OMT260553ISSUEH3(ENGLISH)

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofitsconstituents areknowntotheStateofCaliforniatocausecancer, birthdefects,andotherreproductiveharm.

Ifthisproductcontainsagasolineengine: WARNING

Theengineexhaustfromthisproductcontains chemicalsknowntotheStateofCaliforniatocause cancer,birthdefectsorotherreproductiveharm.

TheStateofCaliforniarequirestheabovetwowarnings. AdditionalProposition65Warningscanbefoundinthismanual.

DOWNLOAD OPERATOR

Introduction

Foreword

READTHISMANUALcarefullytolearnhowtooperate andserviceyourmachinecorrectly.Failuretodoso couldresultinpersonalinjuryorequipmentdamage. Thismanualandsafetysignsonyourmachinemayalso beavailableinotherlanguages.(SeeyourJohnDeere dealertoorder.)

THISMANUALSHOULDBECONSIDEREDapermanent partofyourmachineandshouldremainwiththemachine whenyousellit.

MEASUREMENTSinthismanualaregiveninboth metricandcustomaryU.S.unitequivalents.Useonly correctreplacementpartsandfasteners.Metricandinch fastenersmayrequireaspecificmetricorinchwrench.

RIGHT-HANDANDLEFT-HANDsidesaredeterminedby facinginthedirectionofforwardtravel.

WRITEPRODUCTIDENTIFICATIONNUMBERS(P.I.N.) intheMachineNumberssection.Accuratelyrecordall thenumberstohelpintracingthemachineshoulditbe stolen.Yourdealeralsoneedsthesenumberswhenyou orderparts.Filetheidentificationnumbersinasecure placeoffthemachine.

WARRANTYisprovidedaspartofJohnDeere'ssupport programforcustomerswhooperateandmaintaintheir

equipmentasdescribedinthismanual.Thewarrantyis explainedonthewarrantycertificateorstatementwhich youshouldhavereceivedfromyourdealer.

ThiswarrantyprovidesyoutheassurancethatJohn Deerewillbackitsproductswheredefectsappearwithin thewarrantyperiod.Insomecircumstances,JohnDeere alsoprovidesfieldimprovements,oftenwithoutcharge tothecustomer,eveniftheproductisoutofwarranty. Shouldtheequipmentbeabused,ormodifiedtochange itsperformancebeyondtheoriginalfactoryspecifications, thewarrantywillbecomevoidandfieldimprovements maybedenied.Settingfueldeliveryabovespecifications orotherwiseoverpoweringmachineswillresultinsuch action.

THETIREMANUFACTURER'Swarrantysuppliedwith yourmachinemaynotapplyoutsidetheU.S.

Ifyouarenottheoriginalownerofthismachine,itisin yourinteresttocontactyourlocalJohnDeeredealerto informthemofthisunit'sserialnumber.ThiswillhelpJohn Deerenotifyyouofanyissuesorproductimprovements.

DX,IFC7-19-03APR09-1/1

ManualIdentification—READTHISFIRST!

IMPORTANT:Useonlysupportingmanuals designatedforyourspecificmachine.If incorrectmanualischosen,improperservice mayoccur.Verifyproductidentification number(PIN)andenginemodelnumberwhen choosingthecorrectmanual.

ChoosingtheCorrectSupportingManuals

JohnDeerefourwheeldrive(4WD)loadersareavailable indifferentmachineconfigurationsbasedonthevarious marketsintowhichtheyaresold.Differentsupporting manualsexistfordifferentmachineconfigurations. Whennecessary,productserialnumbersandengine modelnumbersarelistedonthefrontcoversof4WD loadermanuals.Thesenumbersareusedtoidentifythe correctsupportingmanualforyourmachine.

