At Paramount Construction, family, hard work and trusted partnerships form the foundation of a business that has grown from small concrete jobs in Hartford to multimillion-dollar infrastructure projects across Connecticut.

Owned today by Chez Pace Sr. but led by his sons, Chez Pace Jr., vice president, and Alex Pace, field operations, the company operates with more than 30 employees, a full equipment fleet and annual revenues of $20 million to $25 million.

But the story of Paramount is much more than numbers. It is the journey of an immigrant family, the lessons of three generations and the value of strong relationships with suppliers.

On Loughlin Road in Oxford, Conn., less than a halfmile uphill from state Highway 34 and the adjacent Housatonic River, Eightmile Brook is flowing at a languid 250 cu. ft. per second or so.

But that is just a trickle compared to the raging, lifethreatening flood that it became on the afternoon of Aug. 18, 2024.

Casey Lucarelli was staying at her father’s house on that rainy afternoon when in only 15 minutes, the usual tranquil stream became a debris-strewn rising river that practically surrounded the 1805 farmhouse and its even-older shed.

As Lucarelli was evacuating, Loughlin Road partially caved in behind her car from the force of the swollen creek that starts at Lake Quassapaug in Middlebury, slows at Papermill Pond in Southford Falls State Park south of Conn. 67, then tumbles sharply downhill before emptying into the Housatonic River.

Today, the piles of trees and boulders that cascaded onto the Lucarelli property are gone, but she and her father Gary are still picking up debris.

SENNEBOGEN, in kee philosophy to maxim created UPTIME Kits

eping with their mize uptime, has Whether you are a service technician i road, these kits have need for every service and PM task in one p created to save you t Managing hundreds o parts, from belts and and special tools bec single part number to n-house or on the everything you e, maintenance place. They were ime and money.

They are:

• Easy to order and ea t d t ockst asy to s l dow NO I th Norour intspar om c with omerscust

• Ideal for stocking se and trucks

Choose from the follo

• Central lubrication

• Preventive mainte

• O-Ring kits

• Electrical service k

• Hydraulic service k

Hydraulic service k : kits shops ols ervice owing kits system kits nance service kits its kits

And the best thing is in stock and ready to built to match your m and series. Count on

in-house. For more in UPTIME Kits, scan th

s that these kits, go, are custommachine model SENNEBOGEN nformation on he QR code.

e orf ) OCT(Ownership of

of related service d nuts to O-Rings omes easy with a o order and stock C OND YBE E H HE HIN T MA virtua lI entim lose llyt

xim ma ommitmentc h about e morad ontract Demolition C parepairtsinsthavether andvirtuinanothermachineI onttoback.If very e ctomehavea Theyechnician machine, wntim w American o-shiptady- of oriesinventplete orf uptime izes aftersale achine”M he yond “Beour ow , Bloomfield Hills, MI or theunitbackquickly. kIg losedonoSinctheey ally Ihaveasituation,[they]bringjust ogooverthroncougheamontht wntime… ock.get theSENNEBOGEN y-t t act OGEN f tor ained technicians tr ned tec cians components and too

PARAMOUNT from page 1

Marcelino Pace, father of Chez Sr., was born in 1929 in a small Abruzzo town north of Rome. Raised amid the devastation of World War II, Marcelino left Italy as a young man in search of opportunity, first heading to Venezuela before securing sponsorship to enter the United States. He arrived in Hartford in 1955, where relatives had already established a small construction firm.

Starting in concrete work, Marcelino spent a decade honing his skills before joining the local cement finishers’ union in Hartford. Known for his natural engineering mind despite having only an eighth-grade education, he was able to envision and build concrete forms with precision and creativity.

In 1976, Marcelino partnered with Bruno Santilli to form P&S Concrete Contractors. By 1978, his teenage son, Pace Jr. was working full-time at his side, and together they created Pace & Son, focused on foundations, slabs, and residential flatwork. Their small Hartford shop on Benton Street was the launchpad for a business built on long days pouring concrete by hand and wheelbarrow.

By 1984, Pace & Son won its first city contract — a $284,000 reconstruction job in Hartford’s Bellevue Square. Despite a crew of just five, the company delivered the project successfully, earning credibility with municipal customers. The firm soon shifted from residential driveways and patios to road reconstruction, sidewalks and storm drain work across the city.

