy equipment and rental sectors, MPE and CRA are aligning efforts to enhance the overall show experience for exhibitors, attendees and

industry professionals.

“This partnership is about more than just putting on great events—it’s about bringing people together and making these shows even

more valuable for everyone involved,” said Mark Cusack, National Show Manager at Marketplace Events. “Working with CRA helps us build stronger connections, deliver meaningful education and create a better experience for both exhibitors and attendees.”

The collaboration begins with the Atlantic Heavy Equipment Show (AHES), held March 26 and 27 in Moncton, New Brunswick.

AHES is celebrating 40 years of driving the heavy equipment industry in Atlantic Canada. The show is the region’s largest showcase of equipment, services and technology. With more than 200,000 square feet of indoor and outdoor exhibits, it attracts more than 10,000 people.

In 2026, the partnership continues with the National Heavy Equipment Show (NHES), held April 23 and 24 in Mississauga, Ontario.

NHES is Canada’s largest heavy equipment trade event, brings together industry leaders, machinery and innovative solutions.

The partnership will extend into future events, including Expo Grands Travaux and the Alberta Equipment Expo in 2027.

“We’re excited to bring our members closer to these key industry events. Our collaboration with Marketplace Events ensures the CRA community is not only present but actively contributing to the success and vibrancy of the shows,” said Melanie Misener, Executive Director of CRA.

No matter the application, whether its for heavy muckshifting or fine grading, the Liebherr PR 716 is the dozer you need. Powered by the latest Tier IV Final engines to give class leading pushing capability combined with low fuel burn, this Generation 8 dozer is engineered for efficiency, power, and performance.

www.liebherr.ca

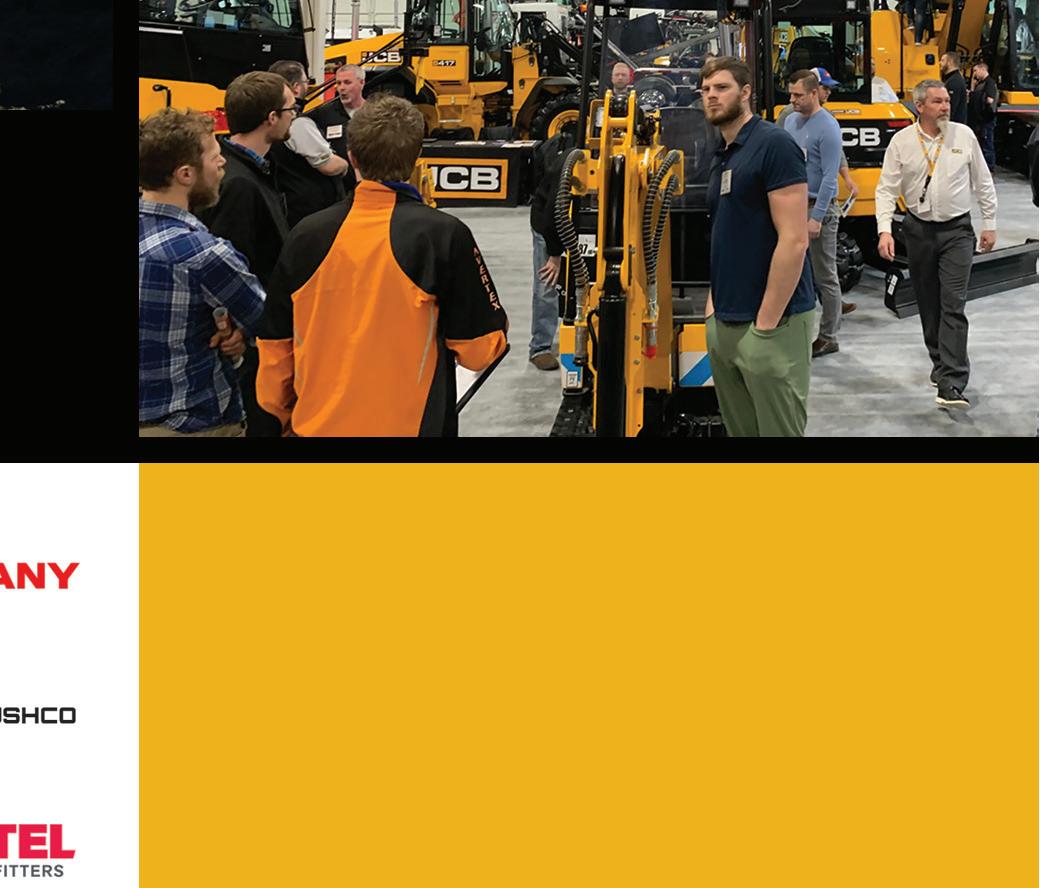

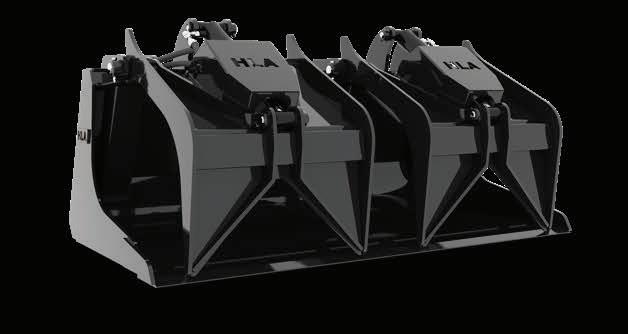

AMI Attachments recently invited icons of the construction industry to tour its headquarters and manufacturing facility in Hawkesville, Ontario.

The tour included 100-year-old Russel Cox, who founded Guelphbased Cox Construction in 1947, 94-year-old Bev Dekay, who founded London-based Dekay Construction 71 years ago, and 93-year-old Don Benson who worked in heavy equipment marketing in southern Ontario for about 50 years before retiring.

Together, the three industry veterans represent more than 200 years of experience in the construc-

tion and heavy equipment industry.

“It was just natural to make this happen. We're just really glad to have these gentlemen here,” said Bernie Howorth, Vice President of Market Development for AMI Attachments.

The idea for the tour was planted during the Toromont Cat Operator Challenge earlier this summer.

During the competition, Ho worth ran into Russel Cox and his son Regan as well as Bev Dekay’s son John.

from all my years in the business as a dealer and then as a manufactur er,” Howorth said. “So, I suggested

maybe it would be nice to have them come and tour our factory, which they were very open to.”

The Dekays suggested their mutual friend Don Benson also join the facility tour.

“I know Don quite well as a former competitor and as an icon of our industry, and we're glad to have him join us as well,” Howorth explained.

able to find that bucket and trade a new attachment to retrieve the piece of company history.

“It was bucket number one and it's up in the boardroom,” Howorth said.

Since building that first backhoe bucket, AMI has grown into an international provider of attachments for excavators, backhoes, wheel loaders and other heavy

ber worldwide to earn certification in both Hardox In My Body and My Inner Strenx programs.

“It must be very rewarding,” Russel Cox said, noting the tour was quite interesting.

While on site, the industry veterans were able to see the manufacturing process, from welding to painting, as well as see new developments in fabrication and

The Prinoth Panther XL is heading to the South Pole.

The Norwegian Polar Institute has selected Prinoth’s high-performance Panther XL tracked vehicles to support transport and logistics at the Troll Research Station in Antarctica.

Prinoth was awarded a US$17 million contract to supply 10 Panther XLs with a relevant spare parts and service package.

Built at Prinoth’s facility in Granby, Québec, the Panther XL combines expertise from across Prinoth’s divisions to

create a machine designed for the world’s harshest environments.

A product of internal collaboration, the Panther XL draws from both Prinoth’s snow grooming (Sterzing) and crawler carrier (Granby) business units, with additional innovations developed specifically for this model.

