Construction is set to resume on the Champlain Parkway project in Burlington, Vt., which would connect Interstate 189 in South Burlington to the city’s downtown. The road project has been in the works since the 1960s. In 2022, crews worked on stormwater, utility and the subbase for the new section of roadway between Home Avenue and Lakeside Avenue, according to Chapin Spencer, the director of Burlington Department of Public Works (DPW). This year, city officials have circled April 17 on their calendars as the date to begin work on the parkway to make the corridor more pedestrian-friendly and repave roads like Lakeside Construction On Champlain Parkway Project in Burlington, Vt., Set to Resume By

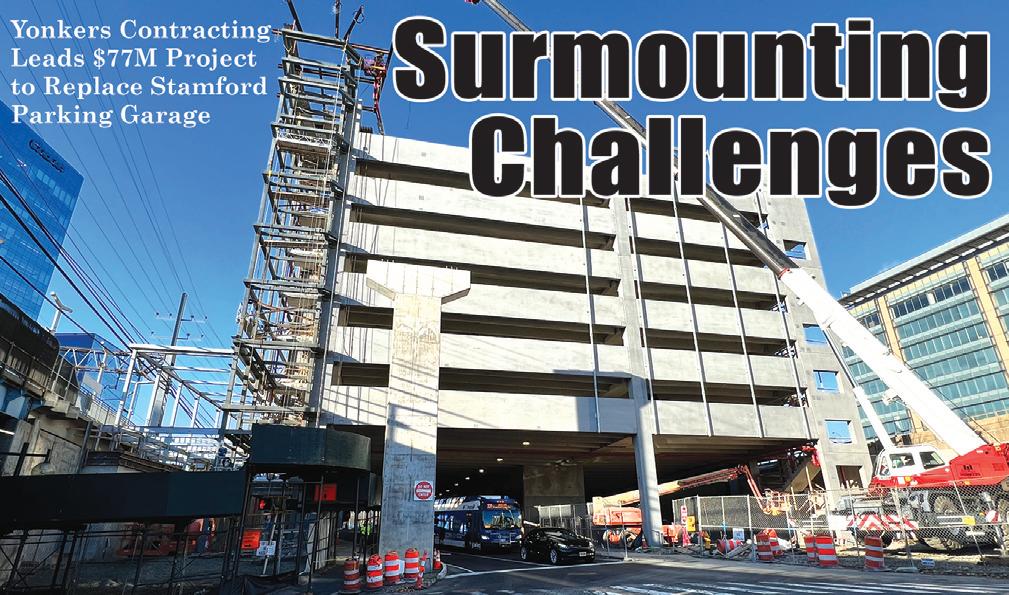

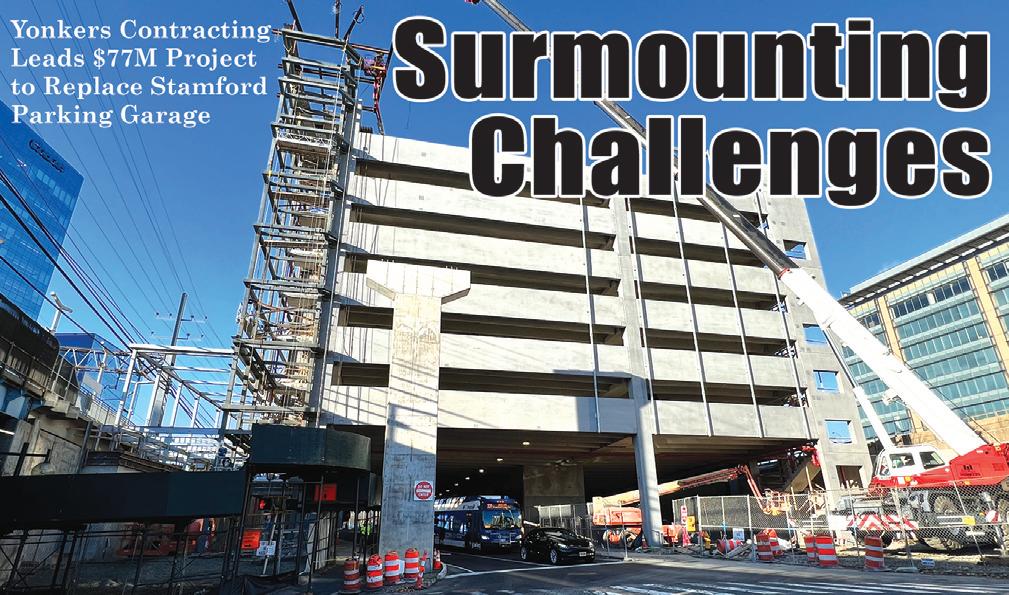

CEG CORRESPONDENT Yonkers Contracting Company Inc. started work on the Connecticut Department of Transportation’s (CTDOT) $77.2 million, design-build Stamford Station Parking Garage project in September 2021 to provide additional parking via a new facility and to improve services at the train station. The project is expected to be delivered this August. The 928-space, seven-and-a-half level parking garage is located on South State Street in Stamford. It includes a THE NEW ENGLAND EDITION A Supplement to: Your New England States Connection • Kent Hogeboom 315-866-1423 ® “The Nation’s Best Read Construction Newspaper… Founded in 1957.” April 26 2023 Vol. LXI • No. 9 The 928-space, seven-and-a-half level parking garage is located on South State Street in Stamford. see STAMFORD page 16 see PARKWAY page 10 Tibbits Equipment Services, Inc. www.tibbitseq.com 802-479-9696 Specialty Construction Equipment SALES • RENTALS • HAMMERS Since 1989 KWIK KLEET® Traction Cleats 938G,H • 950G,H • 966G,H WANTED LOW HOUR CAT LOADERS Phil (413) 427-7171 CALL YOUR ONE-STOP HAMMER SHOP™ TODAY!!! CALL 888-81-GORILLA(46745) • Largest hammer repair facility in North America • Demolition tools and parts for ALL makes and models • Hammer-equipped excavator rentals • Backed by a 75 year family owned business CALL 800-367-4937 *On approved credit Financing Available SHIP WITHIN 48 HOURS SAME DAY PARTS AVAILABILITY 24 HOUR TECHNICAL SUPPORT BACKED BY A 75 YEAR BUSINESS State Supplement sponsored by: Affordable Price. Premium Service. Thousands in Service! www.foleyengines.com • Exhaust Scrubbers • Perkins Engines • Deutz Engines • Twin Disc/Rockford Clutches m PUSHIN G G. DRAC U 978-454 T T, , MA -3320 BROCKTON, MA 508-484-5567 OW B W, , N H 603-410 -5540 omDoosanCorp underlicensef used s , ademark TheDoosant Group striesIndu avy a He Hyund e of at l an affi s acore an Inf s a Doo Hyund reserved rights undaiDoosanInfracore.AHy 2023 © poration.

Irwin Rapoport

Page 2 • April 26, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide See Our Complete Inventory at www.wiclark.com

stk# 26327, 653 Hrs, ROPS, Deutz diesel, single drum vibratory, good rubber, like new condition..............................................$64,500

2018 HAMM H7I

2014 DEERE 60G stk# 27845, 1400 hrs, hyd thumb, 24" bucket.. $64,500

2018 DEERE 50G

Cat power, 6'5" 15mm drum, rigid conveyor, 60% bottoms, good belting with grade, stk# 26377................................................$125.000

2010 WIRTGEN 2100

2009 DEERE 624K

stk# 27812, 3300 hrs, skid steer cplr, coupler, 1yd bucket............................................$62,500

2015 DEERE 204K

2300 hours, push blade, hyd thumb, 80% tracks, Stk#27970................................$42,500

2012 DEERE 35D

2019 LEEBOY 8500D stk# 28000, Kubota, 8-15' propane screed...... $99,500

Call Mark Doty @ 203-823-2316

C/air, angle blade, hyd thumb, 24" bucket, new tracks, Stk#27764................................$67,500

1771 hours, stk# 27248......................$89,500

2015 JOHN DEERE 75G

stk# 28115, 11,800 hours, a/c, aux hyds, JRB hyd cplr................................................$87,500

OPRROOVVEN U WITH UPTI

PTIME IME KITS

SENNEBOGEN, in kee philosophy to maxim created UPTIME Kits

n-house or on the everything you e, maintenance place. They were ime and money. of related service d nuts to O-Rings omes easy with a o order and stock :kits

Easy e for (TCO) Ownership of thinki We’re equipment.

