Foam Fix

Utah Turns to Innovative Solution for Highway Ramp

“Geofoam is another tool in our toolbox to efficiently build the roads, trails and bridges we all need to get where we want to go,” said Rex Harris, UDOT project director of the West Davis Highway.

Crews working for the Utah Department of Transportation (UDOT) are using geofoam blocks — similar to the Styrofoam used in packaging materials and ice chests — to build a freeway ramp that will connect the future West Davis Highway with southbound I-15 in Farmington.

These blocks allow crews to build the new ramp in close proximity to I-15 as well as the Union Pacific Railroad and Utah Transit Authority tracks without causing additional shifting or settlement.

see FOAM page 10

6382 West 2100 South, Salt Lake City, Utah 84128 • (801) 972-8939 • www.utahtrackandwelding.com • sam@utahtrackandwelding.com Specializing in New, Used & Rebuilt Replacement Parts • Undercarriage Parts • Attachments • New and Used Parts • Field Service • Full Service Shop • Track Repair • Equipment Sales • Hydraulic Cylinder Repair • Teeth & Edges We Buy Salvage Equipment Alternative to the dealer for all makes & models Utah Track & Welding Service & Sales

August 27 Vol. I • No. FOUR CORNERS STATES EDITION ® “The Nation’s Best Read Construction Newspaper… Founded in 1957.” Your Four Corners Connection • Dennis Hogeboom • 1-877-877-4997 • dennishogeboom@cegltd.com

Construction crews are rebuilding the ramp to southbound I-15 by placing 3,000 geofoam blocks. Once in place, a concrete slab is poured on top to evenly distribute the load of the ramp pavement and concrete walls are installed along the sides.

Arcosa Inc., President Biden Announce New $1B Plant in N.M.

Arcosa Inc. recently announced President Biden toured the new Arcosa Wind Towers manufacturing site in Belen, N.M.

“The IRA and IIJA have been game changers and the Arcosa facility in Belen is an early proof point of this success,” Biden said. “We congratulate our partners at Arcosa and we value our 18-year partnership building clean energy and jobs together. When America innovates, the world wins, starting here in Belen.

“Since I signed the [Inflation Reduction Act] into law, Arcosa has received $1.1 billion of orders for new wind towers and today we are here breaking ground on a new plant that is going to create 250 new good paying jobs,” Biden said. “And meanwhile we are speeding up permitting for new transmissions lines so that wind energy produced by these towers reaches people’s homes.”

Antonio Carrillo, Arcosa’s president and CEO, commented, “Arcosa is proud to have hosted President Biden at today’s event. This new plant demonstrates the expected longterm positive impact of the Inflation Reduction Act that is driving the transition to clean energy and job creation. When com-

pleted the Belen plant will produce wind towers to meet the growing demand for renewable energy.”

Roger Martella, vice president of GE Vernova Government Affairs and Sustainability, commented, “The IRA and IIJA have been game changers, and the Arcosa facility in Belen is an early proof point of this success. We congratulate our partners at Arcosa, and we value our 18-year partnership building clean energy and jobs together. When America innovates, the world wins, starting here in Belen.”

Arcosa announced last spring a plan to invest between $55 to $60 million to purchase property, modify the existing plant and procure necessary equipment for the new wind tower manufacturing facility in Belen, N.M. This project is supported by attractive incentives from the state of New Mexico and the city of Belen. Production is expected to begin in mid-2024. Since the passage of the Inflation Reduction Act, the company has received wind tower orders in excess of $1.1 billion.

For more information, visit www.arcosa.com.

