When disaster strikes, it takes a concerted effort among many people to help communities recover.

In the aftermath of the deadly floods in Texas’ Hill Country over the July 4 weekend, the construction industry is playing a critical role in helping the community return to some semblance of normalcy.

While first responders were engaged in life-saving

efforts, contractors, along with their equipment partners, were playing a critical role in recovery, debris cleanup and removal, utility restoration, as well as road and bridge reconstruction. Additionally, humanitarian aid and in-kind support are being provided on an ongoing basis.

By Lucy Perry CEG CORRESPONDENT

No project can really start until the machinery arrives and is fired up. That’s why load securement is step number one in transporting heavy construction machinery. Assets can be damaged or destroyed, employees can be injured or worse during either loading or unloading, so hauling contractors cannot risk taking safety precautions lightly.

There are endless sources for solid information on proper load mobilization, starting with the

That’s why there’s no excuse for cutting corners during such a critical phase of the construction project.

2019 John Deere 850K LT, Stk#: HR-1207, EROPS, A/C & Heat, Radio, 6 Way Blade, 6,728 hrs., 90% U/C, 24" Pads, Multi Shank Rear Ripper, 14 ft. Wide ..................$179,500

hrs. Since Certified, Refurb. 2015., 4WD, IN445/50D710 Tires $69,500

2023 John Deere 130P, Stk#: HR-1435, EROPS, A/C & Heat, Radio, 1,465 hrs., 36" Bucket w/Hyd Thumb, 28" Pads, Rear View Camera $159,500

2018 Bell B30E, Stk#: 13464, EROPS, A/C & Heat, Radio, 5,453 hrs., 30 Ton Dump Cap., Auto Greaser, 23.5Rx25 Tubeless Tires $169,500

2020 John Deere 650K LGP, Stk#: HR-1182, OROPS, 6 Way Blade, 2,385 hrs., 24" Pads, 100% U/C, 10' 4" Wide $79,500

2021 John Deere 450K LGP, Stk#: HR-1232, OROPS, 6 Way Blade, 2,278 hrs., 24" Pads, 9' 7" Wide $79,500

2016 Cat 330FL, Stk#: 13598, EROPS, A/C & Heat, Radio, 7,301 hrs., 47" Bucket w/Manual Thumb, 31" Pads, Quick Connect. $139,500

2021

145X LC,

Aux. Hyd. $89,500

2020 Linkbelt 210X4EX, Stk#: HR-1322, EROPS, A/C & Heat, 5,445 hrs., 35" Bucket w/Hyd. Thumb, 31% Pads $99,500

2020 John Deere 750L LGP, Stk#: HR-1427, EROPS, A/C & Heat, Radio, 6 Way Blade, 7,194 hrs., 33" Pads, 13' 5" Wide ....$159,500

2019 Cat 330 GC TC, Stk#: HR-1122, EROPS, A/C & Heat, 6,169 hrs., Aux Hyd., 32" Pads, 47" Cat Bucket w/Thumb, 1.74 yd., AM/FM Radio, Bluetooth Phone Connection, Rear & Side Cameras. $159,500

Intermountain Health announced on July 9, 2025, that it selected The PENTA Building Group in partnership with Jacobsen Construction to build the first-ever standalone comprehensive children’s hospital in Nevada.

The Oklahoma Transportation Commission on July 8, 2025, approved the County Improvements for Roads and Bridges Plan for Fiscal Years 2026 to 2030.

Central Power Systems & Services will now sell, rent and service Takeuchi compact excavators and track loaders in Woodward, Okla.; four locations in Kansas; and three locations in Texas (Hutto, San Antonio and Corpus Christi).

For the second year in a row, the mountain village of Ruidoso in south-central New Mexico fell victim to deadly floods. Both years, the flooding was exacerbated by burn scars left by wildfires early in 2024.

14 BOBCAT’S ‘BUILD TOGETHER, PLAY TOGETHER’ BENEFITS LOCAL PARKS

Bobcat Company is giving back to local parks in celebration of the National Recreation and Park Association’s Park and Recreation Month. Throughout July, Bobcat invites individuals to join in giving back to their communities.

14 VOLVO CE TO POWER SUSTAINABLE TRACK BUILDING IN FIA WORLD RX

Volvo CE is accelerating electromobility across the all-electric World RX championship through the use of its high-performing zero-emission solutions in building and maintaining the tracks at key locations around the world.

18 EQUIPMENT THEFT’S RISING COST, WHAT DATA DEMANDS

July is National Vehicle Theft Prevention Month, which offers our industry a crucial opportunity to understand the growing issue of equipment theft and how its data is driving change.

18 CATERPILLAR’S RESOURCES HELP CUSTOMERS MAINTAIN EQUIPMENT

Caterpillar has recently launched a comprehensive library of how-to videos and articles for customers that prefer to do their own maintenance and repairs. This library includes a new series of do-it-yourself (DIY) videos.

20 BLUE DIAMOND INTRODUCES NEW HDX SERIES ATTACHMENTS

Blue Diamond Attachments has announced the launch of its HDX Series Grapples, a new addition to the lineup between their current HD and Severe Duty Grapples.

23 FELLING NAMES IVY’S LEGACY AS ITS ‘TRAILER FOR A CAUSE’ BENEFICIARY

Felling Trailers Inc. announced Ivy’s Legacy Foundation as the beneficiary of the 13th annual 2025 Trailer for a Cause auction. This tradition involves auctioning a custom FT-3 utility trailer online.

28 CASE DISCUSSES EV EVOLUTION IN MODERN EQUIPMENT

The construction industry is in the midst of a new kind of change — a wave of electrification in construction equipment with the potential to change the way we work on the job site.

36 OKLA. AWARDS $72M CONTRACT TO FIX ‘ROLLER COASTER’ BRIDGE

KRMG reported that OBC Inc. was awarded a $72 million contract to fix the two State Highway 364 bridges nicknamed the “Roller Coaster Bridge,” where they pass over Haikey Creek. 36 IOWA STATE’S HALIL CEYLAN RECEIVES ARTBA NATIONAL RESEARCH AWARD

Halil Ceylan of Iowa State University (ISU), is the 2025 recipient of the American Road & Transportation Builders Association’s (ARTBA) S.S. Steinberg Award.

The AED Foundation (AEDF) announced that Warrick Pathways and Career Center in Booneville, Ind., has become the 115th Recognized High School Program under its national workforce development initiative. 48 BAR NONE AUCTION EXPANDS ITS WEST COAST SALES FORCE

To support sellers across the West Coast, Bar None Auction has expanded its sales team, adding two seasoned territory sales representatives to help business owners move equipment faster, smarter and more profitably. 29

Intermountain Health announced on July 9, 2025, that it selected The PENTA Building Group in partnership with Jacobsen Construction to build the first-ever standalone comprehensive children’s hospital in Nevada.

The selection of these construction firms brings a wealth of experience to the historic project, combining PENTA’s familiarity and expertise in large-scale projects in Nevada with Jacobsen’s expansive knowledge in health care construction, which includes the second Intermountain Primary Children’s Hospital campus that opened in Lehi, Utah, in early 2024.

“It was vital for us in the contractor selection to bring both ingenuity and craftsmanship along with the aspect of homegrown Nevada connections,” said Lawrence Barnard, president of the Intermountain Health Nevada Children’s Hospital. “The Nevada Children’s Hospital is poised to be state-of-art, welcoming families close to home with the compassionate service for which Intermountain is known.”

The new Intermountain children’s hospital represents one of the most significant and exciting opportunities to elevate children’s health in Nevada. Philanthropy and community partnerships are critical to make this vision a reality, and campaign planning is underway.

When complete, the Intermountain pediatric health care facility will be the first stand-alone hospital in Nevada that is fully and comprehensively dedicated to children’s health. This includes specialty-based care, such as oncology and cardiovascular services, among others that patients currently must travel out-of-state to receive.

“The Intermountain Health Children’s Hospital is going to be an incredible addition to the Las Vegas community, and The PENTA Building Group is excited to partner with Jacobson Construction to help make it a reality,” said John Cannito, president and CEO of PENTA. “As a local Las Vegas contractor, we see this as more than just another construction project; it’s an opportunity to be part of something amazing that is going to make southern Nevada a better place for our families and friends. We are proud to be selected by Intermountain Health as a partner in this historic initiative.”

“For Jacobsen Construction, joining Penta in the building and delivery of this project is the culmination of two decades of continuous close work with Intermountain Healthcare to deliver inspiring projects that serve the most vulnerable in our commu-

Intermountain Health, The Gardner Group and the UNLV Research Foundation signed agreements in July for a children’s hospital to be built at the UNLV Research and Technology Park.

nities,” said Jacobsen President and CEO Gary Ellis. “We have treasured the many years of working on impactful projects at Primary Children’s and many other Intermountain facilities. To be entrusted by them with this truly once-in-a-generation project, and to be able to draw on that longstanding relationship to solve problems together for this facility is an amazing privilege.”