“Antarctica demands the very best technology,” said Klaus Tonhäuser, President of Prinoth. “By bringing together the strengths of our snow grooming and crawler carrier teams, and adding targeted innovations, we’ve built a vehicle that’s made to perform well in the toughest conditions and underlines our group-wide leading engineering capabilities and our focus on customer needs.”

The Panther XL is powered by an 800 hp Caterpillar C18 ACERT engine. The 20,000-kg machine features a 32,000-kg payload, 75-cm tack width, 50-cm ground clearance and 16 km per hour travel speed.

From Prinoth’s snow grooming division, the Panther XL features a large, intuitive and customizable touchscreen display adapted from snow groomers to meet the specific demands of Panther XL operations, heated windows and wipers designed to endure the most severe weather, a high-comfort air suspension seat, intuitive steering wheel and cruise control system, providing operators with exceptional comfort and con-

trol for long-haul missions.

From Prinoth’s crawler carrier expertise, the Panther XL benefits from Prinoth’s patented rubber track undercarriage, incorporating large wheels and automatic track tensioning for reliable performance in difficult terrain and an advanced powertrain integration, drawing on Prinoth’s experience with Caterpillar power pack systems.

As well, the Panther XL introduces innovations developed specifically for polar operations, including a full suspension cab design for superior ride quality and operator comfort.

Prinoth’s patented fourtrack drive dynamics for optimized traction and stability as well as a patent-pending operator assist drive function, are designed to support operators during long-distance hauls in extreme conditions.

The Troll Research Station is Norway's only all-year research station in Antarctica. The station is used to as a base and starting point for biological, glaciological and geological field work during the summer season, and year-round for long-term monitoring in meteorology, radiation, atmosphere, upper atmosphere, environmental toxins and seismology.

The Norwegian Polar Institute will use the Panther XLs to transport fuel, building materials, parts and tools for the station, as well as materials for research purposes.

Loved for the features. Trusted for the performance.

Do more without feeling like it in Hyundai’s NEW HX355ALCR compact radius excavator.

• RH and rear camera (standard)

• LED lights

• Dozer blade (option)

• Engineered to redefine efficiency, comfort, and safety

• AAVM 360° camera with ultrasonic system (option)

• Free Hi-MATE mobile telematics for 5 years

• 8” touchscreen color LCD monitor (standard) and 2nd monitor (optional)

JLG Industries newly rebranded ES1330M and ES1530M micro-sized electric scissor lifts are joining the ES1930M in North America.

The new ES1330M and ES1530M micro-sized scissor lifts provide purpose-built solutions for equipment users needing to work at height on construction, remodelling and facility maintenance projects in restricted access areas, such as data centres, hospitals, libraries, museums and commercial facilities. These models are also well-suited for fit-out and finish work like painting and installing HVAC, electrical, fire suppression, IT infrastructure and signage.

Key features include a zero turning radius that enables exceptional manoeuvrability in tight areas. As well, fixed rails fit through

standard doorways for easy access without compromising structural integrity.

A leak containment system is now standard to help protect delicate flooring by capturing potential hydraulic leaks with custom-fit trays.

Featuring a lightweight design, the micro scissor lifts can be used across weight-sensitive flooring and fit into freight elevators. This allows trades crews to operate multiple machines in one area at the same time.

JLG’s exclusive load-sensing system for zero-weight load calibration includes variable tilt functionality to maximize the machines’ work envelopes when working on slight slopes. The ClearSky Smart Fleet IoT (Internet of Things) platform enhances machine connectivity and diagnostics.

Equipment Sales & Service Limited (ESS) has expanded its Toronto service shop.

The expansion features state-of-the-art equipment to cater to the growing needs of the Greater Toronto Area (GTA) and the surrounding regions.

"The expansion of our Toronto service shop marks a significant step forward for ESS as we continue to enhance our infrastructure and capabilities,” said Morgan Cronin, President and CEO of ESS. “We are dedicated to upholding the highest standards of quality, and the expansion underscores our ongoing commitment to providing top-tier equipment sales and services."

The expanded service shop includes two 25-tonne overhead cranes, a tandem lift capacity of up to 50 tonnes and a maximum hook height of 7.6 metres.

As well, the service centre is equipped with 6-metre oversized doors and 30metre drive through bays and a heated, covered wash bay.

The shop now has the capacity to service 100-tonne

The ES1330M weighs 900 kg and features a platform height of 3.96 metres (indoor/outdoor) and a platform capacity of 227kg. The lift measures 76-cm wide and 143-cm long. The ES1330M has a 2 (indoor) and 1 (outdoor) occupant rating.

The ES1530M weighs 880 kg and features a 4.57-metre platform height indoors, a 3-metre platform height outdoors and a platform capacity of 227-kg. The lift

measures 76-cm wide and 143-cm long. The ES1530M has a 1 occupant rating for indoor or outdoor use.

Operators can customize their JLG micro-sized lifts with a growing suite of optional accessories, including a soon-to-be-released enclosed, four-rail integrated mid-rail deck, a hostile environment package, a multi-display indicator to quickly view the machine’s battery life and any diagnostic trouble codes (DTCs), SkySense enhanced detection system and lithium-ion batteries.

trucks, 125-tonne excavators and 300-tonne mobile cranes.

ESS has also equipped its shop with a 400-tonne track press with two undercarriage production lines. Servicing all makes and models, ESS has the capacity for D3 to D11/D475 track assemblies.

"Our expanded Toronto service shop is a testament to ESS's dedication to customer-centric service,” said Peter M. Willis, Executive Co-Chairman of ESS. “The enhancements in this facility further empower us to deliver comprehensive support and services to our customers, reinforcing our position as a trusted value-added partner."

Equipment Sales & Service was founded in 1946 and is now a third-generation family-owned business.

In addition to heavy equipment sales, ESS is one of Canada's largest national service providers, supporting all makes of machinery with factory-trained service technicians and the nation's largest inventory of OEM, wear parts, and aftermarket parts.

5-YEAR/5,000 HOUR Full Machine Warranty

5-YEAR/10,000 HOUR Machine Structure Warranty

Operating Weight: 18,900 lbs || Net HP: 54 hp || Max Dig Depth: 13’9” || Reach at Ground Level: 22’9”

• The 80 X3 Spin Ace is powered by a quiet, EPA-certified Final Tier 4 Isuzu engine that strikes the ultimate balance between power, productivity and fuel efficiency...without the need for a Diesel Particulate Filter (DPF).

• Comfortable and quiet pressurized cab - 8% larger than X2 series cabs, 6% more floor space and 8% stronger climate control system with 8 vents.

• Optimum visibility - sunroof with sunshade, additional mirrors, rearview camera, and wiper blade stores off front glass.

• Up to 18% more fuel efficient, up to 8% faster and up to 15% more lift capacity.

• Equipped with the most efficient hydraulic pump layout, keeping engine rpm’s low while producing plenty of hydraulic muscle and conserving fuel.

• RemoteCARE® lets you remotely monitor and track machine location, operational performance, working status and periodic maintenance requirements, providing 24/7 remote monitoring and security with zero subscription charges or fees.

Equipment Sales & Service Ltd.

Edmonton (780) 440-4010 essltd.com ALBERTA

Inland Truck & Equipment

Campbell River, BC 250-287-8878

Castlegar, BC 250-365-2807

Cranbrook, BC 250-426-6205

Fort St. John, BC 250-785-6105

Kamloops, BC 250-374-4406

Langley, BC 604-607-8555

Nanaimo, BC 250-758-5288

Penticton, BC 250-492-3939

Prince George, BC 250-562-8171

Quesnel, BC 250-992-7256

Terrace, BC 250-635-5122

Vernon, BC 250-545-4424

Williams Lake, BC 250-392-7101 inland-group.ca

Itec 2000

Rosslyn (888) 574-8530

Thunder Bay (888) 574-8530

Timmins (705) 267-0223 itec2000.com

McDowell B Equipment Ltd.

