ENGINEERING & EQUIPMENT www.drycargomag.com SEPTEMBER 2023

DCi 136

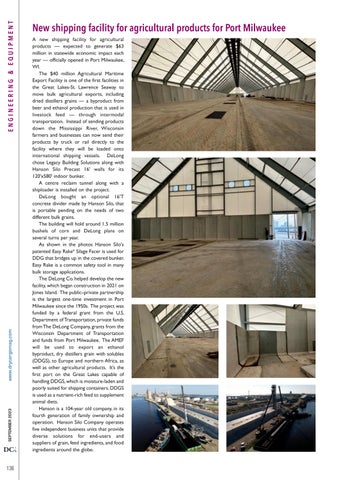

New shipping facility for agricultural products for Port Milwaukee A new shipping facility for agricultural products — expected to generate $63 million in statewide economic impact each year — officially opened in Port Milwaukee, WI. The $40 million Agricultural Maritime Export Facility is one of the first facilities in the Great Lakes-St. Lawrence Seaway to move bulk agricultural exports, including dried distillers grains — a byproduct from beer and ethanol production that is used in livestock feed — through intermodal transportation. Instead of sending products down the Mississippi River, Wisconsin farmers and businesses can now send their products by truck or rail directly to the facility where they will be loaded onto international shipping vessels. DeLong chose Legacy Building Solutions along with Hanson Silo Precast 16' walls for its 120'x580' indoor bunker. A centre reclaim tunnel along with a shiploader is installed on the project. DeLong bought an optional 16'T concrete divider made by Hanson Silo, that is portable pending on the needs of two different bulk grains. The building will hold around 1.5 million bushels of corn and DeLong plans on several turns per year. As shown in the photos Hanson Silo's patented Easy Rake® Silage Facer is used for DDG that bridges up in the covered bunker. Easy Rake is a common safety tool in many bulk storage applications. The DeLong Co. helped develop the new facility, which began construction in 2021 on Jones Island. The public–private partnership is the largest one-time investment in Port Milwaukee since the 1950s. The project was funded by a federal grant from the U.S. Department of Transportation, private funds from The DeLong Company, grants from the Wisconsin Department of Transportation and funds from Port Milwaukee. The AMEF will be used to export an ethanol byproduct, dry distillers grain with solubles (DDGS), to Europe and northern Africa, as well as other agricultural products. It’s the first port on the Great Lakes capable of handling DDGS, which is moisture-laden and poorly suited for shipping containers. DDGS is used as a nutrient-rich feed to supplement animal diets. Hanson is a 104-year old company, in its fourth generation of family ownership and operation. Hanson Silo Company operates five independent business units that provide diverse solutions for end-users and suppliers of grain, feed ingredients, and food ingredients around the globe.