Marmora, Ontario, welcomes a new crawler loader to its landfill operations and dubs it Eve in a nod to Wall-E

This letter is about space construction, and yes, I’m sober

One of my favourite elements of trade shows are concept machines.

I know most of the concepts presented will never actually operate on a real-world jobsite, and some are probably solely on the stand to help draw a crowd, but they all represent a vision from the manufacturer’s research & development teams.

While the exact concept almost certainly will not come to fruition, elements of these R&D projects will become commercially available.

When I started here at Equipment Journal, the idea of electric excavators, robotic surveying dogs and autonomous compact machinery was considered far-fetched. ese ideas were trade show attractions, or, in the case of Boston’s Robotics’ Spot robot dog, the villain in a post-apocalyptic episode of Black Mirror

However, all three have become reality. Now, humanity’s greatest entrepreneurs are beginning to conceptualize building in outer space.

Amazon Founder Jeff Bezos recently predicted millions of people could be living in space by the 2040s.

e inhabitants of the new elite postal code would live alongside environmentally unfriendly heavy industries that will perform better outside the atmosphere. Earth would be reserved for sustaining life.

Bezos’ prediction is in line with Google’s recently launched Project Suncatcher, a research initiative to place data centres in orbit to run large-scale machine-learning workloads. e satellites would use solar energy and avoid Earth’s shortfalls in terms of land and cooling requirements.

As well, Elon Musk’s SpaceX is developing large infrastructure to build giant spacecraft in orbit and eventually construct buildings on Mars, including habitats and industrial systems.

Musk plans to launch first unmanned starship to Mars by the end of next year, with human missions to follow by 2030.

e plan to inhabit space goes beyond the United States’ most well-known billionaires.

NASA’s Artemis program is developing technologies for lunar surface construction, including 3D-printing structures using Moon dust. Robotic 3D-printing systems are in development to build habitats, landing pads and roads on the Moon.

The European Space Agency, Axiom Space, Orbital Assembly Corporation and Northrop Grumman also

all have plans in motion to build in space.

ese projects will certainly approach building from a far different angle than current Earth-based methods, harnessing robotics and arti cial intelligence. Whether or not these plans ever emerge as they are envisioned is a gamble, but I imagine the technology that arises from these ideas will be out of this world.

My

ARROWHEAD PAVING INC.: THE ROAD TO SUCCESS IS PAVED WITH BOBCAT.

For nearly 50 years, Arrowhead Paving Inc. has been a trusted name in Southern Ontario’s paving and concrete industry. Established in 1976, the company has evolved from a small residential outfit into a leading commercial and infrastructure contractor, powered by dedication, experience, and a strong partnership with Bobcat of Hamilton.

Owner Ted Tuttle purchased Arrowhead in 1999 after years of running his own landscape construction company. “I was using Arrowhead for my landscaping projects back then,” Ted recalls. “When John told me his daughters weren’t going into the business, he said, ‘You should buy it.’ So, I sold my house and bought the company, and I’ve never regretted it.”

Today, Ted and partner Paul Grego leads a thriving operation that’s flipped the script on rrowhead’s beginnings. “We’re now about 90 per cent commercial and 10 per cent residential,” he says. “We’ve gone from driveways and patios to major infrastructure and development work.”

From its Stoney Creek headquarters, Arrowhead’s team handles concrete and asphalt paving projects across Niagara Falls, Brantford, Guelph, Kitchener,

BARRIE

Bobcat of Barrie

705-726-2228 oakenequipment.ca

GREY BRUCE

Bobcat of Grey Bruce 519-372-9100 bobcatoftc.com

PARRY SOUND

Bobcat of Parry Sound Ltd. 705-342-1717 bobcatofparrysound.com

TORONTO WEST

Bobcat of Toronto 416-679-4172 oakenequipment.ca

Bobcat of Brantford 519-752-7900 bobcatofbrantford.com

HAMILTON

Bobcat of Hamilton 905-643-3177 bobcatofhamilton.com

PETERBOROUGH

Cambridge, and the GTA. “We’ll go wherever we need to for our regular clients,” Ted says. “But ideally, we keep it to akville and west tra c’s brutal to the east,” he adds with a laugh.

Ted’s path into construction began early. “In high school, I wasn’t great at playing with other people, so I started cutting grass,” he says. “That little business grew into 150 weekly clients. I was running that while doing my BA at university but eventually switched to Ryerson for landscape architecture.” That transition led him into landscape construction, and later into paving, a trade he describes as “less creative but still very rewarding.” t the heart of rrowhead’s operations is a fleet of Bobcat® machines Ted says are essential to the company’s productivity and success. “We run six Bobcat S770 compact skid-steers, an E50 compact excavator and we use them for everything,” he says. “They’re grading, moving asphalt, breaking out concrete, doing curb and sidewalk removals. On tight sites, they’re even transporting asphalt from the dump trucks to the spreaders. The versatility is incredible.”

Arrowhead’s crew prefers tire models over tracked machines for their primary fleet, as much of their work involves tearing out asphalt. “Tracks don’t last long in that environment,” Ted explains. “But we’re looking at

adding a dedicated track unit this winter just for grading they’re unbeatable for that.”

Ted’s connection to Bobcat goes back decades. “My stepfather was a builder and had a Bobcat in the early ’ s,” he says “ hen I finally bought my own, I went straight to Bobcat. It’s what I learned on, and we’ve never looked back. My crews wouldn’t run anything else. They’re so familiar with the machines that watching them grade is like watching an art form.”

The relationship with Bobcat of Hamilton runs deep. “I’ve known John Quast since he took over the dealership our shops were about a mile apart,” Ted says. “We became friends, and I even travel with him. He’s more than a dealer, he’s a friend. And working with Derek Brooker, sales specialist over the last few years has been fantastic. The service and support we get from Bobcat of Hamilton are second to none.”

Through it all, Bobcat remains a key partner in Arrowhead’s continued success. “We rely on our machines every day,” Ted says. “They’re dependable, tough, and e cient, e actly what you need in this business Between the quality of the equipment and the support we get from Bobcat of Hamilton, we couldn’t ask for a better partnership.”

CASSELMAN

Bobcat of Stratford 519-393-6040 bobcatofstratford.ca BRANTFORD

Bobcat of Ottawa Valley 613-764-2033 bobcatov.com

KITCHENER

Bobcat of Tri-Cities Ltd. 1-866-214-3939 bobcatoftc.com

STRATFORD

Bobcat of Ottawa Valley 613-932-2034 bobcatov.com

LONDON

Bobcat of London 519-455-4900 bobcatoflondon.ca

Stratton Equipment 807-483-5505 strattonequipment.com

Bobcat of Durham East Ltd. 905-404-9990 bobcatofdurhameast.com

MUSKOKA

Bobcat of Muskoka 249-390-7000 oakenequipment.ca

SUDBURY

Bobcat of Peterborough 705-748-9119 bobcatofpeterborough.com COURTICE

THUNDER BAY

Equipment World Inc. 807-623-9561 bobcat-tbay.com

SAULT STE. MARIE

Bobcat of Sault Ste. Marie 705-949-7379 bobcat-ssm.com

Bobcat of Windsor 519-737-0120 oakenequipment.ca

McDowell B Equipment Ltd. 705-566-8190 bmcdowell.com

WYOMING

Advantage Farm Equipment Ltd. 519-845-3346 advantage-equip.com

FRANKFORD

John’s Equipment 613-398-6522 johnsequipmentsales.com

OTTAWA

Bobcat of Ottawa Valley 613-831-5166 bobcatov.com

TORONTO EAST

Bobcat of Toronto 416-679-4171 oakenequipment.ca

Terex Corporation and Rev Group have entered into a definitive agreement to merge via a stock and cash transaction.

The merger will create a diversified company that manufactures equipment for the emergency, waste, utilities, environmental and materials processing industries.

Alongside news of the merger, Terex also announced it plans to exit its aerials segment, which includes Genie. The company will consider a sale or spinoff of the aerials business.

Headquartered in Brookfield, Wisconsin, Rev Group is a manufacturer of recreational and specialty vehicles, including fire apparatus, ambulances, buses and RVs, along with related parts and services. The

company has more than 210,000 vehicles in service today.

The merger with Terex will create a substantial manufacturing footprint in the United States.

When the deal is finalized, Terex CEO, Simon Meester, will serve as President and Chief Executive Officer.

"This transaction represents a transformative step for both companies. By combining our complementary portfolios and leveraging our collective strengths, we are creating a large-scale, diversified industrial leader well-positioned to capitalize on long-term secular growth trends,” Meester said.