ProductSerialNumberIdentification

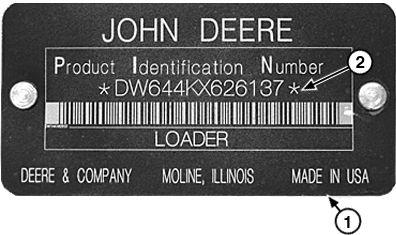

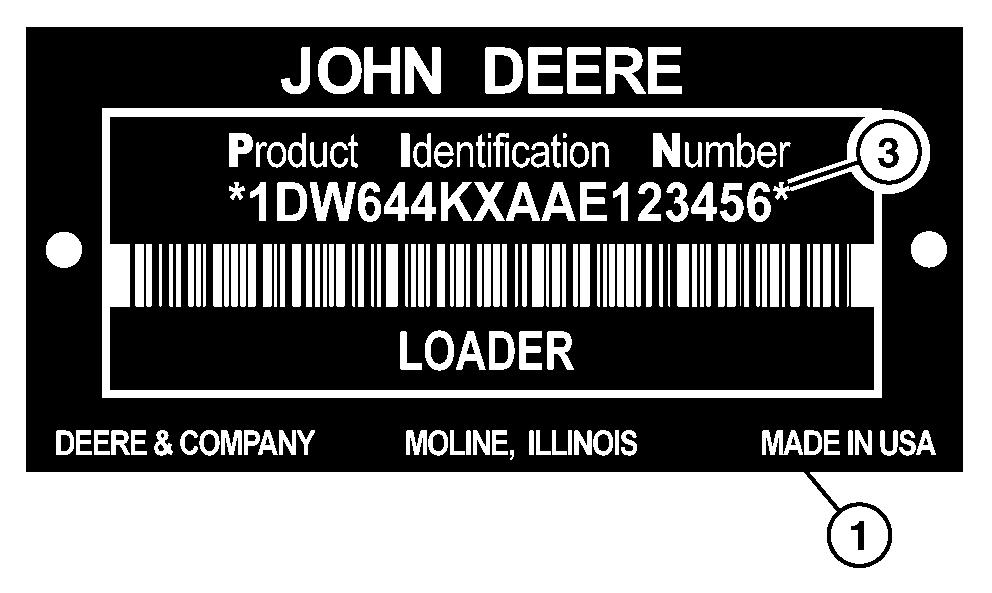

Theproductidentificationnumber(PIN)plate(1)islocated onleftsideofmachineframeunderthecabdoor.Each machinehasa13-characterPIN(2)or17-characterPIN (3)shownonthisplate.Thelast6charactersofthePIN representthemachine'sproductserialnumber.

1—PINPlate 2—13-CharacterPIN 3—17-CharacterPIN

PINPlateLocation

PINPlate(13-character)

PINPlate(17-character)

