see NCDOT page 28

NCDOT photos

The North Carolina Department of Transportation (NCDOT) has been monitoring the multi-year, $360 millionprojectsinceworkbeganin2018.

see NCDOT page 28

NCDOT photos

The North Carolina Department of Transportation (NCDOT) has been monitoring the multi-year, $360 millionprojectsinceworkbeganin2018.

By Lucy Perry CEG CORRESPONDENT

By Lucy Perry CEG CORRESPONDENT

The equipment finance picture is encouraging, six months after a report indicated it would be a so-so year. The Equipment Leasing and Finance Association (ELFA) reports that June new business volume was up 6 percent year-over-year.That’s an excellent indicator of a healthy construction industry, one of the leading bigticket financing sectors.

The association’s Monthly Leasing and Finance Index (MLFI) shows overall new business volume for June was $10.9 billion. Volume was up 15 percent from $9.5 billion in May. Year-to-date, cumulative new busisee FINANCING page 26

For almost a decade, Cumberland Pipeline, headquartered in Columbia, Ky., has blossomed into one of the top underground utilities contractors in the central part of both its home state and that of Tennessee.

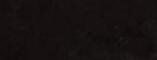

The massive $2.92 billion Mid-Barataria Sediment Diversion aims to recreate the river's ancient, natural land-building processes by diverting a portion of the Mississippi's freshwater, sediment and nutrients into the Barataria Basin.

After multiple hurricanes battered Florida’s coasts, Blew Bayou Services LLC recently began dredging a canal system for the city of Port St. Lucie to restore access to the main channel.

Superior Construction, an American family-owned infrastructure contractor, has received the 2023 Design-Build Institute of America Florida Region’s Transportation Structures HonorAward for its Wekiva Parkway Section 6 project.

North Carolina officials and top VinFast executives met July 28 in Chatham Countytoofficiallystartconstructiononthecarmaker’sfirstmanufacturingfacility outside its native Vietnam.

The product support team at Terex Utilities hosted 58 participants from equipment dealers, utilities and utility contractors from all across the United States and Canada.

The Kenworth truck assembly plant in Chillicothe, Ohio, recently held its second annual Kenworth Truck Parade in downtown Chillicothe. This year, the parade paid tribute to Kenworth’s 100th anniversary.

Founder Emeritus (1930-2021) Edwin M. McKeon Sr.

Southeast Publisher Richard C. McKeon

Executive Publisher Teddy McKeon

Editor In Chief Craig Mongeau

Senior Editor Robby Chakler

Editorial Assistant Katherine Petrik

Contributing Editor Eric Olson

Production Mgr. John Pinkerton

Controller Judith Nixon

Circulation Mgr. Cathy Printz

Main office 470 Maryland Drive Fort Washington, PA 19034

215/885-2900

Toll Free 800/523-2200

Fax 215/885-2910

Web site www.constructionequipmentguide.com

Advertising e-mail production@cegltd.com

PACCAR and Toyota Motor NorthAmerica Inc. announced an expansion of their joint efforts to develop and produce zero emissions, hydrogen fuel cell Kenworth and Peterbilt trucks powered by Toyota’s hydrogen fuel cell modules.

There is a labor shortage in the construction industry — and it’s not exactly breaking news. Headlines declare that “nobody wants to work anymore” but is this explanation really at the root of what’s a longstanding, industry-wide issue?

Approximately 20 percent of the more than 25,000 attendees and exhibitors who attend Equip Exposition, the international landscape, outdoor living and equipment exposition, are women.

The current skills gap and workforce shortage issues facing OEMs and equipment distributors are daunting. To address these problems, the AED Foundation created Vision 2025.

The Lane Construction Corporation has been awarded a highway construction project by FDOT to improve the safety and operations of the Interstate 4 (I-4) / State Road (S.R.) 535 interchange in Orange County, Fla.

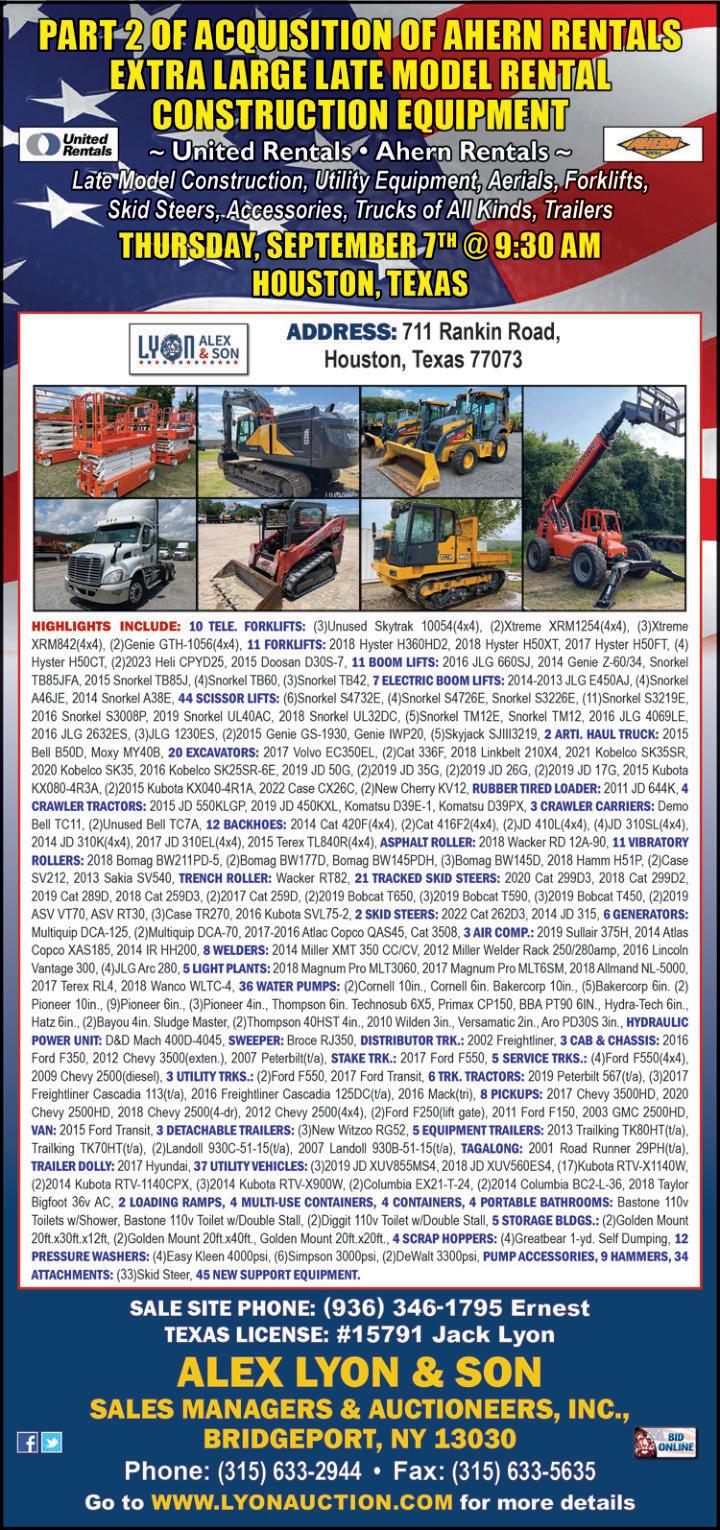

What’s hotter than south Georgia inAugust? The auctioning at RebelAuction on Aug. 9 and 10 in Hazlehurst, Ga., was … metaphorically. The auction attracted a fantastic turnout of onsite and online bidding on both days

Richard C. McKeon

• North & South Carolina

• Tennessee • Virginia 704/553-8888

Cell 704/726-1452

e-mail rmckeon@cegltd.com

Construction Equipment Guide Southeast Edition (ISSN 1058-6474) is published biweekly by Construction Equipment Guide Ltd. Advertising and Editorial Offices are located at 470 Maryland Dr., Ft. Washington, PA 19034. Toll Free 800/523-2200 or Fax 215/885-2910. Annual Subscription Rate $65.00. Call for Canadian and foreign rates.

Periodicals postage paid at Ft. Washington, PA and at additional mailing offices. POSTMASTER: Send address changes to Construction Equipment Guide Southeast Edition, 470 Maryland Dr, Ft. Washington, PA 19034.