Jacobsen’s construction leadership will be headed by Vice President Blake Court, whose continuous work with Intermountain spans more than 19 years.

In January, the firms Shepley Bulfinch and Gensler were announced as architects for the project and subsequently began design work.

Earlier in July, Intermountain Health, The Gardner Group and the UNLV Research Foundation signed agreements for a comprehensive children’s hospital to be built on the land at the UNLV

Research and Technology Park.

Groundbreaking is expected in early 2026, with the hospital projected to open by 2030.

The 200-bed hospital will provide highly specialized care for children and families in Nevada, give the state a $724 million economic boost during five years of anticipated construction, and deliver $841 million in annual economic output once the hospital opens, according to an independent research study conducted by Applied Analysis.

Intermountain Health offers patient care at more than 80 clinics at more than 65 locations across southern Nevada. With its extended provider network, Intermountain Health delivers patient-centered primary, specialty, and urgent care services to approximately 350,000 southern Nevadans in Clark and Nye counties.

The Oklahoma Transportation Commission on July 8, 2025, approved the County Improvements for Roads and Bridges Plan for Fiscal Years 2026 to 2030.

The updated five-year plan includes nearly $930 million in scheduled upgrades to county roads and bridges outside of ODOT jurisdiction across all 77 Oklahoma counties.

One of the major, newly added projects is a $12.5 million project that includes Congressionally Directed Spending funds and will reconstruct 5 mi. of Oswalt Road and bridge replacement in Love County.

Established by the Oklahoma Legislature, the CIRB Plan targets aging and deficient county infrastructure. Over the next five years, the updated plan aims to

replace or rehabilitate 230 county bridges, including 82 structures classified as structurally deficient or functionally obsolete, and improve 422 mi. of county roadways.

“ODOT appreciates the Transportation Commission’s continued support and the legislature’s commitment to strengthening the county road network,” said Tim Gatz, ODOT executive director. “We’re proud to partner with county commissioners across Oklahoma to deliver these critical infrastructure projects. They will enhance safety, improve mobility and support economic development statewide.”

Administered by ODOT, the CIRB Plan is a collaborative effort involving county governments and the state’s eight Circuit Engineering Districts. Projects are prioritized

based on need, and funding is coordinated through a mix of state, federal, local and tribal sources. The cooperative structure allows counties to pool resources for large-scale improvements that would be difficult to fund independently.

Since the CIRB Plan began in 2006, it has played a vital role in upgrading the condition and safety of Oklahoma’s county road system. The plan is reviewed and updated annually.

Highlights in the plan include:

Cherokee County: A nearly $5 million project over Petitt Creek near Park Hill for bridge replacement and realignment of Indian Road.

Pottawatomie County: A $4.8 million bridge replacement project and widening

of 4 mi. of Moccasin Trail Road.

Harmon County: A $12.5 million project to reconstruct 8 mi. of East 1550 Road from State Highway 30 to North 1790 Road.

Woodward County: A $3 million project will continue the reconstruction of 2.5 mi. of East County Road from South County Road. 199 to South County Road 196.

Love County: A $12.5 million project that includes the reconstruction of 5 mi. of Oswalt Road and bridge replacement in Ardmore; this project includes Congressionally Directed Spending funds.

Ottawa County: A $7.2M road and bridge improvement project on South 520 Road and East 120 Road, including a new bridge over Coal Creek in Miami.

Central Power Systems & Services photo

A Central Power Systems & Services location

Central Power Systems & Services will now sell, rent and service Takeuchi compact excavators and track loaders at its location in Woodward, Okla.; four locations in Kansas (Wichita, Salina, Colby and Garden City); and three locations in Texas (Hutto, San Antonio and Corpus Christi).

“We’re excited to add the Takeuchi product line to our construction equipment offering,” said John Cosgrove, president of Central Power Systems & Services. “Takeuchi’s reputation for quality, innovation and performance aligns perfectly with the values we bring to our customers. This partnership strengthens our ability to deliver reliable, industryleading equipment solutions backed by the service and support our clients have come to expect.”

Founded in 1963, Takeuchi is an ISO 9001 certified manufacturer of an extensive line of compact track loaders, compact excavators, compact wheel loaders and a compact crawler dumper.

Central Power Systems & Services, headquartered in Kansas City, Mo., has been a trusted provider of power generation, distribution and heavy equipment solutions since 1954. With 20 locations and 700 employees across Kansas, western Missouri, northern Oklahoma and Texas, the company delivers comprehensive sales, service and rental support for industries ranging from construction and transportation to critical infrastructure.

Central Power offers custom-engineered systems, a robust rental fleet, certified technical expertise and 24/7 emergency service to meet the evolving needs of its customers. Guided by core values of integrity, humility, partnership and innovation, the company continues to grow its capabilities — most recently with the addition of a 750,000-square-foot power generation facility in Platte City, Mo.

“We’re proud to welcome Central Power Systems & Services to the Takeuchi dealer network,” said Shay Klusmeyer, western division sales manager of Takeuchi-US.

“Over the years, Central Power has built a strong reputation for outstanding customer service and deep industry expertise, and we’re confident they will represent the Takeuchi brand with excellence. We look forward to a successful partnership that brings even greater value to customers in Oklahoma, Kansas and Texas.”

For details about Central Power Systems & Services, visit cpower.com. For details about Takeuchi, visit

us.com.

Bingham Equipment

binghamequipment.com

Tucson, AZ 520-889-6396

Cisco Equip

cisco-equipment.com

Artesia, NM 575-748-1314

Lubbock, TX 806-745-9595

Odessa, TX 432-550-9181

Ditch Witch of the Rockies

*Compact Equipment Only ditchwitchrockies.com

Nampa, ID 208-376-8394

Pocatello, ID 208-646-4360

Farm Equip USA

farmequipmentusa.com

Fruitland, ID 208-941-6000

G4 Const Equipment, LLC

g4hyundai.com

Commerce City, CO 888-987-3352

Jet City Equip

jetcityequipment.com

Oak Harbor, WA 360-675-4441

Marysville, WA 360-651-9079

Mecom Equipment

mecomequipment.com

Stockton, CA 209-466-5135

National Equipment Dealers

nedealers.com

Houston, TX 800-234-5007

Dallas TX 866-270-1700

Nueces Power Equip

nuecespower.com

Corpus Christi, TX 361-289-0066

Laredo, TX 956-725-0066

San Antonio, TX 210-310-0066

San Benito, TX 956-361-0066

Victoria, TX 361-576-0066

El Paso, TX 915-541-0066

Oklahoma Territory

Const Equip callotce.com

Oklahoma City, OK 866-339-6827

Oregon Tractor oregontractor.com

Roseburg, OR 541-679-6211

Porter Rents

porterrents.com

Corona, CA 951-674-9999

Lakeside, CA 619-390-1197

Pacoima, CA 818-834-0102 Wildomar, CA 951-678-9902

Powerscreen of Washington, Inc.

powerscreen-wa.com Helena, MT 253-236-4153

Powerscreen of Northern California, Inc.