“The transaction will unlock significant value for both Terex and Rev Group shareholders and creates

exciting opportunities for our team members and customers by strengthening our ability to invest in the combined business, innovate and deliver quality solutions."

The agreement was unanimously approved by the boards of directors of both companies, Rev Group shareholders will receive, for each Rev Group share, 0.9809 of a share of the combined company and $8.71 in cash ($425 million in total). Upon closing, Terex shareholders will own about 58 per cent, while Rev Group shareholders will own about 42 per cent of the combined company's fully diluted shares on a pro forma basis. Following the closing of the deal, the combined com -

pany will continue to be traded on the NYSE under the symbol TEX. Both parties expect to pay dividends in the ordinary course of business through closing.

The combined company is expected to have about $7.8 billion in net sales.

"Joining forces with Terex is a natural evolution of our strategy of building a stronger, more profitable and scaled company by bringing together two highly respected organizations with shared values and a commitment to innovation, operational excellence, and customer success,” said Mark Skonieczny, CEO of Rev Group.

“We are beginning an exciting new chapter that will generate meaningful value for our shareholders, customers and employees."

Komatsu has announced it will double the size of its Canadian parts distribution footprint by transforming its Edmonton, Alberta, parts depot into a full-service distribution centre. This expansion marks a significant step in Komatsu’s ongoing effort to enhance service levels, reduce lead times and better support dealers and customers across Canada.

The new facility will span about 135,000 square feet, doubling the capacity of Komatsu’s existing warehouse.

The upgrade enables Komatsu to store and distribute parts directly from Edmonton, significantly improving delivery times, including 24-hour delivery capabilities to its dealers in western Canada.

“Our customers rely on Komatsu for uptime and productivity, and this in -

vestment ensures we can meet those expectations faster and more efficiently than ever,” said Danny Murtagh, Vice President of Parts and Infrastructure.

“By bringing parts closer to where our customers operate, we’re cutting lead times, boosting availability and improving customer service.”

By transforming into a fully integrated parts distribution hub, the Ed -

monton facility will serve as a cornerstone of Komatsu’s North American logistics network and streamline supply routes from Komatsu’s global manufacturing hubs in Japan and Indonesia.

Key features of the new facility include:

· Expanded capacity for faster-moving and strategic inventory.

· Advanced system integration with Komatsu’s global planning and

warehouse management system (WMS) platforms.

· Improved warehouse efciency through updated layouts, automation and new equipment.

· Enhanced workforce capacity, with plans to add additional sta and technological support.

With the country’s mining, forestry and construction sectors continuing to grow, the upgraded fa -

cility ensures Komatsu is well-positioned to support increased demand while maintaining its industry-leading service standards.

“Canada is a core market for Komatsu,” said Rod Bull, CEO of Komatsu North America. “This expansion is not just about space, it’s about service, and making sure our dealers and customers have what they need, when they need it.”

Nors and Volvo CE have donated an electric compact wheel loader to Habitat for Humanity GTA, the first donation in a new community initiative.

On Oct. 30, representatives from Nors and Volvo Construction Equipment handed over the keys to the L25 Electric compact wheel loader to Habitat for Humanity GTA at the dealership’s Mississauga location.

“At Volvo, we aspire to build the world that we want to live in collectively. at includes partnering with our dealers across North America and the world, but also with local organizations such as Habitat for Humanity,” said Agako Nouch, Head of Sales Development for Volvo CE North America.

The idea to donate the machine was born after Volvo CE team members volunteered at a Habitat for Humanity jobsite.

“At the end of the day, we saw the output of our work. So, it wasn't just team building, but it was something that had real output for the organization,” Nouch said.

New community initiative

e L25 donation is also the rst machine donated under Nors’ new Compact Solutions, Community Impact campaign, which aims to assist nonprofit organizations with sustainable construction equipment.

e machine is the rst of three donations Nors plans to make this year.

“We’re proud to partner with Volvo to o er equipment that reduces emissions and noise on jobsites, helping build a better world for future generations,” said Paul George, Regional Vice President for Ontario at Nors.

“ rough this initiative, we aim to raise awareness and accelerate the adoption of electric mobility solutions across Canada, promoting both innovation and accessibility in this new era of construction.”

For the second and third donations, Canadians are invited to submit nominations and share input on nonpro t organizations or municipalities that could bene t from the donation of a Volvo CE compact electric machine. is initiative is a public consultation, not a contest.

e selected recipients will be determined by a review panel from Nors and Volvo CE, based on eligibility and community impact. Public input will help inform the decision, but Nors retains sole discretion in selecting the recipient organizations in its eastern and western territories.

Nominations were received until Nov. 22 on the campaign website, and input will be gathered from Nov. 25 through Dec. 10.

e two recipients will be announced Dec. 16.

To nominate an organization for the campaign, visit construction-equipment-st. nors.com/green-powerstrong-performance/.

The L25 at work with Habitat for Humanity Habitat for Humanity GTA was founded in 1988 and has built more than 600 homes for families in the Greater Toronto Area.

“ is year is our busiest year ever,” said Ene Underwood, CEO, Habitat for Humanity GTA. “We struggle, of course, as a nonpro t, to have the equipment we need.”

The organization’s fleet includes a 22-year-old telehandler, a 20-year-old aerial lift and a 15-year-old forklift.

“So, when you think about it, it means we started using our equipment when Trey Yesavage was in diapers,” Underwood said. “So, this is a really big deal. It’s a really exciting day for us.”

e loader’s rst job will be helping Habitat for Humanity at its May eld Build Factory where it will assist in creating prefabricated walls.

“We've never actually had a wheel loader before so we’re very excited,” JC Manrique, Site Superintendent for Habitat for Humanity GTA said, noting the L25 is also Habitat’s first electric machine.

From the prefab factory, the loader will head to one of Habitat’s jobsites.

“I'll use it there for everything from pushing snow around to helping clean up the roads to moving material around on site,” Manrique said.

The L25 is a 5-tonne machine with a 0.9 cubic metre bucket capacity and a 3,350-kg tipping load.

Equipped with a 40 kWh battery, the loader can operate up to 8 hours. The loader will help ease repair and maintenance for Habitat for Humanity, as electric equipment requires at least 30 per cent less parts requirements compared to diesel machines.

“They're absolutely quiet. There are no emissions. So, when you think about the kind of work that Habitat for Humanity does, which is a lot of construction in urban areas, this is going to be an extremely good application for it,” Nouch said.

5-YEAR/5,000 HOUR Full Machine Warranty

• With new features on all models, such as custom flow balance, customizable joystick function buttons, new work modes and Trimble-Ready components, the new X4S delivers improved e ciency and up to 5 per cent improved cycle times.

• Yanmar - Tier 4, diesel engine. Superior fuel e ciencyup to 19% better fuel consumption over it’s predecessor.

• Cab is 9% bigger than previous generation, designed for shift-long comfort including new air ride seat, and front sun visor.

Equipment Sales & Service Ltd.

Edmonton (780) 440-4010 essltd.com

Inland Truck & Equipment

Campbell River, BC 250-287-8878

Castlegar, BC 250-365-2807

Cranbrook, BC 250-426-6205

Fort St. John, BC 250-785-6105

Kamloops, BC 250-374-4406

Langley, BC 604-607-8555

Nanaimo, BC 250-758-5288

Penticton, BC 250-492-3939

Prince George, BC 250-562-8171

Quesnel, BC 250-992-7256

Terrace, BC 250-635-5122

Vernon, BC 250-545-4424

Williams Lake, BC 250-392-7101 inland-group.ca

Itec 2000

Rosslyn (888) 574-8530

Thunder Bay (888) 574-8530

Timmins (705) 267-0223 itec2000.com

McDowell B Equipment Ltd.

Sudbury (705) 566-8190

Barrie (416) 770-7706 bmcdowell.com

Stratton Equipment Sales & Service

Stratton (807) 483-7777 strattonequipment.com

Terapro Rental

Vars (613) 443-3300

Stittsville (613) 836-0654 terapro.ca

Top Lift Enterprises Inc.

Stoney Creek (905) 662-4137

Bolton (905) 857-5200 toplift.com

5-YEAR/10,000 HOUR Machine Structure Warranty

• Heavy duty arm option available and additional heavy duty counterweight.

• Equipped with RemoteCARE® (GPS fleet management system) with a new dualband modem with improved range and real-time capabilities -providing 24/7 remote monitoring with zero subcription charges or fees!

• 270° WAVES (Wide-Angle Visual Enhancement System) 3-Camera System, ideal for safety.

• Other extras are LED lights all around and 10” monitor.

Équipement JYL Inc.

