By Brittney Christopher CEG CORRESPONDENT

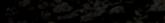

The Beckley Z-Way project, a highway and infrastructure project totaling more than $111 million in Raleigh County, W.Va., continues to progress as both sections currently remain under active construction.

Beginning in Spring 2024 and expected to last approximately two years, the Beckley Z-Way project has made great strides in a short window of time. Broken down into two major sections, Shady Spring to Beaver and Beaver to S. Eisenhower, the project spans approximately 5.5 mi. into Beckley, W.Va, a highly traveled and regularly congested area. With more than 17,000 residents and known for its long history of coal mining and ties to the Appalachian culture, Beckley, W.Va., resides near the New Rover Gorge National Park and Preserve and offers attractions like shopping, locally made arts and crafts, miles of hiking and even underground mining tours.

Ranked as the ninth most densely populated city within West Virginia and with more than 16,000 traveling vehicles passing through daily, the need for improved infrastructure and work to major highways US 19, WV 3 and I-64 only grew.

see Z-WAY page 44

By Craig Mongeau CEG EDITOR IN CHIEF

James D. Morrissey Jr. of Lafayette Hill and Philadelphia, president of James D. Morrissey Inc., Eureka Stone Quarry Inc. and JDM Materials Co. Inc., passed away peacefully at the age of 85 on Oct. 15, 2025.

Mr. Morrissey Jr. was a proud graduate of La Salle College High School in 1957 and Villanova University in 1961, graduating with a degree in civil engineering.

After graduating from Villanova, Mr. Morrissey Jr. joined his father and mother in the business founded by his dad, James D.

Outback Parts is linked nationwide with three used parts networks, so finding dependable parts fast and conveniently is never a

Outback Parts also supplies replacement parts for Non-Cat® machines. So when you’re needing parts, call or visit us on-line.

Five Star Equipment, one of the Northeast’s leading John Deere dealerships, is making a significant move into the rental market with the launch of its new division, Warhorse Rentals.

Based in West Chester, Pa., Alliance specializes in environmental remediation and demolition. Since 1994, Alliance has provided comprehensive services that range from mold and asbestos removal to full-scale demolition projects.

Harry Wells is retiring with a title that says a lot about the path he’s taken: chairman of American Equipment. Before that, he served as managing vice president and president of operations.

New York Gov. Kathy Hochul announced Oct. 20, 2025, that a $36.6 million infrastructure improvement project on the New York State Thruway/Interstate 87 is now complete in the Hudson River Valley’s Orange County.

Based in AED’s Washington, D.C., office, Lamy will play a vital role in advancing the association’s legislative and regulatory priorities in both the United States and Canada.

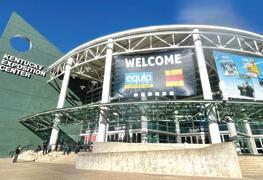

22 LANDSCAPE INDUSTRY GATHERS IN LOUISVILLE FOR EQUIP EXPO ’25

The 2025 Equip Expo once again drew thousands of industry professionals to the Kentucky Exposition Center in Louisville for one of the largest trade shows in the outdoor power, landscaping and light construction markets.

32 PA TURNPIKE USES PAVEMENTS INNOVATION TO IMPROVE ROADWAY

Through the PA Turnpike’s Materials Laboratory, a team of PA Turnpike employees are testing the materials provided by contractors to ensure it complies with PA Turnpike’s specifications.

It will cost nearly $200 million to complete the major work on a thruway project in central Pennsylvania, based on the bids opened Sept. 25 by the Pennsylvania Department of Transportation (PennDOT).

50

Designed by Studio Twenty Seven Architecture of Washington, D.C., the building is reminiscent of a lantern. Integrated into the building’s design are eight Schweiss Doors liftstrap bifold doors, measuring 12 ft., 2.5 in. by 9 ft., 3 in.

77

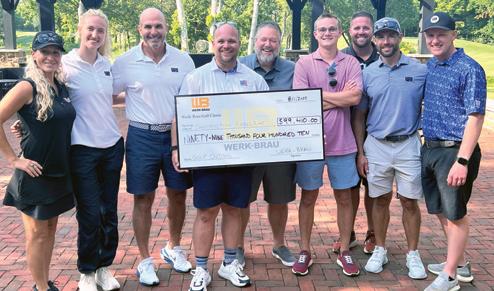

The Golf Gods smiled on the 3rd Annual Werk-Brau Golf Outing to benefit Construction Angels, as the weather was great, smiles were plenty and there were many memorable shots (good and bad) — including a hole-in-one.

79

Stellar Industries announced that it is a 2025 Employer of Choice Award recipient, presented by the Mason City Globe Gazette. Stellar was nominated by its employees who believe the company has the qualities to hold this title.

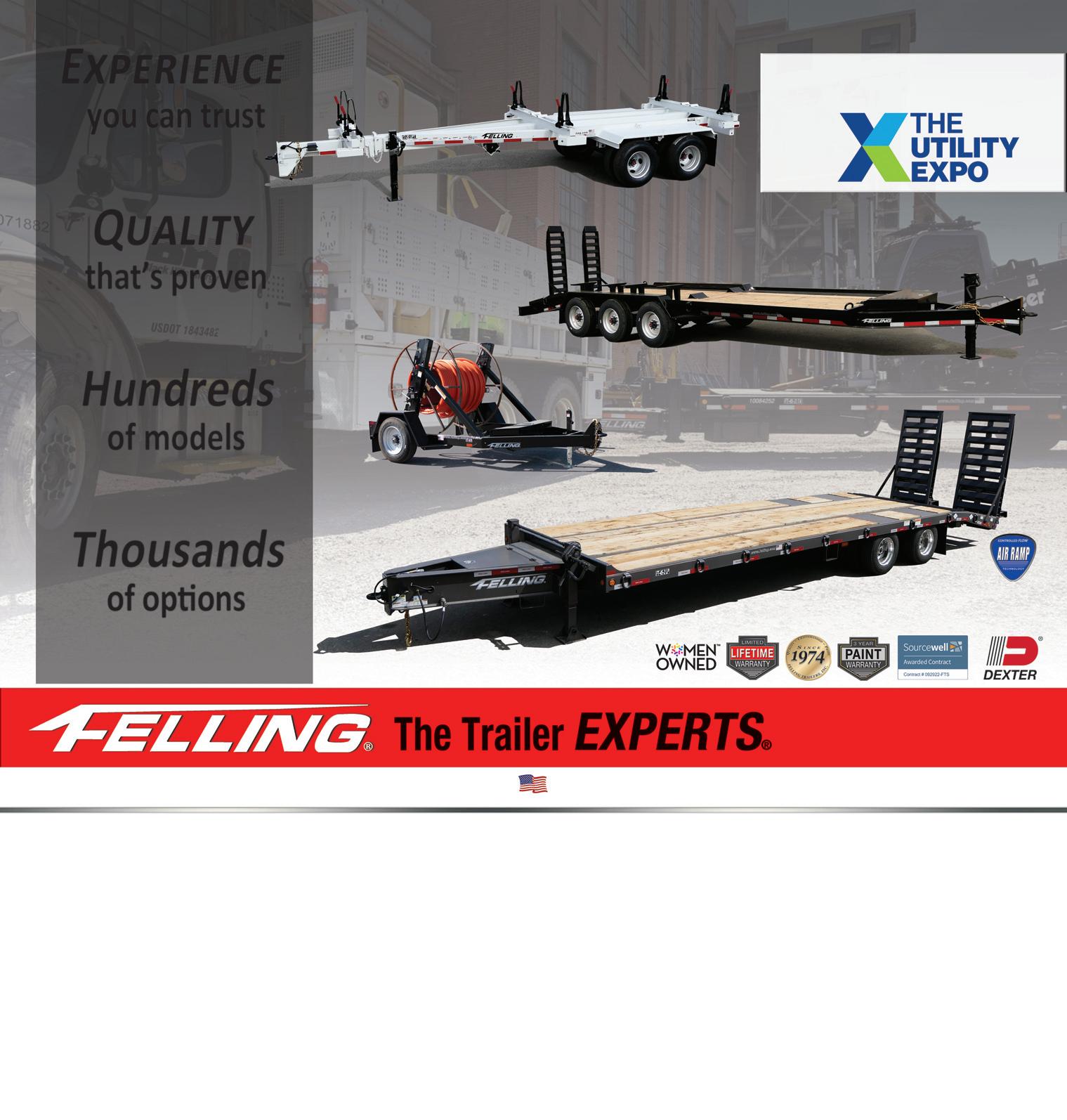

FireLake contacted Felling for assistance with its mobilization project. The design would need to incorporate user safety, providing adequate space on the platform (deck) for users to move around.

Several state departments of transportation across the country are gearing up for winter: inspecting snow removal equipment, hiring seasonal employees and engaging in outreach efforts.

BACKHOES:

2019 NEW HOLLAND B110SPC, 747 HRS, CAB HVAC, QUICK TACH FRONT BKT, EXTENDAHOE, FRONT HYDRAULICS..........................................................

$88,995

2021 NEW HOLLAND B95C TLB, 139 HRS, CAB, HVAC, 4 IN 1, EXT HOE........................................................$99,995

CHIPPERS:

2017 BANDIT 250XP 12” CHIPPER, CAT 120HP DIESEL ENGINE, 2305 HRS, AUTO FEED, WINCH..............$41,995

2022 BANDIT 250XP CHIPPER, 400 HRS, WINCH, 12" CAPACITY, CAT 120 HP..........................................$64,995

EXCAVATORS:

2017 HITACHI ZX135-6, 3900 HRS, HYD THUMB, FRONT BLADE, COUPLER, PATTERN CHANGER................$98,500

2023 KOBELCO SK130LC-11, 516 HRS, CAB, HVAC, HYD THUMB, COUPLER................................................$149,995

2022 KOBELCO SK170LC-11, 256 HRS, CAB, HVAC, HYD THUMB..................................................................$169,995

2023 KOBELCO SK350LC-11, 397 HRS, CAB, HVAC, 54” BUCKET, PLUMBED..............................................$295,000

2019 KUBOTA KX033-4, 2421 HRS, CAB, HVAC, 3 BUCKETS, HYD THUMB, COUPLER............................SOLD

SCREENERS:

2021 VIBROSCREEN SCM40 $79,995

2021 VIBROSCREEN SCM27 $62,995

NEW VIBROSCREEN SCM75C BOX SCREEN W/CONVEYOR, TIER 3 ENGINE....................................................SOLD

NEW VIBROSCREEN SCM115T TROMMEL, NO DPF, NO DEF......................................................................$179,995

SKID STEER LOADERS:

DOZER:

20212 CASE 850M, 850 HRS, WIDE TRACK, CAB, HVAC, COLD WEATHER START KIT, DRAW BAR, 24” TRACKS, 112”DOZER BLADE, HYD PUMP W/PTO..............$159,995

MISCELLANEOUS:

AFE ROTARY FORESTRY HEAD, SKID STEER MOUNT $14,900

HLA 96” SNOW BUCKET, SKID STEER MOUNT, 47.3 CU. FT. HEAPED................................................................$3000

$49,995

2016 KUBOTA SVL95-2 TRACK SKID STEER, 936 HRS, CAB HVAC, HIGH FLOW, RADIO....................................

2012 KUBOTA SVL90-2 TRACK SKID STEER, 1446 HRS, CAB HVAC, HIGH FLOW, LEXAN DOOR, COMES W/BKT, FORKS....................................................................