powerscreenofcalifornia.com Dayton, NV 888-797-7276

Dixon, CA 707-253-1874

Rifle Equipment, LLC

*Compact Equipment Only rifleequipment.com

Rifle, CO 970-625-2580

R&S Industries Inc. rsindinc.com

Amarillo, TX 806-737-9410

Clovis, NM 575-769-8659

Tri-State Equipment

*Compact Equipment Only tristateequipmentrentals.com

Lake Havasu, AZ 928-680-6748

Fort Mohave, AZ 928-704-0101

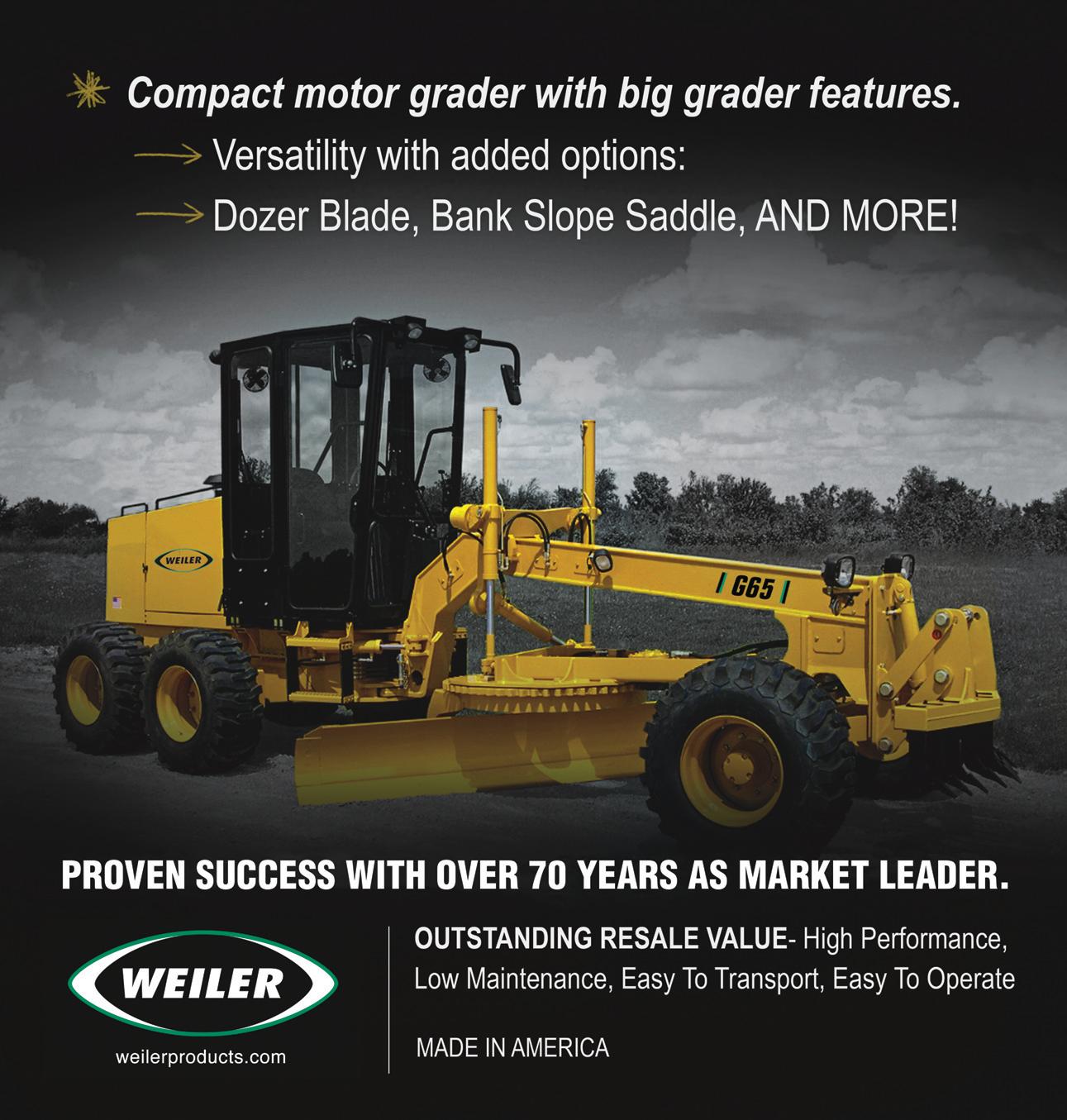

Loved for the features. Trusted for the performance.

Hyundai wheel loaders have the power and performance, not to mention top-notch interiors, accurate onboard weighing system, industry proven drivetrain durability, clear sightlines, and handy tech that make life on the jobsite easier. So you can do more without feeling it. No wonder so many first-time Hyundai users become longtime fans.

See the Hyundai difference yourself at your local dealer or na.hd-hyundaice.com.

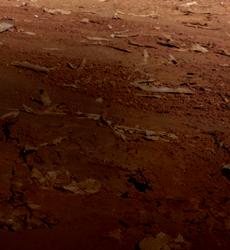

Ruidoso sits at an elevation of nearly 7,000 ft. in the Sacramento Mountains in Lincoln County, N.M. The town is a popular destination for west Texas residents seeking to escape the summer heat. In the background is the Sierra Blanca Peak on the Mescalero Reservation. The peak rises to 12,000 ft.

While the devastating floods in Texas received massive media attention, tragic flooding in neighboring New Mexico received less national coverage.

For the second year in a row, the mountain village of Ruidoso in south-central New Mexico fell victim to deadly floods. Both years, the flooding was exacerbated by burn scars left by wildfires early in 2024. The most recent flooding resulted in three fatalities.

Ruidoso is best known as a favorite summer vacation destination for west Texans looking to escape the heat. It also is popular in the winter, boasting the southernmost major ski resort in the United States — Ski Apache. Recovery is now underway in the scenic mountain town.

Excavators, loaders, bucket trucks and motor graders line the streets running from the main tourist area, Sudderth Drive, down to the numerous bridges — what’s left of them — over the Rio Ruidoso. The river rose 20 ft. in just more than 30 minutes on July 8, wreaking havoc on a town still recovering from the 2024 disaster.

A Hyundai excavator fitted with a grappler attachment performs necessary cleanup work in Ruidoso on July 17. The village experienced flash flooding for several days after the

During June and July of 2024, the South Fork fire burned nearly 18,000 acres in Ruidoso and destroyed more than 1,400 homes and structures. Flash flooding damage in the following days and weeks was made worse by burn scars left behind by the earlier fires. The scars remain a year later, and so does the heightened risk of flood damage.

Ruidoso Downs Race Track is a microcosm of the situation faced by the entire area. The 2024 floods forced the closure of the track, which hosts the top quarter horse racing in the country.

On May 21, the track’s Facebook account announced the facility’s reopening.

“The Track is Ready! We’re proud to share that the Ruidoso Downs Racetrack has just been hydro-seeded and is looking absolutely stunning,” it declared.

Then, just weeks later, the flooding of July 8 destroyed the track again, forcing the closure for the season. CEG

(All photos in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

Volvo CE is accelerating electromobility across the all-electric World RX championship through the use of its high-performing zero-emission solutions in building and maintaining the tracks at key locations around the world — mirroring the electric rallycross cars that will soon be racing on them.

As Official Track Building Partner, Volvo CE is tasked with building new features on existing racetracks or sometimes building courses entirely from scratch — in the most sustainable and efficient way possible and always under tight timeframes. The company also is tasked with maintaining the tracks and recovering crashed cars during the races themselves with its safety solutions.

These challenges require power, precision and adaptability. Volvo CE's advanced electric machines are engineered to handle the unique challenges of shaping and maintaining these high-intensity circuits while reducing reliance on fossil fuels, according to Volvo. With their near silent operation, electric machines increase efficiency by making it possible to build tracks during the night or during unsocial hours.

By integrating electromobility into track construction, the company is demonstrating the strength of its sustainable solutions in

demanding, real-world applications like motorsport. This year, the solutions are getter bigger and better with the inclusion of new mid-size machines like the L120 electric and L90 electric wheel loaders and the updated EC230 electric excavator, now boasting a full day of operation. This approach to drive efficiency and sustainability both on and off the track, allows the partnership to maintain the fast-paced thrills of motor-

sport with a lighter carbon footprint. Volvo CE's commitment to sustainability extends beyond construction. The electric-powered CE Dealer team by Volvo Construction Equipment, the only gender-balanced team in World RX, returns to competition this season. It is a clear demonstration of how to combine high-performance motorsport with a bold, forward-thinking approach and brings the company's performancedriven, purpose-led mindset to the track.

Bill Law, head of brand marketing and communications of Volvo CE, said, “The FIA World RX Champion-ship continues to be a fantastic format to raise awareness of the transition to a more sustainable future for construction and motorsport alike. Through an unbeatable mix of state-of-the-art sustainable power and digital innovation, we are proud to be leading the way for a new era of high-performing electromobility. Thanks to our continued partnership with the FIA, the 2025 season is set to be more dynamic than ever before.”

To keep up to date with the latest race schedule, visit fiaworldrallycross.com/calendar.

Bobcat Co. gave back to local parks in celebration of the National Recreation and Park Association’s (NRPA) Park and Recreation Month.

Throughout July, Bobcat invited individuals to join in giving back to their communities. Participants were encouraged to share a photo on social media of Bobcat equipment doing work worth doing — whether it’s their own, a neighbor’s or a machine spotted at a park or a job site.

For every shared photo between July 1-31, 2025, Bobcat donated $10 to NRPA, with a goal to contribute up to $150,000 to support environmental preservation.

“Community is at the heart of everything we do,” said Laura Ness Owens, Bobcat vice president of brand and marketing. “Our partnership with the NRPA allows us to contribute to the creation of vibrant, sustainable park and recreation spaces that benefit people of all ages. These spaces are essential resources for individuals and families to connect, stay active and promote overall health — opportunities that enhance the fabric of communities and create stronger

futures.”

Through its support of NRPA, Bobcat is fostering environments where communities can thrive.

“Build Together, Play Together” was the theme of this year’s Park and Recreation Month. In its 40th year of celebration, Park and Recreation Month uplifts park and recreation professionals and how they improve lives through the lasting impact of park and recreation programs.

“Park and Recreation Month is a time to honor the park and recreation professionals and agencies that make our communities stronger,” said Kristine Stratton, NRPA president and CEO. “We’re incredibly grateful for partners like Bobcat, whose unwavering support and shared commitment to the power of parks helps drive lasting impact. Their belief in the importance of local park and recreation spaces — places that foster well-being, build resilience and prepare communities for the challenges of today and tomorrow — is a true inspiration.”