Chicoutimi (418) 698-6656 equipementjyl.com

St-Aug-D-Desm (418) 878-2241 micanic.com

Paul Equipment (506) 826-3289 paulequipment.ca

Terapro

Val d’Or (819) 825-4299

Plaisance (819) 718-0945 terapro.ca

Top Lift Enterprises Inc.

St-Laurent (514) 335-2953

Paul Equipment

Balmoral (506) 826-3289 paulequipment.ca

Inland Truck & Equipment

Whitehorse, YT 867-668-2127 inland-group.com

Sherbrooke (819) 612-5438 toplift.com

www.lbxco.com/X4S

The next generation Cat 440 and 450 backhoes are equipped with an advanced hydraulic system, new engine and increased versatility compared to previous machines. Offering more options and advanced machine control, the new models also feature the latest Product Link technology.

e new design aligns the new 440 and 450 backhoes

with the next generation 416 through 430 series models in both engine platform and electronic architecture.

“Having similar platforms throughout the range provides more component commonality and enhanced operating similarity bene ts for customers,” said David Young, Senior Product Consultant at Caterpillar.

“We’ve also integrated Cat

Soft Key and Touchscreen display options, as well as a new pod-mounted joystick option, giving operators more choice over machine control.

On the 450, we updated the design of the four-lever hoe control option. Prior to this update, it was a mechanical linkage design and now has four electronic levers. This new electronic setup also has the ability to set response

and modulation rates for the boom, stick, bucket and swing functions."

e new Cat 440 and 450 models will be available for North American customers beginning in the fourth quarter of 2025.

Performance improvements

e new backhoes feature the Cat C3.6 engine that meets Tier 4 Final and EU Stage V emissions standards with selective catalytic reduction (SCR) technology and a diesel oxidation catalyst (DOC).

Compared to the previous 440 design, the gross power rating increases by more than 9 per cent to 130 hp, while the 450 maintains 145 hp.

e updated models feature a load-sensing piston pump that delivers full hydraulic lifting and digging forces at any engine speed. The variable flow pump automatically adjusts hydraulic power to meet work demands, enhancing operating e ciency. Caterpillar's advanced hydraulic system allows operators to adjust the loader and backhoe auxiliary flow to match attachment speci cations, program the loader bucket kickout and return-to-dig functions and enable parallel lift.

control

Continuing the legacy of advanced operator comfort and ergonomics on previous designs, the new 440 and 450 will still o er adjustable seat-mounted joystick controls. e controls swivel with the operator to perform loader and backhoe functions and enable dual mode operation, which o ers e cient machine repositioning and allows the operator to sit at an angle while controlling the machine to improve visibility.

A new option for the 440 and 450 is a pod-mounted joystick that positions the advanced electronic joysticks on rear pod control towers to give operators a familiar interface. It also includes a dedicated electronic joystick for loader control that integrates a forward/neutral/ reverse (FNR) rocker switch. Along with the standard FNR lever positioned on the steering column, this option gives operators more exibility in control preferences.

Standard for all new backhoe loader canopy configurations, a new soft key display aligns with the interface used on Cat 416 to 430 models to provide a familiar and reliable interface for operators. For all cab con gurations, the 440 and 450 models feature an upgraded Cat touchscreen display, enhanced with the latest intuitive interface to enable machine control customization and allow operators to achieve greater precision. e touchscreen now includes a speedometer on the home display to provide operators with real-time ground speed information.

Loader modulation and response settings on the touchscreen enable the operator to independently adjust modulation for the lift and tilt cylinders, matching machine behaviour to speci c tasks like material handling with forks or other Cat attachments.

For the backhoe’s excavator, hoe modulation and response control allow operators to adjust settings for each hydraulic function to tailor machine performance to preferences and job requirements. A new material handling mode delivers precise, efficient operation by reducing hoe modulation and response speed and synchronizing all hydraulic functions.

Operator training

Also new for cab configurations, a convenient QR code is integrated directly into the touchscreen display, so operators can quickly access Cat Operator Training on their mobile device.

Operator Training’s comprehensive library of instructional videos and guides covers key operating techniques, maintenance best practices and advanced machine features to empower operators to maximize machine performance and longevity. In-Vehicle Health Monitoring (IVHM) provides operators with insight into upcoming service intervals and allows them to view speci c maintenance tasks and access additional information.

With the new 440 and 450 models o ering adjustable auxiliary hydraulic ow, the available Integrated Tool Carrier (IT Coupler) for the loader increases machine utilization and versatility. Available from the factory or as a field-installed kit, the IT Coupler provides a quick connection to a variety of Cat attachments for fast tool changes. Beyond the IT Coupler, customers can select from a variety of mechanical and hydraulic Cat hoe couplers, including dual lock pin grabber couplers and pin lock couplers. The upgraded standard Cat Product Link features an integrated network manager for enhanced connectivity and eet management. Customers can customize machine operating data gathered like fuel usage, scheduled service reminders and fault code alerts, to meet speci c needs for improved eet management.

Hamm is expanding its HC Series with the HC 130i C VA compactor that enables automatic compaction to a target value by working with Smart Compact.

e new 13-tonne model joins the 20 and 25 tonne HC 200i C VA and HC 250i C VA in the roster.

The HC 130i C VA compactor is equipped with the new variable amplitude (VA) drum that enables automatic compaction depending on the ground conditions and machine capacity. The VA technology ensures homogeneous compaction and increases cost-e ectiveness by reducing the number of double passes and lowering diesel consumption. The machine meets exhaust emission standard EU Stage V and EPA Tier 4 Final.

In day-to-day work, drivers can choose between an

automatic and a manual mode. In automatic mode, the amplitude is regulated by the machine control system. In manual mode, ve xed amplitudes are available. Before compaction, the target compaction value in MN per square metre can be speci ed, based on typical load-bearing capacity values. e basis for the automatic regulation of the compaction forces is the Smart Compaction Value (SCV), which is also now determined by Hamm and is continuously and precisely recorded independently of influencing factors such as driving speed, frequency or direction of travel.

The new VA compactors o er numerous advantages for operators and construction companies alike.

Messe München has announced the inaugural bauma Saudi Arabia, scheduled for April 2027 in Riyadh.

e o shoot of the world’s leading trade fair for construction machinery and mining will be launched in cooperation with dmg events as exhibition organizer and local project partner. Both companies have signed a Memorandum of Understanding (MoU) to develop the trade show.

Saudi Arabia is one of the most dynamic growth markets in the Middle East. Its construction sector alone is expected to reach a volume of around €130 billion by 2030. As the country relies heavily on imported goods, this creates ideal conditions for bauma and its clientele.

“ e economic momentum in Saudi Arabia is tremendous. With bauma Saudi Arabia, we are becoming part of it, showcasing innovations and technologies for our customers and driving investment. At the same time, we are strengthening our international presence and securing Munich’s position as a trade fair location,” said Messe München CEOs Stefan Rummel and Dr. Reinhard Pfei er in a joint statement.

As the world’s leading platform for machinery, technologies and services in the construction and mining sectors, bauma connects international suppliers with investors and decision-makers from business, politics and academia.

e partnership between Messe München and dmg events offers numerous

Automatic adjustment of the amplitudes not only ensures homogeneous compaction but also e ectively prevents over-compaction and particle crushing at the same time. These features make the new VA compactors a suitable choice, even for less experienced operators.

As well, the cost-effectiveness of construction projects is improved by the reduced number of double passes, which leads to lower diesel consumption and less mechanical stress on

machines. Furthermore,

passes translates into a reduction of carbon dioxide emissions. e machine control system reliably prevents jump operation, contributing to a longer service life of the ma-

advantages: dmg events is a strong local partner with expertise in planning and executing trade shows in the region, Messe München is one of the most experienced global trade fair organizers, with a strong international network and industry expertise in the eld of construction and mining equipment trade shows.

“With over 40 years of the Big 5 championing the Middle East construction market in Dubai and 15 years of Big 5 Construct Saudi shining a spotlight on the burgeoning Saudi Arabian market, we are pleased to enter into another exciting chapter with Messe München and bauma in Saudi Arabia," said Matt Denton, President of dmg events.

In January 2026, Saudi Arabia will host IFAT, the world’s leading trade fair for environmental technologies. bauma will be Messe München’s second proprietary event in the region, scheduled to take place in April 2027 at the Riyadh Front Exhibition & Conference Center.

Messe München also organizes bauma China in Shanghai and bauma ConExpo India in Greater Noida near Delhi.

In March 2017, the bauma Network was expanded through a licensing agreement with SOBRATEMA (Brazilian Association of Technology for Construction and Mining) to include the M&T EXPO in Brazil. bauma in Munich remains the largest trade fair in the world in terms of exhibition space.

