7 minute read

Streamlining grain terminals with TBA Group’s CommTrac system

Waterside grain terminals are complex facilities handling many product varieties through intricate conveying systems. There are a number of factors that are paramount in operating a successful grain terminal: Cross contamination: systems need v to be put in place to ensure that the risk of contaminating one product with another is reliably mitigated. Food standards: compliance with v international food standards, such as TASCC and AIB.

Traffic management: minimizing v turnaround times and scheduling delivery/shipping times as effectively as possible.

Accurate billing: ensuring that v customers are accurately invoiced and minimizing lost revenue.

CommTrac from TBA Group addresses each of these factors, along with many others, to provide a scalable, robust and feature-rich terminal operating system (TOS). CommTrac is a highly respected and multi-award-winning product, designed to manage all aspects of bulk cargo operations. Developed over the past 20 years, CommTrac is in use in over 40 operations around the world and operates in sectors including coal, breakbulk and fertilizers; however, TBA’s CommTrac team have specific and long-standing experience in grain handling.

Traditionally, grain terminals will have an ERP system in place that takes care of commercial inventory, finance and maybe some order processing. They will also have weighing and control systems, but these will be completely separate and lack a centralized system to tie everything together. All too often, this gap will be filled with spreadsheets and manual processes, providing the links between the various systems, but prone to failure and inefficiencies.

Without a central hub, we end up with several isolated stakeholders (such as operations, management, finance and the customer) with multiple points of data collection and different IT systems. This inevitably leads to difficulty in obtaining real-time operational data, but it’s also hard to scale and maintain.

This is where a terminal operating system (TOS) such as CommTrac comes into its own. By integrating with all of these previously isolated and separate systems, we not only end up with a more efficient and well-managed operation, we also have a ‘single version of the truth’ — a hub of all the terminal’s information, which enables us to gain better insights, spot problems early and plan for the future.

Here are a few specific examples of CommTrac’s functionality and how it can make a real difference in the scenario of a grain terminal:

CommTrac’s inventory management v mitigates the risk of cross contamination and maintains product quality and traceability through a robust material handling process. It interfaces into automation systems to control conveying routes through the terminal to give clear visibility of cargo movement and prevent cross contamination.

The Quality Specification Monitor v enables the tracking of grain quality specifications by averaging accumulative specifications across a silo to improve blending decisions and create maximum value for the terminal.

The Weighbridge Management module v fully integrates with a terminal’s truck and rail weighing systems, improving turnaround times and reducing administration.

Web-based customer access terminal v allows customers to log in and view the status of their account and specific shipments, reducing the administration involved in handling these enquiries manually and providing greater accuracy and customer satisfaction.

Real-Time Service and Rental Accrual v automatically accrues revenues based on service and storage activities, ensuring more accurate and fully documented invoicing.

Alternatives to CommTrac are often developed locally, either in-house or in partnership with local software suppliers. There has long been the perception that the large variation in operational processes necessitated bespoke development, specifically designed to meet the needs of individual sites. However, software such as CommTrac is highly configurable and can be customized to meet the needs of any type of operation.

Furthermore, by selecting an established and mature solution such as CommTrac, terminals also get the benefit of the millions of pounds invested into the product’s development. Such an investment would naturally be difficult to justify for individual ports — TBA has the resources needed to continually invest in the software’s security, functionality and stability, plus the industry expertise to satisfy the hugely variable needs of its customers.

One example of how this investment has resulted in real-world benefits is in use of mobile devices. ‘On the ground’ workers cannot work effectively with desktop computers as they need to be in their working environment close to the activity they are performing. Traditionally they might have to resort to paper-based means of documenting events and information, which then need entering digitally later. Similarly, they may have to refer to printed documentation, which may be out of date and difficult to manage.

However, if they can receive timely information and record their activities directly into the system, this can greatly enhance their efficiency and that of the whole operation. Software designed for this environment needs to be simple, easy to use with minimal inputs and able to run on a mobile device, such as a smartphone.

CommTrac Mobile can be used for a range of use cases, including: event/delay logging during vessel v activities; tallying of cargo; v work instructions for payloader and v forklift drivers; and scanning of cargo barcodes. v

To ensure that operations are uninterrupted, CommTrac Mobile seamlessly operates over WiFi, 5G and offline modes, switching between the modes as required. If the app needs to operate in offline mode, it automatically synchronizes with the main system when going back online.

In summary, implanting a system such as CommTrac can dramatically improve the effectiveness of a grain terminal. All aspects of operation can be positively impacted, providing a central hub of information, integrating with all stakeholders and maximizing revenue, profitability, compliance and growth potential while reducing risk.

