ILPRA GROUP The single destination for total packaging solutions. An extraordinary journey to the next exhibitions with the ILPRA GROUP, the Italian excellence in packaging. 10064 PINEROLO - ITALIA Tel. +39 0121393127 info@chiriottieditori.it www.foodexecutive.com Supplemento al n. 07, settembre 2023 di Industrie AlimentariSped. in A.P.D.L. 353/2003 (Conv. in L. 27/02/2004 n° 46) art. 1 comma 1 DCB TOn. 104 anno 2023IP n. 104 - September 2023 ISSN 1590-6515 FOOD

TECHNOLOGY ITALIAN

& PACKAGING

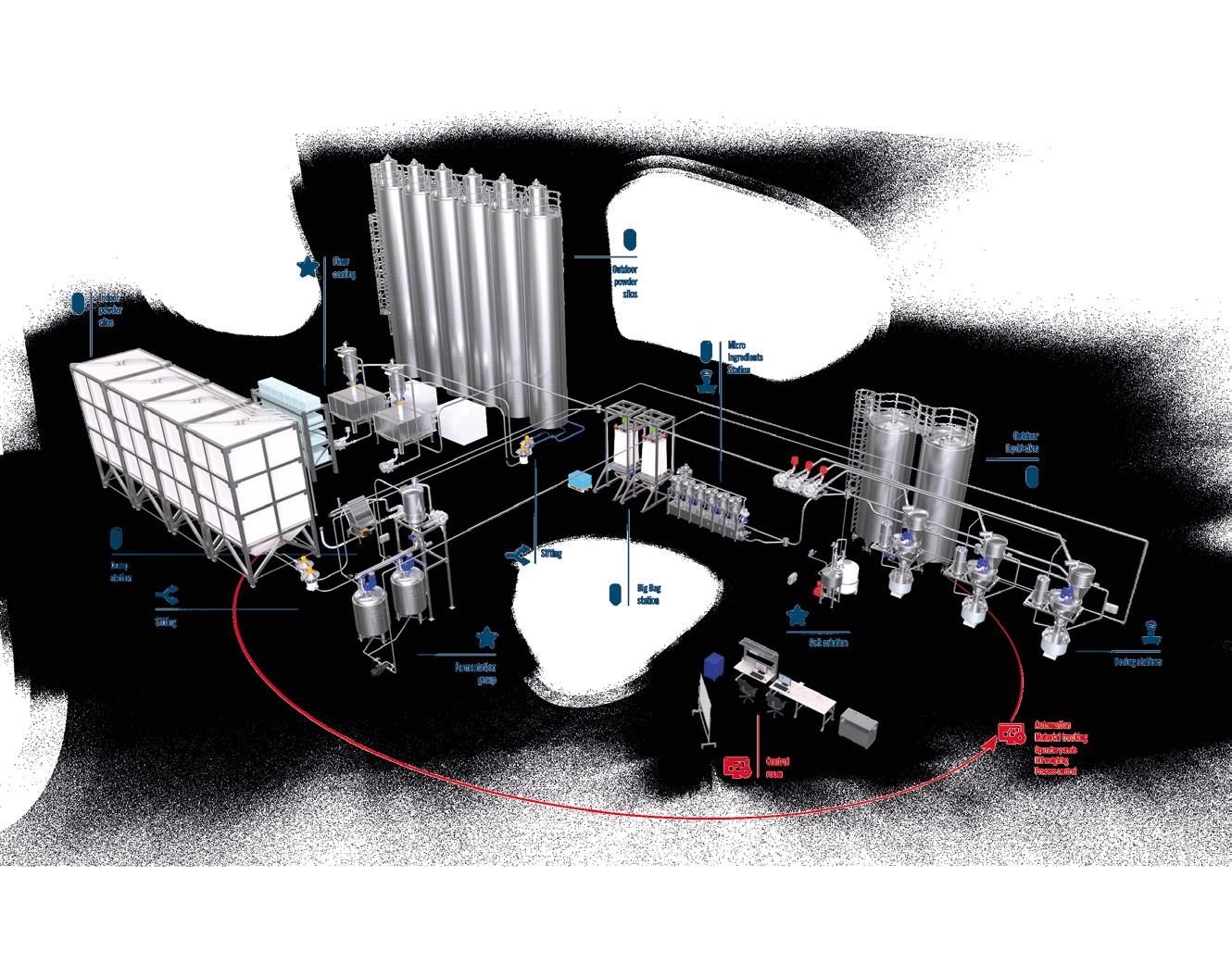

BULK-HANDLING SYSTEMS SINCE 1985

Turn-key, fully automated and customized

Process and product analysis

Engineering and control

Direct manufacture

Commissioning Service

cepisilos.com

linkedin.com/company/cepisilos

youtube.com/cepisilos

22-26 October 2023 Munich Booth 354 Hall C1

22-26 October 2023 Munich Booth 354 Hall C1

CIRCULAR PRODUCT Suitable for reuse 83% Suitable for recycling 15% Recycling efficiency 84% Durability 30 years

STORING TRANSPORT DOSING AUTOMATION

departments

3

14

PRODUCT TRENDS - Mechanically separated meat market - Coffee: world markets and trade - World dairy markets and trade

FOOD PROCESSING - High quality stainless steel filters and pumps

- Dosing solutions - LM at Interpack with its “loops” - Innovation in jelly production - Pinsa line by Albaequipment - Megadyne food safety solution - Being refined is simple - Two-stage process for energy valorization of cheese whey - Decarbonizing process heat in the food and beverages industry - Impact of different processing techniques on the black truffle - Estimation of harvested fruit weight with distance sensors - Infrared and microwave alternate thawing method for frozen pork - Influence of low-pressure tumbling on the quality characteristics of thawed pork

28

34

PACKAGING TRENDS - Baked goods: Automated packaging for sensitive goods - The european market for carton board

PACKAGING EQUIPMENT - Digitalisation in the packaging process

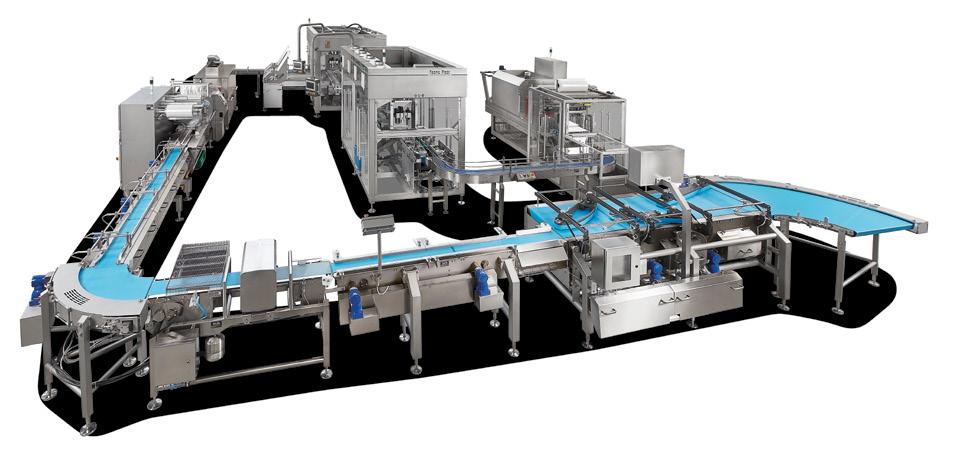

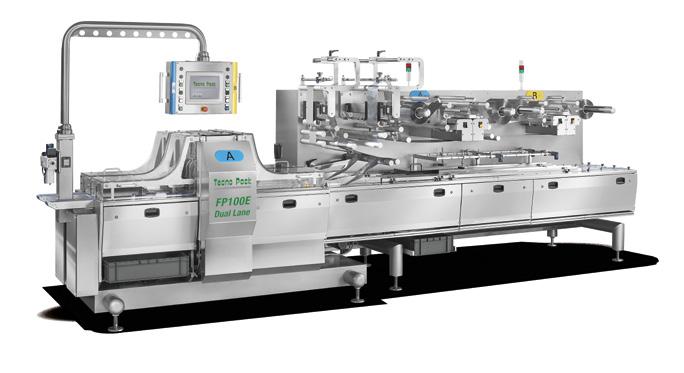

- SMI solutions for Arden’s Garden juices - ILPRA Group: the single destination for total packaging solutions - New bioplastics based on polybutylene succinate (PBS) - Improving the sterilization of PET bottles

44

NUTRITION - Optimizing consumer acceptability of chocolate through roasting treatments - A novel mayonnaise-type dressing added with avocado pulp and oil - Developing a herbal drink from green asparagus - Effects of various milk powders on cocoa butter substitute-based chocolate - Saltiness enhancement of bread

48

RESEARCH - Rapid determination of the roasting degree of cocoa beans - New method to produce skim milk concentrateApplications of various natural pigments to a plant-based meat analog - Valorization of industrial spent coffee grounds - Protein modifications due to homogenisation and heat treatment of cow milk - Influencing factors of oil deterioration during frying

- Enhancing emulsifying and encapsulation properties of plant proteins - Effects of high hydrostatic pressure treatment on the digestive properties of whey protein - Thermal treatment of green barley malt to produce functional clean-label ingredients

- Decaffeination of coffee and tea using mid-infrared raysFeasibility of protein aerogel particles as food ingredient: the case of cocoa spreads - Effect of microfiltration on milk protein microstructure - Physical characterization of chocolates prepared with various soybean and milk powders

58 NEWS - Number of people facing acute food insecurity rose to 258 million in 58 Countries in 2022 - The NOVA project develops the next generation of antimicrobial coating technologiesInternational events in Italy - A revolutionary almond pasteThe meat industry will return to the spotlight in Milan in 2024

- Ipack-Ima Milano 2025: global technological excellence meets innovation

64 COMPANY INDEX SEPTEMBER - issue 104

Four-monthly - ISSN 1590-6515

September

issue 104

for free subscriptions

call to +39 0121 378147 or send an e-mail to:

abbonamenti@chiriottieditori.it

Chiriotti Editori s.r.l. Viale Rimembranza 60

10064 Pinerolo - To - Italia Tel. 0121 393127

info@chiriottieditori.it www.chiriottieditori.it

La riproduzione, anche parziale, di articoli ed illustrazioni pubblicati sulla rivista è riservata e non può avvenire senza espressa autorizzazione scritta dell’Editore. L’Editore non assume alcuna responsabilità per quanto riguarda eventuali errori contenuti negli articoli e per quanto espresso dagli Autori.

Publisher

Alberto CHIRIOTTI Direttore Responsabile alberto@chiriottieditori.it

Contributing Editors

Laura SBARATO, Simonetta MUSSO, Rossella CONTATO, Matteo BARBONI

Assistant Editor

Chiara MANCUSI mancusi@chiriottieditori.it

Graphics

Anna BOSCOLO

Marketing Manager

Monica PAGLIARDI pagliardi@chiriottieditori.it

Advertising Manager

Luca RUSSO russo@chiriottieditori.it

General Manager

Giuseppe CHIRIOTTI

All Rights reserved. Reproduction, even partial, of articles and illustrations published in the journal is forbidden and can not take place without written permission of the Publisher. The Publisher assumes no responsibility for any errors contained in the articles and for what is expressed by the Authors and/or by the companies.

PRINTED by Graf Art

Officine Grafiche Artistiche Venaria (To)

COPYRIGHT:

© 2023 Chiriotti Editori srl Supplemento del mensile

“Industrie Alimentari”

AUTORIZZAZIONE: n. 262 (19-11-1962)

del Tribunale di Pinerolo

PERIODICITÀ:

mensile - sped. in A.P. comma

20/B, art. 2, legge 662/96Torino

INTERNET:

www.chiriottieditori.it

Unione Stampa Periodica Italiana Copyright Clearance Center

www.chiriottieditori.it shop.chiriottieditori.it www.foodexecutive.it

www.tuttogelato.it

OUR WEBSITES

www.pasticceriainternazionale.it

www.alimentifunzionali.it

PRODUCT TRENDS

Mechanically separated meat market

Companies involved in the mechanically separated meat industry are trying to optimize their production facilities by incorporating new technologies and adhering to guidelines while obtaining certifications to ease consumer concerns. The frozen segment occupies a major market share due to the prevalence of a highly extensive fast food industry that relies primarily on frozen meat for consumer consumption. The manufacturers should take the opportunity to invest and place similar focus on keeping up a steady supply for fresh meat consumers instead of targeting a single segment. Similarly, focus should be placed on increasing brand presence in markets with lower share due to their untapped potential. Survey of such markets to understand the needs of the consumer while adapting and evolving production lines can help companies maximize their profits while diversifying product offerings.