Contents Copyrighted ©2023, by Construction Equipment Guide, which is a Registered Trademark, registered in the U.S. Patent Office. Registration number 0957323. All rights reserved, nothing may be reprinted or reproduced (including framing) in whole

Cell

or part without written permission from the publisher. All editorial material, photographs, drawings, letters, and other material will be treated as unconditionally assigned for publication and copyright purposes and are subject to Construction Equipment Guide's unrestricted right to edit and comment editorially. Contributor articles do not necessarily reflect the policy or opinions of this publication. Call or write for advertising rates, publication schedule and media kit. The Construction Equipment Guide is not responsible for clerical or printer's errors, every care is taken to avoid mistakes. Photographs of equipment used in advertisements are not necessarily actual photographs of the specific machine. Similar photographs are used occasionally and every effort is taken to depict the actual equipment advertised. The right is reserved to reject any advertising.

For almost a decade, Cumberland Pipeline, headquartered in Columbia, Ky., has blossomed into one of the top underground utilities contractors in the central part of both its home state and that of Tennessee.

That success came after enduring several years of rough sailing following its founding in 2009, and through the efforts of Bo Ellison, its current co-owner, president and project manager, who worked to steer the business into much calmer waters.

In fact, Ellison was specifically hired by Cumberland in 2014 to accomplish that very task. He managed to steadily bring prosperity to the company so that in 2023, the contracting firm is the preferred choice of many municipalities, water districts and waste districts to plan, install and repair their underground water and sewage utilities.

“Along with a lot of help from other people, we were able to stabilize the ship to the point that now we are sought after, and people call us to come work on their projects,” he said.

Among those on the Cumberland management team with Ellison are Terry Stephens, also a co-owner of the firm, as well as the owner of Stephens Pipe and Steel, the nation’s largest chain-link fence supplier.

“He has almost 50 years of business experience,” Ellison said.

In addition, he considers Jeremy Sneed to be “my righthand man. Jeremy is the vice president of operations. He helps hold it all together. We have a lot of talented people working for us.”

Overall, he said, Cumberland is a well-experienced, but

young and energetic company.

“I am 50 years old, and one of the older people here,” Ellison said. “I have a mechanic, a project manager and one equipment operator older than me, but the field management teams probably have an average age of 35 years. We’re fortunate that most of the people working here have done this work their entire adult lives.”

Some of the assistance that Cumberland received in recent years to become more profitable has come from Parman Tractor & Equipment, the Nashville, Tenn., full-service dealership. It has partnered with Cumberland to help the contractor procure a number of machines, the most important being several Link-Belt excavators. Parman also provides Cumberland with Takeuchi compact tract loaders and Hitachi wheel loaders.

“What drew me to Parman in 2021 was that they carry Link-Belt, Hitachi and Takeuchi,” Ellison said, noting that the distributor is now Cumberland’s primary source for its equipment. “But we also get attachments for the skid steers, and we go to them for our parts and service on those pieces of equipment.Additionally, we purchased five 12,000-pound Epiroc hammers from them.”

When asked about what he likes about Parman, beyond the fact the dealer sells the construction equipment brands he prefers, Ellison said, “They have just met all of our needs, including being able to get new machines for us in a time when equipment was not readily available. For instance, I had my eye on the Link-Belt 355 X4S since the 2020 ConExpo.”

Ellison called Casey Bohanon, one of Parman’s sales representatives, to see if he could help find a Link-Belt 355 X4S for Cumberland.

“After we had established the account, they were able to get us everything we needed,” Ellison said. “Since that time, just 18 months ago when our first 355 X4S was delivered, Cumberland now has five of them, with another on the way. We like that Link-Belt because it is the largest reduced-tailswing excavator on the market.”

He also prefers the 355 X4S because it is perfectly suited for construction, residential or commercial excavation, site prep, pipeline construction, sewer, and utilities work, with minimal tail swing.

Such excavators are ideal when digging and backfilling trenches in a confined area, the type of work Cumberland regularly does as an underground utility contractor.

“I just don’t care for excavators with a large counterweight,” he added. “The Link-Belt 355 is a large machine and has the capabilities of an 80,000-pound excavator, but it has a small footprint.”

Notably, Cumberland now has more Link-Belt 355s in North America than any other contractor, according to Colin Hockenberger, the general manager of Parman Tractor & Equipment.

Additionally, Cumberland relies on Parman to get most of its parts and its maintenance services, Ellison said, if the problem is with machines under warranty or is something his mechanics cannot diagnose. He noted that when a machine issue arises on site, Parman is quick about making the necessary fixes and getting the piece back up and running on the job site.

I-85 Exit 74 (Julian Rd. Exit) Salisbury, NC (704) 630-4994 (800) 665-6532

Walt Reddick (336) 749-4661 Taylor Johnston (704) 746-1496

2013 Mack CXU613 Tandem Axle Daycab, Mack MP8 Eng, 415 HP, 278K Miles, Mack M-Drive Auto. Trans., 196" WB, Dual Wet Kit, Headache Rack, Jake, Cruise, Air-Ride, Air-Ride Cab, Power Windows & Locks, ATC, Inter-Axle Lock, Susp. Dump,

$44,900

2013 Freightliner Coronado SD TriAxle 48" Sleeper, 10 Spd, Detroit DD15 Engine, 530 HP, 732K Miles, Headache Rack, Cruise, Jake, Air-Ride, Susp Dump, Inter-Axle Diff, Power Windows, Power Pass. Mirror, Air-Ride Cab, 258" WB, #13K Front Axle, #20K Lift Axle, #46K lb Rears, 3.73 Ratio, AM/FM, AC (#6102) $54,900

2007 Western Star 4900FA Tri Axle

2013 Landoll 440 48' Sliding Axle Galvanized Tilt Trailer, 40 Ton, 38' Bottom Deck, 7' Flat Section of Top Deck (9' 8" Total), Winch, Wood Floor, 50,000lb Conc. Load in 10', Crank Landing Gear, Alum. Outsides, LP 17.5, Air-Ride(#6054) $79,900

2016 Freightliner M2 26' x 96" Tandem Axle Box Truck, ISL Cummins, 350 HP, 396K Miles, Allison 3000RDS Auto. Trans., Aluminum Box, 2 Rows E-Trac, 4,000lb Liftgate, Exhaust Brake, Diff. Lock, ATC, Cruise, Air-Ride, 272" WB, AM/FM, AC (#6041) $64,900

2016 Ford

20' x 102" EZ-Loader Hydraulic Tail Truck, V-10 Triton Gas, 135K Miles, Auto. Trans., 12K lb Bed, Wood Floor, 7' Hyd Tail, 4' 7" Flip Tail, Winch, Cruise, TCS, Power Windows, Locks & Mirrors, Tow/Haul Package, Spring Susp, Hyd. Brakes, Alum. Outsides, Non-CDL, LP 19.5 Tires, AM/FM CD, AC (#6084) $64,900

2017 Peterbilt 337 25' x 102" EZ-Loader Hyd. Tail, Paccar PX-7, 184K Miles, 250 HP, Allison Auto. 2500 RDS-P, Exhaust Brake, Cruise, ATC, Air-Ride, Susp Dump, Power Pass. Window, Wood Floor on Main Deck, Winch, 17' Main Deck, 8' Tail, 5' Flip Tail, 18K lb Bed Rating, AM/FM, AC (#6085) $84,900

Gov. John Bel Edwards officially kicked off the construction of Louisiana's most ambitious wetlands restoration effort to date on Aug. 10 at a groundbreaking ceremony near Ironton along the west bank of the Mississippi River.

Decades in the making, the massive $2.92 billion Mid-Barataria Sediment Diversion aims to recreate the river's ancient, natural land-building processes by diverting a portion of the Mississippi's freshwater, sediment and nutrients into the Barataria Basin.

The hope is that the project will rebuild up to 21 square miles of land and sustain as much as 26,000 acres of wetlands in Jefferson and Plaquemines parishes in the next halfcentury.

The area has been experiencing some of the highest rates of land loss in the world.

"Today will be remembered as a critical turning point for Louisiana's coast,” Edwards told an audience that included the Louisiana Coastal Protection and Restoration Authority (CPRA) as well as several federal and state leaders.

“The Mid-Barataria Sediment Diversion will restore and rebuild thousands of acres of coastal land and provide better protection to our most vulnerable communities and critical

infrastructure. I’m grateful to CPRA and our federal, state and local partners for their decades-long effort to make this first-of-itskind project a reality.”

The diversion will include a 2-mi.-long channel built along a 1,600-ft. corridor between the river and the Barataria Basin, with a complex structure of gates on the river side and a wide outfall on the basin side, aimed at moving the sediment and water into areas of open water and existing wetlands when it is completed in about five years, according to the New Orleans TimesPicayune.

Bren Haase, chairman of the CRPA, told the newspaper that the project “could build anywhere from about 20 to 40 square miles within this space.And what we know is while that may not sound like a lot in the grand scheme of things, in terms of what's in the basin, at the end of 50 years or so, that actually represents about 20 percent of the coastal wetlands remaining within this basin, so it's a pretty significant contribution to those wetlands.”