Sudbury (705) 566-8190

Barrie (416) 770-7706 bmcdowell.com

Stratton Equipment Sales & Service

Équipement JYL Inc.

Chicoutimi (418) 698-6656 equipementjyl.com

Stratton (807) 483-7777 strattonequipment.com Micanic St-Aug-D-Desm (418) 878-2241 micanic.com

Terapro Rental

Vars (613) 443-3300

Stittsville (613) 836-0654 terapro.ca

Top Lift Enterprises Inc.

Stoney Creek (905) 662-4137

Bolton (905) 857-5200 toplift.com

Paul Equipment (506) 826-3289 paulequipment.ca

Terapro Location Val d’Or (819) 825-4299 Plaisance (819) 718-0945 terapro.ca

Paul Equipment

Balmoral (506) 826-3289 paulequipment.ca

Inland Truck & Equipment

Whitehorse, YT 867-668-2127 inland-group.com

In the remote Aleutian Islands, Alpha Welding and Boat Repair have taken delivery of a 90-tonne Liebherr LRT 1090-2.1 rough terrain crane.

The crane will be used for multiple projects around the island including, construction, fishing vessel modification and repair, as well as lifting fishing gear and related equipment.

Due to the enhanced lift capacity and reach of the new crane, docked ships can be worked on without the need for turning them in both directions.

“This crane is by far the newest and most advanced piece of machinery to come to the island in decades,” said Ian Bagley, President of Alpha Welding and Boat Repair.

“It will be a tremendous asset to local businesses and building projects in the future.”

The Aleutian Islands are a chain of 14 main, and 55 smaller, islands off the coast of Alaska. Alpha Welding and Boat Repair was founded in 1990 as a small welding shop. The company has since grown into one of the largest locally owned fabrication shops in Western Alaska, supporting Dutch Harbour, the largest grossing fishing port by tonnage in the United States.

At Dutch Harbour, Alpha Welding and Boat Repair currently provide a variety of services including welding, fabricating, machining, commercial fishing boat modifications and boat and dock repair.

Galileo Wheel, the creator of CupWheel tire technology, has successfully achieved ISO 9001:2015 certification from the United Registrar of Systems (URS).

The certification validates the company's quality management system for the development of off-road tires.

Following extensive preparation and a rigorous audit process, Galileo Wheel successfully demonstrated compliance with international quality management standards. The ISO 9001:2015 certification covers the company's complete scope of off-road tire development.

"Achieving ISO 9001 certification represents a significant milestone in our journey to revolutionize tire technology," said Armin Schon, CEO of Galileo Wheel.

"This certification validates our systematic approach to quality management and demonstrates our commitment to delivering products that meet and exceed our customers' expectations. As we continue to expand our market presence and develop new tire solutions, this certification provides our customers with additional confidence in our capabilities and processes."

The ISO 9001:2015 standard is the world's most widely recognized quality management system standard, focusing on meeting customer requirements and enhancing customer satisfaction through effective application of quality systems.

The company's commitment to quality extends throughout its operations, from research and development to manu-

facturing partnerships and customer support.

All Galileo tires — including the IrriCup irrigation tire, SkidCup skid steer tire and Agricup tractor tire — feature the patented CupWheel technology with its unique concave sidewall design, combining track-like terrain performance with solid tire durability.

The IrriCup irrigation tire eliminates costly downtime from flats while reducing soil compaction compared to traditional pneumatic tires. The SkidCup for skid steers provides puncture-proof operation with improved shock absorption compared to solid tire alternatives. The Agricup tractor tire brings the same reliability and performance to farming operations.

Alpha Welding and Boat Repair selected the crane due to the Liebherr’s customer service support and the overall capabilities of the crane. This is increasingly important due to the remote area this crane will support.

The Liebherr LRT 10902.1 rough-terrain crane was designed with safety in mind. The crane is outfitted with an outrigger monitor, which automatically detects the support status and includes it in the crane control system.

The LRT is also equipped with VarioBase variable support base to enhance flexibility on the job site and increases the crane’s lifting capacity.

VarioBase enables work to be carried out safely in constricted areas. The maximum lifting capacities are calculated individually for every situation. This ensures safe working practice with any chosen support base.

The 47-metre telescopic boom on the rough terrain crane features time-tested rope pull technology. This telescoping technology enables the boom to be extended quickly to any length using a two-stage hydraulic cylinder with a rope extension mechanism.

The system is very easy to operate enabling the operator to set the ideal lifting capacities using two different telescoping paths, for either power or length.

New Holland Construction’s new W100D marks the next generation of the manufacturer’s compact wheel loaders.

The W100D includes a fully redesigned cab built for a variety of jobsites. Engineered for landscapers, agricultural or snow removal crews, the W100D combines reliable power with an intentional design to perform in a compact class size where there have been few options.

“The W100D is all about giving the operator a better experience, from the layout of the cab to the responsiveness of the controls,” said Dan Kakareka, Product Manager for New Holland Construction North America.

“We’ve built this wheel loader to perform in the real-world, where comfort, visibility and intuitive design make a difference day in and day out.”

New cab

To redesign the cab, New Holland focused on what matters most in real-world operating conditions — space, visibility, control and ease of use.

The cab features a roomier layout and improved sightlines via the redesigned front windshield, which provides

clear views to both the bucket edges and tire alignment for more precise operating.

Inside, operators will find enhanced comforts and advanced features that are typically reserved for larger machines, such as:

· Heated air-ride seat

· Bluetooth, FM and AM radio

· HVAC system

· High-visibility LED lighting

As well, a new in-cab LED monitor and standard rearview camera offer access to real-time machine data and elevated awareness on the jobsite, helping operators stay efficient and confident in their surroundings.

One of the new cab’s standout features is the seat-mounted joystick, part of a true pilot control system. The system moves in sync with the operator’s seat, delivering better control and stability, especially in environments where there is uneven ground. This added precision and comfort improves operator productivity and safety by contributing to fatigue reduction during long hours of operation.

The W100D compact wheel loader is powered by a Stage V certified FPT Industrial engine, delivering

performance with the added benefits of fuel-saving features like eco mode and auto idle.

Ride control and creep mode are standard, and high-flow hydraulics options are available for applications that require more specialized performance.

New Holland Construction designed the new compact wheel loaders with jobsite flexibility in mind, featuring a standard JRB-compatible coupler and an optional ISO-compatible coupler to accommodate a range of attachments.

Operators can choose between the standard 1.9-cubic-yard bucket or a high-capacity 2.2-cubicyard light material bucket for a wide variety of lifting, loading and scooping tasks.

Compatible attachments for the W100D include grapples, snow throwers, snow pushers and a full range of buckets.

Maintenance is also made simple on the machine with three wide-opening service panels that offer unobstructed access for efficient maintenance of the engine and other critical service components.

The compact wheel loader also includes a five-year telematics subscription.

jstewart@jgstewart.ca www.jgstewart.ca

Saskatchewan Premier Scott Moe has signed onto a memorandum of understanding (MOU) to build more pipelines, railways and other energy and trade infrastructure in Canada.

Moe joins Alberta Premier Danielle Smith and Ontario Premier Doug Ford in signing onto the MOU, which aims to introduce Ontario’s critical minerals and western Canada’s oil and gas to new markets.

“We are sending a clear signal that Canada’s energy future will be built by Canadians, for Canadians,” Moe said.

“This agreement commits our provinces to work together to unlock new markets, shore up our supply chains from mine to port and advocate for the federal reforms our industry needs. By advancing pipelines, rail connections and

critical-mineral processing capacity, we are safeguarding thousands of jobs, strengthening our energy security and fostering sustainable growth.”

The MOU calls for the construction of new pipelines using Ontario steel along a route that will connect western Canadian oil and gas to new and existing refineries in southern Ontario, as well as a new deep-sea port in James Bay.