Market overview

The substantial growth in the demand from the meat industry, increasing production capacity, and high capital investments contribute to filling the supply & demand gap. Some of the major driving factors for the mechanically separated meat market include high nutritional value, minimal space requirements, and low environmental impact, due to which the market is estimated to grow rapidly.

According to this latest report published by Transparency Market Research, the global mechanically separated meat business register a high growth

rate during the forecast period 2022-2032, due to its high demand from consumers and growth in the fast food & ready to eat industry. In terms of revenue, the global mechanically separated meat industry is expected to reach a valuation of US$ 369.3 Mn by the year 2032, growing at a CAGR of 4.2% during the forecast period.

Rising demand for poultry meat fueling the growth of the global mechanically separated meat market

The increasing demand for poultry meat from emerging countries such as China, Mexico, and India, owing to market manufacturers expanding their sales footprint across these regions, is triggering the demand for mechanically separated meat.

Frozen mechanically separated poultry meat offers numerous benefits, including prolonged shelf life and food safety, which is projected to boost the global market throughout the forecast period. Furthermore, frozen mechanically separated meat products are simple to prepare and help reduce food waste.

Manufacturers anticipating a constant growth in demand for halal meat

The demand for halal meat, which is an integral part of the Muslim lifestyle, is increasing significantly. Nearly all types of meat in the Middle East and North Africa region are halal by default; however, in AsiaPacific, which also has a sizable Muslim population, demand for halal-certified products is increasing.

Furthermore, growing demand for halal meat is seen in several European nations, including the

italian food & packaging technology - civ (2023) - september 3

UK, France, and Germany. Turkish or Arabic-focused companies take benefit of these opportunities by selling meat that has received the halal certification. Consequently, halal meat sales have increased throughout the continent of Europe.

Growing demand for frozen meat creates opportunities for producers to make novel innovations

The global demand for frozen foods has skyrocketed, owing primarily to the trend of food traceability among new-age customers seeking healthy options. Due to the convenience component, consumers in various regions are expected to invest more in frozen foods.

Rapid developments in freezing techniques to prolong the lifespan of meat products without compromising quality are driving frozen meat sales in the mechanically separated meat sector. Thus, the rising customer demand is anticipated to motivate manufacturers in the mechanically separated meat industry to develop cutting-edge innovations in terms of appearance, taste, and packaging to increase the adoption of frozen meat products.

One of the key factors influencing consumer demand for convenience foods is shelf life. The distribution and supply of products are made easier and more effective by a product’s prolonged shelf life. Retailers are responding to the increasing working population and fast-paced life by increasing shelf space for food offerings in their stores. This is anticipated to increase the demand for ready-to-eat food offerings over the forecast period, resulting in increased demand for frozen meat.

Manufacturers in emerging economies can capitalize on waste processing and value addition

Meat processing manufacturers in developing economies can embark on the extension of their processing facilities to further add value to the waste generated. It is estimated that the livestock industry generates 1.4 billion pounds of waste annually – this dire statistic represents a sizeable untapped opportunity.

Deboning operation is a waste valorization concept that can result in significant income generation for small to medium-scale meat processors in the emerging markets of Asia Pacific and Latin America. The deboned meat along with other associated ingredients can further facilitate in improving the cyclic economy in this sector.

Regular consumption of meat to provide lucrative opportunities to msm manufacturers

Regular meat consumption can result in a variety of ailments. Regular consumption of red meat, poultry meat, and processed and unprocessed meat causes a number of diseases. Due to the accompanying health issues, producers have been obliged to develop alternate products for consumers who do not want to compromise on taste and texture. Thus, product diversification in their portfolios will provide lucrative opportunities to the manufacturers in the market.

According to a study conducted by the University of Oxford, it has been observed that higher consumption of poultry meat, unprocessed red meat, and processed meat was associated with a higher risk of pneumonia, diabetes, ischemic heart disease, diverticular disease, gastroesophageal reflux disease, and gallbladder disease, among others.

Poultry segment to lead the market: type segmentation

The poultry segment is expected to occupy a market value share of 61.5% in 2032 and is currently valued at US$ 144.5 Mn. The market was divided into poultry, beef, and pork segments where pork holds a greater potential as compared to the beef segment. The beef segment has the lowest forecast CAGR of 3.0%.

4 italian food & packaging technology - civ (2023) - september product trends

Frozen form of mechanically separated form segmentation

The form segment is subdivided into fresh and frozen which currently holds the major market share of around 63%. The likely reason for this is due to the easy transportation of frozen foods when compared to its counterpart. The rise in fast food consumption like burgers and other bite-sized foods presents the highest opportunity for market growth.

Geographic outlook

The highest value share is held by Europe followed by North America and East Asia at approximately 29%, 19%, and 16% respectively. The highest forecast value CAGR was in the East Asian region at 6%.

In the European region, Germany has the current highest value of US$ 13.97 Mn, and Russia is expected to show the highest growth in the upcoming years.

North America also holds a pretty large share of the mechanically separated meat market, with the U.S. occupying 88.7% of the current market share. China accounts for the highest value in the East Asian region of about US$ 18.25 Mn and is expected to rise at a CAGR of 6.5% and reach a valuation of US$ 34.35 Mn in 2032.

Major Players Analysis

The global mechanically separated meat market is expanding rapidly and major players are putting in the effort to provide consumers with the desired products. Customers are gradually becoming aware of unhealthy cultivation practices, focusing on clean and healthy food. Increasing regional supply and ontime delivery of products is paramount in order to placate consumer demand while collaboration with key players in the same industry is being adopted by the companies to increase brand presence and have greater footprints in emerging markets. Attending conferences while showcasing new products helps companies highlight their innovations in order to gain consumer attention and loyalty. The major players in the industry are Tyson Foods, Inc, J.A. ter Maten B.V., Belwood Foods, and Polskamp Meat Industry holding 55%-65% of the market.

Global market: key developments

Belwood Foods invests heavily in new ideas and technologies to ensure product innovation and meet the increasing consumer demand for its products. For instance, with efficient manufacturing, the company maintains the same high standards in its pro-

duction and supply to its customers on time around the world.

In 2018, Damaco group made a huge investment in infrastructure and production at the Kipco-Damaco headquarters. The company is focusing on sustainability, the quality of its products, and delivering to its customers in a timely manner.

DTS Meat Processing NV works collaboratively with renowned MDM processors worldwide to offer natural products to its customers, mainly in the meat industry. The company strives to establish strong, mutually beneficial business relationships with suppliers and customers.

In October 2020, Trinity GMBH participated in conferences & expos in the Netherlands. The company showcased its MDM and other products at Sial 2020. Local experts communicated with customers about the trends and opportunities of mechanically deboned meat.

The players mentioned above have been profiled in the global mechanically separated meat market report based on numerous parameters that include business strategies, financial overview, business segments, company overview, product portfolio, and recent developments.

italian food & packaging technology - civ (2023) - september 5 product trends

www.transparencymarketresearch.com

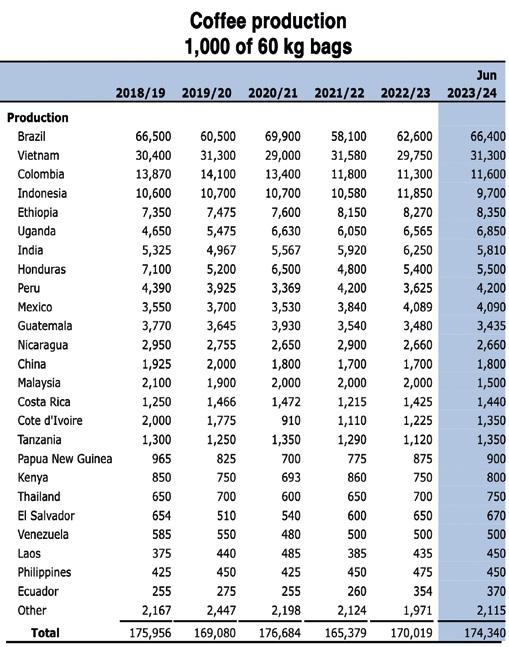

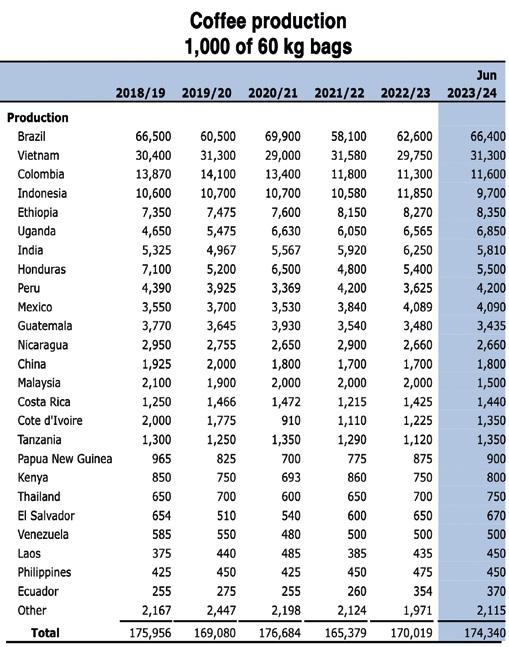

Coffee: world markets and trade

According to the Foreign Agricultural Service of USDA, world coffee production for 2023/24 is forecast 4.3 million bags (60 kg) higher than the previous year to 174.3 million. Higher output in Brazil and Vietnam is expected to more than offset reduced production in Indonesia. With additional supplies, global exports are expected up 5.8 million bags to a record 122.2 million primarily on strong shipments from Brazil. With global consumption forecast at a record 170.2 million bags, ending inventories are expected to remain tight at 31.8 million bags.

Brazil

Combined Arabica and Robusta harvest in Brasil is forecast up 3.8 million bags to 66.4 million in 2023/24. Arabica output is forecast to improve 4.9 million bags to 44.7 million. In January 2023, coffee trees in top growing region Minas Gerais experienced higher than average rains during the fruit development stage that caused difficulties for some growers in controlling plant diseases and pests. However, increased precipitation resulted in coarser and heavier beans compared to the last crop, which contributed to production gains. Although output is expected to expand, this quantity is below previous crops that peaked at nearly 50 million bags. Arabica trees in many growing regions continue to recover from severe frosts, high temperatures, and below-average rainfall that occurred in 2021 that lowered production in 2021/22 and 2022/23. Following 6 years of expansion, the Robusta harvest is forecast to decline 1.1

6 italian food & packaging technology - civ (2023) - september product trends

million bags to 21.7 million as reduced rains and cooler temperatures leading up to the flowering stage lowered yields in Espirito Santo, where the vast majority is grown. Coffee bean exports are forecast to rebound 8.0 million bags to 41.0 million, fueled by higher supplies and an expected stocks drawdown.

Vietnam

Vietnam production is forecast to rebound 1.6 million bags to 31.3 million due to higher yields attributed to favorable weather. Cultivated area is forecast unchanged, with nearly 95% of total output remaining as Robusta. Bean exports are forecast to decline 1.5 million bags to 24.5 million, with output gains boosting ending stocks to 2.7 million bags.

Central America

Central America and Mexico production is forecast nearly unchanged at 17.9 million bags, with Arabica accounting for 95% of total output. Modest gains in Honduras, El Salvador and Costa Rica are expected to

offset a slight dip in Guatemala. Bean exports for the region are forecast nearly flat at 14.7 million bags on steady shipments to top markets.

Colombia

Arabica production in Colombia is forecast up 300,000 bags to 11.6 million on slightly higher yields. Despite rising, yields remain nearly 15% below normal because growers limited fertilizer use due to its price spike. Bean exports, mostly to the United States and European Union, are forecast up just 100,000 bags to 10.9 million as supplies remain tight.

