5 minute read

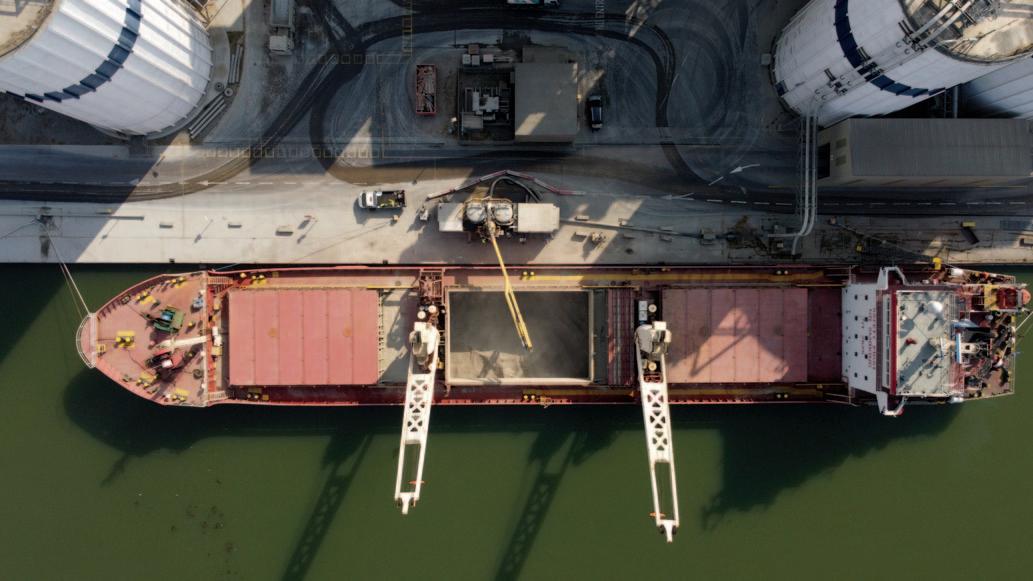

Streamlining port operations: the dynamic world of dry bulk material mobile ship-unloading

In the intricate tapestry of global trade, ports are crucial nodes facilitating the movement of goods across international borders. Within the multifaceted landscape of port activities, unloading dry bulk materials from ships occupies a central position. These bulk commodities, encompassing products like coal, grains, ores, and dry bulk powders, constitute the cornerstone of the global economy. Every year, millions of tonnes are loaded and unloaded within ports worldwide. The efficient handling of these materials hinges on utilizing specialized equipment and meticulously executed techniques for (mobile) ship-unloading. This article delves into the bustling activities that revolve around unloading dry bulk powder materials (like cement, fly ash, alumina, etc.) from ships in ports, encompassing the operational dynamics and technological innovations that shape this critical process.

The Dynamics Of Dry Bulk Material Unloading

Unloading dry bulk materials from ships is a multifaceted process that requires precision, expertise, and specialized equipment. The complexity of the task is rooted in the diverse nature of the materials being transported. As such, a variety of unloading methods have been devised to cater to the unique characteristics of each cargo. The mobile ship unloading process encompasses several vital stages:

1. Vessel arrival and berthing: the process commences with the arrival of ships at the designated port. Skilful navigation and berthing are crucial for the vessel’s safety and optimizing cargo transfer efficiency.

2. Unloading equipment setup: ports are equipped with an array of machinery tailored to handle distinct types of dry bulk powder materials. These include (mobile) unloaders such as mechanical grab cranes, mechanical ship-unloaders or pneumatic ship-unloaders. These unloading systems are strategically positioned to facilitate efficient cargo transfer.

1. Cargo discharge: the selected unloading equipment is employed to extract the cargo from the ship’s hold. Grab cranes utilize mechanical grabs to hoist and transfer materials to designated storage areas or conveyors. Mechanical shipunloaders employ a continuous bucket chain or conveyors for cargo transfer. Pneumatic conveyors, on the other hand, leverage air pressure to transport bulk materials to storage facilities.

4. Material transportation: following the unloading process, the bulk materials are conveyed to storage facilities within the port premises. Conveyors, trucks, and rail systems are frequently employed to facilitate this transfer.

5. Quality control: ports often implement rigorous quality control measures to ensure the delivered materials meet specified standards. Samples are extracted and subjected to testing to verify parameters such as moisture content, particle size distribution, and chemical composition.

6. Storage and distribution: the unloaded materials are then stored in silos, stockpiles, or other designated storage structures within the port. These materials can be further distributed via trucks, trains, or ships to their final destinations, depending on market demands.

Challenges And Innovations

While the activities surrounding dry bulk material mobile ship-unloading are essential for global trade, they are not without their challenges. Adverse weather conditions, mechanical breakdowns, and environmental considerations can all impact the efficiency of the unloading process. To mitigate these challenges, the industry is increasingly embracing technological innovations:

Automation: automation and remote v control systems are becoming integral to the operation of unloading equipment. These advancements enhance efficiency by optimizing processes and reducing the need for constant manual intervention.

