By Cindy Riley CEG CORRESPONDENT

Beneath sunny skies, local leaders and project supporters gathered near a corn field in Evansville, Ind., as ground was officially broken on Section 3 of the I-69 Ohio River Crossing (I-69 ORX) project. The Indiana Department of Transportation (INDOT) is overseeing the $216 million design-build effort, which will improve the state’s infrastructure.

“This is a transformational project that will complete the interstate connection between Evansville, Indiana and Henderson, Kentucky,” said INDOT project manager Matthew Bullock. “That connectivity will be a tremendous benefit to both communities, states and the entire region. It will support the safer and more efficient movement of both people and goods in the region and will open the door to new opportunities.”

I-69 ORX Section 1 involves the approach work in Henderson, Ky., and is being overseen by the Kentucky Department of Transportation. Work is expected to be complete later this year. I69 ORX Section 2 is a bi-state project between Indiana and Kentucky and includes the new four-lane river crossing.

By Lucy Perry CEG CORRESPONDENT

Saying it’s “common sense to allow all eligible projects

the same access” to low-interest financing, Sean Duffy, U.S. secretary of transportation, announced in July an update to the Transportation Infrastructure Finance and Innovation Act (TIFIA). This move will allow the financing of up to 49 percent of costs on all types of transportation infrastructure projects. see CREDIT page 88

Construction crews competed an important milestone in the bridge building process as they worked through the night on July 16 and completed the concrete deck pour for the Fourth Street Northwest bridge over Interstate 90 in Austin.

The McCullough family hosted its grand opening of McCullough Kubota’s newest facility on July 18 at 21730 LaGrange Rd. in Frankfort, Ill. The new 16,000-sq.ft. facility is situated on five acres with six service bays.

16

The event offered attendees a hands-on look at the latest in heavy equipment, technology and attachment solutions, as well as the opportunity to connect directly with manufacturer representatives and the CMC team.

20

The event welcomed contractors, operators and industry professionals from across the region for a full day of live equipment demonstrations, networking and celebration.

30 CHICAGO FIRE FC REVEALS DETAILS FOR ITS $650M STADIUM

Chicago Fire FC released renderings and further details of the club’s $650 million soccer-specific stadium in downtown Chicago on July 16. The stadium, announced in early June, will be entirely privately financed by Joe Mansueto.

32 TAKEUCHI-US HOSTS MEDIA EVENT AT HEADQUARTERS IN PENDERGRASS, GA.

Takeuchi hosted construction equipment journalists and dealer representatives to its United States headquarters in Pendergrass, Ga., July 21-22. The focus of the event was to introduce the new Takeuchi TL11R3 compact track loader.

34 ROLAND ANNOUNCES JEFF PRICE AS NEW TERRITORY MANAGER

Roland Machinery Company announced Jeff Price as its new territory manager. Price will be working out of RMC’s Eau Claire location covering Eau Claire, Pepin, Pierce, Buffalo, Trempealeau, Jackson, La Crosse and Monroe counties.

34

Roland Machinery Company announced Dan Thurs to its newly created position of territory manager of forestry covering all of Wisconsin. This new position allows RMC to grow and invest in its forestry sales and service.

The Iowa and Wisconsin Departments of Transportation are proceeding with a revised plan for the construction of the new Iowa 9/WIS 82 bridge over the Mississippi River between Lansing, Iowa and Crawford County, Wis.

38 HIPOWER NAMES KYLE TINGLE DIRECTOR OF SALES

In this new role, Tingle will lead HIPOWER’s sales strategy for mobile power solutions across North America, with a primary focus on the rental and construction industries, as well as general prime power applications.

44

July was National Vehicle Theft Prevention Month, which offered the industry a crucial opportunity to understand the growing issue of equipment theft and how its data is driving change.

48

WORKSHOPS FOR WARRIORS

Foley Equipment, providing Caterpillar parts, services, sales and rental in Kansas and northwest Missouri, announced the launch of its “Parts with Purpose” campaign, supporting veterans transitioning to skilled trades.

56 IOWA DOT UNVEILS ONE-MAN POTHOLE FILLING MACHINE

In June 2025, the FAYAT Group signed a definitive agreement to acquire LeeBoy. This acquisition represents a key strategic move for FAYAT Group as part of its ongoing commitment to expand in the United States and Canada. 97 BIGIRON, SULLIVAN ANNOUNCE VINTAGE SALE AT ILLINOIS FARM PROGRESS SHOW

BigIron and Sullivan Auctioneers announced a vintage truck and tractor auction at this year’s Farm Progress Show in Decatur, Ill., Aug. 27. The auction will feature nearly 50 lots of vintage and rare equipment.

Earlier this year, the Iowa Department of Transportation (Iowa DOT) purchased the state’s first self-contained pothole filling truck — a more efficient and safer option for fixing potholes on state roadways. 66 FAYAT SHARES FURTHER INSIGHT INTO AGREEMENT TO ACQUIRE LEEBOY

Cape Girardeau, MO

KOMATSU PC210LC-11 $129,500 STK# KM2023069, 5422 HRS,

STK# KM2022307, 4628 HRS, Bridgeton,

KM2024119,

HRS, Franksville, WI 2020 Komatsu PC170LC-11 $139,500 stk# KM2024104 1404 hours, Slinger, WI

2021 Case TV450B, S/N JAFTV450KLM487291, 541 Hrs, CAB/AIR/HEAT, 2 SPEED, HYDRAULIC COUPLER, 84" GP BUCKET, HIGH FLOW PERFROMACE PACKAGE, SERVICED AND READY TO GO, UNIT WILL HAVE A NEW DOOR

$69,900

2022 Case SV280B, 171 Hours, S/N JAFSV280HMM403668, CAB/AIR/HEAT, HYDRAULIC COUPLER, 72" GP BUCKET, 2 SPEED, RADIO, EXCELLENT CONDITION FULL MACHINE WARRANTY UNTIL 11-22-24

Mike Garrard • (630) 492-9115 Bolingbrook, IL Contact us at Used@McCannOnline.com

our complete Used & “Like New” inventory at

2018 Case 521G, S/N NHF240998, 813 Hrs, Cab/Air/Heat, JRB Coupler 3 Yard GP Bucket Third Valve Ride Control Limited Slip Diff

$107,500

2022 Case 321F, S/N NNHP04331, 241 Hours, CAB/AIR/HEAT, HIGH SPEED TRANSMISSION, SKID STEER STYLE COUPLER, 1.7 cu yd BUCKET, LIMITED SLIP DIFFERENTIAL, THIRD VALVE HYDRAULICS TIRES LIKE NEW, PREMIUM CAB

2023 Case TV370, S/N 2023 Case TR370B, 176 Hrs, CAB/AIR/HEAT, HYDRAULIC COUPLER, 84" GP BUCKET, DELUXE CAB, PREMIUM DISPLAY PANEL, GOOD TRACKS

$82,500

$72,500

2019 Case Cx130D, S/N DAC130K7NKS7D1558, 358 Hours, CAB/AIR/HEAT, HYDRAULIC COUPLER, 18" BUCKET, AUX HYDRAULICS

$109,900

2023 Case TR270B, S/N JAFTR270LNM421971, 281 Hours, CAB/AIR/HEAT, E-H CONTROLS, HYDRAULIC COUPLER, 78" GP BUCKET, RIDE CONTROL, SELF LEVEL, HIGH FLOW HYDRAULICS, REARVIEW CAMERA, PREMIUM DISPLAY MODULE, FULL MACHINE WARRANTY UNTIL 1-30-25, JUST SERVICED READY TO GO $54,900

2018 Case CX245DSR, S/N NJS7K1152, 1306 Hours, Cab/Air, Kent Coupler, Aux Hydraulics, No Bucket, Bucket available at additional charge, Rental Fleet Roll Out

McCann Rents a full line of heavy and light construction equipment. Call us today to supply your next rental.

Roadtec RX100e - ‘18, approx. 500 hrs. Includes grade controls

$165,800 Sandvik CJ412 - ‘14, approx. 1400 hrs. Mobile jaw plant $540,800

Sakai R2H-4 - ’19, approx. 900 hrs. 83” triple drum static

$85,500

ROADTEC RP195 PAVER - ’08, approx. 8890 hrs. Carlson EZIV 10 screed, Moba grade & slope controls ....................................$35,200

Liebherr A904C Wheeled Excavator - ‘16, approx 550 Hrs, 2-piece boom, pin grabber coupler, aux hyd

ASTEC GT205MF, (’18), 3,296 Hrs, 5 x 20 top deck, 5x18 bottom deck, 8 cu. yd. hopper, 5' wide double deck multi-frequency screen w/hydraulic vibrators, #C005896 $229,900

HAUL TRUCKS

LIEBHERR TA230 LITRONIC, (‘23), 361 Hrs, #C005550 $CALL

hrs., #C002777, Double drum Oscillatory $148,400 Sakai SW300 - approx. 450 hrs, 39” drum, #C000211 $26,850.

BROOMS

Superior DT74J - ’19, approx. 1300 hrs. AC, Side shift, gutter brush, #C001774 $35,400

MILLING MACHINES

BOMAG BM600 - ‘16, 565 Hrs, 24” Drum, Load Out Conveyor $152,800 Roadtec RX-300 - ’18, approx. 600 hrs. 4’ drum ..............................................

$311,400

$P.O.R. Liebherr R946 - ‘14, approx.. 800 Hrs, 12’6” stick, QC66 coupler, aux. hyd ..............

$P.O.R.