The MOU also calls for new rail lines, also built using Ontario steel, to connect critical mineral deposits located in Ontario’s Ring of Fire region to ports in Western Canada.

“This agreement sends a clear message: Ontario, Alberta and Saskatchewan are ready to get shovels in the ground and move forward on projects that will secure our long-term prosperity,” Ford said.

As part of the agreement, the three provinces will advocate for a more competitive federal regulatory environment alongside an updated federal review process based on the “One Project, One Process” principle with deference to provincial processes.

“We’re taking action to grow our economy, build real infrastructure and get major projects moving,” Smith said. “Alberta is proud to lead the way in uniting with provinces that share a vision for responsible development, economic freedom and common sense. We’re standing up for our oil and gas sector and making sure our world-class resources reach the markets that need them.”

Kip Eideberg, AEM Senior Vice President of Government and Industry Relations, applauded the announcement that Saskatchewan has joined the MOU, noting it’s an opportunity for Canadian equipment manufacturers.

"Canada’s equipment manufacturers are committed to meeting the opportunity to build up the country’s economy headon, using Canadian-made equipment powered by Canadian labour,” Eideberg said. “New pipelines that connect western Canadian oil and gas to new and existing refineries in Ontario and a new deep-sea port in James Bay will help meet increasing demand for Canadian energy abroad –further cementing Canada’s status as a critical player in the global clean technology supply chain.

“We look forward to working with all levels of government to ensure these vital projects move from feasibility studies to reality, creating lasting benefits for Canadian workers, communities and the Canadian national economy."

“ People call a skid-steer a Bobcat. They invented the skid-steer, and in our opinion, they still build the best ”

Proud Ontario Farmers & Lifelong Bobcat® User

“Louise and Maurice Turcot, from L&M Beef Farms, just purchased their third Bobcat compact skid-steer. “We keep coming back for one reason: reliability and the service we get from our friends at McDowell B Equipment. People call a skid-steer a Bobcat. They invented the skid-steer, and in our opinion, they still build the best. We’ve had a Bobcat compact S175, an S570, and now an S64 skid-steer. Each one fits perfectly into our operation, being compact enough to fit through tight barn doors yet powerful enough to handle everything from cleaning out the barn to picking up large round hay bales and clearing snow from the driveway.

Maurice and I have been farming this land for over 50 years. We both grew up on local dairy farms, but after we got married, we transitioned to raising Limousin beef cattle. We strongly support supply management because Canadian milk is clean, with

BARRIE

Bobcat of Barrie

705-726-2228 oakenequipment.ca

GREY BRUCE

Bobcat of Grey Bruce 519-372-9100 bobcatoftc.com

PARRY SOUND

Bobcat of Parry Sound Ltd. 705-342-1717 bobcatofparrysound.com

TORONTO WEST

Bobcat of Toronto

416-679-4172 oakenequipment.ca

BRANTFORD

Bobcat of Brantford 519-752-7900 bobcatofbrantford.com

HAMILTON

Bobcat of Hamilton 905-643-3177 bobcatofhamilton.com

PETERBOROUGH

Bobcat of Peterborough 705-748-9119 bobcatofpeterborough.com

THUNDER BAY

Equipment World Inc. 807-623-9561 bobcat-tbay.com

no hormones, only vitamins. Our cattle are raised the same way: hormone-free. That’s why our beef, certified hormone-free, is trusted by Mennonite buyers and sold in Kitchener, Ontario. We sell about 35 to 40 each year.

We raise beef cattle and chickens, grow our own food, and feed our family right here on our farm. This isn’t just a hobby, it’s our way of life. We rely on our equipment every single day. Our Bobcat skidsteer can’t be down for more than two days. When we had an issue recently, service was available, and we were back up and running quickly. That’s why we stay loyal to McDowell B Equipment. Their service has been outstanding, including Matthew Allen, the parts manager, who has been there for us every time we need parts, and especially with Nick Morin, Bobcat sales specialist and our longtime friend, Brent Nixon, rental manager – surface equipment. We’ve followed Brent for over 30 years because we trust him.

What I love about the Bobcat compact skid-steers is how easy they are to operate, with no shifting like a tractor, and they turn on a dime. They even have a backup camera now, which makes them safer for the operator and our animals. I have luxuries I didn’t have before with my other machines. If I tried to maneuver the hay for them to feed in their pen with a tractor, I would have to back up and pivot at least six or seven times to get out. With this Bobcat S64

CASSELMAN

Bobcat of Ottawa Valley 613-764-2033 bobcatov.com

KITCHENER

Bobcat of Tri-Cities Ltd. 1-866-214-3939 bobcatoftc.com

STRATFORD

Bobcat of Stratford 519-393-6040 bobcatofstratford.ca

SAULT STE. MARIE

Bobcat of Sault Ste. Marie 705-949-7379 bobcat-ssm.com

CORNWALL

Bobcat of Ottawa Valley 613-932-2034 bobcatov.com

LONDON

Bobcat of London 519-455-4900 bobcatoflondon.ca

STRATTON Stratton Equipment 807-483-5505 strattonequipment.com

WINDSOR

Bobcat of Windsor 519-737-0120 oakenequipment.ca

compact skid-steer, I only have one backup, and away I go. With over 15,000 hours of experience across all five skid-steers we’ve owned, I can confidently say that Bobcat is the one we trust.

We’re a dying breed: farmers who live off the land, raise animals, and pass down our respect for nature to our grandchildren. During the COVID-19 pandemic, shelves were bare, serving as a poignant reminder of how fragile life can be. Climate change isn’t far off either; it’s been 41 degrees on my birthday for the past three years, and I’ve seen our cattle with sunburns for the first time in my life. That’s why the best thing we can do is teach our children how to live off the land. The world is changing fast, but we’re doing everything we can to hold on to what matters, and thanks to McDowell B Equipment, we can do it more efficiently and with a little less strain on our bodies.”

COURTICE

Bobcat of Durham East Ltd. 905-404-9990 bobcatofdurhameast.com

MUSKOKA

Bobcat of Muskoka 249-390-7000 oakenequipment.ca

SUDBURY

McDowell B Equipment Ltd. 705-566-8190 bmcdowell.com

WYOMING

Advantage Farm Equipment Ltd. 519-845-3346 advantage-equip.com

FRANKFORD

John’s Equipment 613-398-6522 johnsequipmentsales.com

OTTAWA

Bobcat of Ottawa Valley 613-831-5166 bobcatov.com

TORONTO EAST

Bobcat of Toronto 416-679-4171 oakenequipment.ca

David LaRocque began his career in forestry but quickly pivoted to building a successful contracting business serving northern Ontario’s mining industry.

After finishing school in 2000, LaRocque planned to work as a forestry technician in Ontario. Trained to operate excavators, dozers and other heavy equipment for logging, he soon realized the industry was stagnant at that time.

Encouraged by contacts in the mining sector, LaRocque applied his skills to

construction projects supporting mining operations in northeastern Ontario and northwestern Quebec. This led him to start Canadian Exploration Services Limited.

Over the past 25 years, the company has grown into a trusted partner for major metal mines, such as gold mines. LaRocque and his team improve mining roads, build new access routes and handle site preparation, road construction and civil works related to mining.

“We focus on servicing lar-

ger, senior mining companies that offer more stable, yearround construction work,” LaRocque explained. “This ensures consistent workloads and long-term partnerships, allowing us to upgrade our fleet with advanced equipment.”

In addition to heavy equipment contracting for mines, the company also undertakes general construction for nearby municipalities. Having a versatile fleet of construction equipment is in LaRocque’s favour and helps

keep his workers busy.

Moving forward

Rising competition and pressure on profitability in recent years keeps LaRocque on his toes. Additionally, regulatory challenges, including emission standards, require staying current on emerging technologies, equipment operation and maintenance.

