1 minute read

The best bulk truck loader in the world

conveyor to handle different kinds of alternative fuels at the Outão Cement Plant in Portugal. This project further strengthens the co-operation started with SECIL more than 20 years ago and it is part of the major R&D Clean Cement Line (CCL) Project which aims to develop and demonstrate a new cement production technology.

The CCL project aims to bring the Outão cement plant to the forefront of energy efficiency and the lowest CO2 emissions among European cement producers. The project is partly funded by the Portugal 2020 government incentives programme, and it aims to develop a new concept of cement production. Bedeschi’s delivery to SECIL Group will contribute to eliminating the dependence on fossil fuels. The concept of Industry 4.0 will become essential for the plant’s management for improving efficiency and optimizing the processes, therefore a digitalized system will be integrated into the whole plant.

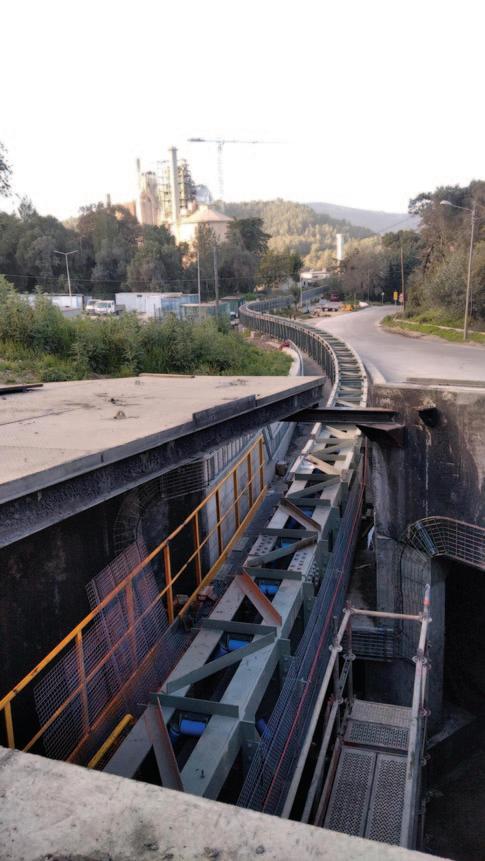

The pipe conveyor has a diameter of 250mm and conveying length of 350m and will grant safe and clean transportation of alternative fuels at a rate of 300m3/h. It has been designed with vertical curves to follow the ground profile and to overtake obstacles and with horizontal curves to fit with the layout constraints without intermediate transfer points. The belt forms a closed tubular section both in the carrying and return path; the conveyed material is protected from wind and rain all along the route.

Bedeschi’s engagement in this project is among the activities implemented by the Italian company to contribute to reaching some of the sustainable development objectives, especially environmental protection, as established in the Agenda 2030 by the United Nations and one of the achieving goals present in Bedeschi’s sustainability report.

Thanks to research and development in green technology, Bedeschi is able to design and produce machines and turnkey installations reaching the highest environmental standards. All involved are committed to the fundamental aim: guaranteeing a sustainable model for the future.

Bedeschi designed and supplied the complete pipe conveyor system, delivering the structure in pre-assembled transportable modules to allow a smooth and trouble-free installation process.

The pipe conveyor solution has been selected for this application being a modern and environmentally friendly transport system solving numerous problems associated with conventional conveyor systems and transportation of difficult materials.

The Dust Filter Concept For Dust Reduction And Pressure Reduction At Transfers

Highly Effective Against Dust Formation

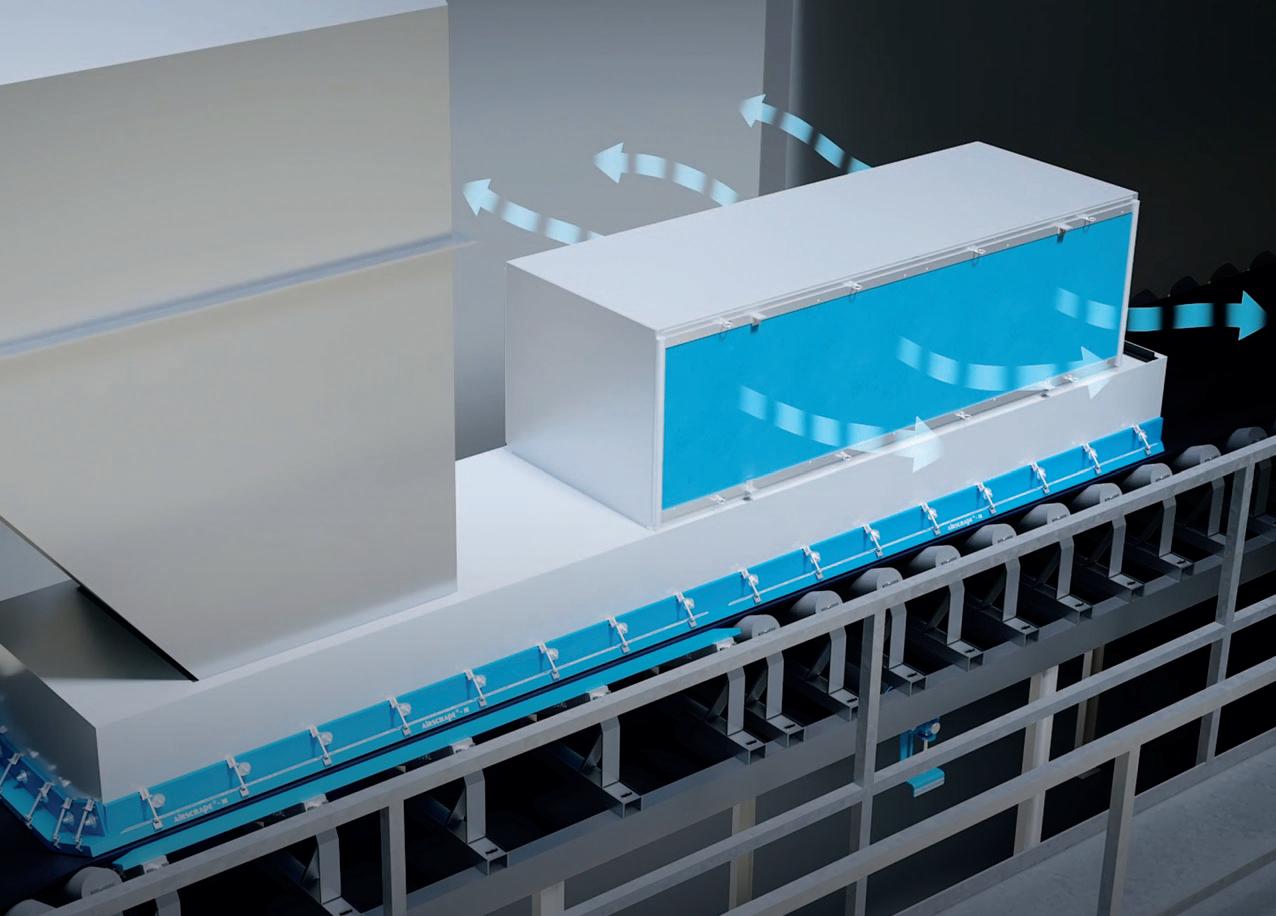

The special filter medium of the DustBox retains dust particles that are generated due to material movement, and at the same time is permeable for the circulating air. The air escaping through the filter medium reduces the air pressure in the transfer, which is distorted by material movement. Used in combination with the AirScrape, the DustBox unfolds its special properties and increases the efficiency of the ScrapeTec dust removal system. Dust and spills are thus completely avoided.