$38,900

2013 NEW HOLLAND L230, 2303 HRS, CAB, HVAC, 2 SPEED, PILOT CONTROLS, BLOCK HEATER..........$26,500

2017 NEW HOLLAND L218, CAB, HVAC, 776 HRS, 2 SPEED, HYD COUPLER, BLOCK HEATER, PILOT CONTROLS, STANDARD FLOW..............................................................$25,000

2021 JOHN DEERE 317G TRACK SKID STEER, CAB HVAC (NEEDS DOOR), 1739 HRS, BKT COUPLER, RADIO $34,500

2018 BOBCAT T770 TRACK SKID STEER, CAB HVAC, 2011 HRS, HIGH FLOW, 2 SPEED, KEYLESS $41,500

KUBOTA KX080 EXCAVATOR TO SKID STEER COUPLER ADAPTOR $3,199 48” REVERSE LUG GRADING BUCKET, FITS KUBOTA 57&55, NEW CONDITION..........................................$2,500 2024 WERKBRAU CEMETERY

Five Star Equipment, one of the Northeast’s leading John Deere dealerships, is making a significant move into the rental market with the launch of its new division, Warhorse Rentals.

The new business unit reflects a strategic step forward for the company, designed to broaden its customer reach and provide a complete spectrum of jobsite support across Pennsylvania and New York.

According to Bill Bochicchio Jr., COO of Five Star Equipment, the creation of Warhorse Rentals represents a natural evolution for the company — one that aligns with how today’s contractors operate.

“If you’re in the equipment business today, you almost have to be in the rental business if you really want to take care of your customer,” Bochicchio Jr. said. “It’s hard to serve them fully without being able to offer both rent-to-own and rent-to-rent options.”

Unlike many dealerships that simply append “Rentals” to their name, Five Star chose to build a completely separate identity for its new division.

“A lot of dealers just tack the word ‘Rentals’ onto their name, and it all gets mixed in with the main dealership,” Bochicchio Jr. said. “We wanted to create a clear distinction so customers can see that this is a dedicated operation. That’s why we created Warhorse Rentals — with its own branding, its own staff, and its own focus.”

The long-term vision is to establish Warhorse as a fully independent business line with stand-alone rental facilities in key markets. For now, it is being launched from within Five Star’s existing network of branches while new sites are being scouted and developed.

tual ownership. Warhorse will complement that program with a full rent-to-rent fleet of compact and aerial equipment designed for short-term and job-specific use.

“The business is operating out of our current locations for the time being,” Bochicchio Jr. said. “But the plan is to expand into separate facilities. We’re already in the process of identifying the right properties in our major markets.”

Two Paths, One Strategy

Five Star has long been active in traditional dealership rentals that allow customers to apply payments toward even-

“We’re basically separating the heavy rent-to-own operation from this new rent-to-rent business,” Bochicchio Jr. said. “Warhorse will focus on the light and medium side — boom lifts, scissor lifts, compaction equipment and the general jobsite support tools that contractors need every day.”

By offering both models, Five Star aims to serve everyone from long-term heavy equipment owners to small contractors who may only need a lift or compactor for a week.

“Our customers use a wide range of tools on their job sites,” he said. “They’ve already relied on us for the larger iron and the service that goes with it. Warhorse allows us to fill in the rest — to be alongside them from shovel to ribbon-cutting.”

Bochicchio Jr. sees a clear difference between what a dealer-based rental operation can offer versus a traditional national rental chain.

“When it comes to technical support, parts availability and technology, that’s where a dealer has the advantage,” he said. “We’re a Topcon dealer, we have full-time product support specialists, and we already handle machine setup and calibration. If a contractor wants to try grade control on a rental machine, we can make that happen — and we can send someone to show them how to use it.”

He believes that kind of integrated support simply isn’t available through most large rental chains.

“The national companies do a great job moving equipment,” Bochicchio Jr. said. “But sometimes there are gaps in factory-trained technicians, warranty situations or the manufacturer relationships that we have built. That’s the difference — we can deliver the machine and the know-how.”

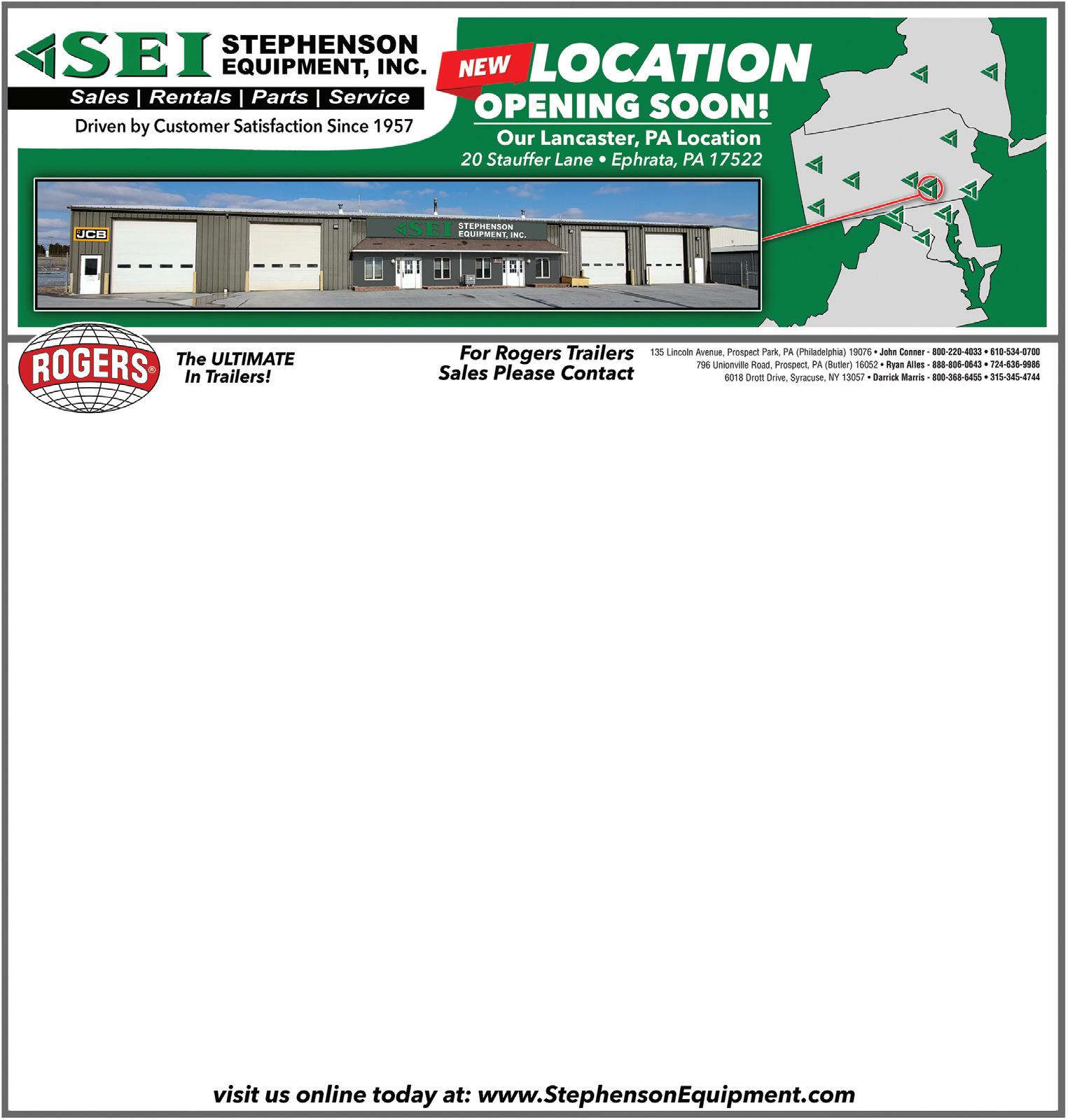

New Model TAG25, 24’ or 26' deck with 6' Tail, Safety Lighting Pkg., Bucket Pocket' in Deck & Tail, Black Paint In Stock!

Rogers TAG21XXL, 24' deck, 6' tail, 235's on aluminum outers, 8' Air Ramps. Safety Lighting Package. Red Paint.. IN STOCK!

Rogers TAG25-32, 26' deck, 6' tail, 8' air ramps, dual gear, side steps, broom/ shovel chutes, Safety Lighting package, 235's on aluminum outers, Viper Red Paint........IN STOCK

Rogers 40 ton Tandem, No-Foot Neck, 24' deck, adjustable width ramps, bucket pocket, 275's, aluminum outers, night lights, work lights, strobes. Rogers Black............ IN STOCK!

Rogers TAG21XL, 22’ + 6’ Tail & TAG21XXL, 24’ + 6’ tail, 235's on Aluminum, Air Ramps, Safety Lighting Pkg. with Strobes. Black Paint.. IN STOCK!

Rogers 55 Ton CobraNeck, Severe Service Design. 2-position pin, ratchet ride height, adjustable width bi-fold steel ramps, 26' clear deck, deep well pocket, chain bins, tool boxes, 275's, alum. outers, side reinforcing, extra lights, strobes, night light pkg. Air Lift 3rd Air Lift 4th axle, Black Paint..........IN STOCK!

Rogers TAG25's, 24' or 26' deck. Wood or Ladderbar Style 6' Tail. Wood or Ladderbar Style 8' Air Ramps Full floor or Custom Bucket Pocket in the deck. Safety Lighting Package........ In Stock and In Production!

New Rogers 35 ton CR35GR Gentle Risers In Stock, No-Foot Neck w/ tool box, Gooseneck work lights, 24' deck, 16* slope, adj. width bi-fold ramps, side reinforcing full length, chain boxes, outriggers, 275's on alum. outers, Air Ride, Air Dump, Aux. Night Light Battery, Extra Markers & Turns, Rear Strobes. Side Strobes Viper Red and Black................In Stock!

