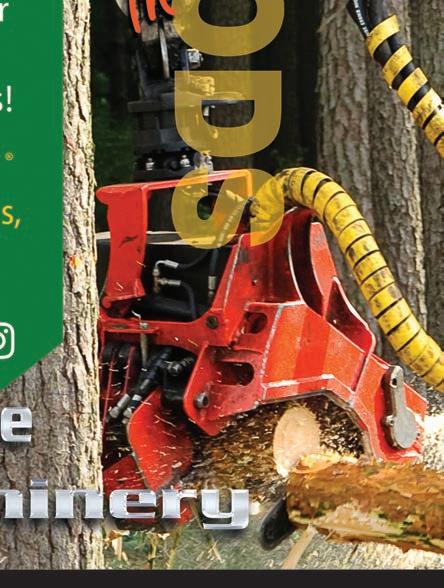

All Choice Rentals keeps equipment moving to help tackle wildfire in Jasper

Labour rights are a hallmark of western civilization.

Thanks to Canada’s labour movement, we have minimum wage requirements, overtime pay, parental leave and, most importantly, safety standards. Labour rights are a major component in the distinction between developed and undeveloped countries, and it's thanks to the people that fought for these rights that children are free to go to school rather than sew sneakers.

However, when these historic labour battles were fought, Canadians knew why they were fighting, which is seldom the case nowadays. The recent strike/lock-out at Canadian National (CN) and Canadian Pacific (CP) is a great example.

Canada’s railways move $1 billion in goods daily. After factoring in the spin-off of transporting those goods, a

rail stoppage is clearly devastating to our economy.

Worker safety was the prevailing concern mentioned publicly by the Teamsters union. Yet, Canada already has stringent laws in place to ensure safe places of work.

It’s ridiculous to think the Teamsters can gut punch Canada’s economy without really explaining their reason.

It’s equally ridiculous the federal government waited about 24 hours beyond the last minute to impose binding arbitration. Even though the strike was less than a day long, Labour Minister Steven MacKinnon said it would take days to get trains moving again, which equals billions of dollars in stalled goods.

The effect of the strike created concern for equipment manufacturers. In a letter to Canadian Parliament, AED President and CEO Brian P. McGuire outlined the impact

a railway work disruption will have on North American trade and commerce.

“A disruption in our North American railway system would have immediate effects on thousands of businesses across Canada,” McGuire said in the letter.

“All Canadian ports, logistics and warehouse operators and suppliers would be impacted.”

I think the solution to private sector labour unrest is simple. The federal government should legislate an “importance” threshold for unions, like the employees that fall under essential services at the provincial level. For unions representing workers with the power to severely impact national interests, any notice of strike action should force the public disclosure of all demands and negotiations.

Any future negotiations

should also be

I believe this approach would have both sides of the labour dispute working much harder towards finding a solution in private. Canadian workers deserve a career they can be proud of, but if you’re asking the country to sacrifice its wellbeing for your battle, we’re owed a detailed explanation of what you’re trying to achieve.

When it comes to quality and economy, Liebherr sets the standard. Our earthmoving solutions and technology redefine construction efficiency, ensuring projects are completed faster and budgets are optimized. www.liebherr.ca

Earthmoving Machines

• Get after your brush and trees up to 8” in diameter while the leaves are off

• In the comfort and protection of a Gradall, work the canopy clearing overhangs and increase your roadway sightlines

• With the the Promac LDM50’s robust flail design, throw debris chips down into the ditch vs scattered across the road

In its latest economic forecast, the American Rental Association (ARA) is predicting slightly softened revenue growth for the Canadian market.

The updated forecast for total Canadian equipment rental revenue shows a 6.6 per cent growth totalling $5.75 billion, compared to last quarter’s projection of 7.2 per cent growth, totalling $5.79 billion.

Broken down by segment, general tool and construction and industrial equipment (CIE) are both expected to see growth.

Construction and industrial equipment rental will grow to $4.67 billion in 2024, while general tool revenue this year is projected to expand by 6.8 per cent reaching $1.08 billion.

“What we’re seeing across our markets is pretty slow, but Stephenson’s is still growing. It’s a mixed bag. Residential activity represents 60 per cent to 65 per cent of those markets and that activity is down,” said Rob Wilson, Chief Operating Officer for Stephenson’s Rental Services in Mississauga, Ontario.

Wilson is optimistic the latter half of 2025 will be strong. The 2025 projection for Canada’s combined rental revenue is $6.14 billion, a 6.7 per cent year-over-year growth. Broken down by segment that equals $1.14 billion in general tool rental revenue and $5 billion in CIE rental revenue.

“I wouldn't characterize Canada's economy as robust, but CIE is one of the strongest investments in particular,” said Scott Hazelton, Managing Director at S&P Global. “We do expect the economy to get stronger as a whole by 2027."

Looking to the United States, the ARA also projects growth softening.

but there is uncertainty out there.”

The most current projections indicate an 8.9 per cent revenue increase in 2024 totalling $78.7 billion in construction and general tool rental revenue and a 5.3 per cent growth in 2025. This is a decrease from last quarter’s projection of a 9.7 per cent increase totalling $79.2 billion. Broken down by segment, CIE is projected to reach $62.3 billion and general tool rental revenue is expected to total $16.4 billion.

“While the rental industry and opportunities continue to expand, we are experiencing softer growth,” said Tom Doyle, ARA Vice President of Program Development. “The ARA quarterly survey results confirm this softening.”

What’s driving this forecast? S&P Global believes interest rates will not come down until December, despite the Chair of the Federal Reserve, Jerome Powell's, most recent testimony. Powell wants to see inflation staying under control before any moves are made.

Hazelton also believes when the cuts come, they will come slowly.

“The forecast for construction and industrial has not changed much since last quarter, perhaps a few tenths of basis points, but there has been more change to general tool,” Hazelton said.

“The market is still doing well but slowing. Next year’s GDP growth is lower than trend at 1.6 per cent growth, the trend is around 2.1 per cent.

The overall view of rental is positive moving forward,

2024 LINK-BELT 3240 PROCESSOR, Isuzu Final Tier 4 diesel engine-160 hp, 20’2” boom, 11’arm, 36’5”reach, Waratah H424 processing head, stk #B160-3240

CAT 725C, 730, 735B • VOLVO A25F, A30F, A35F - READY TO HAUL!

BAUMA LIGHT

CXC530 BRUSH CUTTER Fits 2-10 ton excavator, 3 blades, 30” cutting width, ACK#35-5000

2024 LINK-BELT 3740 LOG LOADER, Isuzu Final Tier 4 diesel engine-177 hp, 20’10”, 38’4” reach, 85,033 lbs operating weight, rear entry encl. cab, stk #B160-3740

2024 LINK-BELT 380 X4 , Isuzu Final Tier 4 diesel engine-268 hp, 29’7” boom, 22’1” arm, 50’5”reach, encl.cab w/hyd. cab riser, 20kw genset Baldor/Hubbell, stk #B160-3804

2018 CASE CX490D, Isuzu Tier 4 final engine, 12’9” stick, hyd Q/C & plumbing, A/C, rear & side

DENIS CIMAF DAH-100C MULCHER Mounted on LinkBelt 145 excavator, 42” cutting width, ACK#20-0003

CAT 966F WHEEL LOADER LOG GRAPPLE, Craig Manufacturer coupler, ACK# 25-0021

West Coast Machinery Inc. has announced it has acquired the Strathroy, Ontario-based Shear Power Corp.

As the parent company of ShearForce Equipment and Work Truck West, the acquisition strengthens West Coast Machinery's position in the equipment industry, expanding its reach and capabilities across Canada.

“The acquisition of Shear Power Corp. is exciting news,” said Brad Dewit, President of West Coast Machinery.

“This is a strategic move that marks a significant milestone in our journey to better serve our customers in the excavator attachment business across all of Canada. This

move also enables us to accelerate the growth of our Work Truck West brand nationwide.”

By combining the strengths of Shear Power Corp., ShearForce Equipment (its hydraulic attachment division) and its service truck division, Work Truck West, West Coast Machinery can offer a comprehensive range of equipment solutions to customers from coastto-coast.

“Our mission has always been to provide the highest quality products and services to meet our customers evolving needs. By joining forces with Shear Power Corp., we are taking a major step forward in fulfilling this mission,” Dewit said.

