More brains, more brawn

Liebherr’s new Generation 8 wheel loaders deliver stronger breakout forces and new intelligent technologies

Liebherr’s new Generation 8 wheel loaders deliver stronger breakout forces and new intelligent technologies

The most positive person I know is a restaurateur in southern Ontario.

Now, if there’s anyone that could be understandably pessimistic in this day and age, it’s restaurant owners. The pandemic and its associated restrictions beat them down. Now, they face skyrocketing ingredient prices, labour costs and a clientele that is more prone to stop dining out as prices rise.

Despite non-stop challenges, my friend’s businesses have not only survived, they’ve thrived.

It’s not because he’s the best chef in the region or has the best locations, it’s purely due to his positive outlook.

He omits the “why me?” phase when faced with a setback and immediately looks for ways to adapt. His mentality consistently puts him ahead of his competition.

Currently, positivity is rare in the Ontario business world.

According to the Ontario Chamber of Commerce’s annual Ontario Economic Report, a slim majority of businesses remain confident in their own outlook, with 53 per cent expecting growth this year.

“Business confidence in the economy has plunged from 29 per cent at the height of the pandemic to just 13 per cent two years later – driven by the rising costs of living and of doing business,” said Daniel Tisch, President and CEO of the Ontario Chamber of Commerce.

However, my restaurateur friend’s positive outlook is shared by most of the construction industry.

According to the Ontario Construction Secretariat’s annual Contractor Survey,

contractors are expecting more business growth in 2024, which is attributed to an abundance of current work and more projects on the horizon.

The survey found that 66 per cent of contractors surveyed are feeling positive about the coming year. In unionized workplaces, that number is even stronger at 71 per cent.

A positive outlook was most obvious in Northern Ontario, a response to increased mining and institutional projects. The Ontario Economic Report echoed these findings, noting the mining industry has the highest confidence level in the province’s economy at 46 per cent, followed by utilities at 27 per cent.

The construction industry is far from immune to the current economic pressures

generating doubt in the business world.

Like food service, construction is also burdened with labour shortages as well as rising material and interest costs.

Food and shelter are often referenced as two of the main elements required to survive. Perhaps from a business standpoint, a positive outlook is just as important.

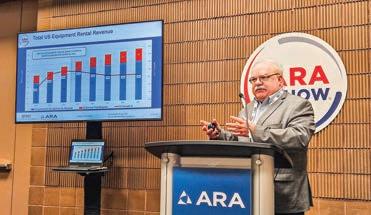

Growth in rental equipment revenue in the United States will outpace Canada in 2024, according to the American Rental Association (ARA). However, Canada’s rental growth will more than triple the national GDP growth.

The ARA released its latest economic forecast during the ARA Show held in New Orleans in February. Since 2005, the ARA has partnered with S&P Global to estimate and forecast North American rental revenue.

According to the Business Development Bank of Canada (BDC), Canada’s GDP will grow by 0.9 per cent, while the ARA predicts rental revenue will grow by 3.1 per cent to US$974 million in 2024.

Looking stateside, rental revenue will grow by 7.9 per cent to $77.3 billion for construction and general tool rental.

“Canada is not quite as rosy a picture,” said Scott Hazelton, Director of S&P Global Market Intelligence. “They had a much stronger economy coming into the current year, and they've got some pretty good growth rates. But there isn't the same degree of federal service money in Canada as in the U.S.”

Alongside a lower investment from government,

Hazelton explained several other factors are hindering growth in Canada. Fewer new housing starts in Ontario, for example, will equal a downtrend in the rental market. As well, the United States is recording more construction to support manufacturing.

Canada’s energy sector is also usually a contributor to rental revenue. However, growth in energy is currently limited.

“Canada's growth typically comes out of the oil sands or offshore on the East Coast,” Hazelton said. “There’s not a lot of new activity going on with energy in Canada.”

The forecast also predicts

that interest rates in the United States will decline before Canada.

“They probably won’t start cutting rates until maybe a quarter after we do, which gives you a temporary exchange rate issue as well,” Hazelton said. “So, thinking about (Canada’s) growth picture, it's a little bit flatter than you might expect for a recovering economy.”

In the United States, the ARA predicts its GDP will grow by about 1.5 per cent. Rental revenue growth will hit 7.9 per cent, thanks to government spending initiatives, the Infrastructure Investment and Jobs Act, supply chain

improvements and the calming of inflation and interest rates.

“There's a lot of good tailwinds that we're seeing to increase this rental revenue up to this level of 7.9 per cent,” said Tom Doyle, Vice President of Association Program Development at the ARA.

Looking ahead, revenue growth in the United States will continue with estimates of 4.3 per cent in 2025, 3.9 percent in 2026 and 3.8 per cent in 2027.

Throughout the year, fleet growth is expected to soften compared to recent years. Aerial access equipment will grow by 9 per cent, concrete

equipment 7 per cent, earthmoving equipment 9 per cent and all other rental equipment by 8 per cent. In 2023, all four categories recorded growth rates between 16 and 23 per cent.

The ARA has also adjusted its forecast to include data from specialty rental equipment in the construction industry, such as portable toilets and ground protection equipment.

wright, Product Marketing Manager at Toro.

Introduced at The ARA Show in New Orleans in February, The Dingo TX 1000 Turbo features a turbo-powered diesel engine and the new patent-pending Smart Power feature to maximize engine, auxiliary and traction torque.

The new Dingo TX 1000 Turbo will begin shipping this spring.

“We’ve worked closely with our customers to understand their needs and are excited to introduce the next iteration of the Dingo TX 1000, redesigned from the ground up to maximize strength and productivity," said Kyle Cart-

The Dingo TX 1000 Turbo’s new engine has more torque to deliver more productivity, especially when using the trencher and auger attachments.

The 24.7 hp Yanmar diesel engine is engineered with a focus on vibration reduction. The result is an engine more than capable of handling demanding applications while delivering up to 6.6 km per hour ground speeds in both forward and reverse.

“Smart Power essentially optimizes torque on the engine, the traction control and the auxiliary to make sure everything is operating correctly,” Cartwright said. “So, for instance, if you're trenching, and the machine senses itself starting to bog down, the engine itself will

slow down that traction speed to let the auxiliary power catch up. So, you're doing it more efficiently.”

Toro engineers also added a larger hydraulic filter, found in the Dingo TX 1300 model, for longer maintenance intervals and less down time.

The narrow-track model is 1,282 kg and features a standard track with “B” style tread. The wide-track version weighs 1,320 kg and features a less aggressive tread pattern that’s gentle on turf and minimizes damage.

“The reality is the Dingo TX 1000 changed the compact utility loader game. That’s why, when we approached the design, we wanted to ensure all the beloved and trusted features remained,” Cartwright said. “The new Dingo TX 1000 Turbo simply builds on the standard set

by the original, and we’re so excited to get this new turbo-charged machine in the hands of operators.”

Like its predecessor, the Dingo TX 1000 Turbo has a rated operating capacity of 454 kg. When the loader arms are at full reach, the hinge pin measures 2 metres from the ground to allow the machine to easily reach over the side of dumpsters and one-ton trucks.

As well, the new Dingo TX 1000 Turbo features a vertical lift loader arm design, which keeps the load closer to the machine to allow operators to lift more weight with greater confidence. Additionally, this feature increases the reach at full height to make dumping more efficient and accurate.

The new Dingo TX 1000 Turbo is equipped with the Toro-exclusive patented

traction control design. The controls are intuitive and effortless, providing operators with all-day productivity. Other operator-centric features have been carried over, including thigh and hip padding on the operator station for a comfortable experience and an auxiliary foot control on the suspended platform, which frees the operator’s hands to focus on ground speed and attachment positioning.

The machine features a single, 39-litre diesel fuel tank on the operator’s left-hand side and the hydraulic oil reservoir on the operator’s right-hand side for improved serviceability.

“With the introduction of Turbo, we’re also excited to share that we've invested in expanding production capacity across the full line, so we can continue to meet the needs of our customers,” Cartwright said.

Hitachi Construction Machinery Americas has opened its new sustainable, state-of-the-art headquarters facility in Newnan, Georgia.

Hitachi constructed the adaptive-use facility to help propel the company’s growth in the Americas. It will facilitate the development and production of new machinery and elevate customer support.

Encompassing 8,187 square-metres of office space and 2,572 square-metres of space dedicated to conferences, the ConSite command centre and training space, the headquarters has been designed to enhance creativity and inspire future growth.

“In March 2022, we set out on a path to establish a

more direct connection with customers. Our culture has been very much involved with listening, understanding and implementing customer feedback,” said Al Quinn, CEO of Hitachi Construction Machinery Americas.

