By Irwin Rapoport CEG CORRESPONDENT

Sundt Construction started work on several sections of the city of Lewisville, Texas, Corporate Drive project in spring 2024 and is on track to finish in the winter of 2027.

Sundt secured the $69.6 million contract in 2023, which is being financed by local and federal funds.

“Plans for Corporate Drive began more than a decade ago,” according to a Sundt project page.

“Divided into two projects, Segments 2 & 3 and Segments 4 & 5, the roadway will create a continuous east-west thoroughfare that spans across the Elm Fork of the Trinity River.

“Although two separate projects, Sundt is managing the projects as one to provide consistency and continuity to the City. The extension of Corporate Drive will transform the connectivity of the region, offering a critical new link for Lewisville residents and businesses.”

Key elements include a new 15,500-ft. four-lane concrete roadway, 5-ft. wide sidewalk and 12-ft. wide trail enhancements, substantial drainage and water improvements, retaining walls and two bridges — a 178-ft. long single-span channel bridge and a 2,010-ft. long bridge over the Elm Fork of the Trinity River and the 100-year floodway.

see LEWISVILLE page 59

By Lucy Perry CEG CORRESPONDENT

In July, the White House announced its action plan for winning the global AI race. Innovation, infrastructure and international diplomacy are named pillars of the administration’s plan to push AI development and deployment.

Near-term goals are set and implementation actions are recommended.

The AI Age is good news for

civil contractors who specialize in site prep and pre-construction. Under its pillar to accelerate AI innovation, the Trump administration calls for reduced red tape and onerous regulation, among many other changes in policy.

EQ TIONPLU QUA USPOWE ALS ER excavation, g

Whether it's large-scale

Sonsra PR ayoffersa OG rangeofC GRES CASEdoze S rmodels toughest jobs.

DOZER to tackl fine grading, w e the e have the reduced

Cabde suitab Cab de Advanc noise, and exc signproideac le for vario sign provide a c cedGPSandtele ay offers a ellent visibility. comfortableo us applica comfortable wo ematicssystem range of C sallowfor rkingenironm tions. rking environmme

CASE doz ent, r models

Easy m accura nents. intenance acc e grading and ced GPS and tele ess points to ke leveling. ematics system ey s allow for

compo

2019 John Deere 750K LGP, Stk#: HR-13327, EROPS, A/C, AM/FM Radio, 6,496 hrs., 6 Way Blade, 28" Pads $169,500

lbs., Trailer Mounted. Lots to chose from $5,500

2023 John Deere 130P, Stk#: HR-1435, EROPS, A/C & Heat, Radio, 1,465 hrs., 36" Bucket w/Hyd Thumb, 28" Pads, Rear View Camera $159,500

2023 John Deere 75G, Stk#: HR-1466, EROPS, A/C & Heat, Radio, 1,157 hrs., 23" Bucket, 91" Blade, 17" Rubber Pads $89,500

2017 Doosan 185CFM, Stk#: HR-13670, 3,074 hrs., 125 PSI, 2,700 Eng. RPM, Weight 2,325 lbs. $12,500

2021 John Deere 450K LGP, Stk#: HR-1232, OROPS, 6 Way Blade, 2,278 hrs., 24" Pads, 9' 7" Wide $79,500

2023 John Deere 35G, Stk#: HR-1469, OROPS, 764 hrs., 16" Bucket, 68" Blade, 12" Rubber Tracks $48,500 2007 Cat 740, Stk#: HR-12885, EROPS, A/C & Heat, Radio, 14,784 hrs., with Tailgate, 6 Way Drive, 42 Ton Cap., 29.5Rx25 Tires @ 90%, 10' 6 Wide ..............................$139,500

2017 Gehl RS6-34, Stk#: HR-1625, 6,000 lbs., 34 ft., 2,224hrs., 4WD $39,500

2018 Snorkel S3219E, Stk#: HR-13655, 550 lbs., 19 ft., 3,501 hrs., Electric Power $4,250

JCB North America is making progress on its $500 million manufacturing facility in San Antonio, Texas, reinforcing its commitment to United States manufacturing and the region’s construction and agriculture equipment industries.

Grand Sierra Resort (GSR) broke ground on Sept. 30, 2025, on a new 10,000-seat arena, the first phase of the property’s $1 billion redevelopment project — the largest private capital investment in Reno’s history.

Related Digital was joined on Oct. 7, 2025, by Wyoming Gov. Mark Gordon, Cheyenne Mayor Patrick Collins, CoreWeave, Clayco, Black Hills Energy and others at the groundbreaking of a new $1.2 billion data center.

A symbol of engineering excellence and mining innovation, the shovel has been relocated from Milwaukee, Wis., to serve as a monument to the legacy of P&H Mining Equipment and it’s long history of manufacturing in the United States.

20 ECO MATERIAL TECHNOLOGIES RELEASES SUSTAINABILITY REPORT

The report highlights progress in reducing the environmental footprint of the industry through innovation, large-scale fly ash utilization and the expanded use of domestic materials as sustainable alternatives to traditional cement.

Founded in December 1956, Industrial Tractor Parts (ITP) can trace its roots to Cesar Mevorah, who emigrated from Bulgaria to the United States in the 1940s. In Europe, he had developed expertise in tractor parts.

28 WYO. TRANSPORTATION COMMISSION AWARDS NEW HIGHWAY CONTRACTS

At its October regular business meeting, the Wyoming Transportation Commission awarded seven contracts valued at approximately $38 million for Wyoming Department of Transportation construction projects.

28

The Wyoming Department of Transportation and its contractor, Croell Inc., began working on the westbound lane of Interstate 90 in late March 2025, focusing on repairing five slope failures along a 6-mi. stretch of shoulder.

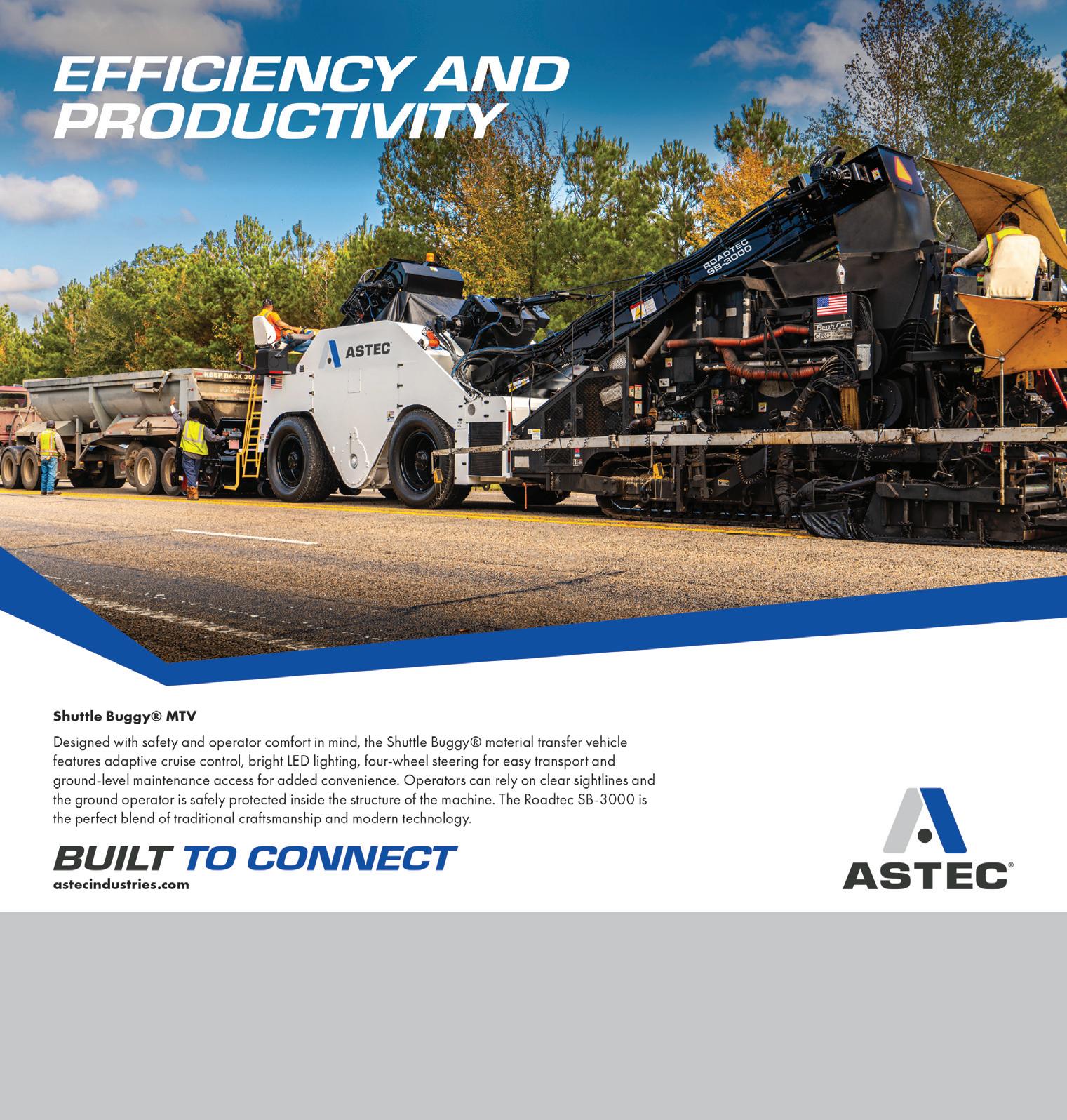

32 EFFICIENT TECHNOLOGIES MEET QUALITY DEMANDS HEAD-ON

Project completion deadlines in road construction are tight, especially when they involve the construction or rehabilitation of busy arterial roads. At the same time, contracting authorities demand the very best in paving quality.