Indonesia

Combined Arabica and Robusta harvest in Indonesia is forecast down 2.2 million bags to 9.7 million. Robusta production is expected to drop 2.1 million bags to 8.4 million. Excessive rain during cherry development lowered yields and caused sub-optimal conditions for pollination in the lowland areas of Southern Sumatra and Java, where approximately 75% is grown. Arabica production is seen dipping slightly to 1.3 million bags. Bean exports are forecast to plummet 2.5 million bags to 5.2 million on sharply reduced supplies.

Ethiopia

Arabica production in Ethiopia is forecast nearly flat at 8.4 million bags and remains the world’s third-largest Arabica producer behind Brazil and Colombia. Yields have been stubbornly stuck around 14 bags per hectare while other top Arabica producers average yields that are 40-60% higher. Improved crop management practices have not been widely adopted because 95% of production occurs on non-commercial plots typically one- half hectare or less. Few non-commercial growers are interested in incurring investment costs due to the informal nature of their growing method, while commercial growers note that 5 to 10 years are needed to realize a return on their investment. Yields are also low due to limited use of fungicides despite the presence of coffee berry disease, coffee wilt disease, and root rot disease. Bean exports are forecast unchanged on stable supplies.

India

India combined Arabica and Robusta harvest is forecast to decline 400,000 bags to 5.8 million. Robusta production is forecast to drop 300,000 bags

italian food & packaging technology - civ (2023) - september 7 product trends

to 4.6 million due primarily to a prolonged dry spell from December 2022 to March 2023 which was followed by poor pre-monsoon rains. Arabica production is seen slipping 100,000 bags to 1.2 million. Bean exports are forecast up just 100,000 bags to 4.3 million on a slight inventory drawdown.

European Union

European Union imports are forecast up 3.0 million bags to 47.5 million and account for 40% of the world’s coffee bean imports. Top suppliers in calendar year 2022 included Brazil (35%), Vietnam (22%), Uganda (7%), and Honduras (6%). Ending stocks are expected to rise 500,000 bags to 13.1 million.

The United States

The United States imports the second-largest amount of coffee beans and is forecast to gain 2.5 million bags to 26.5 million. Top suppliers in calendar year 2022 included Brazil (31%), Colombia (19%), Vietnam (10%), and Guatemala (6%). Ending stocks are forecast up 1.1 million bags to 6.8 million.

World production

World production is lowered 2.7 million bags from the December 2022 estimate to 170.0 million and the world ending stocks are revised down 2.5 million bags to 31.6 million.

www.usda.gov

8 italian food & packaging technology - civ (2023) - september product trends

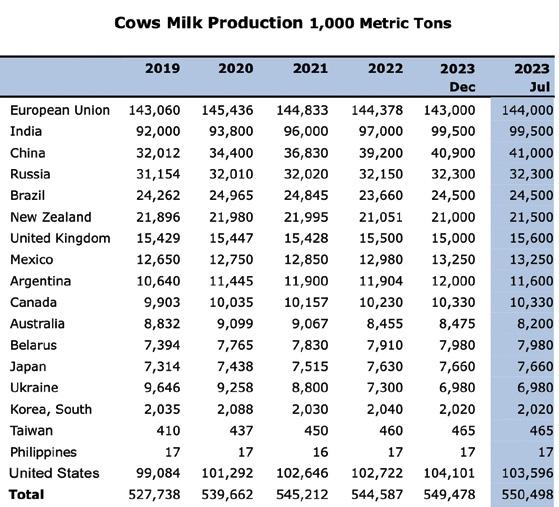

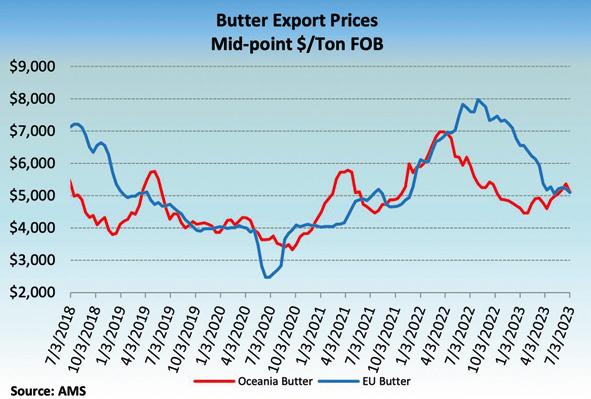

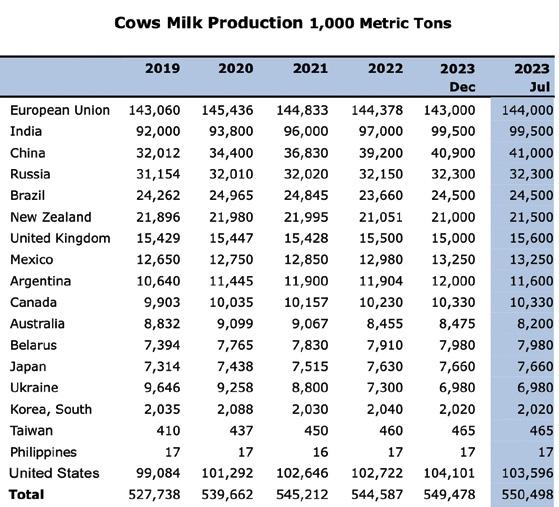

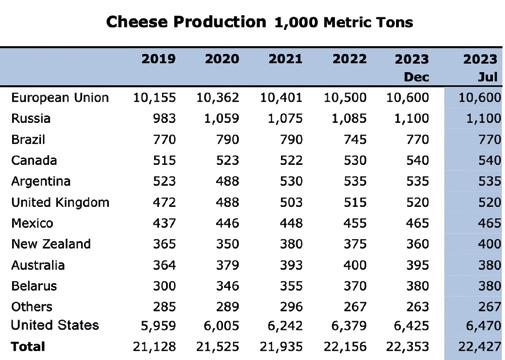

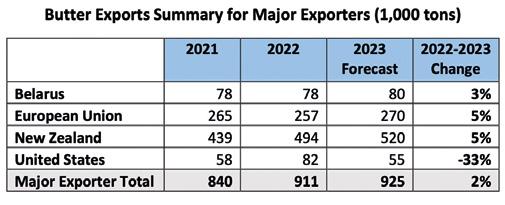

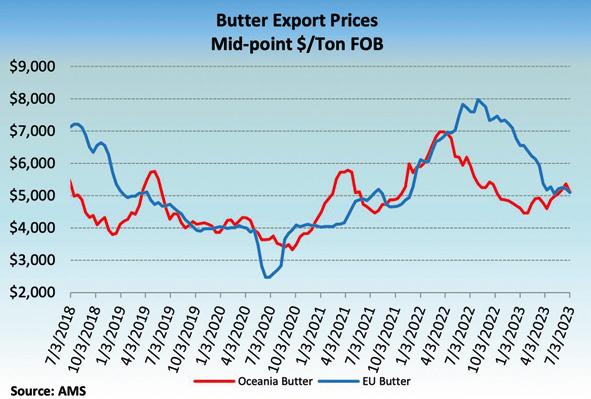

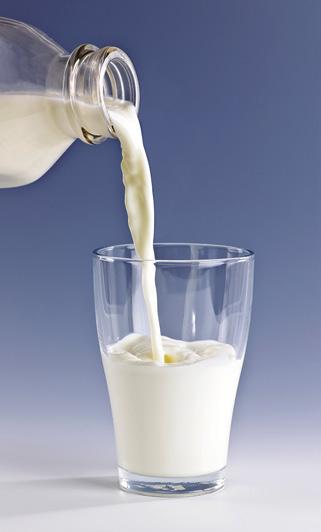

World dairy markets and trade

According to the latest report by the Foreign Agricultural Service of USDA , resilient global milk production, currently on a 10-month streak of annual gains on a monthly basis dating back to last July, has put downward pressure on prices of manufactured dairy commodities. Through May, exports of dairy products on a value basis to Southeast Asia have totaled $561 million, down 33% from the same period last year. There have been broad declines across multiple commodities, including skimmed milk powder, whey and cheese. This is coming in a period where SMP prices are down 37% and whey prices are 52% from the peak in February 2022.

As the world enters a post-COVID lockdown world, governments are now under pressure to reign in fiscal spending and combat high food inflation, which have reached an all-time in high in many countries in the region, typically done via higher interest rates. In the Philippines, food inflation reached 11%, driven by increases in dietary staples like vegetables. Increasing food costs have forced consumers to reduce discretionary spending (a category which includes spending on dairy products which are not a major part of traditional diets). Lower discretionary spending is impacting both the restaurant industry and retail purchases. Demand for whey and lactose has also fallen in several countries. In Vietnam, swine herds continue to recover from African swine fever, reducing demand for whey and lactose for feed use (export volumes to Vietnam for both products are down 11 and 23%, respectively). In the Philippines, another market that has been impacted by ASF, exports of whey and lactose have fallen 26 and 9%, respectively. There also continue to be regulatory pressures in Southeast Asia hindering U.S. dairy exporters this year, specifically halal certifications processes.

The development of dairy exports on the global market has been one of the biggest success stories for U.S. agriculture over the last 2 decades. Growth in the Southeast Asia market has been an important factor in expanding exports from $1 billion in 2003 to $9.5 billion in 2022 (dairy exports to Southeast Asia totaled $1.7 billion in 2022, the third largest regional market in the world for dairy exports behind North America and East Asia). U.S. dairy exporters have captured sizeable market share, but stiff competition continues from Oceania and the European Union, which benefit from long-standing trading infrastructure in the region and tariff advantages granted in free trade agreements. The recently established Indo-Pacific Economic Framework for Prosperity (IPEF) is a potential avenue to gaining similar advantages for U.S. agriculture in the region.

10 italian food & packaging technology - civ (2023) - september product trends

FLUID MILK

In Argentina, milk production is forecast to decline 3% as severe drought has resulted in poor forage conditions and expensive, poor-quality hay. In addition, significant peso depreciation continues to hover over dairy production. In the past, strong depreciation in the peso has corresponded with declines in milk production because most inputs, mainly concentrates, are dollar denominated, and their prices are set by the open market. Meanwhile, the price of milk, of which nearly 80% is destined for domestic use, can take several months to adjust to the new dollar value and compress margins in the near term for producers.

Milk production in Australia is forecast to decline to 8.2 million tons for 2023. Extreme Spring rains resulted in a shortage of hay supplies and strong beef prices in recent years continues to incentivize dairy farmers to shift to beef production, with the dairy herd size forecast to shrink 0.7% to 1.325 million cows. Producers are also still grappling with labor shortages that stem from COVID-related border crossing restrictions in 2020 that reduced the number of visa approvals for holiday and backpacking travelers, a historical source of on-farm workers. Since Australia has re-opened its borders, finding on-farm labor has become easier, but on-farm labor has not returned to pre-pandemic levels. To make up the gap in fewer employees, dairy operations have turned to different production practices that naturally depress milk output, including decreasing daily milkings from three to two or converting to ten milkings per week. As a result, milk yields are forecast to fall 2.3%. These factors offset otherwise favorable conditions for milk production including strong milk prices, improved water availability, and high quality, affordable domestic feed.

European Union milk production is forecast relatively unchanged, marginally declining to 144.0 million tons. Milk production grew during the first 5 months of the year due to year-over-year increases in productivity, despite a decline in the milk herd of over 100,000 cows. However, newly implemented environmental and animal welfare policies introduced in many EU member states have contributed to herd size reduction and have stressed growth in yields that have previously helped continue to grow the milk pool. In particular, dairy cow numbers are expected to decline in the Netherlands, which capped nitrogen usage for pasture production and banned

farmers from spreading manure on fields as fertilizer. Complying with the new regulations puts producers in a dilemma: either invest large amounts of capital to adopt new production processes or shift production to beef and increase slaughter. Declining EU farmgate milk prices and increasing cost of production –higher feed, energy, and labor costs – have also accelerated exits from the dairy sector. Narrowing margins have driven closures in small and medium-sized operations in Spain, France, Germany and Poland, and is expected to continue to weigh on production as the year goes on.