“By combining the resources of the excavator, loader and mining businesses, the company has experienced a tenfold demand from previous years. The investment in a regional Americas facility helps strengthen that direct connection to the customer.”

The new headquarters will help the company focus on key growth areas, including a robust compact and construction business network that establishes a direct link to the customer in North,

Central and South America. Hitachi is also expanding sales of mining excavators for construction and quarry sites in addition to mining sites. In addition to the new regional headquarters facility, Hitachi Construction Machinery Americas is also creating operating bases for parts remanufacturing and expansion of the rental business that will also provide the customer with additional support and options.

Sustainable construction

The Hitachi campus spans 19 acres and was initially created as a wheel loader assembly and manufacturing facility in 1987.

Embracing sustainable practices, Hitachi Construc-

tion Machinery Americas opted for adaptive reuse principles in the development of the existing property. More than 7,000 square-metres of greenspace was reclaimed from the site by reconfiguring the employee parking areas and eliminating buildings and concrete.

Noteworthy sustainable practices included the recycling of concrete, steel and wood already on the site. Reclaimed materials included 3,900 cubic metres of recycled concrete repurposed for roadway, fill and redistribution; 3,770 cubic metres of exterior metal wall panels recycled and 113 metric tonnes of steel frame structure reused. In addition, 6,500 square metres of

existing concrete slabs were reused, 1,500 square metres of roof purlins and 4,550 square metres of old metal roof panels became decking for the new roof. Stairways and stair seating areas utilize 471 metres of reclaimed heart pine wood. Recycled plastics were used to manufacture all carpet products.

“Establishing a direct connection with customers means listening and aligning with their needs and values,” Quinn said. “The industry has actively embraced a move toward sustainable practices, and this thoughtful consideration is reflected in the design of the new headquarters.”

The headquarters stands out for its energy-efficient design, featuring Low-E glass

that blocks 62 per cent of solar energy while allowing 70 per cent of visible light to pass through. Skylights and roll-up doors contribute to natural lighting, integrating the indoors with the outdoors. An advanced energy management system monitors and optimizes energy consumption and temperature changes.

As well, Hitachi Construction Machinery Americas continues to expand employment opportunities as it strengthens customer offerings and support.

Since taking the lead for the brand’s construction and mining equipment in the Americas, the company has more than tripled its employee count.

Teleo and Storm Equipment have partnered to develop a remote-operated and autonomous industrial snow plow.

The machine harnesses Teleo’s autonomous heavy equipment technology and Storm Equipment’s commercial snow removal equipment and expertise.

With support from Teleo dealer RDO Equipment, the companies worked to retrofit a John Deere 332G skid steer loader with Storm Equipment’s Metal Pless snowplow blade and Teleo Supervised Autonomy — the company’s technology that enables remote and autonomous operations.

The machine is designed for mass snow clearing in large open areas such as industrial parking lots. Customers can order the retrofit for any make and model of heavy equipment for remote-operated and autonomous operations from Teleo, along with an autonomous-ready snow plow blade properly sized for each machine type from Storm Equipment.

“Remote operation of snowplows is a truly disruptive prospect for the industry,” said Jordan Smith, Owner of Storm Equipment.

“Snow removal companies typically don’t have just one make or model in their fleets, so the fact that Teleo’s technology can be retrofitted onto virtually any make and model of heavy machinery makes it a great option for the industry.”

Once outfitted with Teleo’s kit, the machines are supervised by an operator sitting in a central command centre, a more comfortable and attractive working environment than a traditional snow plow operator working from the cab. The machines aim to help solve staffing shortages in the commercial snowplow industry, where snow contractors are covering larger regions and working long overnight hours. The system allows a single operator

to work in multiple regions simultaneously. Initially, the plows will be remote-operated and autonomous capabilities will be added in the first half of 2024.

“Utilizing Teleo’s gamechanging system, the shrinking pool of skilled snowplow operators can cover a lot more ground in a shorter time period,” Smith said. “With the click of a button, they can move to a different loader and plow on a jobsite across town, or even in a different state. This effectively could quadruple the productivity of a single skilled staff member, creating massive operational efficiencies for the snow contractor.”

Smith added the Teleo tech could open up snow plowing opportunities to those who are not already heavy equipment operators.

“We like to joke that today’s streaming gamers could become tomorrow’s remote snowplow operators,” he said. “Simply put, remote-operated and autonomous snow removal demonstrates undeniable value for contractors looking for the best return on their heavy equipment investments.”

Fleets of machines that are used for applications such as loading gravel, peat moss and other bulk materials in warmer months are often used to move snow in the winter months. Teleo’s technology can be easily retrofitted on those fleets, introducing the ability to integrate remote and semi-autonomous technology without the need to purchase new machines.

The same machines can be used year-round for snow removal, landscaping and other site work.

“Commercial snow removal, specifically mass snow clearing in large parking lots and on other long stretches of open, flat surfaces, is yet another ideal application for our technology,” said Vinay Shet, Co-founder and

CEO of Teleo. “When heavy snowfalls occur, there is an immediate need to clear parking lots and commercial sites so businesses can continue operating. The collaborative Teleo-Storm Equipment approach introduces a way to get the job done more efficiently, safely and without customers having to purchase new machines; that makes it a realistic solution for companies of all sizes.”

As part of its performance tiering strategy, John Deere has introduced the 950 P-Tier and 1050 P-Tier dozers. Replacing the 950K and 1050K, the dozers are the next generation of models to join the increasing lineup of John Deere P-Tier machines.

The new 1050 P-Tier dozer boasts an increase in engine power and a redesigned hood and front-end design. In addition, both the 950 P-Tier and 1050 P-Tier

offer enhanced visibility and improved safety features to boost productivity and protection on the jobsite.

“John Deere is dedicated to providing its customers with large dozer options that fit the needs of every job site, and the new P-Tier machines offer the durability and reliability our customers demand from machines of this size class”, said Matt Costello, Product Marketing Manager for John Deere Construction & Forestry.

“The 950 P-Tier and 1050 P-Tier dozer models were updated with the customer in mind, helping them increase efficiency, visibility and gradeability in even the most demanding conditions.”

Now equipped with standard LEDs, operator efficiency is improved during night-time or low-light operations. Also helping to improve uptime, the cold weather hydraulic lines are specially tailored for cold climate operations. These

hoses, which replace the standard option, are rated for lower temperatures, ensuring smooth hydraulic function in harsh winters and weather conditions. The cab of the 950 P-Tier and 1050 P-Tier can be tilted for easy serviceability access under the cab.

To improve safety, the Operator Presence System ensures the operator is present in the seat of the cab, with the seat belt fastened, before the parking break can be released. This ensures a critical layer of safety, preventing accidental movement or operation before the operator is buckled in.

The P-Tier system also integrates the parking brake switch into the system status monitor, eliminating the need for traditional park lock levers. This integration not only streamlines the operation process but also enhances the overall safety mechanism of the machine.

To enhance comfort and functionality, both dozers now feature a premium heated and ventilated seat option, which is air-suspended with adjustment controls for optimal ergo -

nomics. The seat design remains at a 15-degree angle to provide optimal comfort when operating the rear ripper.

As well, the updated cab features new ergonomic controls, neutral counter rotate and an integrated forward neutral reverse switch. This ergonomic focus ensures operators can work for extended periods with reduced physical strain, helping to enhance productivity on the jobsite.

Remaining the largest Power-Angle-Tilt (PAT) dozer in the market, the 950 P-Tier dozer features SmartGrade, John Deere's factory integrated mastless 3D grade control.

Tag link

Receiving an increase in operational advantages upon its entry to the P-Tier portfolio, the newly upgraded 1050 P-Tier dozer boasts a range of features and enhancements that improve upon overall functionality and efficiency. One notable upgrade is the tag link and blade design that brings the blade 25 cm closer to the frame.

Along with the tag link, inverted tilt and pitch

cylinders were added. The inverted tilt and pitch cylinders, lowered hood and larger front window help improve operator visibility to the blade. The repositioning of the 4.3 metre blade, due to the updated tag link design, paired with double-bogie undercarriage provides operators with a more balanced machine and a clearer view of the blade corners, which is a critical factor for precision work.

JD14 engine

In terms of power, the 1050 P-Tier dozer features a revamped JD14 13.6 litre engine that replaces the 13.5 litre engine in the 1050K. The JD14 enhances durability, reduces fuel consumption and uses a single canister in the aftertreatment system to meet emission regulations without the need for a diesel particulate filter.