Page 2 • August 27, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

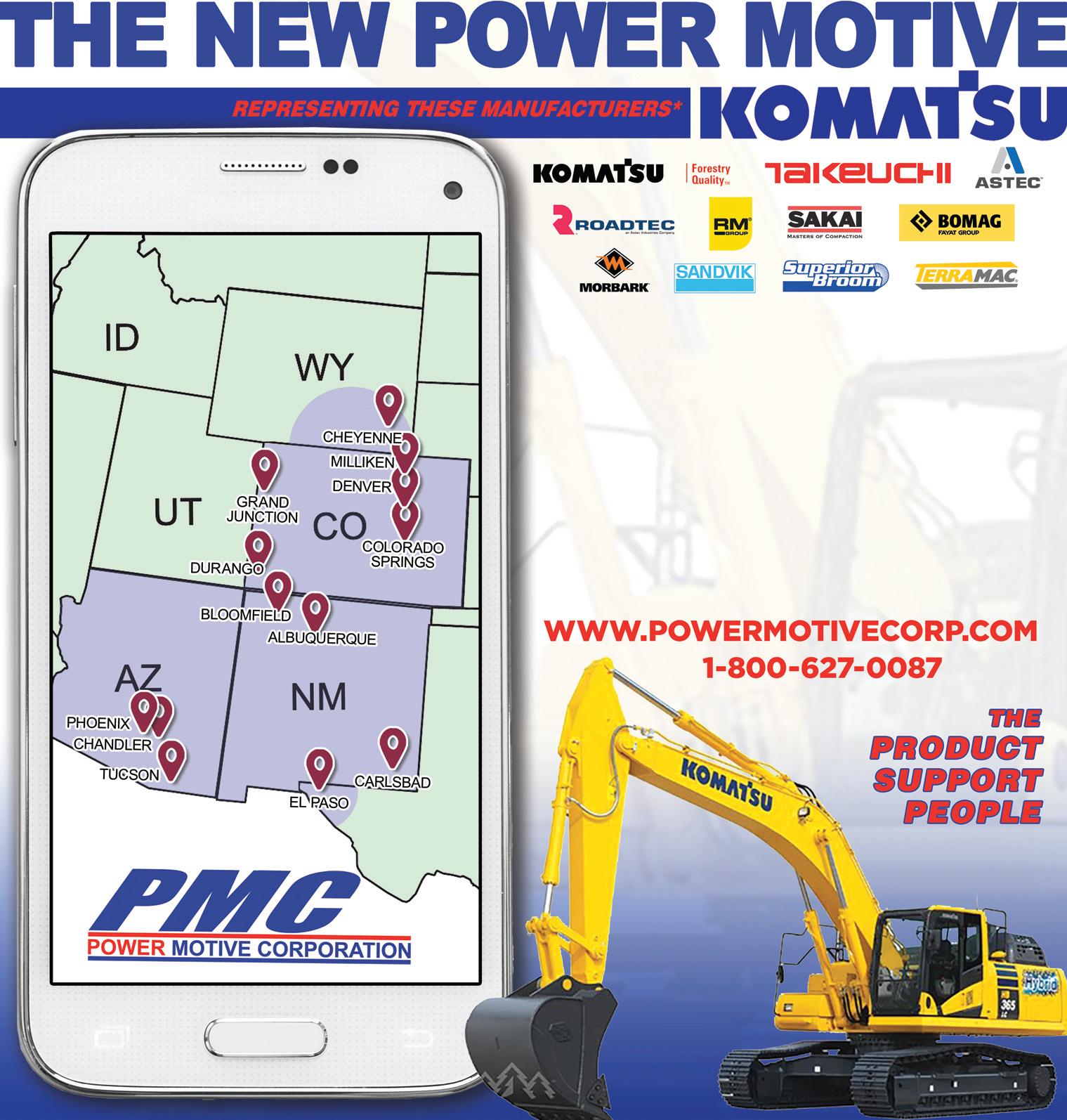

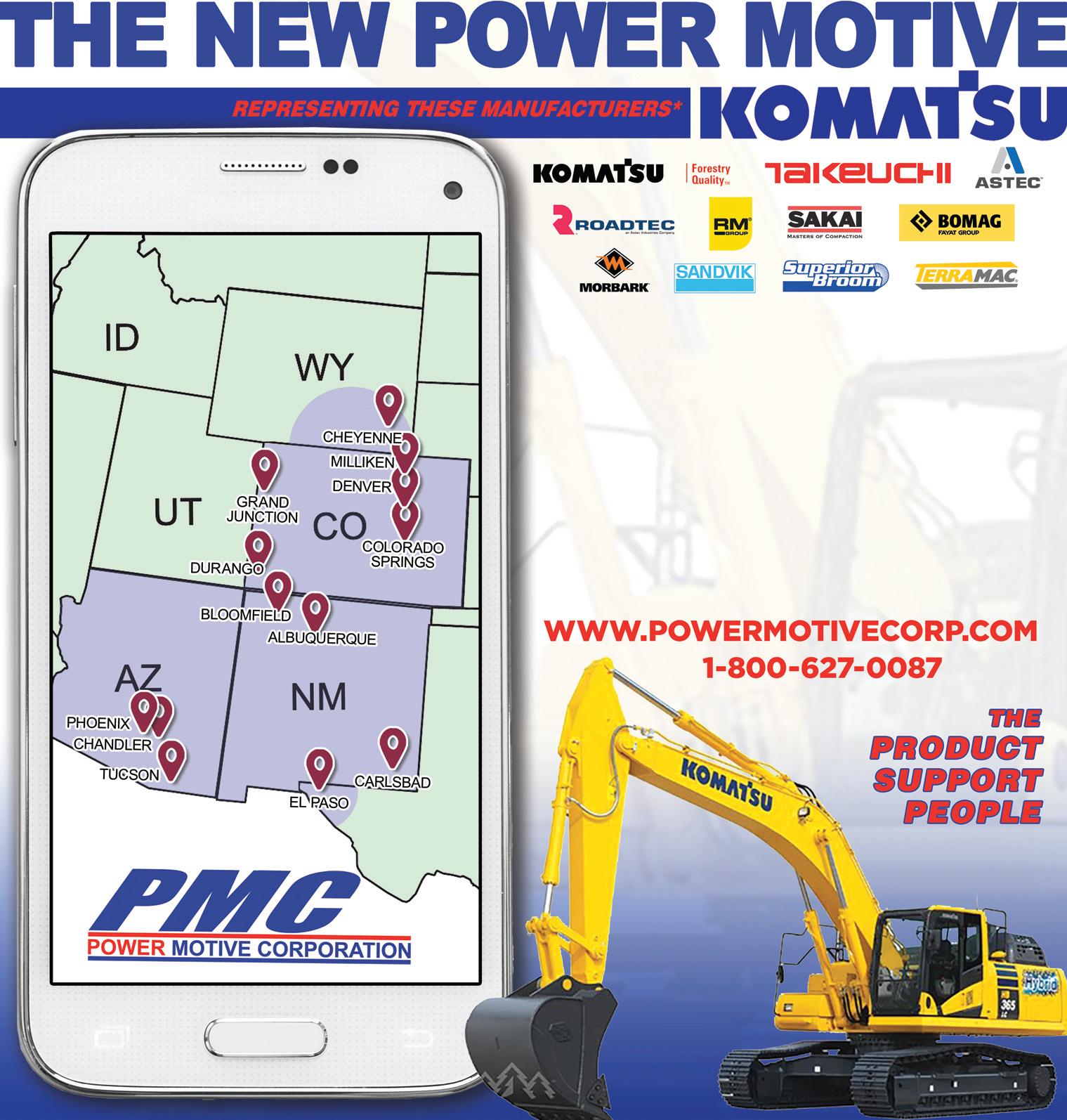

Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • August 27, 2023 • Page 3 COLORADO Corporate Office 5000 Vasquez Blvd. Denver, CO 80216 303.355.5900 Grand Junction 970-241-1550 Colorado Springs 719.576.5541 Milliken 970.587.1188 Durango 970.259.0455 WYOMING Cheyenne 307.634.5149 NEW MEXICO Albuquerque 505.345.8383 Bloomfield 505.324.8601 Carlsbad 505.485.1700 TEXAS El Paso 915.872.1001 ARIZONA Chandler 602.463.3772 Phoenix 602.986.3003 Tucson 520.649.2858 *some representation varies by state Watch for New Branches Opening Soon!

BOMAG Americas Signs PMC as New Full-Line Dealer of Arizona

BOMAG Americas has signed Power Motive Corporation (PMC) as the new dealer for the state of Arizona.

From the company’s Phoenix, Chandler and Tucson locations, PMC will provide its customers with sales, service and parts support for the full BOMAG product line, spanning from light equipment to landfill compactors.