Shear Power specializes in hydraulic attachments to the metal recycling, demolition, construction, forestry and mining industries.

This year, Shear Power is celebrating its 10th anniversary. Since it was established in 2014, the company has grown to employ 11 people and now operates from a 930 square metre purpose-built facility.

“We are excited to be a part of WCM and look forward to growing together in the years ahead. I feel that we have always shared the same focus, to be the most trusted attachment and equipment supplier in the industry,” said Shear Power Manager Greg Morley. “By joining the WCM team, we have strengthened our ability to meet the strong expectations of our customers across Canada. The experience, and abilities held by both of our businesses is sure to create a team that our customers look forward to working with.”

Since its founding in 1973, West Coast Machinery has experienced rapid growth. The integration of Shear Power Corp. into West Coast Machinery will enhance the company's ability to meet the diverse equipment needs of its customers, providing a wider range of products and services.

Heavy equipment technicians will soon have the oppor tunity to show the world their skillset.

Caterpillar is hosting its first Global Dealer Technician Challenge to emphasize the essential role dealer technicians play in providing customer service.

The challenge, open to independent Cat dealers that choose to participate, is designed to showcase how skilled technicians are part of a high-tech, high-impact, high-demand career.

“This hands-on, skillsbased competition will test the technicians' agility, resilience and versatility," said Henry Venneman, Caterpillar Global Service Vice President.

"These trained experts are on the front line of support,

working to keep machines and engines up and running to help ensure our customers' critical projects are completed."

The Global Dealer Technician Challenge is also designed to help raise awareness of the opportunities in this career field.

Cat dealers globally are experiencing a growing opportunity for technicians. By the end of 2026, it is estimated that Cat dealers may need to hire more than 44,000 technicians.

"There are thousands of opportunities available globally for those who are interested in a hands-on career," Venneman said.

"Cat dealers are often looking for individuals who are problem solvers, mechanically inclined and tech savvy."

Loved for the features. Trusted for the performance.

Do more without feeling like it in Hyundai’s NEW HX355ALCR compact radius excavator.

• Engineered to redefine efficiency, comfort, and safety

• RH and rear camera (standard)

• AAVM 360° camera with ultrasonic system (option)

• LED lights

• Dozer blade (option)

• 8” touchscreen color LCD monitor (standard) and 2nd monitor (optional)

• Free Hi-MATE mobile telematics for 5 years

Bob Mark Equipment Sales & Rentals bobmark.ca

42 Center St Sunderland, ON LOC 1H0 705-357-3121

1138 County Rd. 41 Napanee, ON K7R 3L2 613-354-9244

551 Grand Road Campbellford, ON KOL 1L0 705-653-3700

2197 Little Britain Rd Lindsay ON K9V 455 705-324-2221

Hood Equipment Canada Inc. hoodequipmentcompany.net 14 Haniak Road Thunder Bay Ontario P7KOC8 888-413-5454

1355 Riverside Drive Timmins, Ontario P4R1A6 705-288-4685

RTI Equipment Solutions, Inc. 2528 Bowman St. Innisfil, Ontario L9S 0H9 705-734-3350

No wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, or na.hd-hyundaice.com.

Mecalac is introducing its 12MTX wheeled excavator loader to the North American market.

The 12MTX combines the capabilities of a compact excavator, loader and telehandler into a single machine that is capable of digging, loading and material handling. It is also a tool carrier that can handle attachments, such as asphalt planers and flail mowers, that require high-flow hydraulics.

“Anyone who subscribes to the philosophy of ‘do more with less’ or is simply forced to do more with less will appreciate the 12MTX,” said Peter Bigwood, General Manager for Mecalac North America.

“It’s a compact machine that can work in a tight envelope and do virtually anything you’d expect from the typical jobsite mainstays.”

The wheeled excavator loader is

equipped with a three-piece, variable angle, side-mounted boom. It can extend nearly straight in almost any direction or fold back on itself for compactness and higher lifting capability. Its compactness shines when working near structures or roads where a mono-boom excavator’s footprint is too large. Operators can enjoy an increased working envelope while limiting the need to reposition the machine. For example, when digging a trench, the 12MTX doesn’t need to move and can continue digging, even until the bucket is under the machine if necessary. When it’s time to switch to a different application, a selector switch allows operators to change modes between park, excavator, loader and travel.

The 12MTX’s 32 km per hour top speed allows the machine to quickly navigate jobsites and gives operators the option to

drive to a site without loading it onto a trailer.

Operators can take advantage of using the 12MTX for static loading thanks to the low position of the dipper stick cylinder. The machine can lift up to 4 tons and the engine is positioned in the rear, offering a removed counterweight for greater freedom of handling and movement with larger roads.

The 12MTX is a capable handler in all types of terrain. An articulated undercarriage, fourwheel drive and five different tire options keep the machine sufficiently grounded to ensure precision and control.

The machine features high-flow hydraulics with a 140 litre-per-minute maximum flow rate. Operators can equip the wheeled excavator loader with a range of attachments, such as a loader bucket, snow removal equipment, mowers, compactors and planers utilizing Mecalac’s Connect quick coupler system.

The 12MTX uses a flow rate memory function that allows users to save up to six different profiles to quickly switch tools without the need to input manual settings.

The 12MTX is designed with user experience in mind, ensuring a safe and comfortable operation. A step automatically unfolds allowing the operator to enter and exit the cab — eliminating the risk of slipping on a tire. Once inside, the cab delivers a spacious, ergonomic layout with great visibility and minimal blind spots.

The 12MTX provides ample visibility due to the boom’s position to the left of the cab so that even when dumping from its maximum height of 5 metres, the operator maintains an unobstructed view.

An optional heated pneumatic seat, heat and air conditioning offers improved comfort in cold climates.

Experience the force live in action of the CBI 6800CT Horizontal Grinder and the duality of the CBI 7544 Flail Debarker/Chipper combo. If maneuverability is what you’re after, take a tour of the CBI 5800BT Horizontal Grinder, a must-see for contractors with transportation restrictions.

HORIZONTAL GRINDER

Track-mounted mobile horizontal grinder with a CAT C-18, 765 HP engine, offering high versatility and portability tailored for contractors.

HORIZONTAL GRINDER

Market-leading mobile horizontal grinder with a CAT C-27, 1050 HP engine, and 40” rotor, built for high-volume throughput and maximum reliability.

FLAIL DEBARKER & DISC CHIPPER

This portable high-volume, high production debarker and whole tree chipper on a single chassis is designed for top-quality chip production.

To meet the needs of modern jobsites, Hitachi Construction Machinery has developed a new fleet management system: Solution Linkage (SL) Connect.

Providing access from phones, tablets or computers, SL Connect users can monitor machines on different worksites from any location.

“Mid to large-sized construction companies in North America manage a large number of equipment using multiple systems, facing challenges

of management workload and efficiency,” said Satoshi Inose, General Manager of DNA Development and Promotion Department, Hitachi Construction Machinery.

“Solution Linkage Connect aggregates machine operation data by entire fleet, project and worksite, enabling management and analysis through a dashboard. From executives to field personnel, necessary information can be efficiently accessed via smartphones and tablets. The system currently targets Hitachi Construction Machinery models, but in the future users that own machines from other companies will also be able to manage them with SL Connect.”

Using the latest technological open-source tools, SL Connect offers innovative, flexible solutions that were created with close attention to customer feedback. To meet customers’ needs, SL Connect allows users to:

With a quick glance, users can see their fleet’s operating status, operating hours and alerts on hundreds of Hitachi Construction Machinery machines. Fuel usage and carbon dioxide emissions can also be reviewed, enabling any company to track its environmental impact and meet its sustainability goals.

· View information from their Hitachi machines quickly from one place

· Monitor the utilization information from all their machines

· Geofence an area on the map to separate projects and specific worksites

· Graph and view operating information for each project and worksite

· View the information of machine alarms remotely, in real time

· Download a report detailing the operating and alarm information

When users create a geofence to group machines in a specific worksite, SL Connect automatically identifies and categorizes machines by operating status. Site managers are able to see how many machines are up and running, how much fuel they are consuming and the number of machines that are non-operational. This allows project managers to plan better and keep their projects on schedule. Managers will also be able to keep stakeholders and executives up to date by creating and downloading reports directly from the system. SL Connect is also integrated with Hitachi Construction Machinery's ConSite, Parts Catalogue and Owner’s Site. This allows for a seamless solution process when users receive an alert from SL Connect. They can access the ConSite ‘quick action’ instructions along with a parts list. Users with access to Hitachi Construction Machinery's Global e-Service can try SL Connect today. They can find it on their homepage and sign in with their Global e-Service credentials.