36 NIGHT-TIME INSTALLATION AT GERMAN FAIRYTALE CASTLE

In order not to disrupt visitor operations at Neuschwanstein Castle, work could only be carried out at night. The contractor therefore opted for the Vögele Paver Super 1800-5 X with the integrated light package plus.

48 CIVIL ENGINEERS’ SALARY GROWTH OUTPACES OVERALL U.S. WORKFORCE

Civil engineers are in demand, and salaries in the profession are rising, as professionals take advantage of a job market where their skills are needed, according to the 2025 ASCE Civil Engineering Salary Report released ASCE.

48 ARTBA ELECTS CAT GROUP PRESIDENT ANTHONY FASSINO ITS

Anthony (Tony) D. Fassino, group president, construction industries, Caterpillar Inc., was elected 2025-2026 chair of ARTBA. The announcement was made during ARTBA’s national convention, held Sept. 28-Oct. 1 in Dallas, Texas. 50 USACE TULSA DISTRICT AWARDS TWO CONSTRUCTION CONTRACTS

The U.S. Army Corps of Engineers, Tulsa District (USACE) awarded a construction contract to build a software integration lab at Tinker AFB, Okla., on Sept. 30, 2025.

Re-powering a mobile machine with a Tier 4 Final engine is a cost effective way to achieve a second life for your equipment while meeting CARB emissions standards.

At Smith Power Products, Inc. we understand the rigors of off-highway diesel engines and mobile machinery. Which is why our industrial products are designed to meet these tough everyday standards. We emphasize performance and reliability to provide you with a product that maximizes your production and profitability.

Our re-power capabilities cover a vast range of mobile machinery and our years of experience has taught us that proper installation is a key component in the second life of a machine.

All of these re-powers were completed using FPT and MTU Tier 4 Engines which DO NOT USE DPF technology!

➡ Less costly than buying a new machine

➡ Maintain or improve machine performance

➡ Makes good business sense

Over 400 machines successfully re-powered by the most skilled shop in the Western US! Tier 4 Final solutions featuring:

• Industry leading fuel economy

• Rugged heavy duty design

• Bosch electronic controls • Industry leading & Patented SCR emission control system • NO DPF!

JCB North America is making significant progress on its $500 million manufacturing facility in San Antonio, Texas, reinforcing its commitment to United States manufacturing and the region’s construction and agriculture equipment industries.

The facility, located on a 400-acre site, is expected to create 1,500 jobs and will serve as a hub for producing JCB’s telehandlers and mobile elevating work platforms. The project, the single largest investment in the company’s 80-year history, remains on schedule, with hiring set to begin in late 2025 and production launching in mid 2026. An open house was held on Oct. 16, 2025.

In April, JCB announced an increase in the size of the San Antonio facility, bringing the total footprint to 1 million sq. ft. This expansion reflects JCB’s continued confidence in the U.S. market and supports the company’s strategy to increase production closer to customers, improve delivery timelines and reduce supply chain risk.

“This expansion highlights our longterm commitment to U.S. manufacturing,” said Richard Fox-Marrs, CEO of JCB North America. “The decision to grow our presence in San Antonio is not only about bricks and mortar. It’s about delivering value to our customers, strengthening our supply chain and investing in the future of American industry.”

Since the groundbreaking in June 2024, JCB has made rapid progress on site preparation and infrastructure.

The architectural design is being led by RVK, a women-owned firm with a track record in commercial and industrial projects. R&S Excavation Ltd. completed mass grading, and Ella Contracting led utility work. More than 1 million tons of dirt and 119,000 tons of select fill were moved, and nearly 19,300 linear ft. of sewer, water and storm lines were installed.

“The efficiency and expertise demonstrated by our site development teams have been outstanding,” said David Carver, operations director, JCB San Antonio. “Their work has built a strong foundation for what will be a world-class manufacturing facility.”

With foundational work complete, vertical construction has now begun on the production and office buildings. Texas-based Joeris General Contractors is leading the next phase of development.

“Joeris is proud to partner with JCB on a project that powerfully reflects our mission of transforming people and places,” said Burton Hackney, president of Joeris General Contractors. “This facility is more than just a building — it’s a sign of what’s possible for San Antonio’s future.”

JCB has begun hiring key roles in San Antonio and is focused on building a workforce from the local community and veteran populations.

“JCB is deeply committed to the local workforce and creating meaningful career pathways,” Carver said. “Through education partnerships and a focus on veterans, we’re building a team that reflects our values and the community we’re joining.”

“What remains clear is JCB’s continued and growing investment in San Antonio, Texas and the broader U.S. market,” Fox-Marrs added. “This expansion strengthens our U.S. footprint and supports our customers with faster delivery and greater production capacity.”

(All photos courtesy of JCB North America.)

Honolulu (Oahu): 808-839-7202

Wailuku (Maui): 808-244-9158

Hilo: 808-935-8595

Kailua-Kona: 808-326-1212

Lihue (Kauai): 808-245-8472

Belgrade: 406-388-5815

Billings: 406-245-3188

Great Falls: 406-452-9551

Casper: 307-472-1818

Rock Springs: 307-362-4000

Grand Sierra Resort (GSR) broke ground on Sept. 30, 2025, on a new 10,000-seat arena, the first phase of the property’s $1 billion redevelopment project — the largest private capital investment in Reno’s history.

Martin-Harris Construction of Las Vegas is the project’s contractor.

“We’ve been building in Nevada for nearly 50 years, and delivering on a client’s trust has always been at the heart of what we do. Being part of this next chapter for Reno means a great deal to our team. We’re proud to partner with GSR and the Meruelo Group to deliver a project our entire community can take pride in,” said Guy Martin, president of Martin-Harris Construction, in a previous news release.

The event drew more than 500 civic leaders, university officials and community partners, underscoring its significance for Northern Nevada.

The milestone ceremony featured arena renderings, a ceremonial shovel dig and celebratory cold sparks and confetti. Speakers included GSR owner Alex Meruelo, University of Nevada President Brian Sandoval, Athletics Director Stephanie Rempe and Reno Mayor Hillary Schieve.

“This project represents a transformative moment for Reno and northern Nevada,” Meruelo said. “Our investment reflects not only our commitment to this community, but our belief in its future as a premier destination for sports, entertainment and hospitality.”

The $435 million GSR Arena will span 300,000 sq. ft., feature premium hospitality clubs, suites and a central plaza, and serve as the future home of Nevada men’s basketball. Designed to seat more than 10,000 guests, it is expected to

host about 95 events annually upon completion in fall 2027.

“Today’s groundbreaking is a major milestone in the continued rise of Nevada Athletics and our basketball programs,” Rempe said. “This state-of-the-art facility will deliver an unmatched homecourt experience for our studentathletes, our fans and the entire Northern Nevada community. The GSR Arena is a powerful example of what’s possible when our community comes together with purpose — and we’re proud to partner with the GSR and Alex Meruelo to bring this transformational project to life.”

“This groundbreaking signals a new era for northern Nevada and our University,” Sandoval said.

“When completed, the Grand Sierra Resort Arena will become our region’s most compelling entertainment and sports venues while providing Wolf Pack Athletics with a dazzling home court that will be second to none. We are proud to partner with Grand Sierra Resort, the city of Reno and our community in sharing this monumental moment in northern Nevada and the University of Nevada’s storied history.”

According to Hunden Partners, the city of Reno’s consult-

ant, the arena and related development are projected to generate $850 million to $1.135 billion in direct economic impact, with as much as $1.34 to $1.8 billion in benefits over 28 years.

The arena is the first step in GSR’s decade-long redevelopment plan, which also includes a 2,800-space parking garage, a new community ice center, the reimagined Grand Bay aquatic golf facility, a fan-centric central plaza and future housing and hotel expansion.

Related Digital, a vertically integrated data center development and investment platform, was joined on Oct. 7, 2025, by Wyoming Gov. Mark Gordon, Cheyenne Mayor Patrick Collins, CoreWeave, Clayco, Black Hills Energy, other development partners and local officials at the groundbreaking of a new $1.2 billion data center.

The event marks the first phase of a 115acre campus in the Cheyenne Business Parkway with up to 302 MWs of critical IT capacity.

Clayco will serve as the construction manager, and Black Hills Energy will serve as the electric service provider for the initial phase.

CoreWeave will be the anchor tenant through a long-term lease for 88 MWs of critical IT capacity. Recognized as the essential AI cloud across industries, CoreWeave provides high-performance compute purpose-built for training, inference and other AI workloads. The first data center building will occupy 184,000 sq. ft. on 36 acres and is expected to be completed in late 2026. Phase I of the development is expected to generate more than $250 million in tax revenue to the state of Wyoming and the city of Cheyenne in its first 15 years of operations and create more than 700 construction jobs

and 40 well-paying, permanent jobs. To preserve Wyoming’s precious water resources, Related Digital’s Cheyenne project will use high-efficiency air-cooled chillers, and the project will require only nominal water consumption, primarily for domestic use.

“Welcome to Wyoming Related Digital. Today’s groundbreaking gives us the opportunity to celebrate our Cowboy State probusiness culture and extend warm regards to Related Digital,” Governor Gordon said. “Companies that bring jobs, invest in our communities and use innovation offer smart growth opportunities and will always have a home here in Wyoming. Related’s high-efficiency, air-cooled technology is remarkable — using only nominal water primarily for domestic use — avoids putting strain on our precious water resources.”