New Rogers 55 ton, CobraNeck, 2-position pin, Ratchet Ride Height, 26' deck, 18" ride height, deep well pocket, 275's on aluminum outers, air lift 3rd,& 4th. Night Light Pkg., Strobes, 3 or 4 Axles............ IN STOCK!

Rogers TAG25XXL, 25 Ton Capacity, Premium Specs, Superior Quality, 235’s Aluminum, 7-Year Warranty, Black Paint, 24’ deck + 6’ tail, 8’ Air Ramps IN STOCK!

No interruptions, no hiccups – it’s business as usual for you, with compressor rentals from Milton CAT.

• Contractor, high-pressure and instrument-quality models.

• Range from 2 hp to 500 hp.

• Portable models from 185 cfm to 1,600 cfm; up to 500 psi.

• Diesel and electric models.

• Meeting all emission requirements.

• After-cooler, sound-attenuated enclosures available.

• Prices to fit all budgets.

• Expert service and support.

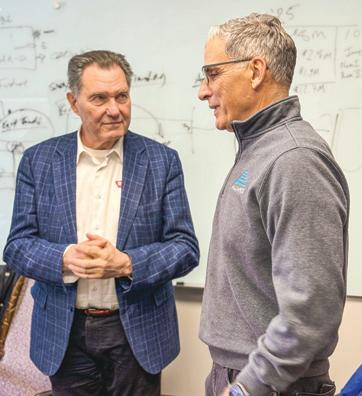

Komatsu East photo

Komatsu East’s Jim McKeever (L) discusses newly acquired Komatsu equipment, Montabert attachments and Lehnhoff quick couplers with Alliance Environmental Systems’ Rodney Goodwin.

Alliance Environmental Systems Inc. has built its reputation in the demolition industry on experience, efficiency and reliability. Based in West Chester, Pa., the company specializes in environmental remediation and demolition. Since 1994, Alliance Environmental Systems has provided comprehensive services that range from mold and asbestos removal to full-scale demolition projects.

“We take on projects of all sizes,” said Project Manager Rodney Goodwin. “Some days, we have a single operator cutting a small piece of concrete. Other times, we have 15 or 20 excavators working on a million-square-foot demolition job. Our flexibility is one of our biggest strengths.”

Alliance Environmental Systems operates primarily in Pennsylvania, Delaware and New Jersey, with plans to expand into Maryland and Virginia. Its success stems from strong leadership and a cohesive team. Many employees have been with the company for decades, creating a culture of reliability and expertise. This longevity translates into smooth operations and consistent quality.

“We have a good solid crew of people, and a lot of them have been with us for 30 years,” Goodwin stated. “They know the work, they trust each other, and they get the job done safely and efficiently. That consistency is a huge asset for us. We get a lot of repeat work based on our reliability.”

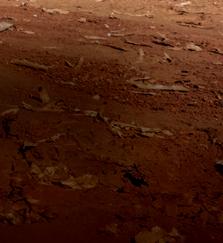

An operator uses a Komatsu PC390LC-11 excavator equipped with a Lehnhoff quick coupler and a Montabert grapple attachment to pick up scrap metal, providing dependable results even in snowy conditions.

East photo

An operator uses a Komatsu PC390LC-11 excavator equipped with a Lehnhoff quick coupler and a Montabert grapple attachment to pick up scrap metal, providing dependable results even in snowy conditions.

East photo

Alliance Environmental Systems President Robert Casciato (R) meets with former Montabert President Maurice Stanich to discuss the implementation of Montabert’s products.

has since built a strong partnership with the brand.

“We call it a soup-to-nuts process,” Goodwin explained. “We handle everything from utility shutoffs and asbestos removal to final cleanup. Clients don’t have to worry about coordinating multiple contractors because we take care of it all.”

On the jobsite, Alliance Environmental Systems handles every aspect of a project from start to finish. A typical project begins with environmental remediation, followed by demolition and material processing. This end-to-end service allows clients to work with a single contractor, streamlining project timelines and minimizing logistical challenges.

To complete its work efficiently, Alliance Environmental Systems relies heavily on Komatsu equipment from Komatsu Company-owned dealer Foley Inc., including a WA200 wheel loader and PC240LC11, PC360LC-11, PC390LC-11 and PC490LC-11 excavators. Alliance Environmental Systems transitioned to Komatsu equipment in the late 1990s and

“We had some issues with service and repair work with the previous brand we were using,” Goodwin commented. “As the industry knows, downtime is our worst enemy, and Komatsu helps us keep everything running smoothly. Now, all of our excavators and loaders are Komatsu.”

Alliance Environmental Systems has also

Harry Wells is retiring with a title that says a lot about the path he’s taken: chairman of American Equipment.

Before that, he served as managing vice president and president of operations. The titles changed, but the through-line never did — sell honestly, answer the phone, solve problems fast and build relationships that last. His career spans from the late 1960s on dealer yards and job sites across upstate New York to building American Equipment, the sister company to Villager Construction, into a multi-state supplier, renter and service operation.

Wells studied at Williamsport Community College — known then as Williamsport Tech and today as Pennsylvania College of Technology, affiliated with Penn State — where programs covered equipment operation, diesel technology and the trades. In 1968, he joined Syracuse Supply, then the Caterpillar dealer for upstate New York. Soon after, he was drafted into the U.S. Navy Seabees (Construction Battalions) and spent nine months in Vietnam before an early out.

Returning home in the early 1970s, Wells found Operating Engineers Local 832 on strike during construction of Rochester’s Keeler Street Expressway. That pushed him away from an operator’s path and back to Syracuse Supply, where he worked seven years as a technician before management noticed something else: he could run iron, and he could talk to people.

They put him in a “Sentry Line” sales demonstrator role with a 10-wheel Ford and a 20-ton tag trailer, hauling the first-in-state Cat D3, 910 and 931 to contractors statewide. His first sales set a pattern —

quality prospects, plain talk and follow-through — placing those inaugural units with Keeler Construction (a D3), a glass manufacturer in Brockport (a 910) and Lewis Tree in Rochester (a 931).

Through the 1970s, he sold across a broader roadbuilding lineup Syracuse Supply carried alongside Cat — Blaw-Knox pavers, Road Widener/Road Widener equipment, GOMACO, Cedarapids and related lines—while Cat’s own product range was far smaller than it is today. Training at Cat’s Peoria school then covered “a couple motor graders, a couple trucks, dozers,” as Wells recalled — nothing like the breadth now.

Wells rose to large-account sales in the Rochester area, handling major contractors. When Milton Cat acquired Syracuse Supply in the early 2000s Wells decided to explore options outside of the Caterpillar world.

He interviewed broadly with other heavy equipment distributors. Then Dick Clark, owner of Villager Construction in Fairport, called. Wells had sold to Clark for years; there was mutual respect. Clark wanted Wells to help restructure and grow a related company that had existed mainly on paper and was brought on board as sales and marketing director.

American Equipment existed before Wells arrived — “on the books” by 2002 — as an entity that purchased equipment and leased it to Villager. The structure was straightforward and common: American bought machines, sheltered sales tax upfront and Villager paid tax as it paid rent,

New York Gov. Kathy Hochul announced Oct. 20, 2025, that a $36.6 million infrastructure improvement project on the New York State Thruway/Interstate 87 is now complete in the Hudson River Valley’s Orange County.

The project, which began in 2024, included full and partial depth repairs on approximately 48 lane miles starting in Woodbury, just a short distance north of the thruway’s Exit 16 onto U.S. Highway 6 and N.Y. 17, to the highway’s Exit 17 in Newburgh, which connects motorists to I-84.

Approximately 53,000 drivers use this section of I-87 in both directions each day.

“New York State continues to deliver smoother, safer roads across the state, improving the driving experience for commuters, commercial drivers and visitors,” Hochul said in a news release from her Albany office. “Repaving the Thruway and keeping the road smooth for drivers is a critical investment given the important role the 570-mile superhighway serves in our transportation network and our state’s economy.”

both the northbound and southbound directions.

The contractor for the highway upgrades was Crisdel Group Inc., based in South Plainfield, N.J.

Its crew installed a 2-in. asphalt overlay to make the driving surface smoother. Other work included safety improvements such as the installation of new guiderails, new reflective line striping and upgrades to drainage and culverts.

Approximately 85 percent of the thruway’s roadway base dates to its original construction in the early 1950s, highlighting the need for heavy maintenance, reconstruction and rehabilitation activities to keep the riding surface in a state of good repair.

Frank G. Hoare, executive director of the New York State Thruway Authority (NYSTA) added, “Thousands of motorists depend on this section of I-87 each day to connect them to major roadways in the Hudson Valley like Interstate 84 and Route 17. This project enhances the reliability of the roadway and keeps it in good shape for those who depend on it.”

The improvements to I-87 stretched from mileposts 48 to 60.1 and included full and partial depth pavement repairs to address the most deteriorated portions on the highway in

Associated Equipment Distributors (AED) announced the addition of Matt Lamy as government affairs manager.

Based in AED’s Washington, D.C., office, Lamy will play a vital role in advancing the association’s legislative and regulatory priorities in both the United States and Canada.

In his new position, Lamy will work closely with Daniel B. Fisher, AED’s senior vice president of government and external affairs, to advocate for pro-growth policies impacting the equipment industry. His responsibilities will include engaging with lawmakers and policymakers in Washington and at the state level, coordinating congressional visits for AED members and helping members build direct relationships with key officials.

“We’re excited to welcome Matt to the AED government affairs team,” said Fisher. “His background working in multi-client and trade association settings will be a tremendous asset as we continue to expand our advocacy efforts and deepen our engagement with policymakers at all levels of government.”

Before joining AED, Lamy served as a federal affairs research analyst of McAllister & Quinn, where he focused on helping clients navigate the federal appropriations process. He also previously held a communications and government relations internship with the Household and Commercial Products Association (HCPA).

“I’m honored to join AED and contribute to its strong reputation as a leading voice for the equipment industry,” said Lamy. “I look forward to working with our members to ensure their voices are heard in Washington and Ottawa and to help further the association’s mission.”

AED maintains a full-time presence in Washington, D.C., Ottawa and Sacramento, advocating on behalf of its members before key lawmakers and regulators, The association ensures the equipment industry’s priorities receive full consideration on both sides of the border and provides members with access to the most influential decision-makers in North America.

For more information, visit aednet.org/. Matt Lamy AED photo

The New York State Thruway is one of the oldest components of the National Interstate Highway System and one of the longest toll roads in the United States. The freeway’s mainline extends north and west for 496 mi. from the New York City line at Yonkers to the Pennsylvania state line at Ripley by way of I-87 and I-90 through Albany, Syracuse and Buffalo.