2,200

1,300

Spectra Precision has signed a definitive agreement to acquire Unicontrol.

The acquisition will marry Unicontrol’s 3D machine control technologies with Spectra Precision’s laser positioning product lines.

“We are excited to bring Unicontrol’s dynamic machine control systems into the Spectra Precision family of solutions, driving forward our mission to enhance the efficiency of our customers across a broad range of construction applications,” said Drew Ladau, President of Spectra Precision and CEO of Precisional LLC. "This strategic acquisition promises to deliver a wider range of advanced solutions

to customers, driving new standards in the construction industry.”

Unicontrol joins Spectra Precision in Precisional’s portfolio of construction-related measurement businesses along with Seco and Loadrite.

“The complementary strengths of our companies create an exciting foundation for innovative new products to support the growth of collective dealers and enhance the productivity of our end users,” said Steve Mokler, Vice President of Sales and Marketing at Spectra Precision. Since its creation in 2018, Unicontrol has expanded into 27 countries, enhancing machine operations with thousands of systems in use.

On its new site in the Hive Business Park in Tupelo, Mississippi, Liebherr plans to expand its logistics network for North and South Americ a with a state-ofthe-art spare parts logistics centre.

Liebherr has acquired 480,000 square metres of land for the project. The continental warehouse of Liebherr-Logistics GmbH will handle logistics and service operations, such as warehousing, distribution, value-added services, pre-assembly, kitting, repackaging as well as customs and export services. The establishment of the new logistics centre will create about 180 new jobs in the region.

With a staff of more than 430 employees, Liebherr-Logistics GmbH provides logistics services for the product segments earthmoving machinery, components, concrete technology, tower cranes and maritime cranes, serving more than 70 Liebherr sales and service companies worldwide with more than 20 different product lines. Since 2015, Lieb -

herr-Logistics GmbH has been supplying its markets from Oberopfingen in southern Germany. In 2023, a second distribution warehouse was opened in Born, the Netherlands, to be closer to customers in Northern and Western Europe.

In addition to the continental logistics centre, the Liebherr Group plans to establish additional facilities for various Liebherr companies and offer additional services on the acquired site in the future.

The Liebherr Group plans to invest more than $200 million for the development of the future campus. The planned buildings will be used to render services and produce innovative products, meeting the highest technological standards. This underscores the family-owned company's commitment to working on solutions for the future in the field of product development and building and strengthening long-term partnerships. In the long run, Liebherr plans to create more than 300 new jobs on the campus.

The acquisition represents an opportunity for Unicontrol to achieve its mission of becoming a global leader in machine control technology for the construction industry.

“We are excited to join forces with Spectra Precision, whose technological expertise and global infrastructure will enable us to expand our reach and accelerate our innovations,” said Niels Bjerregaard, CEO of Unicontrol. “This partnership not only supports our growth ambitions but also strengthens our ability to serve and

expand our customer base.”

The acquisition will not affect Unicontrol’s product line, distribution or dealers of the technology.

Spectra Precision designs and manufactures levelling, positioning and alignment instruments used for general, exterior and underground construction. The instruments incorporate laser and optical technology for general contractors and specialty contractors serving large and small commercial job sites as well as residential builders and remodellers.

By Justin Wharton, Cooper Equipment Rentals, Director of Operations - Canada West

Aerial construction equipment has always required a heavier dose of caution than equipment that keeps operators closer to the ground.

It also comes with its own unique risks — electric shock from power lines, weather events, falls from heights or even machine tip-overs. Thanks to technological advancements, more reporting and tighter rules and regulations, this equipment is now safer than ever.

Some of these changes have led to new challenges for contractors. But as the saying goes, “in every challenge lives a greater opportunity.”

Batteries may be heavier and equipment more complicated to operate, but it’s led to a big opportunity to improve safety on the jobsite. When you have an operator suspended 30 metres in the air on a 4,500 kg lift with a lot of horsepower, you want to be confident they’re following safety protocols because aerial accidents from those heights almost never end in injury … they end in death.

Do you have a rental partner supplying you with properly maintained, up-todate aerial equipment, as well as training and education on new safety regulations? It’s about thinking beyond just the equipment — you may be leaning more into rental because you don’t want to worry about costs, but it’s more than that. Staying ahead of the competition, keeping costs down and keeping workers safe is a big task, and you need the right partner to help get you there.

Following safety guidelines

No one wants to make that dreaded call after an accident. Ensuring all workers are properly trained to operate aerial lifts and have the right safety certifications and knowledge is key.

To start, requiring any individual working on or around aerial equipment to have the skills and training to proactively identify, evaluate and control potential hazards is a must. Safety programs need a continuous improvement mindset — this means creating a culture of safety in the workplace, retraining experienced employees and encouraging workers to share concerns. You could consider pairing new hires with mentors to hold them accountable and make sure they understand and internalize safety practices. This can go a long way in preventing incidents from occurring.

Your equipment partner should provide aerial training programs that consist of in-class courses and on-site evaluations to verify your operator’s ability to work on a specific lift. On successful completion of both parts of this program, the participant is certified to operate power elevated mobile aerial work platforms, booms and lifts.

Some Canadian provinces have a mandatory working at heights training program for workers on construction or industrial projects who use any fall protection systems. This helps workers understand the elimination of fall hazards and how to use and care for fall protection equipment and understand when and how it is required.

Tech can go a long way

With the latest advancements in aerial equipment design, both safety and equipment use has improved. Data extracted from the machine can provide information on how equipment is being used (or not) to its maximum efficiency. It’s not uncommon to see contractors using lifts that aren’t the right size for the job — either too large or too small. This can lead to unsafe working conditions.

Built-in technology combined with new ANSI regulations have also made aerial equipment safer. The latest lifts are equipped with equipment sensors to tap into insights around machine health and operator productivity.

Load-sensing hydraulics can measure weight in the platform and stop elevating if overloaded. Machine tilt sensing requirements allow equipment to operate on slight slopes — the tilt sensor sounds an alarm and disables boom and drive functions if the incline surpasses the machine’s rated slope tolerance. Apart from the safety benefits, this level of understanding can be a useful tool to help uncover gaps in operator knowledge and highlight when additional training may be needed.

Electric

Electric booms and telehandler machines are typically used in indoor or confined space applications where exposure to fumes can be harmful to operators.

1.99% APR for 48 months

2.99% APR for 60 months OR 6% Cash in lieu of financing

5,000 HOUR Full Machine Warranty 5-YEAR/ 10,000 HOUR Machine Structures Warranty

• up to 5% cycle time improvements to get your work done quicker.

• 17% increase in engine HP and 19% improved fuel economy

• X4S all new features such as Custom Flow Balance allowing the operator to prioritize hydraulic functions based on application, customizable joystick function buttons, 4 new work modes, Trimble-Ready components, all to increase efficiency and productivity.

• Additional options such as HD arms, WAVES +, reversible

Equipment Sales & Service Ltd.

Edmonton (780) 440-4010 essltd.com

Inland Truck & Equipment

Campbell River, BC 250-287-8878

Castlegar, BC 250-365-2807

Cranbrook, BC 250-426-6205

Fort St. John, BC 250-785-6105

Kamloops, BC 250-374-4406

Langley, BC 604-607-8555

Nanaimo, BC 250-758-5288

Penticton, BC 250-492-3939

Prince George, BC 250-562-8171

Quesnel, BC 250-992-7256

Terrace, BC 250-635-5122

Vernon, BC 250-545-4424

Williams Lake, BC 250-392-7101 inland-group.com

Itec 2000

Rosslyn (888) 574-8530

Thunder Bay (888) 574-8530

Timmins (705) 267-0223 itec2000.com

McDowell B Equipment Ltd.

Sudbury (705) 566-8190

Barrie (416) 770-7706 bmcdowell.com

Stratton Equipment Sales & Service

Stratton (807) 483-7777 strattonequipment.com

Terapro Rental

Vars (613) 443-3300

Stittsville (613) 836-0654 terapro.ca

Top Lift Enterprises Inc.