“The exponential growth of data centers is providing a powerful new economic engine to states like Wyoming, who are helping lead the way in keeping America competitive in the global AI race,” said Jeff T. Blau, CEO of Related Cos. "I want to thank Gov. Gordon, Mayor Collins, Clayco and of course our partner CoreWeave for coming together to begin development of this site, which will create meaningful tax benefits for the city and state, bring hundreds of new construction jobs, support Cheyenne’s small businesses and create the digital infrastructure our country needs."

“We’re delighted Related Digital has chosen Cheyenne as the location for their new data center and I’m happy to welcome them to our city,” Collins said. “I appreciate the collaboration between Related Digital and our local partners as we plan for the future. Cheyenne is a great place for businesses to locate, and this project will provide benefits to our community for years to come.”

Komatsu announced the arrival of a P&H 2100BL electric rope shovel to serve as a landmark at its Elko, Nev., campus. A symbol of engineering excellence and mining innovation, the shovel has been relocated from Milwaukee, Wis., to serve as a monument to the legacy of P&H Mining Equipment and that company’s long history of manufacturing in the United States.

The P&H 2100BL, manufactured in 1979, has played a significant role in mining operations for more than four decades. Now standing prominently in front of the Elko facility, the machine is as tall as a five-story building and weighs more than 1 million lbs. Its visibility from Interstate 80 makes it a striking testament to the industry’s progress and the impact of Komatsu’s equipment in the mining sector.

“The P&H 2100BL electric shovel is a remarkable piece of engineering. Its journey from Milwaukee to Elko marks a significant moment in our company’s history,” said Tom Suess, Komatsu’s vice president and general manager of United States mining distribution. “This machine will now be prominently displayed in front of our Elko facility, symbolizing the evolution of mining technology, the enduring legacy of P&H Mining Equipment, and Komatsu’s deep connection to and pride in being part of the Elko community. We are excited to share this iconic shovel with the community and celebrate its past and future contributions to the industry.”

Komatsu’s Elko service center is a regional hub for mining and construction support. Since initiating development of the site, Komatsu has invested a total of $57 million to build and expand the facility in response to customer needs.

The service center, which opened in 2019, is equipped to service haul trucks, hydraulic shovels, electric rope shovels and other mining support equipment.

In 2023, Komatsu further reinforced its presence in Elko with the addition of a 50,000-sq.-ft. warehouse, enhancing parts availability for local mining and construction operations.

The arrival of the P&H 2100BL monument underscores Komatsu’s commitment to honoring its past while continuing to advance mining technology. The community is invited to visit and experience this historic machine up close, offering a unique opportunity for families and industry professionals alike to appreciate the evolution of mining equipment.

For more information, visit komatsu.com.

At

Niece 8,000 gallon water tanks

installed on 40 ton Articulated Off Highway chassis. This combination is the workhorse of the dust control and water needs for quarries and large construction sites

The NWT9500 9500 Gallon water tank mounted on articulated truck. Pictured: Deere 460E with 9,500 gallon tank. Tanks come with 6X5 pumps.

The NFL3000 Off Road, Fuel and Lube Bed offers 3,000 gallons of diesel fuel.

The NFL10000 Fuel & Lube Can be mounted on any 100,000 lb rigid frame truck. Holds 10,000 gallons of diesel. 5 additional fluid tanks. Holds up to 3,000 gallons of oil.

Eco Material Technologies Inc. released its 2024 sustainability report, detailing the company’s environmental and social impact across its operations.

The report highlights significant progress in reducing the environmental footprint of the construction industry through innovation, large-scale fly ash utilization and the expanded use of domestic materials as sustainable alternatives to traditional cement.

Cement manufacturing is responsible for nearly 8 percent of global carbon emissions. Eco Material’s sustainable SCMs — including fly ash and proprietary Green Cement products — now displace more than 5 percent of total United States cement consumption annually, resulting in more than 5.5 million tons of avoided CO₂e emissions in 2024 alone.

Other key highlights from the Eco Material 2024 report include:

● 6.2 million short tons of fresh fly ash and bottom ash diverted from landfills;

● 467,806 tons of harvested legacy ash put to beneficial use;

● 73,292 tons of Green Cement produced, avoiding more than 65,000 tons of CO₂;

● more than 2 billion gal. of water use avoided by using fly ash; and

● 20 percent of fleet replaced with fuelefficient trucks, cutting operational emissions.

“Our mission is to build a greener world by rethinking what’s possible with construction materials,” said Grant Quasha, CEO of Eco Material Technologies. “We’re proving that domestic fly ash is not only a powerful climate solution, but also a resilient and scalable one. The infrastructure trans formation is already under way, and we’re proud to be leading it.”

As the construction industry recognizes the benefits of using alternatives to imported cement and carbonintensive building materials, Eco Material’s products offer a domestic, scalable solution. The company’s proprietary cement technologies — PozzoSlag and PozzoCem — can replace up to 100 percent of ordinary portland cement (OPC) in select applications, without compromising and often improving performance. These innovations are enabling a transition

toward near-zero emissions concrete while also reducing water usage, with more than 2 billion gallons of water use avoided in 2024 through SCM substitution for OPC.

Eco Material operates at more than 125 sites across 42 states, serving more than 5,000 unique customer locations with more than 1,100 employees — 14 percent being women compared to the national average of 10.9 percent in the construction industry. Its expanded logistics footprint and recent investments in fuel-efficient transportation have further reduced operational emissions.

In 2024, the company replaced 20 percent of its heavy truck fleet with more sustainable alternatives and reported a Total Recordable Incident Rate (TRIR) of 0.83, remaining below the industry average and demonstrating a strong commitment to workplace safety and health.

The company’s SCMs are already playing a critical role in high-profile infrastructure projects across the country. This includes the Gross Reservoir Expansion in Colorado,

where Eco Material supplied 90,000 tons of fly ash for what will become the tallest roller compacted dam in the United States.

In California, Eco Material’s fly ash was used in the John Madden Football Center at Cal Poly, helping reduce the carbon footprint of the new LEED-targeted facility. In Texas, the company’s PozzoCem H-65 green cement was successfully deployed in the plug and abandonment of a historic oil well, demonstrating novel applications for its cement technologies in the energy sector.

Looking ahead, Eco Material remains focused on doubling its annual volumes of recycled material to 20 million tons by 2030. The company’s vision aligns with the United Nations Sustainable Development Goals (SDGs), particularly SDG 9 (Industry, Innovation and Infrastructure) and SDG 12 (Responsible Consumption and Production). Its commitment to emissions transparency and circular resource use positions Eco Material as a key partner in the transition to climate-resilient infrastructure and lower-carbon construction practices. For

Founded in December 1956, Industrial Tractor Parts (ITP) can trace its roots to Cesar Mevorah, who emigrated from Bulgaria to the United States in the 1940s. In Europe, Mevorah had developed expertise in tractor parts during an era when mechanized farming and tracked machines were becoming more common.

Forced to flee Eastern Europe during World War II, he arrived in New York City with little more than knowledge of the trade and the determination to start anew.

To support his family, Mevorah initially imported a wide range of goods — including Bulgaria’s famed roses and fragrances — until he could bring his wife and daughter to America. The family eventually spent time in Fargo, N.D., where Mevorah established his first warehouse and began importing tractor parts in earnest. Later, he returned to Queens, N.Y., where in December 1956, Industrial Tractor Parts was formally founded.

The business began with a small New York office and a Brooklyn warehouse. Mevorah focused on importing quality tractor and crawler parts and distributing them across the region, laying the foundation for a

company that would span generations.

Industrial Tractor Parts has welcomed Larry Gindville as the new general manager of its Illinois branch. Gindville, a seasoned equipment industry professional, brings more than two decades of dealer-side leadership experience to the company.

Gindville’s career began in the contracting world before he transitioned to dealerships in 2001. He has held key leadership roles, including vice president and general manager with both Volvo and Komatsu dealer groups, overseeing multiple locations across Wisconsin and the Upper Peninsula.

Gindville said his focus will be on “expanding growth” by strengthening customer relationships, improving inventory and expanding the territory this branch can serve.

“We’re a stocking distributor, which sets us apart from competitors who act as middlemen,” he said.

Gindville emphasized that his goal is to continue branding Industrial Tractor Parts in the market as a trusted source for undercarriage and parts, highlighting its nearly 70-year history and longstanding role as a Berco stocking distributor. With his addition — and a growing team in Illinois — Gindville sees significant potential to serve customers across Illinois and surrounding states.

Following Mevorah’s passing, the next generation — his son-in-law — took the reins. In the 1960s, he forged what would become a defining partnership. Traveling to Italy, he met with Berco, already a well-regarded name in the undercarriage industry. With little money in hand and his Italian routes, he asked Berco’s leadership to extend credit and trust. Berco agreed, providing containers of parts on consignment — an extraordinary show of faith at the time.

That trust paid off. With Berco’s product line behind it, Industrial Tractor Parts quickly established itself as a premier aftermarket supplier. By the mid-1960s, shipments were coming into New York and a second branch in New Orleans, fueling rapid growth.

For decades since, Berco has remained central to ITP’s business, with its signs displayed proudly at every ITP warehouse.

Nearly three years ago, the company welcomed its fourth generation of fam-

ily leadership with the arrival of Jack Sitzer. Bringing a fresh perspective and forward-looking mindset, Sitzer has quickly made an imprint on the organization while continuing to learn from the third generation, his two uncles, whose decades of experience provide both guidance and continuity. Sitzer’s leadership has not only carried forward ITP’s long-standing tradition of quality and service, but also accelerated its modernization and expansion efforts.