Lastly, on the 1050 P-Tier, the new cooling system has been redesigned with a single plane layout, positioning coolers side-by-side instead of stacked.

This new design not only improves cooling efficiency, but also simplifies access for cleaning.

The new Vermeer SC1052 stump cutter is the largest cutter in the company’s lineup and capable of grinding large stumps with minimal repositioning. The new cutter features

a 115-hp Origin 4.3-litre gas engine with a 68.1-litre fuel tank, the Vermeer cutting system (VCS) and the SmartSweep control system.

With the ability to cut up to 78.4 cm high, 63.5 cm below the surface and a straight-line cutting width of 182.9 cm, the SC1052 can remove a 1.8-metre stump without repositioning.

“The Vermeer SC1052 stump cutter is the next generation of large stump cutters,” said Josh Vrieze, Senior Product Manager for Vermeer Environmental Equipment.

“Diesel emission regulations impacted the production of 100-plus horsepower stump cutters, including our popular Vermeer SC1152 stump cutter unit. To fill this void in the market, our team designed a new economic gas engine model that will meet the performance levels tree care professionals expect. The SC1052 complements many of our customers' gas engine fleets, as they have started operating more gas-powered chippers and trucks in recent years.”

Vermeer’s SC1052 is equipped with the new VCS that solves many challenges associated with traditional cutting systems. Rather than using a bolt to secure teeth to the cutter wheel, the VCS has a mounting and retention structure that helps keep teeth from shifting in the pocket and absorbs the shearing force while operating. In addition, two-sided carbide V-profile cutter teeth help optimize the cutting performance of the stump cutter and can be flipped to the other side of the cutter wheel for extended wear life.

The Vermeer team designed the SC1052 to fit where many large stump cutters are unable to travel.

The SC1052 is 90-cm wide without its dual wheels. That means it can fit through a standard residential gate. The SC1052 can also traverse difficult and uneven ground conditions thanks to its full-time, four-wheel drive system and differential lock.

Once in place, the cylinder and linkage bar design help to position the cutter wheel out and away from the machine as the boom drops. This gives operators a wide cutting range and minimizes the need to reposition.

Vermeer SmartSweep

While cutting, the Vermeer SmartSweep control system monitors engine load to provide a smooth and consistent cutter wheel sweep rate and helps minimize wear and tear on the machine.

Once cutting is done, an 86.4-cm hydraulic chip blade helps pile or spread chips for fast and efficient cleanup.

Vermeer designed the SC1052 to be efficient to service. It has access panels that can be removed with no tools required.

Like other Vermeer stump cutters, the SC1052 is beltless, so users won’t have to think about replacing a belt. As well, the SC1052 control handles have operator-sensing capabilities that will disengage the cutter wheel if a user steps away from the controls during operations. Optional accessories from Vermeer include a remote for propel, boom and steering function control and telematics to help with fleet maintenance.

At a young age, Mike Diehl enjoyed working alongside his dad in the trades and working with machines and other equipment. In 2003, Mike decided to open up his own company, MLD Concrete Construction Inc., out of the Sebringville (Stratford) area. They specialize in all residential concrete projects including house floors, garage floors, patios, driveways, porches, steps, and all the fun stuff in backyards. They also do their own excavating and prep work.

When Mike was asked why he chose Bobcat® machines, his reply was, “Service is

YOUR LOCAL AUTHORIZED BOBCAT DEALERS

BARRIE

Bobcat of Barrie 705-726-2228

oakenequipment.ca

GREY BRUCE

Bobcat of Grey Bruce 519-372-9100

bobcatoftc.com

PARRY SOUND

Bobcat of Parry Sound Ltd. 705-342-1717

bobcatofparrysound.com

TORONTO WEST

Bobcat of Toronto 416-679-4172

oakenequipment.ca

BRANTFORD

Bobcat of Brantford 519-752-7900

bobcatofbrantford.com

HAMILTON

Bobcat of Hamilton 905-643-3177

bobcatofhamilton.com

PETERBOROUGH

Bobcat of Peterborough 705-748-9119

bobcatofpeterborough.com

THUNDER BAY

Equipment World Inc. 807-623-9561

bobcat-tbay.com

the number one reason and I love the way the Bobcat machines operate. Smooth, reliable and great visibility. I am a person who likes to stick with one brand, and Bobcat has always been a really good fit.”

“The Bobcat E20 and E26 compact excavators are a perfect size to get into residential backyards. These two excavators work nicely hand in hand together. The Bobcat T66 and T450 compact track loaders have great operator comfort and smoothness of controls. The newer Bobcat T66 compact track loader has even greater visibility as there is no mesh, it’s a clear cab. The increased visibility when loading dump trucks is great. We use our Bobcat machines as needed to fit the jobs we are on. Whether it be for grading, excavating, topsoil work, loading and unloading material, driveway and floor prep, armour stone, etc.,” stated Mike.

“It was a smooth transition to Steve Brown, sales specialist, at Bobcat of Stratford. Back in 2006, we purchased our first Bobcat machine which was a S175 skid-steer

CASSELMAN

Bobcat of Ottawa Valley 613-764-2033 bobcatov.com

KITCHENER

Bobcat of Tri-Cities Ltd. 1-866-214-3939

bobcatoftc.com

STRATFORD

Bobcat of Stratford 519-393-6040

bobcatofstratford.ca

SAULT STE. MARIE

Bobcat of Sault Ste. Marie 705-949-7379 bobcat-ssm.com

CORNWALL

Bobcat of Ottawa Valley 613-932-2034 bobcatov.com

LONDON

Bobcat of London 519-455-4900

bobcatoflondon.ca

STRATTON Stratton Equipment 807-483-5505

strattonequipment.com

WINDSOR

Bobcat of Windsor 519-737-0120 oakenequipment.ca

loader. After that machine, Steve sold us a Bobcat compact track loader and we never looked back. They make less of a mess on residential properties. The tracks are more universal, don’t harm the lawns and for grading are much smoother. It has been awesome working with Steve and the dealership has always been great to us too. I would definitely recommend Steve Brown, Bobcat of Stratford if you are in this field looking for machines.”

Thank you, Mike.

COURTICE

Bobcat of Durham East Ltd.

905-404-9990

bobcatofdurhameast.com

MUSKOKA

Bobcat of Muskoka

249-390-7000

oakenequipment.ca

SUDBURY

McDowell B Equipment Ltd.

705-566-8190

bmcdowell.com

WYOMING

Advantage Farm Equipment Ltd.

519-845-3346

advantage-equip.com

FRANKFORD

John’s Equipment 613-398-6522

johnsequipmentsales.com

OTTAWA

Bobcat of Ottawa Valley 613-831-5166 bobcatov.com

TORONTO EAST

Bobcat of Toronto 416-679-4171

oakenequipment.ca

Liebherr’s new Generation 8 wheel loaders represent a fundamentally revised and redevloped range of midsized machines.

The Generation 8 lineup includes the L 526, L 538 and L 546, which provide bucket sizes between 2.2 and 3 cubic metres in the standard version and deliver a signifi-

cant increase in performance compared to the previous generation.

The new L 526, for example, has about 20 per cent more engine power and more than 20 per cent higher breakout forces than its predecessor. The 13,170 kg machine is equipped with a 158 hp engine, a 2.2 cubic-metre

bucket and features a tipping load of 8,730 kg.

The L 538 and L 546 models also deliver performance increases in all areas. For example, the optimized travel drive provides increased traction to ensure that the new wheel loaders accelerate dynamically in everyday work, and can powerfully push into all materials.

The 14,530-kg L 538 loader is powered by a 175 hp engine and is equipped with a 2.6 cubic-metre bucket and a 9,650 kg tipping load.

At 15,410 kg, the L 546 is the largest new Generation 8 loader and features a 188 hp engine, 3 cubic-metre bucket and an 11,010 kg tipping load.

The newly-designed lift arm ensures maximum breakout, holding and lowering forces. It has optimized z-bar kinematics and improved working hydraulics.

Liebherr reinforced the steel construction of the front section of the new loaders to prepare the machines for handling heavy loads. Structural reinforcements on the new lift arms or cross tube, for example, increase robustness.

try-specific challenges. High Lift lift arms, for example, are an extended variant of the z-bar kinematics and ensure greater range and efficient loading processes at all heights.

the bucket.

While redesigning the lift arms, Liebherr revised the bucket design of the new mid-sized wheel loaders.

The optimized z-bar kinematics with electro-hydraulic pilot controls include larger hydraulic cylinders and more powerful working pumps. The combination of these innovations enables faster cycle times and dynamic and powerful work movements – even with heavy attachments such as high dump buckets or log grapples.