The maintenance and operation of the thruway system is funded primarily by tolls. NYSTA does not receive any dedicated federal, state or local tax dollars and is paid for by those who drive the route, including one-third of drivers from out of state.

In 2024, NYSTA processed more than 400 million toll transactions and motorists drove 8.2 billion miles on the road.

The agency’s 2025-2029 Capital Plan invests $2.7 billion into infrastructure and equipment, an increased commitment of $742 million (a 38 percent increase) since the approval of a multi-year toll adjustment plan in 2023. The additional investment will lead to work on approximately 61 percent of the thruway’s more than 2,800 pavement lane miles as well as the replacement or rehabilitation of 20 percent of its 819 bridges.

Constant vigilance on the part of NYSTA crews has helped to make the highway one of the safest in the country with a fatality rate far below the nationwide index, and toll rates are among the lowest in the United States compared to similar toll roads.

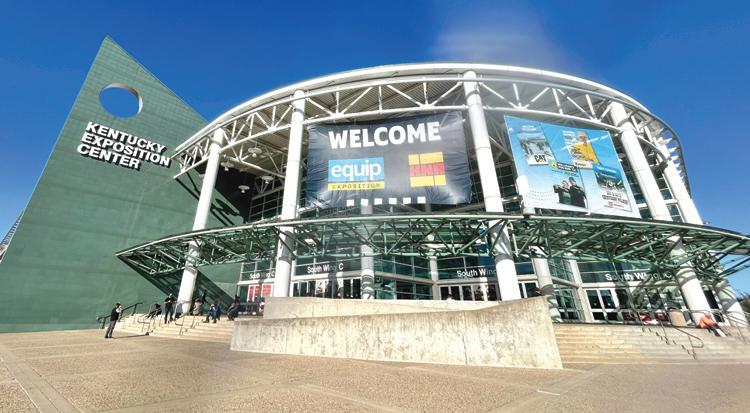

2025 Equip

Tand

he 2025 Equip Expo once again drew thousands of industry professionals to the Kentucky Exposition Center in Louisville for one of the largest trade shows in the outdoor power, landscaping and light construction markets.

(L-R): Brett Hart, marketing director of KAGE Innovation, Oceola, Wis., with KAGE technicians Kyler and Kasen Stephan were representing KAGE and its popular SS 10-ft. plow system.

Greg Worley, marketing professional of Caterpillar, explained the features of the 1-10-ton mini-excavators at Cat’s press event.

(L-R) are Paul Malmanger and Shane Hilliard, engineers; Lucas Brown and Nate Tangen, sales; co-founder Ron Bergman, all of MUSKOX, Grand Forks, N.D., with Dan Sauber, senior product manager, CTLs and Autumn Skoog, key account manager of ASV/Yanmar, Grand Rapids, Minn. At the outdoor display, MUSKOX used ASV machines to demonstrate its new T-Tach shock absorbing mounting system for all attachments.

More than 1,000 exhibitors showcased the latest machines, technology and attachments across expansive indoor and outdoor spaces. The event remains a must-attend gathering for contractors, dealers and manufacturers eager to connect directly and experience products in action.

The 30-acre outdoor demonstration area gave attendees the chance to operate compact loaders, trenchers, mowers and utility vehicles in real-world conditions. Manufacturers emphasized efficiency, comfort and performance across their latest models.

Snow and ice management also took the spotlight as companies showcased durable, productivity-focused attachments and spreader systems designed to help fleets handle the winter ahead.

The event helped strengthen relationships with dealers and end users while educational sessions throughout the week explored electrification, workforce development and sustainability — all key themes shaping the industry’s future.

As Equip Expo 2025 wrapped up, attendees were left energized by the innovation, networking and business opportunities that continue to define this annual industry highlight.

Plans are already under way for Equip Expo 2026, to be

Case Construction of Racine, Wis., brought a mini-excavator with the company’s retro graphics scheme provided by Dirty Graphix of Stillwater, Minn. Michael Cline (in cab) of J & R Property Services, Cicero, N.Y., is in the demo area as Ryan Ramey, Case product specialist, answers his questions.

held Oct. 20-23.

For more information, visit equipexposition.com. CEG (All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

see EQUIP page 26

outdoor booth featured a working demonstration area, where attendees could see these miniexcavators in action.

Bobcat Co. of West Fargo, N.D., had a line to try the equipment in the live demo area. Jodin Smith (L) and RJ Steineke of RD Lawn and Snow Removal gave this compact E20 R2 Series mini-excavator a quick run through.

Hamm 3412P, 2012, 84” vibratory padfoot compactor, EROPS w/ heat & A/C, 1,200HMR .

$82,500

Cat 815F, 2006, EROPS cab, 12’4” S-Blade w/ tilt, new paint job, very good condition, 9,400 HMR . .$195,000

Hamm GRW-5 Pneumatic Roller, 1994, Deutz Diesel, ROPS Canopy, (9) Ea. 7.50-15C1 Tires

$15,500

(4) Cat 825C’s, 1981-1990, EROPS, S-blade w/tilt, all work ready

From $79,500

Rammax Walk Behind Rollers, over 25 in stock, lever & remote

$4,000 to $10,000 (8) Sheepsfoot, 48" and 60", double drum & single drum, tow type

$4,000 - $6,500

Volvo A40, 1998, 40 tons, 10991 hrs, 395 hp, 8WD, 29.5R25, A/C, 29 cy cap. sideboards, tailgate (currently off work), work ready

$127,500

Volvo A40, 1996, 40 tons, 395 hp, 6WD, A/C, 29.5R25, working everyday

$145,000

Volvo A40, 1996, 40 tons, 11,000 hrs, 6WD, 20.5R25, A/C, P/S trans, 29 cy cap., 6/06 hitch rebuilt .$115,000

Volvo A40, 1995, 40 tons, 395 hp, 8WD, 29.5R25, A/C, P/S trans, tailgate, work ready

$115,000

Volvo A35C, 1998, 35 tons, 6WD, 26.5R25 tires, approx 7,000 hrs, good condition

$147,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5x25, A/C, P/S trans, working everyday on jobsites

$87,500

Broderson IC80-2E, 1997, 8.5 ton, 24’ boom, dual fuel, 10.00R15 tires, 3,400 hrs .

$21,500

Grove RT58C, 1981, down cab, 18 ton r.t., 70' boom anti-two block, GM dsl, clean

185’s, JD diesels

CALL

(12) Allmand Light Plants, 2008-2010, diesel, s/a towtype, (4) MH lights, excellent

Cat 336EL, 2012, 33.5” TBG pads, Q/C, aux hyd, 6,700 HMR, work ready

$162,500

Volvo A35, 1995, 35 tons, 326 hp, 6WD, 26.5R25, A/C, P/S trans, 26 cy, working everyday on jobsites

$89,000

$224,500

Cat 336FL, 2015, 33.5” TBG Pads, Q/C, aux hyd, 4,300 HMR, work ready

Komatsu PC220LC-8 Longreach, 2011, Young Boom/Stick 60’ reach, 3,500 HMR

Volvo A30C, 1996, 30 tons, 11,000 hrs, 296 hp, 6WD, 23.5R25, 21 cy cap, A/C, P/S trans, works everyday

$179,000

$122,500

$72,500

Kobelco SK210LC, 2007, Q/C, aux hyd, 31.5” TBG Pads, 3,900 HMR

Cat D5NXL, 2006, 10’ PAT Blade, Paccar PA55 winch, 22” Pads, 4,100 HMR

$82,000

$49,500

Cat 613C Water Wagon, 1994, 5000 gal drop tank, ROPS, spray heads

Cat 621F, 1996, Scraper, OROPS, 33.25x2, very good condition

Cat 621E, 1989, Scraper, OROPS, 33.25x29, very nice CALL

Cat D6NLGP, 2008, VPAT Blade, Drawbar, 33” Pads, 9,900 HMR

$87,500

Cat D6NLGP, 2014, Foldable VPAT Blade, Paccar PA55 winch, 7,200 HMR

$142,500

100 Excavator, Loader, Specialized & Grapple Buckets in Stock -Call For Your Needs FORKS (8) IT28F/G Forks, Balderson qc, 48"-60" pallet style, excellent

$229,500

Komatsu D155AX-6, 2007, Sigma S-U Blade, 4-bbl Single Shank Ripper, 8,400 HMR

Cat D6TXW, 2013, 13’6” VPAT Blade, Carco 70APS winch, 28” pads, 7,300 HMR

The Western Products team gathered at Equip Expo 2025 to highlight its snow and ice product line, commemorating the company’s 75th anniversary with a special “Battered Bastards of Bastogne” theme honoring resilience and service.

EQUIP from page 22 see EQUIP page 42

Joe Twomey, sales manager of Ignite Attachments, shows off Ignites newest soil conditioner attachment. It effectively prepares seedbeds, levels gravel and breaks up clumps in the soil, even in tougher conditions.

Norm Klimko, Fisher Engineering representative, shows off the brand’s latest snow and ice control solutions at Equip Expo 2025, featuring the new Storm Boxx pusher plow and Tempest spreader lineup designed for reliable performance in demanding winter conditions.

Attendees arrive at the Kentucky Exposition Center in Louisville, Ky., for Equip Expo 2025. The show hosts 30,000 attendees for the outdoor power, landscape and hardscape industries.

Durham (L) and John Arnold of Company Wrench, showcased JCB’s compact track loaders and skid steers at Equip Expo, highlighting the versatility and performance of the JCB teleskid.

Cook

and Brenda

welcomed attendees to the Bandit booth, sharing the company’s full line of tree care equipment including hand-fed chippers and stump grinders built by their employee-owned team.

for

and

NEW BELL MODELS ARE HERE

B45E Articulated Truck

• 45-ton (90,390 lb) rated payload

• Mercedes-Benz 6-cyl diesel, 523 hp @ 1,700 rpm

• Allison 7-speed; wet-brake retarder + Jacobs engine brake

• Auto tailgate; 26 m³ bin

Bell B30E Articulated Truck

Available for Rental & Purchase

• 30-ton payload class efficiency with optimized power & fuel use

• Allison transmission & A-frame suspension for a smoother, more independent ride

• Automatic traction control with inter-axle differential lock (IDL)

• Fleetm@tic® onboard diagnostics with 72-hour data storage & proactive warnings

Introductory Price: $425,500

NEW: Fiori Site Dumpers

Available for Rental & Purchase

Several Models to Choose From

• Payloads from 5 to 12 tons

• Swivel or front-tip skips for precise material placement

• 4WD hydrostatic drive for maximum traction & control

• Compact design for confined worksites

• ROPS/FOPS cabs with ergonomic controls for operator comfort & safety

• Low-maintenance engineering with easy service access

Financing & Incentives Available

Loved for the features. Trusted for the performance.