In New Zealand, milk production is forecast at 21.5 million tons, up 2% from 2022. Wet conditions in December and January and improved soil moisture have been greatly beneficial for summer pasture growth in key dairy regions in the North Island. As a result, milk production in the first 5 months was 3% higher compared to 2022. The outlook through September is promising as rainfall is expected to be average or above average in many key dairy regions in the North and South Island. Warmer-than-average sea temperatures should help reduce intense cold winds in the South, which should benefit milk production during the winter. The farmgate milk price continues to be strong this year, though down from 2022. Fonterra listed its outlook for the upcoming year at a range from NZ$7.23 to NZ$8.75 per kilogram milk solids compared to the range from last year at NZ$8.78-NZ$10.25 per kilogram milk solids.

italian food & packaging technology - civ (2023) - september 11 product trends

Lower prices and rising farm input costs due to inflation and higher interest rates will lead to a decrease in profitability, smaller herd sizes and reduced use of imported feed.

Some dairy farm operations will be impacted by the ban on live animal exports that went into effect on April 30. Live animal exports to China provided a reliable revenue stream for some dairy producers as prices ranged from NZ$1,600-NZ$2,000 USD per cow; however, the 2-year transition period granted by the government after passage of the new legislation has now expired. Trade data indicates that 280,000 live cattle were shipped to China from April 2021-April 2023. Domestic industry studies estimate that there could be an additional 150,000 bobby calves in the market as a result of the ban. Expectations are that the influx of calves would be raised for beef, slaughtered for calf- veal or used for the pet food market.

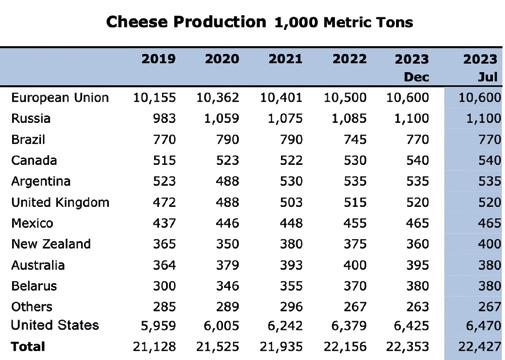

CHEESE

European Union cheese production is expected to rise by 1% despite declining milk production. Stronger relative prices to other dairy products will see processors allocate a larger portion of the milk pool to cheese production. Growing domestic retail demand for cheese and growth in the hospitality and tourism sectors are expected to support further cheese production.

Australia cheese exports are revised down to 120.0 million tons, reflecting a weak start to the year that saw exports decline 22% through May compared to last year. Shipments to large export markets in East and Southeast Asia have been weak across the board. The industry believes that buyers have shifted to purchasing on an “as- needed basis” while global commodity prices have been high. Shipments are expected to moderately improve in the second half of the year as economic conditions improve in some of Australia’s larger markets (especially China) but import demand across other East and Southeast Asian markets is forecast to remain weak through the end of 2023.

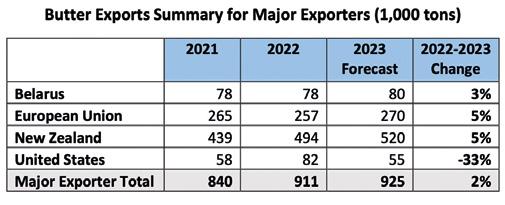

BUTTER

Butter production in New Zealand is forecast to increase to 530,000 tons, in part reflecting better returns for manufacturing skimmed milk powder (SMP) shifting larger allocations of the milk pool to butter and SMP. Exports are forecast to increase 5%, reflecting price competitiveness against major exporters of butter, notably the European Union. Through May, exports are up 11% over year-ago levels, with strong growth to Mexico (more than doubled), Australia (+80%), Saudi Arabia (+49%), and the United States (more than tripled). Growth in these markets more than offsets weaker shipments to China (-4%).

Butter imports by China are forecast to reach 135,000 tons, a decline from last year as sustained high import prices weigh on demand from bakeries, Exports were flat to start the year, reflecting weaker global demand for commodity cheeses, particularly in the United States and Japan. While tighter milk supplies and higher prices, may negatively impact the competitiveness of commodity cheeses, specialty cheeses remain popular and expected to support growing exports. Through May, shipments to the United Kingdom (+3%) are more than offset by weaker shipments to the United States (-9%) and Japan (-12%).

12 italian food & packaging technology - civ (2023) - september product trends

the food processing sector, and retail consumers. Despite heavy investment in dairy production in country, imports account for 55% of butter consumption.

SKIM MILK POWDER

Australia exports of SMP are forecast to decline 16% due to the combination of lower production and lower beginning stocks. Exports through May have slowed significantly compared to the same period in 2022. During January-May, overall exports fell by 21,000 tons (29%), led by slower shipments to Indonesia (down 8,500 MT or -53%), Vietnam (down 5,000 MT or -89%) and Malaysia (down 3,200 MT or -86%). Shipments to China have been strong this year, up 4,500 tons (+15%), and continue to account for half of Australia SMP exports as Chinese import demand for SMP has grown in response to lower global SMP prices.

European Union SMP production is forecast down 1% from 2022 reflecting tighter milk supplies. However, global demand for EU SMP has been strong through May, as attractive prices have supported EU competitiveness on the global market. Shipments have grown in each of the top seven markets, primarily in Africa, Middle East, and Southeast Asia. Exports to the two largest markets historically, China and Algeria, have more than doubled.

Although United States SMP is being competitively priced on the global market, exports are forecast to decline 1% from 2022 to 823,000 tons. Contributing to the lower SMP export forecast is slow exports to Southeast Asia, which has been an important market for growing SMP exports, as food inflation and regulatory issues in those countries impact demand for dairy products. Through May, exports have been 2% below 2022 in the same period, with shipments to the Philippines (-43%), Indonesia (-16%), Vietnam (-41%), Malaysia (-52%) and China (-39%) all significantly off last year’s pace. Growth in exports to Mexico (+43%), the largest export market for U.S. SMP exports, offsets the decline in Asian demand, as improving economic conditions drive consumer discretionary spending and higher processor demand for

raw materials for processed

dairy products.

WHOLE MILK POWDER

New Zealand WMP production is forecast at 1.45 million tons in 2023, a 4-percent increase from 2022, but still below the five-year average. Higher returns

for whey, protein concentrates and SMP have seen processors shift milk production away from WMP. That said, WMP production still accounts for more than half of all milk processed for factory use on a milk-equivalent basis and remains the top exported dairy product on a value basis. Through May, exports are 7% higher than 2022 with strong demand from Algeria (shipments have more than doubled) and the United Arab Emirates (+33%). Continued demand from these markets will support year-over- year gains while exports to China and Indonesia moderate.

WMP production in China is forecast to increase to nearly 1.2 million tons due to strong growth in domestic milk production. Milk supplies have outpaced processing demand, prompting local governments in major dairy production regions to allocate funds to subsidize whole milk powder production. Given small capacity for butter and cheese production and high domestic demand for milk powders due to longer shelf life, dairy companies generally purchase raw milk and process it into milk powder for storage in accordance with the “Fresh Milk Purchase and Sales Contract.” Rising domestic WMP production, combined with continued high import prices, has driven a significant decline (-34%) in imports of WMP year-over-year, exacerbated by the General Administration of Customs of the Peoples Republic of China announcing that New Zealand, traditionally the dominant supplier of WMP, was poised to exhaust its preferential quota for 2023 and that safeguard measures would be implemented as built into the free trade agreement between both nations. Imports from New Zealand are down 45% through June.

www.usda.gov

italian food & packaging technology - civ (2023) - september 13 product trends

FOOD PROCESSING

High quality stainless steel filters and pumps

Bruno Wolhfarth, leader in filtration and food transfer technologies, for almost 60 years has been designing and producing stainless steel filters and pumps in its factory on the outskirts of Milan. The quality of the materials and the duration of the equipment are the two points that Bruno Wolhfarth has always considered essential and on which it has built its success.

Within the production process, the electric pump is the least complex and conspicuous element – it actually represents the core, pumping the product that is to be transformed, into the system, or collecting the finished product to be sent to the packaging machines.

System builders and end users are aware of the importance of the pump within the process and fear

the possibility of having to stop the system due to a pump malfunction, while waiting for a spare part or the repairs to be completed by the maintenance technician.

The strength of Wolhfarth electric pumps is the simplicity of disassembly and maintenance: the pump can be easily disassembled and reassembled, even by unskilled personnel.

Furthermore, the pump body machining from the solid bars of stainless steel, with no melting or welding processes guarantees the durability and the finish of the surfaces, in compliance with the most stringent standards in the food and pharmaceutical sectors.

The flexible elastomer impeller allows a strong intake and the more powerful models can gently handle creamy products, such as yoghurt or even very dense products, such as honey and jam.

An ATEX execution is possible for uses in areas at risk of explosion and the materials of the impeller and gaskets are suitable for use in contact with food, in accordance with current regulations.

14 italian food & packaging technology - civ (2023) - september

Bruno Wolhfarth is looking forward to participating in the new edition of Cibus Tec 2023 in Parma -Italy, after the pandemic-related hiatus.

The company will display filter and pump models that have been used for decades in the most im-

duction and washing cycle (clean in place). The possible connection of a Venturi vacuum generator to the solenoid valve facilitates both emptying and fast filling of the pump in the initial phase of work, even with very dense and viscous products.

Given its commitment, even in the challenging years of the pandemic, to offer technologically

Dosing solutions

advanced products, the company is confident that its long-standing and potential customers also have the drive to start over by appreciating machines that can improve and optimise their production process.

(Bruno Wolhfarth - Via Cavour 31 - 26858 Sordio - LO - Italy - Tel. +39 02 9810153 - email: info@ wolhfarth.it - www.wolhfarth.eu)

portant industries in the sector, naturally updated to take account of new user requirements, new applications made possible by advances in electronics, and always in compliance with the latest hygiene and safety regulations.

At the Wolhfarth stand, the electric pump with on-board electronic inverter can be seen in operation as it transfers a high-viscosity gel (90,000 cps.)

This year’s new product will be the patented Hygienic Rapid Sanitary series, an evolution of the historic Rapid and Rapid Sanitaria series: the first electric pump with flexible impeller and drainage system for emptying the pump at the end of work without the need for disassembly. The application of a solenoid valve allows automatic emptying, which is particularly useful in plants where the same pump can be used in both the pro-