With the increased performance providing a strong basis, Liebherr offers numerous equipment options for the lift arms for indus -

For wheel loader applications that require different attachments, there is a view-optimized quick coupler and the fully automatic Likufix quick-coupler system. This allows the machine operator to change between mechanical and hydraulic working tools from the cab quickly and safely with the touch of a button. This saves time and reduces the risk of accidents.

Well thought-out details make day-to-day work with the wheel loaders easier. The operator is able to activate the parallel guidance of the lift arms at the push of a button and work efficiently and safely with forks. The new bucket-tilt assist helps when working with sticky materials, such as damp soil or compost, and ensures accurate loading by shaking out

Customers can now more accurately tailor the individual elements and wear parts of the buckets to their needs at the time of ordering.

Intelligent equipment

In addition to the new lift arms, the optimization of the hydrostatic travel drive in particular contributes to the increased productivity of the wheel loaders. The new, more powerful engines are characterized by a higher maximum torque at a lower nominal speed. In this way, performance and efficiency can be increased with the same low fuel consumption.

More powerful hydraulic components, such as larger travel motors and travel pumps, ensure greater traction in all three models to provide quick loading cycles.

For a high degree of robustness, Liebherr has reinforced the axles, as well as travel drive components; depending on the model, all three wheel loaders have larger front or rear axles than their predecessors.

A modern design is reflected in the engine compartment, which was redesigned for optimized visibility, as well as the comfortable operator’s cab and intelligent equipment.

The new loaders feature active personnel detection with brake assistant. This optional assistance system, which is installed at the rear of the wheel loader, warns the machine operator on the display and with acoustic signals of dangers in the rear area of the wheel loader. To provide a specific warning of imminent injury to persons, the assistance system independently distinguishes between humans and objects using smart sensors.

As soon as the active personnel detection emits a warning signal, the brake assistant automatically reduces the speed of the wheel loader to a standstill to avoid a potential accident.

Polaris is expanding its line of heavy duty UTV with the introduction of its first electric Pro XD model.

The all-new, all-electric Pro XD full-size Kinetic utility vehicle is engineered to withstand tough jobsite duty cycles and enable all-day operation.

Polaris previously entered the electric UTV space with the Ranger XP Kinetic. Polaris Commercial has leveraged

that innovation for its commercial customers with the introduction of the Pro XD Kinetic, rounding out the Pro XD family that also includes gas and diesel, full-size and mid-size, standard and crew models.

“Going all-electric with the professional-grade Pro XD UTV empowers customers to meet sustainability obligations without sacrificing capabilities,” said Aaron

Stegemann, Vice President of Polaris Commercial. “We are really thinking about the environmental impact of our product and eliminating emissions where we can.”

The electric powertrain for the UTV was developed through Polaris’ 10-year partnership with Zero Motorcycles. The UTV can deliver the same 567 kg cargo load and 1,134 kg towing capacity as a full-size gas or diesel Pro

XD UTV, while its all-electric powertrain delivers instantaneous torque and precise handling. Due to the 140 footpounds of instant torque of electric power, Polaris altered the drive calibration to be specific to the needs of jobsites.

“The acceleration curve was detuned, so it’s not doing zero to 60 instantly,” Stegemann said. “It’s going to slowly ramp up to the top speed to keep the worksite safe.”

The UTV uses a 14.9 kWh Lithium-Ion (Li-ion) battery to power the motor, delivering a 72 km range on average.

“We found in a standard shift, they’re not getting close to using the full 100 per cent,” Stegemann said. “That allowed us to keep the cost down slightly.”

The Pro XD Kinetic is equipped with several charging options designed to fit any electrification infrastructure. The vehicle’s battery can be charged by a standard wall outlet or even a similarly powered generator in about eight to 10 hours. The Pro XD Kinetic is also compatible with 220V to en-

able fast charging options in as little as three hours.

An electric powertrain also requires less maintenance, which translates to more vehicle uptime, while its quieter operations enable access to restricted areas where heavy-duty gas and diesel UTVs were previously excluded.

Scheduled maintenance costs are roughly 60 per cent less than average maintenance costs for similar gas-powered vehicles meaning fewer replacements and less waste. The Lithium-Ion battery in the Pro XD is designed to last the vehicle’s lifetime.

“Fuel savings alone are USD $2,800,” Stegemann said.

The Pro XD Kinetic is engineered with the same features to meet and exceed jobsite compliance, improve worker safety and provide peace of mind. Orange seatbelts, vehicle decals and optional lighting accessories improve visibility of the vehicle and surrounding

workers, while a standard horn and backup alarm provide audible alerts for the operator and surrounding crew.

Furthermore, the top speed of the Pro XD Kinetic can be calibrated between 8 km per hour and 65 km per hour, with many customers selecting a top speed of 40 km per hour for jobsite compliance.

The electric drivetrain also provides reduced sound levels that improve the operator’s situational awareness, allow easier communications between crew members and enables quiet-zone usage.

As well, heavy-duty boots, bearings and bushings, thick eight-ply tires and a rust- and dent-free poly bed ensure the electric model is built just like its gas and diesel counterparts.

For the interior, the seat fabric incorporates Kevlar to reduce wear and tear.

“We noticed on jobsites that occupants are getting out with a tool belt on. The Kevlar-backed seats will keep it from being torn or wearing out quickly,” Stegemann said.

Yanmar is celebrating the 30th anniversary since the launch of its ViO series compact excavators.

The original launch of the Yanmar CE ViO range of compact excavators popularized the zero tail swing excavator concept.

Unlike other excavators of its kind at the time, rotation of the rear of the superstructure of the ViO machines extend beyond its tracks. This meant the machines could operate in tight spaces without fear of a rear collision with nearby buildings, vehicles or people. The concept was embraced by construction companies around the world. Collectively, thousands of collisions have been avoided.

The zero tail swing concept requires more than a reduction in the size of the superstructure.

In traditional excavators, a protruding counterweight at the rear of the excavator is useful in balancing loads at the front, when lifting or digging, for example. But with this removed, the engineers at Yanmar CE needed to create similar counterweight forces by other means, while still maintaining lift capacity. Now in its 7th generation, the ViO range has expanded and is still going strong.

Recently the designed-for-Japan ViO80-7 was declared a winner in the Japan Institute of Design Promotion’s 2023 Good Design Award.

The ViO zero tail swing concept has consistently developed over the last 30 years. The ViO17 is a good example of the current breed. Neither the counterweight, nor the front

part of the upper frame extend beyond the track width. This gives the 1.8-tonne model an extremely tight turning radius. And yet, thanks to its 1.3 metre wide undercarriage, large counterweight and good weight distribution, it maintains great lifting capabilities.

Yanmar’s first CTLs

Yanmar is also celebrating its first compact track loader production models, the TL100VS, rolling off the line for the North American market.

The expansion to Yanmar’s compact equipment offering is the culmination of four years of extensive research and development following the company’s acquisition of ASV.

The compact track loaders also signal Yanmar’s emergence as a comprehensive compact equipment solutions provider for its customers.

“It’s immensely satisfying to see these first machines roll off the line,” said Matt Deloglos, Vice President of Commercial, Yanmar Compact Equipment North America. “Our team has worked tirelessly towards this goal for the last four years with designing, testing and manufacturing these machines as well as getting the plant and our team ready to launch these products.”

Alongside the TL100VS, Yanmar’s line of compact track loaders includes the TL65RS, TL75VS and TL80VS.

The remaining three new Yanmar compact track loaders are set for production later in 2024.

14,000 sq. ft.

available in Barrie, Ontario. 3 x 16’x 16’

Available May 1, 2024. Partial space available sooner.

5 YEAR/5000 HOUR FULL MACHINE WARRANTY

5

2023

Equipment Ontario Incorporated has acquired the major ity interest of the Waterloo, Ontario-based Advance Construction Equipment Limited.

Together, the two companies will service more than 16 counties throughout Ontario, from the shores of Lake Huron in the west to Peterborough County in the east with dealership locations in Elmira, Harriston, Lindsay, Listowel, Mildmay, Port Perry, Waterloo, and a future location near Alliston.

Jeff Marshall: 1-807-628-6300

Trevor Hynnes: 1-807-629-3007

Darren Hynnes: 1-807-252-6556

Jason Dennis: 1-705-288-4685

The Advance Equipment name will remain and become a division of Equipment Ontario.

“Our employees and customers are like family. We wanted to partner with a company with the same morals and values,” said Ric Thompson, Advance Construction Equipment General Manager.