As the 1980s progressed, Pace Sr. became a full partner in the business, formalizing the father-son relationship legally to avoid the pitfalls common in family operations. By the 1990s, the firm’s municipal workload was steadily growing. In 1997, Pace Sr. made the difficult decision to retire his

PARAMOUNT page 8

WE’RE IN THE BUSINESS OF KEEPING YOU IN BUSINESS.

DISCOVER THE ASV GENUINE PARTS & SERVICE ADVANTAGE.

ASV Genuine Parts are specifically engineered and guaranteed to maintain the integrity of your ASV machine. They’re designed, built, tested and re-tested to ensure equipment performance and reliability always stay at an all-time high – because less downtime for your machine means more uptime for you. Contact us now to learn more!

father, who by then was nearly 70, to allow for the company’s continued growth.

“I give my father credit every single day,” Pace Sr. said. “For the sacrifices he made, the work ethic he instilled and for giving me the foundation to build on.”

The next chapter came in 2012 with the formation of Paramount Construction. Recognizing that infrastructure work was increasingly complex, Pace Sr. brought in Steve Riley, a civil engineer, who excelled at matching the evolving DOT and MDC requirements. Riley became a partner, and together they positioned Paramount as a general contractor capable of managing full public works contracts — excavation, underground utilities, road prep and traffic systems.

Paramount’s first major step up came with the Park Road Interchange project in West Hartford, a DOT-funded reconstruction of Exit 43 that included extensive utilities, roadwork and site improvements. Though initially questioned as an unknown bidder, Paramount quickly established credibility when DOT staff realized they were dealing with the Pace family name.

“That was a game changer for us,” Pace Sr. said. “It showed we could handle projects of that magnitude.”

Today, Paramount regularly delivers multimillion-dollar contracts for the Connecticut DOT, the Metropolitan District Commission and municipalities across the state. Recent work includes the Stafford Springs round-

to the west, adjacent to the southbound leg (on-ramp). The existing northbound vertical curve will be lengthened to improve the sightline and stopping sight distance. To accommodate the second left, turn lane from Park Road, SR 501 on-ramp will be widened to three lanes. PARAMOUNT from page 4

improvements project calls for the north-

about, downtown Plantsville corridor improvements and major streetscape projects in Hartford.

The company also has diversified into deep sewer, water main and rehabilitation projects, currently averaging 15,000 linear ft. of water main installed annually, alongside extensive lining and rehabilitation work.

For Chez Pace Jr., construction was almost inevitable. After graduating from Xavier High School in 2007, he pursued construction management at Central Connecticut State University, gaining real-world experience through an internship and full-time work with Derita Construction. There, he learned GPS surveying, estimating software and scheduling — tools he later introduced to Paramount when he joined full-time in 2012.

“I brought over everything I had learned — survey, software, scheduling — and we’ve used those systems ever since,” he said.

Concord, NH Berlin, CT

Middleboro, MA

Scarborough, ME

Zero percent financing for 60 months on JCB skid steers including wheeled, tracked, and even the revolutionary Teeleskid!

Zero percent financing for 60 months on JCBcompact excavators including the 19C, 50Z, 55Z, 85Z, and 86C!

Zero percent financing for 72 months on JCB35Z!

Zero percent financing for 60 months on the JCB3CX and 4CX backhoe loaders!

Zero percent financing for 60 months on JCB411, 417, 427, 437, and 457wheel loaders!

Oh... and don’t forget to ask about our 5-year/3,000 hour warranty!

Officials in Middleborough, Mass., broke ground Aug. 21, 2025, on a new water treatment facility, marking a significant investment in the town’s water quality and public health.

The $33 million East Grove Street Water Treatment Facility is funded through the Massachusetts State Revolving Fund in partnership with the U.S. Environmental Protection Agency, according to a news release from the city.

Located at 55 East Grove St., the project will include a 9,500-sq.-ft. masonry water treatment plant and a 4,500-sq.-ft. pre-engineered vehicle storage building.

The new system is designed to treat up to 600 gal. of water per minute from the East Grove dug well, and will remove iron, manganese and harmful per- and polyfluoroalkyl substances (PFAS) to ensure the town meets and exceeds state and federal water quality standards.

The facility also will house office space, a break room, locker rooms, chemical storage, an electrical room, a laboratory and a water treatment process area. In addition, plans call for the existing historic water pump building located nearby to be rehabilitated.