ASTEC GT104 - ‘17, 325 Hrs, 5.25cyd Hopper, 4’x9’ Top & Bottom Screens, #C001154

KPI FT2650 – ’19, approx. 1800 hrs. Tracked jaw crusher

$148,900

$546,950

Mauldin 1560 paver – ’22, approx. 600hrs. 8-14’, electric screed heat $99,600

P.O.R. items may be on rent causing pricing and hours to vary.

HAZEMAG APPH1515QL, (’93), Primary Impactor Portable Plant, 400HP electric crusher drive, 15 cu. yd. hopper, #C005559

LIEBHERR TA230 LITRONIC, (‘23), 367 Hrs, #C005511 $CALL LOADERS AND EXCAVATORS:

$370,000

HAZEMAG APS1315, (’10), 7'x20' triple deck screen, #C005792

$362,500

SIMPLICITY 6203, (’96), Dual Portable Screening Plant, 6’ x 16’ Triple Deck Primary Screen, 6’ x 20’ Triple Deck Secondary Screen, #4873

LIEBHERR L550 XPOWER, (’17), 2,722 Hrs, innovative machine concept which combines performance, fuel efficiency, robustness and comfort. Power split driveline, #C003118 $125,747

$295,000

SUPERIOR BROOM SM80K, (‘17) 2,250 Hrs, Enclosed Rops, AC, #C006107

$26,500

SUPERIOR BROOM SM80K, (‘17) 2,090 Hrs, Enclosed Rops, AC, #C006106 $26,500

GROVE GHC85, (’23), 164 Hrs, #C005208 $CALL

LIEBHERR R924 LITRONIC, (‘23), 10 Hrs, The R 924 (Tier IV) crawler excavator replaces the predecessor R 924 (Gen 6) model. Its completely updated design is characteristic of the new range of "generation 8" machines, #C005679 $CALL LIEBHERR R934 LITRONIC, (‘23), 485 Hrs, The new R934 weighs approx. 35 tons, completely updated design is characteristic of the new range of "generation 8" machines, #C005399 $CALL

$1,099,000

GROVE GHC130, (’19), 932 Hrs, 130-ton lift capacity, #C004141

LIEBHERR R936 COMPACT LITRONIC, (‘18), 1,042 Hrs, Convenient and service-friendly, the R 936 Compact makes for safe working. With its tight slewing radius, this machine is especially well suited to urban applications, #C003377$CALL

$885,850

GROVE GRT880, (’22), 807 Hrs, 80-ton lift capacity, #C005002

GROVE GRT880, (’18), 2,476 Hrs, 80-ton lift capacity, #C004982

LIEBHERR R956 LITRONIC, (‘22), 1,800 Hrs, 35' boom and 21' stick, #C004867 $CALL

$628,750

SAKAI SV544TB, (‘23), 2 Hrs, #C005470 $CALL

Construction crews competed an important milestone in the bridge building process as they worked through the night on July 16 and completed the concrete deck pour for the Fourth Street Northwest bridge over Interstate 90 in Austin, Minn.

Highway traffic resumed on Interstate 90 in the early-morning hours after the concrete work was completed. Traffic was detoured for approximately seven hours.

As crews wrapped up, they covered the newly poured concrete with wet burlap and plastic, which is required for one week while the concrete cures or strengthens. Workers will monitor it and keep it wet as part of the standard process.

Meanwhile, crews also are working on the westbound Interstate 90 bridge over the Cedar River to the east of Fourth Street Northwest. Crews have been removing an abutment and pier as they prepare to build the new bridge to replace the old one.

Crews continue to work on other retaining walls around Fourth Street Northwest and storm sewer.

Crews also are doing work as part of the repair effort on the Sixth Street Northeast bridge.

Watch also for work rebuilding the traffic ramps at Fourth Street Northwest.

535 HRS

2022 KOMATSU D39PX-24 DOZER, 442 HRS

2023 ZX250LC-6 EXCAVATOR, 1106 HRS

ZX300LC-7 EXCAVATOR, 6 HRS

2025 ZX350LC-7 EXCAVATOR, 5 HRS

2025 ZX350LC-7 EXCAVATOR, 8 HRS

2024 ZX490LC-6 EXCAVATOR, 592 HRS

2024 ZX490LC-6 EXCAVATOR, 4 HRS

2024 ZX690LC-7 EXCAVATOR, 0 HRS

2019 KOBELCO SK140SRLC-5 EXCAVATOR, 1853 HRS $89,000

2023 KOBELCO SK170LC-11 EXCAVATOR, 226 HRS $155,000

2023 KOBELCO SK 210LC-11 EXCAVATOR, 321 HRS $210,000

2019 KOBELCO SK260LC-10 EXCAVATOR, 2797 HRS

2024 KOBELCO SK260LC-11 EXCAVATOR, 145 HRS

ZX17U-5N MINI EXCAVATOR, 12 HRS

ZX30U-5N MINI EXCAVATOR, 17 HRS

ZX30U-5N MINI EXCAVATOR, 3 HRS

ZX35U-5N MINI EXCAVATOR, 38 HRS

2024 ZX35U-5N MINI EXCAVATOR, 35 HRS

2024 ZX35U-5N MINI EXCAVATOR, 29 HRS

2023 ZX35U-5N MINI EXCAVATOR, 25 HRS

2025 ZX17U-5N MINI EXCAVATOR, 12 HRS

2025 ZX17U-5N MINI EXCAVATOR, 0 HRS

2025 ZX35U-5N MINI EXCAVATOR, 24 HRS

2025 ZX35U-5N MINI EXCAVATOR, 5 HRS

2025 ZX35U-5N MINI EXCAVATOR, 22 HRS

2025 ZX35U-5N MINI EXCAVATOR, 10 HRS

2025 ZX35U-5N MINI EXCAVATOR, 22 HRS

2025 ZX35U-5N MINI EXCAVATOR, 16 HRS

2025 ZX35U-5N MINI EXCAVATOR, 39 HRS

2025 ZX35U-5N MINI EXCAVATOR, 3 HRS

2025 ZX50U-5N MINI EXCAVATOR, 5 HRS

2025 ZX50U-5N MINI EXCAVATOR, 86 HRS

2025 ZX50U-5N MINI EXCAVATOR, 5 HRS

2025 ZX60U-5N MINI EXCAVATOR, 3 HRS

2025 ZX60U-5N MINI EXCAVATOR, 4 HRS

2024 ZX85USB-7 COMPACT EXCAVATOR, 92 HRS

2024 HITACHI ZX85USB-7 EXCAVATOR, 79 HRS

2020 LINKBELT 80X3 EXCAVATOR, 2187 HRS

2022 SANY SY16C MINI EXCAVATOR, 3 HRS

2022 SANY SY26U EXCAVATOR, 129 HRS

2022 SANY SY26U EXCAVATOR, 186 HRS

2022 SANY SY26U EXCAVATOR, 117 HRS

2023 SANY SY35 MINI EXCAVATOR, 73 HRS

2023 SANY SY35U MINI EXCAVATOR, 491 HRS

2025 SANY SY50 MINI EXCAVATOR, 11 HRS

2022 SANY SY80U EXCAVATOR, 450 HRS

SANY SY80U EXCAVATOR, 322 HRS

YANMAR VIO35-6A MINI EXCAVATOR

2023 YANMAR VIO35-6A

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$CALL

$74,500

$CALL

$33,500

2024 ZW120-6 WHEEL LOADER,

ZW140-6 WHEEL LOADER, 339 HRS $CALL

2024 HITACHI ZW150-6 WHEEL LOADER, 67 HRS $CALL

2024 HITACHI ZW150-6 WHEEL LOADER, 838 HRS $CALL

2024 HITACHI ZW150-6 WHEEL LOADER, 97 HRS

HITACHI ZW180-6 HIGH LIFT WHEEL LOADER, 5510 HRS

HITACHI ZW180-6 WHEEL LOADER, 4 HRS

HITACHI ZW180-7 WHEEL LOADER, 7 HRS

HITACHI ZW180-7 WHEEL

715-752-8112

JD 50G, A/C, Hyd Thumb, 5’7” Long Arm, Blade, Aux, #292872 ......................................$45,000

Kubota KX057-5, A/C, Hyd Thumb, Angle Blade, Aux Hyd, #296470 ........................$76,000

JD 331G, A/C, Hi Flow Aux, 2 Speed, Ride Control, #262952 .. $65,000

JD 850K, A/C, Ripper, Semi U Blade, LGP, 36” Pads, Screen, #299904 $134,000

JD 130G, A/C, Hyd Thumb, Aux, 9’11” Stick, 24” Shoes, #261469 ....................................$119,000

Komatsu PC138LC-11, A/C, Long Arm, CPLR, Rubber Pads, #298908 ......................$165,000

JD 550K, A/C, XLT 18” Pads, 6 Way 105” Blade, 4th Function Aux, #262480 $105,000

JD 950K, A/C, LGP, 36” Pads, 184” Blade, Ripper, #301142 ...... $375,000

JD 135G, A/C, 9’11” Arm, 24” Shoes, Reduced Tail Swing, #249203 ........................$87,000

New Holland E57C, A/C, Hyd Thumb, Cplr, Aux Hyd, Blade, #293430 ........................$64,000

JD 650K, A/C, LGP, 28” Pads, 6 Way 128” Blade, Rev Fan, IGC, #262371 $114,000

JD 444K, A/C, JRB Coupler, Ride Control, #262773 ..$76,000

JD 210G, A/C, Hyd Thumb, Coupler, 9’7” Arm, Rev Fan, #261276 ......................$127,500

Volvo EC240BLR, A/C, 60’ Long Reach, 60” Ditch Bucket, #292240 ........................$84,000

JD 700K, A/C, LGP, 36” Pads, 6 Way 132” Blade, Rev Fan, #291338 $155,000

JD 544K-II, A/C, Rev Fan, 20.5 Tires, Air Seat, GP Bucket, #262551 $127,000

JD 245G, A/C, Aux Hydraulics, 9’7” Arm, 32” Shoes, Air Seat, #262242 ......................$198,000

JD 325G, A/C, Joysticks, 2 Speed, Aux Hyd, #293433 ......................................$52,000

JD 700L, A/C, LGP, 30” Pads, 6 Way 127” Blade, Drawbar, #298880 $158,000

JD 624L, A/C, 3rd Spool, Ride Control, Roll Out BKT, Rev Fan, #292312 $85,000

The McCullough family hosted its grand opening of McCullough Kubota’s newest facility on July 18 at 21730 LaGrange Rd. in Frankfort, Ill.