Data analytics: the integration of v advanced data analytics and sensor technologies enables real-time monitoring of the unloading process. This proactive approach allows for predictive maintenance, streamlined workflows, and data-driven decisionmaking.

Environmental concerns: ports are v keenly aware of the environmental impact of their operations. To address this, they are adopting eco-friendly and dust-free technologies to minimize dust emissions, noise pollution, and energy consumption. Dust suppression systems and noise reduction measures contribute to sustainable practices.

LION BULK HANDLING: REVOLUTIONIZING DRY BULK MATERIAL UNLOADING

One prominent player in the realm of unloading equipment is Lion Bulk Handling, a manufacturer at the forefront of developing cutting-edge solutions for dry bulk material handling. With a commitment to innovation and excellence, Lion Bulk Handling has significantly contributed to enhancing the efficiency and sustainability of the unloading process in ports.

Company Background

Lion Bulk Handling is a pioneer and expert in maritime and portside material handling. It designs and engineers its key components, adding other proven technologies from leading manufacturers to form its integrated systems with more than 55 years of design and engineering experience in equipping dry bulk ships, barges, supply vessels, harbour loading and unloading equipment, cement terminals, drilling rigs and floating terminals.

Lion Bulk Handling’s business brands, Kintec, H.W.Carlsen, Ruyter Offshore and

Bulk Academy, offer a wide range of reliable and sustainable systems and products in the field of material handling. Together with its business brands, Lion Bulk Handling has hundreds of excellent references worldwide. Lion Bulk Handling is part of the Lion Marine Group.

INNOVATIVE & DUST-FREE SOLUTIONS

Lion Bulk Handling’s product portfolio includes a variety of state-of-the-art dry bulk conveying (loading and unloading) systems designed to address the challenges posed by various dry bulk materials (such as cement, fly-ash, alumina, barite, bentonite, lime, etc.).

Lion’s unloading equipment for ports include:

Ship-to-silo unloaders or pneumatic v ship unloaders (PSU): Lion’s PSUs require a pipeline connection to handle the entire conveying process from ship to store. These highly efficient pneumatic ship-to-silo unloaders are available in road mobile, dock mobile, gantry mobile, barge mounted and stationary configurations. Next, all configurations are available with a manipulator arm for open hatch (option 1) unloading or delivered with a flexible hose connection for closed hatch (option 2) unloading. The closed hatch unloading option can only be used with a fluidized floor vessel and can be operational in any weather condition.

Ship-to-truck unloaders or v continuous suction pumps (CSP): ship-to-truck unloaders are ship and barge unloaders for unloading directly into bulk trucks. Due to the continuous suction pump (CSP) system included in each unit, a long line of simple, flexible and nonexpensive installations are available. The ship-to-truck unloaders are used as dry bulk mini terminals in several ports and terminals and are available in road mobile, dock mobile, gantry mobile, barge mounted and stationary configurations. Next, all configurations are available with a manipulator arm for open hatch (option 1) unloading or with a flexible hose connection for closed hatch (option 2) unloading. The closed hatch unloading option can only be used with a fluidized floor vessel and can be operational in any weather condition.

Technological Integration

Lion Bulk Handling stands out for its integration of cutting-edge technologies into its bulk handling equipment. The company’s unloading systems are often equipped with highly advanced automation and remote monitoring capabilities, allowing for remote operation, real-time performance tracking, and immediate issue resolution. This integration enhances safety and efficiency and reduces operational disruptions. These technological developments are part of Lion’s larger vision to implement the Industry 4.0 philosophy within every bulk handling system.

Environmental Commitment

Lion Bulk Handling recognizes the importance of environmental sustainability in modern port operations. Its equipment is designed to incorporate dust suppression mechanisms for reliable and dust-free ship-unloading; from picking up the product in the ship’s hold to discharge at the storage facility, the entire unloading process is enclosed, ensuring dust-free operation. Also, other aspects like noise reduction technologies and energy-efficient components, aligning with the industry’s green initiatives, are part of Lion’s conveying solutions.

Maintenance And Spare Parts

Downtime and reduced productivity are a nightmare for any user of ship-unloaders. Lion understands the challenges of carrying out maintenance and repairs. Lion’s mission is to provide its customers with a seamless shopping experience.

All the equipment displayed around the unloader are spare parts, which Lion offers through its webshop, and are used in unloaders. Customers looking for spare parts for its ship-unloaders should head to the company’s webshop, or contact the technical support team.

Conclusion

The bustling activities surrounding the mobile ship-unloading of dry bulk materials in ports are pivotal for the seamless flow of global trade. These activities, driven by precision and technological innovation, enable the efficient transfer of commodities that underpin economies worldwide. As the industry continues to evolve, companies like Lion Bulk Handling stands at the forefront, shaping the future of dry bulk material handling with its advanced and environmentally conscious unloading equipment. Through a harmonious blend of operational excellence and technological integration, the dynamic world of dry bulk material (mobile) ship-unloading is poised for continued growth and transformation.

One of our hard-working spreaders

Dedicated Top Lift Spreader with tilting function for bulk material handling. Meet the rest of the team at elme.com