In business for more than 60 years, PMC has focused on a customer-centric business model, building long-term relationships that carry through the life of the machine. The heavy equipment distributor offers a full range of earthmoving and construction equipment and has a well-earned reputation for being “The Product Support People.”

BOMAG’s complete line of compactors, pavers and milling machines, as well as the landfill equipment, enables PMC to be a one-stop solution for its customers.

“Power Motive’s business model of offering strong product support aligns with ours, and their reputation for providing superior after-the-sale services is already paying off for BOMAG in Arizona,” said Cole Renken, vice president of sales and marketing of BOMAG Americas.

“We are proud to welcome them into the BOMAG network. This partnership is truly a winning combination for all contractors in the state.”

With Arizona’s year-round construction and paving season, PMC’s primary objective in adding the line was to partner with a manufacturer that supplies rugged, innovative equipment to round out the company’s construction and earthmoving lines.

“We found this and more with BOMAG,” said Dan

Burget, vice president of Power Motive Corporation. “Beyond the one-stop shopping experience for our existing customers, BOMAG’s broad range of paving and milling equipment allows us to serve a broader range of contractors. We are excited to move forward and foster more customer relationships with BOMAG.”

Integrating decades of compaction experience into machine design, the extensive BOMAG range of light equipment features vibratory tampers, single and reversible plate compactors, multipurpose compactor, and small single and double drum rollers. The manufacturer’s more than 30 single drum and high-speed soil compactor models include smooth and padfoot drum designs reaching 31,000 lb. and widths of 84.1 in.

BOMAG’s purpose-built landfill compactor line ranges in size from 57,000 lb. to more than 124,000 lb. with an exclusive wheel design that delivers enhanced compaction results.

PMC now sells and supports a full range of equipment for paving contractors, including asphalt rollers, cold planers and pavers. More than 40 double drum and pneumatic tire rollers deliver compaction widths from 35.4 to 84.1 in. and integrate exclusive BOMAG technologies like BOMAP, ECON-

OMIZER and ASPHALT MANAGER.

With 14 models to choose from, the BOMAG range of cold planers offer milling withs from 20 to 87 in. Offering exclusive features like FRAMERAISE, SMARTRAC, MAGMALIFE and SIDEVIEW, BOMAG pavers range from the compact BF 200 C-2 for paths and small construction sites to the mainline CR 1030 Series. BOMAG’s versatile recyclers and stabilizers deliver fast and efficient fulldepth reclamation of roads and soil stabilization for a variety of projects.

For more information, visit www.bomag.com/us-en and www.powermotivecorp.com.

G4 Construction Equipment Joins Hyundai Dealer Network

HD Hyundai Construction Equipment

North America recently announced the addition to its North America dealer network of G4 Construction Equipment, Denver, Colo.

The dealership will represent the full line of Hyundai construction equipment products throughout the Front Range region of eastern Colorado and southeastern Wyoming, from the New Mexico state line up through the Cheyenne area.

“The Hyundai brand is a perfect fit for our dealership,” said Terri Priday, president, G4 Construction Equipment. “The Hyundai product line fills a need in our market for reliable, high-performing equipment. The machines are designed to enhance productivity, efficiency and safety on construction sites, recycling yards and in farming and ranching operations. We believe the Hyundai brand is a great value for our customers. We are already seeing immediate demand for Hyundai wheel loaders, excavators, compact equipment models and articulated trucks.”

Priday continued, “Our dealership management team has an extensive background in infrastructure development and energy markets, which gives G4 a deep understanding of our customers’ needs and perspectives. We are dedicated to supporting our

customers’ success by providing high quality machines and exceptional service and support.”

In addition to the strengths of the Hyundai product line, Priday said the company’s industry leading equipment warranties,

financing options and parts support provide additional value to G4’s customers.

“Hyundai is excited to add a new, energetic dealership to our network,” said Matt Brown, district manager of Hyundai. “G4 and its management team bring a fresh per-

spective from their long experience on the customer side of the construction equipment business. We are confident that will translate into successful customer relationships for G4.”

HD Hyundai Construction Equipment NA offers sales, service and parts through its dealer network. Hyundai delivers regular product and service training to ensure dealer partners are able to provide top-caliber support to meet the growing business needs of Hyundai construction equipment customers.