Louisiana first requested permits for the project in 2016, but its origin actually stretches back to the end of the 19th century, he said, when scientists at that time raised concerns

about levees along the Mississippi River cutting off the supply of sediment that built the state's coastal wetlands.

It was not until 1998 that proposals for diversions similar to Mid-Barataria were included in state plans and in its first coastal Master Plan in 2007.

The new effort calls for the diversion to operate at times between December and June when the water flow is at 450,000 cu. ft. per second (cfs) or greater and designed to allow a maximum flow of 75,000 cfs to enter the basin, likely only during high-river years when the river's flow reaches one million cfs or more.

During low periods, as much as 5,000 cfs will still flow through the channel to keep it clear of sediment.

The Mid-Barataria Sediment Diversion is the state's largest effort to date to reduce the effects of subsidence, sea level rise and tropical storm and hurricane damage, which together have led to the loss of more than 2,000 sq. mi. of the Louisiana's coastline since the 1930s.

Construction is anticipated to take more than five years to complete and is projected to produce an economic impact of nearly $1.5 billion in sales and approximately 12,400

jobs in the region, according to recent economic studies.

The Times Picayune reported that Entergy started relocating utility poles and other equipment earlier this summer, and a temporary rerouting of Louisiana Highway 23 will be built this fall, along with the beginning of construction of a permanent bridge replacement across the diversion. Additionally, crews will build a new railroad bridge atop the diversion site in the next few months.

In June, surveying began to identify flooding risks to buildings outside the levee system south of the diversion. The results will be used in discussions with residents and businesses of possible mitigation projects during the last quarter of this year and the first quarter of 2024.

Some projects aimed at elevating roadways and bulkheads between Myrtle Grove and Happy Jack are already under way as well, CPRA officials told the New Orleans news source.

The state has set aside $360 million of the project's construction cost for projects aimed

After multiple hurricanes battered Florida’s coasts, silt, sand and debris clogged many of the canals running between neighborhoods, limiting boat use for residents.Along the east coast of Florida, Blew Bayou Services LLC recently began dredging a canal system for the city of Port St. Lucie to restore access to the main channel. The project required a unique solution, but Blew Bayou Services is adept at working on job sites other companies shy away from.

“Our company name is a combination of Blew for the wind and Bayou for the swamp,” explained owner Daryl Nowling. “As the name implies, we like working in or near the water and prefer the amphibious projects other companies don’t like to do.”

Nowling continued, “On this job, the storm pushed sand through the culvert pipes and washed in on the banks, which keeps boats from reaching the docks. Our scope of work is dredging around the docks and down the canal to restore access. Because of several factors, we had to work with the city to find a solution that wouldn’t disturb the residents but offered access to the canal and a place to dump and remove the dredged material.”

After eight months of securing residential approval and funding, Blew Bayou Services began work in the fall of 2022. To dredge the canal, the company outfitted a Komatsu PC240LC-11 excavator with a longreach, 50-ft. boom and OLKO pontoons, which allow the excavator to work in the canal instead of along the banks. After dredging, material is loaded onto a barge and shipped down the canal where it is eventually removed via crane, and the process is repeated.

“The city couldn’t use a traditional dredging contractor because the homes lining the canal don’t leave enough room for equipment to access the canal or remove the slurry,” noted Nowling. “Without the long-reach excavator and the OLKO pontoons, this project couldn’t be completed. The residents and city have been impressed with the work that’s been done so far.”

Blew Bayou Services worked closely with Linder Industrial Machinery Company and sales representative Daniel Tafoya to purchase the pontoons and install them onto the excavator.

“We’re pleased with the steel tracks and design of the pontoon, which holds up better than an aluminum frame,” stated Nowling. “A lot of our work is in wetlands with stumps and rocks, which are very tough on the tracks. We’ve found that the reliability and efficiency of the OLKO pontoons outmatches anything we have tried in the past.”

Nowling continued, “On this particular project, the OLKO pontoons provide better maneuverability in the water, propel the machine faster through the water, and provide more stability. The excavator has more counterweight than some of the lighter machines, so the extra weight from the steel frame on the pontoons is helpful. The drivetrain on the pontoons also helps tremendously. Overall, the OLKO pontoons allowed us to take on a project that otherwise would not have been possible.”

(This story was reprinted with permission from Linder Link Magazine, July 2023 issue.)

Border Rents

borderequipment.com

Augusta, GA 706-737-7253

Norcross, GA 770-609-8299

Don Allison Equipment, Inc. (Compact Excavator Only) donallisonequipment.com

Arley, AL 800-669-6450

First Choice Farm and Lawn firstchoicekubota.com

Brookland, AR 870-790-2301

Dyersburg, TN 731-882-1855

Eads, TN 901-616-5129

Mayfield, KY 270-856-4355

Savannah, TN 731-925-2141

Union City, TN 731-885-1315

Forsythe Tractor

(Compact Excavator Only) forsythetractor.com

Shreveport, LA 318-687-1341

Hi-Low Equipment of Florida (Compact Excavator Only) hilowequipment.com

Ocala, FL 352-820-4200

Larry Stovesand Equipment (Compact Excavator Only) lsetractor.com

Murfreesboro, TN 615-442-6738

Mid South Machinery

gomidsouth.com

Jackson, MS 601-948-6740

National Equipment Dealers

Carolinas

nedealers.com

Charlotte, NC 704-228-0455

Clayton, NC 886-629-3784

Grimesland, NC 252-752-1500

Lexington, NC 866-629-3784

Columbia, SC 888-865-1002

Conway, SC 800-968-0754

Piedmont, SC 864-434-1154

Summerville, SC 843-501-0566

National Equipment Dealers Florida nedealers.com

Apopka, FL 407-401-8956

Fort Pierce, FL 772-212-4043

Tampa, FL 813-940-4405

National Equipment Dealers Georgia

nedealers.com

Dallas, GA 770-445-9019

Douglas, GA 912-384-4664

Macon, GA 478-257-8300

Richmond Hill, GA 912-756-7854

Southern Lift Trucks

southernlift.com

Mobile, AL 251-278-2247

Springdale Tractor

Springdale, AR 479-361-2513

State Machinery

statemachineryeq.com

Kenner, LA 504-464-0431

Stone Equipment Co., Inc.

stoneequipmentco.net

Alabaster, AL 844-786-6373

Montgomery, AL 844-786-6373

Taylor Construction Equipment

taylorconstructionequipment.com

Louisville, MS 833-773-3421

Philadelphia, MS 833-733-3421

Maryville, TN 662-773-3421

White House, TN 615-392-4803

Van Keppel

vankeppel.com

North Little Rock, AR 501-945-4594

Hyundai leads the industry with great warranties and a trusted dealer network that will support you.

Loved for the features. Trusted for the performance.

Hyundai articulated dump trucks have the power and performance — not to mention top-notch interiors, clear sight lines and handy tech — that make life on the jobsite easier. So you can do more users become longtime fans.

See the Hyundai difference yourself at your local dealer or hceamericas.com.

Superior Construction, an American family-owned infrastructure contractor, has received the 2023 Design-Build Institute of America Florida Region’s Transportation Structures Honor Award for its Wekiva Parkway Section 6 project.

The contractor’s signature project also was awarded the Florida Transportation Builders’ Association 2023 Best in ConstructionAwardinthedesign-buildcategory.Theseprestigious awards recognize companies and individuals who workedonFlorida’smostinnovative,complexandimpactful transportation projects.

Section 6 of the Wekiva Parkway is a testament to the fusion of functionality and beauty. The $247 million project rehabilitated a vital stretch of the Florida Department of Transportation’s (FDOT) Wekiva Parkway through conscientious design and construction practices. It increases capacity between Lake and Seminole counties, redirects traffic from Florida’s congested I-4 corridor and integrates harmoniously with its natural surroundings.

The project scope included a shared-use path, a non-tolled service road for local travel and several wildlife bridges to allow animals to pass safely between the Seminole State Forest and Rock Springs Run State Reserve, for a total of 18 bridges with more than 1.268 million square feet of deck.

Three of the bridges, dubbed the Wekiva River Crossing, were built across the federally designated Wild and Scenic River. They feature pier shapes inspired by trees and a concrete stain to match their surroundings, an excellent example of environmental stewardship incorporated into the design.

“We’re immensely proud of our team for receiving both awards. It not only honors the dedicated professionals involved in bringing this project to fruition, but I hope it will also inspire future generations of bridge designers and engineers,” said Superior Construction CEO Nick Largura.

Superior andWGI, Inc. developed their creative construction concept alongside Shelby, a qualified team with unique segmental bridge construction experience, and through a strategic partnership with FINLEY Engineering (now COWI).