With the partnership, Equipment Ontario is able to expand the JCB agriculture line across the full servicing area and offer the JCB construction line at Harriston, Port Perry and Waterloo. However, not all dealerships will carry JCB equipment. The agriculture and construction landscape are changing, and with this partnership they are building a stronger entity to provide stability for their staff, customers and suppliers.

Advanced Construction Equipment was founded in

1965 by John A. Ball of Ball Brothers Limited to complement the family’s growing construction business.

Sydney W. Brown became a shareholder and general manager of operations six years later, and established Advance as a dealer for Allis Chalmers.

In 1984, Advance formed a new dealership agreement with JCB to market its backhoe loaders, eventually expanding to sell JCB’s front end loaders, material handling and rough terrain forklifts.

After the passing of Brown in 2003, long-time employees Ron Teske, Ric Thompson and John Gleeson took over the company.

The company moved to its headquarters in Waterloo in 2012.

Equipment Ontario and Advance will continue to represent all existing brands, and current team members will remain in their roles.

All Choice Rentals (ACR) is expanding its presence in Alberta with the acquisition of St. Albert-based Select Equipment Rentals.

Based in Drayton Valley, Alberta, All Choice Rentals said the acquisition represents a significant milestone, enabling the company to expand its geographic presence across Alberta and western Canada.

“We’re thrilled to welcome Select Equipment Rentals into the All Choice Rentals family,” said Blake Menning, Vice President of All Choice Rentals.

“This acquisition unlocks new opportunities for All Choice Rentals through an expanded fleet of equipment and enhanced service capabilities. With nine branch locations across Alberta, we now have the capacity to service approximately 85 per cent of Alberta within two hours of a phone call, something very

few rental companies are able to do.”

Select Equipment Rentals is a locally owned and operated company that has been providing equipment rentals, sales and service since 1997.

The company serves customers from its five locations in Alberta, including St. Albert, Athabasca, High Prairie, Slave Lake and High Level.

To ensure minimal disruption for existing customers All Choice Rentals and Select Equipment Rentals will remain two separate entities until a transition plan is implemented for Select Equipment Rentals.

ACR was formed in 2009 when the Cat Rental store in Drayton Valley was purchased by an investors group made up of current ACR employees and several local business owners. ACR opened its second location in Rocky Mountain House in 2017, followed by stores in Hinton and Olds.

The Develon DTL35, the company’s first compact track loader, is now in its real-world validation phase.

Introduced as a prototype at ConExpo 2023, the DTL (Develon Track Loader) is now on several jobsites to test its capabilities in rotary cutter and forestry applications.

“We have it on a variety of different applications and in different climates right now, all utilizing our Develon brand attachments,” said Jacob Sherman, Product and Dealer Marketing Manager for Develon. “Part of the process is not only validating the machine, but also how the machine interacts with and performs with our attachments. So, that way when we launch, we know the package performs well together and meets expectations of the customer.”

The DTL35 compact track loader is on track to be commercially available sometime this year.

With an operating weight of 5,642 kg, the DTL features a rated operating capacity of 2,312 kg at 50 per cent. The machine also features a standard auxiliary flow of 84 litres per minute and a high flow of 151.4 litres per minute.

“This complements our current customers fairly well for more heavier construction type applications,” Sherman said.

The DTL is powered by a 116-hp 3.4-litre diesel Develon engine, placing it on the large frame size of compact track loaders from a horsepower perspective.

“We’ve utilized this engine on other platforms and we’re very experienced with it and very competent in this power plant,” Sherman said.

For its initial launch, Develon has developed 13 attachments for the machine, including a snow blower snow pusher and a broom. A second set of attachments created for the DTL will be available later in 2024.

“We recognize the importance of attachments, and we will prioritize by demand,” Sherman said.

The DTL35 will come standard with a torsion suspension system, providing a smooth ride for operators and durability for use on construction job sites. Additional stability when lifting and carrying loads is an -

other benefit of the torsion suspension system for the DTL. A standard rearview camera gives operators better visibility to their surroundings. An optional 360-degree around view monitor (AVM) camera system will be available for enhanced visibility of the job site.

Develon is still in the process of determining which features will be standard and which will be optional. For example, the CTL will be available with bucket shake, which helps remove material from the bucket.

“We borrowed some technology from our dozer. We have what we call blade shake on the dozer, and we have bucket shake on the DTL,” Sherman said.

Depending on the width of the machine’s tracks, operators can expect as low as 5.4 psi of ground pressure.

“We will have a variety of different track tread patterns available for various applications,” Sherman said. “So, multi bar, staggered bar, etc. Whatever application the customer may have, we should be able to accommodate it from a traction perspective.”

•

•

•

•

•

WE

Nors Group has reached an agreement to acquire Great West Equipment for about $150 million.

After entering the Canadian market with the acquisition of Strongco in 2020, Nors is expanding in to Western Canada with the purchase of Great West Equipment, a major construction and forestry equipment dealer with operations in the provinces of British Columbia and

Yukon. Like Strongco, the company is also one of Volvo Construction Equipment's major representatives in the Canadian market.

"We are very excited to welcome Great West Equipment to the Nors family, amplifying our presence in Canada, a market that has proven to be very relevant and strategic for the group,” said Nors CEO Tomás Jervell.

“We believe that Great West Equipment will bene-

fit from the global presence and growth momentum that Nors is experiencing, combined with our 90 years of experience, to improve its performance and promote its future growth.”

With the acquisition, Nors' operation now has a total of 37 branches and more than 750 employees in Canada, covering more than 80 per cent of the Canadian market, from west to east, and starting a new year by reinforcing

its growth strategy.

“Nors has been a great partner in North America through its subsidiary, Strongco, and I know this move will benefit our cus-

tomers in Western Canada,” said Scott Young, Head of the North America Region for Volvo CE.

“Great West has been a vital link in our dealer network, serving some of the most remote areas of Western Canada. We are grateful for their two decades with Volvo CE and excited that we’ll continue working together to serve customers in a fast growth industry.”

Great West Equipment currently has about 250 employees spread across 11 branches in Canada. The company represents several equipment manufacturers, including Volvo Construction Equipment, Madill, Metso, Sennebogen, Falcon and others.

"We are very proud of the legacy of 'Service First' attitude that our incredible team

at Great West Equipment has ensured for our many customers," said Colin Matejka, CEO of Great West.

"As part of the Nors Group, we now have access to resources that will enable us to elevate GWE's ability to serve the territories in which we work. We remain committed to listening to our customers and growing alongside them."

More than three years after the acquisition of Strongco, this North American market already represents around 12 per cent of the group's aggregate sales, with an estimated turnover of $513 million in 2023. The construction equipment sector is one of Nors' big focus areas in its strategy until 2030, having recently completed an operation in the same sector in the Brazilian market.

Caterpillar Safety Services has launched two updates to its programs, including a Safety Perception Survey and a program focused on human and organizational performance.

The new Safety Perception Survey updates language and modern concepts, adding questions related to psychological safety and human and organizational performance.

The survey reports measure five safety activities — hazard identification, event learning, inspections, near miss and safety meetings — and address 11 cultural indicators, including caring climate, employee involvement, feedback, management credibility, training effectiveness and risk reduction.

As well, the data shows how safety is perceived differently among staff.

Human and organizational performance is a framework concept for talking about safety and creating a resilient safety culture. It’s a mindset that allows organizations to build error-tolerant systems by teaching leaders that expecting perfection from workers, processes or procedures is not realistic.

Traditional methods of

managing safety systems centre around designing policies, standard work and processes assuming work happens in a straight line. Management sets the expectations, tells workers what to do and the workers do it the same way, every day.

However, the method does not account for organizational factors that can disrupt the system, such as employees not having the right tools for the job and adapting or making trade offs because they are still required to meet production targets. Nor does it account for the individual factors that impact a worker’s awareness, or lapses in attention due to events in his or her personal life.

Using human and organizational performance principles, Caterpillar Safety Services applies a new understanding of human behaviour to safety. Leaders create an environment where employees feel empowered to speak up to share their ideas, struggles and mistakes.

The organization learns to improve its safety system continuously. Through recognition of workers’ contributions, they want to be more involved, resulting in a proactive safety culture.

Most TRUSTED in the world doesn’t happen by accident.

Not only is JCB the world’s biggest backhoe manufacturer, but we also sell as many backhoes around the globe as all other manufacturers combined. It’s not that big makes us better. Rather, we’re big because we’re better. Buy better at JCB.com.