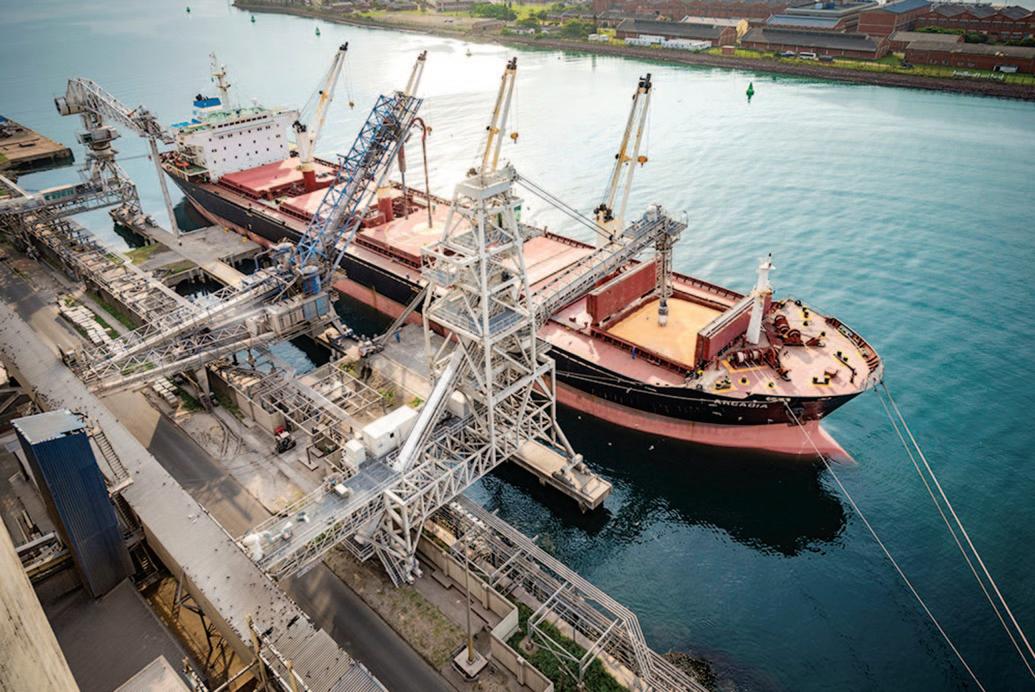

CASE STUDY: SOUTH AFRICAN BULK TERMINALS, PORT OF DURBAN

SABT owns and operates two world class bulk terminals (DBS and RBT) in the Port of Durban. The RBT terminal at Maydon Wharf 5 (MW5) has a combined silo/flat bin storage capacity of 150,000 tonnes and the DBS terminal located at Island View 3 (IV3) has a silo storage capacity of 70,000 tonnes.

As South Africa’s largest bulk grain handler, SABT plays an integral role within the South African economy allowing both import and export cargoes to flow through the Port of Durban efficiently and effectively. SABT, who are also about to embark on a site wide automation upgrade, selected CommTrac based on its industry leading functionality as well as its ability to fully integrate into the terminals automation layer. TBA’s engineering experience alongside CommTrac’s functionality provides SABT the ability to eliminate the potential risk of cross contamination by handling all the critical routing decisions within the terminal as well as recording all plant stoppages and events automatically.

“We are really looking forward to take our company to the next level with the CommTrac Terminal Management Software,” said Mr Jackie Goodwin, Managing Director of SABT.

Sales at TBA Group: “We are delighted and excited to be working with SABT on this project. The enterprise software solution being delivered will allow for the standardization of operational procedures across both locations as well as simplifying their master data from a product, customer and finance perspective. The enterprise solution also enables senior management to quickly report on activities at either a terminal or company level, allowing key decisions to be made in an efficient and timely manner.”