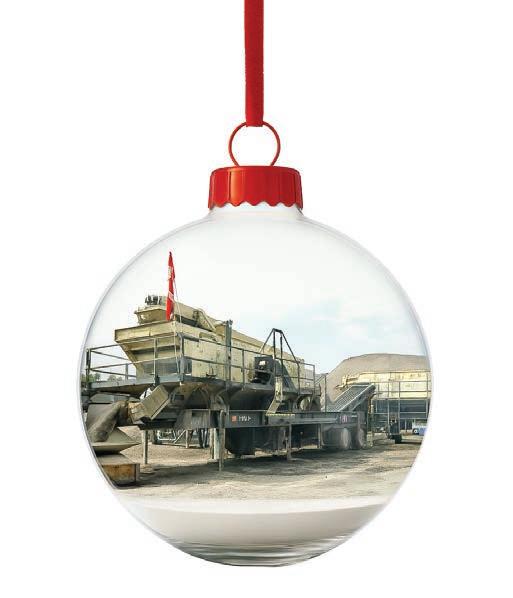

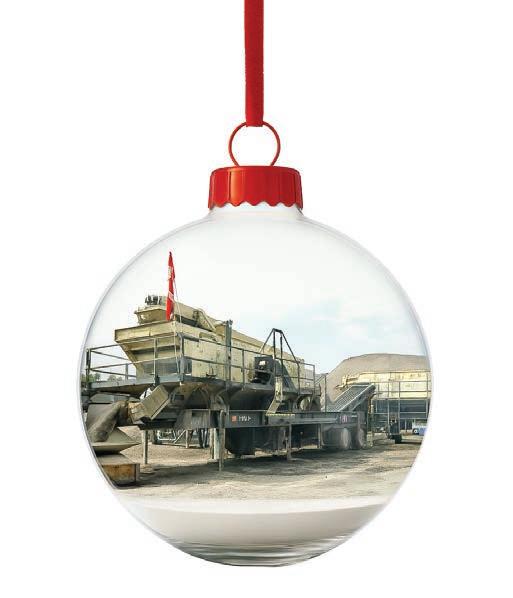

With a new 655K on the job and a Pixar-inspired name, Marmora aims to keep its landfill cleaner, friendlier and running smoothly

The purchase of a new crawler loader is helping the Ontario Village of Marmora manage its landfill as well as channel a Pixar movie classic.

In September, Marmora purchased a John Deere 655K crawler loader from Brandt to work alongside its Caterpillar 816F Series 2 compactor at the landfill.

The machine arrived with everything the site needed, except a personalized name.

Acting Landfill Manager Brandon Abraham, a father of four daughters, is wellversed in the world of Pixar movies. When deciding on a quick nickname for the compactor to log the municipal equipment’s fuel usage, he turned to one of his family’s favourite Pixar productions: Wall-E.

“A lot of places now have contests to name snowplows and other municipal machinery. We thought,

why not name the landfill machinery, too?” Abraham said, who operates the track loader for the village. “We're trying to make the landfill a nicer place for residents to visit, even if they're visiting to drop off their trash.”

The film Wall-E is about a lonely trash-compacting robot, with its own personality, who exists on a ruined Earth. Wall-E meets a sleek probe robot named Eve, and together they help humanity return home and rebuild their planet.

“When we got the new crawler loader, Eve seemed like the logical choice for a name. It's been well received in the community, too,” Abraham said.

The Marmora Landfill is a 11.71-hectare site with 4.6 hectares approved for landfilling. The site is licensed to accept domestic and commercial non-hazardous solid industrial and agricultural waste.

The new crawler loader is tasked with spreading and moving cover to the tipping face as well as loading construction waste bins.

“I also use it to smooth out and compact the areas where residents drive and walk to keep the mud and muck to a minimum. I want to keep the landfill as clean, dry and accessible as possible,” Abraham said.

The 655K crawler loader

The 655K was purchased to replace the municipality’s 2011 crawler loader, which has reached the end of its lifespan. The aging machine required constant repairs that forced the municipality to postpone work as the village waited for parts.

“Breakdowns were becoming more frequent, and repairs were becoming more expensive for a machine that had reached the end of its useful life,” said

Kayla McLean, Marmora’s

Manager of Environmental Services.

John Deere introduced the 18-tonne 655K crawler loader in late 2019, which included increased productivity and uptime, as well as lower daily operating costs compared to its predecessor.

Featuring a certified Final Tier 4 John Deere PVS 6.8-litre engine, the 655K uses the building-block approach based on a solid foundation of John Deere engines. Its net power has increased to 155 hp compared to its predecessor, and Deere equipped the loader with a hydrostatic transmission. The transmission provides customers with infinite speed control, power management, live power turns, counter rotation while staying in gear and dynamic braking. As well, Total Machine Control allows customized machine response that can be

tailored to meet the needs of individual operators.

Hydrostatic transmission control options give operators the ability to choose between multiple transmission control settings — speed-in-grip and a V-pattern control with foot pedal steering.

Inside the cab, on-board hydrostatic and hydraulic pressure sensors make it quick and easy to read pressures in both the hydrostatic and hydraulic systems without the need for external gauges.

The 655K crawler loader is also equipped with eco mode, delivering up to 20 per cent less fuel consumption without loss in productivity. Another key fuel-saving feature, auto idle, automatically lowers engine speed when the machine is not moving and no functions are being activated. An adjustable timer can be set in the monitor — and coupled with auto shutdown — to lower fuel costs for customers and save warranty hours.

“With operating and fuel costs being so expensive, the eco mode and auto idle are features we look forward to using,” McLean said.

While the 655K met Marmora’s power requirements, the machine also checked several other boxes needed to meet the landfill’s needs, including:

· Glow plugs, block heater and dual batteries

· Automatic reversing engine fan

· Rotary ejector engine air precleaner

· Final drive trash guards

· A 2.4-yard general purpose bucket

· 55-cm track pads with extended life track bushings

From a comfort perspective, the village required a loader with in-cab features such as heat, air conditioning, rear-view camera, tinted safety glass, LED work lights and an adjustable air suspension seat.

“There were a lot of features we liked. It’s a versatile piece of equipment,” McLean said.

“Brandt has been a great company to deal with. Their service team has been fantastic with any questions we have had. They came onsite and made sure we felt comfortable with the new equipment and went over all the features with us so we could get the max potential from the new machine.”

From an operator’s perspective, Abraham explained the 655K’s controls are a welcome improvement.

“We went with the joystick controls, so all controls are done with your hands instead of foot control steering. This allows for quick understanding of the controls and ease of operation,” he said.

The 655K quickly helped improve efficiency at the landfill, thanks to features like Return to Dig, which has helped simplify tasks like top skimming. Deere’s Return to Dig feature automatically resets the bucket to a preset position for a new digging cycle, which increases efficiency by reducing operator effort and guesswork.

“There's simply no comparison between the new machine and the old one,” Abraham said. “It's night and day in terms of convenience, ease of access, adaptiveness and intuitive controls. It's also a lot of fun to operate.”

When you are running an equipment rental yard, there’s always pressure to reduce downtime and improve operational eciency. Sometimes, this means implementing sweeping changes. More often, the devil is in the details.

As an example, treating attachments as more than an afterthought will have a positive impact. Here are four ways to run your yard smarter by paying attention to how you manage attachments, including storage, safety and selection.

Prioritize proper storage

Are attachments cluttering up your yard? In your computer system, inventory can look

neatly organized. But out in the real world, it might be a mess with buckets, forks and augers everywhere.

Your operations will be more efficient when you add storage solutions. With the right racks in place, it is easy to put your hand on any attachment at a moment’s notice.

The impact:

· Increase available space

· Ful ll orders faster

· Reduce clutter

· Boost storage capacity

· Decrease accident risks

· Make maintenance easier

· Improve inventory visibility

Display attachments prominently in your yard so contractors become aware of all the additional options available. Better visibility can lead to increased demand since attachments make it possible for crews to use the same piece of equipment for multiple tasks on the job site.

Stock attachments that improve utilization Trash hoppers, grapples, brush cutters and brooms are all helpful attachments to have on hand for customers. Here are additional popular attachments that drive revenue for equipment rental companies: Buckets: Buckets are the backbone of jobsite versatility. Built for high wear and

easy attachment, they turn a skid steer or telehandler into a do-it-all tool for digging, lifting, grading and hauling. With rugged construction and universal compatibility, rental customers can use the same machine across multiple trades and project phases —keeping equipment out longer and increasing utilization.