Hyundai wheel loaders have the power and performance, not to mention top-notch interiors, accurate onboard weighing system, industry proven drivetrain durability, clear sightlines, and handy tech that make life on the jobsite easier. So you can do more without feeling it. No wonder so many first-time Hyundai users become longtime fans.

See the Hyundai difference yourself at your local dealer or na.hd-hyundaice.com.

from page 16

smoothing cash flow.

Wells joined April 2, 2004. On day one there wasn’t even a dedicated desk — “anybody not here today, use their chair.” He wrote a one-page plan to “bring American Equipment out of the closet,” renting and selling not just to Villager but to competing contractors, as well. Clark agreed immediately.

Wells listed American’s starting fleet: a Barber-Greene paver, several Cat 322 excavators, five or six wheel loaders, a Road Widener, trench boxes, and assorted support gear. Villager’s contracting revenue then ran approximately $20–$25 million annually as an open-shop, non-union pipe and paving contractor.

Two moves set American’s trajectory:

• Rental Alliance with Milton Cat. American committed to buy an initial tranche — four or five machines — then rent and grow from there with Milton’s support.

• Permanent Home at Exit 44. American bought 30 acres on NY-332 in Farmington, less than a half-mile from I-90’s Exit 44 — “gateway to the Finger Lakes.” Two pole barns became the nucleus. Within six months, the company opened the west building, put an American flag and a Rental Alliance sign out front, and were “officially open for business.”

Villager started in the milling business with a new and late-model fleet of cold planers. When Wirtgen introduced a mill with a folding conveyor — easier transport — and stronger electronics and promised support, Wells recommended buying Wirtgen. Loyal as he was to the company’s current supplier, he told Clark, “I feel like I’m shooting my dog,” but the mill was the right tool. So, they bought it.

The work also supports the milling program. The company is licensed as a contractor in North Carolina, South Carolina, Georgia, Virginia and others, bidding from Fairport and relying on local Cat/Wirtgen dealers for support in the Southeast. Transport is in-house: five lowboys in New York, another down south and the willingness to roll 12–14 hours to wherever the next spread needs to be.

“I owe my success to American and Villager, and I owe them a debt of gratitude.”

The choice proved out. American and Villager have since taken delivery of more than 65 Wirtgen mills (three in the most recent year alone), turning them at 6,000–7,000 hours. Trucks stay longer; high-hour mills turn for uptime and cost control. Over time, with ownership transitions at Villager, most equipment purchasing migrated back under American because of its credit strength and service capacity.

Today, the combined operation runs five mobile crushing and screening crews across the Northeast, with contract-crushing at large quarries and aggregate producers (for example, Seneca Stone and operations in the Buffalo area), taking on million-ton programs priced per ton.

• Headquarters and Yard: Farmington, N.Y., on NY-332, a half-mile from I-90 Exit 44 on 30 acres.

• Divisions/Scope: Equipment rental, sales, service, contract crushing/screening and heavy road support (milling fleet for Villager and outside customers).

• Service Capacity: 18,000-sq.-ft. shop; track press; Cat-certified hose manufacturing; hydraulic testing; 12–13 technicians; open to outside customer work.

• Fleet: 90 excavators plus dozers, loaders, pavers, cold planers; five lowboys in N.Y., and one in the Southeast.

• Geography: Northeast base; licensed and active on subcontract work in N.C., S.C., Ga., Va., and beyond; bids centralized from Fairport.

Approximately six years ago, American opened a new 18,000-sq.-ft. service shop with a track press, hydraulic hose manufacturing and testing and modern flow-test capability. The hose operation filled a gap — American is a Caterpillar-certified hose rebuilding/manufacturing facility, the only such option between Rochester and Buffalo. The shop supports Villager, American’s rental fleet and outside contractors. On any given week there may be machines from Buffalo RED, Bayside Paving and several towns in the bays. Current headcount runs 12–13 service technicians.

Harry Wells American Equipment

Wells said it starts with relationships and response time. Villager bids against many of the same firms American serves, but American has earned trust by calling back immediately, saying what it can do, and — if it doesn’t own the exact piece — finding it fast. That responsiveness brought in repeat business from out-of-state EPCs and solar developers and steady local work with firms like Admar (approximately $200,000 a year in rental/gear), DeMarco and municipalities. American focuses on “large dirt” and road work, as well as pipe contractors, stays out of commodity small-tool niches, and partners when it makes sense.

The fleet is broad and deep: approximately 90 excavators and the surrounding dozers, loaders, pavers, mills and support. American buys complete spreads when contractors exit — moving quickly due to credit and remarketing capacity — competing head-to-head with auctioneers like Ritchie Bros. and dealers when needed. Export is routine; American sells into multiple countries each year.

Wells’ philosophy is blunt. He hires slowly, fires quickly and screens first for attitude because “you can teach aptitude.” Every new hire gets a simple Code of Conduct: the customer has the right to be unhappy; return calls immediately; apologize when needed; do the commonsense things every time. It isn’t complicated; it is enforced. The payoff is in repeat work and a reputation for being easy to do business with.

• Customers: Villager; regional contractors (site, paving, municipal); national developers entering for solar and infrastructure; export buyers.

• Approach: Rapid response, fair dealing and practical product choices (for example, Wirtgen mills at 6–7K-hour turn; keeping trucks longer; buying complete spreads).

Wells’ last promotion — chairman — formalized what he was already doing: mentoring leaders, guarding the brand and ensuring the phones still get answered.

The job titles over the years — managing vice president, president of operations, chairman — reflect growth more than hierarchy. The mission stayed the same: equip Villager to perform, build American into a credible supplier to everyone else and defend the simple rules that win repeat business.

He summed up the arc without sentimentality. In 2004, American Equipment “had a sign on a pole barn and a few machines.” Today, it has a shop full of technicians, a book of business spanning municipalities to multistate contractors and a yard that turns iron constantly.

The cold-planer lineup numbers well north of 65 Wirtgens purchased over the years. The crushing spreads are busy. The phones are still answered on the first ring.

Harry Wells is retiring, but the culture he set — answer fast, do what you say, pick the right machine for the job — remains bolted to the frame.

“I owe my success to American and Villager, and I owe them a debt of gratitude as well as to my family, my employees and all our customers and suppliers,” Well said, “Thank you to all of you.” CEG

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

22E019 – 2016 CAT 325FL CR, EROPS W/AC, REVERSE CAMERA, AUX HYDRAULICS, HYD. QUICK COUPLER, 31” SHOES........................................$99,500

24E009 – 2018 CAT 320, EROPS W/AC, REVERSE/SIDE CAMERA, 9’.6” STICK, AUX. HYDS, QC, 48” BUCKET, GRADE CONTROL, 31” SHOES..............................$109,000

22E056 – 2007 CAT M318D, EROPS W/AC, 9’.6” STICK, AUX. HYD, HYD Q/C, 36” BUCKET, FRONT AND REAR STABILIZERS, RIDE CONTROL, 10.00X20 TIRES..... $60,500

24E012 – 2017 CATERPILLAR 315FL, EROPS, W/AC, REVERSE CAMERA, 9’.10” STICK, AUX. HYDRAULICS, TWIST WRIST, 36” BUCKET, 20” SHOES W/RUBBER PADS................................................................................................................$95,000

24E028 – 2015 CAT 308E2CR, EROPS W/AC, REVERSE CAMERA, 7’.7” PUSH

BLADE, 7’.3” STICK, AUX HYDRAULICS, Q/C, 36” BUCKET, RUBBER TRACKS...........

$60,000

24E029 – 2016 CAT 308E2CR, EROPS W/AC, REVERSE CAMERA, 7’.7” PUSH BLADE, 7’.3” STICK, AUX HYDRAULICS, Q/C, 36” BUCKET, 18” SHOES W/RUBBER PAD INSERTS..................................................................................................$60,000

25E008 – 2016 CAT 303.5E2, EROPS W/AC, REVERSE CAMERA, 5’.10” PUSH BLADE, 5’.2” SITCK, AUX HYDRAULICS, HYD. THUMB, Q/C, 24” BUCKET, RUBBER TRACKS..........................................................................................................$43,000

25E027 – 1986 CAT 235B, EROPS, 9’.6” STICK, 36” BUCKET, 36” SHOES, CAT 3306 ENGINE............................................................................................................$15,500

PREWIRE, DRAW BAR..................................................................................$145,000

25JV005 – 2008 CAT 325DL, EROPS W/AC, 10’.6” STICK, AUX. HYDRAULICS, HYD. Q/C, 48” BUCKET, 31’.5” SHOES....................................................................$67,500

Four locations serve Maryland, Delaware, Washington, D.C. and parts of Virginia, New Jersey, and Pennsylvania

Elliott & Frantz can show you the latest Gradall models, including Series IV excavators with highway speed travel capability. Featuring AutoDrive™, these models integrate a 6-speed automatic transmission and a new transfer case for efficient, simplified travel as well as convenient jobsite repositioning from the upper cab.

Gradall excavators also feature the job-proven telescoping, tilting boom that enables you to do more different jobs with just one machine – even under bridges and trees.

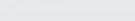

PA Turnpike photo Pavements that offer greater sustainability and longevity provide less construction congestion and interference, which in turn provides greater safety for our customer.

The Pennsylvania Turnpike (PA Turnpike) is finding innovative methods to enhance roadway durability and performance.

Turnpike photo

The Pennsylvania Turnpike (PA Turnpike) is finding innovative methods to enhance roadway durability and performance.

Through the PA Turnpike’s Materials Laboratory, a specialized facility in Somerset that tests and analyzes materials for construction projects, a team of PA Turnpike employees are testing the materials provided by contractors to ensure it complies with PA Turnpike’s specifications. Technicians use equipment to simulate wear, pressure, rutting, heat and extreme conditions to test asphalt mixture durability over time.

Beyond testing samples of new asphalt, the team also is taking cores from the roadway to access the condition of the existing asphalt. During this process, they discovered that approximately 70 percent of the asphalt samples were deteriorating faster than expected. Their investigation led to new specs for asphalt materials on the PA Turnpike, requiring asphalt producers to now incorporate a Silane-based antistrip additive. This will help extend the asphalt’s service life. Testing will continue at the lab over the next few years to assess how well Silane-based anti-strip works in extending the life of the roadway.

Brian Paroda, supervisor of the PA Turnpike’s Materials Laboratory, is eager to bring safety to the forefront for PA Turnpike customers. Pavements that offer greater sustainability and longevity provide less construction congestion and interference, which in turn provides greater safety for our customer.