Guests were treated to lunch and a chance to win Keith Urban tickets, plus other great prizes, including an RTIC cooler. A special 10 percent off Kubota parts, as well as 15 percent off Stihl units were offered during the event and team members were on hand giving demonstrations of various machines.

The new 16,000-sq.-ft. facility is situated on five acres with six service bays.

“We’re excited to bring our family business into the Frankfort community and to serve the southern Chicagoland market,” said Matthew McCullough, CEO of McCullough Equipment Group.

McCullough Kubota carries Kubota, Stihl and Land Pride at its new Frankfort store. McCullough & Sons was founded in 1940 by T.J. McCullough, as an AllisChalmers dealership in Watseka, Ill.

In 1977, Steve McCullough, third generation, bought into the business making it a staple for the community it serves in Watseka. In January of 2021, Matthew McCullough, fourth generation, became a shareholder and quickly grew the business into a multi-location dealership. In 2024, Dan Elliot, son-inlaw of Steve McCullough, bought into the company and helped launch the fourth location in Gurnee, Ill.

For more information, visit McKubota.com. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

the

welcomed customers, partners and vendors during a successful open house. The event showcased CMC’s commitment to service, innovation and strong industry relationships.

Construction Machinery Company (CMC) welcomed customers, vendors and partners to its open house event held at its facility in Owensboro, Ky. The event offered attendees a hands-on look at the latest in heavy equipment, technology and attachment solutions, as well as the opportunity to connect directly with manufacturer representatives and the CMC team.

Guests were greeted with giveaways, goodie bags and smiles. A lineup of impressive equipment from Link-Belt, Hitachi, Rammer, KEMROC, FRD and other top brands was on full display throughout the grounds. Live equipment demonstrations highlighted new capabilities and product innovations, while vendor booths under the tent gave attendees a chance to speak with experts from Rammer, Midland Machinery, Furukawa Rock Drill and KEMROC.

CMC’s dedicated team played a key role in bringing the event to life — from planning and setup to customer engagement and technical support. Lunch was served as attendees networked, explored offerings and enjoyed a sunny summer day among peers in the construction and demolition industries.

The open house served as both a celebration of CMC’s strong partnerships and a showcase of its continued commitment to delivering high-performance equipment and outstanding service across the region.

For more information, visit cmcky.com. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR $195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires $15,500 (4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready

From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote $4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs

$21,500

Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

IR 185’s, JD diesels

$49,500

CALL

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready $224,500

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR $179,000

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$122,500

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent From $5,200 Case 580L Rubber Tire Loader Backhoe, 1997, OROPS, std stick, 24" bkt

$24,500

(2) Balderson Broom Attachment for Cat IT Machines, 8' wide, good condition $4,000 Ea. NUMEROUS Rivinius R600’s, 10’ Wide, Mount on Dozer Blade

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR .

$72,500

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition CALL

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl

Single Shank Ripper, 8,400 HMR

$229,500

$25,500 BUCKETS Over 100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent $4,000 Others Available Call Prices Are Negotiable - At Your Inspection

$152,500

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

and hands-on experiences — supported by local dealer, Murphy

Ben Moskowitz (L) and Ken Skala showcase the U-21J concrete crusher during the NPK Demo Day. This powerful NPK attachment features a booster mounted to the cylinder that multiplies the pressure in the cylinder by a factor of X3 thus increasing crushing power and performance. The use of a smaller cylinder enables the NPK crusher to achieve faster cycle times.

NPK Construction Equipment, in partnership with dealer Murphy Tractor and Equipment Co., hosted a successful Demo Day event on July 18, 2025, at NPK’s headquarters in Walton Hills, Ohio. The event welcomed contractors, operators and industry professionals from across the region for a full day of live equipment demonstrations, networking and celebration.

Guests experienced NPK’s lineup of powerful attachments firsthand, including the U-21J concrete crusher featuring a built-in booster for faster cycle times and the K-3JREH demolition shears, known for their precision and power. Additional demos included hydraulic hammers and compactors, giving attendees the chance to see these tools in real working conditions and even operate select machines themselves.

Guests and attendees were

successful Demo Day moment with the

hydraulic

treated to lunch from Antonio's food truck. NPK team members, many of whom have worked together for decades, were on hand to answer questions and guide guests through product features, capabilities and applications.

The event also marked a major milestone of NPK’s 40th anniversary, celebrating four decades of innovation, customer service and trusted performance in the construction and demolition industries.

Supported by Murphy Tractor, the Demo Day was more than just a product showcase; it was a celebration of long-standing relationships, industry excellence and the future of equipment solutions. For more information, visit npkce.com. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

for

Trimble announced APEX Technologies as the newest Trimble Technology Outlet. Headquartered in Dubuque, Iowa, APEX will sell Trimble grade control, site positioning systems and correction services technology directly to customers using John Deere construction equipment and/or LevelBest, SharpGrade and Burchland attachments.

Trimble technology from APEX includes the Trimble Works Subscription, which provides an easy entry-point, predictable monthly payment, upgrade flexibility, software and firmware maintenance and more.

Trimble Technology Outlets are a new and important part of Trimble’s civil construction distribution strategy. By adding authorized resellers representing a wide variety of manufacturers to the Trimble distribution channel, it is easier for users of all machine types to purchase, install and use Trimble technology for improved job site productivity and profitability.

As an authorized Trimble reseller, APEX will offer Trimble grade control solutions — including site positioning systems and correction services — directly to customers across the McCoy Construction & Forestry footprint. APEX and McCoy customers can expect to receive a superior level of support, including installation, service and training.

For more information, visit apexconstructiontech.com and mccoycf.com.

Developed for rugged off-road use, the TA 230’s efficient drivetrain, permanent 6 x 6 all-wheel drive, reliable traction control and solid axle mounts enable the dump truck to tackle any terrain. www.liebherr.com

Chicago Fire FC released renderings and further details of the club’s $650 million soccer-specific stadium in downtown Chicago on July 16. The stadium, announced in early June, will be entirely privately financed by Joe Mansueto, the club’s owner and chairman. The stadium will anchor The 78, Related Midwest’s 62-acre development located along the Chicago River just south of Roosevelt Road.

The new stadium will seat approximately 22,000 fans, striking a balance between an electric, high-demand atmosphere and a world-class matchday experience. It was designed by Gensler in “Chicago School” fashion with the enduring elegance of the warehouses that represent the city’s grit and hard work. From sweeping riverfront views to open public plazas, every element of the stadium design is being thoughtfully considered to honor Chicago’s classic and historic identity while igniting an exciting modern era for the Club and its supporters.

“I love this city and its architecture,” said Mansueto. “This stadium is adding to Chicago’s iconic skyline, so I want it to look timeless. It will look like it’s always belonged here, but with the modern innovations required for a world-class soccer club.”

The brick, steel and glass facade will wrap an interior designed to deliver unmatched comfort, style and service, reimagining what it means to not only experience a Fire match in Chicago, but to experience a soccer match in the United States.

The bowl is designed to prioritize the match viewing experience with seating positions that are dramatically lower and closer to the action. The stadium will feature a variety of hospitality spaces, amenities and premium seating options across multiple tiers with 50 suites, more than 500 Loge seats and 3,500 Club seats, including some with access to exclusive clubs-within-clubs. An exposed steel canopy over the seating bowl will help enhance the intimacy of Fire matches by directing light and crowd noise back to the pitch, creating an environment that will enhance the Fire’s home-field advantage.

A dedicated supporter section will be built at the core of the stadium for the most passionate fans in the league. The section is purpose-built to be loud with room for approximately 2,000 die-hard fans on safe-standing bleachers.

“We are creating a fortress for our team and a home for our fans,” said Dave Baldwin, Chicago Fire FC president of business operations. “The open-air stadium with grass playing surface and intimate environment is intentional to give our team an edge and bring our supporters even closer to the team they love.”

In addition to Fire matches, the Club is

excited for this stadium to be a true community asset. It can host a variety of other sports and entertainment events, such as international soccer matches, rugby matches, concerts, festivals, live performances, fundraisers and charity events, trade shows, corporate events, conferences, community events and much more.

“The vision for the Chicago Fire FC sta-

dium was set during our interview with the team — to exemplify ‘MLS 3.0’ and establish a new standard for the fan and hospitality experience,” said Kirk Funkhouser, principal-in-charge, Gensler. “We design every space with an eye toward elevating the match day experience and look forward to delivering an exceptional venue that Chicagoans, players, coaches and staff will

enjoy for years to come.”