Last spring, Middleborough Town Meeting voters approved the project’s fund-

ing. Members of the Massachusetts Clean Water board of trustees approved a zero percent interest loan for the community earlier this summer, with at least 11 percent principal forgiveness — which could go as high as 20 percent — and save the town millions in repayment.

Weston & Sampson in Reading, Mass., designed the East Grove Street Water Treatment Facility project, along with its site planning and treatment building engineering. The new treatment plant’s general contractor is Halifax-based WES Construction

Corp., and GHD USA in Burlington, Mass., serves as the owner’s project manager.

The facility promises to employ technology in helping remove PFAS from the water supply and meet the town’s goal of supplying water to residents and businesses that has non-detectable levels of PFAS, also known as “forever chemicals.”

Found in a large number of everyday products, PFAS are synthetic chemicals used in non-stick cookware, food packaging, clothing and firefighting foam. They also are extremely resistant to heat, oil, water and stains and do not easily break down in the environment or the human body, leading to widespread contamination.

“We’re here to break ground on an important PFAS treatment plant that’s an essential step forward in protecting drinking water for the health of everybody in our town and the surrounding towns that depend on it,” said Middleborough Town Manager Jay McGrail. “As everybody here knows, PFAS chemicals are extremely persistent and harmful, but today is proof that we’re not backing down from this challenge, and we’re taking actions to protect ourselves.

“Today isn’t just about breaking ground — it’s about saying thank you to the people involved, building trust, protecting health and preparing for the future,” McGrail said.

At the construction’s kickoff, McGrail and other Middleborough municipal officials took time to extend their gratitude to the town’s select board, department of public works, state Sen. Kelly Dooner, R-3rd Bristol and Plymouth District; and state Reps. Kathleen LaNatra, D-12th Plymouth District and Norman Orrall, R-12th Bristol District.

In addition, Weston & Sampson, WES Construction Corp., GHD USA and Middleborough’s ratepayers were recognized for making the water treatment facility’s investment possible.

John Washburn was six years old when his father, a stonemason, first taught him to mix cement.

Now, 33 years later — and a stonemason himself — Washburn is putting that knowledge and decades of lithic expertise into what might be his most famous work: a granite stone wall at the corner of White Rock Road and Springbrook Road in Westerly, R.I.

A casual observer might not find anything remarkable about it — after all, a wall is a wall.

But Washburn’s project is both a work of craftsmanship and a labor of love for his grandmother, his crew and the art of masonry itself.

The project began last winter when the cold weather froze the ground and dried up most area construction work. Washburn has a crew of seven men, and he was looking for ways to keep them employed.

“I depend on them, and they depend on me,” he told the Providence Journal for a July 14 article.

His 94-year-old grandmother, who lives in Florida, had recently bought a home in Westerly as an investment and the fence needed work.

Washburn saw it as both an opportunity to both pay his crew and get a job done.

Over the years, his business, Mason Masters in Charlestown, R.I., has built split granite walls at sites across New England. His work can be seen in private residences and public spaces in the state, such as on Atlantic Avenue in Westerly and along Windsor Avenue, near Pawtuxet Village, in Warwick.

Washburn’s walls are large, stately structures and the one at his grandmother’s house is to be no different.

Masonry is as much construction work as it is a craft, Washburn told the Journal. Stonemasons learn to “read” stones to know how and where to cut them.

Before his crew broke ground at the wall site last December, they used electric blankets to defrost the ground so an excavator could punch into the dirt and haul granite slabs from discarded foundation stones at other construction sites. At night they draped thermal blankets over the wall to prevent the stone from freezing.

Following that, they used cardboard cutouts to sketch out a pattern and find, measure and cut stones to fit it.

“Each stone is a personal achievement,” he said.

Rhode Island’s Department of Labor and Training does not have estimates for how many stonemasons are employed in the state, but Washburn lamented that fewer people are going into the trade, and it is becoming harder to find qualified stonemasons for hire.

One can learn the basics quickly, he said, but it takes decades to become a master.

A closer look at Washburn’s wall at White Rock Road and Springbrook Road, however, indicates that his crew is not made up of novices.

Slabs of stone sit on top of each other, at times forming waves and fitting so snugly that they look like Tetris blocks. Crosssectionally, the structure resembles a pyramid, with either side slanting toward the top.