“One of the biggest issues we deal with is the freeze and thaw cycle of Pennsylvania’s seasons, which creates expansion and contraction that correlates to cracking and the premature failure of the asphalt,” said Paroda. “We’re always looking to increase the efficiency of our roadway through innovation, and this is a great example of how the PA Turnpike continues to find new ways to improve the quality of our roadway.”

“We are committed to providing the best experience for our traveling public and a part of that is a well-maintained

PA Turnpike photo

Brian Paroda, supervisor of the PA Turnpike’s Materials Laboratory, is eager to bring safety to the forefront for PA Turnpike customers.

and smooth pavement,” said Christopher Forry, PA Turnpike materials management supervisor. “Improving the service life of our pavements is critical to reducing construction for customers. A longer service life is a win not only for the PA Turnpike, but for our customers as well.”

For more information, visit paturnpike.com.

ROBERT H. FINKE AND SONS, INC.

Selkirk, NY 518-767-9331 Colchester, VT 802-316-3805

www.finkeequipment.com

TRACEY ROAD EQUIPMENT

East Syracuse, NY 315-437-1471

Kirkwood, NY 607-775-5010

Henrietta, NY 585-334-5120

Adams Center, NY 315-788-0200 Utica, NY 315-765-8746 • 800-872-2390 DuBois, PA 814-371-3600 Erie (McKean), PA 800-872-2390 COMING SOON! Pittsburgh (Zelienople), PA 800-872-2390

www.traceyroad.com

MARSHALL MACHINERY, INC.

South Abington Twp., PA 570-489-3642 Tannersville, PA 570-895-4884 Honesdale, PA 570-729-7117 Millstone, NJ 732-446-7600

marshall-machinery.com

It will cost nearly $200 million to complete the major work on a thruway project in central Pennsylvania, based on the bids opened Sept. 25 by the Pennsylvania Department of Transportation (PennDOT).

The low bid of almost $186.4 million to pave and do other assorted work on the southern section of the Central Susquehanna Valley Thruway (CSVT) was submitted by a joint venture made up of two Allegheny County, Pa., firms, Trumbull Corp., in Pittsburgh and Golden Triangle Construction Co. in Imperial.

The bid is approximately $1.3 million lower than the one submitted by a Bedford County contractor, one of three other companies that sent in bids.

“We are looking forward to starting the last major contract for this long-awaited project,” said Eric High, a PennDOT district executive. “The new highway will not only improve safety by separating trucks and other through traffic from local traffic but also facilitate economic growth in the region by connecting to other major transportation arteries.”

The low bid is close to the design estimate, he told the Patriot-News, which serves the greater Harrisburg-Carlisle area of Central Pennsylvania.

PennDOT anticipates awarding a contract within a few weeks, with construction beginning later this year, Hugh said.

That work will include:

• paving the CSVT mainline along with interchange ramps, and installing new guiderails, lighting, overhead signs and traffic signals;

• completing the Pa. Highway 61 connector that will provide direct access between the Thruway and the Veterans Memorial Bridge over the Susquehanna River between the communities of Shamokin Dam and Sunbury;

• adjusting local roads and property access along U.S. Highway 522 and U.S. 11/15 to accommodate CSVT’s southern interchange on the south end of Shamokin Dam;

• constructing a noise wall along the CSVT southbound lanes near south Old Trail;

• replacing the overpass carrying Pa. 61 across the existing lanes of U.S. 11/15 in

Shamokin Dam;

• completing the Cortland Drive connector between the Weatherfield and Orchard Hills neighborhoods in the town;

• reconnecting County Line Road between Park Road and U.S. 15; and

• resurfacing U.S. 11/15 in Shamokin Dam and Hummels Wharf between CSVT’s interchanges as well as Mill Road, 11th Avenue and nearly a mile of Park Road.

PennDOT anticipates a late 2027 opening of the southern section, which will connect the northern end of the U.S. 11/15 Selinsgrove Bypass with the Winfield U.S. 15 interchange that was built as part of the northern section of the new thruway.

The agency noted that the Pa. 61 connector project is scheduled for completion in late 2028.

PennDOT chose to delay that phase of the work until traffic was using the new highway so as to lessen congestion on U.S. 11/15 in Shamokin Dam while the overpass is being replaced.

The paving contract is the last major effort planned for the CSVT project. A smaller one is expected to be awarded in 2026, the Patriot-News reported, to install Intelligent Transportation Systems devices that include message boards and traffic cameras.

Chicago-based Walsh Construction Co. is completing a $106 million contract it received in late 2023 to build the nine bridges and four noise barriers.

The first contract for the Thruway’s southern section, valued at $115 million, was awarded to Trumbull in May 2022 for needed earthwork.

It has been 10 years since the first contract was awarded on the nearly $1 billion, 12.5mi. CSVT, which went to Trumbull for $156 million to build a nearly mile-long bridge over the West Branch of the Susquehanna River. After the structure was completed in 2020, the thruway’s northern section, of which it is a part, was opened in June 2022.

PennDOT said its data shows there has been a significant decrease in traffic on other roads since the northern section of the thruway was opened.

Milford, MA

508-634-3400

North Reading, MA

978-276-2400

Stoughton, MA 781-399-8580

MILTON CAT • www.miltoncat.com

Wareham, MA

508-291-1200

Brewer, ME

207-989-1890

Scarborough, ME 207-883-9586

Londonderry, NH

603-665-4500

Batavia, NY

585-815-6200

Binghamton, NY

607-772-6500

Clifton Park, NY 518-877-8000

N. Syracuse, NY 315-703-7000

Syracuse, NY 315-476-9981

Tonawanda, NY

716-799-1320

Cranston, RI 401-946-6350

Richmond, VT 802-434-4228

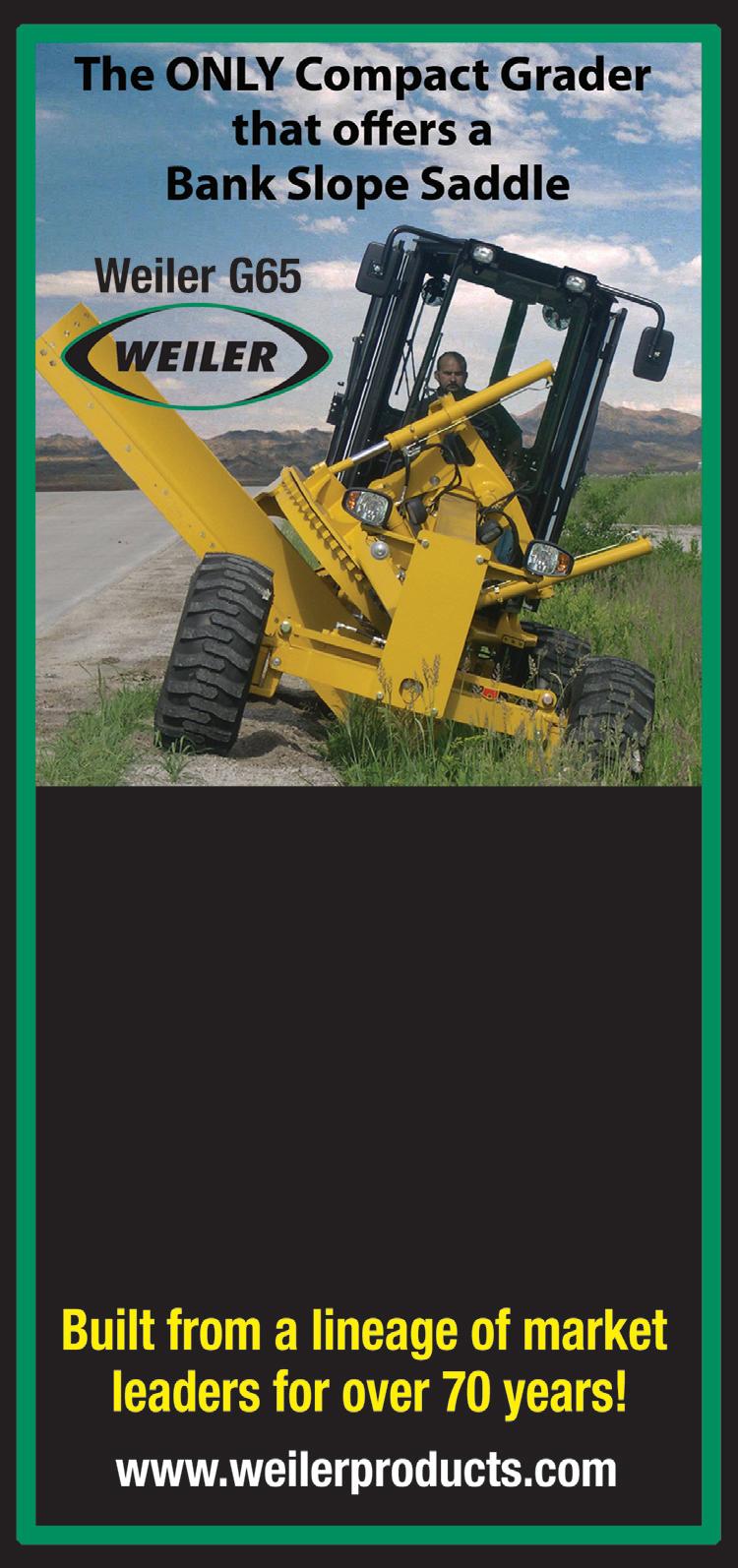

Realistic Scale Models of Construction

Caterpillar No.12 and 12M3 Motor Graders, Evolution series on mounted plaque, 1:50 scale - $200

Caterpillar 977D and 963K Traxcavators, Evolution series on mounted plaque, 1:50 scale - $200

Caterpillar 966A and 966M Wheel Loaders, evolution series on mounted plaque, 1:50 scale - $175

The rollout of Warhorse Rentals is already under way, anchored by several Five Star locations that have fresh inventory, and begun staffing and building out dedicated rental spaces.

• Orchard Park, N.Y. (Buffalo area) — Four full-time staff members. Looking for an additional field representative.

• Rochester, N.Y. – three full-time staff members. Looking for an additional field representative.

• Syracuse, N.Y. – Looking for two additional field representatives.

• Kirkwood, N.Y. (Binghamton area) — One field representative and looking for an additional field representative and inside coordinator

• Dunmore, Pa. (Scranton area) — A dedicated rental operation is being built out in a converted building adjacent to the dealership. Looking for two additional field representatives.

• Waterford, Pa. (northwest Pennsylvania) — A newly acquired facility next to the existing Five Star location is under renovation and will serve both dealership and Warhorse functions. Looking for an additional field representative.

• Williamsport, Pa. (central Pennsylvania) – In process of identifying external facility for growth.

Together, these sites service the upper-half of Pennsylvania and Western New York.

“We will look to expand from there based on customer needs and market opportunity.” he added.