Stoney Creek (905) 662-4137

Bolton (905) 857-5200 toplift.com

engine fans, and Precision Grade on select models add to the perks of owning and operating a Link-Belt excavator.

• WAVES (Wide-Angle Visual Enhancement System) with 270° birds-eye view standard, therefore improving site.

• The spacious cab offers unprecedented ergonomics and comfort. A high-back seat with air, tilt, and heat features is standard. Adjustable pivoting armrests, headrests, seat height, and lumbar support provide operators comfort on long workdays.

Équipement JYL Inc.

Chicoutimi (418) 698-6656 equipementjyl.com

St-Aug-D-Desm (418) 878-2241 micanic.com

Paul Equipment (506) 826-3289 paulequipment.ca

Terapro Location Val d’Or (819) 825-4299 Plaisance (819) 825-4299 terapro.ca

Top Lift Enterprises Inc.

St-Laurent (514) 335-2953

Paul Equipment

Balmoral (506) 826-3289 paulequipment.ca

Inland Truck & Equipment

Whitehorse, YT 867-668-2127 inland-group.com

Sherbrooke (819) 612-5438 toplift.com

These new models can better support those operating in small indoor spaces and environmentally sensitive worksites where diesel exhaust is restricted.

Uncertainty around battery performance is not uncommon. But when customers are able to test drive electric equipment, they can experience the benefits (and potential challenges) for themselves. For example, electric or battery-powered aerial equipment is heavier than diesel counterparts, which can be a deterrent for some sites where equipment may be moved or relocated. But with the right level

of awareness, even the biggest skeptics can see they’ll have enough power to work through a full eight-hour day on one charge. Not to mention how electric equipment can support contractors for specific applications or when bidding on a new job that requires zero emissions.

There’s also the opportunity for substantial cost savings around fuel, depending on the length of the project.

A learning curve

As equipment evolves, so does the way we operate it. Lean on your equipment provider to help get through this learning curve. They can

provide access to a whole range of new equipment plus the technology to help you do your job better, safer and faster. Education and training are key — they help create safer jobsites people want to be a part of. Any injury or loss of human life is always unacceptable — not to mention the financial costs associated with an incident. It can be devastating to a business. Construction may be regulated by health and safety acts but the industry as a whole needs to lead by example and raise the bar on safety when it comes to the aerial equipment we use day in and day out.

Cutting drums are the core element of Wirtgen’s surface

At MinExpo 2024 this September, Wirtgen Group will include insights into its cutting technology solutions. The focal point will be a new cutting drum that enables the cost-efficient extraction of resources with uniaxial compressive strengths of more than 14,500 psi. The new cutting drum expands the range of applications for surface miners in hard rock and stone.

The drum is equipped with a HT14 toolholders and features a redesigned cutting geometry. The field-proven and established central-drum concept ensures optimum utilization of the machine weight, while the direct belt drive guarantees the transfer of high usable power to the cutting drum, also contributes to the ability of surface miners to profitably extract very hard rocks and minerals. With uniaxial compressive strengths of 14,500 psi, the drum is able to extract limestone, gypsum or anhydrite.

The new cutting drum cele-

brated its premiere in practice on a limestone quarry, carried out by a Surface Miner 280 SM(i) in Louisville, Nebraska. In addition to the extraction of hard limestone at the quarry, the elimination of the need for drilling and blasting made it possible to extract previously unexploitable limestone deposits and extend the working life of the quarry and all downstream production systems by several decades.

For the quarry operator, surface mining is a cost-effective extraction solution that also contributes to safeguarding jobs, increases safety in the quarry and enables responsible management of resources.

Wirtgen expanded its portfolio of products and applications with the cross-application miner 260 SX(i) two years ago. The cross application miner speeds up construction times by eliminating the need for drilling and blasting, with the construction of stable embankments, in-situ grading of railroad tracks and the recycling of the extracted material in-place for use in further construction.

As residents of Jasper, Alberta, were forced to evacuate the town due to wildfire, All Choice Rentals was tasked with heading towards the blaze.

In late July, more than 20,000 people were evacuated from the town, as the region’s largest wildfire in a century spread through Jasper National Park and quickly moved towards the town. Although the fire would burn more than 80,000 acres and consume about a third of the town’s structures, Firefighters were able to protect critical infrastructure, including the hospital, schools and emergency service buildings.

All Choice Rentals’ (ACR) Hinton branch, located about an hour north of the Town of Jasper, became an epicentre for supplying equipment to the various agencies battling the blaze, from the RCMP to firefighters to the Red Cross.

For the three weeks following the mobilization of the response, ACR staff were working around the clock, with fuel deliveries running 24 hours a day.

“The guys were kind of riding the adrenaline, and they love being able to actually help instead of just sitting from the sidelines,” said Owen Smith, Manager of ACR’s Hinton branch.

“All the guys at the shop have friends and family that live there, and we're always in Jasper, so just seeing it kind of in chaos and emptied out was hard.”

ACR was immediately tasked with supplying generators, fuel and fuel storage to power lights, water pumps and communications. Skid steers were also an immediate need for firefighters. Using a hose line attachment, the skid steers were used to run water lines closer to the blaze.

“They also have their own sprinkler systems that they need to move around with forks because they're just massive, massive systems. So, they use skid steers to move those around in the difficult terrain areas.”

As the first responders organized, ACR was tasked with supplying light towers, portable toilets and excavators, as well as the trucks and trailers needed to move the equipment and fuel. The company’s water and vac trucks were also deployed to transport potable water, while its all-terrain lifts were used to pre-emptively spray buildings for fire protection.

“It was a massive operation, and it was all kind of within the first 48 hours everything got deployed,” Smith said. “We had pretty much cleared out our Hinton location on power generation within the first 36 hours after Jasper was evacuated.”

Supplying the response required assistance from other rental locations within All Choice Rentals. To meet demand, ACR began supplying machines and labour from its locations in Drayton Valley, St. Albert, Athabasca, Rocky Mountain House and Slave Lake.

“Everyone has the right or the obligation to refuse unsafe work, but in times of crisis, it seems like everybody wanted to help and step up,” said ACR Vice President Blake Menning. “So, I couldn't be more proud and thankful to have such an amazing team.”

The ACR Hinton branch’s proximity to Jasper National Park has built a strong relationship with Parks Canada, and the company is on the approved vendor list for when rental equipment is required.

As equipment demand intensified during the wildfire, ACR was able to work with its industry partners to ensure the numerous agencies fighting the blaze had the necessary machines to tackle the job.

“We've built a strong network of rental partners that we deal with. If we didn't have it, we could rent it from other providers, and then bring it into the park on their behalf,” Menning said. “We try to be a one stop shop provider for everything in terms of equipment. To do that, you must surround yourself with a good network of industry partners.”

As the situation in Jasper intensified, companies began contacting ACR via phone, text and social media to offer their support.

“The outpouring was overwhelming and great to see. It's kind of like, at the end of the day we all work together.”

ACR was formed in 2009 when the Cat Rental store in Drayton Valley was purchased by an investors

group made up of current ACR employees and several local business owners.

Today, the company has grown to include nine locations throughout Alberta.

Unfortunately, the Jasper fire was not All Choice Rentals’ first experience supplying equipment to a natural disaster response.

Last year, the company’s hometown of Drayton Valley was evacuated for two weeks due to a threat from wildfires.

“We were dangerously close to losing our community due to wildfire. It came right up to our town limit,” Menning said.

Many of ACR’s staff

members stayed in Drayton Valley to ensure first responders had the equipment necessary to hold off the fire.

“One of our big philosophies with running our own business is if you support the community and support others, they'll support you,” Menning said.

In demolition, two significant factors determine success: safety and cost-saving solutions. Sennebogen engineering has continued to respond to the market's demands.

For the 830 R-HDD demolition machine, Sennebogen has introduced a new threepart long front boom and stick to extend reach.

The AB23 three-part system not only increases the distance from the site but also enhances the machine’s utilization. With the help of a fully hydraulic quick-change system, equipment can be picked up or put down at the push of a button quickly and safely and even switched to shorter handling equipment without the operator having to leave the cab. Further-

more, with the 23-metre reach, the 830 R-HDD can master new heights, increasing jobsite safety. It can work over projecting edges with its articulating boom.

Thanks to the removable counterweight, the Sennebogen 830 R-HDD can be transported on a lowboy trailer from site to site quickly and more cost-effectively in up to three sections.