The stadium will serve as a catalyst for the first phase of The 78, whose 62-acre master plan was also designed by Gensler. Drawing its name from Related Midwest’s vision of creating Chicago’s 78th neighborhood, the walkable, pedestrian-oriented campus will create a dynamic, 24/7 district with new residential and commercial buildings, a halfmile riverwalk and a network of interconnected community spaces that support yearround programming. The initial phase will include restaurants, storefronts and a range of complementary spaces that serve as a vibrant extension of the fan experience.

“With this stadium, we have a once-in-ageneration opportunity to catalyze investment that transcends The 78, benefiting area residents while drawing visitors to this vast expanse of downtown riverfront,” said Curt Bailey, president of Related Midwest. “Our plan gives us the flexibility to consider every aspect of the fan experience — not only before, during and after matches, but throughout the year.”

Construction at The 78 is anticipated to begin by the beginning of 2026, and the new stadium is expected to open in 2028. The stadium will create thousands of jobs, both during and after construction and will generate millions of dollars in tax revenue for the city of Chicago.

This month, Major League Soccer (MLS) Commissioner Don Garber added, “Joe Mansueto isn’t just building a soccer stadium — he’s reshaping the future of soccer in Chicago. This is one of the most ambitious stadium projects in Major League Soccer history, and a powerful reflection of Joe’s extraordinary commitment to the Fire, the fans and the city. I toured the site recently, and there’s no doubt that this will be a transformative moment for the club and a landmark for Chicago sports.”

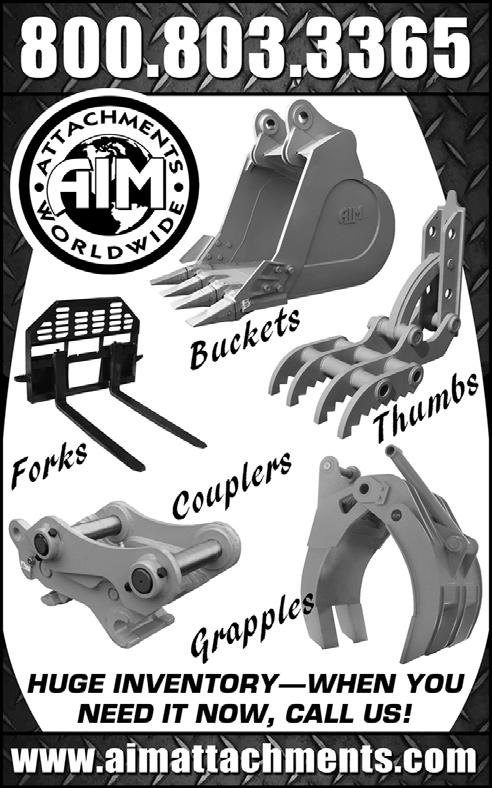

Huge attachment inventory. Over 300 attachments in stock. We Buy, Sell, and Trade. Inventory changes daily, please call to discuss your needs and how we can help.

DOZER BLADES IN STOCK

D10R/T, D9R/T, D8R/T, D7R, D7R LGP, D7E, D6R LGP, D6K, D5G, D5C.

DOZER RIPPERS IN STOCK

D10R/T SS ripper, D11R/T SS ripper, D7R MS ripper, D6N MS ripper, D5K MS ripper, D5C/D4C/D3C ripper.

EXCAVATOR ATTACHMENTS IN STOCK

Quick Couplers for Most Models from Mini - 374D/E

336 Excavator - 30”, 36”, 42”, 54”, 60” all in stock.

315 Excavator - Most Sizes from 24” - 60” ditch cleaner

312/314 Excavator - 24”, 30”, 36”, 60” ditch cleaner

320/321/312 Excavator - 24”, 30”, 42”, 54”, 80” ditch cleaner

345/349 Excavator - 36”, 48”, 54”, 60”, 72”

QUICK COUPLER FORKS IN STOCK

420 D/E/F, 950-972 Fusion, 953, 972 HPL, Cat Telehandler

WHEEL LOADER BUCKETS FROM 914-992

Many sizes and styles available. Pin-on and Quick Coupler.

M/H SERIES GRADER RIPPERS IN STOCK Also front pushblock counterweights.

RECENTLY PARTED MACHINES INCLUDE

D4c, TH83, 988F, 769C, TH460B, TH360B, 242B, 320C, 345C, 420E IT, 836G, 345CMH, M325DMH, D6T

Stephen Odum (R), Takeuchi national marketing manager, welcomes the newest Takeuchi Brand Ambassadors, Erika and Cody Archie of Bar 7 Ranch, Gatesville, Texas, to the event.

Many rooms of the 37,000-sq.-ft. training center house virtually every Takeuchi product for technical training for company and dealership salespeople, technicians and trainers.

The new TL11R3’s are arriving daily and are merging in with the massive quantities of other Takeuchi machines in the warehousing area.

Guests were provided a complete tour of the facilities and an opportunity to interact with staffers in all departments.

Takeuchi hosted construction equipment journalists and dealer representatives to its United States headquarters in Pendergrass, Ga., July 21-22. The focus of the event was to introduce the new Takeuchi TL11R3 compact track loader and to showcase the entire Takeuchi line.

Takeuchi-US President Jeff Stewart spoke and was in attendance at all of the events. Stewart and the entire Takeuchi staff conducted an extremely enjoyable two-day event of learning and machine operation.

Press representatives and dealer representatives were given individualized and comprehensive machine introductions. Attendees operated the all-new TL11R3 and had the opportunity to operate other machines that were staged in the demo area situated directly behind the training center.

A complete tour of the corporate campus, walkarounds of all Takeuchi machines and attachments and an opportunity to interact with all departments and product mangers provided attendees a greater understanding and knowledge of Takeuchi. CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

Johnson (L), Takeuchi brand ambassador of Elite Earthworks, Joplin, Mo., and Dylan Freeman, Takeuchi product manager discuss the new TL11R3 compact track loaders at the demo area.

(L-R): Takeuchi’s Lee Padgett, David Pearson and Andrew Summerlin tell a tour group that Takeuchi is one of the only manufacturer’s that prep machines, including attachment installation prior to shipping to the dealers.

Takeuchi introduced the sixth model in its compact track loader product line — the TL11R3. This new machine features new electric-over-hydraulic (EH) controls for greater precision in loader arm, bucket and travel speed operation.

“The TL11R3 delivers impressive torque and horsepower along with leading bucket breakout and lift-arm forces for maximum performance,” said Dylan Freeman, product manager of Takeuchi-US. “And, with the addition of low-effort EH controls, this track loader helps even the most skilled operators work with more precision and control — elevating their craft while reducing fatigue.”

The TL11R3’s EH controls also enhance job site productivity by making several new features possible, according to Takeuchi. Operators can instantly switch between ISO and H patterns through the machine’s monitor to match their preferences. The TL11R3’s self-leveling up-and-down feature automatically keeps the bucket or attachment level while raising or lowering the loader arm for improved load handling.

A 14-pin detent provides continuous power to electrically operated attachments for uninterrupted operation. Operators also can adjust the track loader’s boom, bucket and travel sensitivity to match their needs for greater control during high-precision work. In low-clearance environments, the arm height limit feature prevents the TL11R3’s loader arm from exceeding a predetermined height, protecting attachments and surroundings from accidental damage, according to Takeuchi.

Available in both standard- and high-flow configurations, the TL11R3 allows operators to adjust flow rates and attachment presets from inside the cab. The high-flow configuration delivers up to 40 gal. per minute

of auxiliary flow for use with more powerful attachments like mulchers, cold planers and stump grinders. Both configurations come equipped with a 14-pin connector enhancing versatility and functionality for a wide range of attachments. Swapping attachments is simple with the mechanical universal quick attach on canopy models and the hydraulic universal quick attach on cab models. A 270-degree rearview camera comes standard on the high-flow configuration and is optional on the standard-flow configuration, according to Takeuchi.

The TL11R3 has an operating weight of 11,650 lbs. (canopy model), an ROC of 2,735 lbs. and a bucket breakout force of 7,958 lbs. Its radial-lift boom design is engineered to deliver superior breakout forces for exceptional lifting power with fewer moving parts, making it particularly well suited for grading and dirt work, according to Takeuchi. Rugged steel construction and a one-piece, purpose-built, fully welded frame offer greater strength and rigidity while protecting the engine and hydraulics.

With a 12.4-in. ground clearance, the TL11R3 provides excellent flotation, traction and stability for navigating on challenging terrain with ease, according to Takeuchi.

The machine’s undercarriage features heavy-duty sealed rollers with metal face seals to keep dirt and debris out, while double-reduction planetary drives and 18-in. tracks deliver powerful tractive effort.

Inside the TL11R3, operators will find a six-way, adjustable high-back suspension seat and an 8-in. touchscreen display for real-time machine vitals and visibility to the rearview camera, as well as access to the Bluetooth radio, HVAC controls and other machine functions. The track loader can operate whether its overhead roll-up door is open or closed, regardless of the loader arm position.

A lockable hood, steel rear door and integrated bumper protect vital engine components, with the rear door also providing access to a swing-out cooling module for easy cleaning and inspection. The TL11R3’s 107.3-hp engine meets Tier IV Final emis-

sions standards with a DOC, DPF and SCR after-treatment system.

Takeuchi’s Fleet Management (TFM) telematics system is standard on the TL11R3 for five years. TFM reduces downtime and controls costs by providing owner/operators with machine health and condition, run time (hours) and machine location, as well as remote diagnostics, scheduled maintenance reminders and customizable alert settings. TFM also gives owners the ability to geofence their machines, helping them protect and secure their investments, according to Takeuchi.