They are: rain e • T ervic ts • S Par

order and par ing • Application Special customer very to machine” the “beyond ng

stocking NEBOGENNN BOGEN SEN ctor suppor xible Financing lists • Fle

• Hydraulic service k

D T shops ols ervice owing kits system kits nance service kits its kits

trucks Choose a uptime dependable deliver througho t ttachments • A

Cost Total lower and its of life the out

And the best thing is in stock and ready to built to match your m and series. Count on in-house. For more in UPTIME Kits, scan th a more Learn

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • April 26, 2023 • Page 3

C BEYOND E H HE HIN

MA virtual I ntime losellyt

•

to

ea t d t stock asy to s l dow NO North our in parts com with customers maxim commitment h about more Read ontract Demolition C st in parts repair the have virtu and I machine another in If back. to front every come t a have They echnician machine, wntim warehouse. American ready-to-ship of inventories plete for uptime izes aftersale Machine” he “Beyond our ow , Bloomfield Hills, MI or quickly. back unit the g I k they Since do no lose ally bring just [they] situation, a have I over go to month a once through wntime… ock. get theSENNEBOGEN y-t t act OGEN f tor ained technicians tr ned tec cians components and too • Ideal for

se and

eping with their mize uptime, has Whether you are a service technician i road, these kits have need for every service and PM task in one p created to save you t Managing hundreds o parts, from belts and and special tools bec single part number to from the follo • Central lubrication • Preventive mainte • O-Ring kits • Electrical service k Hydraulic service k

s that these kits, go, are custommachine model SENNEBOGEN 2-6351 ) 29 (800 ongmead ast L E oa er R 1 Shak 25 yle t.ww our to commitment our

nformation w bout

on he QR code. (800 Berli 1980 28 A 010 , M ow d om omers

requipment.c cust

52-4473 ) 3 0 7 in, CT 0603 urnpike 0 Berlin T sennebogeen-na.com/beyond-the--machine

Salem Unveils Second Phase of City Park Overhaul

The next leg of the rehabilitation work at Salem Willows, a city park in Salem, Mass., was unveiled at a forum March 14. The effort will connect to and overlap with the construction of a new pier in the year following the overall project’s second phase.

City officials and contractors on the Willows’ share of the Signature Parks program showcased an early glimpse of the park’s Phase II, designed to target the extreme northeast portion of the park — an area covering the mostly paved area beyond the Salem Willows gate at the end of the park’s restaurant boardwalk.

In the meantime, Signature Parks continues to work on other public spaces nearby, including Camp Naumkeag and efforts to swap it with Pioneer Village in Forest River Park, another Signature Park property.

Construction is slated to begin this fall and carry into next spring, wrapping up in time for summer 2024, according to Jason Bobowski, a landscape architect and senior project manager at Hatch, an Australianbased consulting firm with an office in Boston.

The second phase will precede the construction of a new pier at the end of the to-be-replaced walkways.

“We’ll be coordinating everything with the pier project and working with their schedules,” Bobowski told the Salem News. “When construction really ramps up, the pier project schedule has them going out to bid in the fall [of 2023] and [work beginning] in 2024, but we’ll see how that goes. [The City of Salem] still has a number of permits they’re going through right now.”

Phase II Will Extend Outside Park

The second phase follows the initial work that will be wrapping up in the months ahead, he added. The first phase created new parking, multi-purpose courts, and walking paths toward the entrance of the park — all of which were completed in 2022.

This spring, the final parts of that project — including the restoration of a field used for temporary parking and updates to parking along Restaurant Row — are planned for the coming months, according to Bobowski.

The second phase will extend past the boardwalk to its metered parking area, past the Salem Willows gate, and to the asphalt sea beyond.

The plans, presented as a “preliminary concept,” would not touch any buildings throughout the property, instead focusing on

the paved and landscaped areas between the structures.

Bobowski told the News that it would create a new concrete sidewalk wrapping around a programmable “central lawn.” With two new paths leading from the restaurants to the water, the work and one of the pathways, would tie directly into the new pier.

The concept also proposes two bio-retention basins, also known as rain gardens. These types of basins are used to filter stormwater runoff in parking areas full of cigarette butts and other trash that collects between storms. Such a garden was installed outside the parking area at Winter Island’s hangar in 2019 and celebrated by local officials in 2021.

In addition, Phase II of the Salem Willows project has tapped the Public Archaeology Laboratory in Rhode Island to “do an archaeological and historic review, and really usher the project through that part of the process,” Bobowski said.

“[It will] also help inform and guide our design to make sure we’re working in compliance with and respecting historic components,” he added.

Finally, the project plans to eliminate all power and utility lines in the park by running

them underground. Park lighting, currently attached to utility poles slated for removal, will be installed at “pedestrian scale” — like those on Salem Common — at a later stage, Bobowski noted.

Public Comments Target Timeline, Dilapidated Blue Shack

The March 14 forum about the park project eventually opened to public comments, at which point concerns on the periphery of the effort dominated attention. Comments on the quality of the concept were mostly positive, as was the general reception to the first phase.

Questions included several from members of Salem United over the timing of the improvement project and whether it would affect the organization’s Negro Election Day festivities, which, for generations, have operated from the park on the third Saturday of every July. Officials assured attendees, though, that the park’s construction would not start until the fall and would be finished by the Memorial Day weekend of 2024.

Answers were less clear regarding the pier construction, which is being developed independently, the News reported.

Comments from Salem residents also focused heavily on a blue shack owned by

the city that sits on the extreme edge of the construction area. The structure was most recently used by Mahi Cruises, which now runs out of Pickering Wharf.

“Has anybody actually looked at that building because it’s collapsing?” asked Cynthia Jerzylo, a local resident. “It’s very eroded underneath and washed out. If the city is going to be putting ... money in the project and they have this eyesore building [that] may collapse and is a hazard, why wouldn’t they … do something to fix it?”

Bobowski called the shack’s demolition “a project in and of itself. It’s a can of worms, something we did discuss as we went through [the project’s] concept.”

But acting Salem Mayor and Ward 1 Councilor Robert “Bob” McCarthy assured the Salem News that the shack will be gone long before construction even begins.

“It sits on top of, for the lack of a better word, a vault, which back in the day, used to be a bath house as we can nearly tell,” he said. “The building itself has become a nuisance, so we put it out to various city departments. Nobody wants to [use] it, so more than likely it’ll be removed in the short-term, and we’ll have to [then] figure out long-term how that vault the building sits on is addressed.”

Page 4 • April 26, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

salemma.gov rendering

The redesign will prioritize pedestrian circulation, accessibility, resiliency, and will tie-in to the Pier Replacement Project.

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • April 26, 2023 • Page 5 AUTHORIZED DOOSAN DEALER www.equipmenteast.com DRACUT 978-454-3320 61 Silva Lane Dracut, MA 01826 BROCK T 508-484- 5 196 Manle Brockton, TON 5567 ey St. MA 02301 BOW 603-410-5540 1474 Rte 3A Bow, NH 03304 PUS N E V S HING . OP T ER S PS W PO ThenewDo I ON T A V O N ERED B eho edozerdeliversmor oosan® N. Y er eorsepow oug o push thr better visib The new Do TheDoosantradem yundai Doosan In H yundai Do ©2023 H isit Equip Vi V our biggest challenges. gh y ation to h ility and easier oper e ho er delivers mor om Doo , is used under license fr ark, fracoreisanaffiliateofHDHyundai ved eser ll rights r e. A acor osan Infr . ipment East for a demo ou o help y , ation. san Corpor

Pedestrian Bridge at MBTA Stop Closes for Station Work

The ongoing renovation and construction project at the Massachusetts Bay Transportation Authority’s (MBTA) Natick Center commuter rail station is making progress, which means another closure is upon its riders.