A button on the remote control reduces the transport weight of the 830 by about 9,050 kg using a hydraulic ballast rack. Additionally, for transportation, the telescopic undercarriage can be reduced to 2.9 metres, while the three-part demolition arm is taken to the next site in a transport frame in a simple, cost-saving, and efficient manner.

As demolition work often takes place in urban areas characterized by confined spaces and limited working areas for machines, the addi-

tional reach on this platform has increased the flexibility of the jobs that can be undertaken while also enhancing safety.

The 830 R-HDD has proven itself to be an ideal machine for work in cramped, urban locations. Its environmentally friendly engine, compact dimensions, flexibility in operations and attachment selection capability make it the go-to machine for these demolition jobs.

In addition to the standard safety features already built into the unit, such as bulletproof windshields, skylights and rear-view and right-side camera systems, the machine has an exceptionally wide working mode stance of 4.5 metres, ensuring optimal stability and a vibration-free working environment, even when dismantling structures at maximum height.

The hydraulically elevating Maxcab tilts up to 30 degrees and allows operators

to maintain a comfortable working position while keeping a safe distance from the danger zone. The high-flow hydraulics enable a wide variety of attachments, including shears, grabs, hammers and pulverizers. These attachments can be quickly changed on-site, thanks to a fully hydraulic quick-coupler system.

The Canadian Equipment Dealers Association (CEDA) board of directors has ratified a membership vote in favour of merging with the Associated Equipment Distributors (AED). The merger is expected to be a seamless transition for CEDA and is scheduled to be finalized by November 1.

"We are pleased with the outcome of the vote and look forward to the future with AED," CEDA President and CEO Beverly J. Leavitt said, adding CEDA board members carefully evaluated various factors before selecting AED.

"AED offers the best benefits and resources for our members going forward. AED's history of providing first rate dealer education and advocacy on behalf of the equipment industry played a big role in our decision.”

Leavitt will take on the role of Vice President at AED and will be responsible for seeing a smooth integration of CEDA's over 160 members into AED. She will also work on member recruitment for AED in her new role.

"We are confident that CEDA members will see increased value with the merger of their organization into AED. CEDA has a long history of delivering outstanding service to its members and we look to build upon this strong foundation," said AED President and

CEO Brian P. McGuire. "The industry will be stronger as we unite as one organization."

CEDA members will gain access to the full range of AED resources and benefits including educational conferences and seminars, online courses, multiple industry reports and advocacy in Ottawa.

AED will carry on CEDA's representation at the provincial level in Ontario.

"CEDA has been a trusted resource for equipment dealers for over 78 years, helping them navigate the ever-changing challenges of running a dealership," said CEDA Chairman Brian Osterndorff. "As we look ahead, it's important for us to align with AED to continue providing the level of support our dealers expect. Our decision to enter into discussions with AED was based on the strong alignment of our values and the clear representation AED provides in Canada, making this partnership a natural choice.”

Osterndorff added the merger will ensure dealers have access to even stronger resources and support.

"We are excited to welcome CEDA members into the AED family and are eager to support them in navigating the challenges of running successful businesses," said AED Chairman John Shearer.

ASV’s new generation RT-65 Posi-Track loader is redesigned in every facet compared its predecessor and delivers numerous productivity, ease-of-use and performance benefits.

The midsize machine is ideal for contractors and owner-operators in the landscaping and construction markets.

ASV’s RT-65 is a brand-new radial-lift machine with new hydraulics, engine, controls,

wiring, pumps, hoses and frame. The improvements maximize power from the compact track loader’s 67.1hp Tier 4 Final Yanmar diesel engine and optional 101 litres per minute high flow hydraulics. A highly efficient hydraulic system and direct drive pumps transfer more flow and pressure directly to the attachment, resulting in a 900-kg rated operating capacity and 2,590-kg tipping load. Additionally, a highly efficient cooling system and optimized hydraulics allow the compact track loader to operate at 100 per cent load, 100 per cent of the time up to 48C.

“We’re committed to providing increasingly durable and high-performing equipment to our customers, and this new RT-65 is a significant addition,” said Peter Ovrebo, Product Management Director — North America for Yanmar Compact Equipment.

“Not only is the RT-65 now powered by Yanmar — it is redesigned from top to bottom, making it an entirely new model that promises to allow operators an easier and more productive time on the jobsite in virtually every way.”

The 3,350-kg compact track loader achieves maximum traction and mobility thanks to ASV’s Posi-Track rubber track undercarriage. It includes a suspension system made up of two independent torsion axles per undercarriage, allowing for a smooth ride over every type of terrain and speeds as fast as 14.6 km per hour.

The torsion axles allow the flexible track to maximize contact with the ground, increasing pushing power and lowering ground pressure as low as 4.2 psi. This optimal weight distribution means greater performance in steep, wet, muddy and slippery conditions. It also reduces risk of damage to sensitive turf.

The RT-65 is available with several optional technology features to improve jobsite performance and ease of use.

Auto 2-speed provides operators with improved control while grading, in tight spaces or other precise applications by creating a seamless transition between low- and high-speed modes. Similarly, speed-sensitive ride control improves material retention at higher speeds without the need to switch off the feature when moving to slower-moving applications. Self-levelling features further boost those efficiency-enhancing benefits.

The self-levelling technology automatically levels the load both while raising the machine’s arms and while lowering them.

Other new tech features improve jobsite productivity.

The RT-65’s work-tool positioner provides the ability to create a button preset for the angle of the attachment based on the application. Return-to-position technology complements that with the ability to set a preset for the height of the loader arms. The two features can be paired or used independently, depending on the task at hand.

Operator experience

ASV’s RT-65 is a MAX-Series model, providing all the premium comforts associated with that class. Operators can better see the attachment and their surroundings with 360-degree visibility. An 18-cm colour display improves convenience with access to vital monitoring tools, view from the backup camera and integration with service schedules and history.

The RT-65 also includes electronic controls, meaning fewer switches and a more ergonomic working space. This is complemented by an adjustable suspended seat, which improves comfort, especially when paired with the machine’s torsion axle suspension, a feature not found on most machines of this size class. As well, the RT-65 includes a roof escape hatch, a rare feature for a compact track loader.

ASV’s optional Yanmar SmartAssist telematics system includes features ranging from error detection and notification to real-time operational status updates and daily work reports. Owners also benefit from integrated theft protection, allowing users to set a range from a specific location and trigger an alert if the machine moves outside of that range. ASV builds the RT-65 to allow operators to spend more time working and less time maintaining their machine. ASV makes this possible with a swing-out radiator, top hood and side doors that provide access to all sides of the engine compartment, including filters and other daily checkpoints. Additionally, the machine’s cooler swings out with the door, allowing easy access for cleaning.

You can meet expectations. Or you can crush them. The JCB Telehandler is the ultimate material handling machine. So, while everyone else is getting the job done, you can get it done better. Learn more at JCB.com

ALBERTA

Liftboss JCB

Calgary: 403-301-0041 Edmonton: 780-474-9900 liftboss.ca

BRITISH COLUMBIA

Williams JCB

Surrey: 604-930-3316 williamsjcb.com

NEW BRUNSWICK

A.L.P.A. Equipment

Edmundston : 506-735-4144

Balmoral : 506-826-2717

Fredericton : 506-452-9818

Moncton, N.B. : 506-861-2572 alpaequipment.com

NOVA SCOTIA

A.L.P.A. Equipment

Truro : (902) 897-2717 alpaequipment.com

Harvey JCB

Corner Brook: 709-639-2960

St. Johns: 709-738-8911 harveyco.ca

ONTARIO

D&W Group Inc.

Doughty & Williamson Jarvis: 519-587-2273

Brant Tractor Burford: 519-449-2500

Redtrac International Vineland: 905-562-4136 dwgroup.ca

Delta JCB

Dunvegan: 613-527-1501

Renfrew: 613-432-4133 Winchester: 613-774-2273 deltapower.ca

ONTARIO

Fulline JCB

Glencoe: 519-287-2840 fullinefarm.com

Equipment Ontario Harriston: 519-510-5878

Lindsay: 705-324-6136

Port Perry: 905-982-1500 Waterloo: 519-742-5878 equipmentontario.com

John’s Equipment Sales Frankford: 613-398-6522 johnsequipmentsales.com

Moore JCB Toronto, York & Peel Region: 416-747-1212 moorejcb.com

ONTARIO

North Rock JCB

North Bay, Sault Ste. Marie, and Sudbury: 705-897-7369 northrockrentals.com

ReadyQuip Sales & Service Ltd. Timmins: 705-268-7600 readyquip.com

WPE Landscape

Equipment - JCB Hamilton/Halton: 905-628-3055 wpeequipment.ca

PEI

A.L.P.A. Equipment (506) 861-2572 alpaequipment.com

QUEBEC

A.L.P.A. Equipment

Bas-Saint-Laurent : (506) 735-4144

Gaspésie : (506) 826-2717 alpaequipment.com

Bossé Quebec Inc.