One of his first major initiatives was the implementation of a new ERP system, creating efficiencies across operations and strengthening the company’s ability to scale. Alongside this, he has overseen the recruitment of several new hires, building a stronger team equipped to support growth and innovation. Sitzer is also spearheading a complete redesign of the company’s website, with integrated e-commerce capabilities currently in development and slated to launch in early 2026. This will provide customers with faster, more seamless access to ITP’s extensive product catalog and enhance see ITP page 26

www.cpower.com

9200 Liberty Drive

Liberty, MO 64068

816-781-8070

Wichita, KS

316-943-1231

Great Bend, KS

620-792-1361

Liberal, KS

620-624-7274

Woodward, OK

580-256-6014

Salina, KS

785-825-8291

Colby, KS

785-462-8211

Springfield, MO

417-865-0505

Joplin, MO

417-726-5373

Riverside, MO 816-415-6787

Wichita, KS

316-789-7370

Yukon, OK 405-324-2330

Maryland Heights, MO 314-427-4911

Liberty, MO 806-415-6700

Tulsa, OK 918-984-6565

With the federal government’s seal of approval, centers continue to be designed and built across the country.

That drive to lead the AI infrastructure race creates many opportunities not only for building contractors but for contractors whose focus is earthwork and site prep. Depending on the scale of the facility, this pre-construction phase can be a considerable undertaking, according to construction software provider Autodesk.

“The site is levelled and cleared to prepare it for construction, then excavations for footings, utility and infrastructure placement begin,” it said.

“Construction begins on sub-floors, and electrical grounding grids are laid to protect equipment,” added Autodesk in a blog post.

Site development contractor Muller said the demand for reliable data storage and processing has skyrocketed in recent years. Businesses, government agencies and institutions all rely on data centers to power their operations, the company noted.

As the foundation of the digital economy, data centers require meticulous planning and construction to ensure long-term reliability and performance, it said.

“Building a data center is a complex endeavor that involves multiple considerations.”

That includes every phase, “from site selection to utility installation, and from erosion control to regulatory compliance.”

The size of the digital facility determines the intensity and detail of the pre-construction phase. A chosen site is leveled and cleared for footings, utility and infrastructure placement.

Whether the project is for a co-location, cloud or enterprise data center, defining the type and purpose of the facility early on is essential, said the contractor.

“Is it meant to serve a local region, a specific company or a global network? Will it need to expand in the future to accommodate growing storage demands?”

The ideal data center should meet both current and future requirements, said Muller. A critical part of this process involves determining the scalability needs.

This process also should ensure that the design can accommodate growth without disrupting the data center’s operations, it said.

“Additionally, compliance with standards for security, energy efficiency and environmental impact is essential, particularly for government and military projects.”

Budgeting is a crucial part of any construction project, but data centers require special attention due to their scale and complexity, said the company.

A provider of equipment to contractors who specialize in site prep work, Sunbelt wrote in a blog post that new data centers are more than just big buildings.

“They have redundant HVAC systems designed to keep everything cool and dry and backup generators to keep things running in case of a power failure.”

Companies have to factor the effects of climate change into the design and location of new AI centers, Sunbelt continued.

Can it be cooled if average temperatures rise? Must the structure be hardened against extreme weather? Is there reliable, long-term

The North American “hyperscale” data center market is set to grow from $9 billion in 2022 to more than $20 billion in 2025, according to Sunbelt Rentals.

water and power?

“These are questions that affect every phase of construction from design to commissioning,” wrote Sunbelt in a walk though of data center construction phases.

The company suggests that planning helps in ensuring stakeholders have what they need to keep the project on schedule and within budget.

“The first step in any successful data center project is clearly defining the data center design and construction objectives,” said Muller. “This involves understanding the scope of the project, the expected future capacity, and the necessary compliance and security standards.”

“Balancing the budget with the long-term operational needs of the data center facilities is essential to ensuring that the project remains sustainable and efficient over time.”

Choosing the right location for a data center is one of the most critical factors for longterm business success, said Muller.

The site, it said, must meet specific requirements to ensure the data center’s smooth operation and ability to handle expansions.

“A data center requires more than just a large plot of land,” said Muller. “You need to evaluate the proximity to power sources and fiber networks.” see AI page 26

As AI expansive data centers become more visible in communities across the country, contractors are staying busy.

In Louisiana, the Richland Parish Data Center project is taking shape with the help of drones outfitted with innovative scanning technology.

Mortenson Construction addressed the issue of underground hazards, including high-pressure gas lines and abandoned wells with the technology. The MagArrow Scan technology uses drones equipped with advanced sensors to detect abnormalities in the earth’s magnetic field.

“This bold, new approach allowed the team to locate metal objects deep underground, such as gas lines and old wells,” said Mortenson.

These structures might not be documented or easily found through traditional locating methods, the construction company explained.

“The accuracy of the scan was a lot more detailed than I thought it was going to be,” said Brian Nelson, senior superintendent II.

According to Mortenson, the scan not only uncovered this hidden gas line but also validated the locations of old irrigation and gas wells.

The irrigation and gas wells were previously inaccurately mapped, so the precision of the scan significantly narrowed down these locations.

Mortenson said it acts as a vital safety check, preventing accidents that could seriously endanger team members and disrupt projects.

“In addition to the scan, the project also employed innovative solutions,” said the construction contractor.

Bridges were installed to allow large equipment to safely traverse over gas lines without applying pressure directly over the gas line.

The pressure could have caused disruptions to the

gas lines, resulting in leaks or more catastrophic events.

Mortenson said the scan gave the team the precise location to place the bridges.

Jopy Willis, Mortenson general superintendent, described the bridges as multifaceted.

“We’re using them not only to navigate over gas lines but also to cross wetlands, ensuring that our logistics remain efficient and safe.”

The drone scanner’s ability to detect these hazards is not just about safety; it's about efficiency and accuracy, added Mortenson.

“By identifying these underground features, construction teams can plan their projects with greater confidence.”

That’s because these teams know they won't inadvertently hit something dangerous underground.

“This proactive approach to safety and planning is a testament to our team’s commitment to innovation and the well-being of its workers.”

apcoequipment.com North Las Vegas, NV 702-871-7474

scottequip.com

Fontana, CA 800-316-0327

Santa Fe Springs, CA 562-777-0775

Temecula CA 951-355-3085

ttjequipment.com Jasper, TX 409-384-4611

Longview, TX 903-803-3365

Lufkin, TX 936-634-3365

cpower.com Midland, TX 432-248-8344

San Antonio, TX 210-591-6807

Corpus Christi, TX 361-737-0049

Oklahoma City, OK 405-324-2330

Tulsa, OK 918-984-6565

Woodward, OK 580-256-6014

stewartandstevenson.com Albuquerque, NM 505-881-3511

Denver, CO 303-287-7441 El Paso, TX 915-790-1848

Lubbock, TX 806-745-4224

Wichita Falls, TX 940-322-5227

During the site survey and engineering phase, reference points and markers will be staked to guide the construction of everything on the data center site.

“The work starts with existing conditions, including the terrain, structures ad aboveand below-ground infrastructure,” said Sunbelt.

The local climate also is a factor, said the site developer, Muller. Zoning laws, permits and environmental regulations also can impact site selection.

Once a site has been selected, proper site development is critical to ensuring a strong foundation for the data center.

In the excavation, grading and erosion control phase, these crews will remove, add, shape and compact soil and prepare it for the foundation.

“That could require a perfectly level base or one with a set slope,” noted the Sunbelt blog post. “Once complete, the general contractor brings in … onsite power and gets ready for pipe and utility line installation.”

Erosion control is a vital consideration for any construction project, but for data centers site stability and regulatory compliance are key concerns, said Muller.

The federal government’s goal of leading the AI infrastructure pack means many opportunities for contractors whose focus is earthwork and site prep.

“Without proper erosion control, stormwater runoff can wash away soil, destabilize the foundation, and introduce contaminants into the local ecosystem.”

This can threaten both the integrity of the data center facility and the surrounding environment, said the firm.

“Effective erosion and sediment control

measures can prevent costly damage and ensure compliance with environmental regulations.”

Further, data centers depend on access to a robust network of utilities, including power, water and high-speed data connections.

“Utility installation is one of the most critical steps in the pre-construction phase,” said the company.”

Data centers require large amounts of electricity to power both servers and cooling systems. Water may be needed for the cooling system, and reliable fiber networks are essential for data transmission. That’s why both wet and dry utility installations are necessary to support the operations of a data center, said Muller.

Utility installation affects power, gas and water lines as well as underground cables and sewage pipelines.

A site utility contractor can determine the exact location, depth and layout of any existing infrastructure.

“They keep the worksite safe while overseeing electrical and plumbing contractors, who install additional underground utilities,” said Sunbelt. “The grading contractor ensures surfaces are level in preparation for pouring the foundation.”

The type of structure to be supported, the soil it will lay on, bedrock depth and environmental risks become critical factors in foundation design.

“Ultimately, a combination of concrete and steel below keeps the structure above stable,” said Sunbelt. CEG

their overall purchasing experience.

Operational expansion has been another hallmark of his leadership. Sitzer directed the completion of a new warehouse in St. Augustine, Florida, extending ITP’s reach in the Southeast and reinforcing its ability to deliver quickly across key markets.

He has also driven initiatives around greater branding on parts and products, aligning with his broader vision of strengthening ITP’s identity as not only a trusted distributor, but also an emerging brand in its own right.

Sitzer’s early tenure represents more than just incremental improvements—it marks the beginning of an overall modernization strategy for ITP. From technology upgrades and infrastructure investment to brandbuilding and talent development, his initiatives have positioned the nearly 70-year-old family enterprise for its next phase of growth.