Forks: Whether it’s lifting pallets, loading materials or staging supplies, forks help machines move from site prep to material handling with ease. Quick-switch fork attachments reduce machine downtime and eliminate the need to rent specialized

Continued on Page A15

Continued from Page A14 - For rental yards, attachments shouldn’t be an afterthought

forklifts, allowing customers to squeeze more tasks out of a single rental.

Truss and jib booms: Perfect for lifting heavy or bulky loads, booms increase the vertical reach and precision of telehandlers and cranes. By transforming a telehandler into a light-duty crane, rental branches expand machine capabilities without expanding their eet, reducing idle time and boosting ROI.

Concrete hoppers: Hoppers let crews pour concrete exactly where they need it without a separate pump truck. Mounted to telehandlers, these attachments are a game-changer for small pours and hard-to-reach spots—helping your customers complete concrete work faster while keeping machines busy.

Augers: From fencing to footings, augers add drilling power that can handle everything from hard rock to frozen ground. These attachments allow crews to handle earthwork tasks e ciently with equipment they already have rented, increasing the value of every hour on the job.

e impact is fewer idle machines, more rental days per asset and happier customers. Having the right attachments on hand greatly improves the odds that you’ll land a rental deal where the customer is requesting a speci c attachment with the equipment.

Built-in safety lowers liability

Nothing slows down work and hurts morale more than a safety accident, whether it happens on your rental yard or a customer’s job site. Here’s what to prioritize when selecting attachments to reduce risks:

· Falls from a height are a common cause of fatalities on job sites. OSHA compliance should be built into the attachments — especially work platforms, safety cages and rigging racks.

· Safety isn’t just about how attachments are used. It’s also about how much safety is engineered into the product. Check for design features like load-tested forks, headache racks, reinforced buckets and easy visibility of key parts for daily inspections.

e impact is fewer safety incidents, easier to train customers on proper use and more confident shop teams during handling.

Invest in durability

This may seem like a no-brainer, but rented attachments must be designed to take a real beating. You’ve seen what happens to equipment that comes back to the yard after a job! Here are some signs that an attachment will stand up to challenging conditions. Avoid attachments where corners have been cut to deliver a cheaper product. e service life will be shorter, and the warranty may not o er su cient coverage for problems with craftsmanship or materials.

You want to ensure maximum ROI and end up with an attachment you can condently sell when it’s time in rotation at your yard is nished.

Powder-coated finishes and reinforced stress points are quality details to notice. Protecting the surface and the key functions of an attachment means it will be less susceptible to

Ditch Witch has announced its parent company, The Toro Company, plans to acquire the Calgary-based Tornado Infrastructure Equipment, a manufacturer of vacuum excavation trucks and infrastructure equipment solutions. While the acquisition is subject to regulatory approvals, the deal will help build on Ditch Witch’s position in underground construction.

In 2022, Ditch Witch collaborated with Tornado Infrastructure Equipment to co-develop an exclusive line of Ditch Witch-branded hydrovac trucks.

Based in Calgary, Alberta, Tornado Infrastructure Equipment is recognized for its innovation in delivering

corrosion and damage in challenging environments. ese features extend product life and lower total cost of ownership.

Attachments should be designed and improved based on feedback from real rental customers. Look for a supplier who continuously improves their products.

Making changes in your attachment inventory management adds up to better utilization, more profitable rentals and a more efficient yard. Start with a review of your current inventory to determine what to stock and how to store it.

powerful and high capacity hydrovac solutions.

Designed for safe excavation around utility lines and other sensitive infrastructure, Tornado’s tech uses high-pressure water or air alongside vacuum systems, providing contractors with solutions that reduce risk while maximizing e ciency on urban and complex projects. Since the initial manufacturing agreement, Tornado’s relationship with Ditch Witch focused on the Warlock Series, including the W12 and W8. These models have become known for their digging power, improved payload capacity and ability to tackle demanding projects.

Jesse Lariviere, a technician with Equipment Sales and Service (ESS) in Edmonton, Alberta, has placed rst in the 2025 Global Skills Contest.

In early November, Sumitomo Construction Machinery (SCM) hosted the competition in Chiba, Japan.

e event is held every two years and brings together top service technicians from around the world to showcase their technical expertise and dedication to safety.

In preparation for the event, Link-Belt Excavators Training Manager Grant Kirk worked closely with LBX dealers to identify and select the technician who would represent LBX and North America at this prestigious event.

After a thorough evaluation, Lariviere was selected for the opportunity to compete.

“Jesse is a shop technician with 15 years of service. He was highly motivated and driven to excel at the 2025 Global Service Skills Contest,” Kirk said. “Over the

last eight months, Jesse and I have met multiple times to reinforce his product knowledge on the 210 X3 excavator. I could not have chosen a more qualified candidate.”

Lariviere’s enthusiasm and determination, supported by Grant’s technical expertise and training experience, proved to be an outstanding partnership. Together, they brought home rst place overall, a tremendous achievement for both LBX and ESS.

is accomplishment reects the dedication of the LBX team and the strong

support of its dealer partner, Equipment Sales and Service.

This year, 11 countries joined the contest in Chiba. eir technician skills were tested in ve areas, including:

· Safety: While not an event on its own, each contestant was monitored closely to ensure that safety was the highest priority in everything they were tasked with.

· Troubleshooting: Machines were faulted in various ways. e technicians were monitored by two judges, who were

evaluated on their ability to follow procedures, accuracy and time.

· Engine repair: Tasked with replacing injectors while adhering to procedures, torque speci cations and time.

· Maintenance proposal: Inspect a machine and determine what issues need to be addressed. This was based on a 162-line-item checklist. e contestants had one hour to complete.

· Written test: A 25-question test relating to all areas of service.

The Alberta-based Apex Structural Design has won a Trimble Construction Innovation Award for Best Tekla/BIM project.

Trimble announced the winners of the annual Trimble Construction Innovation Awards in Las Vegas during the Trimble Dimensions conference.

The awards recognize exceptional use of Trimble technology to improve workflows, processes and project management by North American customers.

Apex is a steel detailing, design and BIM service provider. e company utilized Tekla Structures and Trimble Connect for a complex, hybrid timber-steel project that required balancing innovation with constructability.

The integration allowed full parametric modelling of custom connections, highly detailed custom modelling and a high level of accuracy. e use of technology has enabled real-time decision making and increased collaboration and communication between trades.

The Trimble Construction Innovation Awards invited applicants in five award categories that highlight the bene ts of a wide range of Trimble construction hardware and software solutions, including Connected Construction, Process Transformation,

Most Challenging Project, Workforce Achievement and Best Tekla/BIM Project. Many entries emphasized unique advantages of integrating multiple technologies from Trimble and from other suppliers to improve collaboration, data sharing, e ciency and overall performance. Companies of all sizes and from a wide range of commercial and civil sectors applied for the Trimble Construction Innovation Awards. Improvements in real-time communication, work ow connectivity and time saving were among the common themes highlighted, along with reductions in errors and rework.

Speci c achievements included reducing monthly nancial closes from 12 to ve days, cutting concrete use on a large data centre project by 20 per cent, cutting excavation time in half and saving as many as 10 hours per person, per week using project management software.

Alongside Apex Structural Design, the winners include: Klorman Construction, California (Connected Construction); JE Dunn, Missouri (Connected Construction); Central Builders, Texas (Process Transformation) McCarthy, Missouri (Most Challenging Project); and Dvorak, Maryland (Workforce achievement).

A special installation in honour of JCB’s 80th birthday is drawing a crowd to the manufacturer’s headquarters in Sta ordshire, England. At the lakeside HQ, an eighttonne JCB 3CX Sitemaster backhoe loader is presented in the style of the iconic 1:32 scale models loved by collectors worldwide.

“Scale models of our iconic machines have been a part of the JCB family for as long as I can remember.

e Backhoe in a Box at JCB’s World HQ is an amazing tribute to our market-leading backhoe and is a truly spectacular sight,” said George Bamford, JCB Deputy Chairman.

The special Backhoe in a Box

will be on display beside the JCB lake at Rocester until January. e installation stands about 4.5 metres high by about 7.5 metres wide. e machine and its packaging are also illuminated at night.

The exhibit also marks a milestone in JCB’s history: more than 1 million replica models of its machines have been produced under Tomy’s Britains brand, celebrating nearly 60 years of partnership between the two companies.

Earlier this year, JCB also celebrated the production of its one-millionth full-sized backhoe loader.

“ e most successful Britains JCB

replica model has been the backhoe loader, so Tomy is delighted to see this product in the form of this giant model displayed at the JCB world headquarters in Sta ordshire,” said Tomy Europe MD Mary Wood.