While Warhorse Rentals is still in its early stages, Five Star has already secured partnerships with several major brands to complement its John Deere line.

“We have partnerships with a variety of reputable brands in aerial and light equipment,” Bochicchio Jr. said. “The goal is to have a broad, balanced lineup that serves everything from compaction to power generation”

That lineup will include:

• Aerial lifts (boom and scissor)

• Compact loaders, skid steers and excavators

• Compaction equipment

• Generators and air compressors

• Site support and specialty tools

Every unit will be maintained through Five Star’s service network, ensuring the same level of support customers have come to expect from the dealership’s core business, Bochicchio Jr. said.

Within existing branches, Warhorse will have its own signage, uniforms and segregated display areas to distinguish it from the dealership’s sales floor.

“It’s important that customers recognize Warhorse as its own operation,” Bochicchio Jr. said. “We don’t want it to feel like just another department in the dealership. It’s its own business, with its own processes, people and goals.”

Machines in the rental fleet will be cleaned, inspected and re-certified before each deployment.

“When a machine goes out, it’s charged, serviced, and ready,” he said. “We’re setting a high standard for presentation and turnaround. Our customers expect that from Five Star, and Warhorse will meet the same expectations.”

For Bochicchio Jr., the move into rentals isn’t just about short-term growth — it’s about positioning Five Star for the next era of the construction equipment industry.

“This isn’t a side project,” he said. “It’s a major investment and a long-term commitment. We believe rental will strengthen our customer relationships and make us more resilient as a company.”

He added that the rental market’s growth has been impossible to ignore — both regionally and nationally — and that Warhorse allows Five Star to meet its customers where the market is headed.

“We see what’s happening,” he said. “Contractors want flexibility. They want options. Warhorse gives us the ability to provide that while maintaining the same level of service and trust that Five Star is built on.”

As the company continues to roll out Warhorse Rentals across its network, Bochicchio Jr. envisions a division that will eventually stand shoulder-to-shoulder with Five Star’s sales and service operations.

“We want Warhorse to grow into a full-scale brand of its own — one that customers recognize immediately,” he said. “At the end of the day, it’s about helping contractors do their jobs more efficiently. If we can give them the right tools at the right time, with dealer-level support behind it, that’s a win for everybody.”

Warhorse Rentals is now operational through Five Star Equipment’s network in Pennsylvania and New York, with expansion continuing through 2026.

For more information, visit www.fivestarequipment.com.

(All photographs in this article are Copyright 2025 Construction Equipment Guide. All Rights Reserved.)

Erb & Henry Equip., Inc.

www.erbhenry.com

New Berlinville, PA 19545 610/367-2169

ADMAR Construction Equipment & Supplies

www.admarsupply.com

Vestal, NY 13850

607/798-0333

Tonawanda, NY 14217

716/873-8000

Canandaigua, NY 14424

585/396-0031

Rochester, NY 14623 585/272-9390

Cicero, NY 13039 315/433-5000

Eagle Power Kubota

www.eaglepowerkubota.com

West Chester, PA 19380 610/458-7054

Doylestown, PA 18901 215/348-9041

Pennington, NJ 08534 609/737-7400

Marshall Machinery, Inc.

www.marshall-machinery.com

Honesdale, PA 18431

570/729-7117

Middletown, NY 10940 845/343-6683

Binghamton, NY 13790 607/729-6161

South Abington Township, PA 18411 570/489-3642

Tannersville, PA 18372 570/895-4884

Belvidere, NJ 07823 908/475-8111

Millstone, NJ 08535 732/446-7600

Westchester Tractor Inc.

www.wtractor.com

Brewster, NY 10509 845/278-7766

Chappell Tractor Sales, LLC

www.chappelltractor.com

454 Route 13 South

Milford, NH 03055 800/698-2640

Section one of the Beckley Z-Way project involves widening a three-lane roadway and converting a two-lane road into a three-lane road by adding a center turn lane within US-19 and WV-3 and stretches 3.6 mi.

Mountaineer Contractors Inc., awarded section one and based in Kingwood, W.Va. and a part of MCI Group, specializes in highway and utility work and work in eight states across the eastern side of the country including Ohio, Pennsylvania, Maryland, West Virginia and more.

Section one, consisted of 10 phases, currently has six active construction sites. These phases include relocating and reconfiguring utilities to the area, installing culverts and retaining walls, roadway build-up and more. Travelers can expect delays during underground line and pole relocation and overhead line work, which may extend beyond the project deadline. Areas most heavily affected include Glenwood Lane, Ransom Drive, Glade Springs/Lake Drive, Raleigh Center Road, the Green River Garden Center and Bobcat of Beckley. Minor detours include temporarily shifting into the existing shoulders — reduced to 10 ft. — and existing lanes. Paving began the second week of October 2025.

Once these phases are complete, Mountaineers Contractors will move the highway and infrastructure work to Raleigh Center Road, 4-H Lake Road, Regency Drive and Granby Circle. The bulk of remaining work consists of water line and sewage line relocations, drainage structure installation, roadway build-up and roadway widening. Once complete, Granby Circle will then tie into the second section of work, the Beaver to S. Eisenhower project.

While section two of the Beckley Z-Way project only consists of a total of 1.93 mi. and 6,000-9,000 travelers daily, the complexity of the work, including relocating and adding a

roadway as well as realigning a stream, requires an experienced contractor. West Virginia Division of Highways awarded Kanawha Stone Company for the specialized work, a family-owned and -operated company. Based locally and with years of experience across the Appalachian region,

Kanawha Stone Company began its work in late 2024.

First, Kanawha Stone Company began blasting sections between Old Crow Road and Airport Road in late 2024. While the project has required blasting intermittently within the past year, roads have remained open and operational with the exception of a few overnight, full closures. Simultaneously, Kanawha Stone Company cleared trees and began relocating utility lines in the first steps of early construction.

Today, Beaver to South Eisenhower remains under active construction while Shady Springs to Beaver maintains traffic patterns while under construction. The new connector off

from page 1

Morrissey Inc., and began a career that would span more than seven decades. His concrete plants, stone quarries and asphalt plants, spanning multiple locations in the Philadelphia, Bucks, Montgomery, Lehigh, Monroe and Pike counties of Pennsylvania, have supplied material to nearly every major highway construction project for the past 70 years including the Pennsylvania Turnpike, I-95, Route 1 and the Blue Route, on which trucks bearing his and his late father’s name can be seen.

“He took over the family business in 1982, after the passing of his own father,” said Jim Morrissey III, who oversees the company’s materials division. “Together, my grandfather and grandmother had built the foundation of what you see today. Not just the roads, malls or terminals, but a reputation, a standard of work, and most importantly a way of life. And when it became his turn, he never looked back. From January of 1982 until just days before he passed, he was out there, stopping by the jobsites and paving projects.”

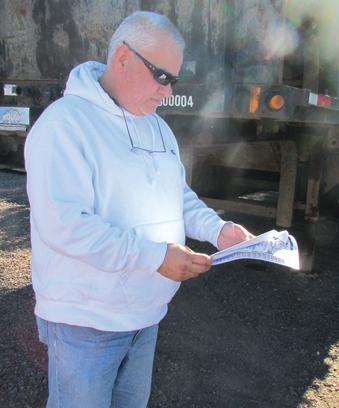

James D. Morrissey Jr. reviews plans with Keith Gay, superintendent of the Pennsylvania Turnpike job of James D. Morrissey Inc., in August 2025.

The Friday before he passed away, he was still on a job site, Morrissey III added.

“My brother Joe, who runs our construction side of the business, had him out that afternoon. It meant a lot to our dad. Being out on a site was not work — it was where he came alive. He did not just love work — he knew it was what he was put here to do. It was not about legacy. It was about doing what was right, every day. He knew exactly who he was. He never lost sight of it.”

Work and family were always in the same breath for Mr. Morrissey Jr.

“We lost my mom in 2003,” said Morrissey III. “She was an incredible woman and an amazing mom to me and my siblings. After my mom passed away, my father and LA Glasgow began dating and in 2010, they got married. LA, who also grew up in a very well-known construction family, was amazing to our dad. LA shared his love of the business. She would ride to job sites with him on weekends. I would call him on Sunday, and he would say, ‘Oh, LA and I are heading out to check on a few job sites.’ That was him. Until the very end.”

Mr. Morrissey Jr. was not a man of many words. He did not hand out nuggets of wisdom or long-winded advice, but you always knew where you stood with him, Morrissey III added.

“He lived by his principles, and he never wavered. Never got sidetracked. He was presented with a tremendous opportunity from his parents, and he honored that gift every single day.”

There were big jobs, of course. In the late 1980s and into the 1990s, he landed two sections of the Blue Route — Route 476 — a massive project. Other major jobs included building the UPS terminal at the Philadelphia International Airport, Franklin Mills Mall, Willow Grove Mall and excavation work along I-78 in eastern Pa. Those jobs solidified his place in the industry. They were not just jobs — they were statements. Proof of what hard work and determination could achieve. More recently, his jobs included the rebuild-

ing of sections of Route 309, the Pennsylvania Turnpike and the new Bellwether District site in South Philadelphia as well as the construction of the Keystone Trade Center, on the grounds of the former U.S. Steel Plant in Fairless Hills, Pa

“He was still president of the company when he passed,” Morrissey III said. “My brother, Joe, and I have been managing day-to-day operations for the past few years — Joe in construction, me in materials. But my father was always there. He was our mentor. Even on the days when he could not make it out to see the jobs, in recent months, he was calling the guys on a Saturday morning, checking in on work.”

Mr. Morrissey Jr. was the devoted husband to LA Glasgow. He was predeceased by his first wife, Mary Alice (Fasy) with whom he shared seven children: Mary Beth Stefanowicz and her husband, Brian; Alice Meehan and her husband, Mike; Louise “Weez” Boyd and her husband, Patrick; Jim Morrissey III and his wife, Siobhan: Carsy Missett; Joe Morrissey and his wife, Dana; Paul G Morrissey and Paul DiIorio. He also was the proud “Pop Pop” to 27 grandchildren and four great-grandchildren.

Mr. Morrissey Jr. made it a point to attend as many of his children and grandchildren’s sporting events, graduations and birthday parties as he was able. He was a member of several golf clubs and made a vast number of lifelong friends, especially at Huntingdon Valley Country Club, The Union League Golf Club at Torresdale, Sunnybrook Golf Club and Saucon Valley Country Club. In the winter months, he spent time at his home in the Ocean Reef Club in Key Largo, Fla.

“My father’s story isn’t flashy,” concluded Morrissey III. “It is not full of speeches or grand declarations. It is about showing up. Knowing who you are. Staying true to what matters and never wasting the gifts and opportunities with which you were presented. He was put on this earth to work. And he did.”