ALBERTA

Liftboss JCB

Calgary: 403-301-0041

Edmonton: 780-474-9900

liftboss.ca

BRITISH COLUMBIA

Williams JCB

Surrey: 604-930-3316 williamsjcb.com

NEW BRUNSWICK

A.L.P.A. Equipment

Edmundston : 506-735-4144

Balmoral : 506-826-2717

Fredericton : 506-452-9818

Moncton, N.B. : 506-861-2572 alpaequipment.com

NOVA SCOTIA

A.L.P.A. Equipment

Truro : (902) 897-2717 alpaequipment.com

NEWFOUNDLAND

Harvey JCB

Corner Brook: 709-639-2960

St. Johns: 709-738-8911

harveyco.ca

ONTARIO

Advance JCB

Waterloo: 519-742-5878

Harriston: 519-510-5878 advanceequipment.net

D&W Group Inc.

Doughty & Williamson

Jarvis: 519-587-2273

Brant Tractor

Burford: 519-449-2500

Redtrac International

Vineland: 905-562-4136

dwgroup.ca

ONTARIO

Delta JCB

Dunvegan: 613-527-1501

Renfrew: 613-432-4133

Winchester: 613-774-2273 deltapower.ca

Fulline JCB

Glencoe: 519-287-2840 fullinefarm.com

Equipment Ontario

Lindsay: 705-324-6136

Port Perry: 905-982-1500 equipmentontario.com

Jade Equipment

Simcoe County and Districts of Parry Sound & Muskoka 705-325-2777 jadeequipment.com

John’s Equipment Sales

Frankford: 613-398-6522 johnsequipmentsales.com

ONTARIO

Moore JCB

Toronto, York & Peel

Region: 416-747-1212 moorejcb.com

North Rock JCB North Bay, Sault Ste. Marie, and Sudbury: 705-897-7369 northrockrentals.com

ReadyQuip Sales & Service Ltd.

Timmins: 705-268-7600

readyquip.com

WPE Landscape Equipment - JCB

Hamilton/Halton: 905-628-3055 wpeequipment.ca

PEI A.L.P.A. Equipment (506) 861-2572 alpaequipment.com

QUEBEC

A.L.P.A. Equipment

Bas-Saint-Laurent : (506) 735-4144

Gaspésie : (506) 826-2717 alpaequipment.com

Bossé Quebec Inc.

Desmaures: 418-878-2241 Saint-Augustin-debosse-frere.com

Moore JCB

Montreal: 514-333-1212 moorejcb.com

SASKATCHEWAN & MANITOBA

Westcon JCB

Regina: 306-359-7273

Saskatoon: 306-934-3646

Winnipeg: 204-694-5364 westconjcb.com

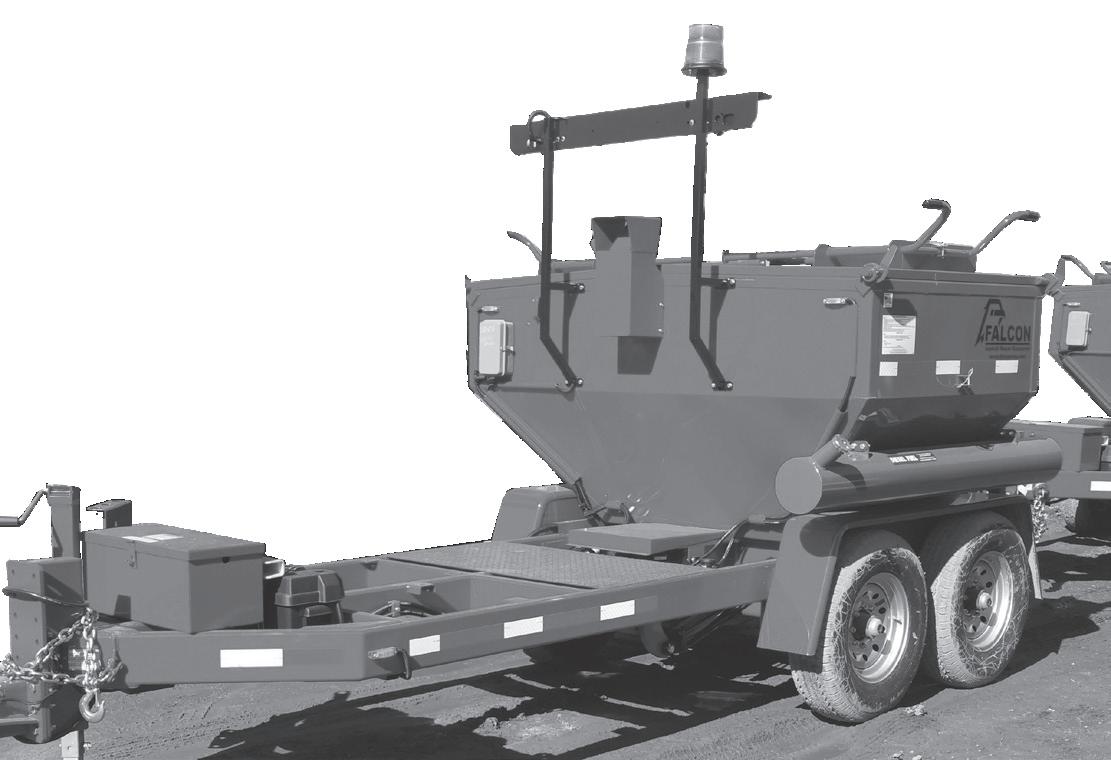

ton and 4 ton units available.

Low profile design + dumping capabilities, joined with oil jacketed heating system, make this the most advanced patching trailer in the world!

• Green friendly exhaust = Green back in your pocket!

• Your all-in-one sealcoating trailer!

• 850 gall steel tank w/7 gauge heads, 10 gauge sidewalls and reinforced tank ends.

• With so many options & extra deck space, this sealcoating trailer is ready to work!

SR-700

• Double Your Production using soft heating infrared tech in all yourcrack sealing & asphalt repairs.

• The fastest asphalt reclaimers & the most efficient portable crack sealing equipment on the market.

• Your all-in-one sealcoating trailer!

• 700 gall steel tank w/7 gauge heads, 10 gauge sidewalls and reinforced tank ends.

• Comes complete w/hyd agitation system and spray system, so all you have to do is add sealer and to to work!

• With its innovative dual selective steering option, this cutting-edge striper excels at tackling challenging tasks such as intersections, long straight lines, and wide curves that traditional stripers struggle with.

• The PROSTRIPE 400 DC is the perfect choice for roundabouts, local city jobs, DOTs and intersections, ensuring professional results

• Accurate material delivery and line precision for striping application such as parking lots, crossways, ports, athletic fields, city road maintenance and local striping jobs.

• The first vibratory plate compactor specifically designed for asphalt applications.

MBW’s Vibratory ScreeDemonTM Electric!

You can’t get any easier than this!

THE #1 ASPHALT REMOVER FOR ROAD CONSTRUCTION PROFESSIONALS AROUND THE WORLD.

• The better than diesel paving solution.

• 60% decrease in maintenance.

• 100% biodegradable.

JCB is introducing two new tandem roller compaction machines, the CT160 and CT260, to the North American market.

At 1,710 kg to 2,740 kg, the machines are easily trailered. The CT160 offers a choice of either an 80 cm or a 1 metre drum. The CT260 comes with a 1.2 metre drum.

“We are re-entering the North American market with a strong, proven product,” said James Gill, Product Manager for Backhoe Loaders, Site Dumper and Compaction Equipment at JCB North America.

“These machines have been in Europe for four years now, so they’re tried and tested. There’s going to be no teething problems, it’s the exact same machine. They’ve become market leaders in their sector within Europe, so we’re hoping they have the same impact over here.”

Both machines provide contractors with precision and high uptime compaction operations.

“By re-entering the North American market with a product that we have confidence in, it paves the way for the rollout of an extensive portfolio of compaction equipment,” Gill said.

Vibromax

The machines will be branded once again as Vibromax, after the German company acquired by JCB in 2005.

“The Vibromax was a well-respected product, with the North American arm of the original company being based out of Racine, Wisconsin,” Gill said.

The JCB Vibromax soil compaction machinery line is used globally. JCB has put all the engineering expertise acquired from Vibromax into the development of the new compaction products.

With this expansion of the Vibromax line come a variety of features and benefits. On

both machines, the responsive directional drive lever enables smooth fore and aft movements. From a bird’s eye view the CT160 and CT260 have an hourglass profile.

“We have a really good hourglass shape so there’s really good visibility,” Gill said.

“When you’re sitting in the seat, you have really good visibility of the front and rear drums.”

On the control panels, work modes are easy to understand, and the switches are sized to create positive tactile feedback even with gloved hands.

Anti-vibration mounts reduce fatigue by isolating the operator from the drum vibrations.