JCB’s 80th anniversary JCB was founded in a 3.6-metre x 4.5-metre garage in Uttoxeter, Staffordshire by Joseph Cyril Bamford CBE on Oct. 23, 1945 – the same day as his son Anthony was born. Bamford rented the garage, which had no electricity, for 30 shillings a week and it was there he made his first product: a farm trailer built largely from wartime scrap. The

trailer sold for £45 at Uttoxeter market. Bamford stayed at the garage for 18 months until the owner asked him to leave because she didn’t approve of his work on Sundays. He then moved down the road to a stable block at Crakemarsh, a few miles north of the town. is year on Oct. 23, his son, now JCB Chairman Lord Anthony Bamford returned to the spot where the company was founded and unveiled a blue heritage plaque where the original garage stood on High Street in Uttoxeter.

“My earliest memory of the business is of me playing in my father’s workshop. Other than my time at

school and my apprenticeship in France with another company, I’ve been around ever since,” Bamford said. “We have developed the business and products along the way enormously. Probably one of the greatest pleasures for me has been in developing products with our formidable team of highly quali ed engineers. As we celebrate JCB’s 80th birthday, it’s wonderful to be back at the spot where it all began and to mark the location with a special blue plaque. I’m delighted that in a small way we can highlight where it all began and re ect on the continuing importance of our home county of Sta ordshire.”

has introduced the LS3600TX low speed shredder, its latest innovation for the recycling industry.

e single-shaft shredder incorporates exclusive innovations from Vermeer to e ciently process contaminated waste streams and safeguard machine components. e Vermeer LS3600TX is specifically designed to excel at processing various materials, including light construction and demolition waste, wood waste with contaminants and municipal solid waste.

The machine is ideal for waste facilities and land clearing operations, as well

as compost, mulch and biofuel producers.

“For 30 years, Vermeer has been a leading manufacturer of high-speed grinders,” said Je Bradley, Vermeer Recycling and Forestry Product Manager.

“During that time, recycling has become a common practice at public and private waste handling facilities and has become another source of revenue for many organizations. To help our customers optimize their processing capabilities and handle a wider range of incoming materials, we have developed the LS3600TX low speed shredder. This

shredder allows companies to process contaminated materials not suited for a tub or horizontal grinder.”

The LS3600TX shredder was engineered with a strong focus on maintenance and accessibility. e engine bay prioritizes ease of maintenance and serviceability, featuring large access doors, multiple ladder points and a spacious service platform. e design allows for quick and e cient maintenance. Additionally, the LS3600TX is equipped with a hydraulically operated access system that provides full exposure to the rotor, comb and belly conveyor,

which helps to streamline maintenance procedures. As well, the belly conveyor can be easily removed without detaching the discharge conveyor, minimizing the invasiveness of service operations.

The LS3600TX shredder is powered by a 456-hp Cat Tier 4 Final engine. It operates at a sound level of 111.9 dbA. e shredder features a tracked undercarriage, which enables operators to reposition and manoeuvrer it around a jobsite. It also comes with a full-function remote control, allowing operators to adjust the feed, access machine data and

diagnose fault codes from the comfort of the feed loader's cab or a safe distance from the shredder.

e LS3600TX is equipped with a 3-metre-long rotor featuring wear-resistant plates for enhanced durability and dual-bolt tips to help maintain clamp load. It utilizes individual bolt-in comb teeth, each with two usable edges, which extends their lifespan. e shredder is built with a fully mechanical driveline designed to optimize horsepower transfer to the rotor.

To safeguard the driveline system against unshreddable objects, the LS3600TX

includes a reversible mechanical transmission with an external torque limiter that will automatically disengage the drive when maximum torque is reached.

An optional cross band magnet is also available for the LS3600TX to enhance its capabilities. This magnet e ectively reduces steel contaminants from the end material, minimizing contamination in the nal product.

The Vermeer LS3600TX joins Vermeer’s line of highspeed tub grinders and horizontal grinders for the waste processing and recycling industries.

Demonstration

Booth W42500, West Hall March 3-7, 2026

Meet the contractor-strong, feature-rich machine that’s ready to carry the load for your crew. The all-new Hyundai HT38 CTL delivers 115 HP, a 3,807-lb. rated operating capacity, and 10’9” of lift height. All backed by Hyundai’s 3-year / 3,000-hour warranty.

Hyundai Canada Dealers

Alberta Chinook Equipment chinookequipment.ca

•Hi-Flow Hydraulics

•Torsion Suspension

•Reversible Fan

•Lift-Arm Float

•Auto Self-Leveling

Nova Scotia

EMSCO Heavy Equipment emsco.ca

British Columbia

Handlers Equipment Ltd. handlersequipment.com

Manitoba

Mazergroup mazergroup.ca

New Brunswick

A.L.P.A. Equipment alpaequipment.com

Newfoundland and Labrador

Reefer Repair Services kenworthnl.com

•Ride Control

Mazergroup mazergroup.ca Introducing Hyundai's HT38 Large Frame CTL

•Rearview (Backup) Camera

•Pressurized Cab with Heat & A/C•Bluetooth + 8” Smart Touch Display

Hurricane Industrial Equipment hurricanelift.com

Ontario

A.M.B. Lift Inc. amblift.com

Bob Mark New Holland bobmark.ca

CIMI Inc. excavatrice.com

Equipements Marquis equipementsnordmax.com

Hood Logging Equipment Canada hoodequipmentcanada.com

RTI Equipment Solutions rtigroup.ca

Quebec Agribiti agritibirh.com

Cimi Inc. excavatrice.com

Hydromec Inc. hydromec.ca

Nordmax, Inc. equipementsnordmax.com

Saskatchewan

EMSCO Heavy Equipment emsco.ca

wonder so many first-time Hyundai users become longtime fans. See the Hyundai difference yourself at your local dealer, or na.hd-hyundaice.com.

ALBERTA

Liftboss JCB

Calgary: 403-301-0041 Edmonton: 780-474-9900 liftboss.ca

BRITISH COLUMBIA

Williams JCB

Surrey: 604-930-3316 williamsjcb.com

NEW BRUNSWICK

A.L.P.A. Equipment

Edmundston : 506-735-4144

Balmoral : 506-826-2717

Fredericton : 506-452-9818 Moncton, N.B. : 506-861-2572 alpaequipment.com

NOVA SCOTIA

A.L.P.A. Equipment

Truro : (902) 897-2717 alpaequipment.com

ONTARIO

For 80 years, JCB has stood for more than machinery – we’ve stood for engineering excellence, relentless innovation and a commitment to reshaping what’s possible on every jobsite. To celebrate 80 years of challenging the status quo, we’re offering this amazing deal, because building better never stops, so neither should you.

Advance Construction Equipment (Division of Equipment Ontario)

Harriston: 519-510-5878

Waterloo: 519-742-5878 advanceequipment.net

D&W Group Inc.

Doughty & Williamson

Jarvis: 519-587-2273

Brant Tractor Burford: 519-449-2500

Redtrac International Vineland: 905-562-4136 dwgroup.ca

Delta JCB

Dunvegan: 613-527-1501

Renfrew: 613-432-4133 Winchester: 613-774-2273 deltapower.ca

ONTARIO

Equipment Ontario

Alliston:705-320-0506 Lindsay: 705-324-6136 Port Perry: 905-982-1500 equipmentontario.com

Fulline JCB

Glencoe: 519-287-2840 fullinefarm.com

John’s Equipment Sales Frankford: 613-398-6522 johnsequipmentsales.com

ONTARIO

North Rock JCB North Bay, Sault Ste. Marie, and Sudbury: 705-897-7369 northrockrentals.com

ReadyQuip Sales & Service Ltd. Timmins: 705-268-7600 readyquip.com

WPE Landscape Equipment - JCB

Hamilton/Halton: 905-628-3055 wpeequipment.ca

Moore JCB Toronto, York & Peel Region: 416-747-1212 moorejcb.com PEI

A.L.P.A. Equipment (506) 861-2572 alpaequipment.com

QUEBEC

A.L.P.A. Equipment

Bas-Saint-Laurent : (506) 735-4144

Gaspésie : (506) 826-2717 alpaequipment.com

Bossé Quebec Inc.

Desmaures: 418-878-2241 Saint-Augustin-debosse-frere.com

Moore JCB

Montreal: 514-333-1212 moorejcb.com

SASKATCHEWAN & MANITOBA

Westcon JCB

Regina: 306-359-7273

Saskatoon: 306-934-3646

Winnipeg: 204-694-5364 westconequip.ca

Liebherr has recorded a 400 per cent increase in demand for electrically powered mobile harbour cranes since 2019

Liebherr, a global supplier of mobile harbour crane technology, is recording rapid gains in the adoption of electric drives for the port machinery.