About HD Hyundai Construction Equipment NA

HD Hyundai Construction Equipment North America offers a full line of crawler excavators, ranging from compact models to heavy excavators; wheeled excavators; wheel loaders; articulated dump trucks; skid steer and compact track loaders; compaction equipment and hydraulic breakers. Hyundai construction equipment sales, service, parts and rentals are available through the brand’s network of more than 190 dealer locations. Learn more about HD Hyundai Construction Equipment NA’s products or dealership opportunities at www.hceamericas.com or call 877-509-2254.

Page 4 • August 27, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

BOMAG’s complete line of compactors, pavers and milling machines, as well as the landfill equipment, enables Power Motive Corporation to be a one-stop solution for its customers.

G4 Construction Equipment President Terri Priday (fourth from L) and members of the G4 team — including Guillermo Grossi, owner; Jeff Silletto, sales and rentals; and Ben Sands, service — display the company’s Hyundai dealership plaque.

ADOT, City of Flagstaff Complete Repairs, Add Capacity to U.S. 180

The Arizona Department of Transportation has completed interim repairs and improvements to increase the capacity of a stormwater drainage system along U.S. 180 in northwest Flagstaff, in an area below the Pipeline Fire burn scar.

Heavy runoff from a record-setting snow season earlier this year exposed damage to an existing drainage pipe parallel to U.S. 180, also known as North Fort Valley Road, between the Schultz Creek culvert and Stevanna Way.

ADOT and the city of Flagstaff collaborated on an accelerated project to repair the existing drainage pipe and add a second nearby 48-inch interim pipeline. Flagstaff provided an easement for the new pipeline.

“We need to emphasize that these are interim improvements,” said Brenden Foley, district administrator for ADOT’s Northcentral District. “The new line provides an important increase in the system’s drainage capacity while Flagstaff plans for future capacity improvements. We appreciate the city’s help

on this project.”

Stormwater damage had caused sections of the ground above the old pipeline parallel to southbound U.S. 180 to sink. Repair work included installing a new pipe and pavement and the replacement of a sidewalk and driveways, including those for the city’s Fire Station No. 5.

“The partnership between the city and ADOT has been very successful,” said Flagstaff Mayor Becky Daggett. “This involved collaboration and accelerated action on behalf of neighborhoods in the area. I want to thank the Grand Canyon Trust and other property owners for working with us on the easement for the new interim drainage line. Our team is already working on the design for a permanent drainage system that will handle much more runoff.”

Flagstaff has installed other storm runoff mitigation measures along Schultz Creek above US 180, including detention basins.

(Photo courtesy of ADOT.)

Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • August 27, 2023 • Page 5

ADOT and the city of Flagstaff collaborated on an accelerated project to repair the existing drainage pipe and add a second nearby 48-in. interim pipeline. Flagstaff provided an easement for the new pipeline.

Page 6 • August 27, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • August 27, 2023 • Page 7

Ames Replacing Oldest Bridge On Colorado Highway System

Construction has started to replace the Alameda Avenue (Colorado Highway 26) bridge over the South Platte River, a project designed to improve safety for drivers, bicyclists and pedestrians.

Ames Construction is the prime contractor for the $22.3 million project. It is scheduled for completion by the end of 2024.

Originally constructed in 1911 — and widened in 1966 — it is the oldest bridge on the state highway system.

In addition to replacing the bridge, the Colorado Department of Transportation project includes:

• Building a multi-modal corridor by modifying the West

Alameda Avenue intersection at South Santa Fe Drive; removing South Platte River Drive between Alameda and Cedar Street; and diverting traffic to a widened South Lipan Street, north of Alameda;

• Reconstructing the South Platte River Trail with improved sight distances, including a 12-ft. concrete trail, a 4-ft. finely crushed stone trail and 3-ft.vegetated shoulders for an overall trail width of 22 ft.;

• Constructing an on-street, two-way protected bike lane on the north side of Alameda between South Lipan Street and South Kalamath Street with a connection to the South Platte River Trail;

• Installing a water quality pond;

• Improving sidewalks on the north and south side of the bridge.