For more information, visit bobcat.com/na/en

from page 1

Excavators, skid steers and material handlers are among the machines most in demand across the devastated region.

Molly Miksch, a spokesperson of Compact Construction Equipment, the Bobcat dealer in south Texas and Vermeer Texas-Louisiana, described her company’s response to the flooding:

“The Compact Construction Equipment branch [Ranchers ATV] is located in Kerrville and has been helping local contractors and first responders keep their equipment running since the recovery work began,” she said. “The facility has set up an equipment triage station on the yard to help get quick and easy repairs completed on the trailer at little to no cost to the customer. In addition, they brought in extra equipment including excavators, loaders, grapples and thumbs, as well as chainsaws and other outdoor power products.

“Later in the week, team members from Ranchers ATV and Vermeer Texas-Louisiana gathered brush-clearing

equipment and trailers loaded down with hydraulic oil, grease and DEF fluid and visited the contractors and first responders working in the areas to hand out the supplies free of charge. We have also brought in additional team members to help support the needs at the branch location.”

Miksch said efforts will be ongoing.

“We intend to continue with the repair triage, enhanced staffing and equipment inventory as long as it is needed,” she said.

A spokesperson for ASCO Equipment, the Case dealer in Texas, said the company has deployed machines to Kerr County.

“We have several customers out there. We have a CX300 out to a customer that is using it to help with cleanup, and we also have a CX80 out there. One of our drivers here in San Antonio went out to cook for volunteers last Saturday and Asco contributed food to the effort,” the spokesperson said.

Individual team members of various equipment dealerships stepped up to volunteer their time with cleanup. Vermeer Texas-Louisiana employees took a BC1800XL chipper to the Brushy Creek/Leander area to help with clean-up in that area west of Austin.

Monetary contributions also have been forthcoming. Among the more notable gifts:

see FLOODS page 36

Caterpillar has recently launched a comprehensive library of how-to videos and articles for customers that prefer to do their own maintenance and repairs.

This library includes a new series of do-ityourself (DIY) videos designed to help customers confidently maintain their Cat equipment. These how-to instructional videos provide simple, clear and easy-to-follow instructions for common maintenance, repair and inspection tasks, according to

Caterpillar. Developed by Caterpillar experts, the series instills confidence in customers that they can properly perform these tasks.

“Customers can view these short how-to videos with the goal of making it simple, clear and easy for them to maintain their Cat equipment,” said Jay Ramasamy, vice president, sales and marketing of Caterpillar’s Construction Industries Services Division (CISD). “They were developed in direct

response to what people are requesting most for common repair and inspection items. They are designed to help save customers’ time and money and assist those who prefer to do their own maintenance at a time that’s convenient with their production schedule.”

The Caterpillar DIY video series serves as a supplement to the machine’s operation and maintenance manual (OMM) and boosts the confidence of visual learners to get the job done right. The current library includes nearly 60 how-to videos produced in English with subtitles in 23 different languages, and Caterpillar continues to expand the variety of videos offered.

As a complement to the DIY videos, Caterpillar also has developed a blog series covering the most popular maintenance tips. The articles break down inspection, maintenance and repair and replacement information into easily understandable steps. The blogs provide another solution to help boost the confidence of DIY customers.

While often featuring a machine as an example, the maintenance information applies to all machines in general and are not

specific to a particular model or type. The videos and articles cover everything from maintaining dozer precision cutting edges to installing batteries and from replacing your fuel filter to testing the service brake on Cat equipment.

For customers upgrading their equipment, the series also offers clear and concise instructions on how to install various Cat upgrade kits, such as light guards, cab guards and fire extinguisher mounts. Expanding beyond maintenance, the video catalogue dives into tips for selecting steel tracks for excavators, dozers and loaders. They also provide an overview of Cat rubber track designs, how they function, and guide customers through the diverse options for Cat compact track loader and mini hydraulic excavator rubber tracks.

The articles and videos enable customers to quickly access the instructions they need. In addition, customers can shop for the correct replacement parts or contact a Cat dealer directly from the article.

“If the task requires a part or the repair becomes more involved than the customer anticipated, we have designed the blog site to allow the customer to quickly get the additional support they need,” said Ramasamy. For more information, visit cat.com.

July is National Vehicle Theft Prevention Month, which offers our industry a crucial opportunity to understand the growing issue of equipment theft and how its data is driving change.

Recent reporting indicates that instances of equipment theft are on the rise — creating new challenges on job sites and driving up costs for operators, contractors and business owners. Let’s drill down into this data to better understand why enhanced security solutions, like Bobcat’s Machine IQ and other telematics systems, are now more important than ever for machine/ fleet protection.

• $1 Billion: The estimate annual loss from equipment theft on construction and farm sites.

The National Equipment Register estimates the average cost of a single instance of equipment theft is $30,000. This does not even include consideration for loss of productivity from shutdowns or delays that stem from instances of theft.

• 36 percent of construction site thefts involve wheeled and track loaders* Equipment that is easy to move, valuable and re-sellable makes ideal targets

on unsecured job sites. Wheeled and tracked loaders sometimes share universal keys or lack immobilizers, and without real-time monitoring, can go unnoticed until the crew arrives the next day.

• 21 percent of stolen construction equipment gets recovered.

Only 21 percent of stolen construction equipment gets recovered**. This means targeted operators, contractors and business owners incur additional costs as they rebuild their fleets through new investments or rental. Furthermore, stolen equipment can result in disruption to cash flow, extended timelines and increased project budgets, and an insurance premium increase after filing a claim.

*Reported by Sirix, Construction Site Theft Statistics, 2023.**Reported by the National Equipment Register, Verisk Insurance Solutions and the National Insurance Crime Bureau (NICB), 2016.

While there are a variety of factors that can impact the likelihood of equipment theft — such as work site location or lack of adequate surveillance — enhancing security measures and improving asset tracking may help deter potential thieves.

(Article courtesy of Bobcat.)

Thompson Tractor advises customers to start the hauling process by performing a documented risk assessment.

In an article on the company website, Thompson defined risk assessments as “preemptive compliance documents.” These documents help contractors show how detailed and thorough their fleet management processes are.

“They can be done by a senior manager or supervisor, containing the total operation and transportation timeline and its weight loads.”

Inspecting the hauling capacity of the transport vehicle — truck or trailer — is the next task to be completed. Assess tire condition for pressure.

“Multi-ton machines take a toll on tire air pressure and will quickly deflate any that are already weak,” said Thompson.

The truck or trailer’s front and rear brake lights should work without a hitch, stressed the company. Like tires, brakes can be affected by oversized loads, compromising their effectiveness. It’s key to assure brake functions and components are working.

Tie-down points should be checked for the load’s required point number, securement condition and spacing, said Thompson.

“Most states’ standards mandate a minimum of four tiedown points for loads exceeding 10,000 lbs.”

Each tie-down point must have its own binder or boomer and individual chains connected to trailer hitch points.

“These boomers are responsible for supplying the tension to tighten the actual chain connection,” said Thompson, “and … should be inspected themselves.”

Finally, confirm the tie-down working load limits add up to at least half of the total weight of the load, advised Thompson.

“Any machine with attachments or appendages must have those attachments dislodged and separately secured.”

That means, then, a minimum of five tie-down points.

When it comes to safely loading heavy equipment, remember that a load is only as strong as its weakest link, stressed Thompson.

“Weak links often happen because the process was rushed or done halfheartedly,” said the equipment dealer.

There are actually “a few more points of consideration to ensure you reliably and legally transport heavy cargo,” Thompson said in the website article.

Here are the safety measures the dealer suggests contractors refer to for secure loading operations:

1. Designate Responsibilities

“You’ll need someone to drive the equipment onto the deck … [and] a spotter to deliver hand signals and direct the driver up the ramp and onto the trailer bed.”

That’s because the equipment operator will more than likely not have a clear line of sight to do so themselves, said Thompson.

“No drifting personnel or other vehicles should interrupt loading operations, which are generally unsafe to stop once they have started.”

2. Clean the Ramp and Trailer

Ramps and trailer decks should be as dirt-, oil- and debris-free as possible, especially if they are metal, Thompson advised.

“This ensures the piece of loading equipment has as much traction as possible to move up its ramp.”

A clean ramp and trailer bed also should be dry and clear of ice, snow and water, noted the company.

“If you are still concerned about equipment smoothly moving up ramps, consider employing ramp friction

devices during this step.”

3. Clear and Level the Loading Area

Thompson advises contractors to pick an uninhabited and even space to set up the ramp and perform heavy equipment loading.

Also, ensure the actual ground in the loading area is compact enough to bear the total weight of the loaded trailer, Thompson said in its website article.

“After rain or during seasons with thaw, the combined weight of these two vehicles can cause sinkage.”