As a small business owner, LaRocque wears many hats throughout the day. Each day begins with a toolbox

meeting to review health and safety reminders and make sure everyone understands their tasks.

“I try to visit every job site daily, whenever possible, to make sure everything is moving smoothly,” he said.

“I interact with our clients to make sure they’re happy because we try to make sure what we’re doing fits with what our clients want.”

He collaborates with his operations manager to respond promptly to quotes and pursue new business

opportunities to keep work moving.

“We get phone calls, emails and website inquiries, and we have to answer them all because somebody else will eat our lunch,” LaRocque said.

From time to time, David climbs into the seat of a machine and puts his operating skills to work.

“You have to be a jack of all trades, as I’m sure many small business owners are today,” he said.

Continued on Page A21

“My office is in my truck, though I do have a physical office that I get to see from time to time.”

Managing construction equipment

A mix of compact and heavy construction equipment keeps Canadian Exploration Services on task. With more than 25 pieces of equipment, ranging from compact machines to 30-tonne crawler excavators, the company is well suited to provide complete services supporting the mining industry.

One thing about working around the mines is there isn’t patience for downtime. LaRocque will tell you that if there’s a job to be done, it must be done today.

“The mines are at steady pressure, there’s no room for ‘oh, don’t worry about it, you’ll fix it tomorrow,’” LaRocque said. “We need to be moving.”

machine. Arriving prepared with the correct parts to fix an issue is critical.

“We rely on the technician repairing the machine the first time and minimizing the costs, and telematics makes that possible,” he said.

Beyond repairs, telematics helps improve job site efficiency. The fleet management system allows owners like LaRocque to identify operating trends and where the company can make improvements. For example, they can evaluate a machine’s fuel burn rates and determine whether an operator is excessively idling.

After-sales support is critical to the success of LaRocque’s company.

“Anybody can sell you a piece of equipment, and I’ve been down this road with some dealers I’ve dealt with in 25 years,” he said. “We’ve had very good success with being able to put in a call, a text or an email to our dealer, ReadyQuip, and they have responded.”

technologies, including 2D grading for precise earthmoving and grading work.

down in tight spaces.

Telematics plays a vital role in keeping the equipment fleet operational. It allows LaRocque and his dealer to remotely monitor equipment, diagnose issues early and determine when and how to respond when an issue arises. A service technician might travel two hours from the dealership to get to the

Embracing new tech ReadyQuip in Timmins, Ontario, supports Canadian Exploration Services and regularly shares the latest technology for the construction equipment industry. In 2023, the dealer presented the newest Develon excavator technology to LaRocque’s company: machine-assisted

“The machine-assisted technologies convinced us to order the DX225LC-7X,” LaRocque said. “If we’re doing municipal work or trenching at a mine, it’s nice to be able to set the exact depth. It’s really helping the newer operators that don’t have that skillset yet to finesse a machine.”

“When we’re working close to a highway or a house, it’s nice to be able to set up the virtual walls, both up and to the side, and let the machine do the work for you,” he said. “You pull back on the stick and it just does it.”

around the labourers, plus setting the machine limits for height and swing,” he said.

Larocque’s journey from forestry to mining support exemplifies the adaptability and innovation needed in a challenging industry. By embracing advanced technologies like machine-assisted excavators and leveraging telematics for efficient fleet management, Canadian Exploration Services has positioned itself as a reliable partner to the mining sector. Continued from Page A20

A virtual wall setting lets operators set invisible boundaries for the arm movement, including limits for how far it can extend or move up and

In addition to the productivity features, the machine’s safety features stand out, including the around view monitor (AVM) camera system and the ultrasonic sensors.

“The safety features are invaluable in terms of working

Operators using the DX225LC-7X have more control over what they’re lifting with the fine swing feature. When an operator is lifting a pipe and swinging it left or right, the fine swing feature minimizes the shaking of a lifted object that occurs at the end of the swing movement. LaRocque says the technology makes excavator work easier and more polished by providing greater control and accuracy in lifting applications.

“The DX225LC size is versatile to do the small work as well as the big tasks, plus it’s easy to move from jobsite to jobsite,” he said.

Caterpillar’s new heavyduty 980 GC wheel loader is designed to be an economical solution for a broad range of applications.

Equipped with a bucket capacity range of 4.3 to 5.8 cubic metres, the 980 GC includes an on-demand fan, load-sensing hydraulics and reduced fuel consumption.

“We’ve built the new 980 GC on a long legacy of high performance and highly reliable wheel loaders with proven components and integrated Cat machine systems,” said Frank Stadelmann, Caterpillar Global Product Application Specialist.

“The loader’s simple user interface, intuitive controls and excellent visibility make for comfortable and efficient operation, even with less experienced operators.”

Adding to the full line of Cat medium wheel loader options, the new 980 GC is powered by the Cat C13 engine.

The engine’s Cat clean emissions module works in the background without impacting production. The engine idle management system (EIMS), auto engine idle shutdown, variable speed fan and load sensing hydraulics combine to offer low fuel consumption and reduced sound levels on the machine.

“New features to this model, like our engine idle management system minimize idle rpm and fuel consumption to help deliver low owning and operating costs,” Stadelmann said.

Its field-proven automatic planetary powershift transmission is reliable and

prolongs service life, and four forward/reverse speeds reach a maximum 39.8 km per hour to quickly navigate the site.

The well-known Electronic Clutch Pressure Control (ECPC) shifting system provides smooth, efficient gear changes in all operating conditions. Available ride control improves operating smoothness over rough terrain while ensuring excellent material retention and increasing efficiency, and the optional limited slip differential axle increases traction in poor underfoot conditions.

Productive results

Easy-to-load Cat Performance Series buckets use a system-based approach to balance bucket shape with the machine’s lift and tilt capacity, weight and linkage. The

bucket design improves material retention and reduces dig time with build options that include general purpose, flat floor, heavy duty rock, coal and light material.

Field proven, the Cat Z-bar loader linkage with cast crossmember and tilt-lever provides strong digging efficiency and high breakout forces for superior production capabilities. Load-sensing hydraulics produce flow and pressure for the implement only when needed, improving machine productivity and resulting in low fuel consumption.

As well, the 980 GC can be equipped with the Cat Fusion quick coupler and controls, and combined with optional third-function hydraulics, the coupler allows use of a wide variety of work tools.

Cat VisionLink is standard for the new 980 GC. It allows fleet managers to track critical loader operating parameters like machine location, hours, fuel usage, diagnostic codes and idle time to improve productivity and lower operating costs. Available as an option, Cat Payload weighs material while moving to the truck and lifting for onthe-go weighing (not legal for trade), so the operator can load to exact specification, load more trucks and avoid overloading or underloading.

The Cat Payload for Trade option for Cat Advanced Payload allows you to integrate the scale data directly into your business processes. It is approved by the International Organization of Legal Metrology, while retaining all the features of the standard version of Cat Advanced Payload.

Pilot-operated hydraulic controls deliver low-effort, comfortable operation and include a remote transmission kick-down switch for operating comfort. For safety, ladders are standard on both machine sides, providing easy access to the cab from the lefthand side and to service points from the right-hand side. Extended windows with wide, flat and distortion-free front windshield combined with rearview mirrors with spot mirrors offer clear visibility to the jobsite.

A rearview camera is standard, and a windshield guard option is available. Air conditioning with louvred vents allows the operator to direct airflow for optimum cooling, while the comfort cloth mechanical suspension seat features adjustable armrests, headrest and multiple variations for superior comfort.

Providing a comfortable working environment throughout the shift, the 980 GC’s spacious cab design features intuitive controls and excellent visibility. The complete user interface is designed as an intuitive system, allowing the operator to monitor machine health.

The new loader features convenient service points, one-piece tilting hood with swing-out radiator and sight gauges for quick and efficient daily maintenance. Hard-to-reach pins have remote, conveniently grouped grease fittings for easy preventative lubrication.