Automatic vibration control is standard, and the CT160 and CT260 feature three simple vibration settings.

“In terms of operation you can have the front drum, rear drum or both drums vibrate at the same time, and that’s all done by rocker switches,” Gill said.

“Vibration can be manually or automatically switched on. Automatically, as soon as you reach a certain travel speed, it will turn on. That will help prevent over compaction in certain areas, particularly when changing directions.”

The manually adjustable offset on the front drum enables the operator to avoid damage to curbs and ironwork.

The rear drum is flush with the rear chassis so operators can work close to walls or obstacles with confidence and precision.

Chamfered edges on the drums ensure a smooth finish, a pressurized water spray system keeps the drums clean during operation, and the drum scraper bars (two per drum) are easy to adjust whether working with stone or asphalt.

All engine service points are accessible at ground level, and a high lift, tilt up engine hood gives operators easy access to all daily maintenance checks.

“It’s all about simplicity from maintenance to ease of use,” Gill said.

Fuel efficient engines power both models.

The CT160 uses a three cylinder, Kubota 19.8 hp engine, and the CT260 models get a three cylinder 24.4 hp engine.

All engines are Tier 4 Final compliant and do not require a diesel particular filter or diesel exhaust fluid.

“It has a Kubota engine, which has been really well received. It is simple to service and a lot of technicians are used to it,” Gill said

The radiator sits at the centre of the machines for protection and easy cleaning. This also makes it easier for the operator to access the battery and other service points. The water spray systems are equipped with replaceable, easy-to-fit bayonet nozzles with filters. Rust is eliminated thanks to stainless

steel spray bars. The new central articulation joint is maintenance-free, cutting greasing time and operating cost, while preventing neglect for rental customers.

To make daily maintenance efficient and fool-proof, the CTs’ water tanks are embossed with “water only” lettering and have a white cap. This prevents any confusion that might occur with other machines that have a blue cap for the DEF tank.

LiveLink

JCB’s LiveLink telematics system is standard, providing customers with real-time location and geofencing, utilization monitoring and operational data, including when the vibration system is in use.

JCB LiveLink critical machine alerts can preempt unscheduled maintenance and help with maintenance planning. Remote access to JCB LiveLink historical data and maintenance records can further improve machine and fleet management.

Benninghoven has developed the world’s first burner that can be operated only using 100 per cent green hydrogen.

The first customers have produced several thousand tonnes of asphalt with virtually no emissions.

Heat is required for the production of asphalt. In this process, industrial burners heat and dewater the starting

material, such as aggregates and/or reclaimed asphalt, before it is mixed with bitumen.

To make this process as efficient as possible, Benninghoven developed a new generation of burners that includes the control and drying system alongside the burner itself. With this system, up to four separate burners can be operated at

the same time. This flexible approach to usage increases the cost-effectiveness of the overall facility, as its owner can always use the best-available energy sources.

Hydrogen burner

The hydrogen burner from Benninghoven is supplied with an intelligent control system that ensures the carefully coordinated hardware and software solution can maximize process efficiency during asphalt production. This includes control of the feed systems, the pressure control section, drying section with burner and burner control. Switching between fuels or combinations of multiple fuels is done on the fly, meaning that no shutdown or downtime is required and with only minimal temperature fluctuations in the process.

Emissions, especially the nitrogen oxides (NOx) produced when using hydrogen as a fuel, are minimal.

Lower noise emissions

Alongside the climate-friendly, flexible use of a choice of fuels, the power draw has also been reduced by 20 per cent while keeping the feed capacity constant. Heat transfer efficiency has been significantly improved by maximizing the use of the burner space, and providing

a burner control and geometry that ensures optimum flame production for each fuel.

Another significant benefit for plant operators — especially in urban environments — is the 5 dB reduction in noise emissions.

New or retrofit

Green hydrogen is currently the most sustainable fuel available. It produces zero greenhouse gases and is suitable for the heating process thanks to its high energy density. In many cases, facility operators looking to start using hydrogen as a fuel experience difficulty due to current limitations in infrastructure.

When facing this challenge, they can count on support from asphalt mixing plant specialist Benninghoven and its network.

The burner technologies from Benninghoven can be used to equip both new facilities and existing asphalt mixing plants, while retrofit solutions can also be deployed in plants from other manufacturers. This gives every plant operator the chance to upgrade to the latest technologies at any time — an important aspect for ensuring economic, sustainable asphalt production and long-term plant operations.

•

Isuzu AR-4HK1X F4 turbocharged diesel engine with design improvements to increase durability, performance, serviceability, and operator comfort from the previous model with superior fuel efficiency.

•

Dynamic stability control, payload, height and depth alarm and a digital level, are all standard equipment on the Premium 2 20 X4S machine.

•

WAVES (Wide-Angle Visual Enhancement System) with 270° birds-eye view standard, therefore improving site.

•

The newly designed spacious cab offers unprecedented ergonomics and comfort. A high-back seat with air, tilt, and heat features is standard. Adjustable pivoting armrests, headrests, seat height, and lumbar support provide operators comfort on long workdays. 10” machine monitor enchanes operator experience.

RemoteCARE® comes standard with a new dualband modem to improve RemoteCARE communication and functionality with greater range and real-time data capabilities - providing 24/7 remote monitoring with zero subscription charges or fees. Your LINK-BELT Excavators Dealer has all the details!

ALBERTA

Equipment Sales & Service Ltd.

BRITISH COLUMBIA

Inland Truck & Equipment

Castlegar, BC 250-365-2807

Cranbrook, BC 250-426-6205

Fort St. John, BC 250-785-6105

Kamloops, BC 250-374-4406

Langley, BC 604-607-8555

Nanaimo, BC 250-758-5288

Penticton, BC 250-492-3939

Prince George, BC 250-562-8171

Quesnel, BC 250-992-7256

Terrace, BC 250-635-5122

Vernon, BC 250-545-4424

Williams Lake, BC 250-392-7101 inland-group.com

NEW BRUNSWICK

Paul Equipment

Balmoral (506) 826-3289 paulequipment.ca

ONTARIO

Itec 2000

Rosslyn (888) 574-8530

Thunder Bay (888) 574-8530

Timmins (705) 267-0223 itec2000.com

McDowell B Equipment Ltd.

Barrie (416) 770-7706 bmcdowell.com

Stratton Equipment Sales & Service

Stratton (807) 483-7777 strattonequipment.com

Top

Lift Enterprises Inc.

Bolton (905) 857-5200

toplift.com

QUEBEC

Équipement JYL Inc. Chicoutimi (418) 698-6656 equipementjyl.com

Micanic

St-Aug-D-Desm (418) 878-2241 micanic.com

Lift Enterprises Inc. St-Laurent (514) 335-2953

Sherbrooke (819) 612-5438 toplift.com

YUKON TERRITORY

Inland Truck & Equipment Whitehorse, YT 867-668-2127 inland-group.com

Ammann’s new ARX 10.1

StV light tandem roller is gasoline-powered and features side-free drums that allow compaction on the tight jobsites.

The tandem roller utilizes the 21-hp Honda GX630 gasoline engine, which reduces ownership costs.

The engine is more compact than its diesel counterpart. This smaller size enables positioning that allows cooling from all sides, helping the machine to perform in hot ambient temperatures.

Beyond size, gasoline is generally less expensive, so there is likely a cost advantage with every filling of the tank. As well, there is no need for a diesel particulate filter (DPF) and the cost and has-

sle that go with it.

Maintenance of a gasoline engine is less costly than maintenance of a diesel engine, and the fuel is often more convenient for smaller construction companies and rental customers.

The Ammann ARX10.1 StV is the only machine on the market with unique drum consoles installed from a single side. This innovation is known as “side-free drums.”

The drums are support-free on the operator’s right side. This allows compaction work on the tightest of jobsites. The drum working widths are 90 cm and are installed in-line.

The hydraulic system is the core of the powertrain structure. Both drums are

equipped with drive motors that bring exceptional traction, gradeability and speed.

The motors are equipped with a negative parking brake mechanism that ensures secure parking when the engine is switched off.

The front drum is equipped with a vibratory system capable of delivering 16.4 kN at 76 Hz of compaction power, which is sufficient for a wide range of jobsites. The rear drum is static and has no vibratory unit.

The pressurized water sprinkling system has a tank capacity of 110 litres.

An interval water flow regulation mechanism, controlled by the operator, ensures optimal water flow and extends sprinkling time.

A two-stage filtration sys-

tem is easy to reach and can be cleaned without draining the tank.