“We believe the TL11R3 offers the perfect blend of power, durability and operator comfort to tackle even the toughest projects,” said Freeman. “We listened to our customers and designed the TL11R3 with features that make it one of the most capable, durable track loaders available on the market today. It’s ready to work whenever you are.”

For more information, visit www.takeuchi-us.com.

Roland Machinery Company (RMC)

announced Jeff Price as its new territory manager. Price will be working out of RMC’s Eau Claire location covering Eau Claire, Pepin, Pierce, Buffalo, Trempealeau, Jackson, La Crosse and Monroe counties.

“This opportunity at RMC allows me to focus on building strong relationships and helping customers find the right solutions for their business,” said Price. “It puts me in a position where I can be out in the field, meeting people face-toface, understanding their challenges and being a reliable point of contact they can trust.”

Price will be responsible for selling, renting and leasing all RMC’s product lines, excluding logging equipment. His role also includes problem-solving and acting as a

trusted support channel for customers. Price looks forward to deepening his knowledge of the heavy equipment industry from the technical side of the machines to the specific needs of industries like mining, construction, farming, municipalities, energy and waste management.

“My experience in the mining industry has given me valuable insight into what customers value,” said Price. “Someone they can trust, rely on and who brings honesty and value to the table. I’ve learned that building strong relationships isn’t just about making a sale, it’s about being dependable, responsive and genuinely caring about their success.”

For more information, visit rolandmachinery.com. CEG

Halil Ceylan, a nationally and internationally recognized leader in transportation infrastructure engineering of Iowa State University (ISU), is the 2025 recipient of the American Road & Transportation Builders Association’s (ARTBA) S.S. Steinberg Award.

The honor, named after ARTBA’s research and education division’s founding president, recognizes “an individual who has made remarkable contributions to transportation education.”

Among his work is the development of the first electrically conductive heated pavement test site at a United States airport, which garnered nationwide media attention from NBC’s Today Show, NPR, Discovery Channel and others.

A prolific researcher and scholar, Ceylan has authored more than 500 publications and his work has amassed over 9,200 citations.

He serves as the Pitt-Des Moines Inc. endowed professor in ISU’s department of civil, construction and environmental engineering, and directs the Program for Sustainable Pavement Engineering and Research (PROSPER) at ISU’s Institute for Transportation. He also is the ISU site director for the FAA’s

Roland Machinery Company (RMC) announced Dan Thurs to its newly created position of territory manager of forestry covering all of Wisconsin.

This new position allows RMC to grow and invest in its forestry sales and service. Roland recently was named the exclusive Timberpro dealer for Wisconsin, adding to its Komatsu forestry product line as well as Logmax, Quadco and JP Skidmore forestry attachments.

Thurs grew up in the forestry world helping his family’s log truck company. His college experience in a diesel mechanic and heavy equipment program gave him knowledge of the machines he will be selling.

“I have gained sales experiences in my previous jobs that allowed me to build relationships with customers throughout Wisconsin,” said Thurs. “I have sold equipment from the coast to coast and have acquired many friendships and gained a lot of knowledge along the way.”

For more information, visit rolandmachinery.com. CEG

“With Roland becoming the exclusive Timberpro dealer for Wisconsin, we now have another amazing product line to add to our existing Komatsu Forestry machines,” said Thurs. “With having one salesman able to focus all of his time solely to the forestry customers, it will better grow their trust in Roland at becoming your go to forestry store.”

Valued at more than $27 million, Ceylan’s research portfolio spans more than 145 funded projects supported by federal and state agencies, including the Federal Aviation Administration, Federal Highway Administration, National Science Foundation, Department of Defense, National Cooperative Highway Research Program and multiple state DOTs. His innovations encompass artificial intelligence and machine learning in infrastructure design, advanced infrastructure monitoring systems, heated and self-sensing pavements, sustainable transportation geotechnics and climate-resilient transportation infrastructure systems.

Ceylan’s has mentored more than 70 graduate students and 17 postdoctoral researchers, and taught courses to more than 3,000 undergraduate and graduate students. Under his guidance, dozens of his former students and mentees have become leaders in academia, transportation agencies and industry. According to peers and students, his ability to inspire and develop talent has magnified his influence beyond his own pioneering research, ensuring a lasting impact on the future of transportation infrastructure.

A newly-expanded UTV test track will debut at Equip Exposition’s 30-acre outdoor demo yard at the Kentucky Exposition Center (KEC) Oct. 21-24, 2025.

Thousands of landscapers, contractors and dealers will be given the opportunity to try the latest mowers, UTVs, compact tractors, chainsaws, leaf blowers, trenchers, skid steers, backhoes and the other equipment at this experience.

“Our show is the only place where you can get your hands on and operate so many different types of equipment all in one place,” said Kris Kiser, president and CEO of the Outdoor Power Equipment Institute (OPEI), which owns the trade show. “We know how much landscapers, contractors and dealers rely on the ability to try before they buy. In the outdoor demo yard, you can get a feel for how all the major brand’s equipment handles, and where you can mow, dig, saw, drive and more.”

The outdoor demo yard will be open:

• Oct. 22, 12 p.m. - 5 p.m.

• Oct. 23, 9 a.m. - 5 p.m.

• Oct. 24, 9 a.m. - 1 p.m.

“We’re particularly excited about the expanded UTV test track, which has been relocated for better access and beefed up,” said Kiser.

Attendees can drive and compare the latest vehicles while navigating curves, hills, rocks and bumps. Drivers must be age 16 or older with a valid driver’s license and will drive alongside a representative of the manufacturer who can answer questions about load capacity, features, price and more.

“Outdoor power equipment is an important investment for any business,” Kiser said. “Equip helps our attendees make smart decisions. After all, a landscaper and their staff will spend hours operating that equipment, and they need to feel its maneuverability and weight, know how the different features work and more.”

“Many manufacturers exhibit new products at Equip Expo, so you can also see where the industry is headed and what’s coming next,” said Kiser.

For more information, visit equipexposition.com.

www.burrisequipment.com

2216 N. Greenbay Rd. Waukegan, IL 60087

847-336-1205

Ingleside, IL 815-363-4100

Joliet, IL 815-464-6650

CENTRAL POWER SYSTEMS & SERVICES www.cpower.com

9200 Liberty Drive Liberty, MO 64068

816-781-8070

Wichita, KS

316-943-1231

Woodward, OK 580-256-6014

Salina, KS

785-825-8291

Colby, KS

785-462-8211

Springfield, MO 417-865-0505

Joplin, MO 417-726-5373

Riverside, MO 816-415-6787

Wichita, KS 316-789-7370

Yukon, OK 405-324-2330

St. Peters, MO 314-427-4911

Liberty, MO 816-415-6700

Tulsa, OK 918-984-6565

1555 Atlantic Drive West Chicago, IL 60185 630/510-6050

OH 43207

N State Rt. 1 Watseka, IL 60970 815/432-3965

W US-6 Morris, IL 60450 815/942-6620 21730 LaGrange Rd Frankfort, IL 60423 815/658-2682 McCullough Kubota www.mckubota.com

www.yesequipment.com 7001 Manufactures Drive Madison, WI 53704 888/310-3901 7225 Grand Ave. Gurnee, IL 60031 224/699-2200

50th Avenue West

Inc.

7344 S. Frontage Road Sheboygan, WI 53081 920-564-6555

Shawnee Avenue Kansas City, KS 66105 913-371-0868 St. Louis, MO 314-771-6666 Park City (Wichita), KS 316-744-2061 Oklahoma City, OK 405-577-2222

Equipment Co. www.ronsonequipment.com

18030 Wicker Avenue Lowell, IN 46356 219-696-5680

10761 West Coulter Road Westville, IN 46391 219-785-2909

The Iowa and Wisconsin Departments of Transportation are proceeding with a revised plan for the construction of the new Iowa 9/WIS 82 bridge over the Mississippi River between Lansing, Iowa and Crawford County, Wis. The revised plan requires closure and demolition of the existing bridge in fall of 2025 to ensure that the new bridge can be safely constructed and opened as planned in 2027.

Project engineers reached this decision after extensive discussions between both state DOTs, the contractor and additional analyses. While recognizing the impact to the communities, this plan ensures safety for motorists, construction workers, rail traffic and Mississippi River traffic.

The new bridge is being constructed alongside the existing bridge (also known as the Black Hawk Bridge). Iowa DOT, WisDOT and the contractor have determined that future construction stages could pose a risk to the safety of the existing bridge. This fall, the agencies will close the existing bridge to traffic. Crews will then demolish and remove the old structure so that full construction can continue to meet the planned 2027 opening for the new bridge.

Since construction began in late 2023, project engineers temporarily closed the existing bridge twice. The first closure occurred in early 2024 due

The revised plan requires closure and demolition of the existing bridge in fall of 2025 to ensure that the new bridge can be safely constructed and opened as planned in 2027.

to observed displacement, and the bridge was then re-opened following limited stabilizing work. The second closure happened in May 2025 due to sensor-detected movement, and the bridge was reopened following a detailed inspection and engineering analysis.

The project team is investigating opportunities for alternative river crossings to support businesses, institutions and individuals in Iowa and Wisconsin. This may include restoration of the water taxi service offered

during previous closures or other options, and both states will maintain viable roadway detours. The nearest crossing is U.S. 18 connecting McGregor, Iowa, to Prairie du Chien, Wis.

The exact closure date will be determined later in the year. The Iowa DOT and WisDOT project teams also are communicating closely with government officials and other stakeholders in the affected communities.