4. Begin the Machine/Ramp Line-Up

Slow and steady are key to machine/ramp line-up, with the driver in the cab and a spotter positioned in plain view. Only then should the operator begin driving the heavy equipment up the cleared ramp and onto the transportation vehicle’s deck.

“Note that the machine’s center of gravity will shift during this ramp movement,” said Thompson.

“This is the most dangerous part of the loading process, with the equipment’s weight caught momentarily in a point of limbo.” Just keep moving gradually.

When appropriately positioned on deck, most of the equipment’s weight should be distributed toward the front of the trailer to avoid fishtailing en route.

5. Start Chaining Down Heavy Equipment

The contractor absolutely must check state laws on securing heavy equipment during public highway transportation, advised Thompson.

While the four to five tie-down points are near-universal, each state has additional oversized cargo restrictions and regulations to respect.

“With the heavy equipment safely positioned on the deck, you can initiate one of the most critical steps … tying it down.”

Blue Diamond Attachments has announced the launch of its HDX Series Grapples, a new addition to the lineup between their current HD and Severe Duty Grapples.

The new units are specifically designed for midsized skid steer loaders, CTLs and tractors up to 75 hp. The HDX Series includes both root grapples and grapple buckets, engineered to make easy work of land clearing, landscaping, debris removal and storm cleanup projects. Blue Diamond’s HDX Series grapples deliver the performance and efficiency of a commercial grapple, all while saving you time and money, according to Blue Diamond.

A key advantage of Blue Diamond HDX Series grapples is the wide opening which allows the operator to grab bulkier items in one load. Uneven or awkward material are stable and secured by the independent acting top clamps that have commercial grade hydraulic cylinders for maximum clamping force, according ot Blue Diamond. The updated and heavier construction of the new series also means they can handle rugged use on midsized machines, making them a cost-effective long-term investment, according to Blue Diamond.

The HDX Series root grapples and grapple buckets feature enhanced design elements that take

the overall performance and versatility of the attachments to new levels. These include:

• stronger cylinder protection covers;

• a fully welded cylinder for increased clamping force;

• thicker ¼-in. tubing in the frame weldment;

• pivot point grease fittings;

• enhanced hose protection; and

• dual top clamps for load stability.

“We added the HDX Series grapples to our full lineup to fill a gap in the market for a site cleanup attachment that meets the needs of contractors and landowners looking to work in that 75 horsepower range,” said Drew Truan, CEO of Blue Diamond Attachments. “We listened to those customers and developed this new series, so they had what they need, when they need it. We believe the HDX Series will become the go-to grapples throughout North America.”

The new HDX Series open to 32 in., are 37 in. deep from front to back, and have 72 in. working width.

All Blue Diamond HDX Series grapples come with Blue Diamond’s satisfaction guarantee and are backed by a one year warranty.

For more information, visit bluediamondattachments.com.

Auger Technologies introduced its redesigned bullet tooth puller, a device to quickly and safely remove even the most stubborn conical auger bits from augers, cold planers, asphalt grinders and other equipment with conical bits in blind holes.

Simply fit the split-ring bullet tooth puller collet over the conical auger bit, then slide the driver arm over the collet, locking it in place. Using an impact wrench, drive the extractor screw which in turn backs out the tooth. Once out, reverse the motion on the extractor screw to remove the tooth from the collet.

Powered with an impact wrench (not provided), the patented bullet tooth puller is heftier for more durability and cylindrical for better heat dispersion. It removes conical auger teeth in a fraction of the time normally required, saving time and money, and eliminating the knuckle-busting methods like fork wrenches, used previously, according to Auger Technologies.

Augers with worn teeth that are stuck fast are often relegated to the “bone yard,’ however, now the teeth can be efficiently removed in just minutes, new teeth can be added and an asset is placed back in production. It is ideal for any auger with standard conical teeth, or bits in blind holes like pavement grinders, cold planers and more.

It can be used with an impact wrench (recommended — not supplied) or manually with a wrench. Either method eliminates the knuckle-busting methods previously employed — much safer and faster than fork wrenches.

It is ideal for use with all standard conical teeth and augers. Part #9055, for .865 bit, is in stock for immediate shipment; extractors for larger bits (.990) also are available. Extractors also can be paired with an Auger Technologies driver for easy re-insertion of auger bits.

For more information and a video of the bullet tooth puller in

Felling Trailers Inc. announced Ivy’s Legacy Foundation as the beneficiary of the 13th annual 2025 Trailer for a Cause auction.

This tradition involves auctioning a custom FT-3 utility trailer online, with 100 percent of the winning bid donated to the selected nonprofit organization.

Over the past 13 years, Felling Trailers’ Trailer for a Cause auction has raised more than $51,000 for nonprofit organizations, including ACT on ALZAlzheimer’s, Lymphoma Research Foundation, Minnesota Fire Fighters Foundation, Eagle’s Healing Nest and Backing the Blue. Felling Trailers’ goal is to raise awareness about various nonprofits making a difference while supporting vital work.

The 2025 Trailer for a Cause auction beneficiary, Ivy’s Legacy Foundation, was selected by the Felling Trailers’ employees in the form of a vote. Team members cast their votes for the organization of their choice in late spring this year. When the last of the votes were tallied, Ivy’s Legacy Foundation held the popular vote.

“It is absolutely amazing to be the selected organization; we feel very honored,” said Nicki Vogt, founder of Ivy’s Legacy Foundation. “Ivy’s Legacy Foundation has been assisting families in central Minnesota for over a decade. As it celebrated its tenth year of helping families in need a few months ago, we are honored to acknowledge that this organization has also supported

members of our team and their friends and extended families.”

“It’s comforting to know local organizations like Ivy’s Legacy Foundation exist to step up when tribulations present themselves,” said Brenda Jennissen, president of Felling Trailers, Inc.

Ivy’s Legacy Foundation is a Sauk Centre, Minn.-based nonprofit organization dedicated to helping families who have fallen on hard times. The foundation provides various forms of assistance, including financial support for medical bills and funeral expenses; grieving baskets for parents who’ve lost a baby; chemo baskets for cancer patients; and memorial services. As a 100 percent volunteer-run organization, Ivy’s Legacy Foundation has raised hundreds of thousands of dollars for families throughout central Minnesota and beyond.

“We understand that life can bring unexpected challenges and struggles,” said Vogt. “We hope that, through donations, we can extend our roots of love and branches of hope to even more families in our area who really need it.”

A late Fall 2025 auction is being planned for Trailer for a Cause. Leading up to the auction, Felling Trailers will collaborate with Ivy’s Legacy Foundation to raise awareness about the work they do and the families and community members they serve throughout central Minnesota and beyond.

For more information, visit felling.com.

HIPOWER introduced a new integrated trailer design — engineered exclusively for the T4F HRIW-25 and HRIW-45 diesel generator units.

The new offering reflects HIPOWER’s ongoing commitment to innovation, operational efficiency and real-world usability for rental fleets and jobsite needs.

This trailer’s redesign is focused on practicality and performance. Key features of the new integrated trailer include:

• Reduced footprint: The compact design saves space on-site and in storage, offering greater maneuverability;

• Increased fuel capacity: Operators benefit from extended runtime and fewer refueling stops, maximizing productivity;

• Cost-effective construction: Designed with value in mind, this trailer enhances total cost of ownership without compromising durability;

• Folding tongue: A smart feature that facilitates easier and safer storage, while improving logistics;

• Optimized transportability: The reduced length and folding tongue allow more units per truck bed, significantly lowering transportation costs; and

• Improved stability: Outfitted with five stabilization jacks — a major upgrade from the standard two — for increased safety and balance in demanding environments.

This integrated trailer solution is the result of direct feedback from field operators and rental companies looking for smarter solutions in mobile power. With more compactness, greater autonomy and better transport efficiency, this new design ensures the HRIW-25 and HRIW-45 units are more job-ready than ever.

For more information, visit hipowersystems.com.

Tucson, AZ

520-579-0261 Phoenix, AZ

Petersandkeatts.net

The construction industry is full of changemakers.

We shape the land to make it fit our needs, we build the infrastructure that transforms societies and we innovate to meet new challenges. The construction industry is in the midst of a new kind of change — a wave of electrification in construction equipment with the potential to change the way we work on the job site.

Adoption of this technology is moving faster in some places than others, as urban contractors, municipal crews, utility teams and others weigh the benefits of investing in EVs. Some are embracing the new technology and discovering the unique benefits of electrification, some are waiting for the technology to mature while others are skeptical EVs will benefit their business at all.

Not all projects are suited for an EV. And not all EV machines are created equal to meet the demands of the job. But, projects with special requirements better suited for EVs are on the rise and a wave of practical innovation is under way, resulting in smarter, more efficient machines.

EVs are all about unlocking more opportunities for customers, giving them new tools in their toolbox to meet unique challenges. The fact is, there are more opportunities than most people realize. Think about it: a powerful electric machine that produces zero emissions, minimal noise and requires no diesel fuel — it changes the game for where, when and how crews get work done.