Liebherr has produced more than 2,000 mobile harbour cranes and about 1,600 machines are in active service across more than 100 countries.

Key regions have embraced electrically driven mobile harbour cranes, which underscores their growing importance and reinforces Liebherr’s role in the industry.

India leads in adoption, followed closely by Türkiye. In Europe, the Netherlands, France and Poland also dem-

onstrate steady demand for e-drive technology, alongside the United States and the United Kingdom.

Between 2019 and 2025, Liebherr recorded a signicant increase of 400 per cent in its electric drive mobile harbour cranes. This substantial increase underlines the clear trend within the industry towards integrating more sustainable technologies in port operations.

“Our clients have bene ted from the integration of electric drives into our product range for over two decades,” said Franz Findel, Product Manager at Liebherr-Rostock GmbH.

“Beyond the considerable reduction in carbon dioxide

emissions and noise levels, e-drives require minimal consumables and feature fewer moving parts, signicantly reducing maintenance demands and associated costs. ese advantages contribute directly to improved overall e ciency and operational reliability, without sacrificing speed or lifting capacity.”

The Liebherr drive system portfolio continues to evolve with the different infrastructural and regulatory conditions across global ports. is means an electric drive is not just an option when building a new crane as existing machines can also

be retrofitted. Cranes that have operated reliably for years can be converted from a diesel to e-drive, supported by Liebherr’s customer service network.

Via e-drive retrofits, port operators are not only responding to evolving circumstances, such as state funding programs or infrastructure expansion in ports, but are also modernizing their equipment to ensure continued successful operation with a focus on e ciency.

Future-ready solutions

During heavy lift operations, cranes often experience idle periods when no load is being moved. Due

to idling periods, opting for an e-powered drive o ers a signi cantly more sustainable solution. While a diesel engine will continue to emit about 24 kg of carbon dioxide per hour even when idling, the e-drive consumes no extra energy during a pause in work.

When powered by renewable energy sources, the environmental bene ts improve, handling operations at the quayside with an electric Liebherr mobile harbour crane can reduce carbon dioxide emissions by up to 100 kg per hour compared to a diesel driven mobile harbour crane.

Alongside environmental advantages, e-drive mobile

harbour cranes also deliver economic and operational bene ts.

Many countries offer attractive subsidies for the adoption of alternative energy technologies, supporting industries in meeting national carbon dioxide reduction targets. As well, electric drives require less maintenance than their diesel counterparts, eliminating the need for oil changes, fluid checks and lter replacements.

A reduction in maintenance not only reduces operating costs but also simpli es service routines, making the e-drive a suitable choice for e cient and responsible port operations today.

LJP Construction, a Quebec-based expert in complex and high-rise formwork, is adding a new Liebherr LTR 1150 telescopic crawler crane to its eet.

LJP Construction has been a Liebherr customer since 2009 and now has about 21 tower cranes, 12 mobile cranes, a crawler crane and other products from the group such as concrete pumps, wheel loaders and telescopic handlers.

e company’s new telescopic crawler crane will enable increased exibility and performance on construction sites.

“We already have an LTR 1060 and we’re very happy

with it. To handle the growing demands, however, the 150-tonne crane is going to be the perfect addition to our fleet,” said Axel Côté, Operations Manager at LJP Construction. “Thanks to impressive load charts, it can carry out a wide range of tasks and yet is compact and exible when it comes to moving around on site. e crane is perfect for our jobs.”

Liebherr introduced the LTR 1150 in 2023. The powerful and exible crane features cost-e ective transport options and impresses with state-of-the-art technological features.

e VarioBase system determines the best possible

lifting capacity in real time, depending on the xed track width and variable rotation angle. is results in signicant lifting capacity bene ts, particularly for large radii and reduced track widths.

“When Liebherr launched the LTR 1150 onto the market, we instantly knew that it would t our eet perfectly,” Côté said. “ e integration of VarioBase technology from the LTM series is a key factor behind our purchase.”

LJP Construction operates on construction sites in the Montreal region. Côté is proud of his company, which now employs more than 400 people and has built an excellent reputation for complex and tall

formwork. Côté explained Liebherr and LJP Construction share a similar business approach.

“Liebherr — like us — is

a family-run rm. We truly believe that Liebherr manufactures the best products in many sectors and we are inspired by the company’s

quality and e ciency,” he said. “What’s more, the personal contact and support from the Liebherr team is incredibly valuable.”

Genie has developed a new secondary guarding system that encourages boom lift operators to utilize fall protection equipment.

Available in two con gurations, Lift Guard Lanyard Alert and Lanyard Alert Advanced provide visual and audible alarms when the fall system lanyard is not attached to an anchor point inside the platform.

The advanced configuration enables function cut-o , which prevents operation until the lanyard is attached. Genie is the only OEM to develop a solution that prevents operation.

“In some markets, such as in the UK, many contractors are requiring a lanyard warning device in order to bring boom lifts onto jobsites. In addition, standards are changing, and we anticipate these devices will soon be included in global industry standards,” said Dominik Damm, Genie’s Director of Product Management, Booms Portfolio.

“Lanyard Alert is similar to automotive seatbelt warnings people are familiar with in their cars, which have been

widely successful in increasing the use of seatbelts by drivers.”

On the standard version, the visual and audible warning will continue but machine functions will not be interrupted. e advanced version will additionally disable machine functions until the lanyard is engaged. If the lanyard is unclipped after operation begins, only ground controls and boomlowering functions will be active.

e anchor point is located to the right of the control box where it takes up no additional space in the platform, and the device is compatible with most carabiner clips.

“Keeping the system simple, cost-effective and easy-to-install was critical for reducing barriers to the adoption of this important reminder to utilize your fall protection harness,” Damm said.

Lanyard Alert or Lanyard Alert Advanced can be installed in less than 15 minutes and no calibration is required.

e Lanyard Alert system can be ordered as a factory- t option or retrofitted to all

Genie boom models manufactured as of 2003.

Li Guard Genie has also introduced Lift Guard Zone Lighting for several models of GS scissor lifts to improve awareness of the perimeter around the machine.

Lift Guard Zone Lighting features red laser lights that create a visual boundary at ground level about 61 cm

from the edge of the chassis.

“Employers are increasingly focused on collision and entrapment avoidance, as well as dropped object protection,” said Bryan Williams, Genie Product Manager. “Providing information to the people working on or around scissor lifts helps increase awareness of their surroundings, potentially reducing the risk of these types of incidents.”

e bright beam is about 15 mm thick and visible in any indoor lighting condition. e light uses a glass lens that will not fade over time, unlike plastic LED lights. is helps operators see the perimeter clearance and signals nearby workers that they may be entering the scissor lift’s work zone. Installation is simple, and both the lights and harness routing are protected by

brackets to prevent damage from falling objects.

“Genie is actively improving and expanding available options and accessories across our product lines. e goal is to help end users be more productive and provide rental companies with tools to increase eet utilization,” Williams said.

Lift Guard Zone Lighting will be available in North America in early 2026.

Terex Corporation has completed its sale of its tower and rough terrain crane businesses to Raimondi Cranes.

Manufacturing operations and facilities in Fontanafredda and Crespellano, Italy, and the Terex North America Cranes service and support operations in Wilmington, North Carolina are included in the acquisition.

e transaction does not include Terex's Franna pick and carry cranes business based in Australia.

"For Terex, this move aligns with our strategic focus on reducing cyclicality and accelerating the company's growth," said Simon Meester, Terex President and Chief Executive O cer.

"At the same time, we believe these Italian cranes businesses will strategically bene t from becoming part of Raimondi, a Milan-based lifting conglomerate that is a leader in the construction and heavy lifting sectors. We thank our cranes team members for their contributions to Terex and the industry, and we wish them great success in the years ahead."

e acquisition expands Raimondi’s offerings in terms of luffing jib cranes and tower cranes, while expanding the company’s scope to include new business lines, such as self-erecting and rough terrain cranes.

The acquisition will see about 250 Terex employees join Raimondi. e deal is part of a wider development plan aimed at capturing a larger share of the global heavy lifting sector. It combines Raimondi’s Italian engineering legacy with Terex’s applications and established market presence, offering clients a comprehensive and competitive product lineup designed to meet the evolving demands of the construction and heavy lifting sectors. In a previous news release, Raimondi said it is committed to ensuring a seamless integration process, prioritizing continuity for Terex employees and customers.

Flourish Landscaping began in 2019 with one truck, a lawnmower and a vision. “It was just me at the start,” says owner Tristan Nagler. “Over the past seven years, we’ve grown to offer a full range of services, commercial snow removal, lawn care, decks and fences, interlock and more.”