The highly innovative project used top-down balanced cantilever construction for the segmental bridge spans over the Wekiva River. Doing so minimized environmental impacts by eliminating work in the water. To complete the project, the design-build team also employed Florida’s first useofflexiblefillerforpost-tensioninginacast-in-placesegmental bridge and the state’s first use of a rebar-tying robot on a bridge deck.

This year’s Best in Construction Award winners will be recognized at the FTBA Annual Convention Awards Breakfast in Boca Raton, Fla., onAug. 4. The DBIAFlorida region awards will be presented onAug. 31 at the organization’s annual awards luncheon.

For more information, visit superiorconstruction.com.

North Carolina officials and top VinFast executives met July 28 in Chatham County to officially start construction on the carmaker’s first manufacturing facility outside its native Vietnam.

By 2028, VinFast has committed to employ 7,500 people at the site, about 30 mi. southwest of Raleigh. In terms of projected job creation, it is the largest state-backed economic project in Tar Heel State history.

The Raleigh News & Observer reported that VinFast, which produces fully electric SUVs, is poised to be the first car manufacturer to open a plant in North Carolina, completing a long-held ambition of state leaders.

“We’ve been working on this for decades, folks,” Gov. Roy Cooper said. “[For] decades we’ve wanted an automaker in North Carolina, and you know, somebody was looking after us. We were just waiting for that EV market.”

The state had previously vied to land Volkswagen, BMW, Volvo, Mercedes and a joint Toyota-Mazda plant, only to watch each opt for nearby Southeastern states.

The first construction phase, located in the rural community of Moncure, will include a vehicle manufacturing and assembly plant, which the company hopes to open in 2025 with an initial production capacity of 150,000 vehicles a year.

The plant, which has a Phase 1 total investment of up to $2 billion, spans an area of approximately 1,800 acres and is divided into five main production areas, including a body shop, general assembly, press shop, paint shop and an energy center. There will also be other functional facilities within the factory, according to VinFast.

In the initial phase, the factory will focus on building VinFast’s VF 7, VF 8 and VF 9 electric vehicles. The supplier base for components and materials will be primarily concentrated in the United States, Vietnam and a few other countries, the manufacturer said.

VinFast added that future expansion and updates for the factory will be identified in the next phase of construction. Currently, the manufacturer has appointed Clayco Corp., with headquarters in St. Louis, Mo., to be the general contractor and construction management company to lead the project.

In total, VinFast has pledged to invest $4 billion in the site. Other speakers at the groundbreaking ceremony included VinFast CEO Le Thi Thu Thuy, Vietnamese Ambassador to the U.S. Nguyen Quoc Dzung, and State Rep. Robert Reives, D-54th District, who represents Chatham County.

Earlier in July, the company submitted site plans to the county planning department that contained designs for nearly 3 million sq. ft. of space. Even as officials spoke at the event, construction crews could be seen working in the distance.

VinFast is a relatively new car company, having formed in 2017 as a subsidiary of the Vietnamese conglomerate Vingroup. It is owned by Pham Nhat Vuong, the Southeast Asian country’s wealthiest individual. Two years ago, the company pivoted toward only producing electric SUVs and began targeting foreign markets.

The News & Observer noted that the expansion has come at a hefty price.

In the past six years, the parent company has spent $9.3

billion to fund VinFast operations, according to public filings to the U.S. Securities and Exchange Commission. Since 2021, the year it began ramping up its global EV capacity, VinFast has lost a combined $4 billion.

Last summer, VinFast secured $4 billion in loans from Credit Suisse and Citigroup. In April 2023, the company announced $2.5 billion in additional funding from VinGroup and from Vuong personally.

When announcing the Chatham project in March 2022, the state and county combined to offer VinFast up to $1.25 billion in performance-based payroll tax cuts if the company met its future hiring and investment targets.

The North Carolina General Assembly also appropriated $450 million to improve nearby roads, prepare the site and enhance water and sewer infrastructure around the manufacturing facility.

VinFast also has applied for a $1.4 billion loan from the U.S. Department of Energy, which oversees a program designed to promote the domestic production of fuel-efficient vehicles.

For now, VinFast produces vehicles in Vietnam, but officials hope the North Carolina plant will support its future global ambitions.

“This will better position us to manufacture and distribute EVs in North America and fast-growing markets with greater speed and efficiency,” Thuy said.

According to the company, VinFast has so far delivered 350 VF8s, its five-seat model, to U.S. customers since its first batch of vehicles was shipped in late 2022.

The product support team at Terex Utilities hosted 58 participants from equipment dealers, utilities and utility contractors from all across the United States and Canada.

Held at the Lake Area Technical College Facility, Watertown, S.D., in June, instructors from the Terex Utilities Service School provided hands-on training for digger derricks and aerial devices.

While the training is geared for technicians, many individuals who have responsibility for various aspects of spec’ing, parts management, or even sales, can benefit from this hands-on learning experience. In addition, the experience level of the technicians ranged from just weeks to 29 years on the job.

“Technicians are able to learn from our instructors so they can stay current on best practices in order to be more efficient. Individuals in roles that support technicians get the chance to meet the Terex Utilities tech support team in person so they can get to know them if they ever do have to call for assistance,” said Kenny Vlasman, customer service manager at Terex Utilities.

Participants rotated through 12 different stations, which were held in shop bays, in classrooms and outside. Stations included

instruction on the Hi-Ranger TM Series, Optima and Commander products. In addition to general troubleshooting, maintenance and inspections, other sessions took deep

dives into chassis controllers, aerial device leveling systems and digger derrick planetary rotation and hydraulic overload protection.

Mike Sherman, technical support manager of Commercial Utility Equipment in Canada believed that there were many valuable take-aways from this training experience.

“This is the best training I’ve done for utility equipment, and I’ll be able to use what I learned this week to better support our customers and help them troubleshoot and find the root of the problem. The instructors referenced 30 to 40 different Tech Tips during the sessions and each one was so critical to know about because they could save you hours of your time trying to figure out an issue and thousands of dollars,” said Sherman.

“It’s a great refresher to go through handson training when given the chance. Going through the hydraulics and schematics stepby-step with instructors and hearing them break things down helps me to be more efficient. There are things taught in these classes and in the Tech Tips that expand on standard training materials. Those tips and the connections that I have made with everyone throughout the week are invaluable. Its so important to have a network of people you can call when you need help,” said Aubrey Fortenberry, fleet coordinator from Coserv Electric.

at mitigating the impacts on existing commercial fisheries, and to deal with potential flooding concerns of residentsandbusinessesthatare outside hurricane levees south of the diversion.

The extensive project is being built under a stateallowed “construction manager at risk” program, which requires the construction management firms to deliver the project within a guaranteed maximum price, working with designers throughout the design process.

Alberici, based in St. Louis, Mo., and Atlanta’s Archer Western, a subsidiary of Walsh Construction, was selected to be the lead construction management companies on the Mid-Barataria diversion effort. There also

are 16 subcontractor firms involved in the construction project.

AECOM, which has its headquarters in Dallas, is the enterprise’s lead design studio, with assistance from 15 subcontractors. AECOM also serves as the lead construction services contractor with19subcontractorsworking for it.

Last December, the U.S. Army Corps of Engineers (USACE) approved permits and permissions for the MidBarataria Sediment Diversion after completing an extensive environmental review and analysis of the project,accordingtothegovernor’s office.

The multi-billion-dollar construction cost for the diversion includes $2.26 billion provided by federal and state trustees overseeing the BP Deepwater Horizon oil spill damage settlement, and $660 million from the National Fish and Wildlife Foundation, with the funds coming from criminal fines assessed to BP and Transocean.

The sediment diversion project is not without its critics, among them oyster growers, shrimpers, and other fishers whose catches are likely to be dramatically affected by the diversion's freshwater flow, and a number of politicians, including Lieutenant Gov. Billy Nungesser, who has said the money for the project would be better spent on other projects that build land more quickly.

Other state officials, including Edwards, point to broad support for the project from a variety of scientists and scientific studies, includingtheenvironmentalimpact statement. They have gener-

ally concluded the diversion's benefits will outweigh itseffects,andtheyalsopoint out that Louisiana already is spending much of its coastal restoration money on projects that dredge sediment from the river and pump it into open water to build new lands.

They also assert that the diversion's continued flow of sediment and nutrients will extend the life of such pumpand-fill projects beyond their expected 20-year lifetimes. In addition, the land built by the project is expected to reducestormsurgeonnearby hurricane levees by as much as 6 in.

Haase, for one, told the Times-Picayune that the diversion will improve freshwater fisheries over its lifetime.

Another expected upside to the Mississippi River’s freshwater being used to build new wetlands and improve existing wetlands is that nutrients in the water, including phosphorus and nitrogen, are likely to be taken up by that vegetation before reaching the Gulf of Mexico, he said.