More and more, we’re seeing projects with unique job site requirements. Whether it’s urban centers with rules for noise or emissions, confined or congested job sites, nighttime projects or work that requires indoor operation — EVs provide a clear advantage for these kinds of jobs. EVs also open doors to winning contracts on projects

that prioritize green credentials, which are becoming increasingly common.

These trends will only continue. 83 percent of the United States population lives in urban areas today, according to research from the University of Michigan, and that figure is expected to increase to nearly 90 percent before 2050, which will result in more confined and congested job sites.

Many municipal and state governments are introducing more rules and incentives to encourage construction crews to minimize disruptions and environmental impact. Some states like California are even offering heavy-duty voucher funds to incentivize the purchase of clean off-road equipment. And green construction projects are on the rise, with LEED-certified projects growing at an average rate of 20 percent every year between 2017 and 2022.

Beyond these application and business opportunities, EVs come with a range of benefits that can help crews boost their efficiency and profitability. EVs can deliver performance and power equal to their diesel counterparts, but require less maintenance, zero diesel costs and lower total cost of ownership. Does that mean every contractor should sell their diesel machines and switch to using EVs? Not exactly. There are still some jobs today that are better suited for diesel. But EVs can complement internal combustion engine machines for crews who want to diversify their fleets, offering a solution for projects where EVs may be the best tool for the job.

Remember that electrification in the construction industry is still in its infancy, and the technology is rapidly evolving. Consider how far EVs in the automotive industry have

come in the past decade, as the median driving range has more than doubled in just 10 years. EV construction equipment could see a similar pace of change, which is why continued investment in electrification R&D is worthwhile.

The key to making electrified construction equipment successful on the job is making sure they’re purpose-built for electrification, so they can deliver emissions-free performance in a way that makes sense in the field. Instead of simply retrofitting existing diesel machines, it’s critical to look at every aspect of the machine to see how systems can be optimized for electrification. By purpose-building new machines to be an EV from day one, we can create more energyefficient machines to boost performance in both the battery and the machine. Case considered this as it designed and developed its new electric backhoe loader, the 580EV. After debuting its first electric backhoe concept, named Project Zeus, at ConExpo in 2020, Case gathered a tremendous amount of customer feedback that influenced the final design, according to Case.

The result is a machine that can deliver the same breakout forces and dimensional digging specifications as its diesel counterpart, while also serving up all the benefits of electrification, according to Case.

It’s an exciting time for the industry, as advancements in electrification transform what we can achieve on the job. EVs provide new ways for construction contractors, utility teams and municipal crews to further improve their productivity, efficiency and profitability on projects that require innovative solutions.

Most exciting of all, the EV evolution has just begun. As the technology continues to evolve, we’re sure that crews all over will find new ways to use EV machinery to grow their business

(This article is courtesy of Case Construction.)

For almost three quarters of a century, the Duff family has produced and supplied crushed limestone, sand and gravel to all of west-central Ohio.

As the multi-generational family enterprise approaches its landmark 75th year in business, a new CDE wash plant, capable of processing up to 300 tons per hour (tph) of sand and aggregate, has been commissioned at the company’s Lewistown, Ohio, sand and gravel site.

“It’s an investment in the future of the business and in the future of the mineral production industry in the state,” said Ross Duff, president of Duff Sand and Gravel Inc. and vice president of Duff Quarry Inc. “It’s about honoring the history and heritage of our business and continuing that good work, ensuring we’re equipped and resourced to meet future challenges head on, and that we extract and utilize every valuable grain from our deposits. In short, it’s about longevity.”

In 2023, Ohio was ranked as one of the leading construction sand and gravel producing states, according to data from the U.S. Geological Survey (USGS). Of the 920 million tons of sand and gravel produced last year, the top 10 states by production volume accounted for more than 50 percent of the total combined output.

Similarly, USGS data shows Ohio as a top producer of crushed stone. Last year, an estimated 1.5 billion tons were produced. The 10 leading states, which included Ohio, accounted for more than half of the total output (54 percent).

An essential industry to support the continued economic development of the state, the Ohio Aggregates & Industrial Minerals Association (OAIMA), where Duff serves as an active board member, estimates raw mineral production in the state to be valued at more than $1 billion, employing more than 5,000 directly and up to 40,000 indirectly through associated construction activity, transportation and more.

Duff Quarry first discovered CDE at ConExpo-Con/AGG in 2020, where the

washing experts left a lasting impression on the family enterprise.

“We believed technology of this kind was beyond our reach,” Duff said. “It was everything we needed and more. When we left that show, we left with an impression of CDE and its equipment that would stay with us for the next few years. We knew it would be a major investment — one of the largest in the history of the company — but we knew just how impactful it could be.” It would be another three years before the two companies would meet again at ConExpo-Con/AGG in 2023.

“By then, we were ready to move forward with this project, and CDE was still the preferred supplier all those years later,” said Duff. “That second show just strengthened our resolve to bring this project to life with CDE by our side.”

Ronan Duffy, CDE business development manager, said the solution engineered for Duff Quarry is born from proven solutions and designed specifically for its Huntsville, Ohio, quarry.

“Material gradings can vary from one day to the next, so any solution needs to be approached with real understanding of the customer, their needs and the material to be processed,” said Duffy. “A full site audit, including material testing in our lab, helped inform and develop the best possible solution for Duff Quarry as they begin washing material for the very first time. Equipment specification, site layout — it’s all considered in order to create an optimized site workflow that can help accelerate return on investment.”

The final solution includes CDE’s AggMax scrubbing and classification system, which combines pre-screening, washing, scrubbing, lightweight and organics removal and sizing on a compact chassis to produce a range of washed and graded aggregates ready for market straight from the belt, according to the company.

Alongside this, CDE’s M4500 modular sand washing plant, which integrates feeding, screening, washing and stockpiling, features customizable cut point control and patented Infinity technology to deliver consistent in-spec sand products, according to CDE.

“Seeing the first containers arrive on site for the build, that was pretty neat,” Duff said.

Increased Production

Processing up to 300 tph, the new CDE plant is helping Duff Quarry produce more material per year to better meet the demands

of the local construction market through proven design, efficient processing and optimized operations, according to the company.

A major construction boom is under way in central Ohio where the now $28 billion development of two Intel semiconductor manufacturing plants — the single largest private sector investment in the history of the state — is continuing at pace. A further $90 million has been committed by the Ohio Department of Transportation to improve and enhance infrastructure around the facility.

This is in addition to continued work on the development of a new lithium-ion EV battery plant in Jeffersonville, Ohio, as part of a $3.5 billion joint venture between LG Energy Solutions and Honda.

“Within a matter of hours of booting up the plant, material testing showed concrete sand output to be perfectly in-spec,” Duffy said.

The plant is producing a range of construction materials, including C33 coarse concrete sand, fine sand and three different aggregate fractions: 1-2-in., #57 stone and pea gravel.

“I was amazed,” Duff said. “The result was immediate. Right from the starting block we were producing great looking stockpiles. The plant is making sure we have a constant supply of concrete sand for our six ready-mix plants.”

Since initial commissioning in June last year, the geology and material quality of the limestone deposit at the company’s operation in Huntsville has changed significantly, but Duff said the CDE plant has been able to adjust easily to the new conditions.

“We’ve been extracting here for almost 75 years now. It’s a large deposit about 400 feet

deep, and it spans an area of approximately 400 acres. Given its size and scale, we know that the make-up of the material is going to vary and, down through the years, we’ve invested in new equipment and adapted our operation in response to this,” he said.

The deposit continues to evolve even today.

“It’s a different deposit now to what it was at the outset of this very partnership — however now we’re equipped with a CDE plant,” said Duff. “We’re really impressed by the adaptability of the plant and just how little intervention is needed from our side to make the necessary adjustments in response to variations in the material we’re processing.

“That versatility is keeping us up and running. It’s keeping us competitive and profitable.”

For more information, visit CDEGroup.com.

806-364-5687

613 S. 4th Ave Mansfield, TX 76063 817-473-2110

3871 IH - 10 W. Freeway Exit 693 Columbus, TX 78934 979-732-6902

www.texasbearing.com

Metso has received the relevant regulatory approvals and completed the acquisition of its long-time partner Swiss Tower Mills Minerals AG (STM).

STM’s expertise in vertical grinding mills strengthens Metso’s comminution solutions portfolio for the mining industry, playing a vital role in energy-efficient solutions for the diverse needs of customers and enabling Metso to provide enhanced service levels to customers using stirred mill technology.

solutions improve energy efficiency and reduce carbon emissions, in addition to enhancing productivity with optimized operating costs. The HIGmill is a cornerstone for energy-efficient comminution circuits.”

“Swiss Tower Mills Minerals was founded in 2011 with the vision of achieving outstanding grinding performance and unparalleled energy efficiency with vertical stirred mills,” said Oliver Zlamal, CEO, Swiss Tower Mills Minerals.