Desmaures: 418-878-2241 Saint-Augustin-debosse-frere.com

Moore JCB

Montreal: 514-333-1212 moorejcb.com

SASKATCHEWAN & MANITOBA

Westcon JCB

Regina: 306-359-7273

Saskatoon: 306-934-3646 Winnipeg: 204-694-5364 westconequip.ca

Case Construction Equipment is marking a new milestone in emissions-free heavy equipment with the commercial release of its 580EV, the industry’s first electric backhoe loader.

The 580EV electric backhoe loader carries over the same loading and digging specifications and delivers the same breakout forces as the four-wheel-drive, 97-hp 580SN diesel machine.

Case officially launched the backhoe during a virtual press conference in August.

“Today marks an important milestone, not just for our company as we push the industry forward, but also for the advancement of EV technology and sustainable construction everywhere,” said Terry Dolan, Vice President, North America, Case Construction Equipment.

“Innovation isn't just a buzz word, it's part of our DNA at Case. It's how we've operated for more than 180 years, and how we're leading the industry into the future.”

The 580EV electric backhoe expands its EV options for municipal crews, utility teams, urban construction and other contractors looking to utilize low noise, zero emissions machine.

The next generation of electric equipment offers crews a zero-emissions, low-noise solutions for a wide range of unique jobsite demands — from overnight construction, to work in urban centres or other close-quarter environments where noise and emissions must be kept to a minimum.

“Why EVs? For Case, it's all about unlocking more opportunities for our customers. And let me tell you, there are more opportunities than people realize,” Dolan said. “Think about it, a powerful electric

machine that produces zero emissions, minimal noise and requires no diesel fuel. It changes the game for where, when and how crews can get work done.”

An electrified workhorse

Case originally introduced the concept of an electric backhoe as Project Zeus at ConExpo in 2020. Since then, Case has been gathering input from contractors to help develop the 580EV.

“We listened to what our customers wanted to see in an electric backhoe and purpose built this machine to be an EV from Day 1. After unveiling project Zeus in 2020, we received a lot of customer feedback that influenced this final design,” said Brad Stemper, Product Management Lead, North America, Case.

With the new production unit, Case took customer feedback and optimized everything from thermal management to operator controls to electrify a machine with comparable specs to the widely used 580SN. Case also included new features, like a 20-cm colour display, air conditioning, a front-dash display and adjustable four-corner, multicoloured LED strobe lights.

“Instead of just simply retrofitting a diesel-powered machine, we considered everything that might impact energy efficiency,” Stemper said. “And throughout the validation process, we continue to refine systems across the unit to optimize efficiency without sacrificing anything for lift, anything for digging and any driving performance.”

Powered by a 400-volt, 71-kilowatt-hour lithium-ion battery platform that’s charged with the same type of Level 2 J1772 adapter found in automotive EVs, the new electric backhoe loader is designed

to deliver up to eight hours of operational run time on a single charge, depending on the application.

Battery performance

The battery platform also uses an advanced thermal management system with system-specific cooling circuits to better regulate temperatures and help maintain performance in hot or cold conditions.

A fully depleted battery can be charged to 100 per cent power in about seven and a half hours. As well, the 580EV’s battery can be charged from 20 per cent to 80 per cent in about four and a half hours.

Case estimates a full charge allows four to eight hours of true operation, depending on the application.

“A useful machine like a backhoe loader can do a lot of different tasks with a lot of different energy demands,” Stemper said. “As you know, backhoes are often used with other activities on a job site like plumbing and electrical work. So rarely are they used the entire day.”

He added that unlike a diesel backhoe that will likely sit idling, the 580EV doesn’t consume energy while it’s not operating.

“As a comparison, the duty load for our EV machine aligns with a typical day's workload for a diesel running in similar applications,” Stemper said.

The four-wheel-drive 580EV uses two independent electric motors for the PowerDrive transmission and hydraulic pumps feeding the loader, backhoe and steering systems to minimize energy consumption and improve performance in loading applications.

“We drew from the popular Case 580 Super N and used our energy efficient Case PowerDrive power-

shift transmission with hydraulic clutch and auto shift functionality,” Stemper said. “And we incorporated electrohydraulic loader and backhoe controls to help enhance operator control and further increase the machine's overall efficiency.”

The 4.3 metre backhoe also includes an Extendahoe to boost reach, while features like ProControl swing dampening, PowerLift/ PowerBoost and electrohydraulic controls improve precision and ease of use on the jobsite.

Electrification also provides performance advantages like instantaneous torque response and peak torque at any rpm, so operators don’t need to wait for an internal combustion engine to ramp up to meet load demands.

In the cab, Case takes the same operator-first approach as on other machines, with features like energy-efficient heating and air

conditioning, a 20-cm touchscreen display, customizable work mode or sensitivity settings, push-button start and operator security codes. Case’s EV backhoe loader will soon be followed by the commercial availability of two additional EV machines — the CX25EV 2.5 tonne mini excavator and the CL36EV 3.6 tonne compact wheel loader. The new equipment increases Case’s EV lineup to five models, including the previously launched CX15EV electric mini excavator and the SL22EV small articulated loader.

“All of these new machines represent a new benchmark in electrification and sustainable construction, bringing practical solutions to unique demands on the job site,” Stemper said. “Electrification isn't just an alternative way of doing the same work. EVs are new specialized tools that add to the toolbox for unique job site challenges.”

Vermeer has updated its RTX1250 ride-on tractor with several improvements to increase efficiency and performance.

The new enhancements include updates to the tracks, axles, plow valve and retention pins, cab roof and headliner, as well as the auto stabilizer feature for the rockwheel attachment.

The ride-on tractor is powered by a 127-hp Deutz TCD3.6L diesel engine and can be outfitted with a range of attachments for efficient installation of gas, fibre, water and electrical utilities.

Vermeer Product Manager Nick Olsen explained they have implemented a series of updates to the RTX1250 based on insights and recommendations from their customers in the field.

“These updates have been meticulously tested to deliver productivity in demanding environments,” Olsen said. “Vermeer is dedicated to consistently enhancing and refining their machinery to satisfy industry demands and customer needs. The latest version of the RTX1250 exemplifies this commitment.”

The tractor is equipped with several onboard technologies from Vermeer, including the TrenchSense electronic control system and the EcoIdle engine control system. These systems actively monitor the engine’s operations to promote smooth trenching, prevent stalls and optimize fuel efficiency.

The Productivity Zone feature and Auto Plunge technology of the RTX1250 enhance its performance by determining the optimal operating range and ground speed for the attachments in use by controlling the plunge rate for trencher or rockwheel attachments, respectively.

The RTX1250 is Vermeer Fleet ready, which means owners can optimize productivity by staying in sync with their machine’s operations. Vermeer Telematics allows for monitoring engine operating hours, idle hours, fuel usage, fault codes and the machine’s location. It also incorporates geofencing capabilities.

The ride-on tractor also prioritizes operator comfort and visibility. Its controls are located conveniently on the right-hand side, in line with the seat’s pivoting side.

The RTX1250 is able to operate as a trencher, rockwheel or vibratory plow with interchangeable attachments. These can be switched out in as little as an hour, offering options such as a backhoe, backfill blade or reel carrier attachment for the front of the machine and a vibratory plow, rockwheel, sliding offset rockwheel, sliding offset trencher or a trencher for the back end.

The RTX1250 provides a quiet ride and features an isolated, cushioned operator’s platform. An optional climate-controlled cab is available for year-round operation.

Depending on job requirements, the ride-on tractor can be outfitted with rubber tires or tracks.

O’Song Custom Home Builders was established in 2017 when Brook Song, had a vision to become a leading expert in interior and exterior renovations and construction providing customers with the highest quality of materials and workmanship, in the Greater Ottawa area. Their current project is installing over 40 homes with walnut Smart Wood WPC fencing, with a lifetime guarantee and zero maintenance, in a new subdivision in Ottawa.