In a sense, the wall also is a small engineering marvel as it extends about 200 ft. In addition, it is approximately 3 ft. tall, 3 ft. wide at its base and 16 in. wide at the top, although Washburn plans to install capstones that will overhang on both sides. When completed, it will weigh about 400,000 lbs.

Washburn paid his crew to perform the work out of his own pocket and estimated that the granite wall will be worth more than $300,000 when completed. Currently, the

project has been paused for the time being due to other Mason Masters jobs, but he hopes to finish it by this winter.

The new granite wall also has made him a local celebrity.

“I get calls all the time, [with people asking,] ‘Are you the one doing the wall over there?’” Washburn said.

Indeed, while being interviewed by the Journal for this story, a driver passing by in a black SUV pulled over and told Washburn, “You look like a pyramid builder. I’ve never seen anything quite like it.”

Washburn’s grandmother, who makes photo albums of his construction projects, is already working on one for the wall.

The project has been a labor of love for his grandmother, his crew and the craft of masonry, he told the Providence news source. In fact, Washburn is using the same methods that builders used when first setting the granite foundation of the house in 1864.

A fourth-generation stonemason, he takes comfort in knowing the stuff he builds will long outlive him.

“I like its permanence,” Washburn said. “Knowing that no matter how long after I’m gone, no one is going to want to move this.”

DC1H Heavy Duty Orange Segmented Dry Walk-Behind Blades

A2Z Vacuum Bonded High-Speed Specialty Blades

WHY CHOOSE ABLE TOOL and EQUIPMENT...

CC6561GK Gas Large Walk-Behind Saw Proud to be your Full Service Dealer NEW Inventory In Stock!