Based in Kingston, Ont., the company serves clients from Napanee to Gananoque, predominately in the Kingston area. “The first three years we grew really fast,” Nagler says. “Since then, growth has been steady, and we’re proud of where we are today.”

Nagler says his decision to enter landscaping came after working in the restaurant industry. “I was just looking for some extra weekend work,” he recalls. “I put up a few posters, the phone started ringing, and it grew from there.”

Nagler says equipment reliability and

BARRIE

Bobcat of Barrie

705-726-2228 oakenequipment.ca

GREY BRUCE

Bobcat of Grey Bruce 519-372-9100

bobcatoftc.com

PARRY SOUND

Bobcat of Parry Sound Ltd.

705-342-1717 bobcatofparrysound.com

TORONTO WEST

Bobcat of Toronto 416-679-4172 oakenequipment.ca

BRANTFORD

Bobcat of Brantford 519-752-7900 bobcatofbrantford.com

HAMILTON

Bobcat of Hamilton 905-643-3177 bobcatofhamilton.com

PETERBOROUGH

after-sales support are key factors in choosing a dealer. “We use our machines hard, they’re running all day and really pushed to the limit,” he says. “The machines themselves are usually priced about the same, but the cost of parts and repairs has skyrocketed with the past brand we were using. When we were quoted a ridiculous price for a part, I knew it was time to look for a new dealer. For us, the support after the sale must make sense.”

So, when it came time to expand the company’s equipment lineup, Nagler turned to Bobcat®. “I’d always heard great things, it’s the original skid-steer that everyone else’s is based on, so I figured I’d go to the source and get the best,” he says.

Flourish Landscaping recently added two Bobcat machines to its fleet, a T66 compact track loader and an S64 compact skid-steer loader. “They’ll be plowing downtown this winter in tighter parking lots where maneuverability is key,” Nagler explains. “In the summer, especially the

track machine, we’ll be using for grading and new projects.”

Nagler worked with Bobcat sales specialist Terry Hayduk, from Bobcat of Kingston, who he says made the process smooth and easy. “He’s been super helpful, met me on-site, got me all kinds of quotes, and guided me through every step,” Nagler says. “We went through a few options before deciding, and he was great through it all.”

The company opted for the Bobcat Leasing three-year program on both machines, with plans to either buy them out or upgrade at the end of the term. This program allows me to have more cash flow and lower monthly payments. “The keyless start on the T66 is really slick, just punch in your code and go. It’s pretty sweet,” Nagler says. “They’re nice, smooth machines.”.

Fully insured with $2 million commercial liability coverage, Flourish Landscaping continues to grow, with quality equipment and customer service at the core of its success.

CASSELMAN

Bobcat of Ottawa Valley 613-764-2033 bobcatov.com

KITCHENER

Bobcat of Tri-Cities Ltd. 1-866-214-3939 bobcatoftc.com

STRATFORD

LONDON

Bobcat of London 519-455-4900 bobcatoflondon.ca

Bobcat of Stratford 519-393-6040 bobcatofstratford.ca

THUNDER BAY

Equipment World Inc. 807-623-9561 bobcat-tbay.com

SAULT STE. MARIE

Bobcat of Sault Ste. Marie 705-949-7379 bobcat-ssm.com

Bobcat of Windsor 519-737-0120 oakenequipment.ca

Bobcat of Durham East Ltd. 905-404-9990 bobcatofdurhameast.com

MUSKOKA

Bobcat of Muskoka 249-390-7000 oakenequipment.ca

SUDBURY

Bobcat of Peterborough 705-748-9119 bobcatofpeterborough.com COURTICE

McDowell B Equipment Ltd. 705-566-8190 bmcdowell.com

WYOMING

Advantage Farm Equipment Ltd. 519-845-3346 advantage-equip.com

FRANKFORD

John’s Equipment 613-398-6522 johnsequipmentsales.com

OTTAWA

Bobcat of Ottawa Valley 613-831-5166 bobcatov.com

TORONTO EAST

Bobcat of Toronto 416-679-4171 oakenequipment.ca

JLG Industries has updated its line of rotating telehandlers and announced the new R13100 model.

Developed to tackle demanding job site challenges, the refreshed lineup delivers both horizontal and vertical lift-and-place capabilities for greater productivity, enhanced operator con dence and advanced technology.

“JLG’s rotating telehandler line is built for today’s challenging job sites, where space is limited, loads are heavy and productivity is paramount,” said Catherine Lee, Product Manager for telehandlers at JLG.

“With the addition of the new R13100 model, enhanced operator-focused features and standard ClearSky Smart Fleet connectivity, this line o ers our customers the versatility, power and con dence they need to get the job done eciently and safely.”

The new R13100

The new R13100 replaces the R11100 in JLG’s rotating telehandler lineup. e machine features a 5,987-kg capacity and a 29.5-metre maximum lift height.

Alongside the R1370 and R1385 models, the R13100 shares a nearly identical base configuration,

providing contractors with a consistent, reliable solution across the line.

Powered by diesel engines, the R1370 features 134 hp, while the R1385 and R13100 models deliver 168-hp. All three models are equipped with a 2-speed, stopto-shift hydrostatic transmission, helping deliver a smoother ride over uneven terrain.

Telehandler upgrades e updated rotating telehandler line introduces several enhancements designed to meet evolving job site demands.

All models now include JLG’s ClearSky Smart Fleet, an advanced two-way fleet management and communication platform.

JLG has also introduced a redesigned counterweight with integrated lights for visibility and job site awareness.

In the cab, a new integrated remote-control mount and optimized joystick controls provide operator comfort and e ciency.

The rotating telehandlers are also now compatible with the Woodcracker CS750 smart grip saw attachment, enabling tree felling capabilities.

Every model in the JLG rotating telehandler family comes standard

with three key safety and control technologies:

· Automatic Attachment Recognition: Identi es the attachment and displays the appropriate load chart to the operator.

· Load Management Information System (LMIS): Supports operation outside of load chart boundaries.

· Load Stability Indication (LSI): Provides visual and audible alerts when approaching forward stability limits.

With 360-degree rotation, a wide range of attachments, optional hydraulic couplers and continuous auxiliary hydraulics, JLG rotating

telehandlers deliver e cient exibility. e machines can act as a mobile elevating work platform, a crane alternative or a high-capacity material handler, often replacing multiple machines on-site. The addition of remote boom control, which comes standard on all JLG models, further enhances visibility and control when operating outside the cab.

Operator comfort

The redesigned cab improves both functionality and comfort, featuring dual joystick proportional controls, integrated boom-mounted and reversing cameras and an enclosed climate-controlled en -

vironment. Operators can also take advantage of the VDC controller to adjust speed, rpm and steering modes for specific job requirements.

“Congested job sites present fierce challenges — navigating tight spaces, lifting heavy loads and reaching extreme heights. at’s where JLG rotating telehandlers provide a distinct advantage,” Lee said. “From manoeuvring in crowded environments to lifting and loading in any direction, these machines truly revolutionize productivity on modern work sites. Whatever the project demands, this powerful lineup is built to meet the challenge.”

Skyjack’s new SJ5545 E electric drive scissor lift delivers the highest working height in its range of slab scissors.

Suitable for indoor and outdoor use, the SJ5545 E includes innovative design features and high platform capacities. As well, the machine provides a clean, quiet, sustainable rental solution with zero emissions, lower operating costs and increased utilization.

“Skyjack machines are known for reliability, durability and serviceability. Our new slab scissor provides a simple, quality and environmentally friendly choice

for rental at our highest working height,” said Skyjack President Charlie Patterson. “We are thrilled to see our simply electric E-Drive scissor line continue to grow.”

With a working height of 15.54 metre and a load capacity of 394 kg, this E-Drive model delivers advanced responsive control and manoeuvrability, making it an ideal choice for a wide range of construction, maintenance and industrial applications.

The intelligent adaptive variable speed brushless drive system improves duty cycles and delivers smooth automatic transition from

high to low speed on a grade including 25 per cent gradeability. Fully proportional drive and lift controls offer efficiency, controllability and improved torque and traction.

The scissor stack design of the SJ5545 E features fully welded cross-bracing that increases rigidity and improves operator comfort at height. The SJ5545 E is drivable at full height and offers a two-person wind-rating at 6.7 metres.

The maximized width of the robust, all-steel, anti-slip platform provides the largest working areas in its class, while minimiz -

ing space between platform and workface.

The platform incorporates multiple lanyard attachment points and a manually operated 90-cm roll-out extension deck for an optimized work area and up-andover capability. The modular rail system easily folds down to reduce stowed height for transportation.