Patch, the online local news service, reported March 7 that MBTA officials announced, due to construction and demolition activities, the pedestrian bridge at the station has been closed, and will remain so until another is rebuilt this year.

The update followed shortly after news in mid-February that the entrances to the station were changed for the same construction project. MBTA said the Natick Center entrances are being moved to Washington Street for access to inbound and outbound platforms through the end of 2023.

The adjustment will allow the contractor to safely and efficiently complete work on the west end of the station’s new accessible platforms, according to transit officials.

The Natick Center ranks in the top 25 percent of busiest commuter rail stations in the state’s system, according to MBTA.

MBTA Unveils 2023-24 Timeline to Completion

A contract for the building project was awarded in November 2019, and construction began the following spring.

Anticipated completion of the Natick Center Station has been extended to early 2024, but the facility will continue to operate throughout its renovation.

The $36.2 million project will feature two new elevators, two accessible ramps, and six stairways, all aimed at improving accessibility and rider experience as well as bringing it

into compliance with updated accessibility standards.

MBTA noted that the 2023 work schedule will include the installation of the station’s full-length, high-level platforms for easier boarding, as well as the stairs and elevators. After the first of next year, crews will turn their attention to demolishing existing temporary platforms, creating new streetscapes, and building the Cochituate Rail Trail connection.

Other upgrades to the Natick Center station over the next year include:

• Replacement of the existing pedestrian bridge.

• Improved amenities including new canopies, bicycle parking, better signage, wayfinding and emergency lighting.

• Modern drainage infrastructure for better flood prevention.

Due to upcoming construction activities and demolition, nearby Moran Park at Natick Center was closed March 2 and will remain shuttered until the new pedestrian structure is completed at the end of 2023. MBTA noted the park’s closure is necessary to ensure the safety of residents.

The state transit authority also said its construction at the Natick Center will primarily take place on weekdays during daytime hours, while nighttime work will only be performed as needed.

To keep the public safe, MBTA also has installed temporary supplemental and emergency lighting at the station. It expects the lighting to remain in place until the station’s permanent and emergency lighting fixtures are ready for use. The interim lights are set to be directed downward, the agency said, with little to no light spilling over onto adjacent properties.

Vt. Awards $12.6M to Improve Mobile Home Water System

To improve water systems in 36 manufactured housing communities in Vermont, the state is awarding $12.6 million as part of its Healthy Homes Initiative.

Gov. Phil Scott announced Feb. 8 that the money will go toward repairing and replacing water and sewer systems, as well as assessing what other infrastructure work is needed, at mobile home communities across the state, reported VTDigger, a nonprofit news service.

“Through this round of funding, an estimated 3,975 residents — including 1,100 seniors and 830 children — will be able to more reliably access safe drinking water, and will be served by improved wastewater, stormwater, and drainage systems, protecting both them and the environment,” Scott said.

The help is desperately needed, according to Dave Sawyer, who works in operations at Weston’s Mobile Home Cooperative in Berlin, Vt. It will receive $1.325

million for repair and replacement of its water systems, which have not been upgraded in years.

Weston’s was once privately run, but residents gained ownership of the park in 2017. It has battled problems with improperly installed water lines and wells every year, Sawyer told VTDigger.

“When this money came out, we knew we needed to get our system upgraded to supply [our] middle- to low-income housing,” he said.

ARPA Funds Vermont Program

The Healthy Homes Initiative operates through the Vermont Agency of Natural Resources (ANR), tapping a total of $24.75 million available through the federal American Rescue Plan Act (ARPA).

Funding is being directed through three avenues to improve water systems at manufactured housing communities, according

to Megan Cousino, environmental program manager at the state’s Department of Environmental Conservation.

The $12.6 million will not only repair or replace water systems, she said, but will pay for studies of existing water systems, and what is needed to bring them up to modern standards. It also will help pay for permits so construction can begin, Cousino noted. VTDigger reported that about a third of the projects will involve studies to learn what will improve the water and sewer systems, while the rest will focus on technical help, permitting and construction.

According to ANR, environmental concerns disproportionately affect manufactured housing communities.

In 2011, 40 percent of the people affected by Tropical Storm Irene’s rampage through Vermont were residents in manufactured housing communities, while only 8 percent of the state’s total popu-

lation lives in these communities, noted REJOICE, the Vermont Rural Environmental Justice Opportunities Informed by Community Expertise.

The Healthy Homes Initiative is based on the understanding that improving the water, sewer, and drainage systems will not only help the residents of these communities, but improve the nearby environment.

“If somebody is properly disposing of their wastewater, that means it’s going into the environment in a way that’s better for [the environment and] keeps humans away from where that waste might end up,” Cousino explained.

ANR Keeps Rents Lower for Mobile Home Residents

Thirty-nine mobile home communities in Vermont applied for funding through the Healthy Homes Initiative last summer for about 90 projects involving repairs, upgrades or replacements

of water, sewer and drainage systems, added Cousino.

Leaders of the program are already thinking ahead to future improvements, noted VTDigger.

She hopes that any manufactured housing community that did not apply this year, or any who want to continue their improvements from this round of funding, will apply for the second round of funding from the $24.75 million. ANR hopes to open those applications in late spring.

Sawyer said the money awarded to Weston’s Mobile Home Cooperative will not only improve the water systems in the community but will also ensure financial stability for many residents in the member-owned cooperative.

If Weston’s had to take on the repairs and replacements itself, those costs could significantly affect the price of living there, he said in speaking with VTDigger, adding that many folks may then not be able to continue living in the park.

Page 6 • April 26, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

A rendering of the station elements, viewed from the platform.

Courtesy of MBTA

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • April 26, 2023 • Page 7

The Nice Company, Inc Equipment Sales and Rentals

Project to Boost Safety By Reconfiguring Busy On-Ramp

The Connecticut Department of Transportation (CTDOT) has begun a project to reconfigure the Conn. Route 17 onramp that leads to state Route 9 northbound in Middletown to increase safety for drivers and pedestrians, while also improving traffic mobility.

The road upgrade was announced April 11 by Gov. Ned Lamont and state Transportation Commissioner Garrett Eucalitto.

The work includes removing the onramp’s existing stop sign and creating a fulllength, free-flow acceleration lane that will allow vehicles to merge onto Route 9 without first being required to come to a complete stop. Additionally, the bridge carrying Route 17 over Route 9 will be replaced to accommodate the new acceleration lane, while Harbor Drive access to Route 9 will be removed.

The Main Street Extension intersection will be realigned and signalized, and a new sidewalk will be added to the west side of the Main Street Extension underneath Route 17.

Middlesex Corporation, from Littleton, Mass., was awarded the contract, valued at $50 million. It is supported by funding that Connecticut received from President

Biden’s Bipartisan Infrastructure Law.

The project is expected to be completed in 2026, according to the governor’s office.

Ramp’s Current Design Has Led to Hundreds of Crashes

The new roadwork and improvements are part of a larger, comprehensive CTDOT program to improve driver and pedestrian safety in Middletown, including removing the traffic signals on Route 9 and Miller Street access to the freeway.

The on-ramp’s current configuration has resulted in 319 crashes and 27 injuries between 2019 and 2022.

“Improving the area around Route 9 in

Connecticut Governor

Middletown has been high on my priority list,” Lamont said in a press release from his office. “For far too many years, this has been a notorious spot for congestion and accidents, and the current configuration is the source of many of these issues.

Reconfiguring the Route 17 on-ramp by removing the stop sign and creating an acceleration lane is just one component of improvements on Route 9 in Middletown that we will be making. President Biden’s Bipartisan Infrastructure Law is allowing us to invest in projects like this that will improve traffic flow and increase safety.”

Eucalitto also called the CTDOT effort

critical to improving the safety of drivers through the corridor in Middletown.

“Every construction project of ours is focused on improving the safety of drivers, making it easier to get to wherever you’re traveling,” he said. “The federal infrastructure law passed two years ago allows CTDOT to address the most important roadway and bridge improvements while accelerating our work to make improvements faster.”

From his office, Connecticut senior U.S. Sen. Richard Blumenthal said the interchange “has long been a rampant source of senseless crashes,” while adding that he commended Lamont’s use of the federal funding “to reverse this dangerous trend and make the roads safer for all.”