That could help reduce the size of the annual low-oxygen dead zone along the state’s coast, which is caused when the nutrients create algae blooms that die and sink to the bottom, where they decompose and use up oxygen in the coastal bottom waters.

The state also will focus partofitsmitigationfundson reducing the loss of wetlands in the part of the southernmost wetlands at the river’s mouth,whichareexpectedto shrink because the diversion will capture sediment keeping them above water. One way of doing it is creating more crevasses along channelsrunningthroughexisting delta to encourage the building of more land.

ness volume was up 1.9 percent compared to 2022. The ELF Foundation’s Monthly Confidence Index in July, at 46.4, marks an increase from the June index of 44.1.

“The second quarter concludes on an optimistic note,” said Ralph Petta, ELFA president.

Respondents reported strong business performance coupled with a positive outlook for the short-term future of the industry, he added. “As inflation continues to decelerate, the equipment finance market enters the second half of the year in fine shape.”

Anthony Sasso, with TD Equipment Finance, believes the equipment finance industry has stayed strong.

“The industry has remained resilient through one of the most turbulent periods in recent economic history,” said Sasso. “Despite economic headwinds, like high interest rates, the sector continues to see opportunities for growth and innovation.”

He said the year-over-year increase in overall new business volume is consistent with what his company has seen.

“Customers across many sectors continue to look for financing solutions to help them acquire equipment to keep up with demand.”

In fact, ELFAreported in July that new business increased more than 6.5 percent last year. The association’s Survey of Equipment Finance Activity (SEFA) saw a higher increase of 7.4 percent in 2021. The annual survey found that after the pandemic rebound, 75 percent of survey respondents saw an increase in volume in 2022.

Federal reserve interest rate hikes caused the cost of funds to jump 211 basis points over the year.

“Managing this cost increase will be a major emphasis as finance companies make their way through the higher interest rate climate,” noted the association.

Construction machinery was among the top five most financed equipment, along with transportation, agriculture, IT and industry/manufacturing. The construction sector was among the top five end-user industries contributing the largest share of new business, as well.

The survey found that credit approvals increased year over year, but the percentage of booked approvals declined slightly.

ELFA reports that the number of applications dropped but the dollar volume increased, a symptom of inflation. Reporting on its 2023 construction industry forecast, Wells Fargo noted “cautious optimism” from nonresidential contractors and distributors.

Top concerns include the availability of skilled workers, rising interest rates, economic uncertainty and supply chain disruptions.

Despite the economic challenges of 2022, the non-residential construction industry maintains a hopeful long-term outlook for 2023.

“Economic uncertainty and increasing interest rates are two primary concerns for construction executives,” said James Heron, Wells Fargo Equipment Finance Construction Group. “Despite market variables, the optimism reflected confirms industry leaders maintain a deep-seated belief in economic recovery.”

The economic environment has caused a divide in perspective and expectation among executives, according to the

survey. Those who feel that non-residential construction will remain at current levels also expect activity will begin to increase in 2024 or later.

“However, those who do not believe non-residential construction will remain at current levels foresee a decrease in 2023.”

Among top risks, concerns and opportunities, executives are concerned about workforce, the economy, interest rates and the supply chain.

“Inflation has impacted more than 82 percent of surveyed businesses,” reports Wells Fargo. “Increased material cost has impacted profitability for more than 59 percent of businesses surveyed.”

More than 50 percent of contractors expect to rent heavy equipment at the same pace. The survey found that equipment purchases will be contingent on a stronger backlog of jobs and lower costs. Distributors report continuing to rent the same or more equipment now than a year ago and continue to utilize 70 percent of their fleet.

Thinking of growing your fleet? There are basics you should know about financing or leasing when you’re ready for your next purchase.

The financing process may be easier than you think, according to construction materials supplier White Cap.

“Financing provides construction companies the opportunity to acquire equipment when paying outright is not an option,” said Randy Hall of the company’s resource center.

Depending on your credit, 100 percent loaning financing may be an option. Otherwise, you may have to make a down payment. As with leasing a vehicle, you pay monthly and at the end of the lease period, you either pay the remaining balance or end your lease. Either way, it’s an ideal path to acquiring the equipment you need for your job without the

since work began in 2018.

“The opening of lanes from I-440 to U.S. 70 Bypass in April provides at least two additional lanes in each direction and eliminates a longtime bottleneck that existed where three lanes dropped to two on I-40 East just past the Business 70 exit in Garner,” saidAaron Moody, NCDOT public information officer. “The final four miles of the widening project, from U.S. 70 to Cornwallis Road, and the overhaul of the NC 42 interchange are scheduled to be complete in late summer 2024.”

Until now, traffic along the 9-mi. stretch has been restricted to two lanes in each direction, with barrier wall used to shift and separate the travel lanes from those being worked on. All 13 mi. of roadway serve communities in Wake and Johnston counties, connecting the region to I-95.

“An estimated 35.6 million vehicles traveled the roadway in 2015, causing congestion and frequent delays, especially in the morning and afternoon rush hours,” said Moody. “Traffic is projected to increase 65 percent by 2040. Conditions will only worsen, especially around the I-40/N.C. 42 interchange, an area that’s booming in residential and commercial growth.

“Widening from two to three lanes to four to five lanes in each direction and improving interchanges along this stretch will help ease congestion and delays, make travel safer throughout this heavily traveled area and better accommodate traffic due to future growth.”

The section of I-40 is one of the primary beach routes for people in and west of the Triangle area and passes through one of the fastest growing areas in the state in Johnston County. Moody explained that maintaining staff has been an issue during construction, along with competing for resources with other projects, as well as communicating to the public the progress being made that isn’t always visible. Dealing with motorists also is a challenge.

“With the amount of daily traffic passing through the work zone, the project must be prepared to complete nighttime work promptly, to remove traffic control devices each morning to ensure a safe work zone. The volume also limits the scheduling options for the contractor, restricts hauling of materials to and from the project and increases the amount of time to safely complete operations. Traffic shifts throughout the project take significant planning to ensure their success.”

Workers are tackling paving, median barrier wall construction, the diverging diamond interchange at NC 42, opening the new interchange at Cleveland School Road and constructing the diverging diamond interchange at Jones Sausage Road. Other tasks include the widening of NC 42, grading between NC 42 and Cornwallis Road on I-40 and miscellaneous signage, signals, fiber and water/sewer work that has not been completed.

Moody noted that new flyover bridges at the I-40/I-440 interchange opened in December 2020.

“The contractor is working on wider/longer bridges at the Rock Quarry Road overpass and the U.S. 70 Business interchange [exit 306]. Diverging diamond interchanges will be added to the Jones Sausage Road [exit 303] and N.C. 42 [exit 312] interchanges.”

Moody said inclement weather also is a factor during construction.

“We’ve had a significant amount of rain during the winter, as well as heavy storms we received over the fall and summer. The storms increase the amount of erosion control response and often delays paving, grading and stone operations.”

As for site work, said Moody, “S.T. Wooten constructed a temporary ramp from a bridge on East Garner Road to facilitate hauling operations in the median of I-40. This ramp allowed more than 21,000 truckloads of material to be delivered directly to the median without having to access I-40. By

see NCDOT page 58

Pages 29-33

Caterpillarannouncednewoptionsforthe

Cat Smart Grader Blade and Smart Dozer Blade.

The new external control kit for GB120 and GB124 smart grader blades expands use of these blades to Cat D and D2 series SSL andCTLmachines,enablingcustomerswith previous model fleets to run smart blades. The new 3D grade control kit uses existing connections to easily add automatic blade control to the Cat Smart Dozer Blade.

Cat Smart Grader Blades set the standard for machine and attachment control integration. Previously, these smart blades were made available for customers with Cat D3 series SSLand CTLmachines. The new external control kit provides customers with a means to run smart grader blades on all D-series and select older Cat machines.

Simplifying operation, GB120 and

GB124 blades automatically detect whether they are being operated on a D3 series or machine equipped with the external con troller.

The new external control kit includes a thirdjoystickforoperatingbladeraise/lower, tilt, angle and wing functions like smart con trol for D3 series machines. In addition, it includes the wiring harnesses, a RAM mount, brackets and all the necessary hardware required for smart grader blade control.

Compatible with Cat Grade and Earthworks GO! systems, the new external control features selectable modes for left, right and tandem control. Standard crossslope assist and full proportional control of all functions improve operating efficiency.

A valuable tool for experienced as well as novice operators, the new 3D GPS/GNSS grade control for smart dozer blades on Cat CTL machines guides the operator to accurately grade planes, slopes, contours and complex curves.

The new external control kit for GB120 and GB124 smart grader blades expands use of these blades to Cat D and D2 series SSL and CTL machines, enabling customers with previous model fleets to run smart blades.