For more information, visit iowadot.gov/lansingbridge.

HIPOWER Systems announced the appointment of Kyle Tingle to the company’s new director of sales — mobile power, effective July 14, 2025.

In this new role, Tingle will lead HIPOWER’s sales strategy for mobile power solutions across North America, with a primary focus on the rental and construction industries, as well as general prime power applications. He will play a key role in supporting and expanding HIPOWER’s mobile power product line, aligning it with the evolving demands of the market.

“We are excited to welcome Kyle to our leadership team,” said Rafael Acosta, president of HIPOWER Systems. “His combined engineering and sales background brings unique depth to our organization and will be instrumental in driving

murphytractor.com

Park City, KS 316-942-1457

Great Bend, KS 620-792-2748

Humboldt, KS 620-473-7020

Olathe, KS 913-298-7373

Topeka, KS 785-233-0556

Ulysses, KS 620-356-1071

Dodge City, KS 620-227-3139

Gering, NE 308-436-2177

Omaha, NE 402-894-1899

Lincoln, NE 402-467-1300

Grand Island, NE 308-381-0741

North Platte, NE 308-534-7020

Kansas City, MO 816-483-5000

Springfield, MO 417-863-1000

Des Moines, IA 515-263-0055

Fort Dodge, IA 515-576-3184

Sioux City, IA 712-252-2753

Waterloo, IA 319-235-7085

Brunswick, OH 330-220-4999

Cambridge, OH 740-439-2747

Canton, OH 330-477-9304 Cincinnati, OH 513-772-3232

Columbus, OH 614-876-1141

Jackson, OH 740-688-4100

Lima, OH 419-221-3666

Painesville, OH 440-639-0700

Poland (Youngstown), OH 330-629-6299 Rossford, OH 567-352-7001

Vandalia (Dayton), OH 937-898-4198

www.westsidetractorsales.com

Bemidji, MN 218-759-1996

Duluth, MN 218-722-7456

continued growth and innovation.”

Tingle brings more than 30 years of experience to the position, including 20 years in sales and 10 years in engineering. His professional background includes notable tenures at John Deere (20 years), Clarke Power Services (four years) and most recently, ComAp (five years), where he held a senior sales role serving the power generation market.

“I’m honored to join HIPOWER Systems and look forward to contributing to the company’s continued success in the mobile power market,” said Tingle. “There’s incredible potential in this market, and HIPOWER is positioned to lead the way with innovation, quality and customer focus.”

For more information, visit www.hipowersystems.com

Grand Rapids, MN 218-326-9427

Ashland, WI 715-682-5522

Chippewa Falls, WI 715-834-2924

Merrill, WI 715-536-0633

Escanaba, MI 906-789-9054

Marquette, MI 906-789-7689

Fenton, MO

636-349-0200

Foristell, MO 636-463-2500

Mt. Vernon, IL 618-244-6800

Mitchell, IL

618-931-1034

Cape Girardeau, MO 573-334-0563

Paducah, KY 270-554-1131 Cuba, MO 573-885-0500

Owensboro, KY 270-684-2339

Evansville, IN 812-473-0484

Kingsport, TN 423-349-5001

Knoxville, TN 865-546-3207

Chattanooga, TN 423-855-0633

Nashville, TN 615-501-8600

Bowling Green, KY 270-842-3400 Louisville, KY 502-253-3721

Lexington, KY 859-788-3950

London, KY 606-862-8447

www.brookstractor.com

Madison (Sun Prairie), WI

608-837-5141

Milwaukee, WI

414-462-9790

Green Bay (De Pere), WI 920-336-5711

La Crosse (West Salem), WI

608-786-2644

Stevens Point (Plover), WI

715-254-2777

Racine (Mt. Pleasant), WI

262-898-6700

Sparta, WI

608-351-2101

www.lec1.com

Ashland, KY

606-327-1709

Pikeville, KY

606-432-0321

Marietta, OH

740-373-5255

Cowen, WV

304-226-3299

Beaver, WV

304-255-1525

Elkins, WV

304-636-6421

Cross Lane, WV

304-204-1818

www.martinequipment.com

Goodfield, IL

309-965-2502

Peru, IL

815-224-4711

Rock Island, IL

309-787-6108

Springfield, IL

217-528-4347

Tolono, IL 217-485-6755

Cedar Rapids, IA

319-365-0515

Dubuque, IA

563-588-1950

Columbia, MO

573-657-2154

Palmyra, MO

573-769-2274

cpower.com

Liberty, MO

816-415-6700

Springfield, MO

417-865-0505

St. Louis, MO

314-427-4911

Garden City, KS 620-765-3118

Salina, KS

785-825-8291 Colby, KS

785-462-8211

Wichita, KS

316-943-1231

Oklahoma City, OK 405-324-2330

Tulsa, OK 918-984-6565

goironhide.com

Grand Forks, ND 701-772-5006

Devils Lake, ND 701-662-5331 Williston, ND 701-572-5050

lanoequip.com

Shakopee, MN 952-445-6310

Central Power Systems & Services will now sell, rent and service Takeuchi compact excavators and track loaders at its location in Woodward, Okla.; four locations in Kansas (Wichita, Salina, Colby and Garden City); and three locations in Texas (Hutto, San Antonio and Corpus Christi).

“We’re excited to add the Takeuchi product line to our construction equipment offering,” said John Cosgrove, president of Central Power Systems & Services. “Takeuchi’s reputation for quality, innovation and performance aligns perfectly with the values we bring to our customers. This partnership strengthens our ability to deliver reliable, industryleading equipment solutions backed by the service and support our clients have come to expect.”

Founded in 1963, Takeuchi is an ISO 9001 certified manufacturer of an extensive line of compact track loaders, compact excavators, compact wheel loaders and a compact crawler dumper.

Central Power Systems & Services, headquartered in Kansas City, Mo., has been a trusted provider of power generation, distribution and heavy equipment solutions since 1954. With 20 locations and 700 employees across Kansas, western Missouri, northern Oklahoma and Texas, the company delivers comprehensive sales, service and rental support for industries ranging from construction and transportation to critical infrastructure.

Central Power offers custom-engineered systems, a robust rental fleet, certified technical expertise and 24/7 emergency service to meet the evolving needs of its customers. Guided

by core values of integrity, humility, partnership and innovation, the company continues to grow its capabilities — most recently with the addition of a 750,000-sq.-ft. power generation facility in Platte City, Mo.

“We’re proud to welcome Central Power Systems & Services to the Takeuchi dealer network,” said Shay Klusmeyer, western division sales manager of Takeuchi-US. “Over the years, Central Power has built a strong reputation for outstanding customer service and deep industry expertise, and we’re confident they will represent the Takeuchi brand with excellence. We look forward to a successful partnership that brings even greater value to customers in Oklahoma, Kansas and Texas.”

For more information, visit cpower.com. and takeuchius.com.

Kevin Sell, senior manager of corporate development of Kwest Group, testified on behalf of Associated Builders and Contractors before the U.S. House Committee on Education and Workforce Subcommittee on Workforce Protections on the role that programs like ABC’s STEP Health and Safety Management System play in creating meaningful pathways between the construction industry and the Occupational Safety and Health Administration.

Speaking at the hearing, “Safe Workplaces, Stronger Partnerships: The Future of OSHA Compliance Assistance,” Sell conveyed the importance of collaborative partnerships between the contractor community and OSHA. He pointed to STEP, which enables top-performing participants to achieve incident rates nearly seven times safer than the U.S. Bureau of Labor Statistics construction industry average, as a way for those partnerships to create cultural transformation.

Sell began his career as a firefighter

17035 N. Illinois Hwy. 37 Mt. Vernon, IL 62864 618-242-2273

800-388-6396

1501 Lynch Road Evansville, IN 47711 812-425-4428

800-258-4428

2000 Harlan Drive

and shift commander, which enhanced his ability to make quick and complex executive decisions throughout his 35year career in construction. In construction, Sell worked in safety and quality, workforce development and relationship management roles. He also held leadership roles on both the Kentucky Workers’ Compensation Funding Commission and the Kentucky Occupational Safety & Health Review Commission.

“The area offices of OSHA have provided employees and employers with valuable expertise and support through Compliance Assistance Specialists and their Challenge Program, which serves as a pathway to the Voluntary Protection Program,” said Sell. “By fostering a relationship — or better yet, a partnership — with the area office, employers gain nonenforcement support, allowing them to work collaboratively with OSHA to improve workplace safety and reduce risk for their teams. This is especially important in construction, as many of

us have a mobile workforce that presents a unique set of challenges far different and more complex than most general industry sites.

“In 1999, we met with then-Region 5 Administrator Mike Connors, who challenged us to adapt ABC’s STEP and Challenge Program into a construction version of the Voluntary Protection Program,” said Sell. “We began a demonstration program in 2001. VPP, across all industries, allows employers, employees and labor to apply for an audit that can lead to their VPP designation. Many of us refer to the VPP as OSHA’s ‘seal of approval.’”

Sell went on to explain that STEP, which was founded in 1989 as a safety benchmarking and improvement tool, has evolved into an industry-leading health and safety management system that demonstrates leadership and cultural transformation among its members, regardless of company size or type of work.

For more information, visit abc.org/step.

reporting indicates that instances of equipment theft are on the rise — creating new challenges on job sites and driving up costs for operators, contractors and business owners.

July was National Vehicle Theft Prevention Month, which offered the industry a crucial opportunity to understand the growing issue of equipment theft and how its data is driving change.