According to U.S. Representative Rosa DeLauro, whose district includes Middletown, CTDOT has been working with city officials since 2016 to develop plans for the redesign of the Route 17 onramp to Route 9 northbound.

“This project will help reduce congestion, improve both vehicle and pedestrian safety, and increase access to the waterfront,” she explained. “Simply put, this investment will help Connecticut build a better, stronger economy — with more jobs.”

Page 8 • April 26, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

“For

far too many years, this has been a notorious spot for congestion and accidents, and the current configuration is the

source

of many of these issues.”

Ned Lamont

9 Rosenfeld Drive, Hopedale, MA Toll Free# 508-381-3939 • www.theniceco.com We sell NICE machines!

2016 Hyundai HL980, 7000 Hours, 371HP Scania motor, 7.3 Yd Bucket, AC/Rear Camera, Load scale system, Powershift trans., 29.5 R25 tires 75% or better, Well maintained $189,000

Work Ready............ $219,000 2012 CAT D6N XL, 7600 Hrs, Fleet maintained, Heat/AC, 6-way blade, long track frame, grade control system, GPS/UTS ready, mast & cables included, newer sprockets, u/c good..$124,500 2018 Deere 410L, 2600 Hours, Ride Control, Backhoe Pilot Controls, Powershift Trans., 2017 US EPA Label, QC, Diesel Exhaust Fluid Req., Hyd. Coupler,93" Loader Bucket, 24" Backhoe Digging Bucket, Rear Aux. Hydraulics..$99,000 2015 Kawasaki 90Z7, 9700 Hours, 5.5 Yd bucket, QSM11 Cummins motor, Rear camera, Heat/AC, 26.5 R25 tires 65% or better $139,000 2018 Deere 210G LC, 4000 hours, 36” bucket, QC, Hyd. Thumb, Aux hydraulics, Long undercarriage, Heat/AC, Clean Cab, Work ready $164,500 2012 Volvo L70G, 8100 hours, 3 Yard Bucket, QC, Aux. Hydraulics, Heat/AC, New Rear Tires, Runs Good! $79,000 2020 Hitachi ZX135US-6, 1600 Hours, Aux. Hydraulics, QC, 24" Digging Bucket, Dozer Blade, Heat/AC, Work Ready $124,500

2014 CAT 730 Truck, 9400 hours, 6x6, Tires 65% or Better, Rear Tailgate,

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • April 26, 2023 • Page 9 G - 0 0 8 .c aEquipNE lt A • 82) 5 62-2 4 - 0 0 (8 A -2-ALTTA Go LT com

Project to Be Region’s First Building With Engineered Timber

Business boosters in Concord, N.H., are excited about the expansion of biotech firm United Therapeutics in their city, but the corporate hangar it will build at Concord Municipal Airport is exciting for another reason: Glulam. Lots and lots of glulam.

“The entire skeleton and truss system is glulam,” Evan Herron, project manager of Silver Maple Construction of New Haven, Vt., told the Monitor. “We’ve never done anything like it, and I don’t think many have.”

Glulam is a term for wood beams and panels made by gluing together smaller layers of wood, or laminations, into pieces that are big enough and strong enough to replace steel and even concrete in commercial buildings.

It is part of the industry trend toward using engineered lumber — which has several names including mass timber — that combines smaller pieces of wood in novel ways to build large construction projects.

Engineered lumber is still

uncommon, but its use in growing, and around the world it has replaced structural steel and concrete in buildings as tall as 25 stories. At least one commercial building has been built in New Hampshire with engineered lumber, an office block in Portsmouth made with cross-laminated timber, or CLT.

The 210-ft.-long by 170-ft.wide airplane hangar planned at Concord’s airport by United Therapeutics, a Maryland medical research company, will be the first structure of its kind in the area, according to the Monitor. In addition, the hangar will be about 56 ft. from the floor to the peak of the structure’s curved barrel truss.

Engineered Lumber’s Biggest Benefit Is Environmental

The advantages of engineered lumber are partly aesthetic in that it can be shaped in interesting ways and made to be eye-pleasing since it is wood.

But the big benefit it provides is environmental.

Using wood in commercial buildings can lock away tons of carbon contained in the trees and, more importantly, avoids the carbon pollution that would have been generated by making steel or concrete, both of which produce large amounts of greenhouse gases.

Increasing the use of engineered

lumber in commercial and industrial construction is one of the many changes needed to limit future damage from the Earth’s climate emergency, Evans said, adding that is a big reason United Therapeutics is using glulam in Concord.

“They don’t care just about building nice buildings, but environmentally sustainable buildings,” he noted.

The Concord Monitor reported March 27 that Art Massif, the Quebec firm making the glulam beams, estimates it will trap 522 tons of CO2, which it claims is equivalent to removing 104 cars from the road for a year.

Engineered lumber has another advantage for heavily forested New Hampshire. It provides a new market for loggers for those trees that cannot be turned directly into boards.

Costs Are High in Near Term

The big drawback of engineered lumber for the near future

is cost, the newspaper noted. Evans estimated that the glulam structures were about 50 percent more expensive than traditional steel supports. This cost should come down as more manufacturing facilities are built, and as architects and developers become more familiar with using it.

Using engineered lumber may also require changes in how nearby fire departments respond. The product tends to char rather than openly burn like traditional lumber used in home construction but does carry more fire risk than steel supports.

Another novel aspect of the construction, Herron said, is the use of prefabricated wall panels made at Silver Maple’s Middlebury, Vt., factory.

“It’s also a case study in prefabrication,” he said. “It will greatly speed up construction in the field.”

United Therapeutics, through Silver Maple Construction, hopes to break ground on the airport hangar by the end of April.

Burlington, Vt., Project Has Been in Works Since 1960s

PARKWAY from page 1

Avenue. Supporters say the project will alleviate traffic and congestion on neighborhood streets.

“I’m confident that overall, Burlington is moving in the right direction,” Spencer told MyChamplainValley.com, the online news service for WFFF-TV.

He said DPW officials have worked hard to plan the parkway project so that it is easier and safer for everyone.

“What started out as a limited access four-lane, high-speed highway through Burlington is now a 25-mph multi-model street,” he explained.

Better Access Into Burlington Studied Since 1960s

Totaling 2.8 mi. long, the Champlain Parkway Project’s aim in connecting I-189 to Burlington’s south end via a new two-lane multi-modal road also will transform the existing Pine Street into a more efficient and user-friend route, thereby alleviating neighborhood traffic and congestion.

According to the DPW’s Champlain Parkway project page online, in the 1960s, Burlington city planners identified a need to provide access between I-189, U.S. Highway 7/Shelburne Street and the City Center District in response to a study conducted by the Vermont State Department of Highways, which recommended the construction of a Burlington Belt Line.

From there, DPW developed a new highway concept, known as the Southern Connector, to address the need in the 1970s. A portion of the Southern Connector, between I-189 and Home Avenue, was built in the 1980s before the project

was stalled when a segment referred to as the “Pine Street Barge Canal” was declared a superfund site.

Over the past three decades, Burlington’s DPW, in coordination with the Federal Highway Administration (FHWA) and the Vermont Agency of Transportation (VTrans), has transformed the original four-lane freeway concept for the Southern Connector into the current two-lane, low-speed, multi-modal roadway design — now known as the Champlain Parkway.

Multi-Faceted Road-Building Effort

Included in the Champlain Parkway Project construction is a new roadway from the existing I-189 near its intersection with U.S. Route 7 to Lakeside Avenue, and upgrades to Lakeside Avenue and the section of Pine Street between Lakeside and Main Street.

Other improvements throughout the project area include:

• New roadway signage and pavement markings.

• New bicycle and pedestrian accommodations and con-

nections.

• New and upgraded traffic signal equipment.

• Emergency vehicle preemption and transit signal priority.

• Expansion of the stormwater management system.

• Bus bulb-outs and shelters.

• Roadway drainage.

According to Burlington DPW, the parkway project will upgrade traffic circulation, increase roadway capacity to alleviate the overburdened corridor, and improve safety for all users in the southwestern section of town. The work will expand South End connectivity for all users and reduce truck and commuter traffic through the five Avenue neighborhoods.