EngineModelNumberIdentification

Introduction

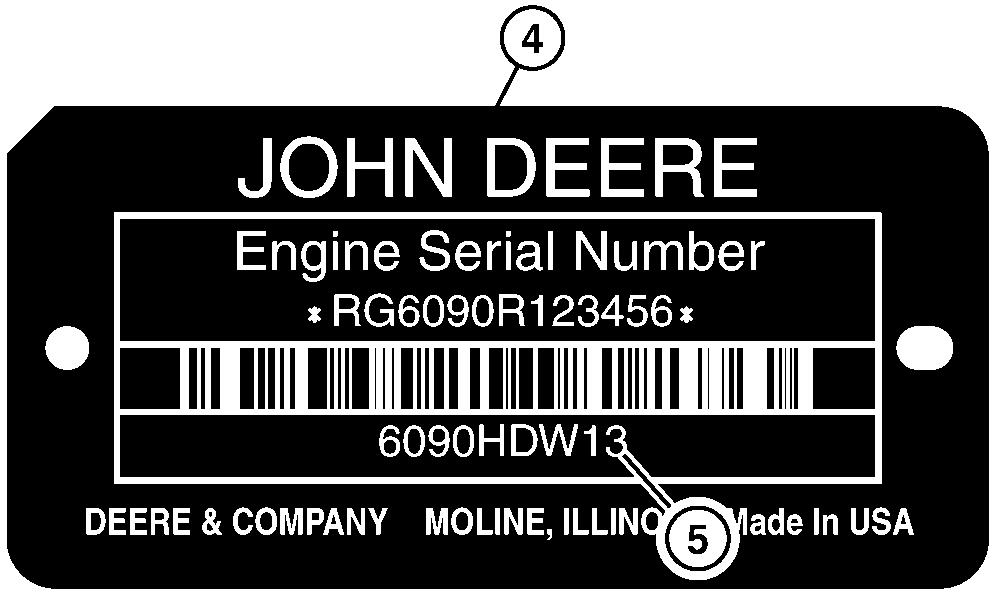

EngineSerialNumberPlate

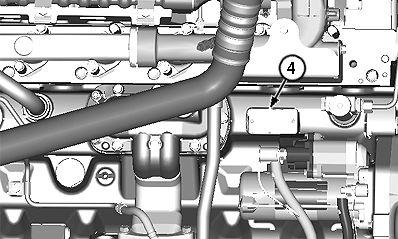

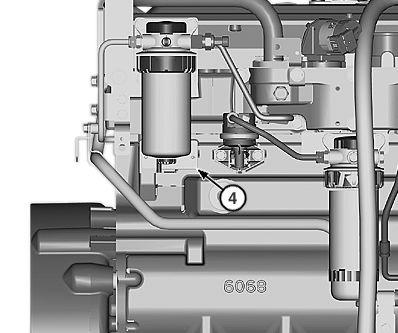

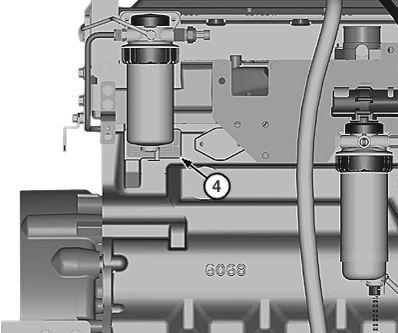

Theengineserialnumberplate(4)islocatedontheright sideoftheengineforenginemodel6090HDW13.It islocatedontheleftsideofengineforenginemodels 6068HDW80and6068HDW83.Eachenginehasa 9-characterenginemodelnumber(5)shownonthisplate.

EngineEmissionsLevelIdentification

The9-characterenginemodelnumbercorrespondstoa specificengineemissionslevel.

EngineModelNumberEngineEmissionsLevel

6090HDW13

6068HDW80

InterimTier4/StageIIIB

Tier3/StageIIIA

6068HDW83 StageII

Formachinesequippedwitha17-characterPIN,where the11th characteris“E”,“D”,or“C”,thischaracteralso correspondstoaspecificengineemissionslevel.

NOTE:Latermachineswitha17-characterPINidentify engineemissionslevel(“E”,“D”,or“C”)with the11th character.Earliermachineswitha 17-characterPINdonotidentifyengineemissions levelwiththe11th character.

17-CharacterPIN(11th character)

xxxxxxxxxxExxxxxx

EngineEmissionsLevel

InterimTier4/StageIIIB

xxxxxxxxxxDxxxxxx Tier3/StageIIIA

xxxxxxxxxxCxxxxxx StageII

4—EngineSerialNumberPlate5—9-CharacterEngineModel Number

EngineSerialNumberPlateLocation—6090HDW13

EngineSerialNumberPlateLocation—6068HDW80

EngineSerialNumberPlateLocation—6068HDW83

IMPORTANT

Warrantywillnotapplytoengineanddrivetrainfailures resultingfromunauthorizedadjustmentstothisengine.

Unauthorizedadjustmentsareinviolationoftheemissions regulationsapplicabletothisengineandmayresultin substantialfinesandpenalties.

VD76477,000104D-19-27JUN12-1/1

EPANon-roadEmissionsControlWarrantyStatement—CompressionIgnition

DXLOGOV1—UN—28APR09

TodetermineiftheJohnDeereenginequalifiesfortheadditionalwarrantiessetforthbelow,lookforthe"EmissionsControlInformation"label locatedontheengine.IftheengineisoperatedintheUnitedStatesorCanadaandtheEmissionsControlinformationlabelstates:"Thisengine complieswithUSEPAregulationsfornonroadandstationarydieselengines”,or“ThisengineconformstoUSEPAnonroadcompression-ignition regulations”,refertothe"U.S.andCanadaEmissionControlWarrantyStatement."IftheengineisoperatedinCalifornia,andthelabelstates:"This enginecomplieswithUSEPAandCARBregulationsfornonroaddieselengines”,or“ThisengineconformstoUSEPAandCalifornianonroad compression-ignitionemissionregulations”,alsorefertothe"CaliforniaEmissionControlWarrantyStatement.”

Warrantiesstatedonthiscertificatereferonlytoemissions-relatedpartsandcomponentsofyourengine.Thecompleteenginewarranty,less emissions-relatedpartsandcomponents,isprovidedseparately.Ifyouhaveanyquestionsaboutyourwarrantyrightsandresponsibilities, youshouldcontactJohnDeereat1-319-292-5400.