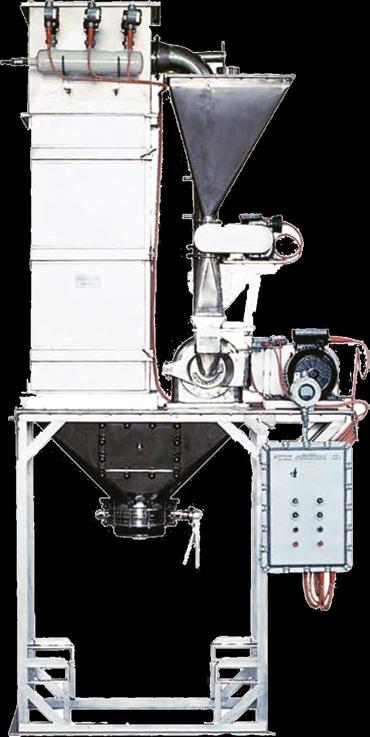

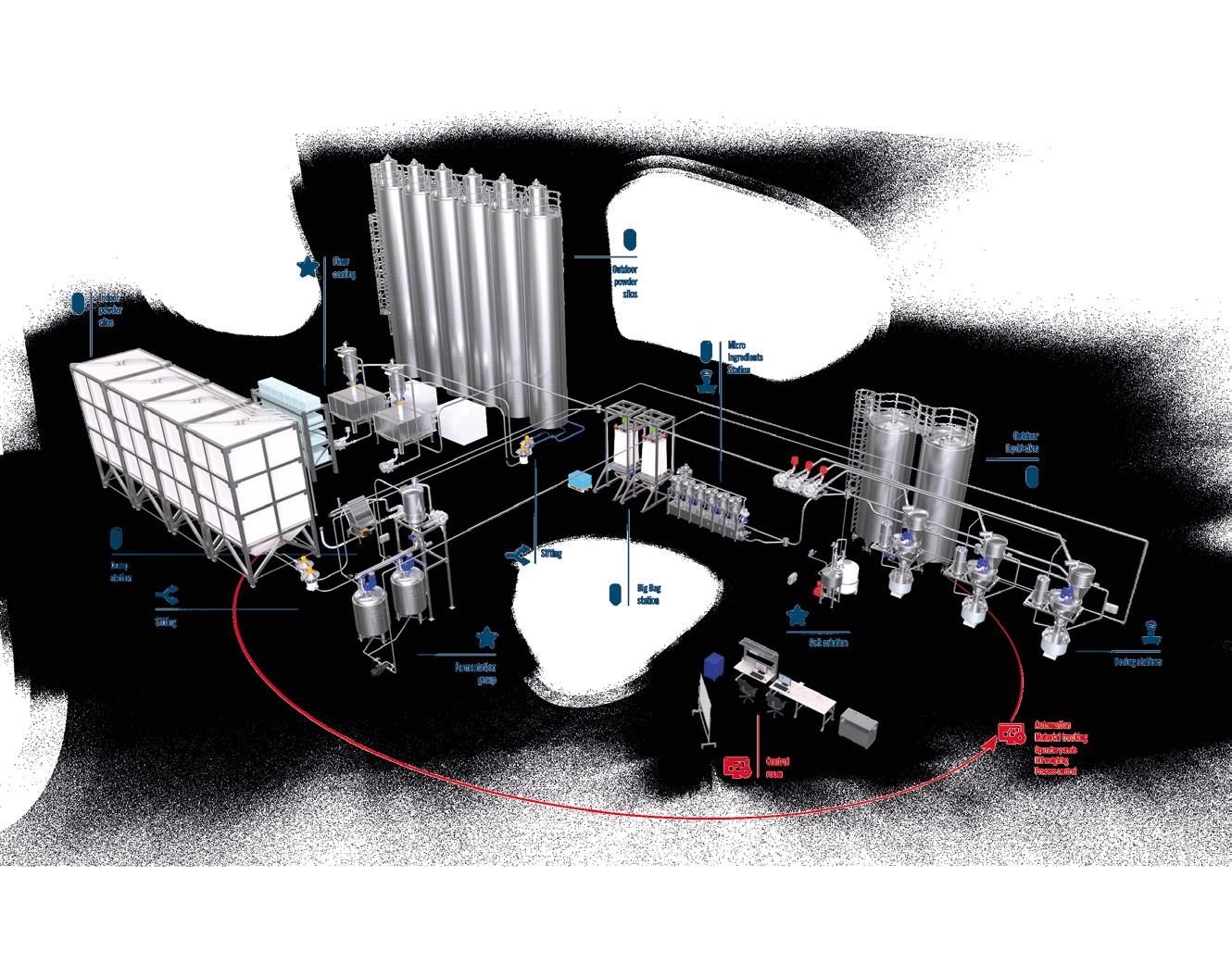

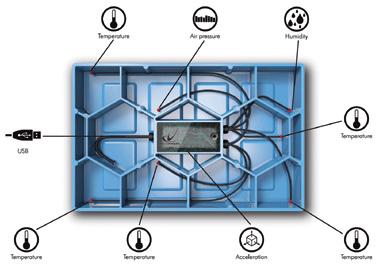

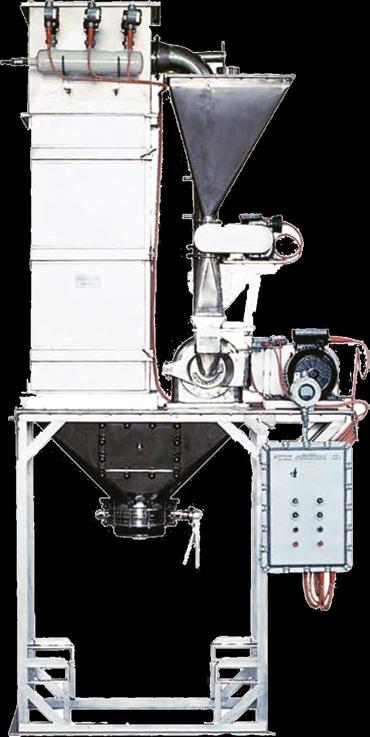

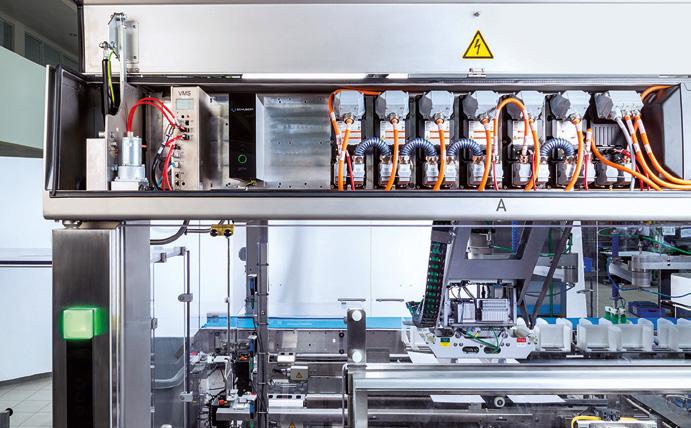

CEPI designs, manufactures and commissions bulk-handling systems for the storage, conveying and metering of raw materials, as well as fully integrated automation and technologies to complete all production processes. A family-run company with an international outlook, CEPI is based in Italy and operates globally, with offices in Malaysia to coordinate operations in the Asian market and a network of local partners spanning the five continents. Since 1985, it has worked with the most important companies from all sectors of food manufacturing.

CEPI’s vision has centered research, customization and flex-

ibility since its beginnings. The mission goes beyond assembling food machinery: it builds turnkey installations that manage the production line from storage to dosing, all the while developing specialized solutions to match diverse and ever-changing needs across the planet. CEPI brings to the table a global knowledge of materials, environments, and markets as well as the continued research that goes into developing around 300 unique systems every year.

Powders, granular products, liquids, fats. Macro, micro, medium volumes. Fermentation, cooling, fluidization, milling, blending,

food processing italian food & packaging technology - civ (2023) - september 15

HRS series stainless steel pump (Bruno Wolhfarth).

CEPI outdoor silos.

rework. CEPI motto is: if your process needs it, we can do it. If we can’t do it yet, we will develop it, just for you. Our technologies evolve to match each individual demand from the manufacturer side, leading to unparalleled technological range.

CEPI’s offer includes multiple indoor and outdoor storing options in stainless steel or antistatic fabric, minisilos and dumping stations for medium production volumes and broad spectrum stations for the storing and accurate dosing of micro ingredients. Materials are moved by clean and efficient conveyance systems designed to minimize energetic impact. Dosing can be continuous or batch, positive, by loss of weight, by volume or by weight, in modular hoppers for powders and tanks for liquids. The 3 in 1 station weighs the ingredient, separates air from product during pneumatic transport and comes with vertical blender for the production of premix. Other applications include flour cooling, fermentation, sugar mills, invert sugar technology, salt solution systems, fat and liquid tanks, fat cold metering, bread

and biscuit rework systems including liquid rework of sandwich biscuits, and CIP washing system for a complete hygienization of tanks and pipes.

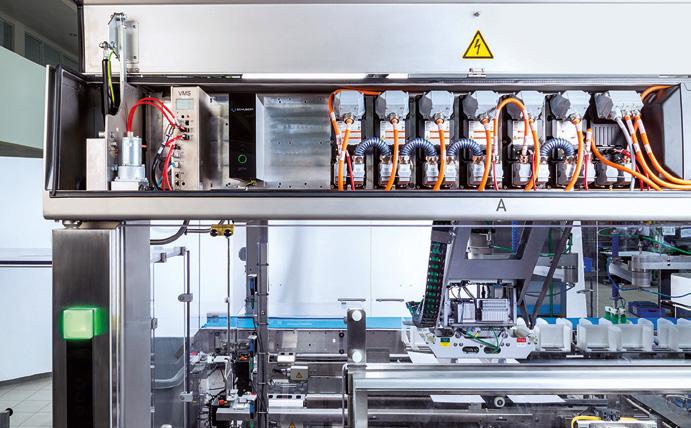

CEPI provides a turn-key system that includes fully integrated automation, with production management through touch panels and software for full traceability and warehouse management. Hardware and software design is done completely in-house. With vast food technology expertise, all the technologies are developed factoring the preservation of flavor and ingredient properties, with automation ensuring repeatability and precision of the recipe. Each system is designed through a comprehensive study manufacturer’s processes that includes all operations from warehouse to marketing, and customized to match analysis of raw materials, site evaluation, environment and consumptions.

CEPI believes in build lasting relationships for lasting projects, through an ongoing conversation which concerns all its aspects: from process and product analysis with hygiene and safety

management and food technology support, to engineering and control, manufacture, installation and service. All these stages are managed internally and with continuity through all operations and all-encompassing support, the company can give each project the care it deserves.

CEPI takes a long-term view when it design systems, in order to create the most flexibile solution for each food manufacturer, one which does not preclude any new path they may take in the future. Because this method is organic and involves all departments, it includes a projection of future productions and makes CEPI installations very easy to adapt to any new developments. One of its strengths is the ability to bring new life to installations that would otherwise be decommissioned. This activity, known as revamping, makes it possible to extend the useful life of the plants indefinitely: systems that were built 30 years ago are still functioning efficiently. The installations are circular products that fit with the circular economy model.

Having experienced continued growth through its history and after the exceptional results of the past few years, CEPI has built a new facility in 2021 that tripled productive area to a total of 15.000 m2. The new home is powered and heated by renewable energy, designed to completely safeguard worker safety, and includes a 240 m2 testing and prototyping room with metrology room as a testament to its dedication to research.

(CEPI - Via Selva 10 Z.I. La Selva - 47122 Forlì - FC - Italy - Tel. +39 0543 940514 - Fax +39 0543 940534 - email:cepi@cepisilos. com - www.cepisilos.com)

food processing 16 italian food & packaging technology - civ (2023) - september

Dosing plant (CEPI).

Food Safety is of paramount importance to protect consumers and their health. As Megadyne, we take up measures to continuously develop solutions improving the level of hygiene and safety in compliance with ISO 22000, EC 1935/2004, EU 10/2011 and FDA standards: Metal & X-Ray Timing Belts, Megafl ex FCM, Megalinear and Megapower FC (Food Contact). Contact us to make your food production safer. www.megadynegroup | info@megadynegroup.com WE

MAKE YOU BUSINESS MOVE NO COMPROMISE IN FOOD SAFETY! Member of Ammega group SUBSCRIBE

to watch the video

Scan

LM at Interpack with its “loops”

The LM Group, with LM, Marpatech and Magnoni brands showed at Interpack quality construction, high versatility and customization.

Similarly to what was shown a year ago at Ipack-Ima, the two installations have made it look two entire lines for the transport and handling, totally conceived to demonstrate the functionality and reliability of the group.

First loop showed a primary packaging transport as cases or flow-pack and itfollows a path that includes a wash down plate divider, a retractable and tilting conveyor, a modular plastic chain curve, a wash down knife edge curve and a sortech. The sortech is a new flexible sorting system highly appreciated around the world and able to meet mul-

tiple sorting, alignment and reject needs. During the transport, product is handled through the various application without being contained by side guides.

In the second line all handling possibilities for empty aluminum cans was shown. The loop has been assembled with a multilaner, an air veil conveyor (which transport and lifts cans through puffs or air jet without moving any me-

Innovation in jelly production

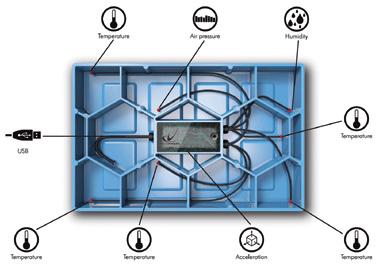

Agathon GmbH – world market leader and benchmark for high quality chocolate moulds – and Pinco SA – drying rooms manufacturer for jelly products – are delighted to announce a cooperation for the development of the logTEC technology for the manufacturing of jellies.