LONGEVITY OF MATERIAL STORAGE SOLUTION FROM SCHENCK PROCESS PROVEN IN DEMANDING CIRCUMSTANCES

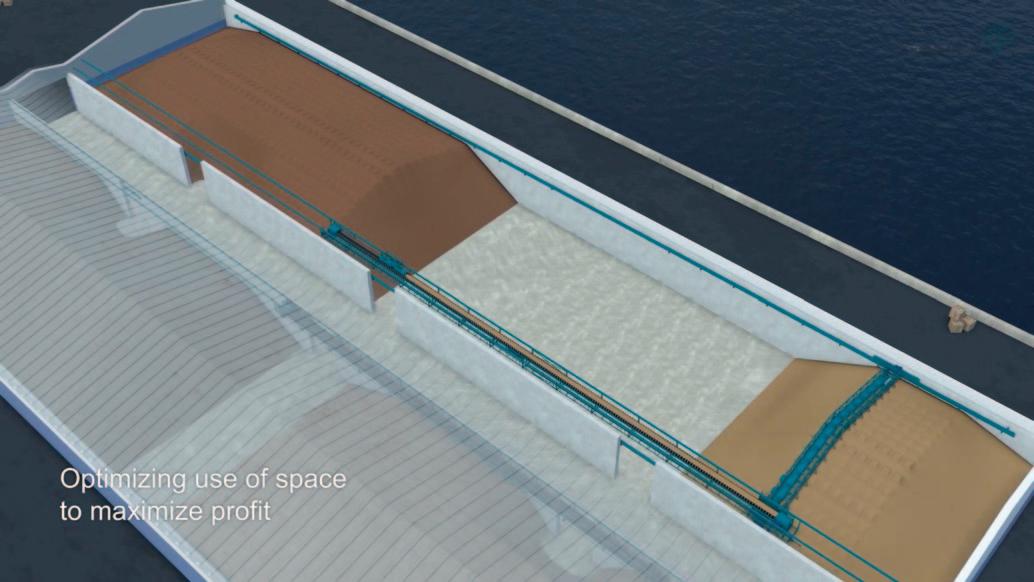

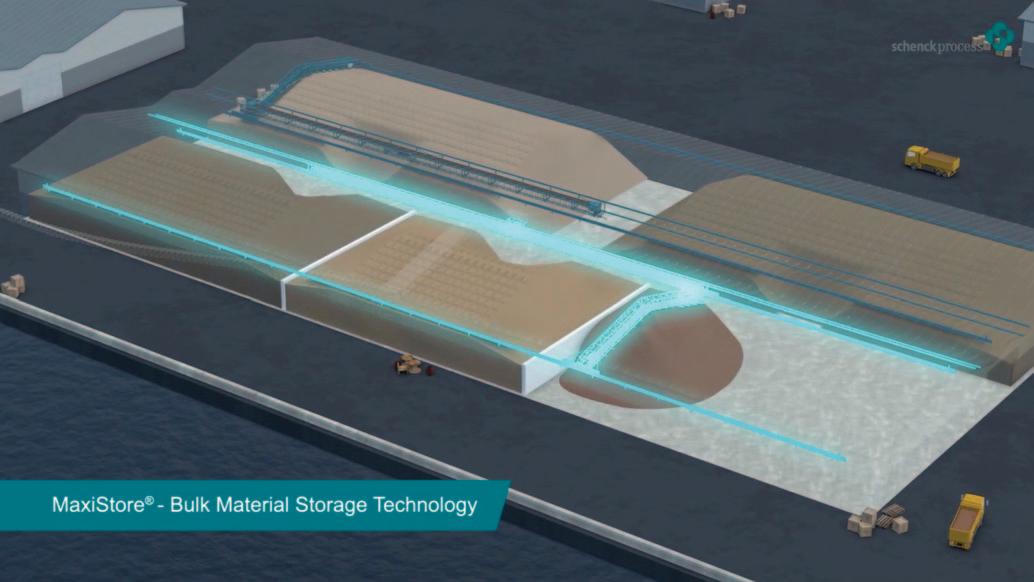

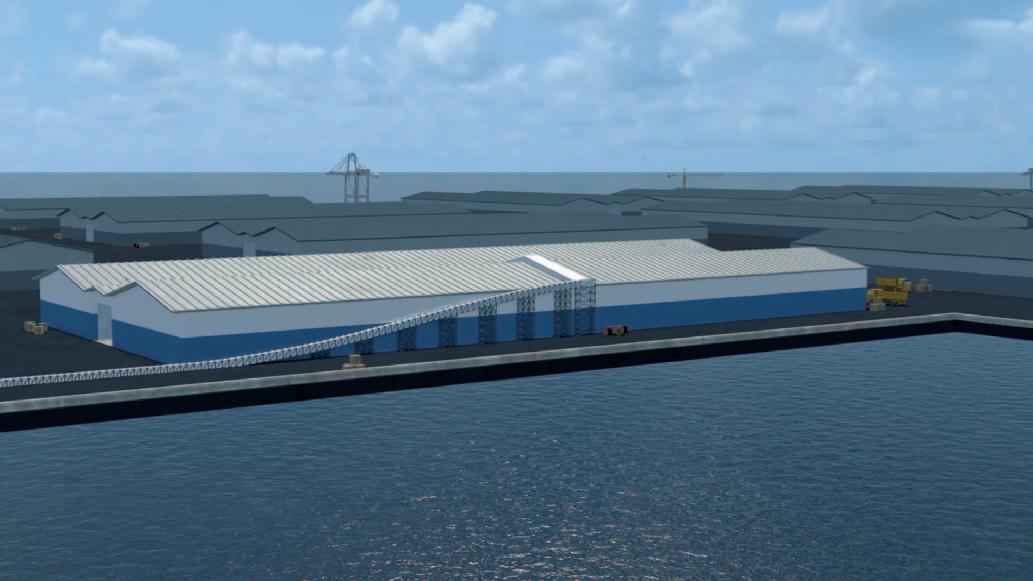

Storing and safely handling bulk materials such as grain in harbours is a challenging prospect and an area where Schenck Process engineers and supplies a unique solution in the form of its MaxiStore®

SOLVING STORAGE CHALLENGES IN DEMANDING ENVIRONMENT

A customer, part of the dry bulk commodities industry, wanted a long-term bulk material storage solution within their limited available space at a harbour. They contacted Schenck Process for a solution that led to the MaxiStore demonstrating its longevity and starting a relationship lasting over 15 years.