Ling Cheng, who had been a previous client, explained that “Brook was extremely generous. He doesn’t just renovate; he teaches you as well. He is very honest and is full of integrity, and that’s why I didn’t hesitate to work for him when he offered me a position at O’Song”.

When Brook Song was asked why he chose the Bobcat® MT 100 mini track loader, his response was, “Bobcat is the brand well-known and trusted for loaders. I did compare them to other brands at the beginning but there was no comparison for us. Bobcat has good resale value and is very reliable. Not to mention the service I receive from Bobcat of Ottawa Valley has been top-notch. I

needed something repaired on the machine, service came right away and fixed it for me, so I had no downtime. Service is most important. I went into the showroom at the new Bobcat of Ottawa Carp location looking for a used machine but decided to buy a brand new high-quality machine as Bobcat is always advancing in the innovation of their machines. The Bobcat MT100 mini track loader is an excellent machine. I just hopped on, and I was good to go. It wasn’t hard to learn at all. This machine is so multifunctional, there are many Bobcat attachments you can get for this machine. We have an auger, breaker, forks and bucket. They make your job handsfree. No more hand calluses or backaches! Next, we want a trencher. That’s another great thing with Bobcat of Ottawa Valley, I can always rent any attachment from them as well.”

“Zack Wiggins, although newer to Bobcat of Ottawa Valley, is a professional. I told him he will be the best. I would not hesitate to recommend Zack and the team at Bobcat of Ottawa Valley for your next machine purchase”.

Thank you, Brook.

BARRIE

Bobcat of Barrie

705-726-2228

oakenequipment.ca

GREY BRUCE

Bobcat of Grey Bruce 519-372-9100 bobcatoftc.com

PARRY SOUND

Bobcat of Parry Sound Ltd. 705-342-1717 bobcatofparrysound.com

TORONTO WEST

Bobcat of Toronto 416-679-4172

oakenequipment.ca

BRANTFORD

Bobcat of Brantford 519-752-7900 bobcatofbrantford.com

HAMILTON

Bobcat of Hamilton 905-643-3177 bobcatofhamilton.com

PETERBOROUGH

Bobcat of Peterborough 705-748-9119 bobcatofpeterborough.com

THUNDER BAY Equipment World Inc. 807-623-9561 bobcat-tbay.com

CASSELMAN

Bobcat of Ottawa Valley 613-764-2033 bobcatov.com

KITCHENER

Bobcat of Tri-Cities Ltd. 1-866-214-3939 bobcatoftc.com

STRATFORD

Bobcat of Stratford 519-393-6040 bobcatofstratford.ca

SAULT STE. MARIE

Bobcat of Sault Ste. Marie 705-949-7379 bobcat-ssm.com

CORNWALL

Bobcat of Ottawa Valley

613-932-2034 bobcatov.com

LONDON

Bobcat of London 519-455-4900 bobcatoflondon.ca

STRATTON

Stratton Equipment 807-483-5505

strattonequipment.com

WINDSOR

Bobcat of Windsor 519-737-0120 oakenequipment.ca

COURTICE

Bobcat of Durham East Ltd. 905-404-9990 bobcatofdurhameast.com

MUSKOKA

Bobcat of Muskoka 249-390-7000 oakenequipment.ca

SUDBURY

McDowell B Equipment Ltd. 705-566-8190 bmcdowell.com

WYOMING

Advantage Farm Equipment Ltd. 519-845-3346 advantage-equip.com

FRANKFORD

John’s Equipment 613-398-6522 johnsequipmentsales.com

OTTAWA

Bobcat of Ottawa Valley 613-831-5166

bobcatov.com

TORONTO EAST

Bobcat of Toronto 416-679-4171 oakenequipment.ca

After the successful launch of its RW 500 wheel saw, Simex has gone further by offering a new model for compact track loaders with fully hydraulic technical features and increased depths to meet the various request of the underground utilities sector.

The new RW 700 is able to reach a depth of 70 cm, while mounting wheels with interchangeable sectors cut widths from 80 mm to 120 mm.

An interesting feature of the RWA 700 model is the lateral tilt,

which is hydraulically operated from the cab. This feature allows the cutting wheel to always be kept vertical, even when the operating machine is not parallel to the road surface, such as when working on sidewalks.

The hydraulic system allows the equipment to be tilted by 6 degrees in either direction to compensate for any grade differences in height on the jobsite.

The segmented wheel allows rapid adjustment of the excavation width while maintaining the same

base wheel. The RWA 700 features 80 mm, 100 mm and 120 mm expansion sectors, depending on the customer's excavation needs, which can be easily replaced, without downtime and without having to dismantle the entire cutting disc. The working depth is adjustable from a minimum of 40 cm up to a maximum of 70 cm.

The special design of the outlets allows a trench to be cleared efficiently at the set-depth, without the use of a scraper, thanks the light weight of the attachment. The

excavated material is discharged on both right and left sides, but it can also be conveyed to one side only by closing one of the outlets, a useful feature when trenching at roadsides or against walls.

Unlike conventional excavations, mini-trenching is quickly executed generating less waste material and considerably lower restoration times and costs. In addition, the possibility of using smaller machines limits the size of road construction sites to the benefit of traffic, especially in urban areas.

The new RWA 700 wheel saw combines the performance and productivity of wheel cutters for in-line excavation, with the precision of small-section cuts for fibre laying, delivering a versatile and complete product into the hands of utilities specialists.

Simex offers more than 18 models of wheel saws specifically designed for reduced set-section trenches.

The attachments are included into three product ranges: RW and T for compact loaders and RWE for excavator boom mounting.

•

•

•

•

McElroy has opened a new museum to commemorate its 70-year history as a designer and manufacturer of pipe fusion equipment.

This summer, the McElroy Museum opened at the company’s new, 18,000 square metre campus in Tulsa, Oklahoma, the museum outlines the McElroy journey from its founding in 1954 to its latest cutting-edge products.

The museum is made up of a series of vignettes, each one showcasing a milestone in McElroy’s history. This includes the first products designed by founder Art McElroy, the company’s foray into fintube and butt fusion equipment, and the evolution of its digital and equipment offerings.

Other vignettes show different marketing collateral and promotional items from decades past, such as vintage shirts and hats.

“What you see here is a testament to the legacy of McElroy’s commitment to quality and the relationships we’ve cultivated throughout our history,” said McElroy President and CEO Chip McElroy. “We can’t wait to share this experience with our channel partners, customers and others who visit this campus.”

A walkway guides visitors through the exhibits, beginning with McElroy ’s founding in 1954 and culminating with the advent of the TracStar and machines for the polypropylene market. In the middle of the space, a nook with seat-

ing showcases some of the different educational and promotional videos produced by the company over the years.

McElroy’s in-house creative team handled all aspects of the museum’s design and execution, from the layout and flow of exhibits to choosing which elements to incorporate. The museum’s design allows exhibits to be rotated or updated as needed, giving guests a unique experience each time they visit.

In addition to curating the wide array of historical photos, documents and items from the company’s history, the creative team also was tasked with creating an archival system that will ensure safe storage for each exhibit both on and off-display.

“It’s been an enormous undertaking, but our team rose to the challenge and cre-

Work truck manufacturer Curry Supply has launched a new utility truck and trailer product line.

The strategic expansion into the utility vehicle market is made possible through key partnerships with several industry manufacturers including Dur-A-Lift, Stellar

Industries, Posi+, Axion and Dakota Bodies.

"Curry Supply is proud to partner with some of the most respected names in the industry to bring this new product line to market," said Jeff Shaw, Vice President of Business Operations at Curry Supply. "We believe that

these partnerships will enable us to offer our customers the best-in-class utility trucks and trailers that will enhance their productivity and safety on the job."

The new utility truck and trailer product line aims to provide high-quality, reliable and versatile vehicles to meet the diverse needs of utility, construction and service industries. With these strategic partnerships, Curry Supply has curated a comprehensive selection of trucks and trailers that can be customized to fit specific requirements.

With products ranging from insulated and non-insulated aerial lifts to crane service trucks, digger derricks and utility trailers, the

new line offers solutions for a variety of tasks, from electrical work to heavy lifting, as well as sign and signal maintenance to roadside repairs.