Once construction gets back under way, the Champlain Parkway will be completed in two phases under a pair of separate construction contracts, which will be executed sequentially.

The initial contract is under way and anticipated to be completed in 2024.

It will include construction of the new parkway road from Home Avenue to Lakeside Avenue — the latter of which will see upgrades — and the section of Pine Street between Lakeside Avenue and Kilburn Street. The first construction season focused on the area between Home and Lakeside avenues.

The final contract will likely begin in 2025 with a 2027 completion. It will see the construction of the Champlain Parkway from I-189 to Home Avenue and upgrades to Pine Street between Kilburn and Main streets.

Page 10 • April 26, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

Once construction gets back under way, the project will be completed in two phases under a pair of separate construction contracts.

A rendering of the 35,683-sq.-ft. hangar planned for the Concord Municipal Airport. SMP Architecture rendering

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • April 26, 2023 • Page 11

Page 12 • April 26, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide CONNECTICUT 410 Burnham St., South Windsor, CT 06074 860-289-2020 MASSACHUSETTS 120 Interstate Dr, West Springfield, MA 01089 413-363-0780 Proud to be your Full Service Dealer • NEW Inventory In Stock! WHY CHOOSE ABLE TOOL and EQUIPMENT... • Local Ownership with flexible approach • Trained staff for repairs and maintenance • Dedicated Parts personnel on site • Focused on the Heavy Construction Industry • Providing the BEST support equipment available • Experienced outside sales staff Sales • Service • Parts • Rentals abletool.net • RTLX Trench Rollers • Reversible Plate Compactors • Light Towers (LED & Halide) • Battery Equipment • Concrete Equipment (Vibrators Internal & External, Battery Backpack Vibrator) • Wheel Dumpers DW30 Wheel Dumper LTV4L Light Tower DPU5545 Reversible Vibratory Plate ACBe Modular Battery-Powered Internal Vibrator RTLx-SC3 Trench Roller aggregates and more soils, capable of screening – Scalper 77C ent or own. to r vailable ommels a Tr eens and Mobile Scr mulch and compost. process topsoil, – ideal for skid steers to Might II sand and gravel. soils, designed to separate rock, – double deck, yder 516T Sp product separation. – perfect for two Scapler 107D technical support. Complete exceptional durability American Made Grade 80 steel for ® compost and green waste – separates topsoil, rommel 612T Tr AlbanyBinghamtonB NY: BuffaloCampbellRochesterSy Worceste Woburn MA: yracuse s Bus Women’ e are a Certified W 585.202. See what we can do Hartford CT: er com monroetractor iness. 2067 for your job-site! TION SINCE 1966 T AMERICAN-MADE INNOVA Albany Binghamton B Buffalo Campbell Rochester Sy

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • April 26, 2023 • Page 13 316 Market Street Fort Kent Mills, ME 04744 207-834-3171 491 Lakewood Road Madison, ME 04950 207-858-4748 Frank Martin Sons, Inc. fms-equipment.com NOW YOUR AUTHORIZED HITACHI DEALER FOR MAINE Toll Free 844-307-2596

Portland OKs Construction of Hotel Next to City Hall

The city planning board in Portland, Maine, approved plans for a 179-room hotel Feb. 14 as part of a major redevelopment of the block on Congress Street just east of City Hall.

The Portland Press Herald reported that board members voted unanimously to approve a site plan for the hotel, which makes up Phase I of the Herald Square project at 385 Congress St. The initial phase of the project also includes nine condominiums on the upper floors of the building and 75 parking garage spaces.

“I think this is a really good project and I look forward to it being built,” Portland Planning Board Chair Maggie Stanley told the news outlet.

The proposal came with conditions, including the stipulation that Fathom Companies, a local real estate firm building the hotel, also submit a handful of updates and finish a public access easement for a pedestrian plaza prior to getting a building permit.

Jim Brady, president of Fathom, which also operates the Press Hotel across Congress Street, said it is too soon to say when construction might start.

“I don’t have a timeline yet,” he replied when questioned by the Press Herald prior to the Feb. 14 meeting. “We’re just finalizing

the site plan approval and will see how things progress to the next steps. It will not be any time within the next six months.”

During the public comment period of the Portland Planning Board meeting, only one person spoke about the project.

“This block needs more street level retail, more green space and more activity,” said Myrtle Street resident Avery Yale Kamila. “The project proposes to add all three. My family and I support this project. I welcome more people in the neighborhood and welcome the project.”

The as-yet unnamed hotel, which will be

located at the corner of Congress and Myrtle streets, is planned to be 12 stories, and occupy a space that previously housed the Press Herald’s printing operations but is now used for private parking.

The city’s inclusionary zoning requirements mandate that hotel projects either build a certain number of low-income housing units based on the number of rooms they will have or pay a fee-in-lieu-of to Portland’s affordable housing trust fund.

Brady told the Portland news source that Fathom plans to pay the fee-in-lieu-of, adding that it would work out to about $700,000 in fees for the hotel’s 179 rooms.

Hotel Just One Part of Larger Redevelopment

The downtown hotel is meant to be one component of a multi-phase redevelopment of the block between Cumberland Avenue and Congress Street, and Myrtle and Pearl streets.

According to a development plan approved last August, the total project will include three attached buildings, including the hotel, 297 condominiums, seven retail units totaling about 11,500 sq. ft., a 5,100sq.-ft. restaurant, recreation space, and more than 330 parking spaces.

It has previously been estimated to cost

$200 million to $300 million total, the Press Herald noted.

Reger Dasco Properties in Portland is the developer behind other phases of the project that will include two condo buildings that have yet to be approved by the planning board. Brady said it has not been determined whether the hotel or the condos will be built first.

Traffic Movement Study Needed Before Construction

In a related matter, the Portland Planning Board also unanimously approved a traffic movement permit for the overall hotel development effort, which is required by the state for any project that generates 100 or more passenger car equivalents at peak hours, the Press Herald reported.

A traffic study conducted by South Portland’s Sebago Technics estimated that together, the hotel, condos and commercial space would generate 119 trips per hour during peak morning hours and 124 trips per hour during peak evening hours.

The permit was approved with several conditions, including upgrades to traffic signals, sidewalks and intersections and that a traffic monitoring program be implemented after the hotel opens to study valet operations and parking.

Page 14 • April 26, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

“I think this is a really good project and I look forward to it being built.”

Maggie Stanley Portland Planning Board

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • April 26, 2023 • Page 15

YEARS STRO

Y

Since 1923 dhidkfC All Rights Reserv © 2023 Caterpillar (845) 733-640 783 Bloomingburg Bloomingburg, NY illdbdihii TERPILLAR, LET’S DO THE WORK, their re T T, ved. CA , CA (718) 863-3 v Bronx, NY 1 0 Road 12721 699 Brush A 844-CAT ill ellow , the “P spective logos, “Caterpillar Corporate Y (631) 758-7 LIE (Exit 660 Union A NY Holtsville, 800 venue 0465 -1923Power Edge” and Cat “Modern 500 62) venue 11742 Y 1 Poughkhkeeps 122 Nox (845) 4 rn Hex” trade dress as we sie, NY12603 xon Road 52-1200 Newin 225 R (86 ell as corporate and product identity ngton, CT 06111 Richard Street 0) 666-8401 used herein, are trademarks of Caterpillar and may not be used without perm ss on. www .com.caterpillar .cat.com / www

equipment and s with the highest forged a legacy i of our local comm Since 1923, H.O. upport we provide ensu level of uptime and prod n providing Contractors unities. The people of H Penn has been building res the bridges are .Theuctivity within the region .O. Penn have the very foundation 100

while we celebr ork and Co New

e are committe W scheduleandsk schedule, and sk completed on tim NG. ate H.O. Penn nnecticut strong, ed to keeping kyscrapersreachnewhe kyscrapers reach new he e, new roadways are op eights ened ahead of

Project Team Overcomes Foundational Design Challenges

STAMFORD from page 1

320-ft. pedestrian bridge over Washington Boulevard connecting the garage to the Stamford Transportation Center (STC), elevators and stairs connecting the garage to the Track 5 platform, 38 electric vehicle parking spaces, more than 100 bike storage spaces, a centralized STC parking management space and customer counter, a unique architectural design and façade lighting program, building-integrated photovoltaics for on-site energy production, minor STC renovations at the pedestrian bridge connection, pedestrian crossing improvements at South State Street and Washington Boulevard and connectivity to the planned Mill River Greenway.