ALBERTA

Liftboss JCB

Calgary: 403-301-0041 Edmonton: 780-474-9900 liftboss.ca

BRITISH COLUMBIA

Williams JCB

Surrey: 604-930-3316 williamsjcb.com

NEW BRUNSWICK

A.L.P.A. Equipment

Edmundston : 506-735-4144

Balmoral : 506-826-2717

Fredericton : 506-452-9818 Moncton, N.B. : 506-861-2572 alpaequipment.com

NOVA SCOTIA

A.L.P.A. Equipment

Truro : (902) 897-2717 alpaequipment.com

For 80 years, JCB has stood for more than machinery – we’ve stood for engineering excellence, relentless innovation and a commitment to reshaping what’s possible on every jobsite. To celebrate 80 years of challenging the status quo, we’re offering this amazing deal, because building better never stops, so neither should you.

Harvey JCB

Corner Brook: 709-639-2960

St. Johns: 709-738-8911 harveyco.ca

ONTARIO

Advance Construction Equipment (Division of Equipment Ontario)

Harriston: 519-510-5878 Waterloo: 519-742-5878 advanceequipment.net

D&W Group Inc.

Doughty & Williamson Jarvis: 519-587-2273

Brant Tractor Burford: 519-449-2500

Redtrac International Vineland: 905-562-4136 dwgroup.ca

ONTARIO

Delta JCB

Dunvegan: 613-527-1501 Renfrew: 613-432-4133 Winchester: 613-774-2273 deltapower.ca

Equipment Ontario

Alliston:705-320-0506 Lindsay: 705-324-6136 Port Perry: 905-982-1500 equipmentontario.com

Fulline JCB

Glencoe: 519-287-2840 fullinefarm.com

John’s Equipment Sales Frankford: 613-398-6522 johnsequipmentsales.com

Moore JCB Toronto, York & Peel Region: 416-747-1212 moorejcb.com

ONTARIO

North Rock JCB North Bay, Sault Ste. Marie, and Sudbury: 705-897-7369 northrockrentals.com

ReadyQuip Sales & Service Ltd. Timmins: 705-268-7600 readyquip.com

WPE Landscape Equipment - JCB Hamilton/Halton: 905-628-3055 wpeequipment.ca

PEI

A.L.P.A. Equipment (506) 861-2572 alpaequipment.com

QUEBEC

A.L.P.A. Equipment

Bas-Saint-Laurent : (506) 735-4144

Gaspésie : (506) 826-2717 alpaequipment.com

Bossé Quebec Inc.

Desmaures: 418-878-2241 Saint-Augustin-debosse-frere.com

Moore JCB

Montreal: 514-333-1212 moorejcb.com

SASKATCHEWAN & MANITOBA

Westcon JCB

Regina: 306-359-7273

Saskatoon: 306-934-3646

Winnipeg: 204-694-5364 westconequip.ca

•

The manufacturer’s new articulated tandem rollers feature a symmetrical cab and fingertip steering

Ammann has developed two new articulated tandem rollers that offer advanced machine control to improve safety and productivity on the jobsite.

The ARX 90-2 and ARX 110-2 articulated tandem rollers utilize the next generation of Human Machine Interface (HMI) that facilitates easy, efficient operation. One component of HMI is fingertip steering (FTS), which makes the rollers more operator friendly, comfortable and easy to control.

Fingertip steering replaces the roller’s traditional steering wheel and allows operators to keep both hands on the armrests for enhanced comfort and control. It also offers palm support that prevents fatigue and injuries from repetitive motions.

“Operators love the fingertip steering,” said Josef Dementev, Global Product Specialist Machines at Ammann. “Their workday is much less stressful, which makes them more productive and makes the jobsite safer, too.”

The operating width of the ARX 90-2 and ARX 110-2 is 1.7 metres. Both rollers are equipped with a two-stage vibratory system with a multiple range of frequencies that help operators precisely adjust compaction output. The ARX 90-2 / ARX110-2 have adjustable frequencies ranging from 37 to 54 Hz and are able deliver compaction output in the range of 47 to 120 kN per drum.

A high frequency (HF) version has an enhanced vibratory system that can reach additional frequencies for further compaction speed.

The machines are equipped with a 121-hp Perkins 904J diesel engine.

Solid Power DNA

The compactors follow the Ammann "Solid Power DNA" motto

and are designed to excel in Pro(D) uctivity, Ergo(N)omics, Service(A) bility. These efforts deliver a wide range of benefits such as operating weight, compaction width, a variable range of frequencies, compaction power and off-set mode (crab mode).

The machines are most productive when used in high volume asphalt applications such as highways, industrial developments, parking areas and airfields.

The ARX 90-2 and ARX 110-2 were designed without front and rear crossbeams. This modification improves visibility and safety.

“The lack of beams was key to creating the new symmetrical cab, which is among the key enhancements,” Dementev said.

Design changes also make the machines more compact while expanding sight lines to all drum surfaces and edges.

The symmetrical cab integrates four ROPS posts directly in the main structure and close to doors, rather than in the cab’s corners.

This provides operators with a 360-degree view of the entire machine. The ARX 90-2 and ARX110-2 operator stations extend beyond the 1-by-1 metre rule (in both directions) — another significant safety feature.

The spacious cab is quiet. It’s suspended and isolated from external heat and vibration to keep operators comfortable and focused.

Fuel and water tanks are also positioned to improve the machines’ appearance and access to components.

Intuitive operation

The innovative operator station has integrated, centralized controls that are easy to reach, regardless of the seat position. This approach re-

duces reaction times for increased safety.

The operator’s seat is fully adjustable, with a 270-degree rotation to optimize visibility.

A new 25-cm control display helps operators manage all machine functions simply, safely and quickly. This includes vibratory parameters, lights and ACE force –Ammann’s proprietary intelligent compaction system.

The display is installed on an adjustable support and moves with the seat for easy viewing.

ECOdrop philosophy

The machines only require a fuel top up once every two shifts thanks to a large 200-litre tank, and reduced fuel consumption that results from a well-balanced hydraulic system and EcoMode’s control of rpm.

The rollers also reflect a commitment to lower the total cost of ownership and machine maintenance. The focus of these efforts is to reduce the volume of fluids required and to make service points extremely accessible. This commitment — known as ECOdrop — makes all new products significantly more environmentally friendly.

As part of ECOdrop, the rollers utilize EcoMode, which enhances fuel economy and lowers fuel consumption by 8 per cent when compared with the previous generation.

Integrated alerts inform the operator when it’s time for machine maintenance. This helps organize scheduling service and parts availability to reduce downtime and lower ownership costs.

An advanced drum drive system reduces gearbox oil usage by 25 per cent when compared with the

previous generation of machines. Drum bearing oil bath fluid has been reduced by 7 per cent.

The articulated joint and hydraulic cylinders are completely maintenance-free.

Machine data is collected from all regions and is now reflected in innovative machine development as well as ECOdrop, which makes the machines mostly maintenance-free and more environmentally friendly.

Maintenance is faster and more convenient thanks to a highly accessible engine compartment with a robust design that protects all major components.

All rollers are equipped with an auto-diagnostics system that communicates with service technicians. External testing ports on hydraulic components enable quick diagnosis and reduce machine downtime.

A wide range of options can make the machines more productive, comfortable and serviceable. Off-set (crab mode) improves

machine versatility by increasing working width and permitting compaction close to curbs.

The machine is also available in a combi version, with four tires to increase usage.

The ARX 90-2 and ARX 110-2 can be equipped with an oscillation drum, which uses the back-andforth movement of the drum with a constant static load to achieve compaction goals in sensitive applications (such as cold joints, thin layers, etc.). When oscillation is not required, the ARX 90-2 and ARX 110-2 utilize a second drum with a heavy-duty, two-stage vibrator and easy adjustment of amplitude and frequency.