CC1800XL Medium Walk-Behind Saw

CC2525KCP Propane EFI Saw

CC3538JK EFI Saw

• Local Ownership with flexible approach

• Trained staff for repairs and maintenance

• Dedicated Parts personnel on site

Walk-Behind Saws & Blades

• Focused on the Heavy Construction Industry

• Providing the BEST support equipment available

• Experienced outside sales staff

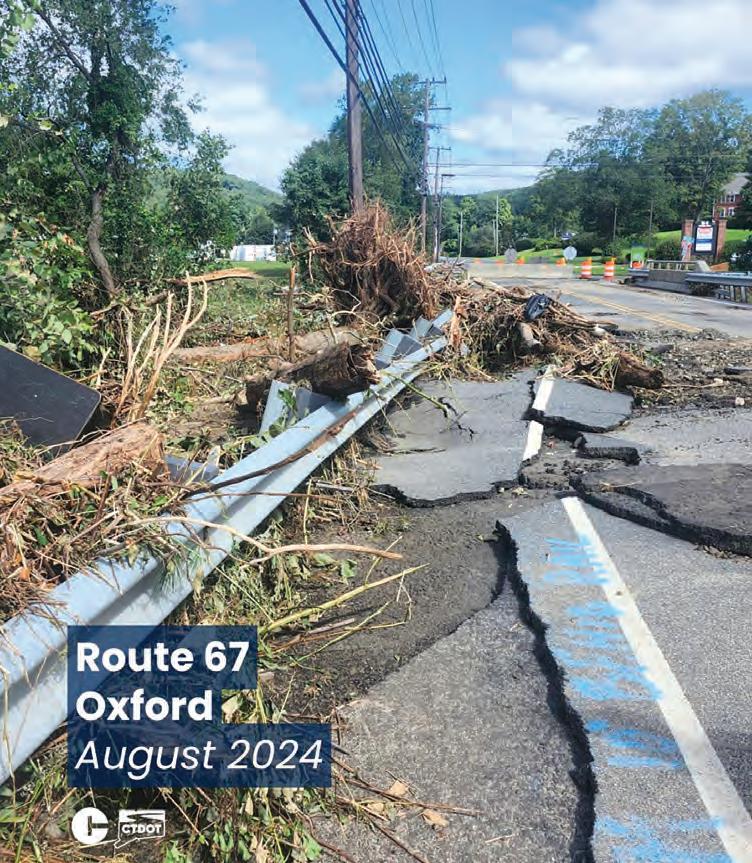

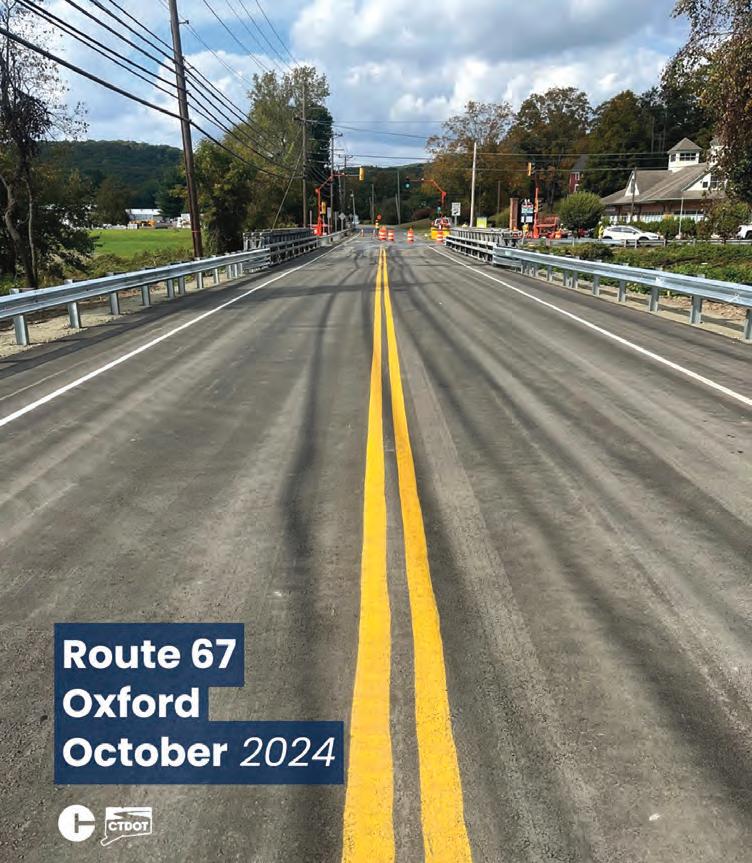

FLOOD from page 1

Downstream, the Conn. 34 bridge has been replaced with a temporary structure by the state Department of Transportation (CTDOT) while the agency makes plans for a larger, permanent span.

About 100 yds. upstream from the Lucarelli’s property, another bridge on the two-lane town road remains washed out, dead-ending Loughlin Road.

The storm, which dropped as much as 12 in. of rain in parts of Southbury and Oxford, prompted Connecticut Gov. Ned Lamont to seek a disaster declaration from thenPresident Joe Biden. Three people died that day, including two in Oxford, where the Little River jumped its banks. The third fatality, a Weston man, was found days later in Westport’s Aspetuck River.

Little-known creeks like them and the Halfway River, which severely damaged the two now-vacant homes on tiny Old Station House Road in Newtown, are back to their scenic, harmless level.

In addition, Boys Halfway River closed Conn. 34 just north of the Lake Zoar Drive-In. The stream spilled over its banks a few yards from the lake surrounding the diner that afternoon and swept away its small but heavily-traveled

bridge.

Fivemile Brook, parallel to and just south of Eightmile Brook, was where a house fell into the floodwaters; in Southbury, Bullet Hill Brook wrecked part of the still-closed town library and one of its branches closed Kettletown Road more than a mile away.

Conn. 67 between Southbury and Oxford also was closed in several spots and most of the businesses in the Klarides Village near downtown Seymour were devastated by the Little River, which runs alongside the roadway.

The Lucarellis are among many families whose homes were among the estimated $300 million in damages from last summer’s flooding.

State officials are planning for bigger, stronger bridges in addition to warning the public that as the Earth’s climate changes and historic rainstorms and floods become more common, the public should acknowledge — and prepare for — the new risks.

Gary Lucarelli, at age 75, has owned the historic Old Stocking Mill house on Loughlin Road since 1999 and was

away on a fishing trip during the storm.

The force of the flooding moved the heavy concrete lid of his septic tank about 40 yds. away; lugging it back took two workers. Fortunately, the flood ran around the house.

“I didn’t get a drop in the cellar, but there was no driveway,” Lucarelli said, while pointing to the next property downstream. “Down there, there was no road. They brought in tons of fill.”

He has nothing but praise for the response of Oxford town officials led by seven-term First Selectman George Temple.

In a phone interview, Temple told CT Insider that Oxford municipal officials approved $4 million in long-term borrowing to pay for those town bridges and culverts not covered by the state. The final destroyed bridge in Oxford is located uphill from the Lucarellis’ property and will likely cost more than $690,000 when the contract is awarded.