Avaluable tool for experienced as well as novice operators, the new 3D GPS/GNSS grade control for smart dozer blades on Cat CTL machines guides the operator to accurately grade planes, slopes, contours and complex curves. It provides blade vertical height and horizontal positioning guidance, or, alternatively, the system controls the blade relative to a design loaded into the grade control system.

Automated blade control takes the guessworkoutofwhatthegradeshouldbe,allowing operators to achieve design plans faster. Veteran operators can work more productively with the system, and those with less experienced can work more confidently and quickly build grading skills. Regardless of operator experience level, the 3D grade control system can reduce rework, labor and materials used on the job.

The base Cat Smart Dozer Blade comes standard with all the required hookups to install 3D grade control components. Software updates and the hardware are available for existing machines and smart dozer blades to operate grade control. For more information, visit

Ideally suited for maintaining farmland, ranches and recreational property, the Brush Cutter Pro delivers the same premium cutting performance and versatility as Diamond Mowers’ Pro X unit, but in a lighterweight model engineered specifically for mediumduty use and applications.

Available in a 72-in. cutting width, the Brush Cutter Pro has a continuous cut capacityof3in.(andamaximum cut capacity of 5 in.), aflowrangeof17to41gpm and is intended for five hours of weekly use (260 hours annually).

• Applications — Farms/ranches, recreational properties

• Materials — Grass, trees, branches and brush up

to 5 in. in diameter

• Compatibility — Standard and high-flow skid-steers

The Brush Cutter Pro is equipped with four hydraulic motors that optimize blade speed for safe operation and perfectly cut vegetation; hardened steel blades that effectively slice through vegetation and are

built to swing and break away when in contact with rocks;easilyreplaceablehex blade bolts that provide the toughest blade retention in the industry; and multi-hex cutting discs that provide greater inertia in tougher conditions.

For more information, visit diamondmowers.com.

You will find the parts you need at MOBRO Marine, Inc. We purchase in bulk directly from the manufacturers to maintain our large inventory. We also have a large inventory of long-lead time parts for cranes that can’t be found anywhere else. Not only does this mean we have the part you need in stock, it also saves you money. Because we buy in volume, we can buy for less and pass the savings on to you.

Our large inventory keeps construction equipment performing at optimum levels. We offer same-day shipping on most partsyou’ll experience minimal downtime. We are a full-service company. We not only supply parts, but we also service and repair construction equipment and cranes of any type.

GRYB International, a manufacturer of heavy equipment attachments, made its grand debut at the 2023 ConExpo.

GRYB International, a company devoted to providing high-end heavy equipment attachments, showcased its six brands of products at ConExpo.

The GTR tiltrotator is designed to optimize excavators with next-level versatility and productivity. This attachment adds a range of new functionalities and enables 360-degree rotation and up to 45-degree tilt on multiple axes — making it easier than ever to get into hard-to-reach areas.

“The GRYB International team is thrilled to participate in the highly anticipated event that brings together industry leaders and innovators from around the world for an expansive display of new products, technologies and services,” the company said.

Witheightcompaniesdedicatedtoservicing the heavy equipment industry, GRYB International showcased the following products at ConExpo:

ï Bateman — Manufacturer of grapples, generatorsandclamshellbucketattachments

for forestry, demolition, port, railway, recycling & waste industries.

ï Winkle — Manufacturer of magnets, crane components, electrical control systems, magnetic lifting devices, magnetic separation equipment, mechanical lifting devices, power supply sources, transfer equipment for scrap and recycling, and steel mill industries.

ï Shearex — Manufacturer of hydraulic attachments, including mulchers and tree shears for the land clearing and forestry industry.

ï Serco — Manufacturer of grapples, truck & trailer-mounted loaders, knuckleboom loaders and saws for multiple industries including forestry and construction.

ï e-Trak — Designer of technology for measuring and safety devices for the heavy machinery industry.

ï GRYB — Complete solution manufacturerofheavyequipmentattachmentsforsix industrialsectorsincludingexcavation,demolition, construction, recycling and handling and snow removal.

For more information, visit gryb.ca.

The Kenworth truck assembly plant in Chillicothe, Ohio, recently held its second annual Kenworth Truck Parade in downtown Chillicothe. This year, the parade paid tribute to Kenworth’s 100th anniversary.

The 2023 Kenworth Truck Parade featured more than 50 new, classic and customized Kenworth trucks, including models built in the 1920s and 1930s, a 1976 Bicentennial W900 VIT-200, two Liberty Edition Kenworths — a K100 Cabover and W900 Conventional, a 1984 W900B from Australia, as well as Kenworth’s 100th anniversary Signature Edition T680 and Limited EditionW900 trucks.

A T680, recently delivered to Heartland Express and representing the milestone 750,000th truck producedattheKenworthChillicothe plant,alsoparticipatedintheevent.

To commemorate Kenworth’s 100th anniversary, the trucks featured in the parade started with those built in the 1920s and followed chronological order ending with trucks built in 2023 to showcase Kenworth’s history and advancements throughout the years. Drivers from across the United States and Canada traveled to Chillicothe to showcase their trucks in the parade. The parade began at dusk, allowing drivers to show off as they made their way through the historic downtown area of Chillicothe.

“After a successful inaugural Kenworth truck parade last year, this year’s event was even bigger

and better as we continue to celebrate Kenworth’s 100th anniversary,”saidJackSchmitt,Kenworth Chillicothe assistant plant manager.“Itwasgreattoseetrucksdating back to the 1920s when Kenworth first opened its doors to our latest models, many of which are built here in Chillicothe. The event would not be possible without the engagement of our Kenworth Chillicothe planning team, the drivers who came from near and far to show off their rigs and the city of Chillicothe for coming out to support the parade.”

Leading up to the truck parade, the Kenworth Chillicothe plant heldeventsatitsfacilityfordrivers and their families participating in and attending the parade. Drivers had an opportunity to tour the Kenworth Chillicothe plant to see where the majority of Kenworth’s

trucks are built. The plant also hosted an employee family event on the plant’s property during the day of the parade.

Chris Koenig, who owns the Kenworth 75th anniversary LimitedEditionKenworthW900L that was used to haul a special Kenworth history trailer for Kenworth’s 75th anniversary tour, showedoffhisbigrigattheparade and attended events held at the Chillicothe plant. The same trailer, owned by the Koenig family, was recently reimagined and is being used during this centennial year as amobilehistoryexhibittocelebrate Kenworth’s 100th anniversary.

“My father Al was a big Kenworth fan and history buff and he passed along his passion for Kenworth trucks down to me,” saidKoenig.“Itwasfuntotourthe plant and meet other Kenworth

enthusiasts at this event. There were some really great looking trucks at the parade this year, including vintage trucks built when Kenworth first got its start.”

Tosupportthelocalcommunity, theKenworthChillicotheplantand the United Way of Ross County teamed up to coordinate a 50/50 raffle, with proceeds going to the United Way of Ross County. During the parade, Kenworth Chillicothe employees and members of the United Way of Ross Countywalkedaroundtheeventto sell raffle tickets. The Kenworth Chillicothe plant also raised moneyforthenon-profitorganization through sponsorships of the VIP area along the truck parade route. In total, more than $22,000 was donated to the United Way of Ross County.

TheKenworthChillicotheplant,

which opened in 1974, is located on a 120-acre site 50 mi. south of Columbus, Ohio.The 622,000 sq.ft. plant features advanced manufacturing technologies, including robotic assembly and a modern paint facility that utilizes the latest technology in the industry. The multi-level paint facility went into production in October 2021 and is equipped with bell spray head technology that improves the appearance and transfer efficiency of the paint.

In 2022, the Kenworth Chillicothe plant received two Manufacturing LeadershipAwards foritsnewKenworthPaintFacility and Henrob Error Proofing project from the National Association of Manufacturers.

For more information, visit www.Kenworth100.com and www.kenworth.com.

of ofesProfe Pr fes es s ailerth ailert ailer aile ail tha tr t

verytim veryti very ver very tim e our ourequequi oureq oure ourYo f r e er t thha

ur equi r qui q ery ry y tim im ailertha ilertha lertha ertha rtha

rustA rust rus rust A T ulers l le ulerlers ers rs s ust st t A

y pment yo ment you ent nt s our b ur ex ust st the t he e exp p ne erha rha

ssional Hau ssi ssio ssion ssiona sional H ional Ha onal nal al l Hau au u verhav verh ver ve ver ha une oune youne tyoune atyoune atyoun atyou atyo t at you ne

rustthe rustth rustt rust rus rust the exp rust the Trust e e. e

ipment is your b ipmentiis ipmen ipme ipm i H lH l i ilH y yoou u never

o usiness, ou siness, our ness, ours ess, i ss, s, , ours urs

Ai st i sur ake ke e ure e

o make su s sure i om oma omak omake s t

owmas owma owmToow T s at ts tsat tsa tper

wmas mas as s oworryaworryaborryaboorryabou ryabou yabou abou u

business, ours is rs is t business busines busine busin bus e o w woorrry y a abboou

o odesigdesign odes ode oddesign a t r er ter ster stert ste

oworry oworr owo ow o worry abou t et vet ve ve

sB s B America Ammerica’ Ame Amer Ameririca ca a B . t. ut. ut t

PACCAR and Toyota Motor North America Inc. announced an expansion of their joint efforts to develop and produce zero emissions, hydrogen fuel cell (FCEV) Kenworth and Peterbilt trucks powered by Toyota’s next-generation hydrogen fuel cell modules.