U.S. Rep. Diana DeGette (D-CO) and CDOT Executive Director Shoshana Lew held a press conference recently to provide an update on the project.

“This project is going to make it safer for all those crossing the river and for the bicyclists and pedestrians connecting to the South Platte greenway trail,” DeGette said. “It will provide more options for people trying to get from one side to the other whether by foot, by bike or by car which will help bring the communities on both sides of the river together.”

in October so crews can construct the north side of the bridge.

A major traffic shift will take place in 2024, when traffic will be moved onto the new north bridge, allowing for the demolition and construction of the south bridge.

“CDOT is also reconstructing the South Platte Trail under the bridge and north and south of the bridge,” Lew said. “Later, next year, we are also constructing an on-street twoway protected bike lane on the north side of Alameda which will include a connection to the South Platte River Trail.”

(All photos courtesy of CDOT.)

In addition to the bridge replacement, this project also includes building a multi-modal corridor by modifying the West Alameda Avenue intersection at South Santa Fe Drive; removing South Platte River Drive between Alameda and Cedar Street; and diverting traffic to a widened South Lipan Street, north of Alameda.

“We love historic bridges, we don't want them to be historic while we’re driving on them,” Lew said. “We have a lot to do to update to make Alameda Avenue work for people for the next one hundred years.”

Lew said the contractor will divert the South Platte River

Crews Complete Drainage System On Interstate 17 in Arizona

A new I-17 regional drainage system designed to reduce the risk of stormwater flooding in underpasses between Peoria Avenue and Greenway Road in Phoenix is ready to operate .

The Arizona Department of Transportation managed construction of the $38 million drainage system on behalf of the Maricopa Association of Governments, the Valley’s metropolitan planning organization. Crews installed new pipelines for the gravity

controlled system and built large stormwater retention basins near Thunderbird Road.

The new system also allowed ADOT to remove outdated pump stations, installed back in 1964, near lower-lying underpasses carrying Peoria Avenue and Cactus, Thunderbird and Greenway roads beneath I17. Those underpasses have been subject to flooding during periods of heavy rain and the new drainage system is designed to limit such events.

Primary work on the new system started in spring 2020. Construction involved extensive trench work as well as tunneling under I-17 for some pipeline installation. Angled pipelines will now move stormwater into retention basins or the Arizona Canal Diversion Channel north of Dunlap Avenue.

Although the upgrades are designed to reduce the potential for flooding, a large amount of rain in a short period of time can tax any drainage system, be it on state highways or local roads. Drivers should

proceed with caution when storms hit and avoid driving into areas with standing or moving water.

ADOT plans and constructs new freeways, additional lanes and other improvements in the Phoenix area as part of the Regional Transportation Plan for the Maricopa County region. Most projects are funded in part by Proposition 400, a dedicated sales tax approved by Maricopa County voters in 2004.

(All

courtesy of Arizona Department of Transportation.)

Page 8 • August 27, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

photos

Ames Construction is the prime contractor for the $22.3 million project. It is scheduled for completion by the end of 2024.

The Arizona Department of Transportation managed construction of the $38 million drainage system on behalf of the Maricopa Association of Governments, the Valley’s metropolitan planning organization.

Crews installed new pipelines for the gravity controlled system and built large stormwater retention basins near Thunderbird Road.