While these changes are already reshaping the company, they represent just the start of Sitzer’s long-term impact on the future of Industrial Tractor Parts.

From past to present to future, a key differentiator for ITP remains its refusal to compromise on quality. The company partners only with manufacturers it has trusted for decades, often testing products in the field before widespread adoption. These strong supplier relationships — built over 20 years or more — enable ITP to respond quickly to issues, collaborate directly with factory leadership, and continually ensure the highest standards.

From Mevorah’s first warehouse in Fargo to today’s ninewarehouse national network, the company has stayed true to its roots as a family-driven enterprise. With global partnerships, a service-first culture, and renewed leadership, ITP looks forward to many more successful decades ahead.

From the 1960s through today, ITP’s core product line has remained consistent: undercarriage parts for dozers, loaders and excavators. The catalog covers:

• Track chains

• Track shoes

• Bottom and carrier rollers

• Sprockets and segment groups

• Idlers

• Rubber road liners for asphalt and street work

• Rubber tracks

• Ground engaging tools

• Track adjusters and assemblies

Each of ITP’s nine warehouses is equipped with a track press, allowing custom assembly of track groups for machines as large as a D8 or D9 class crawler.

While many of ITP’s customers have historically been independent repair shops — especially in the 1980s and 1990s — the company also supplies OEM dealers. According to ITP, what sets it

apart, beyond price, is service. The company prides itself on answering the phone at any time of day, providing in-depth research for obscure parts, and sourcing components globally when needed.

As one example, a Pennsylvania customer required a hard-to-find idler unavailable in North America. ITP tracked it down through a long-standing Italian supplier, imported it and delivered it within six weeks — something the customer could not have achieved without ITP’s global connections.

Today, Industrial Tractor Parts maintains nine strategically placed warehouses to serve contractors, repair shops and dealers across the United States. They are:

• Long Island City, N.Y.

• New Orleans, La.

• Dolton, Ill.

• Scarborough, Maine

• Houston, Texas

• Tulsa, Okla.

• Memphis, Tenn.

• Latrobe, Pa.

• St. Augustine, Fla.

These locations allow ITP to respond quickly to demand across key markets.

While undercarriage remains the cornerstone, ITP is steadily expanding into ground engaging tools (G.E.T.), including bucket teeth, adapters and pins as well as rubber tracks. The company acknowledges this segment is complex and requires careful buildout, but early investments are already paying off, according to ITP. Additionally, ITP is beginning to introduce its own house brand of products under the ITP label — providing customers with another trusted alternative alongside Berco and other manufacturers. The long-term goal: establish ITP as not just a distributor, but also a brand in its own right. CEG

(All photos courtesy of Industrial Tractor Parts.)

Motorists traveling between the Montana state line and Ranchester, Wyo., will notice the road is a little smoother than it was a year ago.

The Wyoming Department of Transportation and its contractor, Croell Inc., began working on the westbound lane of Interstate 90 in late March 2025, focusing on repairing five slope failures along a 6-mi. stretch of shoulder.

A slope failure happens when the underlying soils, commonly clay, become overly saturated and lose their “sticky” factor and give way to gravitational pull. Most of these clays are sitting on a shale base, offering little to no resistance for the clay to adhere to. The soil becomes too heavy and follows the path of least resistance and falls away from the slope, encroaching into the shoulder of the highway and potentially into the lane of travel.

In addition to the slope repair work completed, WYDOT milled and overlayed 6 mi. of the westbound lane and was able to complete paving of just over 2 mi. of the eastbound lane — originally scheduled to be completed next year. Two bridges were removed and replaced with box culverts, and the Parkman Exit bridge decks were repaired.

Year two work, scheduled for 2026, will include realigning approximately 4 mi. of the eastbound lane from mile marker 3.9 to 8.0. This realignment is required to accommodate multiple slope failures that have been encroaching on the shoulder for several years. Two additional bridges will be removed and replaced with box culverts within the realignment road section.

To repair these slopes, the contractor cut away the failing soils, created benches and backfilled those benches with scoria. The lightweight scoria allows moisture to drain through the slope without becoming saturated. Contractors removed more than 180,000 cu. yds. of failed soil and replaced that with more than 170,000 cu. yds. of scoria at these locations.

Jake Whisonant, District 4, Sheridan resident engineer, was pleased with the amount of work Croell was able to complete this year.

“The contractor and their subs moved through year one’s scope efficiently and were also able to complete some additional paving of the eastbound lane to this year, which will lighten up the remaining schedule,” he said.

Work is anticipated to start back up in March of 2026, weather permitting.

At its October regular business meeting, the Wyoming Transportation Commission awarded seven contracts valued at approximately $38 million for Wyoming Department of Transportation construction projects.

The commission awarded a bid valued at approximately $15.4 million to Cheyenne, Wyo.-based JTL Group Inc. for a mill and overlay project involving asphalt paving, aggregate surfacing, grading, traffic control, structure and milling work on approximately 11.9 mi. on the eastbound lane of Interstate 80 beginning at mile marker 199.05 between Rawlins and Creston Junction in Carbon County. The contract completion date is Oct. 31, 2026.

The commission awarded a bid valued at approximately $8.5 million to Montana-based Riverside Contracting Inc. for an overlay and wearing course project involving asphalt paving, traffic control, milling, grading, structure and signing work on approximately 6.3 mi. on the east- and westbound

lanes on I-80 just west of Lyman in Uinta County. The contract completion date is Oct. 31, 2026.

The commission awarded a bid valued at approximately $4.9 million to Cheyenne-based Reiman Corp. for a bridge replacement project involving structure, grading, asphalt paving, traffic control and aggregate surfacing work on approximately .5 mi. on County Road 1A in Weston County. The contract completion date is Nov. 30, 2026.

Reiman Corp also was conditionally awarded a bid valued at approximately $500,000 for a structure removal project involving grading, traffic control and seeding/erosion control work on County Road 210 near Cheyenne. The completion date is June 30, 2026.

The commission awarded a bid valued at approximately $765,000 to South Dakota-based Highway Improvement Inc. for a project involving crack sealing and traffic control work on approximately 52 mi.

on Wyoming Highway 28 in Sublette and Sweetwater counties. The contract completion date is May 31, 2026.

Highway Improvement also was awarded a bid valued at approximately $700,000 for a project involving crack sealing and traffic control work on approximately 89 m. at various locations in Albany, Carbon and Laramie counties. The contract completion date is April 30, 2026.

All the above projects are funded primarily with federal dollars.

Funded primarily with state dollars, Sundance, Wyo.-based Croell Inc. was awarded a bid valued at approximately $7.2 million for a mill, overlay, reconstruction and chip seal project involving aggregate surfacing, asphalt paving, grading, traffic control, fencing, stormwater drainage and chip seal work on approximately 5 mi. on Wyoming Highway 120 and Wyoming Highway 170 beginning at mm 4.21 between Thermopolis and Meeteetse in Hot Springs County. The completion date is June 30, 2027.