The ACEforce system makes it easier for operators to track compaction progress. This measuring system shows the actual kB value on the display and thus significantly reduces the time required to achieve the maximum compaction level.

Delivering minimal noise and zero operating emissions, Vögele’s new electric pavers are an ideal choice for urban road construction.

At bauma, Vögele introduced the Super 1300-5e, the company’s first fully electric compact paver.

Now, its little brothers, the battery-powered Mini 500e and the Mini 502e pavers join the family of machines with zero operating emissions.

Whether it’s environmental standards, noise abatement regulations or sustainability goals, the demand for carbon neutrality is a constant growing challenge for construction companies.

Electrified construction equipment is playing an in-

creasingly important role in the achievement of zero operating emissions in road construction.

To meet demand, Vögele has expanded its range in the e-power segment and rolling out the Super 1300-5e, Mini 500e and Mini 502e.

All three models feature a battery-electric drive concept and an electrically heated extending screed. As low-noise machines with zero operating emissions, they are ideal for paving in urban settings, enclosed spaces or in particularly sensitive areas.

Super 1300-5e

The Super 1300-5e is the first fully electric compact Class paver from Vögele, and simul-

taneously the first electric paver of the Dash 5 generation.

In combination with the AB 340 extending screed, it has a paving widths between 1.8 metres and 4.2 metres, making it the ideal choice for small and medium scale road construction projects.

The liquid-cooled lithium ion battery from Kreisel Electric has a storage capacity of 126 kWh and works with 400 V in the high-voltage range. Depending on the paving method, it provides sufficient power reserves for a full working day.

Performance meets tech

With its powerful battery, the Super 1300-5e achieves comparable drive power

and paving performance to its conventionally powered counterparts.

As a Dash 5 paver, it offers a higher level of operating comfort, automated functions and shorter set-up times than its Dash 3 predecessor. The new technologies include the ErgoPlus 5 operating concept, new assistance and automatic control systems, additional comfort features and a new lighting system.

Mini class pavers

Now available, Vögele’s Mini 500e and Mini 502e are available with a choice of two different battery options. The standard option has a storage capacity of 15 kWh and delivers sufficient power for a

full working day. For longer operating times, Vögele offers a 22 kWh battery option ideal for up to two days of paving without recharging.

Both battery options work with 48V in the low voltage range. In combination with the electrically heated AB 135 extending screed, the mini pavers offer pave widths from 25 cm to 1.8 metres, which enables construction companies to complete even the smallest paving jobs with a machine.

Both the electric mini class pavers and the Super 1300-5e can be charged quickly and easily.

The mini pavers can be connected to a household socket

or a wallbox. Depending on the battery version, the charging process takes about five to seven hours.

The easiest way to charge the Super 1300-5e is by using a wallbox or a charging station. With a charging capacity of 22 kW, charging takes about five hours, while the use of a rapid charging station can shorten the time required to about one hour.

As the compact pavers utilize the same battery and drive technologies as all other compact e-machines from the Wirtgen Group, the manufacturer delivers the added value of synergy effects resulting from common charging procedures, maintenance and spare and wear parts.

The ARX 10.1 offers advanced “side-free-drum” technology that allows you to compact close to obstacles like never before. The uniquely designed drum consoles provide unmatched precision, control, and performance.

You also will:

• Benefit from a safe design that lets you focus on productivity Save on fuel costs

• Reduce engine maintenance spending

In June, the Fayat Group announced it has signed an agreement with ST Engineering for the acquisition of LeeBoy.

This acquisition represents a key strategic move for Fayat Group as part of its goal to expand in the United States and Canada. LeeBoy, with its

decades-long reputation, will complement Fayat’s vision for growth and innovation in North America.

Based in Lincolnton, North Carolina, LeeBoy specializes in the design and manufacturing of road construction equipment. The company offers a range of products, including pavers, compact motor graders, road wideners and rollers. It’s North Carolina facility produces more than 35 models of LeeBoy and Rosco machines.

The company was founded in 1964 by B.R. Lee and became known for its self-propelled pavers. Lee retired in

2000 and sold a majority stake in his company to Crescent Capital. The Singapore-based ST Engineering acquired the company in 2006.

LeeBoy’s broad portfolio of roadbuilding equipment makes it a highly complementary addition to Fayat Group’s global network.

The acquisition will offer customers a broader range of solutions, combining the strengths of Fayat companies.

Fayat Group sees significant opportunities to collaborate in areas such as research and development, manufacturing, purchasing and sales, fostering

enhanced capabilities and innovative solutions.

In a news release, Fayat explained it respects the expertise of the LeeBoy team, and intends to keep the company operating autonomously, under the continued leadership of its current management.

The LeeBoy brand will be preserved, as it has earned customer trust over many years, and Fayat Group plans to maintain its identity. As well, the company said it plans to invest to support LeeBoy’s continued success.

When the acquisition is finalized, Fayat said LeeBoy customers can expect continuity in terms of products, service and support. As well, according to Fayat, customers may benefit from an expanded range of capabilities, enhanced support and innovations generated by the combined strengths Fayat and LeeBoy.

The transaction is subject to customary regulatory approvals, including HSR clearance, with closing anticipated by the

fourth quarter of 2025. Until the transaction closes, both Fayat Group and LeeBoy will continue to operate separately and independently.

Based in France, the Fayat Group operates in 170 countries and employs more than 23,000 people.

In the roadbuilding sector, Fayat Group is the parent company of Bomag, Dynapac and Secmair.

In 2024, Fayat Group acquired a controlling interest in the Indiana-based Asphalt Durm Mixers (ADM), which manufactures asphalt plants and components. The acquisition aimed to help Fayat Group expand its position in North America.

This year, Fayat Group acquired a 100 per cent stake in the Mecalac Group, which offers a wide range of compact and innovative construction equipment for urban worksites: excavators, loaders, dumpers and backhoe loaders. Also based in France, Mecalac operates production sites in France, Germany, the United Kingdom and Turkey.

The Fayat Group recently broke ground on its new 100,000-square-foot parts distribution centre in Fairfield County, South Carolina.

The $13.7 million investment will expand Fayat’s operations in Fairfield County for its road equipment division, which includes Bomag Americas, Dynapac North America, Charlatte North America, Asphalt Drum Mixers, Fayat Cleantech and the newly acquired Mecalac Group. The centre aims to improve after-sales support for customers throughout North America.

“I am proud to announce another strategic investment that will benefit the entire road division in multiple ways,” Fayat Group President JeanClaude Fayat said during the groundbreaking ceremony.

“Groundbreaking for this new Fayat distribution centre in Fairfield County is not just a new facility. It is a symbol of our strategic investment in North America, Fairfield County, our dealers and our customers. This expansion is more than a business decision. It’s a testament to our confidence in the future of North America and our deep appreciation for the hardworking communities here.”

Built adjacent to the com-

pany’s Bomag Americas North American headquarters, the project will also enable Fayat to increase localized production for its road machinery and enhance its training capabilities.

“Ten years ago, the Fayat Group made a strategic decision to invest in Fairfield County,” said Rob Mueckler, Fayat Road Equipment Division General Manager, North America.

“Ever since, we’ve experienced tremendous success, thanks in no small part to the outstanding local workforce. The skill, commitment and work ethic of the people have made a lasting impact on our business. Today, this workforce has become one of our greatest competitive advantages.”

The Fayat road equipment division provides machines for each step of the road’s life cycle, including soil preparation, asphalt production and paving, compaction, road maintenance, recycling and road cleaning.

The new Fayat parts distribution centre is scheduled to be operational in the fourth quarter of 2025. It is expected to bring 75 new jobs to the region, adding to the more than 120 employees at Fayat’s existing facility.

LiuGong is entering the North American motor grader market with the 4215D. Apex Equipment in Oklahoma recently hosted a launch event for the grader, welcoming government officials, contractors and industry leaders from the region to experience firsthand LiuGong’s entry into the market.