The expanded agreement supports ongoing development and commercialized zero-emission versions of the Kenworth T680 and Peterbilt 579 models featuring Toyota’s hydrogen fuel cell powertrain kit, with initial customer deliveries planned for 2024.

PACCAR and Toyota have collaborated on FCEV truck development for the past several years, including a successful pilot program which deployed 10 Kenworth T680 FCEV trucks at the Port of Los Angeles. The pilot provided both Kenworth and Toyota with real-world feedback that further enhanced the performance and range of the vehicle.

Designed for use in heavy-duty commercial vehicles, Toyota’s heavy-duty fuel cell electric powertrain kit was recently awarded the Zero Emission Powertrain certification by the California Air Resources Board (CARB). Toyota will begin assembly of

the modules in the United States in late 2023.

John Rich, PACCAR chief technology officer, said, “Having worked extensively with the Toyota team, we are confident that our combined efforts can deliver industry leading FCEV trucks with all of the quality, reliability and aftermarket support that Kenworth and Peterbilt customers depend upon. This partnership further expands PACCAR’s industry-leading lineup of zero emissions vehicles that enhance customers’ operational efficiency and reduce their environmental impact.”

“We are excited to work with PACCAR to realize a future where Toyota’s industry leading hydrogen fuel cell technology can power heavy-duty trucks that will travel across highways throughout the U.S. with zero emissions,” said Christopher Yang, TMNA group vice president of Business Development.

“This innovative technology enables us to provide our commercial customers with a viable carbon-neutral option to further their business, while also contributing to Toyota’s mission to reduce and ultimately eliminate carbon from the environment.”

EQUIPMENTSHARE

www.equipmentshare.com

10179 US-78 Ladson, SC 29456 843-709-2458

145 Thunderbird Dr. Richmond Hill, GA 31324 912-400-0752

2919 E. Napolean St. Sulphur, LA 70663 337-284-9804

PARMAN TRACTOR & EQUIPMENT

www.parmantractor.com

3570 Dickerson Pike Nashville, TN 37207 615-865-7800

HEAVY MACHINES, INC.

www.heavymachinesinc.com

3930 East Raines Road Memphis, TN 38118 800-432-8902

2115 N. Thompson Lane Murfreesboro, TN 37129 877-200-5654

5200 Hollywood Ave. Shreveport, LA 71109 800-548-3458

364 Bob Jobe Rd. Gray, TN 37615 855-201-7453

10110 Roberts Way Covington, GA 30014 770-788-0888

7651 Theodore Dawes Rd. Theodore, AL 36582 251-653-5955

825 31st Street North Birmingham, AL 35203 205-323-6108

LINK-BELT MID ATLANTIC www.link-beltmidatlantic.com

Ashland, VA 866-955-6071

Chesapeake, VA 800-342-3248

Frederick, MD 833-546-5235

MID SOUTH MACHINERY, INC.

www.gomidsouth.com

3233 Highway 80 West Jackson, MS 39204 601-948-6740

3145 Cliff Gookin Blvd. Tupelo, MS 38801 662-690-6553

14336 Seaway Road Gulfport, MS 39503 228-867-1555

www.gsequipment.net

Tampa, FL 866-586-8956

Pompano Beach, FL 954-327-8808

Ft. Myers, FL 239-334-6063

Tallahassee, FL 850-574-0892

Orlando, FL 407-859-9160

Jacksonville, FL 904-268-4400

Approximately 20 percent of the more than 25,000 attendees and exhibitors who attend Equip Exposition, the international landscape, outdoor living and equipment exposition, are women.

Now a new event at Expo — the inaugural Women’s Leadership Reception — will help them connect and build their industry network. The reception is sponsored by SiteOne and Belgard, and will be held Oct. 19, from 5:00 p.m. to 6:00 p.m. at the Kentucky Exposition Center (KEC).

“Women are a key demographic in the landscape contracting and outdoor power equipment industries. It made sense to create programming that serves them,” said Kris Kiser, president and CEO of the Outdoor Power Equipment Institute (OPEI), which owns Equip Exposition.

Whether registered as exhibitors, landscape contractors, distributors or dealers, all women attendees may participate in the reception. Attendees must RSVP to attend when they register. After the reception, shuttle transportation will be provided from the KEC to the KFCYum! Center for the concerts by Third Eye Blind and Dylan Scott that evening.

“SiteOne is excited to support the inaugural Equip/OPEI 2023 Women’s Leadership Reception,” said Christina Moore, director, Events at SiteOne Landscape Supply. “By partnering with OPEI, we hope to continue advocating for female growth within the industry and encourage Equip and HNA attendees to take advantage of SiteOne career growth tools like our annual WIGI Conference and Women in the Green Growing community groups. We look forward to connecting with this year’s attendees and helping one another.”

Jenny Nail, chief revenue officer, Oldcastle APG, added,

“The Belgard team is thrilled to be a sponsor of the inaugural Women’s Leadership Reception at Hardscape North America. Events like this are important for supporting female colleagues and peers in the outdoor building products industry while encouraging more women to enter this excit-

ing, challenging and diverse field. We are proud to be involved in this event and we look forward to engaging with attendees.”

Equip Expo has learned there is tremendous interest in bringing together women leaders across the green industry.

“I have seen firsthand how promoting and championing a diverse workforce benefits our business. EXPO is a unique opportunity to network with and learn from leaders and experts from all facets of the green industry, and it’s inspiring to see an intentional focus on attracting, connecting, and developing women in our industry,” said Kariné Stuimer, senior vice president at BrightView Landscape Services Inc. “BrightView is honored to be part of an event that attracts such a diverse group of industry professionals.”

For many women, attending Equip Exposition is about seeing the latest equipment and innovations in the field, while also connecting with peers.

“As a woman in a leadership role in what has always been considered a man’s industry, I am increasingly proud to attend events like EXPO and gain strength, knowledge and encouragement from fellow female attendees,” said Donna Vignocchi Zych, president of ILT Vignocchi.

“As someone who does not profess to be a feminist, I will say that we do have different issues than our male counterparts. Being able to network and find support on such a large scale is vital to encouraging women to continue to see the green industry not only a viable place for a career, but a prosperous one.”

For more information visit www.EquipExposition.com.

There is a labor shortage in the construction industry — and it’s not exactly breaking news. Headlines declare that “nobody wants to work anymore” — but is this explanation really at the root of what’s a longstanding, industry-wide issue?

Amid the “Great Resignation,” as Baby Boomers retire and Gen Z workers reject the long hours of the construction industry, it’s more important than ever to examine the causes of this unprecedented labor shortage and explore potential solutions.

Numerous companies are feeling the pressure, especially in the skilled trades, and many have not yet been able to solve their workforce woes. After increasing pay and flexibility with little to no results, a lot of companies find themselves asking — is our company culture to blame?

During an education session titled “Culture in Construction — Is It Really That Bad?” at ConExpo-Con/AGG 2023, speaker and construction industry advocate Wally Adamchik walked through the reasons why the answer to that question is both yes and no.

The good news is that industry-wide survey results indicate the construction industry’s culture issue may not be so bad, according to the 2019 People in Construction Report, saidAdamchik. In fact, 83 percent of

people say that they would reapply for their current position, and 73 percent of people say that they are happy at work. However, these results are not good enough to sustain successful growth and project execution, according to Adamchik. In addition, there is a significant divide between project management in the office and field supervision on the job site.

In the office, 81 percent of employees say that they have a close friend at work — in the field only 50 percent of employees share that sentiment. On top of that, 75 percent of office workers feel that they can maintain a reasonable work-life balance, while again only 50 percent of field employees feel that they can maintain a reasonable work-life balance.

Rather than list off more statistics about the industry’s labor shortage, many leaders want information about creating a more longlasting and motivated labor force. There are several concrete actions that can be taken to improve company culture and keep workers happy, and companies should act now to avoid losing more of their employees.