www.PacWestMachinery.com

8207 South 216th Street

Kent, WA 98032 206-762-5933

Mount Vernon, WA 360-588-3083

Portland, OR 503-252-5933

Eugene, OR 541-302-3762

Spokane Valley, WA 509-534-5933

Pasco, WA 509-547-5933

1519 W Belt Line Road Carrollton, TX 75006 214-819-4100

Austin, TX 512-388-2529

Carmine, TX 979-278-3570

Ft. Worth, TX 817-626-2288

Houston, TX

713-937-3005

Longview, TX 903-758-5576

Midland, TX 432-234-9409

San Antonio, TX 210-648-4600

Corpus Christi, TX 361-881-4891

Mercedes, TX 956-565-0100

Stephenville, TX 254-266-2871

12320 S. Main Street

Houston, TX 77035 713-723-1050

1720 Hicks Street Tomball, TX 77375 281-351-9016

2077 N. Craig Drive Buffalo, TX 75831 903-322-7150

8903 Memorial Blvd Port Arthur, TX 77640 409-721-5305

5732 S MacArthur Drive Alexandria, LA 71302 318-408-3099

7502 Pecue Lane Baton Rouge, LA 70809 225-800-3711 125 E Airline Hwy Kenner, LA 70062 888-974-0532

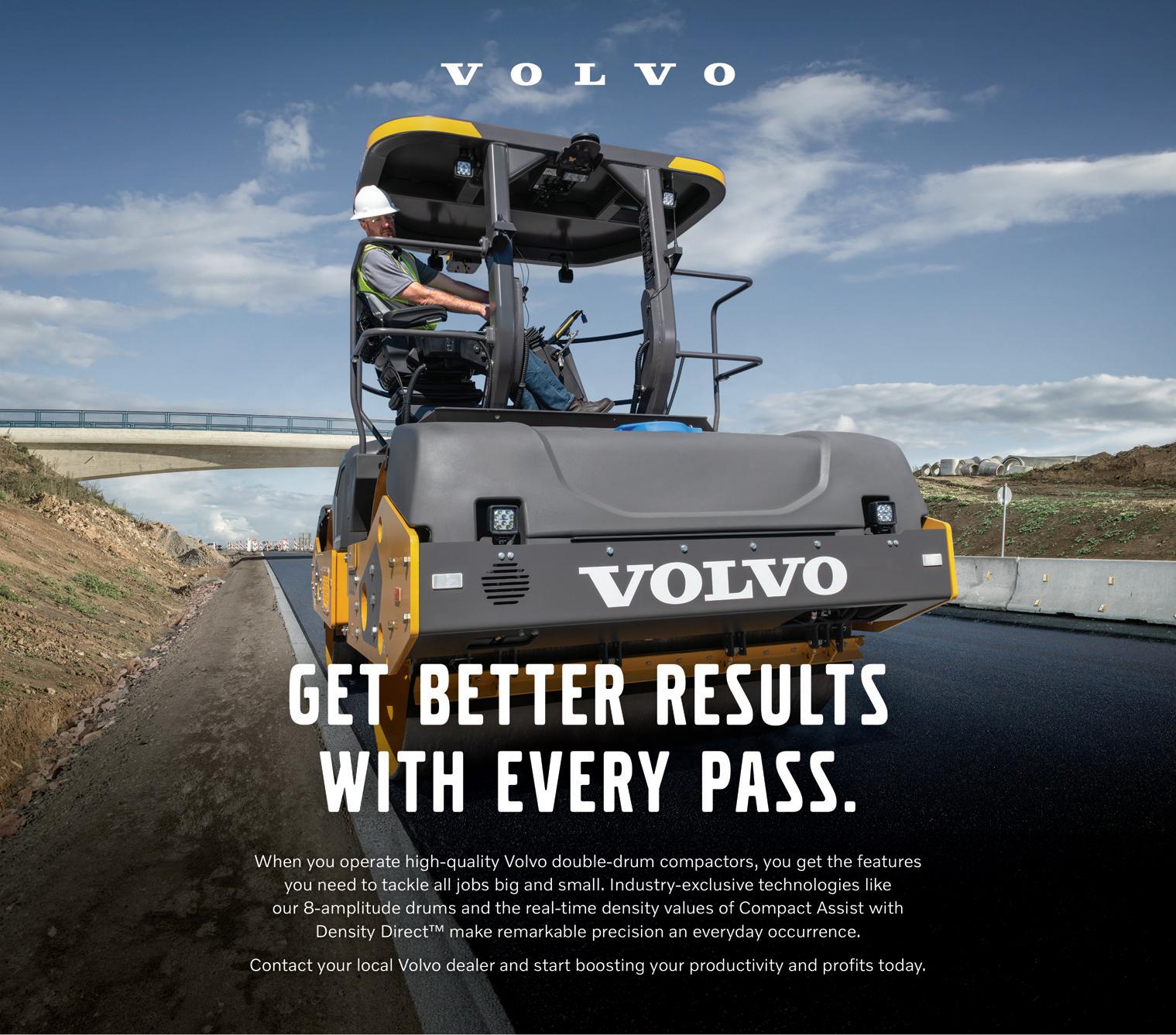

Road construction contractors must meet increasingly stringent environmental and quality standards in asphalt paving, while remaining competitive.

With InLine Pave and SprayJet, road paver specialist Vögele offers two methods that enable faster and more efficient realization of paving projects with lower overall costs.

Project completion deadlines in road construction are tight, especially when they involve the construction or rehabilitation of busy arterial roads. At the same time, contracting authorities demand the very best in paving quality.

Additional pressures arise from stricter environmental requirements and calls for resourcefriendly construction methods — while construction contractors struggle with constantly rising material and labor costs.

InLine Pave and SprayJet technologies are designed to counter these problems, according to Vögele. The two paving methods are suitable for a wide range of applications and have a proven

“Hot on hot” — when using the InLine Pave method from Vögele, the binder course and the surface layer are paved in a single pass.

track record earned in years of successful use around the globe, according to Vögele.

The InLine Pave concept is particularly suitable for the construction and rehabilitation of freeways and expressways — as well as wherever roads need to be reopened to traffic again as soon as possible, according to Vögele.

The machines work “in-line”, one behind the other, whereby the mobile feeder is loaded with the binder course or surface layer mix

and transfers it to the Super 21003(i) IP binder course paver.

With its AB 600 TP2 Plus highcompaction screed, this machine is the key component of the paving train: during the paving process, the screed compacts the binder course to values of up to 98 percent, a level that is so high that the surface layer paver can follow on behind it without damaging the freshly-paved binder course.

The paver for the binder course also features a special material transfer module that transports the surface layer material directly into the material

machine in the train — a Super 1800 Dash 3 or Dash 5 generation paver — which then paves the surface layer.

“Hot on hot” paving offers a number of advantages: optimal interlocking of the binder course and surface layer increases the quality and service lifetime of the surface layer. It allows a reduction of the proportion of surface layer to binder course material, according to Vögele.

Gradients and inclines: Due to the

In order not to disrupt visitor operations at Neuschwanstein Castle, work could only be carried out at night. The contractor therefore opted for the Vögele Paver Super 1800-5 X with the integrated light package plus.

Neuschwanstein Castle is a UNESCO world heritage site and one of the most famous tourist attractions in Germany. A large proportion of approximately 1.4 million visitors each year make the ascent to the castle by horse-drawn carriage. This is because, apart from emergency and maintenance vehicles, only they are allowed to drive on the steep, winding road. However, the horses' iron-shod hooves place a heavy

strain on the asphalt. The Bavarian Palace Administration therefore commissioned the renewal of the surface layer over a total length of 0.8 mi.

Steep inclines, hardly any room to maneuver, darkness: The conditions for rehabilitating the access road were difficult. That is why the construction company opted for the Super 1800-5 X paver. With its 129 kW power output, high traction, compact dimensions and integrated lighting, it

was perfectly tailored to the requirements, according to Vögele.

First, the team milled approximately 70,000 sq. ft. of asphalt surface with a Wirtgen cold milling machine W 100 CFi. Subsequently, the Vögele universal class paver laid approximately 800 tons of surface course material in

Steering by SmartWheel: The rotary knob on the ErgoPlus 5 driver control console enables particularly sensitive control.

three nights, in varying widths of 16.4 to 19.7 ft., and a thickness of approximately 1.57 in.

Given the curves, the new steering via SmartWheel was very helpful: The rotary knob on the ErgoPlus 5 paver's console allows for particularly precise control. In combination with the SmartWheel on the screed control console, the paving team achieved a high-quality and even paving result on curves.

During night-time operation, the Super 1800-5 X also scored points with its new plus lighting package, which includes various lighting elements: lighting integrated into the roof and crossbar of the control panel, LEDs on the levelling cylinders, three flexibly positioned spotlights and powerful, permanently integrated LEDs in a specially developed roof extension.

ARNOLD MACHINERY COMPANY

www.arnoldmachinery.com

Las Vegas, NV

702-642-9000 Phoenix, AZ

602-414-1900 Tucson, AZ

520-294-7677

Albuquerque, NM

505-895-1565

www.ascoeq.com

Beaumont, TX 409-212-8100 Brenham, TX 979-836-6641

(North) Houston, TX 281-987-1990

(South) Houston, TX 713-649-0940

CLOSNER www.closner.com

Schertz, TX 210-732-2131 Rhome, TX 817-708-9108 Manor, TX 512-272-8200

www.romco.com

Artesia, NM 575-746-6592 Austin, TX 512-388-2529 Carmine, TX 979-278-3570

Waller, TX 936-525-9949 NIXON-EGLI EQUIPMENT CO.

Corpus Christi, TX 361-881-4891

Dallas (Carrollton), TX 214-819-4100 El Paso, TX 915-772-0613

Ft. Worth, TX 817-626-2288

Houston, TX 713-937-3005 Longview, TX 903-758-5576

Lubbock, TX 806-745-1511

Midland, TX 432-234-9409

Rio Grande Valley, TX 956-565-0100

San Antonio, TX 210-648-4600

Stephenville, TX 254-266-2871

www.nixonegli.com

Ontario, CA 91761 909-930-1822

Tracy, CA 95304 209-830-8600

2019 Rosco Max 2B distributor, 1950 gallons, Max 2B computer, 12 ft spray bar, diesel burners, Freightliner M2, Cummins 6.7L dse eng, auto trans, front tires new

$149,000

New Marathon TPS250PT tack distributor, Briggs gas eng, 10GPM pump, 250 gal, spray wand w/50 ft hose on reel, Recirculation plumbing, propane burners, flushing system w/10 gallon tank $18,650

2016 Rosco Max 2B distributor, 1950 gallons, Max 2B computer, 12 ft spray bar, diesel burners, INTL 4400, Cummins 6.7L dsl eng, auto trans $130,000

hermannequipment.com

916-783-9333

909-877-5597

2014 Bomag BW11RH pneumatic roller, 9 wheels, Cummins 3.3L dsl eng, water system, 2221 hrs

$29,000

New Marathon TPS250PT tack

distributor, Briggs 5 hp gas eng, 18GPM pump, 250 gal, spray wand w/50 ft hose, hose reel, 6 ft spray bar, Recirculation plumbing, 12 gal waste recovery tank, propane burners, flushing system w/10 gal tank

$22,550

2019 Weiler P385B track paver, s/n 1W90P385PKB002978, Weiler 8-16 ft electric heated vibratory screed, (All new screed platesmain and extensions), 9 ton hopper, joystick controls, dual operator controls, Cat dsl eng, steel tracks, sonic sensors for augers $84,000

They provide illumination over an installation width of up to 32 ft. and up to 13 ft. behind the screed. The light output is comparable to that of lighting balloons, but they do not need to be transported or assembled separately.

“This saved us a lot of set-up time here on the construction site,” said Stefan Keller, senior site manager at Geiger Hoch- und Tiefbau GmbH & Co. KG, the company carrying out the construction work. “With light package plus, we were able to illuminate all relevant paver and work areas in a targeted manner, thereby ensuring maximum safety even in the dark.”