Both innovative companies enter into a partnership supporting the jelly producers’ process monitoring under industry 4.0 standards, e.g. in validation and improvement for the drying cycle.

With the Agathon’s logTEC technology and Pinco´s exper-

tise, a complete data analysis becomes an efficient toolfor all global Pinco customers: an outstanding device for the monitoring of product quality and process transparency, with the

chanical parts), a vacuum system for changing height in a limited space and at the end an automatic twister. This “loop” clearly illustrates some application that LM group, in particular Magnoni brand, can propose for the handling of this very delicate product.

(LM Group - Via delle Nazioni 95 - 41122 Modena - Italy - Tel. +39 0593164411 - Email: info@ lmgroup.it - www.lmgroup.it)

priority on energy analysisand savings.

(Pinco - Via Pra Mag, 9 - 6862 Rancate - Switzerland - Tel. +41 91 640 0800 - Email: info@pinco-sa. com - www.pinco-sa.com)

food processing 18 italian food & packaging technology - civ (2023) - september

Pinsa line by Albaequipment

For an exclusive product like Pinsa, an equally exclusive line is needed.

Pinsa Line has been studied and designed by Albaequipment to process the product as handmade to respect its origins.

The peculiarity of the Pinsa lies in being very digestible because it has less yeast and the dough is left to rest for 24 hours or more. The preparation is based on the right calibration between the mixture of flour and water, in order to give it the appearance of a soft, light and digestible cloud of bread.

The Pinsa dough therefore requires a long process, it is very hydrated and needs careful spreading which, up to now, has been obtained by the fingers of the craftsmen.

But Pinsa Line is the solution. A Line able to work with the yield of hand-made doughs with high hydration.

It is the innovation of the year and is already enjoying enormous success! This line allows you to easily work with highly hydrated dough. The rendering of the bubbles and alveolation is possible thanks to special tools that it was developed after a careful study of the natural movement

of the hands in the dough. You can choose whether you want to automate the entire process or just part of it.

The spreading takes place by working the pinsa with irregularities just like artisanal products.

The production respects the structure of the dough prepared with attention and care. It is possible to insert additional components such as tomato dispensers and spreaders or cheese distributors.

Still not convinced? Come and test your dough in Albaequipment laboratory and what you have read will come to life before your eyes. An artisanal rendering with industrial production!

(Alba & Teknoservice - Via delle Industrie 26 - 35010 Villafranca Padovana - PDItaly - Tel. +39 049 9070380Fax +39 049 9074042 - email: sales@albaequipment.it - www. albaequipment.it)

food processing italian food & packaging technology - civ (2023) - september 19

Megadyne food safety solution

For Megadyne , a global leader in the Power Transmission field and member of AMMEGA Group, food safety is of the utmost importance for the health of all consumers and viability of businesses dealing with food.

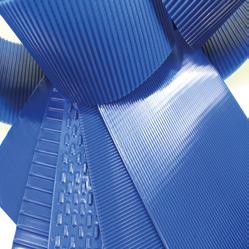

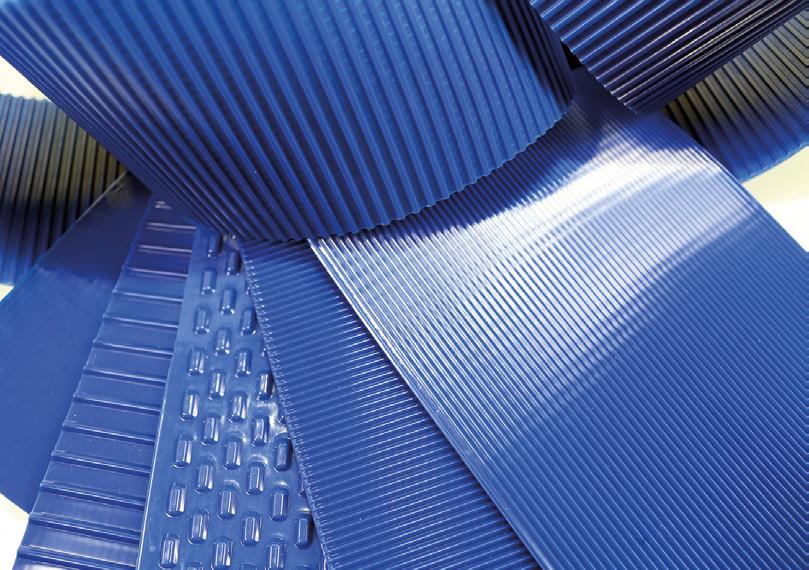

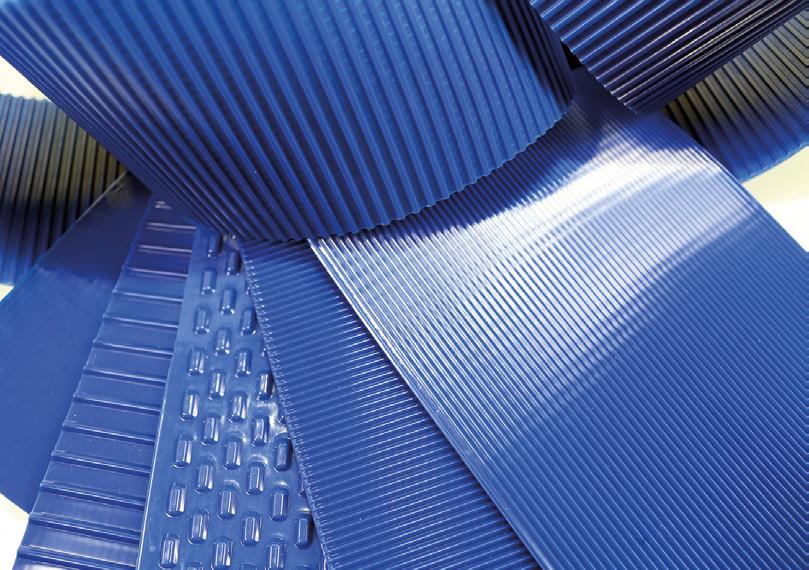

The company has therefore broadened the MEGALINEAR FC (Food Contact) range of belts by introducing new profile options to increase application possibilities in food processing.

Designed specifically for food processing and packaging industries, MEGALINEAR FC is manufactured from materials approved for food contact; according to FDA and European EU 1935/2004, EU 10/2011, EU 174/2015; it’s pro-

duced with T5/T10 pitch without gaps between the teeth to avoid food contamination.

This advanced range of FDA synchronous belts meets the criteria where food contact is required, ensuring maximum reliability and total hygiene without compromising performance.

Indeed, MEGALINEAR FC, matches the power and precision for synchronous conveying (balanced tracking, low running tension, and low vibration) and guarantees excellent resistance to chemicals and corrosion, making it the perfect choice for both wet and dry food contact processing.

MEGALINEAR FC is now available in a wider variety of back-

ing profiles, for all kinds of food processing and packaging applications: Smooth, Longitudinal Ribbed, Transversal Ribbed, Noppen Oval, Roof, Spike Small, Spike Large, Truncated Pyramid, Truncated Cone, Lamella.

In addition, the smooth FC, gap-free belt with T5 and T10 pitch can be further customized with cleats according to your specific need. Contact the experts to learn more about MEGALINEAR FC! By working together, Megadyne can increase your capabilities, implement best-in-class food safety practices, and help you secure and improve your food safety conveying performances.

Food Safety First: Megadyne Binding Promise

Since founded in 1957 in Mathi (Italy), Megadyne has grown to become a Global Leader with a manufacturing and sales presence throughout Europe, Asia and the Americas.

Clean, safe and resistant to oil and grease, their food belts are suitable for contact with all kinds of food products and designed for all food industry processes: from bakery to fruit and vegetables, from confectionaries (including chocolate and candies) to seafood and fish.

(Ammega Italia - Via S. Lucia 114 - 10075 Mathi - TO - ItalyTel +39 011 9268052 - Fax +39 011 9241746 - email: info@ megadynegroup.com - info@ammeraalbeltech.it - www.ammega. com)

food processing 20 italian food & packaging technology - civ (2023) - september

MEGALINEAR FC, the Megadyne food safety solution.

GRINDING MILLS AND PLANTS

ITALO DANIONI manufactures grinding mills, mixers and crushers since 1918. The Company also produces closed circuit, refrigerated and conditioned and explosion proof plants for products in powder Customers have at their disposal a test room with industrial machines for verification of functioning and capacity

Upgrading to existing installations

Via Mecenate, 78/b 20138 Milano - ITALY Tel. +39 02 504095 +39 02 504195 Fax +39 02 5062646 info@danioni.com w w w . d a n i o n i . i t

Being refined is simple

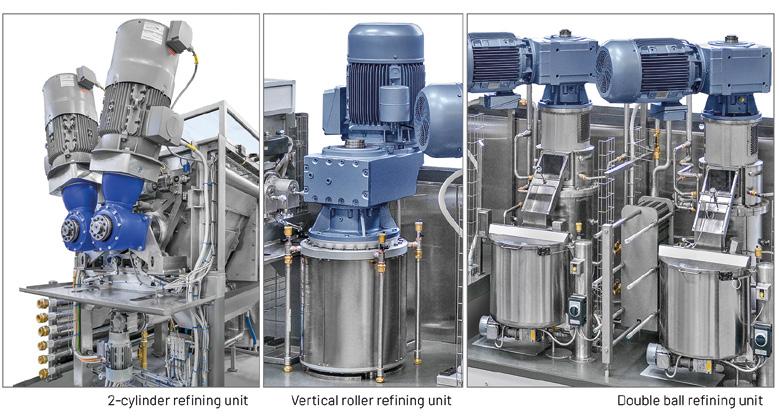

In the field of chocolate and fat cream processing, innovation is a key factor in improving efficiency, reducing space requirements and achieving significant energy savings.

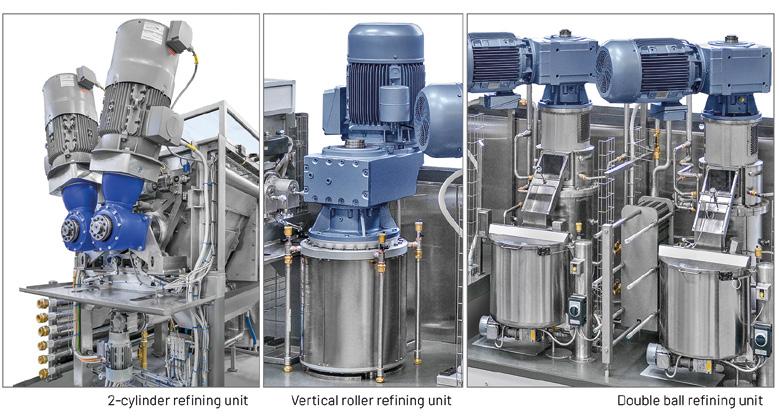

With this in mind, the P10S continuous grinding and refining plant by Tecno 3 proves to be a revolutionary solution.

In addition to simplifying the production process, this compact and precise plant offers extraordinary advantages in achieving optimum fineness for different types of chocolate and fat creams.

Everything goes in the same direction: simplification

The P10S combines grinding and refining in a single step. This represents a major step forward in process simplification, saving precious time and optimising production efficiency. In addition,

the plant reduces the size due to its compact design, offering a versatile solution for limited work space.

Advanced three-stage

technology

The first stage includes a pre-refiner with two horizontal cylinders, followed by a refiner with vertical cylinders in the second stage. The third stage involves the use of a ball refiner to achieve optimal particle size reduction. This combination of grinding units enables consistent, high-precision refining results.

Intelligent process control

Grinding in the ball plant is managed by an advanced electronic logic that considers several critical parameters. The flow rate of product to be refined, rotor speed, working temperature and internal pressure of the refining chamber are carefully monitored

food processing 22 italian food & packaging technology - civ (2023) - september

The P10S plant strives for ever more efficient solutions (Tecno 3).

to ensure ideal particle size distribution. By avoiding the excessive formation of too fine particles (surfins), the resulting chocolate and fat creams have optimal rheological characteristics for the subsequent processing steps.