"This is a machine designed with the operator in mind. It's easy to run, fuel-efficient, and reliable," said Rick Mitchell, Principal of Apex Equipment. "But more than that, it represents what LiuGong is bringing to North America: serious equipment with serious value.”

Built for productivity and affordability, the 4215D is engineered with a Tier 5 Cummins engine and a smooth-shifting six-forward, three-reverse ZF powershift transmission. This combination delivers high torque with low fuel consumption, making it ideal for long workdays in variable terrain. Its limited-slip differential enhances traction in demanding conditions, while the comfortable operator station, equipped

with air conditioning and optional ROPS and FOPS protection, ensures safety and ease during extended operations.

“Public agencies across North America are under pressure to do more with less, and LiuGong is stepping in with equipment that’s reliable, cost-effective, and procurement ready,” said Paul Cranage, LiuGong Sourcewell Manager.

“The 4215D is a perfect example of how we’re bringing smart solutions to hardworking teams who keep our communities running.”

LiuGong’s North American team was also present throughout the event to support live demonstrations, answer technical questions and connect with customers face-to-face.

According to LiuGong, its brand has steadily gained momentum in North America.

"This isn’t just a product launch,” said Darry Stuart, LiuGong Senior Sales Application Manager. “It’s a statement: we’re here, we’re invested, and we’re ready to grow in partnership with dealers and customers who demand more from their machines.”

Every new product begins with an idea.

The story of the Vezos RoadMaster 2.5 began a few years ago, when someone insisted on striping a country road using a walk-behind line striper. Despite the Vezos sales team’s recommendation for a more stable, vehicle-mounted solution, he went ahead and purchased a ProStripe walk-behind unit and set out to complete the job.

A few days later, he called his sales manager — in a panic — asking for urgent assistance.

That moment sparked the creativity of the Vezos engineering team. They got to work, developing a new compact module with high-performance paint pumps, onto a

pickup truck. They integrated it with a custom arm bracket with electro-pneumatic paint actuators, and the result marked the beginning of the entry-level, truck-mounted line stripers.

Today, this concept has evolved into a compact, efficient solution designed for paving contractors, municipalities and road maintenance teams looking to take full control of their striping operations — in-house and on demand.

The RoadMaster 2.5 and 3.5 models are part of a FRAME A road marking series — a product line designed to mount directly onto any pickup truck or small flatbed. The entire system, including the arm bracket and rear beam, is se-

cured directly onto the vehicle bed — making it easy to store, transport and deploy to any job site.

This summer, AllTrade Equipment Corp. sold the first Vezos RoadMaster 2.5 in North America.

Miller Paving, a division of Colas Canada, was the first company to put the RoadMaster 2.5 to work in Canada. It painted its first lines in New Liskard in June.

When developing the RM 2.5, Vezos focused on ensuring users get maximum value from their investment.

Thanks to an in-cabin skipline controller and camera monitoring system, the entire striping process can be handled by a single operator — the vehicle’s driver. No crew

is required to complete line painting.

A large truck is also not required to operate the RoadMaster 2.5. The RM 2.5 module bolts onto any standard pickup truck using just six bolts, transforming it into a fully functional striping vehicle.

Paving companies and municipalities often struggle with scheduling external contractors for striping — especially for small touch-ups or temporary lines, and larger road marking companies may avoid these jobs due to the inconvenience.

With the RM 2.5, contractors gain a cost-effective, autonomous solution that lets them complete these jobs faster, easier and with lower overhead.

Why the right snow removal attachment makes all the difference for your skid steer

By Chris Storr, Key Account Executive for Blue Diamond Attachments

Winter weather months are drawing near, and those in the seasonal snow removal business are preparing for what is coming.

It’s a given that skid steer loaders can quickly transform into a powerhouse snow removal machine, but choosing the right attachment is paramount in getting the most out of your skid loader.

The right snow removal attachment can turn your skid steer loader into a winter workhorse. With so many available, choosing the best snow removal attachment for your specific needs requires careful consideration.

From blades, blowers, brooms, spreaders and pushers, each attachment serves a unique purpose. At Blue Diamond Attachments we recommend considering the following as you choose what’s best for your snow clearing needs.

Assess your environment and snow type

First and foremost, the environment in which the skid steer is used must be evaluated. For example, are you clearing tight residential driveways, wide commercial lots or long rural paths? Is the snowfall light and fluffy or dense and wet?

Below are some quick pointers in assessing the environment.

· Light snowfalls and small areas: A traditional snow blade, angle blade or broom might be enough.

· Heavy snow and wide-open spaces: A snow pusher or snow blower can handle high volumes more efficiently.

· Ice and hardpack: Consider a replaceable cutting edge or a high-capacity snow blower. Be sure when choosing a blade that you match it to the power level of your skid steer loader.

Hydraulic flow and loader specs

Not all skid steers are built the same. High-performance attachments like snow blowers and some angle plows require highflow hydraulics, while other attachments can be used on low or high-flow hydraulic units. Before you purchase a snow removal attachment, be sure to check:

· Hydraulic flow rating of your machine. Mismatched flow rates can lead to inefficient snow removal or damage to the skid steer loader or attachment.

· Rated operating capacity. Overloading your skid steer can lead to tipping, machine damage and increased possibility of on-site accidents. Matching the weight of the snow removal attachment to the skid steer's rated operating capacity is essential for preventing these issues.

· Attachment width relative to the loader’s wheelbase — too wide and it becomes

hard to control, too narrow and you lose efficiency. As a rule, all attachments should be wider than the track or tire path.

Time and efficiency

In snow removal applications, time is money. By design, these attachments are meant to sit idle for long periods of time during non-snow months and are ready to mobilize with little maintenance when snow starts falling. For the most part, they are also designed for easy transport from place to place. So, choosing the right attachment to get on to that next job faster makes your decision even more critical.

As you assess your needs, consider the following:

· For fast snow clearing: Snow pushers are highly efficient for large areas.

· For thorough clearing: Snow blowers, spreaders and brooms ensure walkways, driveways and parking lots are completely free of snow buildup.

· For versatility: V-plows or angle plows adjust to the snow conditions on the fly, providing you with the best of both worlds.

Operator visibility and safety

Snow removal often happens in late night or early morning lowlight, low-visibility conditions.

The right attachment should always:

· Provide clear sightlines from the cab.

· Be equipped with reflective markers or built-in lights as needed.

· Include trip-edge protection to prevent sudden stops if a curb or object is hit.

If you are ready to buy

Whether you're clearing driveways and parking lots or keeping backroads clear, choosing the right tool comes down to knowing your environment, understanding your machine and matching your job requirements to the capabilities of the attachment.

To be sure you’re choosing what’s best for your needs, have a conversation with your dealer.

A well-matched snow tool not only boosts productivity but extends the life of your skid steer, helping keep you and your operators safe and efficient all winter long.

Established in 1995 in Knoxville Tennessee, Blue Diamond Attachments manufactures attachments for construction, landscaping land clearing and agriculture. It’s family of snow removal equipment includes blowers, pushers, plows, brooms, blades and buckets for skid steer loaders and tractors.

To learn more about Blue Diamond Attachments snow removal attachments, visit bdasnow.com.

The Rid Plow from AMI Attachments allows roadway winter maintenance contractors to avoid leaving a snow windrow at the foot of driveways.

Last winter, video of the Rid Plow went viral on social media earning applause from homeowners for its ability to reduce their time spent shovelling snow.

“It's very popular in the metropolitan areas, particularly Toronto. We've got quite a few pending orders,” said Bernie Howorth, Vice President of Market Development for AMI Attachments.

Designed for residential snow clearing, the Rid Plow is a hydraulic blade extension that catches snow spillover, keeping driveways clean and elim -

inating the need for homeowners to shovel the windrow.