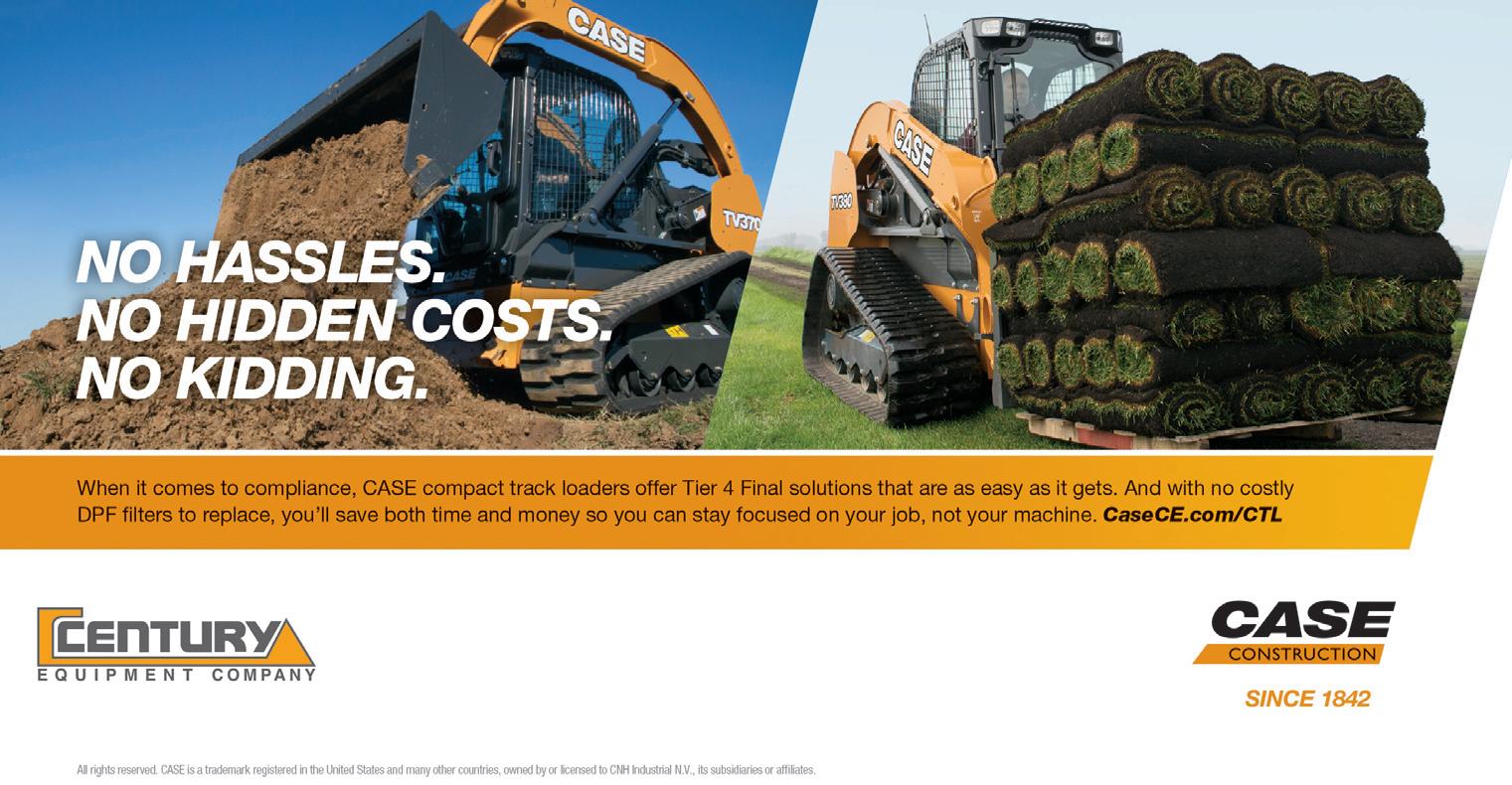

LOGAN, UT 453 North 1000 West Logan, UT 84321 435-752-1533

SALT LAKE CITY, UT 4343 Century Dr. Salt Lake City, UT 84123 801-262-5761

CEDAR CITY, UT 482 North Main Street Cedar City, UT 84720 435-586-4406 Email: del.maxedon@centuryeq.com

SPRINGVILLE, UT 1350 South 2000 West Springville, UT 84663 801-794-1463

CLIFTON, CO 549 32nd Rd. Clifton, CO 81520 970-434-7363

DURANGO, CO 1097 Hwy 3 Durango, CO 81301 970-247-0522

ALBUQUERQUE, NM 6301 Edith Blvd. NE Albuquerque, NM 87107 505-433-2246

Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • August 27, 2023 • Page 9

Crews Utilize Geofoam Blocks to Build New Highway Ramp

Farmington Bay Constructors (FBC) is the general contractor on the large complex project. They are a joint venture of Ames Construction, Wadsworth Brothers Construction and Staker Parson Materials and Construction.