The project, financed 100 percent by the State of Connecticut, is being completed under CTDOT’s Alternative Project Delivery program.

“The project is replacing the aging original parking garage structure for the STC [currently located on Station Place] with a low maintenance, long service life facility that meets the demand for state-owned commuter parking spaces located proximate to the STC,” said Michael Mendick, CCM, district engineer, CTDOT. “It addresses the poor condition and continued degradation of the original garage structure that precipitated the closing of two levels of the garage to traffic and parking; satisfies existing commuter parking demands; replaces the loss of private commuter parking supply for the STC with stateowned and maintained parking spaces that provide similar convenience and commuter amenity as the existing private parking facilities; and meets customer expectations for availability, accessibility, and convenience of commuter parking accommodations of the STC.”

The new garage will provide a net increase of approximately 600 state-owned spaces following the demolition of the original 1987 garage.

Parking has been maintained in the original parking garage structure throughout construction of the new to help

Yonkers Contracting Company Inc. started work on the Connecticut Department of Transportation’s (CTDOT) $77.2 million, design-build Stamford Station Parking Garage project

minimize commuter parking impacts.

“The original garage will be closed upon completion of the proposed garage and will be demolished in the future under a separate construction contract,” said Mendick. “The department previously pursued a new parking project for the STC as part of a transit-oriented development [TOD]. The current project is not a TOD project.”

Traffic-wise, the construction has led to temporary detours and short-term lane closures to facilitate operations.

The rectangular-shaped concrete garage is adjacent to the highway. As of February, for the garage itself, the precast

concrete erection is complete; and structural steel installation for the elevators, support steel installation for the architectural facade, office space construction, building systems installations and site work are ongoing.

For the pedestrian bridge, pier construction is complete, steel structure is being fabricated off site, and the erection of the steel structure is planned to begin in May. Station renovations are ongoing.

Development of the design-build project, via Walker Consultants, began in June 2021.

“Some of the engineering challenges were the geotechnical and ground conditions,” said Tim Caulfield, Yonkers project manager. “The foundations had to be into rock, but the rock elevations varied from 40 feet deep on the west side to 6 feet deep on the east side. The challenge was coming up with the correct foundation design. There was no blasting. We drilled 42-inch diameter shafts through earth and rock. In some areas, we put the foundation directly on the rock without drilling into it. Basically, the garage has two different foundation designs.”

The garage, which has an anticipated lifespan of 75 years, consists mostly of precast concrete panels, and was designed to minimize any cast-in-place concrete.

“We are using GRFC panels at the three stair towers, glass on the one elevator tower and metal baskets around the rest of the garage to complete the architectural look,” said Caulfield.

With six months to go to completion, the location of the work site remains a challenge.

“The northside is adjacent to I-95, one of the busiest highways in the country,” said Caulfield. “And on the southside is the railroad that serves one of the busiest train stations in the country. If that’s not enough, there is an active roadway and sidewalk underneath the construction. There’s no room to store material or much of anything. The project is very close on schedule and the DOT understands our work conditions."

see STAMFORD page 22

With six months to go to completion, the location of the work site remains a challenge.

Page 16 • April 26, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

Equipment used for the installation of the garage includes excavators, front-end loaders, excavators and dozers, mostly Cat models.

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • April 26, 2023 • Page 17 Barry Equipment Co., Inc. F&W Equipment 164 Boston Post Road Orange, CT 06477 203-795-0591 www.fwequip.com Central Equipment Company 45 Dempsey-Greaves Lane Stillwater, ME 04489 207-827-6193 www.centralequipmentco.com www.barryequipment.com 30 Birch Island Road Webster, MA 01570 508-949-0005 7 Harry’s Way Webster, MA 01570 508-949-0005 1608 John Fitch Blvd South Windsor, CT 06074 860-288-4600 Equipment East, LLC www.equipmenteast.com 61 Silva Lane Dracut, MA 01826 978-454-3320 196 Manley Street Brockton, MA 02301 508-484-5567 1474 Route 3A Bow, NH 03304 603-410-5540

Gov. Tours Infrastructure Port Upgrades

Rhode Island Gov. Dan McKee took a tour April 6 of ongoing construction work to upgrade the infrastructure at the Port of Davisville’s Pier 1, located on the west side of Narragansett Bay near its mouth.

He was joined by James Diossa, the state’s general treasurer, and Quonset Development Corporation (QDC) Managing Director Steven King to inspect the work.

McKee and the General Assembly allocated $60 million in American Rescue Plan Act (ARPA) funding to the port in 2022 to assist in the development of Rhode Island’s only public port, continuing Davisville’s evolution as a key hub for the offshore wind industry in the North Atlantic.

As part of the initiative, the World War II-era Pier 1 is being revitalized as part of Quonset’s $234.5 million Port of Davisville Master Plan. The overall efforts include replacing thousands of wooden pilings which have been in Narragansett Bay supporting Pier 1 for more than 80 years with new concrete and steel pilings.

“The Port of Davisville is a jewel

in the state of Rhode Island’s economy,” McKee said following the tour.

“I was encouraged to see our ARPA funds at work today, modernizing Pier 1 at the Port of Davisville. I am confident that our continued investment at Davisville will keep Rhode Island moving forward by upgrading the resources we already have in place.”

Continuing infrastructure improvements as part of the Port Master Plan will position Davisville to stay within the top 10 auto importers in North America, he noted, while expanding capabilities for offshore wind.

The governor also was briefed on other components of the port’s proposals, including construction of a new multi-purpose pier at Terminal 5 and a new docking space to support crew transfer vessels and support offshore vessels for offshore wind construction projects and landside improvements.

“Today’s visit to Quonset’s Port of Davisville exhibited the innovation happening all across Rhode Island — especially as it relates to the offshore

wind industry,” Diossa said. “When we invest in infrastructure our state remains competitive, supply chains are strengthened, and communities are equitably uplifted.”

In his comments, King added, “Our continued infrastructure upgrades at the Port of Davisville will make Rhode Island a leader in the offshore wind industry. We appreciate the consistent support of our partners in state and federal government for their continued advocacy and support of [the state’s] economy here at Quonset.”

The Port of Davisville supports nearly 1,700 jobs and generates $98.9 million in household earnings for Rhode Island families, in addition to $374.3 million in business output annually. The port also brings in $45.5 million in total state tax revenue as well as $10.5 million in local taxes.

Built in 1941, Pier 1 at the Port of Davisville has increased its annual imports by 745 percent over the last 20 years.

The new project to upgrade its infrastructure aims to extend the pier’s life by another 50 years.

Page 18 • April 26, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

Onsite or Quarry • Making aggregates since 1983 Call us today ROCK CRUSHING • (860) 491-2283 GOSHEN, CT www.FAYWRIGHTINC.com

PORTABLE ROCK CRUSHING

Northeast Regiona Evvent |Ma 17–19 (Wed–Fri) 8 am

Equipment includes Excavators, wheelloaders, backhoes, dump trucks, skid steers, compactors, lowboys& much more.

Online bidding foormation

▸No minimum bidsor reserve prices

▸It'salwaysfree to register and bid online in anyofour auctions, create your accountnow!

Location

275 Rte. 32, North Franklin, CT

More items added daily

Callaboutselling: 817.237.6544

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • April 26, 2023 • Page 19 F Feeatured Equippment A Avvailable at North Fra updates inventory atest o see the l t ode an the QR c Sc Y anklinCT Yaard anklin, CT

Mack CL733 Elite

1 of 4 – 2022 Cat 262D3

1 of 2 – 2020 Hyundai HL940A

2017 LeeBoy 8515

2022 Hyundai HX130A LCR

2019 Caterpillar 918M

2019 Hyundai HL940TM

V VeermeerD330X500

T

inf

l

equipment

fullauction & t listings at rbauction.com/North-East Auction Company Bond #0470724, Auction Company License # 001348

2015 Pitts LB55-24D 55 Toon

y

E

See

Page 20 • April 26, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

CONSTRUCTION AUCTION

DAVIS AUCTIONS, INC.