Services for Mr. Morrissey Jr. were recently held at St. Katherine of Sienna Church in Philadelphia.

Contributions in his memory may be made to Penn Cardiovascular Fund, 3535 Market Street, Suite 750, Philadelphia, PA 19104, or a charity of the donor’s choice.

CEG

(All photos courtesy of Jim Morrissey III.)

Five Star Equipment, Inc. www.fivestarequipment.com

60 Paul Rd., Rochester, NY 585-235-3011

1653 NY Route 11, Kirkwood, NY 607-775-2006

284 Ellicott Rd., Orchard Park, NY 716-662-2191

5835 East Taft Road, North Syracuse, NY 315-452-4560

1300 East Dunham Dr., Dunmore, PA 570-346-1701

46 Route 97, Waterford, PA 814-796-2663

2585 Lycoming Creek Rd, Williamsport, PA 570-494-4030

Groff Tractor & Equipment

www.grofftractor.com

6779 Carlisle Pike, Mechanicsburg, PA 717-766-7671

2550 E. Cumberland St., Lebanon, PA 717-273-2616

800-225-4001

3215 State Rd., Sellersville, PA 215-258-5700

800-523-2209

400 Stoke Park Rd., Bethlehem, PA 610-867-4657

800-587-9790

640 Lowther Rd., Lewisberry, PA 717-938-6568

866-787-0001

179 Perry Hwy, Harmony, PA 724-776-3636

963 South Center Ave., New Stanton, PA 724-755-0124

Leslie Equipment

www.lec1.com

Beaver, WV

304-255-1525

Cowen, WV

304-226-3299

Cross Lanes, WV

304-204-1818

Pleasant Valley, WV

304-534-5454

Norton, WV

304-636-6421

Marietta, OH

740-373-5255

Ashland, KY

606-327-1709

Pikeville, KY

606-432-0321

www.jesco.us

Middletown, DE

302-376-0784

South Plainfield, NJ

908-753-8080

800-241-7070

Fairfield, NJ

973-227-2221

800-321-8080

Lumberton, NJ

609-267-2020

888-217-0600

Beacon, NY

845-831-1800

800-724-0725

Deer Park, NY

844-482-0910 United Construction & Forestry www.unitedequip.com North Oxford, MA 508-987-8786

North Billerica, MA 978-667-4345

Plymouth, MA 508-830-9997

Swansea, MA 508-379-9810 Springfield, MA 413-543-5595

Clifton Park, NY 518-371-5111

Gouverneur, NY 315-287-0703 Hermon, ME 207-947-6786

Houlton, ME 207-532-6517

New Canada, ME 207-834-6701 Westbrook, ME 207-773-3777

Pembroke, NH 603-225-2769 Springfield, VT 802-885-6840 Williston, VT 802-658-2121

Plainfield, CT 860-546-4808

A common sight in a visit to the Beaverdam Reservoir Park in Ashburn, Va., during the early evening or on a springtime Saturday morning, will be a few rowing boats — or shells — on the water, crewed by several scholastic rowing teams. The 300acre reservoir has been a popular place for crew teams to practice.

A part of the project that created the park, a dedicated boathouse was constructed to provide shell storage and facilities for the athletes. Designed by Studio Twenty Seven Architecture of Washington, D.C., the building is reminiscent of a lantern. Integrated into the building’s design are eight Schweiss Doors liftstrap bifold doors, measuring 12 ft., 2.5 in. by 9 ft., 3 in.

“During the day, you go inside and you kind of get the sense of the light filtering through the building,” said Bethan Llewellyn-Yen, lead architect at Studio Twenty Seven Architecture. “At nighttime, when you’re outside and the doors are closed, it all kind of glows.”

Studio Twenty Seven wanted the boathouse to match the overall look, feel and aim for the entire park. The Beaverdam reservoir is a man-made body of water, created by damming a portion of the Beaverdam Creek to provide drinking water for the surrounding communities. The reservoir and surrounding land became a popular place to fish, row, hike and just escape to nature in the highly built-up area surrounding Washington D.C.

The project at the reservoir created a new park with upgraded amenities while also working to protect the natural environment and water quality of the reservoir. The project was a partnership between Loudoun Water, which owns the reservoir, and the Northern Virginia Regional Park Authority (NOVA Parks), which operates parks and recreational facilities across northern Virginia. Nelson Byrd Woltz Landscape Architects was chosen as the designer of the overall park. That firm hired Studio Twenty Seven to help with the design of the structures.

“We took to heart this idea of promoting civic infrastructure and water source protection,” Llewellyn-Yen said. “Water was the prime client and we wanted our buildings to showcase the importance of protecting the water source. Every building in the design looks to capture every rain drop and from there directly to the reservoir.”

The welcome center and picnic pavilions all have V-shaped roofs that collect rainwater, direct it off the roof and into a rain basin on the ground. The basins are designed to hold the water temporarily before allowing it to slow drain toward the reservoir. The landscape was created to function as a living water filter, grabbing sediments and pollu-

tants from the water. This helps keep the water in the reservoir clean.

The park also includes upgraded trails and docks. Throughout the park there are educational signs, boards and medallions explaining how the buildings and landscape work to protect and conserve water and the environment.

While the crew facility has less of a direct role in the environmental protection side of the park’s mandate, it was still designed to fit into the larger picture. Instead of water, it filters people and boats through its structure and onto the boat docks and forward into the reservoir itself.

The exterior of the building is clad in a thermal spruce wood siding and the interior is covered in a polycarbonate product that is translucent enough to allow light to filter through it. The wood cladding isn’t tightly installed but instead leaves flaps between each slat. This created a skin on the building that mimics a paper lantern, or a drying barn used to dry and preserve crops.

Providing access in and out of the building are the eight Schweiss bifold doors, four on each side of the building. The doors were engineered to hold the polycarbonate and wood cladding and include side-latch switches, electric photo eye sensors and emergency back-up hand cranks.

Llewellyn-Yen said they wanted a door that could be customized to work with the

vision of the building and have minimal impact on the interior of the boathouse. Inside there are shelves to store more than 60 rowing shells and it requires open space to be able to maneuver the shells in and out.

“The capability of the Schweiss Doors

bifold doors folding outward was critical, so that it didn’t interfere with the space we were trying to get in the building to house as many crew teams as possible,” Llewellyn-Yen said.

As is fitting for a project that includes amenities for a sport that is all about people rowing together as one, teamwork was an important piece of making the park project a success. This includes Schweiss Doors, which worked closely with Studio Twenty Seven and Meridian Construction Company, the general contractor of the Beaverdam Reservoir Park project.

“The Schweiss Doors team was awesome,” Llewellyn-Yen said. “They worked with us through construction and looking at the different options and the different ways we could customize.”

Approximately six school rowing teams use Beaverdam Reservoir as their practice home and store their shells in the park’s crew facility from February through May. Having the boats in the building and rowers using the facility are the finishing touches of the building’s design.

“We are really happy with how it all worked out,” Llewellyn-Yen said. “We’re excited to see the teams really use the building. Now that all of the boats are in there and the teams are in there, the palette of the building and everything has come together.”

For more information, visit bifold.com.

NEW YORK

Buffalo, NY

716/877-1992

Henrietta, NY

585/334-6770

Syracuse, NY

315/463-8673

Albany, NY

518/785-4500

Watertown, NY

315/788-5512

Endicott, NY

607/748-3400

Olean, NY

716/372-8822

NEW HAMPSHIRE Lancaster, NH

603/788-6595 Manchester, NH

603/627-7696

PENNSYLVANIA

Pittsburgh, PA

412/343-2300 Clarion, PA

814/226-4100 Clearfield, PA

814/765-5311 Somerset, PA

814/443-2867 MAINE Bangor, ME

207/942-0177 Gorham, ME

207/591-5482

VERMONT East Montpelier, VT 802/223-9689

Woburn, MA

781/935-1919

Avon, MA

508/584-8484

Whately, MA

413/665-7009

Smithfield, RI

401/942-9191

Newington, CT

860/665-7470

New Haven, CT

203/848-6734

Holmes, NY

845/878-4004

Pine Bush, NY

845/744-2006

www.komatsustores.com

877-566-2878 Laurel, DE

302-715-5382 Baltimore, MD 410-247-2100

South Plainfield, NJ 908-561-9000 Winslow Township, NJ 856-767-5900 Holbrook, NY 631-563-7600 Yonkers, NY 914-738-5100

Frackville, PA

570-874-6140 Harrisburg, PA 717-652-3190

Hatfield, PA

215-822-0145 State College, PA 814-308-5660 Wilkes-Barre, PA

570-824-9891

You might not be thinking about adding electric equipment to your fleet yet, but what if your competitors are? Get a step ahead by learning more about all the ways electric machines are helping contractors like you expand the types of jobs they take on — from working at night and in busy public spaces to indoor demolition and more. Contact your local Volvo dealer to find out if electric is right for you.

When Bob Adams looks at The ASL Group today, it’s a far cry from where he started. What began as one man mowing lawns and cutting grass in high school has grown into a full-service operation in New Jersey, split into two active divisions: paving and landscape/hardscape.

Adams, who founded the company in 2015, said the growth comes from hard work, reputation and a focus on owning the equipment and expertise to control quality.

Adams’ path into construction wasn’t straightforward. He once envisioned a career in the film industry and even spent time working in New York City before returning to his roots in the trades. After graduating from Hofstra University where he earned a degree in business and communications, he partnered with a friend to run a small landscaping venture before striking out on his own.

“I gave myself a year,” he said. “My dad said, ‘If you fail, you fail. But at least you tried.’ I wasn’t married, didn’t have a house, so I took the risk.”

The risk paid off. In 2015, Adams launched his own business, laying the foundation for what is now The ASL Group.

Today, the company is split into two strong arms. The paving division handles both residential and commercial projects, ranging from private driveways to community roadways and small-scale municipal work. Adams’ crews operate with a mix of full-time and seasoned part-time workers who, he said, “can jump in and run a project start to finish.”

The hardscape and landscape division focuses on patios, pool surrounds, walkways, drainage systems and other enhancements that have grown more popular as homeowners seek long-term outdoor improvements. Adams has found opportunity in drainage work especially, as development patterns and changing weather create demand for proper water management.

TREES, BRANCHES, LIMBS, AND

ARE NO MA ,, ATTCH FOR A B From roadways to right-of to road clearing, get your w more efficiently than ever machinery! Choose from d sizes to suit your needs. C yours or to request a dem BANDIT® -ways, lot clearing ork done faster and before with Bandit ifferent styles and all today to reserve onstration.

Equipment is a backbone of both divisions. Adams insists on owning rather than renting.