“Sometimes there are unique challenges on our projects, and they require innovative solutions,” said Rex Harris, UDOT project director of the West Davis Highway. “Geofoam is another tool in our toolbox to efficiently build the roads, trails and bridges we all need to get where we want to go.”

The ramp to southbound I-15 is being built with approximately 3,000 geofoam blocks. Each one weighs approximately 200 lbs. and measures approximately 4 ft. by 5 ft. by 9 ft. The blocks are brought to the construction site and then either placed as-is or cut to fit as needed. Once all the blocks are in place, a concrete slab is poured on top to evenly distribute the load of the ramp pavement and traffic, and concrete walls are installed along the sides.

The weight of using dirt to build the ramp would cause the ground underneath to settle anywhere from several inches to a few feet. This settlement is typical in construction and engineers accommodate this settling with their designs. However, in this case, the close proximity of the existing interstate and rail lines meant they could be negatively affected by typical settling.

UDOT is one of a handful of state transportation departments in the U.S. with extensive experience using geofoam. Some notable projects that also used geofoam include the I15 reconstruction in Salt Lake County prior to the 2002 Olympics; the 1100 South bridge over I-15 in Brigham City; and the 5600 West bridge near 700 South in Salt Lake City.

Geofoam in Utah

UDOT previously emplored the use of a similar product when it upgraded the Union Pacific railroad in 2020. At the time, it marked the largest installation of geofoam ever used in the state and may be among the largest in the United States.

UDOT opted to go with the geofoam first and foremost for its light weight. The light weight prevented the sewer line from collapsing.

The geofoam also saved a significant amount of time in completing bridge construction on the project. Because soil at the site was soft, the contractor would have had to load the soil with surcharge — placing additional material on the

existing ground — building it as high as the embankment, adding even more weight to speed the process along. The surcharge would also have to be drained, adding additional cost.

Geofoam allowed no additional weight on the soils below, and it doesn’t settle like dirt does. There is no additional weight on the sewer line below or native soils below, so no compression causing settlement. The contractor took out enough heavy dirt and replaced it with super lightweight geofoam.

Crews installed the 112,000 cu. yds. of Geofoam, supplied by Oracle and manufactured by Atlas Molded Products, using a 60-ton crane and forklifts.

Geofoam History

The material was first used in road construction in Oslo, Norway in 1972. According to the Geofoam Research Center at Syracuse University (GRC), geofoam can be recovered from previous construction sites and reused.

After more than 20 years, geofoam was exhumed from a project and proved to be in good condition. The blocks exhumed were reused in another project.

Geofoam also can be shredded and formed into new blocks or sheets at the end of its life. According to the GRC, the process of recycling it does not involve chemical processing.

The GRC also said that geofoam is not biodegradable, but when it is installed underground, it does not have adverse impacts on soil or groundwater.

The use of geofoam has shown reduced environmental impacts. Geofoam, unlike soil, does not need to be compacted, shortening project timelines. Shorter project timelines mean less pollution from traffic slowdowns and construction vehicle activity.

(All photos courtesy of UDOT.)

Page 10 • August 27, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide

FOAM from page 1

The blocks are brought to the construction site and then either placed as-is or cut to fit as needed. Once all the blocks are in place, a concrete slab is poured on top to evenly distribute the load of the ramp pavement and traffic and concrete walls are installed along the sides.

Some notable projects that also used geofoam include the I-15 reconstruction in Salt Lake County prior to the 2002 Olympics; the 1100 South bridge over I-15 in Brigham City and the 5600 West bridge near 700 South in Salt Lake City.

Each foam block weighs approximately 200 lbs. and measures approximately 4 ft. by 5 ft. by 9 ft.

The material was first used in road construction in Norway in the 1970s.

Construction Equipment Guide • Four Corners States Supplement • www.constructionequipmentguide.com • August 27, 2023 • Page 11

CORNERS PUBLISHING

Issue Closing Publishing 20 September 13 September 24 22 October 11 October 22 24 November 8 November 19 26 December 6 December 17

FOUR

2023

Page 12 • August 27, 2023 • www.constructionequipmentguide.com • Four Corners States Supplement • Construction Equipment Guide