The paver access control (PAC) function also was practical: This enabled the installation team to commission the Super 18005 X from the ground and activate the lighting before even stepping onto the operating platform.

Using the control unit located on the paving screed, the operators started all the

initial steps at the touch of a button, such as switching on the lighting, starting the diesel engine, booting up the machine control system, raising and locking the roof and lowering the paving screed. After finishing work, they moved the road paver into transport position in the same way.

The latest generation of extending screeds AB 600 ensured high pre-compaction. All components that come into contact with the material are constantly heated, which ensured a homogeneous surface structure. Compared to the previous model, the new extending screed can be heated even more efficiently and is significantly quieter in operation thanks to structural optimizations.

Together with the noise-optimized drive concept of the Super 1800-5 X, the installation team was able to ensure quiet nighttime operation.

For more information, visit wirtgengroup.com.

The Carlson CP100 II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100hp engine, an array of configurations and the class-leading EZCSS single slide screed, it’s time to see why the CP100 II has fast become the contractor’s choice for heavy-duty commercial paver platforms.

The CP100II sets the standard for versatility, component lifecycle and mat quality. With a powerful 100 horsepower engine, an array of configurations and the class-leading Carlson EZCSS single slide screed, it’s easy to see why the CP100II is the ideal choice for heavy-duty commercial paving.

Closner Equipment

www.closner.com

Rhome, TX 817-708-9108

Schertz, TX 210-732-2131

Manor, TX 512-272-8200

www.pacwestmachinery.com

Seattle, WA 206-762-5933

Spokane, WA 509-534-5933

Pasco, WA 509-547-5933

Mt Vernon, WA 360-588-3083

Waller, TX 936-525-9949 PacWest Machinery

Portland, OR 503-252-5933

www.power-equip.com

Farmington, NM 505-326-1413

Durango, CO 970-247-8830

Denver, CO 303-288-6801

Eugene, OR – Branch 541-302-3762 Power Equipment Company

Colorado Springs, CO 719-392-1155

Grand Junction, CO 970-243-0722

Greeley, CO 970-353-1224

Albuquerque, NM 505-345-7811

Tri-State Truck and Equipment

www.tristatetruckandequip.com

Belgrade, MT 406-388-5818

Billings, MT 406-245-3188

Casper, WY 307-472-1818

Great Falls, MT 406-452-9551

wwwshaferequipmentco.com

Sparks, NV 208-801-7772

Rock Springs, WY 307-362-4000 Shafer Equipment

Boxcer Equipment

www.boxcerequipment.com

Tulsa, OK 918-272-7237

closner.com

6532 East Highway 114 Rhome, TX 76078

817-708-9108

21910 FM 2252 Schertz, TX 78154 210-732-2131

13800 FM 973 N Manor, TX 78653 512-272-8200

18851 GH Circle Waller Industrial Park Waller, TX 936-525-9949

ascoeq.com

5980 S M L King Jr Pkwy Beaumont, TX 77705 409-746-5102

202 I-35 Frontage Road Belton, TX 76513 254-613-1500

2800 Hwy 290 E Brenham, TX 77833 979-836-6641

1875 N Earl Rudder Fwy Bryan, TX 77803 979-779-8942

1512 Neptune Dr. #9706 Clinton, OK 580-323-3422

2019 Airport Fwy Euless, TX 76040 817-283-2844

980 N Sam Houston Pkwy E Houston, TX 77032 281-987-1990

6203 Long Drive Houston, TX 77087 713-649-0940

27500 E University Drive Aubrey, TX 76227 972-441-2726

12805 US-290 E Manor, TX 78653 512-272-8922

7100 SW 3rd Street Oklahoma City, OK 73128 405-789-6812

902 SE 9th Avenue Perryton, TX 79070 806-435-7773

1920 S East Loop 410 San Antonio, TX 78220 210-333-8000

3600 US-82 Sherman, TX 75090 903-893-7586

401 FM 148 Terrell, TX 75160 972-563-2171

12210 E 1st Street Tulsa, OK 74128 918-437-5085

2602 E Front Street Tyler, TX 75702 903-593-0201

2900 Henry S Grace Fwy Wichita Falls, TX 76302 940-687-2726

nixonegli.com

2044 S. Vineyard Avenue Ontario, CA 91761 909-930-1822

800 E. Grant Line Road Tracy, CA 95304 209-830-8600

2750 Marion Drive Las Vegas, NV 89115 702-342-8100

Vögele photo

When using the InLine Pave method from Vögele, the paving train consists of three machines following one behind the other — a mobile feeder, the paver for the binder course and the paver for the surface layer.

TECHNOLOGY from page 32

This improves the stability of the pavement thanks to the higher proportion of the stable binder course and prevents deformation. A smaller amount of costly asphalt surface layer material is required. In contrast to conventional paving, there is no need for spraying with bitumen emulsion as a tack coat — this saves material and working time while also reducing CO₂ emissions, according to Vögele.

If the renewal of a surface layer is required, paving thin layers hot over a spray seal is a low-cost, efficient and resource-friendly technology.

With the Super 1800-3(i) SprayJet, Vögele offers a special spray paver that has a track record on projects around the globe, according to Vögele. It sprays bitumen emulsion onto the old pavement and paves the new surface layer over it in a single pass.

The five spray bars with a total of 24 nozzles enable seamless application of the bitumen emulsion over varying paving widths of up to 20 ft. As the SprayJet module is a self-contained functional unit, it also allows the use of the Super 1800-3(i) SprayJet in the role of a classic road paver. The module is easy to maintain and is logically integrated in the Vögele ErgoPlus 3 operating concept, according to Vögele.

SprayJet technology is efficient and is suitable for all paved surfaces used

Efficient, low-cost rehabilitation of surface layers — the

from

emulsion onto the old pavement and paves the new surface layer over it in a single pass.

by traffic. The paving speed is often significantly higher than in conventional paving scenarios and, as the layer thickness is generally .78 in. rather than the usual 1.57 in., this also means potential savings of up to 50 percent of the surface layer material otherwise required, according to Vögele.

The use of the SprayJet method also brings numerous benefits with regard to quality. As spraying the emulsion and paving the surface layer take place in a single pass, the binding agent film cannot be inadvertently driven over and damaged by other construction vehicles, according to Vögele.

The binding agent film seals the entire lower layer and provides an effective barrier against water. This fur-

ther increases the service life of the road, according to Vögele.

Whether for rehabilitation, construction from new, or inner-city construction projects, with In-Line Pave and SprayJet, Vögele offers two technologies that take both the challenges faced by road construction contractors and their clients’ specific requirements into account. Faster, more efficient and more sustainable road construction or rehabilitation; the use of less material and conservation of resources; and the realization of high-quality asphalt pavement surfaces, according to Vögele.

Turlock, CA • 209-632-3931

Fairfield, CA • 707-425-9545

Merced, CA • 209-726-4600

Modesto, CA • 209-538-0911

Newman, CA • 209-862-3760

Santa Rosa, CA • 707-586-1790

Stockton, CA • 209-948-5401

Tulare, CA • 559-686-0054

Ukiah, CA • 707-468-5880

Woodland, CA • 530-615-2828

Madera, CA • 559-674-2496

Fresno, CA • 559-485-9090

CLM EQUIPMENT CO. INC. www.clmequipment.com

Lafayette, LA 337-837-6693 Lake Charles, LA 337-625-5942 St. Rose, LA 504-433-7999

BANE MACHINERY INC. www.banemachinery.com Dallas, TX 800-594-2263

Ft. Worth, TX 800-601-2263 Tyler, TX 800-594-2200

COLUMBIA WESTERN MACHINERY Columbiawesternmachinery.com 11125 SW Tonquin Road Sherwood, OR 97140 503-454-0902

Civil engineers are in demand, and salaries in the profession are rising, as professionals take advantage of a job market where their skills are needed, according to the 2025 ASCE Civil Engineering Salary Report released by the American Society of Civil Engineers (ASCE).

The survey found the average base salary for civil engineers is $148,000, a 6.4 percent increase over last year’s average base salary of $139,000. The survey has found that between 2022 and 2025, civil engineers have seen their salary increase between 6 percent to 7 percent annually, compared to 3 percent to 5 percent annual salary increases for the overall United States workforce, according to the WorldatWork 2024-2025 Salary Budget Survey.

The survey also found that earning a Professional Engineers (PE) License increases a civil engineer’s annual salary by $40,000 compared to those without a license or certification. The median entry level salary for civil engineers also increased to $77,100 in this year’s survey.

“Pursuing a degree and career in civil engineering is one of the best choices a student can make right now. The work to design and build infrastructure systems we rely on for public health, safety and welfare is rewarding, and employers are rewarding the important work civil engineers do to improve communities,” said ASCE President Marsha AndersonBomar. “It is crucial everyone in the profession works to recruit, grow and retain the next generation of civil engineers to ensure we have successful infrastructure systems.”

Recent infrastructure investment programs at federal, state and local levels of government have led to increased demand for civil engineers. The Bureau of Labor Statistics estimates that demand for civil engineers will grow by 5 percent between now and 2034. At the same time, a report from the Brookings Institution estimates 1.7 million infrastructure workers will leave their jobs each year, in large part due to people choosing to retire.

As the need for civil engineers grows, people in the profession are looking to advance their careers. The survey found that 6.9 percent of respondents changed jobs in the last year and received a median pay increase of 20 percent. Higher pay was the top reason people changed jobs (71.7 percent) followed by career advancement opportunities and new job responsibilities (both 61.8 percent).