Recent reporting indicates that instances of equipment theft are on the rise — creating new challenges on job sites and driving up costs for operators, contractors and business owners. Let’s drill down into this data to better understand why enhanced security solutions, like Bobcat’s Machine IQ and other telematics systems, are now more important than ever for machine/ fleet protection.

• $1 billion: The estimate annual loss from equipment theft on construction and farm sites.

The National Equipment Register estimates the average cost of a single instance of equipment theft is $30,000. This does not even include consideration for loss of productivity from shutdowns or delays that stem from instances of theft.

• 36 percent of construction site thefts involve wheeled and track loaders*

Equipment that is easy to move, valuable and re-sellable makes ideal targets on unsecured job sites. Wheeled and tracked loaders sometimes share universal keys or lack immobilizers, and without real-time monitoring, can go unnoticed until the crew arrives the next day.

• 21 percent of stolen construction equipment gets recovered.

Only 21 percent of stolen construction equipment gets recovered**. This means targeted operators, contractors and business owners incur additional costs as they rebuild their fleets through new investments or rental. Furthermore, stolen equipment can result in disruption to cash flow, extended

PIRTEK COVINGTON COVINGTON, KY 41094 (859) 980-4673

PIRTEK LOUISVILLE LOUISVILLE, KY 40218 (502) 357-2300

PIRTEK BOLINGBROOK 181 W. CROSSROADS PKWY, STE. C BOLINGBROOK, IL 60440 (630) 755-5700

PIRTEK GURNEE 450 KELLER DR. PARK CITY, IL 60085 (847) 553-4224

PIRTEK MCKINLEY PARK 3440 S. ASHLAND AVE. CHICAGO, IL 60608 (773) 847-7393

PIRTEK O’HARE 1499 TONNE RD. ELK GROVE VILLAGE, IL 60007 (847) 640-7789

PIRTEK ROCKFORD 1500 E LINCOLN HWY. STE. 3 DEKALB, IL 60115 (815) 676-0960

PIRTEK SOUTH HOLLAND 17077-A WESTVIEW AVE. SOUTH HOLLAND, IL 60473 (708) 339-4673

PIRTEK CEDAR RAPIDS 2301 6TH STREET SW CEDAR RAPIDS, IA 52404 (319) 360-4900

PIRTEK QUAD CITIES WEST DAVENPORT, IA (563) 202-1621

The National Equipment Register estimates the average cost of a single instance of equipment theft is $30,000. This does not even include consideration for loss of productivity from shutdowns or delays that stem from instances of theft.

timelines and increased project budgets, and an insurance premium increase after filing a claim.

*Reported by Sirix, Construction Site Theft Statistics, 2023.**Reported by the National Equipment Register, Verisk Insurance Solutions and the National Insurance Crime Bureau (NICB), 2016.

While there are a variety of factors that can impact the likelihood of equipment theft — such as work site location or lack of adequate surveillance — enhancing security measures and improving asset tracking may help deter potential thieves.

(This article is courtesy of Bobcat.)

PIRTEK MERRILLVILLE 90 W. 79TH AVE. MERRILLVILLE, IN 46410 (219) 771-1794

PIRTEK PERRY 2154 S LYNHURST DR. INDIANAPOLIS, IN 46241 (317) 252-0120

PIRTEK PIKE 4219 WEST 96TH ST. INDIANAPOLIS, IN 46268 (317) 252-0120

OHIO

PIRTEK COLUMBUS NORTH COLUMBUS, OH (380) 203-0860

PIRTEK COLUMBUS SOUTH 1671 TAYLOR RD. GAHANNA, OH 43230 (380) 203-0077

PIRTEK ELYRIA 606 LEONA ST. ELYRIA, OH 44035 (440) 595-8233

PIRTEK AUBURN HILLS

2285 N. OPDYKE RD. STE. D AUBURN HILLS, MI 48326 (248) 997-4800

PIRTEK BATTLE CREEK BATTLE CREEK, MI (269) 832-0488

PIRTEK FLINT

4180 PIER NORTH RD., STE A FLINT, MI 48504 (810) 207-0001

PIRTEK GRAND RAPIDS

3504 ROGER B CHAFFEE MEMORIAL DR. GRAND RAPIDS, MI 49548 (616) 323-3939

PIRTEK KALAMAZOO 241 WEST MOSEL AVE. KALAMAZOO, MI 49004 1-866-6-PIRTEK (1-866-674-7835)

PIRTEK LANSING LANSING, MI MOBILE SERVICE AVAILABLE (517) 798-2010

PIRTEK MADISON HEIGHTS 25355 DEQUINDRE RD. MADISON HEIGHTS, MI 48071 (248) 336-8000

PIRTEK STERLING HEIGHTS 40020 MOUND RD. STERLING HEIGHTS, MI 48310 (586) 276-9100

PIRTEK WESTLAND 28540 VAN BORN RD. WESTLAND, MI 48186 (734) 728-7000

PIRTEK WIXOM 46985 ENTERPRISE CT. STE. 300 WIXOM, MI 48393 (517) 544-4300

PIRTEK BURNSVILLE 1409 CLIFF ROAD EAST BURNSVILLE, MN 55337 (952) 895-5400

PIRTEK MIDWAY 2125 ENERGY PARK DR. ST. PAUL, MN 55108 (651) 641-1414

PIRTEK PLYMOUTH 11350 HIGHWAY 55 PLYMOUTH, MN 55441 (763) 475-0475

PIRTEK WEST METRO MINNEAPOLIS, MN (763) 452-3985

PIRTEK FENTON 316 AXMINISTER DR. FENTON, MO 63026 (636) 600-1981

PIRTEK OVERLAND 9425 DIELMAN ROCK ISLAND INDUSTRIAL DR. OLIVETTE, MO 63132 (314) 423-4600

PIRTEK SPRINGFIELD 2835 E DIVISION ST., STE. K SPRINGFIELD, MO 65803 (417) 342-8075

PIRTEK ST. LOUIS ST. LOUIS, MO 63103 (314) 423-4603

PIRTEK LAKE WINNEBAGO OSHKOSH, WI 54901 (920) 777-4673

PIRTEK MADISON 6354 COPPS AVE. MONONA, WI 53716 (833) 623-4673

www.altaequipment.com

844-GO2-ALTA

18405 115th Avenue Orland Park, IL 60467

420 Nolen Drive South Elgin, IL 60177

26354 N US Hwy 12 Wauconda, IL 60084

480 Blaine St. Gary, IN 46406

613 E Stevenson Road Ottawa, IL 61350

1035 Wylie Drive Bloomington, IL 61705

www.lubyequipment.com

2300 Cassens Drive Fenton, MO 63026 636-343-9970

199 Airport Road Cape Girardeau, MO 63702 573-334-9937

2999 Mexico Road O’Fallon, MO 63366 636-332-9970

2625 North 24th Street Quincy, IL 62305 217-222-5454

4375 Camp Butler Road Springfield, IL 62707 217-744-2233 921 1st Street

Fairmont City, IL 62201 618-397-9971

www.tristatebobcat.com

1200 Highway 13 East Burnsville, MN 55337 952-894-0894

588 Outpost Circle Hudson, WI 54016 715-531-0801

71 Minnesota Avenue Little Canada, MN 55117 651-407-3727

2018 US Hwy 8 St. Croix, WI 54016 715-557-6010

www.lanoequip.com

6140 Highway 10 NW Anoka, MN 55303

763-323-1720 888-448-5266

23580 Highway 55 Loretto, MN 55357 763-479-8200 888-479-4342

3021 West 133rd Street Shakopee, MN 55379 952-445-6310 877-753-6100

www.bobcat-ent.com 9605 Princeton Glendale Road Hamilton, OH 45011 513-874-8945

225 Hughes Blvd Mount Orab, OH 45154 937-444-3865

3666 Lacon Road Hilliard, OH 43026 614-876-1116

182 Humphries Drive Reynoldsburg, OH 43068 614-863-1300

3000 Dillon School Drive Zanesville, OH 43701 740-313-0087

13117 Middletown Industrial Blvd. Louisville, KY 40223 502-245-1911

1309 Cahill Drive Lexington, KY 40504 859-254-3936

51 Harvest Drive Elizabethtown, KY 42701 270-506-4530

13350 Service Rd. Walton, KY 41094 859-449-7272

it’s

than ever to get into a

Manitou Skid Steer Loader or CTL - in stock at a Manitou dealer near you. Low TCO and low financing - plus Manitou exclusives such as the IdealAccess™ fold-up door and the IdealTrax™ automatic track tensioning system. Learn more at Manitou.com

starequip.com Star Equipment, Ltd.

Foley Equipment, a provider of Caterpillar parts, services, sales and rental in Kansas and northwest Missouri, announced the launch of its “Parts with Purpose” campaign, a cause-driven initiative supporting veterans transitioning to skilled trades.

From July 29 through Veterans Day (Nov. 11, 2025), Foley Equipment will donate $20 to Workshops for Warriors for every customer’s first online order placed during this period at parts.cat.com/FOLEYEQUIPMENT. Each eligible order directly supports career training for veterans and military spouses in advanced manufacturing and skilled trades.

“Veterans have the discipline, work ethic and mindset our industry thrives on,” said Edward Duggan, Foley’s director of parts, and a veteran himself. “Partnering with Workshops for Warriors allows us to give back in a meaningful way by helping service members build the next chapter of their careers.”

Workshops for Warriors (wfw.org) is a nonprofit organization dedicated to training, certifying and placing veterans into highdemand advanced manufacturing careers such as Computer Numerical Control (CNC) machining and welding. The organization boasted a 97 percent job placement

rate in 2022.