The labor shortage isn’t exclusive to the construction industry. Even organizations with good company culture can implement some of these changes to elevate employee experience:

• Standards and values. Approximately

90 percent of respondents agreed that ignoring the core values of their workplace would get them into trouble. This shows that workplace values still matter, and the most visible way to manifest this is to enforce standards across the board. There should be no double standard when it comes to values. Employees will take standards and values more seriously when they are a part of company culture, and see leadership being held accountable to the same standards as employees.

• Creating lasting change. Three quarters of senior leadership (those who are supposed to be spearheading change in the workplace) say that their efforts fall short. Change requires organizational capacity and requires a significant personal investment from leaders. Creating change with concrete steps to follow along the way will help companies maintain organization and encourage both employees and leadership to follow through.

• Encouraging, participating in recognition. There are a multitude of opportunities to tell employees how much they are appreciated. Chances are, on a daily basis there are numerous opportunities to give positive and relationship-building recognition. And companies that regularly participate in positive recognition are more likely to attract and retain loyal employees.

• Amping up one’s referral program.

About 84 percent of employees surveyed say they would recommend their workplace to a friend (but don’t). Furthermore, 83 percent of employees say that they would reapply for their current position if given the chance. There also are several ways to increase the effectiveness of a referral program, including using an easy-to-use option, offering a mixture of incentives, announcing or reannouncing the program and recognizing current employees for referring candidates.

• Bridging the gap between teams and departments. In construction, there are several discrepancies between survey answers from field and office staff members that could be corrected with a little work. For example, creating teambuilding opportunities for one’s entire staff on a monthly or quarterly basis can go a long way toward building camaraderie.

While there are several improvements that would benefit the construction industry’s culture, and company culture in general, the survey results show that the situation may not be as bad as advertised. There are several actions that employers can take to improve company culture, from enforcing values to bringing employees together. Even small actions make a big difference, and there is no better time to start than now.

Kleemann uses three different drive concepts that offer the best possible solution depending on the tasks at hand. Whereas electric drives score very well with regard to the CO2 footprint, in some situations a fuel-saving diesel drive is the better solution.

E-DRIVE, D-DRIVE and H-DRIVE represent the variants diesel-electric, diesel-direct and diesel-hydraulic.

The decision on the most efficient solution depends on many factors: For example, whether there is a power supply option available on site, whether the machines are used in an urban environment or which local environmental regulations apply.

The E-DRIVE drive concept offers two options: Diesel fuel or all-electric.

All-electric operation is environmentally friendly: there are no CO2 emissions on site. A precondition for this is a good power infrastructure, which is often available in quarries or in larger recycling yards.

If only an insufficient power supply, or none at all, is available, a diesel-electric work option is available — for example, if the complete plant in the quarry is to be moved along the rock face. Power is then supplied from a long cable, which is often too complex, or even no longer possible. In this case, power comes from the fuel-efficient diesel engine.

The crusher and all conveyor belts are then still driven electrically by a generator. Depending on the local situation, the E-DRIVE concept offers high flexibility.

The diesel-direct drive D-DRIVE provides power directly from the engine to the crusher. In the last few years, it was possible to reduce consumption, for example, through the load-dependent fan drive of the new EVO2 Generation.

With regard to the degree of efficiency, the diesel-direct drive has the edge in lowering fuel consumption significantly. Due to their compact size and well thought-out transport options, the machines can be positioned in any place on the work site.

If continuous use of the all-electric drive is not possible, the D-DRIVE is the better, more sustainable choice — whenever flexibility is required. This is the case with demolition and processing work in urban areas, but also in road construction where the machines have to be moved along as construction progresses.

The screening plants from Kleemann use an effective diesel-hydraulic drive. In this case, hydraulic pumps operate all machine parts such as screen, belts and drive system.

The power requirements of the screens are considerably lower than a crusher — fuel consumption during operation is therefore more favorable. The optionally available StartStop system can reduce consumption even more.

With the configuration with Dual Power, Kleemann screening plants have an option for an all-electric power supply. If a mains connection is available, the plant operates on site free of emissions — for example, in ecologically sensitive areas with strict stipulations.

Many factors play a role in the area of sustainability. Energy required for production, transport, storage, sales and disposal are all incorporated in the ecological footprint of the production process.

As far as CO2 emissions during operation are concerned, an all-electric plant is without doubt the best choice, according to the manufacturer. In other cases, you have to weigh up whether supply via an external power source involving high equipment and material costs is more constructive at the end of the day than technology with lower fuel consumption. Ecology also can mean placing your trust in low material usage and high durability.

For more information, visit www.wirtgen-group.com.

In the mid-1990s Caterpillar changed its approach to automation in mining.

A decade after it began a pioneering research program to drive the tech forward, the company realized that the sector was not ready for automation. Instead, it focused on thebuildingblocksthatwouldneedtobeput in place to make automation possible in future.

Roger Brereton, head of sales at steering system manufacturer Pailton Engineering, assesses whether the construction sector is finally ready for autonomous driving.

In 1985, Caterpillar began a research program into automation. A little over a decade later, it demonstrated two autonomous trucks running at the Caterpillar Proving Ground in Tucson,Ariz.

Atthisstageitwasclearthecompanywas well ahead of its time, but the feeling was that the sector was not ready for automation. This brought an end to the first generation of automation.

In the next phase, rather than continuing to focus on the development of the trucks, the engineers stepped back and began looking at the building blocks that would be needed to make automation a reality, such as improved GPS and on-board monitoring systems.

Today, Caterpillar remains a pioneer in this particular field of driverless tech. Currently, there are Command autonomous haulage system fleets operating at 17 mine locations around the world. However, Caterpillar faces stiff competition from other OEMs developing driverless off-highway vehicles.

VolvoAutonomousSolution(VAS)isone example of a company that is making inroads.

Partnering with Holcim, the company has developed an autonomous hauler that is currently being trialed at Holcim’s limestone quarry in Switzerland and it hopes that this will be commercially available soon.

Do these technological developments mean the construction sector is finally ready to embrace automation after all these years?

The development of driverless vehicles has thrown up many novel engineering challenges that were not anticipated a decade ago, from user skepticism to the difficulties of developing an artificial intelligence (AI) that can respond correctly to situations that have never been encountered before, the socalled ‘’edge case’’.

Whatisbecomingclearinthisstoryisthat each sector throws up different challenges andopportunities.Forexample,thedevelopment of ‘’robo taxis’’ was thwarted by the complexityofurbanenvironments,butlonghaul trucking, which involves more pre-

dictable journeys on long, straight roads, is now emerging as a key area for technological uptake.

In the construction sector, there are many different vehicles that fulfil different roles. This makes it difficult to generalize about the prospects for automation.

According to research by Arthur D Little associates, automation will play only a ‘’minor role’’ in the near future, with the majority of vehicles remaining at level two for the next 10 to 15 years. In this context, level two autonomy refers to operator assistance, like auto-steering, technology which is already widely in use.

The report concluded that construction was a particularly difficult area for automation, because of complex and dynamic construction environments, the fact that machines are used for only limited periods of time and at changing locations, and the need for precise interplay between multiple machines.

VAS has chosen to focus its energy on haulage systems, such as those found at quarries and mines, where the case for automation is strongest.These vehicles fulfil a single, simple function, they operate in a

closed-off environment and involve no onroad use. In these instances, the case for automation is a good one.

Although the key determinant will always be cost and return on investment, the arguments here are becoming stronger. Autonomousminingismoreefficient,thereby reducing overall costs. Near continuous utilization of machines and the elimination of shift change also enhance productivity. Improvements in cameras, sensors and data compression technology are all things that will help bring the cost down in the coming years.

Another key advantage is safety improvements, as these vehicles can remove the need for human operators in dangerous environments. According to Caterpillar, trucks equipped with its Command for hauling have moved more than three billion tonnes of material without a single lost-time injury.

One challenge for these vehicles is navigating inhospitable terrains. Even where these vehicles face only simple, repetitive routes in closed-off environments, they are often exposed to harsh under-chassis environments. As well as extensive testing to make sure theAI can cope with these condi-

tions, the conventional vehicle components, such as the steering parts, also need to be tested extensively to ensure they are designed to last.

Although OEMs will be determined to reach a more competitive price point, compromising on the quality of something like a bevel box has the potential to raise the whole-life costs of vehicle ownership, thereby undermining the arguments about gains in productivity.

Things have come a long way since Caterpillar introduced its first research program into autonomous driving in 1985. In 2022, some of the world’s leading OEMs have developed sophisticated driverless offhighway vehicles that are already successfully in operation at mines and quarries around the world. Driverless tech seems ideal for haulage vehicles, particularly in cases where its introduction can remove workers from unsafe environments. However, whether we can expect more widespread uptake across the sector remains to be seen.