“I’m very grateful to the state and federal government and grateful for our public works and first responders,” he said. “They did a bang-up job. You can fish in the Little River. It’s clean as a whistle. When it rains, I get nervous. Before, I never got nervous [about it]. People down here care about each other and they don’t care what your politics are.”

Approximately 2 mi. upstream from Montpelier, Vt. sandwiched between U.S. Highway 2, a railroad, and the Winooski River, is a mostly undeveloped island of fields and trees.

Close to the road, though, a 19th-century Greek Revival house and a barn connected by an ell stood for many years until recently, when the connecting wing was deconstructed, along with the house’s roof, Vermont Public reported Aug. 15, 2025.

“Today we’re taking the nogging out,” said Dave Giese of Deconstruction Works, a West Dummerston, Vt., firm that specializes in the salvage and reuse of structures across northern New England. “So, in the old houses, they used brick as kind of the insulation.”

The company is taking apart the house and its adjacent buildings board by board — and brick by brick — so the materials can be bought and reused.

In fact, Giese told the statewide media service that the bricks have already been sold.

Earlier in August, Ben Doyle, a Montpelier city councilor and president of the Preservation Trust of Vermont, gave Vermont Public a tour of the work site.

In a plot twist, however, the preservation group is leading the effort to take down the

historic structures despite the fact that the property once belonged to Jacob Davis, Montpelier’s founding settler in the 18th century and the man responsible for naming what is today Vermont’s capital city.

Doyle explained that removing the buildings will solve a few problems.

First, the property has been vacant for more than a decade.

“No one wanted to say, ‘Hey, we own this property, and we’ll take care of it,’” he said.

And then there is the catastrophic flooding that hit Montpelier especially hard in 2023 and has reoccurred in Vermont every summer since, which many scientists believe is part of more supercharged weather patterns linked to climate change.

“I came down here and went through this doorway and [found] water in the basement,” Doyle said. “It’s like 8 feet of water down on the floodplain. And I’m [thinking], ‘This isn’t happening.’”

A coalition led by the Preservation Trust of Vermont received $395,510 from the state’s Flood Resilient Communities Fund to pay off the property’s mortgage and deconstruct the buildings. The Federal

Emergency Management Agency (FEMA) also is reviewing an application that would help fully restore the floodplain on the property.

“And when that happens, we’re going to get dump trucks on site and take out about 24,000 cubic yards of material,” Doyle said, adding that the effort will reduce future localized flooding.

“When you start to aggregate dozens of projects like this across the entire watershed, then you’re really starting to make a difference,” he said.

Rebecca Diehl studies river systems as a research faculty member at the University of Vermont. She agrees that this project, located on a good-sized floodplain, can contribute to downstream flood resilience.

“The stretch around Montpelier doesn’t have substantial access to floodplains, right? It’s fairly well confined in the valley,” she told Vermont Public. “And then you add on top of that … the roads and the infrastructure. So, this project in particular does represent a really amazing opportunity.”

Before the riverside property became a floodplain restoration project, it was the site of a private home for at least seven families

across two centuries as Montpelier developed around it with the addition of railroads, a cement plant and vehicle traffic.

Vermont Public reviewed historical records that the house, barn and ell now being deconstructed did not belong to Davis, who bought the property in 1787. Instead, local historians think that the structures were built right after his family sold the property in the 1830s.

And prior to European-Americans displacing the native Wabanaki peoples from their ancestral homelands, floodplains like this along the Winooski River supported the growth of corn, beans and squash.

Now, the plan calls for returning the island property to its pre-agricultural state, Vermont Public noted.

“The highest and best use of a floodplain is to serve as a floodplain,” Doyle said. “And that’s what this will do.”

He added that he often thinks about giving up a piece of local history for the future.

“But at the end of the day, it’s the reality of climate change,” Doyle said. “I personally believe preservation isn’t about locking everything in amber, right? It’s about how do we take this and make it work for us now and for the future?”

A future which will inevitably bring more flooding to the Winooski River Valley.

Annmarie Drugonis, the first selectwoman in the nearby town of Seymour, echoed Temple’s feeling about the community coming together, especially when it came to the Klarides Village shopping plaza, where shop and restaurant owners found that many people, even folks they did not know, came down to muck out buildings after the flood subsided.

“If we don’t help the small businesses, who’s going to?” asked Drugonis, a former environmental cleanup specialist who donned a hazmat suit to help empty a destroyed freezer of spoiled food at the plaza’s Route 67 Family Diner.