“We warmly welcome our colleagues from Swiss Tower Mills Minerals to the Metso team,” said Piia Karhu, president, minerals of Metso. “Our collaboration on innovative grinding solutions and services combining, for example, the well-established HIGmill and Vertimill vertical grinding solutions and HRC high-pressure grinding roll technology has yielded significant results for our customers.”

“Mining customers value Metso’s vast expertise and the comprehensive nature of our technology and services solutions,” said Christoph Hoetzel, senior vice president, grinding of Metso. “We see a trend towards optimized technology combinations and multi-stage grinding approaches. These

Metso’s stirred milling technologies portfolio consists of Vertimill, HIGmill and Stirred Media Detritor (SMD) mills. These mills are based on gravity-induced and fluidized technologies, allowing for an equipment solution for all comminution circuits in secondary, tertiary, fine, ultrafine, regrind and lime slaking applications. Metso has more than 50 years of experience in developing, testing and delivering stirred mill technology, including a large installed base. Stirred mills are part of the Metso Plus offering.

Metso supports its minerals and metals refining customers with end-to-end solutions and services ranging from testing, equipment and digital solutions to comprehensive service and repair center capabilities.

NEO MR 100

impact crusher! With its c

Efficient when & where xiblefastandversatileTheM compact dimensions and low - the MOBIREX you need it

machineisamazinglyflex

machine is amazingly flex

MR100NEOsetsan transport weight, this MR 100 NEO mobile NEO: ready, set, crush! versions: the electric E-D tool-free, safe crusher op automatic crusher gap ad all-new benchmark in the 60·

m oc.puorg-negtriw.www RIVE or direct D-DRIVE. The M pening in 30 seconds. Choose djustment or Lock & Turn Qui e compact class - with highlig TN 37013,Antioch·ayW 30 Dana xible, fast and versatile The M nnameelk-oen-i001-rm/

OBIREX MR 100 between two drive ck Access for ht features such as elephone: (615) 501-0600

Oklahoma City, OK 405-495-7820

Tulsa, OK 918-438-1700 McAlester, OK 918-310-1550

Abilene, TX 325-692-6334

Amarillo, TX 806-373-2826

Chico, TX 940-678-5046 Dallas, TX 214-371-7777

Ft. Worth, TX 817-378-0600

Hewitt, TX 254-261-1370

Lubbock, TX 806-745-2112

Odessa, TX 432-333-7000 www.kirby-smith.com

www.nuecespower.com

Corpus Christi, TX 361-289-0066

Laredo, TX 956-725-0066 San Benito, TX 956-361-0066

Victoria, TX 361-576-0066

Vinton, TX 915-541-0066

Houston, TX 713-247-0066

San Antonio, TX 210-310-0066

Kubota North America, working in partnership with local dealers Ewald Kubota and Texas Ag Equipment, donated construction equipment, generators and $100,000 to assist the affected communities.

Caterpillar, according to a July 16 company press release, “In response to the July 4 floods in central Texas, the Caterpillar Foundation announced a $250,000 donation to the United Way of San Antonio Bexar County and the Community Foundation of the Texas Hill Country to support the immediate needs and long-term rebuilding efforts

in Kerr County and the surrounding areas.” Sumitomo, the parent company of LBX Co. and Link-Belt Cranes, contributed $50,000 to the Kerr County Flood Relief Fund to support relief efforts.

The Home Depot Foundation is committing $250,000 to support disaster relief efforts in communities impacted by the flash floods in central Texas, according to its website. CEG

In addition, the Texas Asphalt Pavement Association is asking its members to consider donating to the Kerr County Flood Relief Fund at cftexashillcountry.fcsuite.com. CEG

The Oklahoma Turnpike Authority Board recently awarded a contract to start the rehabilitation of the Creek Turnpike in Broken Arrow later in 2025, according to basentinel.com.

KRMG reported that OBC Inc. was awarded a $72 million contract to fix the two State Highway 364 bridges nicknamed the “Roller Coaster Bridge,” where they pass over Haikey Creek.

The 25-year-old bridges will have their concrete deck, parapets and concrete beams replaced. The substructure also will be repaired, according to basentinel.com.

Traffic will be narrowed to one lane in each direction and shifted onto one bridge while work occurs on the other bridge.

Construction is slated to begin in October and be finished by the summer of 2027. The contractors were given a $20,000 per day incentive to complete the project early, according to basentinel.com.

The Sentinel reported in 2023 that this project would be among the first in the

state’s $5 billion Access Oklahoma program.

OTA Deputy Director Joe Echelle told the Broken Arrow City Council at the time that design work is under way at that time to rehabilitate and replace portions of the bridges. Work was to take place from just west of Garnett Road southeast for about a mile on the turnpike, according to basentinel.com.

Many Tulsans call the Creek Turnpike in that area the “roller coaster” bridge, and motorists have long wondered why the bridge’s ride is so bumpy.

Echelle said that in the 1990s, when the Haikey Creek bridges were built, construction workers were installing some of the first concrete bridge beams used in Oklahoma.

“The beams have a bunch of cambers so that whenever you load them, they get flat. And the thought was that over time the steel that holds that beam in this curl position would relax,” he said. “We’ve since learned that does occur, but not to the degree that was planned. So, it left a bunch of humps in the bridge.”

Halil Ceylan, a nationally and internationally recognized leader in transportation infrastructure engineering of Iowa State University (ISU), is the 2025 recipient of the American Road & Transportation Builders Association’s (ARTBA) S.S. Steinberg Award.

The honor, named after ARTBA’s research and education division’s founding president, recognizes “an individual who has made remarkable contributions to transportation education.”

Among his work is the development of the first electrically conductive heated pavement test site at a United States airport, which garnered nationwide media attention from NBC’s Today Show, NPR, Discovery Channel and others.

A prolific researcher and scholar, Ceylan has authored more than 500 publications and his work has amassed over 9,200 citations.

He serves as the Pitt-Des Moines Inc. endowed professor in ISU’s department of civil, construction and environmental engineering, and directs the Program for Sustainable Pavement Engineering and Research (PROSPER) at ISU’s Institute for Transportation. He also is the ISU site director for the FAA’s

Valued at more than $27 million, Ceylan’s research portfolio spans more than 145 funded projects supported by federal and state agencies, including the Federal Aviation Administration, Federal Highway Administration, National Science Foundation, Department of Defense, National Cooperative Highway Research Program and multiple state DOTs. His innovations encompass artificial intelligence and machine learning in infrastructure design, advanced infrastructure monitoring systems, heated and self-sensing pavements, sustainable transportation geotechnics and climate-resilient transportation infrastructure systems.

Ceylan’s has mentored more than 70 graduate students and 17 postdoctoral researchers, and taught courses to more than 3,000 undergraduate and graduate students. Under his guidance, dozens of his former students and mentees have become leaders in academia, transportation agencies and industry. According to peers and students, his ability to inspire and develop talent has magnified his influence beyond his own pioneering research, ensuring a lasting impact on the future of transportation infrastructure.

25015 S McQueen Road Chandler, AZ 85249 602-463-3772

3300 E. Michigan Street Tucson, AZ 85714 520-649-2858

The AED Foundation (AEDF) announced that Warrick Pathways and Career Center in Booneville, Ind., has become the 115th Recognized High School Program under its national workforce development initiative.

This significant achievement marks a new milestone in the foundation’s ongoing Vision campaign, launched in 2020 to address the skilled technician shortage facing the equipment industry.

“The future of our industry — and our country — depends on today’s youth,” said Bob Brucken, CEO of Diamond Equipment Inc. and AED member. “With AI rapidly evolving, we need bright, driven students to help build our industrial and commercial landscape — and that

path doesn’t always require a college degree. Warrick Pathways and centers like it are shaping the future, and Diamond Equipment is proud to support their mission. Skilled trades offer rewarding careers, and we rely on that talent to drive our success. We encourage more schools to partner with the AED Foundation to grow the industry.”

The AED Foundation connects schools, educators and the equipment industry to strengthen the pipeline of future talent. Its success depends on the active support and participation of AED members. The Warrick Pathways and Career Center benefited from many contributors — but especially from the strong involvement

of AED member Diamond Equipment Inc.

In the fall of 2024, Diamond Equipment hosted students from Warrick Pathways and Career Center’s Civil Construction program at its facility, where they had the opportunity to operate a Case CX170E hydraulic excavator equipped with a Hemisphere 3D GPS machine guidance system. Very few of the students had ever been on a machine of that size — much less operated one. They were introduced to the technology used today to help operators dig efficiently and safely.

“The AED Foundation’s ability to connect industry with schools is one of the most powerful tools we have to solve the technician

shortage,” said Brian P. McGuire, president of the AED Foundation. “Our 115th recognized high school isn’t just another number — it represents a real, local partnership that prepares students for indemand careers and strengthens the workforce pipeline for our industry.”