With restricted space within the port, the customer needed to maximize what was available. A traditional loading system uses a high-level conveyor with a tripper supported from the apex of the building roof. Potentially, it could have made for a costly build and resulted in inefficient material loading. Also, controlling the material positioning across the length of the store could have proved difficult for that system.

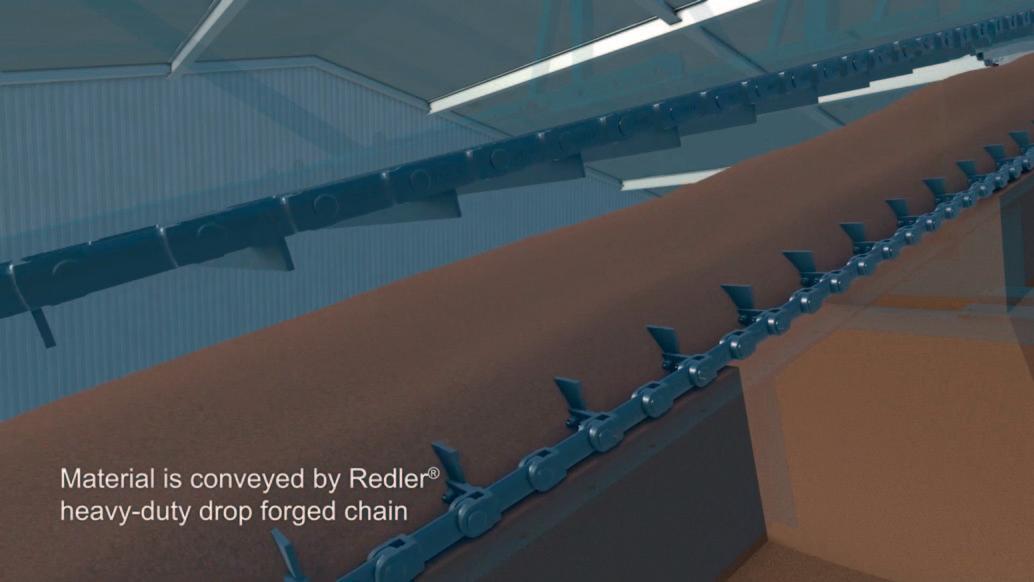

After establishing that the traditional system wouldn’t solve the customer’s challenges and a more innovative approach was required, the team at Schenck Process proposed the unique MaxiStore system. Based on the combined advantages of proven Redler en-masse conveyor technology, and an industry-leading approach to the process of store loading, the MaxiStore system used a cranked en-masse chain conveyor within a steel structure to span the building laterally. The machine could move along the length of the store with material fed through the chain conveyor to drop to the floor. It allowed the material to easily be fed to any required storage bay while having the capacity to fill up to the ceiling and along the entire length of the building, optimizing storage volumes for any given space. MaxiStore manages the area safely by minimizing dust that can lead to explosions.

MAXISTORE : DURABLE AND FULLY ADAPTABLE SOLUTION TO CUSTOMER NEEDS

Each MaxiStore system can be specifically designed to meet the customer’s exact needs, no matter how complex. By working with the customer to understand their particular requirements, Schenck Process developed a robust system that optimized the storage volume for their limited store size and maximized profit. The result empowered them to work within their conditions and have a storage system that could operate continuously.

The MaxiStore system is made to handle large quantities of animal feed, minerals, and other bulk materials at rates up to 1,000 tonnes per hour. It enables the user to maximize their space while providing better and safer material distribution. The MaxiStore was proven to provide the most efficient and flexible filling of dry bulk solid materials throughout a storage building.

Schenck Process offers installation and after-sales support — across the entire lifecycle of its process solutions — assuring the longevity of the systems it designs, manufactures and engineers. With over 100 years of experience in mechanical conveying and storage solutions, the customer benefited from access to a wealth of Schenck Process’s expertise. Maintaining the infrastructure within the harsh marine environment of the port has been crucial to extending the service life of their acquisition, giving them confidence that they had purchased a best-in-industry storage solution.

Having a long-term satisfied customer is a testament to the performance of Schenck Process’s solutions and demonstrates the company’s commitment to developing innovative and efficient automated bulk storage solutions. The system was installed 15 years ago is still working 24 hours a day and remains a fundamental part of the customer’s port operation. DCi