The volunteer assistance likely saved the business owner $10,000 in professional cleansing costs.

Upstream from Klarides Village, Drugonis would like to see dredging on Hoadley Pond, which overflowed that Sunday afternoon a year ago and destroyed the home of Andrew and Emily Brisch and their two children.

Now, with a second mortgage, the family is close to moving into a newly constructed house with a much-higher foundation, he

told CT Insider. It required a second mortgage through the federal Small Business Administration (SBA), and aid from the Federal Emergency Management Agency (FEMA) covered the price of the new foundation.

“We built the new foundation higher by about three or four feet than the old one,”

Andrew Brisch said. “We did higher ceilings to mitigate any damage if it were to ever happen again. It’s [more] structurally sound than the old house. There was no foundation under it. It was just river rock, and it was level with the ground. There was eight feet of water in the house.”

The emergency declaration for major disaster relief came relatively quickly in September 2024, within weeks of Lamont’s request.

Connecticut U.S. Sen. Richard Blumenthal recalled pushing FEMA “really hard” last year and the effort yielded approximately $14.5 million to the state’s homeowners, at least $10 million to cities and towns and $8 million for the SBA.

“We need to build resiliency before the next 100-year storm that comes in a few

years in this new normal,” Blumenthal said.

CTDOT Commissioner Garrett Eucalitto, who in the days after the flood visited dozens of hard-hit sites, including nearly washed-away sections of the Waterbury train line, said that there are plans to make the eventual permanent bridges more capable of withstanding larger floods. He expects the $35 million that the state has already spent on recovery will likely rise to about $55 million.

The agency’s engineering plans for installing permanent bridges — the one over Eightmile Brook near the Housatonic River is only temporary — will include culverts with larger diameters.

“In terms of stream flow and clearance, you have to go through a lengthy permitting process,” Eucalitto said. “That is currently under way. We’ll never be able to do it for a 1,000-year storm, but at least what we can do is build to a current design standard.”

He added that upgrading infrastructure is a national issue.

“Every state DOT is worried about this and they’re seeing more frequency and more-serious storms like we saw in North Carolina, South Carolina and Kentucky last year,” he said. “They’re still recovering from those storms as well.”

Brenda Bergeron, deputy commissioner of the Connecticut Department of Emergency Services and Public Protection, also heads up the agency’s Department of Emergency Management and Homeland Security. During an interview with CT Insider at her Middletown office recently, she noted that her team is still processing municipal data on the costs of the storm response.

She said that the more than $14 million available for homeowners from FEMA included repairs, rental assistance, replacing household appliances such as heaters, washers and dryers and money for temporary housing. Once the White House declared the emergency, her office began assisting towns and cities in developing their projects.

“Twice now in the last few years we have seen regular rainstorms stall and cause catastrophic flooding in a focused area,” Bergeron said. “When you get a notice now that there is a rainstorm in your area, you have to be conscious that it could be catastrophic.”

“Water finds a way,” Eucalitto told CT Insider. “It’s an amazingly powerful feature of the earth. It just finds a way to do what it wants to do and go where it wants to go.”

Pace Jr. began as estimator and project manager, eventually overseeing all bids between 2012 and 2023. Today, he continues to spend part of his time in the field, maintaining hands-on connection with crews. His brother, Alexander Pace, joined a few years later and now leads field operations. Together, the brothers complement each other — one balancing management and estimating, the other driving production in the field.

Longtime colleague Kevin Berry, who mentored Pace Jr. during his time at Derita, also joined Paramount in 2023 as estimator and project manager.

Despite its size, Paramount remains family oriented. Employees are not just numbers but part of a larger family. The company hosts regular events, promotes from within and invests in employee growth.

“Our success has been on the backs of our employees that have been loyal to us, and we recognize that,” said Pace Jr. “We know their families, their children. That’s what makes this work.”

Paramount’s work requires a diverse fleet. Today, the company owns 13 excavators, 11 triaxle trucks, six loaders, multiple rollers and dozers. But productivity depends not only on ownership, but also on having access to specialized equipment and reliable support. That is where Able Tool has become indispensable according to Pace Jr.

Pace Sr. first met Derek Bauer, owner of Able Tool, around 2003 on a difficult courthouse project in Hartford. Paramount needed to get beneath a duct bank where conventional excavation was impossible. Bauer arrived with specialized vacuum/hydro-excavation equipment, personally suiting up and blasting through the utilities safely.