Since Vision’s inception, the AED Foundation has:

• delivered more than 5,600 technicians through accredited programs;

• certified nearly 5,000 more through industryaligned testing;

• raised more than $8 million;

• expanded from 5 to 115 recognized high school programs — a more than 20fold increase in less than five years; and

• added 52 new accredited post-secondary programs to the network Beyond education.

Vision is building a comprehensive support network that includes:

• nearly $10 million in public funding secured to expand Registered Apprenticeships;

• more than $500,000 returned to industry partners through grants;

• more than $200,000 invested in programs introducing youth to equipment industry careers; and

• innovative research such as the joint National Immigration Forum report exploring foreign-born talent solutions.

Since Vision, the AED Foundation has hosted over 75 workforce development events, with 60 more planned for 2025.

For more information, visit aedfoundation.org.

www.wpi.com 12320 S. Main Street Houston, TX 77035 713-723-1050 Buffalo, TX 903-322-7150 Bryan, TX 979-314-1191 Corpus Christi, TX 361-884-8275 Edinburg, TX 956-386-0107 Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056

Pflugerville, TX 512-251-0013

Port Arthur, TX 409-721-5305 San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

Corporate Office 5000 Vasquez Blvd., Denver, CO 80216 303-355-5900 Colorado Springs, CO 719-576-5541 Grand Junction, CO 970-241-1550 Milliken, CO 970-587-1188

www.powermotivecorp.com

Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455 Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601 Carlsbad, NM 505-485-1700

www.geehm.com

5461 S. Nikita Avenue Fresno, CA 93725 559-834-3149

1164 Prestige Way Redding, CA 96003 530-229-3820

El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

5400 Raley Blvd. Sacramento, CA 95838 916-375-3540

45051 Industrial Drive Fremont, CA 94538 510-955-1170

Oklahoma City, OK 405-495-7820 McAlester, OK 918-310-1550 Tulsa, OK 918-438-1700

Abilene, TX 325-692-6334 Amarillo, TX 806-373-2826

Hewitt, TX 254-261-1370

Lubbock, TX 806-745-2112

Odessa, TX 432-333-7000

Chico, TX 940-678-5046 Dallas, TX 214-371-7777 Ft. Worth, TX 817-378-0600

858-278-8338

ALASKA NC MACHINERY

www.ncmachinery.com

800-478-7000

Anchorage, AK • 907-786-7500

Dutch Harbor, AK • 07-581-1367

Fairbanks, AK • 907-452-7251

Juneau, AK • 907-789-0181

Prudhoe Bay, AK • 907-659-6900

Wasilla, AK • 907-352-3400

ARIZONA EMPIRE CAT

www.empire-cat.com 1725 S Country Club Mesa, AZ 85210 800-EMPIRE-1

CALIFORNIA

HOLT OF CALIFORNIA

www.holtca.com

Pleasant Grove • 916-921-8969

NEVADA EMPIRE CAT

www.empire-cat.com 3300 St. Rose Parkway, Henderson, NV 89052 702-649-8777

Elko • 775-738-9871 Reno/Sparks • 775-358-5111

NORTH DAKOTA

TRACTOR AND EQUIPMENT

www.tractorandequipment.com Williston • 701-572-8377

WYOMING

TRACTOR AND EQUIPMENT

www.tractorandequipment.com

713-460-2000 Lufkin • 936-639-5551

1090 W 2181 N Salt Lake City, UT 84116

801-322-1300

atlasmachinery.us

6565 Smith Avenue Newark, CA 94560 510-400-5024

1535 SE 25th Street Oklahoma City, OK 73129 405-310-8700

2035 W Mountain View Road Phoenix, AZ 85021 480-463-4999

Equipmentshare.com

TRANSPORT from page 24

Three chaining concerns are:

• Tight, secure chains: Your chain should have no room for movement. Equipment shouldn’t be able to bounce or shift during transport.

• Properly located tie-down points: Most manufacturers will create labels for the tie-down points to make them easier to follow. Be especially careful if these are by a machine’s hydraulic hoses, cylinders or brake components, though. Thompson noted that tying down heavy equipment at appropriate points prevents equipment damage and ensures the tightest, most compliant links.

• Adequately matched chain and hook binder grades: If you look closely at every four or five chain links, you’ll find a number etched into the metal. Cross-reference that number with the one printed on the boomer handle, ensuring they’re aligned.

“The sum of the working load limits of all your tie-down components must equal at least 50 percent of the weight of the cargo,” said Thompson. “Always ensure the chain’s grade and working load limit don’t exceed the boomers’ listed limit.

Additional reminders include:

• All chains should be fastened linearly, with downward force, with no horizontal twists, bends or angles.

• No slack. Wrap the excess chain around the rest of the link so it won’t come loose.

• At least four chains in use. Use two connecting to the trailer’s front corners and two to the trailer’s back corners.

• Always review chain and hook sizes. Guarantee they’re

complementary and tight, not mismatched.

Safely unloading construction equipment rounds out the compliant transportation process, said Thompson.

Before your transportation vehicle arrives and the equipment is unloaded, inspect the designated unloading area to ensure it’s clear and ready for unloading. Uneven loading grounds and slick ramps can make unloading more challenging than expected. Do more than just clear any obstacles, debris or dirt.

Personnel also should be aware of cargo schedules, so only relevant crew members are present when heavy equipment arrives, advised Thompson.

Once your transport vehicle arrives, guide it to the correct unloading site. Have the unloading ramp ready for deployment. But do conduct an additional visual inspection to ensure the loading ramp is clean and ready to go.

Once the ramp is ready, line it up with the back of the trailer bed as accurately as possible, advised Thompson.

“You won’t have time to reposition once the machinery starts backing up,” the Cat dealer added. “Once you have everything in place, conduct a final walkthrough to better understand your equipment’s condition.”

Check the hitches and tires. Review tasks with personnel, appointing an equipment operator and spotter before breaking down tie points.

“Look at the condition of the tie points before you move forward with the unloading,” advised Thompson. “A shifted load can create a hazard.”

If you’ve found that the load has shifted, hold off on undoing any chains or straps until you create a customized unloading plan.

After the walkthrough and confirmation that everything is in good order, slowly release tie-bounds and chains, Thompson said.

Begin one at a time, starting in the rear corners. If any chains are wrapped around the links, unravel them and loosen them with their wrench boomers.

“Use caution when starting this process since any chains can still be tight or pressurized,” said the company. Moving too quickly can cause a chain to snap.

“As you unload equipment, remember to take it slowly and to keep a safe distance between the spotter and the machinery,” advised the equipment provider.

In unloading, the operator’s visibility can decrease until the equipment is fully unloaded. Ensure the spotter is positioned in a highly visible but safe area.

Other personnel should vacate the unloading site until the machinery has finished unloading.

All eyes should be on removing the rig from the transport truck, stressed Thompson.

Finally, complete one last ground inspection of all equipment, the transport vehicle, anchor points and tools before sending everyone on their way.

The contractor also should document the conclusion of the transport — and pat yourself on the back for successfully completing the safe and legal transport of heavy cargo,” said Thompson. CEG

Here’s How! List Your Wanted Items. If you would like to place your Wanted To Buy listings on our website for inclusion in our newsletters, simply visit: www.ConstructionEquipmentGuide.com/wanted-to-buy and enter your listings. Inappropriate or Sale Ads will be Deleted

WANTED (WA): CATERPILLAR WHEEL LOADERS, MODELS FROM 908 TO 980.

EMAIL: JOHNLEWISDAN1@GMAIL.COM

PHONE: (425) 217-6188

WANTED (WA): CATERPILLAR BACKHOE LOADERS, ALL MODELS.

EMAIL: JOHNLEWISDAN1@GMAIL.COM

PHONE: (425) 217-6188.

WANTED (US): CATERPILLAR 140G MOTOR GRADERS, ACTIVELY LOOKING TO PURCHASE A RANGE OF HEAVY CONSTRUCTION EQUIPMENT AND WOULD APPRECIATE RECEIVING YOUR BEST OFFERS FOR THE FOLLOWING MODELS, RUNNING OR NON-RUNNING: CATERPILLAR WHEEL LOADERS: 950B 950E 966E 966F HITACHI EXCAVATORS:

EX200LC EX270LC EX300LC EX330LC EX400LC EX450LC-5 JOHN DEERE WHEELED EXCAVATORS: 495D 595D CATERPILLAR MOTOR GRADER: 140G CATERPILLAR AND CASE BACKHOES VÖGELE PAVERS: S1800 S1900 CEDARAPIDS ROLLERS/PAVERS.

EMAIL: ILYAS.MTCPK@GMAIL.COM

PHONE: 0923322489350

WANTED (US): JOHN DEERE 850K SMARTGRADE CRAWLER DOZERS, BULLDOZER 850KLGP JOHN DEERE