Designing and building systems that promote public health, safety and welfare also is a very satisfying career, with 86.2 percent of survey respondents saying they are either satisfied or very satisfied with their jobs. Two-thirds (66 percent) of civil engineers surveyed say they are satisfied with their compensation, a 2.2 percent increase from last year’s salary survey.

The ASCE Salary Report is released every fall, collected from responses of Society members about their jobs and financial compensation. This year’s report is derived from 2,061 member responses at all stages of their career.

For more information, visit asce.org.

Anthony (Tony) D. Fassino, group president, construction industries, Caterpillar Inc., was elected 20252026 chair of the American Road & Transportation Builders Association (ARTBA). The announcement was made at ARTBA’s national convention, held Sept. 28-Oct. 1 in Dallas, Texas.

Fassino, a 30-year company veteran, has extensive expertise in engineering, sales, product development and operations across North America and Asia. Today, he is responsible for a global business that includes earthmoving, excavation, building construction products, global construction and infrastructure, construction industries services and Cat rental and used divisions, along with the segment’s supply management group.

His roster of ARTBA volunteer leadership roles includes serving as senior vice chair (2025), first vice chair (2024) and vice chair-at-large (202123). Fassino co-chaired the association’s reauthorization task force, a 27-

www.wpi.com

12320 S. Main Street Houston, TX 77035 713-723-1050

Buffalo, TX 903-322-7150

Bryan, TX 979-314-1191

Corpus Christi, TX 361-884-8275

Edinburg, TX 956-386-0107

Kilgore, TX 903-984-2011

Lufkin TX 936-243-6056

Pflugerville, TX 512-251-0013

Port Arthur, TX 409-721-5305

San Antonio, TX 210-648-4444 Tomball, TX 281-351-9016

Corporate Office 5000 Vasquez Blvd., Denver, CO 80216 303-355-5900

Colorado Springs, CO 719-576-5541

Grand Junction, CO 970-241-1550

Milliken, CO 970-587-1188

www.powermotivecorp.com

Cheyenne, WY 307-634-5149 Durango, CO 970-259-0455 Albuquerque, NM 505-345-8383 Bloomfield, NM 505-324-8601

Carlsbad, NM 505-485-1700

El Paso, TX 915-872-1001 Chandler, AZ 602-986-3003 Phoenix, AZ 602-463-3772 Tucson, AZ 520-649-2858

member group that developed the industry’s policy proposals for the next federal surface transportation bill due by Oct. 1, 2026. “Moving America Forward: A Blueprint for Strategic Highway & Public Investment” was unanimously approved by ARTBA’s board in May 2025.

At an Oct. 1 ARTBA board meeting, Fassino outlined key issues driving the transportation construction industry’s agenda for the year ahead. He noted these items were consistent with the association’s five-year strategic plan. Among them:

• Securing robust and timely surface transportation program reauthorization that increases federal highway and public transportation investment to recapture the lost purchasing power from unforeseen inflation surge from 2021 to 2023.

• Pursuing a regulatory structure that supports expanded infrastructure improvements. Fassino said this means pushing for thoughtful solutions on regulations like Buy

America expansion and the Occupational Safety & Health Administration’s proposed heat rule to ensure they do not impose unnecessary requirements, along with ARTBA’s ongoing legal advocacy efforts to stop federal overreach on issues like the Waters of the United States rule.

• Broadening the infrastructure coalition by partnering with the general business community to articulate how strong federal leadership facilitates a national transportation infrastructure network that promotes economic competitiveness, security and prosperity for all Americans.

• Developing a safety and mobility campaign that highlights the ability of infrastructure improvements to enhance daily life for all Americans and ensures that both roadway workers and motorists — with added emphasis on teen drivers — get home safely at the end of each day.

For more information, visit artba.org.

Abilene, TX 325-692-6334

Amarillo, TX 806-373-2826

OK 918-438-1700

Hewitt, TX 254-261-1370

Lubbock, TX 806-745-2112

Chico, TX 940-678-5046 Dallas, TX 214-371-7777 Ft. Worth, TX 817-378-0600

c ) ol (IMC r achine Cont anced autom tes with adv yg . ned plans ou an help y ation

efully design w and car e

face to design sur uickly

Odessa, TX 432-333-7000 www.clairemontequipment.com San Diego, CA 858-278-8351 Escondido, CA 760-739-9100 Fontana, CA 909-429-9100 Imperial, CA 760-355-7700

Indio, CA 760-863-5558 San Diego, CA 858-278-8338

The U.S. Army Corps of Engineers, Tulsa District (USACE) awarded a construction contract to build a software integration lab at Tinker AFB, Okla., on Sept. 30, 2025.

The Tulsa District awarded the $337 million contract to B.L. Harbert International Limited Liability Corp. of Birmingham, Ala.

Tinker Air Force Base is the home to the Air Force Sustainment Command and the Oklahoma City Air Logistics Complex, and provides global sustainment and logistics readiness to deliver combat power for America through maintenance, supply chain management and installation support for aircraft, engines and related software

Tinker AFB is one of six Air Force and Army installations the Tulsa District supports by providing project management, contracting, design, engineering and construction services through its Military Construction mission.

In addition, the USACE awarded its final fiscal 2025 contract — a construction contract to replace and repair tainter gates at Webbers

Falls Lock and Dam 16 in Webbers Falls, Okla.

The $28 million construction contract went to McMillen Inc. of Boise, Idaho. The contract calls for replacement of Tainter Gate 7 and repairs to Tainter Gate 8 and Tainter Gate 11 at Webbers Falls, Lock and Dam 16 in Webbers Falls, Okla.

A tainter gate, also referred to as a radial gate, is a type of large, curved floodgate used to control water releases from dams.

Webbers Falls Lock and Dam 16 is one of five locks and dams operated and maintained by the Tulsa District that comprise the Oklahoma portion of the of the McClellanKerr Arkansas River Navigation System (MKARNS), a 445-mi. Marine Highway that facilitates riverine transport of goods along the Verdigris and Arkansas River from the Tulsa Port of Catoosa to the Mississippi River.

The MKARNS is operated and maintained by the USACE, Tulsa District and the USACE, Little Rock District.

650M LGP 68 (50.6) 16,936 (7,682) FPT F5C F5HFL463D*G003

650M

68 (50.6) 15,931 (7,226) FPT F5C F5HFL463D*G003

650M WT 68 (50.6) 16,457 (7,464) FPT F5C F5HFL463D*G003

750M LGP 92 (69) 21,005 (9,527) FPT F5HFL413J*A002

750M WT 92 (69) 20,756 (9,414) FPT F5HFL413J*A002

750M LT 92 (69) 20,168 (9,148) FPT F5HFL413J*A002

850M LGP 112 (84) 23,430 (10,627) FPT F4HFE413P*A008

850M WT 112 (84) 22,855 (10,366) FPT F4HFE413P*A008

850M LT 112 (84) 22,319 (10,124) FPT F4HFE413P*A008 1150M LGP 127.4 (95) 33,346 (15,125) FPT F4HFE613F*A002

1650M

D65PX-18 WH

D65WX-18

D71PX-24

(23,165) Komatsu SAA6D114E-6

(24,102) Komatsu SAA6D114E-6

(177 ) 50,927 (23,100) Komatsu SAA6D114E-6

D71PXi-24 237 (177 ) 51,147 (23,200) Komatsu SAA6D114E-6

D85EX-18

D85EXi-18

D85PX-18

D85PXi-18

D85EX-18 WH 264 (197)

(30,670) Komatsu SAA6D125E-7

(31,000) Komatsu SAA6D125E-7

(29,300) Komatsu SAA6D125E-7

(29,700) Komatsu SAA6D125E-7

(32,077) Komatsu SAA6D125E-7

D85PX-18 WH 264 (197) 69,860 (31,688) Komatsu SAA6D125E-7

D155AX-8 354 (264) 89,300 (40,500)

D155AX-8

Liebherr crawler dozers have always been characterized by maximum compatibility with established machine control systems.

With the introduction of Liebherr Unicontrol Easy Link, customers can now benefit from the reliability of Liebherr machines alongside Unicontrol’s 3D control systems, offering a flexible solution for automated grading precision.

The connection through Liebherr Unicontrol Easy Link is available for both new machines and as a retrofit for already delivered G8 crawler dozers in the mentioned size classes.

Integration requires activation of the corresponding software interface in the machine control system, a simple and direct electrical connection to the Unicontrol system and preparation of the cab to accommodate the Unicontrol display.

Unicontrol, founded in 2019 and headquartered in Odense, Denmark, develops modern GPS/GNSS-based 3D control systems for construction machinery. Its solutions are primarily sold in Europe, North America and Australia, with particular recognition in Scandinavia.

“Unicontrol is now a direct option for those looking to activate automatic grade control on their Liebherr machines,” said Martin Kirkmand, product development director of Unicontrol. “It’s a significant step that reflects the industry’s move toward more accessible, flexible technology that works the way contractors need it to.”

For more information, visit liebherr.com.

- TEXAS (Formerly Four Seasons Equipment) www.NEDealers.com Houston, TX • 800-234-5007 Dallas TX • 866-270-1700

www.nuecespower.com 7510 IH-37 Access Rd., Corpus Christi, TX 78409 361-289-0066 Laredo, TX • 956-725-0066 San Antonio, TX • 210-310-0066 San Benito, TX • 956-361-0066 Victoria, TX • 361-576-0066 El Paso, TX • 915-541-0066

MAKE YOUR MOVE

Push

... more material with the new Hyundai HD100 crawler dozer's best-inclass power-to-weight ratio.

See

...more than ever with the unobstructed view to the blade.

Engage

...more accurately and more productively with standard 2D or optional 3D machine guidance.

Doze