Paramount Construction worked on a rotary upgrade to a modern roundabout and traffic signal and railroad upgrades project on Spring Street in the town of Stafford. The project consisted of drainage upgrades, granite curbing, stamped concrete walks, stamped concrete roundabout, bridge improvements, traffic signals, milling and paving. PARAMOUNT from page 8

“From that point on, I knew Derek was the guy for me,” said Pace Jr. “He’s honest, he’s hands-on and he’s not afraid to get dirty. That’s the kind of partner we want.”

Since then, Able Tool has become Paramount’s go-to resource for specialized tools, emergency rentals and mechanical expertise that includes:

•Compaction Technology: Paramount purchased two Wacker Neuson RT trench rollers from Able Tool. These remote-controlled padfoot rollers have solved recurring trench settlement issues, especially in water and sewer installations. “Once you run these on a trench, it doesn’t move,” said Pace Jr.

• Emergency Rentals: When a Paramount mini-excavator broke down, Able Tool had a replacement delivered the same day. “We were back up and running within 24 hours, and kept it until our machine was repaired,” Pace Jr. said.

• Shop Support: Able Tool has a crew of very capable service technicians and maintains a deep inventory of accessories and parts, from jackhammer bits to hoses, ensuring Paramount can keep jobs moving without delays. “It reminds me of the old days when you could walk in and get what you needed off the shelf,” Pace Sr. said.

• Specialized Service: When one of

Paramount’s trench roller drums began leaking hydraulics, Able Tool’s technicians handled the rebuild, tackling jobs too specialized for Paramount’s in-house shop. “Derek brings more than equipment — he brings solutions,” Pace Jr. said. “He and his people are an extension of our operation.”

Paramount today is positioned as a strong, diversified contractor with the ability to weather economic cycles. With the Pace brothers, Steve Riley and Kevin Berry leading opera-

tions, the company continues to expand its scope while maintaining the family values established by Marcelino Pace decades ago.

“Construction is a young man’s game and my sons are taking us to the next level,” Chez Sr. said. “We respect each other’s lanes and we’ve built a culture that works. We’ve stayed strong because we’ve evolved with the times. And with partners like Able Tool standing with us, we’re built to keep moving forward.” CEG

(All photos courtesy of Paramount Construction.)

www.equipmenteast.com

61 Silva Lane

Dracut, MA 01826

978-454-3320

196 Manley Street Brockton, MA 02301

508-484-5567

1474 Route 3A Bow, NH 03304

603-410-5540

www.barryequipment.com

30 Birch Island Road Webster, MA 01570

508-949-0005

7 Harry’s Way Webster, MA 01570

508-949-0005

72 Olde Canal Way Gorham, ME 04038

508-949-0005 1608 John Fitch Blvd South Windsor, CT 06074

860-288-4600 Rhode Island

9:00 A.M.

Davis Auctions, Inc. will tentatively be conducting our next auction of utility and construction equipment and related supplies on September 27, 2025. This auction will consist of equipment from Eversource and subsidiaries; water company; municipality; a rental company; and others. All equipment owned by utility companies and municipality will be sold in absolute.

We are accepting consignments for this auction thru Saturday, September 20. Excess equipment? Need to consolidate? Liquidate? We have the buyers, provide advertising for early consignments and pay consignors 5 banking days after the sale. We accept consignments with realistic reserves.

Looking for equipment to do that job? We never know until the Saturday before the auction what will be here. Inspection is on Friday, September 26. Come see what we have! It may be just what you are looking for.

Consignments for the September 27 Auction will be accepted: August 11 thru September 20 (CLOSED LABOR DAY- September 1)

Hours: Monday – Friday 8:00 a.m. – 4:00 p.m. Saturday, September 20 - 8:00 a.m. - 2:00 p.m.

Please call prior to delivery about space availability

ALL ITEMS MUST BE CONSIGNED AND/OR DELIVERED BY 2:00 p.m. on Saturday, September 20.

JUNK, TIRES, OR APPLIANCES ACCEPTED! FOR CONSIGNMENT FORMS OR INFORMATION

DAVIS AUCTIONS, INC. P.O. BOX 7071

PROSPECT, CT 06712

PHONE (203) 758-4087 • 1-800-201-4368 www.davisauctionsinc.com