SATURDAY, May 13, 2023 9:00 A.M.

LOCATION: 210 CHESHIRE ROAD, RT. 68, PROSPECT, CT

Davis Auctions, Inc. will be conducting our next auction of utility and construction equipment and related supplies on May 13, 2023. This auction will consist of excess equipment from the power companies, municipalities, and others to be sold in absolute. Please call about consigning through May 6.

Early Consignments: EQUIPMENT

Excavator: (2) 2022 AGROTK QH12 Mini; Skid Steer Loader: JCB 260; NEW HOLLAND LS140;

Wheel Loader Backhoe: (3) 2005 JOHN DEERE 310SG; 2004 JOHN DEERE 310SG;

Crane: PETTIBONE Multikrane 30 15 Ton, dsl, 4 outriggers

Dozer: INTERNATIONAL TD8;

Wheel Tractors: (2) JOHN DEERE 5203, w/sickle bar mowers, 3PtH; KUBOTA BX25 w/Backhoe & Loader, full cab, 4x4; MASSEY FERGUSON 374, 3PtH, 59 hp; Skid Steer Attachments: Snow Blowers; Sweepers; Trenchers; Mowers; Hammers; Cement Mixers; Rakes; Vib. Rollers; Grapples; Augers w/2 bits; Forks; Tillers; Sweepers, w/buckets; 3 PtH Set ups; Woodchippers; Graders; Plates; Shears; Buckets;

Misc.: WACKER NEUSON LTV6 Light Plant; MOBIL SWEEPER II, JD Diesel; MITSUBISHI 15 Forklift; Excavator Buckets; Manlift, electric; (3) 750,000 BTU Boiler, trailer mtd; DRY AIR Hose Reel, trailer mtd.; ¾ yd. Dumping Hopper; ¼ yd. Dumping Hopper; 10’ Forks; Tipping Dumpsters;

VEHICLES

Bucket Trucks: 2006 INTERNATIONAL 4400, w/50’ material handler; (2) 2005 INTERNATIONAL 4400 w/material handler; (2) 2012 RAM 5500 w/Altec AT37G Squirt Boom; Dump Trucks: 2002 STERLING L7500; 1995 FORD LN9000 Dump Truck w/plow frame & cover, 10 spd.; 1993 FORD LN9000, 9 sp.; 2012 FORD F150XL SD Dump w/ Fisher 8'6" V Plow, pintle hitch, 5.7 L Powerstroke turbo diesel; Utility Trucks: 2015 CHEV. Express w/Knapheide Utility Body; Misc. Vehicles: 2015 CHEV. 2500HD Crew Cab, w/side boxes, Tommygate lift gate, Fisher 7.5' Stormguard Plow, 4x4; 2004 FORD F250 w/plow, 4x4; 2002 FORD F250 w/plow, 4x4; 2001 MITSUBISHI FH211 Rack Body, w/2V manlift; 1999 GMC C8500, Allison Auto; 1998 INTERNATIONAL 8100 Tiltbed, w/Jerr-Dan Body; 1991 FORD Conventional; 1989FORD L8000 Vac Truck, diesel; 2012 INTERNATIONAL PB105 School Bus, Maxxforce 7 diesel engine;

Pickups: 2012 GMC Canyon SLE Ext. Cab, 4x4; 2012 GMC Canyon, w/toolbox. 4x4; 2010 FORD F350, 4x4; 2010 CHEV. Colorado Ext. Cab, w/hard top tonneau cover, 4x4; 2010 CHEV. Colorado w/toolbox, 4x4; 2005 GMC Sierra, 4x4; 2002 TOYOTA Tacoma, 4x4; Cars/SUV: 2014 JEEP Patriot, 4x4; 2011 CHEV. Volt 4 dr; 2011 FORD Escape, 4x4; 2011 SUBARU Legacy, 4wd; 2010 HONDA Accord 2 dr.; 2005 CADILLAC Escalade; 2004 VOLVO XC70;

Vans: 2014 CHEV. Express 2500; (2) 2014 NISSAN NV200 w/shelving; (2) 2013 CHEV. Express, w/shelving, Stabilitrack AWD; 2012 GMC Savana; 2012 CHEV. Express, w/shelving, Stabilitrack AWD; 2011 CHEV. Express; 2011 GMC Savana;

Trailers: (3) 2003 EAGER BEAVER 12HA Lowbed; 2006 EAGER BEAVER 15 ton; 2000 FRUEHAUF DA5 24 Box; 1989 WITZ RG35; 1989 FRUEHAUF FB6-F2-45-96 Box; 1985 EAGER BEAVER HA; INTERSTATE 20T T/A Trailer; (3) 2005 KENSINGTON K6URE Material; (2) 2002 KENSINGTON K8RE Reel; (2) 2002 HOGG DAVIS T150 Reel; 1997 KENSINGTON K8RE Reel;

Campers: 1972 EVEREST 40’ Motorhome, 892 Detroit dsl; Allison 5 spd; Storage Containers: (4) 40’ Storage Container w/ 4 doors; 9’ Container w/door & window; 8’ Container w/door & window;

Portable Buildings: (3) Portable Bathroom w/ shower; (2) Portable Bathroom w/2 Stalls; Stone: (3) Pallets- 12x12x1.5” Variegated Thermal Pattern; (3) Pallets- 12x18x1.5” Variegated Thermal Pattern; (2) Pallets- 18x18x1.5” Variegated Thermal Pattern; (2) Pallets- 18x24x1.5” Variegated Thermal Pattern; (2) Pallets- 12x24x1.5” Variegated Thermal Pattern; (2) Pallets- 18x30x1.5” Variegated Thermal Pattern; (15) Pallets- 2” Bluestone Patio Kits; (14) Pallets- Patio Stone Pavers; (2) Pallets- 2” Thermal Pattern; (2) Pallets- 1”-2” Snapped Colonial Wall Stone; (2) Pallets- 2” Tumbled Pavers; (Pallet- Blue ¾” Decorative Stone; (3) Pallets- 16x48x6” Thermal Steps; Pallet; 16x60x6” Thermal Steps; (4) Pallets- 2” Thermal Treads; Electrical Supplies: (6) Pallets- Panel Brackets; Misc. Pipe Connections; (6) PalletsFiberglass Fittings; (3) Pallets- Metal Fittings; (2) Crates- PVC Elbows; Large Reel Inner Ducts; (2) Pallets- 90° Pipe; Pallet- Anchors; Pallet- Spacers; Pallet- 1” Conduits; (2) Bags- PVC Fittings; Crate- Spacers; (2) Pallets- Cable Trays; Pallet- Fixtures; (3) WheelsCoax Cable; Ridged Pipe; 1” PVC Conduit; PVC Ridged Coded Pipe; Normal PVC Pipe; (2) Pallets- Ridged 45° Pipe Elbows; (14) Pallets- Misc. Electrical Equipment; (2) PalletsStrain Insulators; (2) Bundle- 20’ Fiberglass Pipe;

Canopy Storage Shelter: (2) 20x40x6’6”; (2) 30x20x12; 20x20x6’6”; Misc.: 2017 KNAPHEIDE PCCR-12DA Utility Body; 2006 MARCO Sand Blaster; YAMAHA Blaster ATV; POLARIS 340 Snowmobile; (5) Dirt Bikes; Compressor w/(2) Jack Hammers; Water Pumps; Chain Hoist; Scaffolding; Jaws of Life; Snow Blowers; Mowers; Generators; Rototiller; Leaf Blowers; Roof Racks; Drill Press; Table Saw; Tool Box; Plate Compactors; Road Saw; Truck Mtd. Electric Crane; Pallet- Chain & Cable; Snowplow; Gas Engine; Chainsaws; Welders; Circular Saws; Nail Guns; Truck Bed Fuel Tank; Power Washers; Siding; Tire Balancer; Tire Changer; Air Compressors; Cement Mixer; Jumping Jack; 6’ Steel Worktables; Road Signs; Toolboxes; Anvil; Pallet- Rope; (2) Stackable Tool Carts; Concrete Stamps w/colors; (2) Bull floats; Tampers; Large Quantity of Unused Items from Home Depot- Tools, Fixtures, Etc.