Notch Equipment

topnotchequipment.com

Customers can take part by placing an online order at parts.cat.com/FOLEYEQUIPMENT. The $20 donation will be made automatically, no special code or addi tional steps required.

Foley Industries is comprised of Foley Equipment, Foley Power Solutions, Foley RIG360 Truck Centers, Foley Rental and SITECH Central and is in its ninth decade of serving customers across Kansas and west ern Missouri.

With more than 1,400 employees, Foley provides sales, rental, parts and service for Caterpillar construction and power genera tion equipment; a broad range of rental solu tions; over-the-road truck service; advanced SITECH construction technology; and Shuttlewagon railcar movers.

Workshops for Warriors is a 501(c)(3) nonprofit organization dedicated to rebuild ing American manufacturing by providing veterans, transitioning service members and wounded warriors with advanced manufac turing training and job placement assistance. Workshops for Warriors offers accelerated

16-week training programs in CNC Machining and Welding, providing students with nationally recognized credentials in their chosen field. Since 2011, Workshops for Warriors has trained more than 1,400 students who have earned more than 19,000 nationally recognized credentials. For more information, visit wfw.org.

BUCK & KNOBBY EQUIPMENT CO. www.buckandknobby.com

6220 West Sterns Road Building #2 Ottawa Lake, MI 49267 855-213-2825

Bruggink’s Inc. www.brugginks.com

7344 S. Frontage Road Sheboygan, WI 53081 920-564-6555

CONSTRUCTION MACHINERY COMPANY www.cmcky.com

2911 S English Station Rd Louisville, KY 40299 502-267-4020 6104 Sable Mill Court Jeffersonville, IN 47130 812-850-6160

2235 Ragu Drive Owensboro, KY 42303 270-683-2000

DITCH WITCH OF MINNESOTA & IOWA ditchwitchmnia.com

12826 Emery Way Shakopee, MN 55379 800-252-5811

1320 Frontier Drive Fergus Falls, MN 56537 800-492-4801

1520 Blue Sky Blvd. Huxley, IA 50124 515-685-3521

VERMEER MIDWEST vermeermidwest.com

2801 Beverly Drive Aurora, IL 60502 630-820-3030

1801 179th Street N. East Moline, IL 61244 309-751-9540

120 East Martin Drive Goodfield, IL 61742 309-965-3300

915 Fournie Lane Collinsville, IL 62234 618-407-3860

621 Spirit Valley E. Drive Chesterfield, MO 63005 636-532-2332

13402 Britton Park Rd. Fishers, IN 46038 317-842-1040

3310 W. Coliseum Blvd. Fort Wayne, IN 46808 260-484-2494

3566 Citadel Circle Newburgh, IN 47630 812-490-4400

940 Garden Lane Fowlerville, MI 48836 800-336-3889

1098 Franklin Street Marne, MI 49435 616-677-5900

2319 Plum Valley Rd. NE Mancelona, MI 49659 231-258-1290

Atlas Bobcat

Elk Grove Village

847-678-3633 88-438-8014

Mokena 708-596-8050 888-438-8014

Wauconda 847-526-4255 888-438-8014

West Chicago

630-293-0606 888-438-8014

Yorkville 630-553-0150 888-438-8014 www.atlasbobcat.com

Bobcat of Champaign Champaign 217-607-1454 www.bobcatgdn.com

Bobcat of Marion Carterville 618-985-8920 www.bobcatgdn.com

Bobcat of Springfield Springfield 217-525-0349 www.bobcatgdn.com

Bobcat of St. Louis Fairview Heights 618-397-1847 www.bobcatgdn.com

Bobcat of Effingham Teutopolis 217-717-4550 www.bobcatgdn.com

Authorized Bobcat Dealers

Atlas Bobcat Merrillville 219-381-3006 www.atlasbobcat.com

Bobcat of Evansville Evansville 812-422-8200 www.bobcatgdn.com

Bobcat of Michiana Elkhart 574-584-7550 www.bobcatofmichiana.com

Bobcat of Bowling Green

Bowling Green 270-842-4253 www.bobcatgdn.com

Bobcat of Michiana Niles 269-210-2299 www.bobcatofmichiana.com

Bobcat of Columbia Columbia 573-886-9435 www.bobcatgdn.com

Bobcat of St. Louis O’Fallon 636-240-9020 Valley Park 636-225-2900 www.bobcatgdn.com

Bobcat of Bemidji Bemidji 218-751-4660 www.goironhide.com

Farm-Rite Equipment, Inc.

Dassel 320-275-2737 888-679-4857

Long Prairie 866-514-0982 320-732-3715

St. Cloud 844-262-2281

Willmar 877-484-3211 www.farmriteequip.com

Lano Equipment, Inc. Anoka 763-323-1720 888-448-5266

Loretto 763-479-8200 888-479-4342

Shakopee 952-445-6310 877-753-6100 www.lanoequip.com

Lano Equipment of Norwood, Inc. Norwood Young America 952-467-2181 www.lanoequipofnorwood.com

Swanston Equipment

Bobcat of Alexandria

320-460-8773

Bobcat of Fergus Falls 218-739-4505 www.swanston.com

Tri-State Bobcat Burnsville 952-894-0894

Little Canada 651-407-3727 www.tristatebobcat.com

Bobcat of Devils Lake Devils Lake 701-662-5331

www.goironhide.com

Swanston Equipment

Bobcat of Fargo 701-293-7325

Bobcat of Minot 701-837-9901 www.swanston.com

Bobcat of Grand Forks Grand Forks 701-772-5006 www.goironhide.com

Bobcat of Williston Williston 701-572-5050 www.goironhide.com

Tri-State Bobcat Hudson 715-531-0801

New Location! 2018 US Hwy 8 St. Croix Falls, WI 715-557-6010 www.tristatebobcat.com

JCB’s special-edition VetsAid teleskid is now available through dealers across the United States, offering operators a powerful machine that doesn’t just move material but moves the mission forward.

This bold limited-edition teleskid, featuring a militarygreen finish, custom-stitched VetsAid seat and personalized dog tags, is part of JCB’s commitment to raise $1 million for veteran support services. For each machine sold, $1,000 is donated to VetsAid, the national 501(c)(3) nonprofit founded by rock legend and Gold Star son, Joe Walsh. The funds directly support grassroots veteran organizations providing critical care to servicemen and women transitioning back to civilian life.

With every purchase, customers aren’t just investing in breakthrough equipment — they’re directly supporting United States military veterans through JCB’s partnership with VetsAid. It’s innovation with intention — a better way to work that gives back.

Founded in 2017, VetsAid is a nonprofit and benefit music festival dedicated to helping veterans return to civilian life with dignity, support and care. To date, the organization has disbursed more than $3.3 million to vetted community-based service groups across the United States.

“VetsAid isn’t just about raising money and awareness for America’s veterans and their families,” said Walsh. “It’s also about finding common ground among music lovers of all backgrounds and coming together to build and rebuild communities around a shared love of coun-

try.”

The VetsAid initiative with JCB was launched with a $250,000 corporate pledge, with additional funds raised through sales of limited-edition machines and merchandise.

“This is a legacy project between two families that will help give veterans and their families in the U.S. a better future and offer them the care and support they deserve,” said Alice Bamford of JCB.

The VetsAid 3TS-8T teleskid is more than a commemorative model — it’s a breakthrough in compact equipment innovation, according to JCB. It gives operators flexibility to:

• lift higher — up to 13 ft. of vertical reach;

• reach farther — more than 8 ft. forward;

• dig deeper —3 ft. below grade; and

• handle more — up to 3,695 lbs. operating capacity.

A 74 hp engine powers robust hydraulic performance, ideal for use with attachments such as buckets, forks, augers, trenchers and grapples. Designed for heavy-duty job sites across construction, landscaping and agriculture, the teleskid maximizes output and minimizes downtime.

Operators benefit from a side-door entry and JCB’s exclusive single-arm boom, enhancing visibility, safety and access. With broad attachment compatibility and allterrain agility, the Teleskid lets users do more — and do it with purpose.

For more information, visit jcb.com/ en-us/about/vetsaid.

Yanmar Compact Equipment provides its customers with more options on the job site with the launch of its full line of compact equipment.

The line is completed following the introduction of Yanmar compact track loaders, now available at dealer lots across North America. The four models complement the existing mini excavators, compact wheel loaders and tracked carriers. The launch is made possible by a 50 percent increase in North American production capacity over the last several years.

Yanmar Compact Equipment North America’s new president, Anna Christine Sgro, said the introduction is a milestone that marks a significant step towards the company’s mission to become a global leader in the compact equipment market.

“This full range of equipment is built on trust developed over Yanmar’s 100 years as a company, 55 of those in compact equipment,” Sgro said. “Our dealers, customers and partners rely on us to deliver machines that are not only dependable but also help them grow their businesses. It’s part of our mission to continue building success and a richer experience for our stakeholders and customers.”

After years of ground-up development,

Equipment provides its customers with more options on the job site with the launch of its full line of com-

the addition of the Premium Red compact track loaders to Yanmar’s compact equipment line expands options for operators looking to take advantage of Yanmar products in more aspects of their operations. It serves as a comprehensive range of products designed to meet the needs of professionals in industries ranging from construction, rental, landscaping, utility and more.

The full line was made possible due to

significant investments Yanmar CE has made in North America that have increased production capacity by 50 percent over the last few years. That includes a 32,000-sq.-ft.