Preserving product characteristics

A key aspect of the P10S plant is its ability to preserve the organoleptic characteris-

tics of the product. Thanks to the process developed continuously, without contact of the product with the outside world, it is possible to keep the sensorial and taste properties intact. Furthermore, the careful management of temperatures during the milling and refining stages helps to preserve the quality of the final result.

At a time when efficiency and optimisation are crucial to progress, the P10S plant stands

out as a state-of-the-art solution that takes simplification to a next level.

A significant breakthrough for the industry that offers to companies the opportunity to increase their competitiveness and improve profitability.

(Tecno 3 - Via Mastri Cestai 2 - 12040 Corneliano d’Alba - CN - Italy - Tel. +39 0173 610564 - Fax +39 0173 619494e-mail: a.mattis@tecno-3.itwww.tecno-3.it )

Two-stage process for energy valorization of cheese whey

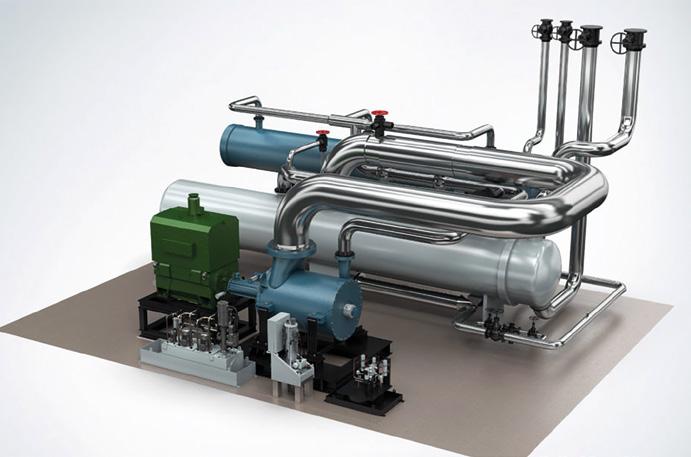

An Italian work published in Fermentation journal investigates a two-stage process scheme for cheese whey valorization through energy recovery in different forms by means of bio-electrochemical systems.

The first stage consisted of an integrated bio-electrochemical process for H2 and electricity production. This combined dark fermentation with an electrochemical system with the aim of overcoming the typical thermodynamic/biochemical limitations of fermentation and enhancing H2 recovery. The second treatment stage involved a single-chamber microbial fuel cell, featuring an innovative configuration consisting of four air cathodes with fly ash as the oxygen reduction catalyst.

The bio-electrochemical process performed in the first stage achieved promising results, displaying a three-times higher H2 production yield compared to

conventional dark fermentation. In addition, the experiments using the MFC in the second stage were found to successfully exploit the effluent from the first

stage, with COD removal yields of 86% ±8% and energy recovery with a maximum current output of 1.6 mA and a maximum power density of 1.2 W/m3

food processing italian food & packaging technology - civ (2023) - september 23

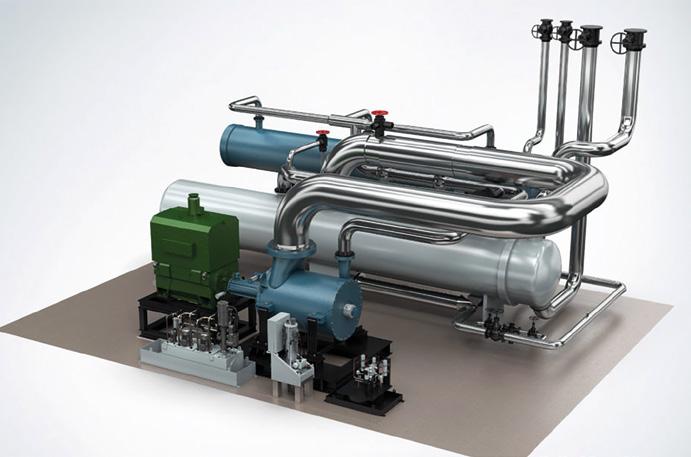

Decarbonizing process heat in the food and beverages industry

High-temperature heat pumps (HTHPs) are an emerging technology to improve overall process efficiency and reduce energy demand while enabling a switch from fossil fuels to renewable electricity. New industrial HTHP technologies aim to achieve an output heat temperature of 250°C, suitable for decarbonising the food and beverages industry considering its temperature requirements of <250°C.

Researchers from Nederland employ a bottom-up approach to investigate the techno-economic feasibility of integrating new HTHP technologies into heat processes of the German food and beverages industry and estimate emissions reduction potentials under waste heat scenarios.

The results published in Resources, Conservation & Recycling journal indicate that the new HTHP technologies

could meet 12 TWh of process heat demand in the German food and beverages industry and cut emissions by 9% considering Germany’s current electricity fuel

mix. A modest carbon tax of 38 E/t CO2 eq. or higher makes the HTHPs cost-competitive with an optimised fossil fuel-based alternative.

Impact of different processing techniques on the black truffle

Fresh truffles which include black truffle (Tuber melanosporum Vittadini) deteriorate and lose aroma rapidly after harvest; therefore, postharvest processing via freeze-drying or encapsulation is an option to preserve truffle aroma for extended supply. However, the aroma profile that directly affects the truffle quality and consumer acceptance is influenced by processing and producers require processing options that balance process-

ing feasibility with retention of a suitable aroma profile.

A study carried out by Australian Researchers aimed to determine the impact of freeze-drying and encapsulation on the profile of key volatiles, consumer discrimination, and overall sensory impression (aroma intensity, liking, and acceptability) of processed truffle products compared to the starting material (positive control). The study, published in the Journal of Food Science, combined experimental-scale processing with GCMS analysis and consumer sensory evaluation to compare and optimize postharvest processing options. Based on the results, some volatile changes were detected in the processed truffle products compared to the positive control which were aligned with the consumer discrimination (triangle

food processing 24 italian food & packaging technology - civ (2023) - september

test) and the aroma intensity score (consumer sensory test). Despite some chemical and sensory differences detected, the consumer panel did not have any preference for processed truffle products compared to the positive control. The overall finding indicates the potential value of processing truffles into a natural flavoring ingredient for food application via freeze-drying or encapsulation, which should be of great interest for the truffle and food industry. According to the correlation analysis, the consumer acceptance of a truffle product may be increased by retaining 1-octen-3-ol

and methional, while reducing the amount of p-cresol in the product.

The postharvest process of turning truffles into a food flavoring ingredient may cause undesirable volatile changes that would directly impact the aroma quality and consumer acceptance of the processed truffle products. Hence, the impacts of freeze-drying and encapsulation on the chemical and sensory profile of truffles were evaluated in this study. Overall, the results of the concurrent instrument and sensory analysis demonstrated that both freeze-drying and encapsulation are potential options for processing.

Estimation of harvested fruit weight with distance sensors

The introduction of fruit tree harvesters on the market allows the opportunity to incorporate new yield monitors. Traditionally, yield has been measured by inthe-field fruit batch weighing systems that employ load cells, which present certain problems as well as oscillations and outliers.

Spanish Researchers propose the development and evaluation of two distance measurement systems (an experimental one using an array of sensors with lowcost, Time-of-Flight technology and another, commercial system, with a 3D camera) to estimate the volume of fruit harvested in a big box and correlate the volume with its weight. To this end, two algorithms were developed to estimate the volume of fruit filling. Several tests were conducted to determine the field of view of the sensors and the influence of illumination, reflectivity of different

surfaces, and vibrations in transit on the measurements they give. Illumination was a limiting factor on the accuracy of the experimental system and required mitigating actions to operate with it. The mean relative error of sensor distance measurement was less than 0.8% and 1.6% for the commercial and experimental systems, respectively, which decreased as distance from the measurement

target increased. Measurements on matte surfaces showed a lower measurement error than those on glossy surfaces, with error being twice as high in the commercial system than in the experimental system. The error in volume estimation was lower in the commercial system and could be reduced to less than 1.6% with pre-calibration. In general, with the accelerations typical of agricultural traffic, in dynamic operation the distance sensors provided less variation in results than the load cells, which would require processing of the recorded signals. In the range of filling a box over 150 kg, the absolute error in weight estimation was 5.4kg for the experimental system and 11.0 kg for the commercial system. However, this error may increase with the use of the experimental system if filling occurs from the center or from the corner.

In general, the systems offer acceptable results for using this technology if extreme accuracy is not required. This work, published in Computers and Electronics in Agriculture journal, establishes the basics of a technology that can be an alternative to load cells and be applied to harvesting machinery to record continuous real-time production.

food processing italian food & packaging technology - civ (2023) - september 25

Infrared and microwave alternate thawing method for frozen pork

The effect of infrared and microwave alternate thawing (IR + MWT) on frozen pork were compared to fresh, air thawing (AT), infrared thawing (IRT), microwave thawing (MWT). The results of this Chinese research were published in Meat Science journal,

The IR + MWT took only about 11.81 min of the thawing time compared to AT 66.5 min, and the Raman spectroscopy and Lowfield nuclear magnetic resonance (LF-NMR) results showed that the IR + MWT maintained better protein secondary structure compo-

sition and moisture state compared to MWT and IRT. In terms of thawing losses, IR + MWT had the lowest loss 1.92%. In terms of texture, IR + MWT had the least effect on the post-thawing textural properties and increased the springiness of the meat. Scanning electron microscopy results also showed that there was reduced damage to the muscle structure with IR + MWT. Regarding the odor of the meat after thawing, IR + MWT retained the odor better and was closer to the fresh sample.

Therefore, IR + MWT can be used to enhance the thawing rate to protect the quality of the thawed pork.

Influence of low-pressure tumbling on the quality characteristics of thawed pork

Maintaining the water holding capacity (WHC) and minimizing the drip loss during the thawing of frozen meat are of utmost importance. With this aim, a Korean study published in the Korean Journal of Food Preservation investigated the physicochemical properties of frozen pork sub-

jected to thawing under different conditions: at room temperature (20°C, under air), at a low temperature (4°C refrigerator, under air), under water (20°C, under water in a vacuum bag), under microwave (microwave-thawing, 260 W), and under low-pressure tumbling (20°C, 0.015 bar, tumbling).

The shortest thawing time for frozen pork was recorded upon low-pressure tumbling thus indicating a fast heat transfer. The lowest drip loss (0.2%) and highest WHC (94.5%) were also recorded under this condition. A significantly higher drip loss was observed upon microwave-(1.0%) and water-thawing (1.2%), which resulted in the lowest WHC in microwave thawing (87.2%). The highest total count of aerobic bacteria and coliform group were observed upon room temp thawing while the low pressure tumbling and thawing resulted in the lowest aerobic bacteria (1.90 log CFU/g) and coliform (0.78 log CFU/g) count. Consequently, thawing by low pressure tumbling afforded the best food quality.