The operator platform is isolated from vibration and equipped with a comfortable seat. All operational elements are conveniently located on the main dashboard and can be easily reached.

A multi-functional dashboard display monitors key operating functions. The ARX 10.1 StV is available with a mechanical drive lever that is directly connected to the hydraulic drive pump. This solution brings simple and safe machine drive control.

Steps are conveniently located on both sides of the rear frame to provide easy access to the operation sta-

Trimble has announced the availability of the Trimble Roadworks Paving Control Platform for Mills and Cold Planers, which extends the functionality of Trimble’s next-generation, 3D paving control system.

The new version of Trimble’s paving control platform enables smoother, more precise paving surfaces, and extends the functionality to an additional machine type.

Trimble Roadworks for Mills and Cold Planers runs on an Android operating system and enables operators to precisely control cutting depth of the mill or cold planer, according to project design.

The system allows operators to meet demanding specs on complex projects, minimizing over-cutting and creating a smoother surface on airport runways, highways, racetracks and other projects that require optimum smoothness.

The 3D design is displayed to the machine operator showing areas that are on, above or below ideal grade, comparing the actual drum position and slope with the digital design.

The platform automatically guides the milling drum to cut the ideal depth

and slope without string lines or manual adjustments.

“Complex paving projects such as airport runways and heavily travelled highways have some of the tightest specifications in the construction industry,” said Kevin Garcia, General Manager of Civil Specialty Solutions at Trimble.

“Trimble Roadworks for milling and cold planing takes both the guesswork and the re-work out of milling, making it easy for operators to mill precisely to a 3D design elevation. The benefits of this extend throughout the entire paving process, creating less work for pavers, decreasing asphalt usage, and increasing overall surface smoothness.”

The milling and cold planing software features the same user interface as existing Trimble Roadworks applications, with intuitive graphics, natural interactions and gestures, and self-discovery features, shortening training time for operators.

The system is compatible with Trimble Works Manager software, which manages data transfer and tracks construction technology equipment across

jobsites, and with Trimble Business Center software, which is used to create 3D milling plans and comprehensive quality and production reports.

Trimble Roadworks for Mills and Cold Planers is now available for customers around the world through the SiTech distributor channel.

tion. An easy-to-grip handle and a design that places the steps outside of the machine contour helps boost safety and convenience.

The narrow design and the longitudinal engine location allows visibility from the operator station to all directions and edges. This improves compaction properties and safety on jobsites.

The ARX 10.1 StV is designed according to the ECOdrop philosophy, which utilizes advanced engineering to deliver maintenance-free solutions, minimize fluid usage and maximize access to filters.

The roller is equipped with

a maintenance-free steering cylinder and articulation joint that utilizes a spherical ball bearing, which is lifetime greased and protected. The vibratory mechanism is lubricated by grease that also lasts for the life of the product, thereby requiring no maintenance and reducing the risk of damage.

The engine location and a wide-opening hood make daily maintenance points and filters easy to reach.

The location of fluid drainage points speeds periodic maintenance.

The compactor is ideal for use on small repair work in city centres, malls and business areas, cycle paths and other applications. 416-801-6014

• Includes everything from

• 3-year warranty

• Made in Italy.

Rover with IMU & UHF

external antenna and

As Mack Trucks’ first Electric MD models hit the road, the company is expanding manufacturing and charging options for the vehicle

Mack Trucks recently began production of its second battery-electric vehicle (BEV), the Mack MD Electric, and delivered units to several customers, who are using the truck in a variety of applications.

Mack made the announcement during Work Truck Week 2024 at the Indiana Convention Center in Indianapolis.

“We’re thrilled that the Mack MD Electric is in full production and that customers are beginning to take delivery of the trucks,” said Jonathan Randall, President of Mack Trucks North America. “We built on the success of the diesel-powered Mack MD Series to bring an electric vehicle to the medium-duty market to help customers meet their sustainability goals with the same Mack promise of durability and reliability.”

The MD Electric complements its diesel-powered MD Series sibling, but with zero tailpipe emissions.

The MD Electric is the second electric vehicle introduced by Mack Trucks. The first was the Mack LR Electric, which went into production in December 2021. The Mack MD Electric is available like its diesel counterpart in Class 6 and Class 7 ratings. The Class 6 model has a Gross Vehicle Weight Rating (GVWR) of 11,800 kg, and the Class 7 model has a GVWR of 14,970 kg.

The Michigan-based Pronto Freightways is one of the first companies to operate the MD electric. The truck will be used to pickup and deliver palletized cargo dock to dock within a 100-km radius. The MD Electric is the first electric vehicle in Pronto’s fleet.

“We were given the opportunity to participate in the program, and we jumped on it,” said Paul Wozniak, President and CEO of Pronto.

Pronto Freight Ways has 25 diesel-powered Mack MD Series vehicles in its fleet and 25 heavy-duty vehicles in its fleet, all of which are Mack.

The MD Electric’s three-phase Permanent Magnet Synchronous motor and all on-board accessories are powered by Nickel Manganese Cobalt (NMC) Oxide lithium-ion batteries, either in a 150 kWh or 240 kWH configuration. The MD Electric can be charged through AC or DC charging

units. The regenerative braking system helps recapture energy from the multiple stops the vehicle makes each day.

Designed with the heavy-duty quality of its diesel-powered counterparts, the MD Electric is available in 4x2 configurations featuring a sharp wheel cut for enhanced manoeuvrability in tight urban settings.

The MD Series cab design features a short bumper-to-back-of-cab measurement of 2.6 metres, an industry best. Similar to the diesel-powered Mack MD Series, Mack matched the look and styling of the Mack Anthem, Mack’s highway model, as a basis for the MD Electric grille and hood design.

The Mack MD Electric will be supported by Mack dealers, many of which are already Mack Certified Electric Vehicle (EV) dealers.

To help customers investigate e-mobility for Class 6-8 vehicles and the feasibility for their fleets, Mack Trucks has built a mobile off-grid charging system that will be integrated into the body of a Mack MD Electric truck.

The mobile Mack MD Electric charging unit can be used for a limited time by customers who want to test the technology, and by dealers when facilitating electric vehicle demos.

“This system will allow the customer or dealer to charge trucks – whether it’s a demo unit or a multi-unit ride-and-drive event at the dealer – without having charging infrastructure readily available at their site,” said Ryan Saba, Energy Solutions Manager for Mack Trucks.

“Mack hopes that this option will help customers more easily experience the benefits of e-mobility and a more sustainable transportation option.”

The off-grid charging system will consist of a generator powered by renewable propane and 120 kW charger. The system will be mounted on the back of the MD Electric truck transporting it. Mack currently does not have plans to make the truck-charger configuration commercially available in its energy solutions portfolio but can support customers interested in purchasing the truck charger combo through their supplier relationships.

To accommodate increased demand for its MD Series and MD Electric vehicles, Mack Trucks is investing $14.5 million to expand its Roanoke Valley Operations (RVO) manufacturing facility in Virginia.

“Mack is committed to making the industrial and product investments we need to be a North American market leader,” said Stephen Roy, Global President of Mack Trucks. “The expansion of the RVO plant will help us grow in a strategic market segment and support our sustainability goals.”

Virginia Governor Glenn Youngkin announced the $14.5 million investment during an event with state and local officials at RVO. Youngkin approved a $255,000 grant from the Commonwealth’s Opportunity Fund for the project. The project will result in 51 jobs. Roanoke County offered a package of incentives totalling $842,420.

“Mack Trucks’ expansion further strengthens Virginia’s manufacturing industry ecosystem, which is a core focus of the Commonwealth’s economic development strategy,” Youngkin said.

Mack’s investment will go toward equipment, tooling and a 6,690 square metre building expansion, making the facility 32,702 square metres. Construction will begin in April, and the expansion project is expected to be completed in the fourth quarter of 2025.

All Mack medium-duty models are produced at RVO. Mack launched the diesel-powered Mack MD Series in 2020 and launched the Mack MD Electric in March 2023. Adding the new model to the product lineup increased the need for more space at the facility.

“Customer demand for the Mack MD and MD Electric continues to grow beyond our expectations,” Roy said. “This investment and expansion will well-position Mack Trucks for the future.”

The MD and MD Electric meet the needs of trucking applications requiring dry van/ refrigerated, stake/flatbed and dump vocations.

The MD6 model does not require a Commercial Driver’s License (CDL) to operate for non-hazardous payloads.

In an effort to set new industry benchmarks, Palfinger has introduced the PAL Pro 58 mechanics truck and PSC 8600 TEC service crane. Both

of the new machines were unveiled at Work Truck Week in Indianapolis, Indiana. “We are excited to launch