The trucks and trailers are designed to withstand the most demanding job sites and weather conditions with safety as the top priority.

As well, each product can be tailored to suit specific industry needs, offering a wide range of configurations, body styles and equipment options.

A family-owned company since 1932, Curry Supply is one of largest manufacturers of commercial service vehicles in the United States, with locations in Pennsylvania, Texas and Arizona.

ated something that we’re all proud of,” said Creative Services Manager Corey George.

“We’re excited to see others get to experience the museum now that it’s complete.”

Mississauga, Ontariobased Unirope has implemented Scope Computer Vision Technologies utility stringing technology for inspection of pilot and pulling lines.

In the utility sector, wire stringing includes all activities associated with the installation of the primary conductors onto the transmission line structures.

Central to operations is stringing the pilot line to install the conductor. A lightweight fibre rope is flown from tower-to-tower by helicopter, threading the line through rollers.

Unirope provides and inspects these pilot lines.

Better known as stringing lines, pilot lines can be anywhere in the range of 1,500 metres to 9,200 metres long.

Scope's technology is an AI-powered solution that augments the human in the loop, providing real-time insights and enhancing the inspectors' ability to detect potential issues quickly and accurately. This advancement ensures safer operations by identifying potential hazards on the line before they become critical.

“Our partnership with Scope has allowed us to enhance our inspection processes significantly for our utility, electric utility contractor, and manufacturer customer base. The integration of their technology into our operations has not only improved safety but also increased the efficiency of our inspections,” said Unirope President Justin Brown.

“It’s incredible that Scope has inspected over 60 mil -

lion feet of rope to date. We are proud to lead the way in adopting innovative solutions that set new benchmarks in the industry.”

There are four major elements to the system: primary and repair scans; the inspection unit; and a tablet.

Rope is spooled in through the Scope device while sensors detect damage and output a projected break strength per segment, and an online inspection report is generated.

The machine identifies areas of concern and a technician, trained in the inspection and repair of fibre ropes, can decide on remediation. The system is able to scan wire at 8 km per hour.

“This is much faster than the human eye can perceive during an inspection. At minimum, it is 400 per cent faster, but it’s the accuracy that is most impressive. When a human is looking at a rope, they are not getting a 360-degree view,” Brown said. “At best, they can only see the side they are looking at or approximately 33 per cent. A single person inspecting a line can very easily miss damaged sections. Also, that person cannot reliably predict with any certainty the overall condition of the rope.”

The successful implementation of Scope's utility stringing inspection technology at Unirope underscores the importance of embracing advanced technologies to improve safety and efficiency in critical operations.

“Our technology leverages AI to enhance human

capabilities, providing a more thorough and reliable inspection process. This collaboration is a testament to Scope’s commitment to innovation and safety, most notably in the utility sector,” said Scope President Mike Poroo.

The machine is trained to specific products and covers an estimated 85 per cent of all stringing lines in service in Canada and the United States.

Maintenance & Inspection Programs

Customer Experience Specialists

Repair Parts & Kits

Free Factory Training

Online Learning Hub

Optimization Consulting

Prince Edward Island

Strongco

Prince Edward Island (902) 468-5010

www.strongco.com

Nova Scotia

Strongco

Dartmouth, NS (902) 468-5010

www.strongco.com

New Brunswick

Strongco

Moncton, NB (506) 857-8425

www.strongco.com

Newfoundland and Labrador

Strongco

Mount Pearl, NL (709) 747-4026

www.strongco.com

Quebec

Strongco

Baie-Comeau, QC 1-866-996-3091

Chicoutimi, QC 1-800-323-1724

St-Augustin, QC 1-800-463-2662

Trois-Rivieres, QC 1-855-840-0828

Val d’Or, QC 1-800-561-4192 www.strongco.com

Top Lift Enterprises, Inc.

St-Laurent, QC (514) 335-2953

Sherbrooke, QC (819) 612-5438 www.toplift.com

Saskatchewan

Redhead Equipment

Estevan, SK (306) 634-4788

Ontario

Strongco

Stittsville, ON (613) 836-6633

Sudbury, ON (705) 692-0552

Thunder Bay, ON (807) 475-3052

www.strongco.com

Top Lift Enterprises, Inc.

Bolton, ON (905) 857-5200

Stoney Creek, ON (905) 662-4137 www.toplift.com

Manitoba

Westcon Equipment & Rentals Ltd.

Winnipeg, MB 1-800-453-2435 www.westconequip.ca

Lloydminster, SK (306) 825-3434

Melfort, SK (306) 752-2273

North Battleford, SK (306) 445-8128

Prince Albert, SK (306) 763-6454

Regina, SK (306) 721-2666

Saskatoon, SK (306) 934-3555

Swift Current, SK (306) 773-2951

www.redheadequipment.ca

Alberta

Strongco

Acheson, AB 1-877-948-3515

Calgary, AB 1-800-342-6523

Fort McMurray, AB 1-855-799-4201

Grande Prairie, AB 1-888-513-9919

Red Deer, AB 1-866-950-3473

www.strongco.com

British Columbia

Great West Equipment

Campbell River, BC (250) 286-0123

Cranbrook, BC (250) 426-6778

Fort St. John, BC (250) 785-4223

Kamloops, BC (250) 372-3996

Nanaimo, BC (250) 716-8804

Prince George, BC (250) 612-0255

Surrey, BC (604) 882-5051

Terrace, BC (250) 635-9033

Vernon, BC (250) 549-4232

Williams Lake, BC (250) 392-9599

www.gwequipment.com

FAE has redeveloped its top-of-the-line tracked carrier to create the PT500, a machine that is ideal to tackle big challenges, like jobs in large, wooded areas and along oil and gas pipelines.

The new PT550 replaces the PT475 in FAE’s equipment lineup.

The new tracked carrier is capable of working on large areas of soft, uneven or swampy ground. As well, the machine is able to handle longitudinal slopes up to 45 degree and transverse slopes up to 32 degrees, while maintaining a low ground pressure of 0.41 kg per square centimetre.

Compared to its predecessor, the new PT550 has many updated features, from design changes to technological upgrades, starting with the completely redesigned cab for added operator comfort and safety.

In the cab

The PT550’s Category 2 ROPS/FOPS/OPS approved cab has a new configuration and an integrated pressurization system. Other improvements for added operator comfort and productivity include large Lexan glass windows, ergonomic joysticks, a pneumatic seat, a large 25 cm touchscreen display to control all operating functions, a 360-degree camera system and a heated and refrigerated compartment with cup holder.

Cat powered

The FAE PT550 is powered by the Caterpillar C13B six-cylinder engine to guarantee strength, reliability and global support.

Equipped with a turbocharger with after

cooler, the Tier 4 Final engine delivers 536 hp. The combined diesel particulate filter (DPF), selective catalytic reduction (SCR) and diesel oxidation catalyst (DOC) guarantee compliance with Tier 4 Final and Stage V emissions regulations.

The PT550 is also available with a Tier 3 engine for markets with lower emissions regulations, rated at 475 hp.

The large 12.5-litre displacement and the electronically controlled proportional and reversible fan cooling system, designed specifically for the FAE PT550, guarantee superior performance for heavy jobs and in tropical climates.

The tracked carrier’s heavy-duty undercarriage is designed to perform while maintaining reliability, even in the most demanding conditions. The lubricated track chains last longer than conventional chains and provide a smoother ride. When combined with the reliable dozer-type rollers and oscillating undercarriage technology, the PT550 offers superior grip and comfort.

There are two roller guard options to adapt to different environments. The conventional geometry means a low centre of gravity and optimal contact between the chain and the drive wheel, two fundamental elements that provide the best performance, even on slopes. The FAE PT550 wheelbase also extends the load distribution area, which means lower specific pressure against the ground.

The undercarriage frames are designed to withstand major stresses and make maintenance easier.

The PT550 can be equipped with a forestry mulcher or a multitask head to crush stone and till soil.

Each machine can benefit from Active Power Management technology, which combines the floating system function with the load control function, ensuring the head always precisely follows along the ground and power is managed effectively during operation.

Combined with the 300/U/Sonic or 500/U/ Sonic forestry mulchers, FAE’s exclusive Sonic technology enables the head to always work at maximum capacity. Sonic technology adjusts the torque in real time according to the force required, delivering up to 30 per cent higher productivity.

New forestry mulchers