food processing 26 italian food & packaging technology - civ (2023) - september

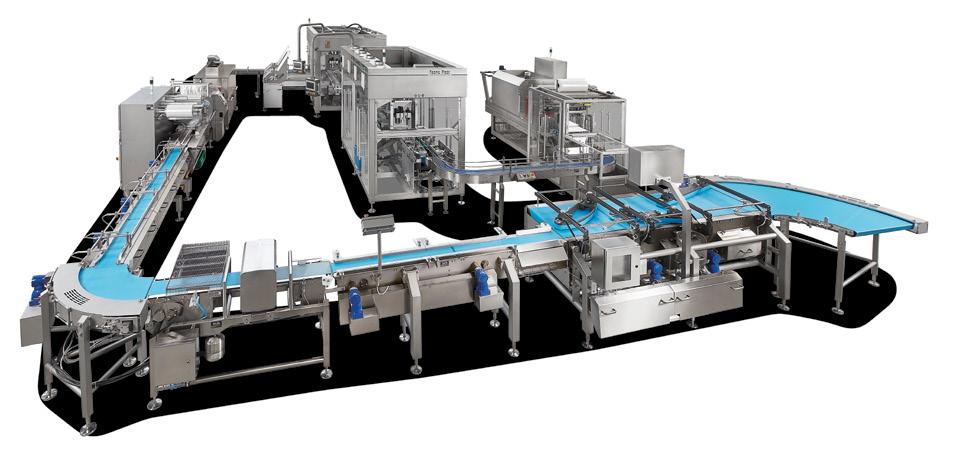

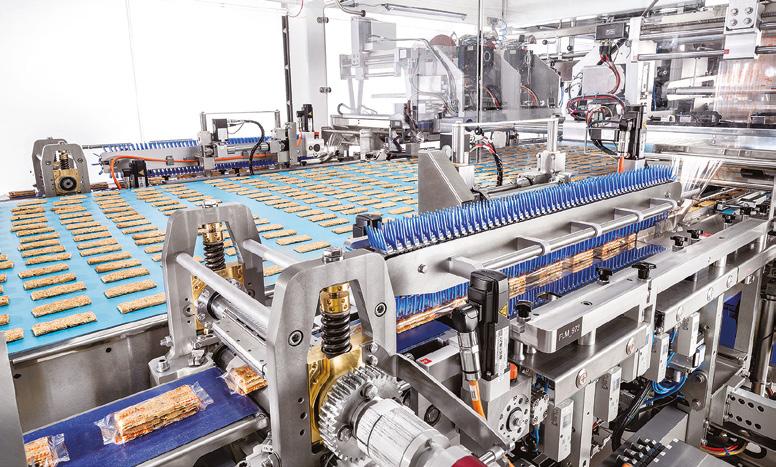

Baked goods: Automated packaging for sensitive goods

Baked goods are popular, which lends them their enormous variety worldwide. Whether from the supermarket shelf or as frozen delivery – bread, bread rolls, croissants, pastries and cakes are sensitive foodstuffs that place high demands on production processes and packaging. Therefore, automation and digitalisation are also becoming increasingly important issues for the bakery industry. And the issue of sustainability has long since arrived in the sector.

Without any form of packaging, bread, bread rolls etc., are usually only available in a bakery. Freshly bought products should however also be promptly consumed. By contrast, industrially produced baked goods cannot do without packaging. Soft croissants or cakes, for example, are very sensitive to pressure, biscuits are often fragile. Robust trays are needed, while other baked goods can be safely packed inside tube bags. But packaging not only protects against mechanical hazards: Certain barrier properties allow packaging to extend shelf life without compromising on high quality. Growing mobility, an increase in single households and increasing consumption outside the home make reusable packaging for use to-go or smaller packaging sizes very attractive. Sustainable packaging materials must meet all these requirements as well, which are increasingly in demand by the market – a real challenge for the producers of baked goods and packaging. But recyclability, reduced usage of material and less packaging have long become trends within the baked goods sector, and

28 italian food & packaging technology - civ (2023) - september PACKAGING

TRENDS

Baked goods are sensitive products that need safe packaging. Image: GHM.

so, monomaterial film, paper-based solutions and cardboard packaging with biobased coatings have already become industry staples.

Europe dominates the consumption of baked goods

Statista has determined the turnovers for the production of baked goods within the European Union: According to the results, Germany with a turnover of 22.7 billion euros and France with 21.5 billion euros are at the top, followed by Italy (6.7 billion euros), Spain (5.8 billion euros) and Poland (4.7 billion euros). On the global market for baked goods, according to Mordor Intelligence, Europe generates the largest share of turnover. According to the market researchers’ infor-

mation, the developed markets in Western Europe are mature and saturated when it comes to baked goods, while the developing countries in Eastern Europe drive sales of biscuits and bread due to their high demand for convenience food products. The European baked goods market is said to be well established in terms of the supply chain, the product range, the sales channels and the preferences of consumers.

Automated solutions for the bakery industry

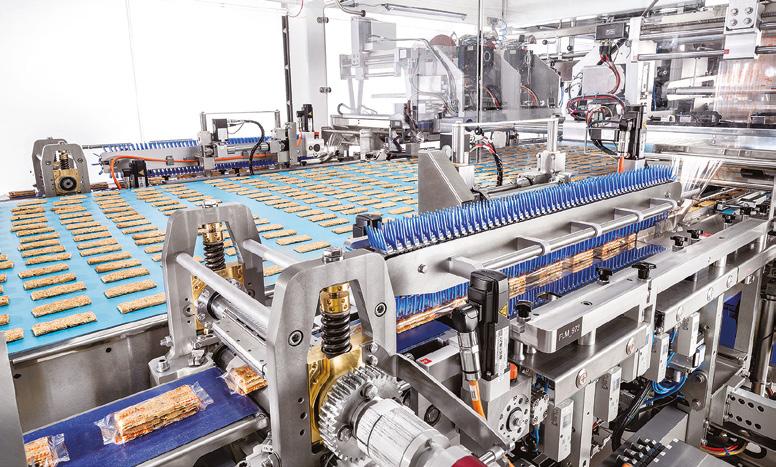

Things are not easy right now for the baked goods industry: High cost pressure, increasing variety of products, a change in consumers’ habits and the demand for more sustainability result in new requirements towards both production and packaging processes. In order to remain competitive, manufacturers of baked goods need flexible systems with which to react to market trends. In the future, it will be almost impossible to avoid a higher degree of automation. Digital processing and packaging machines are therefore of great importance, as is the growing integration of robots. These automated assistants have become an integrated part of the bakery industry as well. Pick-and-place robots, equipped with suitable gripping tools, are even packaging sensitive products like biscuits, bars or other baked goods. If the product or format changes on the packaging line, only the associated gripping tool needs to be changed. Long downtimes are avoided this way. For example, Syntegon has developed a proprietary Intelligent Direct Handling (IDH) pick-and-place system for cookies, crackers and biscuits, which uses linear motor technology for an especially gentle handling of the sensitive products. The system also enables faster production speeds, as it can grip several products at the same time and place them on feeding belts or into trays in a single work step.

Packaging machine manufacturer R. Weiss

Packaging offers complete packaging systems for the bakery industry, which are based on a modular system. This system uses standard modules for all packaging processes, like righting, top loading, closing, marking and palletising. The picker lines consist of several cells in a row, which, depending on the requirements, are equipped with several delta pickers mounted one after the other. They are designed for sorting and packaging unpacked products and products in primary packaging. Products pre-grouped in a line or fed chaotically are recognised by a camera system and fed into the top loading area through a transport system.

packaging trends italian food & packaging technology - civ (2023) - september 29

Robots are also used in final packaging: A strudel dough manufacturer from Vienna, for example, uses two Stäubli robots to meet the increasing demand. Among the special properties of the line are the hanging arrangement of the two robots as well as the absence of a safety guard. The Swiss manufacturer’s robots package strudel dough for the food industry in a 1.5-second-rhythm: four packages wrapped in foil, each containing two sheets weighing 125 grams each, are packed inside a box. One robot grips the units wrapped in foil, while the other prepares the box.

Cobots are fast learners

Collaborative robots, also known as cobots, make production even faster and more flexible. Packaging machine manufacturer Gerhard Schubert uses cobots in their machine concepts for fast feeding of different products. The new Schubert cobots tog.519 are ready for serialised production and are optimally

suited for retrieving light-weight products via pickand-place from a disordered feed and processing them with a frequency of 90 cycles per minute. The AI-supported programming and image processing has been designed in such a way that customers can easily carry out a format change without any necessary programming and in a very short time. In principle, the only thing that needs to be done is to hold the new product up in front of the cobot. According to the manufacturer, the advantages of this cobot solution are flexible application sites, a large variety of pick-and-place tasks, a high processing speed and its very simple operation.

Using different recyclable types of wrap on one system

Depending on their consistency and ingredients, baked goods need packaging with different barrier properties. If products change frequently, manufacturers often have to quickly change between tube wraps with different properties. To solve this problem, Schubert offers a flow packer with matching sealing technology in their portfolio. This makes it possible to use both recyclable mono-plastic wraps and paper-based tube wraps on the same machine.

Interpack exhibitor Multivac, too, is able to fall back on their experience from a wide range of different projects for the bakery industry. These include handling very different products, for example, toasties, bread or pancakes – and individually designed line concepts to match. For example, the company has developed a full wrap labelling solution for foldable plastic trays. Pressure-sensitive baked goods like cookies, muffins, donuts, pieces of pie or entire

packaging trends 30 italian food & packaging technology - civ (2023) - september

A newly developed picker technology based on linear motors guarantees an especially gentle handling due to even movement.

Image: Syntegon Technology.

The Syntegon IDH pick-and-place solution offers a high grade of flexibility for both products and packaging style.

Image: Syntegon Technology

cakes are often packaged in such transparent foldable trays, which are then usually wrapped with a cardboard package band. The conveyor belt labeller by Multivac is said to save up to 70 percent of material compared to labelling with a cardboard package band. The model features servo-driven pressure brushes, which allow for C- and D-labelling of up to 120 packages per minute at a label width of up to 500 millimetres. Other than as a simple top label, a label can be placed in a C-shape over three sides or in a D-shape over all four sides of the packaging. Both the C- and D-labels have the advantage of sealing the package at the same time according to the manufacturer. With the new full wrap labelling solution, Multivac has expanded their portfolio for the baking trade and the bakery industry.

Producing baked goods at high speed

Many systems in the bakery industry work at very high speeds, but at the same time, there is an expectation of constant high quality. Mixing and kneading systems for constant operation, like those of interpack exhibitor Zeppelin, are the tools needed for the job and can produce 20,000 pretzels per hour, two million bread rolls a day or three tons of biscuit dough per hour. Before packaging, many baked goods must be precisely cut to size. Döinghaus offers individual solutions for cutting that utilise ultrasound, among them the universal cutter Ultracut Nado, which cuts both round and angular products. The size of individual piec-

This flow packer with flexible lateral sealing can process different recyclable wraps on the same system.

Image: Gerhard Schubert GmbH.

es and segments, as well as different cutting speeds, are freely selectable using a touch panel with intuitive operation.

And igus GmbH from Cologne, manufacturer of plastic bearings made entirely of plastic as well contributes to seamless operations in the production of baked goods. A greaseless linear system, for example, is being used in an industrial wafer baking system made by specialised mechanical engineering company Walterwerk. The system bakes standardised wafers for the industrial production of ice cream, which are fed into a rolling station and rolled up while still warm. Afterwards, they are transported to the cooling tower over a conveyor belt, before the wafer is given a paper cone in the confection area. In this area, the linear bearings made of tribo-optimised high-performance polymers by igus are used during separating and feeding.

www.interpack.com

A full wrap solution reduces the materials used when labelling foldable trays.

Image: Multivac.

packaging trends italian food & packaging technology - civ (2023) - september 31

The european market for carton board

During the pandemic, online retail virtually exploded – but now the development of e-commerce is slowing down again. Nonetheless, manufacturers and suppliers of shipping packaging can continue to expect growth, even if it is no longer as strong as in the previous record years of 2020 and 2021.

In their new market study on corrugated board, solid board and cartonboard packaging, the analysts at Ceresana forecast that demand in Europe for these materials will increase by an average rate of 1.8% per year until 2032. Individual branches of the economy are suffering from the poor consumer confidence, such as paper goods, stationery, office and household supplies, cleaning and laundry. Conversely, demand for packaging is growing, particularly for e-commerce, electrical and electronics, pharmaceuticals and medicine but also for chilled and frozen food.

Sustainable Corrugated Board for the Circular Economy

Corrugated board is a true closed-loop product made from renewable raw materials and is mainly manufactured from waste paper and used cartonboard; the pulp for virgin fibers usually does not come from trees cut down specifically for this purpose but from scrap and thinned wood. The smooth and corrugated paper webs are glued together with glue made from plant starch. Stable packaging made of corrugated board offers very good product protection and stackability at low weight. They can usually be reused and recycled several times; in some cases, they are compostable after use. In many cases, corrugated board is therefore a more environmentally

packaging trends 32 italian food & packaging technology - civ (2023) - september

friendly alternative to plastic packaging. The current market study by Ceresana examines the demand for corrugated board packaging for 10 individual application areas, such as food, beverages, fashion, furniture and chemical products.

Combining Cardboard and Plastic for Effective Advertising