Inspection: Friday, May 12- 8:00 am to 5:00 pm

Online bidding will be available through Proxibid. Please register for online bidding a minimum of 24 hours before sale.

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • April 26, 2023 • Page 21 Call for more information: AUCTIONEER: DAVIS AUCTIONS, INC. REGINALD LUSSIER (203) 758-4087 or 1-800-201-4368 LYNDONVILLE, VT 05851 www.davisauctionsinc.com NH LICENSE #2413

Sale

Buyer’s Fee

Good

Card &

Terms: 10%

Payment: Cash,

Checks, Credit

Certified Checks

NEW ENGLAND SUPPLEMENT ADVERTISER INDEX

Crews Relocate Every Existing Utility Within Project Footprint

Utilities have been an issue.

“We had to relocate every existing utility within the footprint of the garage, including water, sewer, fiber optics,” said Caulfield. “We also had to relocate the storm drain system including a five-foot diameter main truckline that was 25 feet below street elevation.”

Day shifts are the norm, with some work being done on Saturdays.

The garage itself, which has been put together over 16 weeks, required approximately 800 pieces of precast concrete. They were delivered by truck and lifted and placed using a 330-ton capacity crane.

“They were connected by welding metal plates together and holes for anchor bolts,” said Caulfield. “But precast can’t solve all the issues. The garage had to be smooth to drive on and also for rainwater to be controlled into the drainage system.”

Structural steel was installed for the elevator shaft and it has been painted with fireresistant paint.

“We are in the process of installing glass and the roof at the elevator tower,” said Caulfield. “The challenge of the shaft was building within a short distance of the railroad’s electrical power infrastructure. We’re working with the railroad and informing it of our schedule. On many occasions, they would shut the power in those areas so we could work. We have very good relations with the Metro North Railroad.”

Equipment used for the installation of the garage includes excavators, front-end loaders, excavators and dozers, mostly Cat models.

The installation of the support steel installation for the architectural facade is ongoing, but the location presents challenges, including the road leading to the garage.

“It is very difficult to install the architectural treatment around the building,” said Caulfield. “It’s hard to get cranes and other pieces of equipment in close proximity to the work. So instead, we chose mini-cranes that go on the roof of the garage. We also use the garage roof as an area to store material.”

The new office space is located on the ground floor of the garage. Electrical, plumbing, HVAC and other services are being installed now.

“This work should be completed in the next few months,” said Caulfield.

The installation of the pedestrian bridge should be finished by late June. The pier construction was completed in January.

“There are three cast-in-place piers,” said Caulfield. “We placed the concrete with the

anchor bolts placed at the correct elevations. The bridge is about 320 feet long and it’s going to come in six large pieces. Blue Atlantic from Massachusetts is currently fabricating and delivering the bridge. A crane will set each piece and then it will be connected together as we erect it.”

It should take a week to build the bridge, with the pieces shipped and lifted immediately.

The Yonkers management team is working with many partners.

“Our design firm has a lot of people working on the project,” said Caulfield. “We have a lot of people from the engineering firm on site. Our staff has worked on many projects. The efforts of the crews are good. The guys in the field are union employees and we work with the unions for the laborers, carpenters, iron workers and operating engineers. We have our engineers working with the crews and our staff procures the materials and has them delivered. It requires a lot of coordination to build a facility like this.”

Peak days have approximately 50 people on site, with major subcontractors being McPhee Electric for all the electrical work, MJ Daly for the plumbing and HVAC work and Blakeslee for precasting and erecting the garage structure.

Work activities should generate 25,000 tons of earth and rock. For the most part, materials cannot be recycled on site.

“Some of the earth that is excavated goes to a temporary stockpile off site where it is tested,” said Caulfield. “Whether it is contaminated, hazardous or non-hazardous, it goes to licensed facilities that handle it.”

In terms of new materials, 20,000 cu. yds. of concrete, 1,000 tons of steel, 3,000 tons of asphalt and 5,000 tons of subbase will be used.

Additional equipment being used includes dirt and asphalt rollers, asphalt paving machines, mostly manufactured by Cat.

“We have our own mechanic that is on site every day,” said Caulfield. “If we are using excavators or cranes and something goes wrong, the mechanic is there to fix it. The crews don’t have a lot of down time. Every piece of equipment is checked daily. For the most part we use our own equipment.”

Yonkers purchases and rents equipment from dealerships such as H.O. Penn in New York.

“They are always ready to rent or sell us any piece of equipment that we need,” said Caulfield. “A lot of times on a construction site, early on, you don’t know when the need arises for a specific piece of equipment that will be right for the job.”

(

Page 22 • April 26, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide

CEG

All photos courtesy of

CTDOT.)

STAMFORD from page 16

The Advertisers Index is printed as a free editorial service to our advertisers and readership. Construction Equipment Guide is not responsible for errors or omissions. ABLE TOOL & EQUIPMENT..........................................12 ALTA EQUIPMENT COMPANY/NITCO LLC................1,9 BARRY EQUIPMENT CO. INC.......................................24 CHADWICK-BAROSS INC..............................................11 DAVIS AUCTIONS INC..................................................21 DOOSAN NORTHERN NEW ENGLAND......................17 EQUIPMENT EAST........................................................1,5 FAY & WRIGHT EXCAVATING INC..............................18 FOLEY INC - WORCESTER............................................1 FRANK MARTIN & SONS INC......................................13 GORILLA HAMMERS........................................................1 H O PENN MACHINERY CO INC..................................15 HEAVY MACHINES INC..................................................7 J R VINAGRO CORPORATION........................................1 M G EQUIPMENT............................................................1 MONROE TRACTOR & IMPLEMENT............................12 RITCHIE BROS. AUCTIONEERS..................................19 ROGERS BROTHERS CORPORATION........................23 SHAWMUT EQUIPMENT CO INC..................................18 T-QUIP SALES & RENTAL INC......................................14 THE N.I.C.E. COMPANY..................................................8 THE W. I. CLARK COMPANY..........................................2 TIBBITS EQUIPMENT SERVICES INC............................1 TYLER EQUIPMENT CORPORATION............................3

Construction Equipment Guide • New England States Supplement • www.constructionequipmentguide.com • April 26, 2023 • Page 23 The Ultimate in Trailers® ROGERS BROTHERS CORPORATION ALBION, PA Over a CENTURY of building the very best heavy-duty trailers for your hauling needs! Contact your local dealer for a quote today. TRAILERS TO MEET EVERY HAULING CHALLENGE! Committed to building superior quality, reliability and durability into every trailer. Tyler Equipment www.cn-wood.com 200 Merrimac St. Woburn, MA 01801 (781) 935-1919 140 Wales Ave. Avon, MA 02322 (508) 584-8484 3 Rocky Hill Road Smithfield, RI 02917 (401) 942-9191 C.N. Wood Co., Inc. www.tylerequipment.com 251 Shaker Road East Longmeadow, MA 01028 (413) 525-6351 • (800) 292-6351 Parts: (877) 255-6351 1980 Berlin Turnpike Berlin, CT 06037 (860) 356-0840 • (800) 352-4473 Parts: (860) 356-0848

Page 24 • April 26, 2023 • www.constructionequipmentguide.com • New England States Supplement • Construction Equipment Guide ©2021 Hyundai Doosan Infracore. All rights reserved. Hyundai Doosan Infracore is an affiliate of Hyundai Heavy Industries Group. The Doosan trademark, , is used under license from Doosan Corporation. Doosan® -7 Series wheel loaders are loaded with technologies and new performance features to help you get more work done today and in the future. EQUIPPED FOR TOMORROW. POWERED BY. INNOVATION. Schedule a demo today. barryequipment.com WEBSTER 508-949-0005 30 Birch Island Road Webster, MA WEBSTER 508-949-0005 7 Harry’s Way Webster, MA SOUTH WINDSOR 860-288-4600 1608 John Fitch Blvd. South Windsor, CT

AUTHORIZED DOOSAN DEALER