JOHNDEERE'SWARRANTYRESPONSIBILITY

JohnDeerewarrantstotheultimatepurchaserandeachsubsequentpurchaserthatthisoff-roaddieselengineincludingallpartsofits emission-controlsystemwasdesigned,builtandequippedsoastoconformatthetimeofthesalewithSection213oftheCleanAirActandisfree fromdefectsinmaterialsandworkmanshipwhichwouldcausetheenginetofailtoconformwithapplicableUSEPAregulationsforaperiodoffive yearsfromthedatetheengineisplacedintoserviceor3,000hoursofoperation,whicheverfirstoccurs.

Whereawarrantableconditionexists,JohnDeerewillrepairorreplace,asitelects,anypartorcomponentwithadefectinmaterialsor workmanshipthatwouldincreasetheengine’semissionsofanyregulatedpollutantwithinthestatedwarrantyperiodatnocosttoyou,including expensesrelatedtodiagnosingandrepairingorreplacingemission-relatedparts.Warrantycoverageissubjecttothelimitationsandexclusions setforthherein.Emission-relatedcomponentsincludeenginepartsdevelopedtocontrolemissionsrelatedtothefollowing:

Air-InductionSystem FuelSystem IgnitionSystem ExhaustGasRecirculationSystems

EMISSIONWARRANTYEXCLUSIONS

AftertreatmentDevices

CrankcaseVentilationValves Sensors

EngineElectronicControlUnits

JohnDeeremaydenywarrantyclaimsformalfunctionsorfailurescausedby:

• Non-performanceofmaintenancerequirementslistedintheOperator’sManual

• Theuseoftheengine/equipmentinamannerforwhichitwasnotdesigned

• Abuse,neglect,impropermaintenanceorunapprovedmodificationsoralterations

• AccidentsforwhichitdoesnothaveresponsibilityorbyactsofGod

Theoff-roaddieselengineisdesignedtooperateondieselfuelasspecifiedintheFuels,LubricantsandCoolantssectionintheOperatorsManual. Useofanyotherfuelcanharmtheemissionscontrolsystemoftheengine/equipmentandisnotapprovedforuse.

TotheextentpermittedbylawJohnDeereisnotliablefordamagetootherenginecomponentscausedbyafailureofanemission-related part,unlessotherwisecoveredbystandardwarranty.

THISWARRANTYISEXPRESSLYINLIEUOFANYOTHERWARRANTIES,EXPRESSORIMPLIED,INCLUDINGANYWARRANTY

DX,EMISSIONS,EPA-19-12DEC12-2/2

CARBNon-roadEmissionsControlWarrantyStatement—CompressionIgnition

DXLOGOV1—UN—28APR09

CALIFORNIAEMISSIONSCONTROLWARRANTYSTATEMENT YOURWARRANTYRIGHTSANDOBLIGATIONS

TodetermineiftheJohnDeereenginequalifiesfortheadditionalwarrantiessetforthbelow,lookforthe“EmissionControlInformation”labellocated ontheengine.IftheengineisoperatedintheUnitedStatesorCanadaandtheenginelabelstates:“ThisenginecomplieswithUSEPAregulations fornonroadandstationarydieselengines”,or“ThisenginecomplieswithUSEPAregulationsforstationaryemergencydieselengines”,refertothe “U.S.andCanadaEmissionControlWarrantyStatement.”IftheengineisoperatedinCalifornia,andtheenginelabelstates:“Thisenginecomplies withUSEPAandCARBregulationsfornonroaddieselengines”alsorefertothe“CaliforniaEmissionsControlWarrantyStatement.”

Warrantiesstatedonthiscertificatereferonlytoemissions-relatedpartsandcomponentsofyourengine.Thecompleteenginewarranty,less emission-relatedpartsandcomponents,isprovidedseparately.Ifyouhaveanyquestionsaboutyourwarrantyrightsandresponsibilities, youshouldcontactJohnDeereat1-319-292-5400.

CALIFORNIAEMISSIONSCONTROLWARRANTYSTATEMENT:

TheCaliforniaAirResourcesBoard(CARB)ispleasedtoexplaintheemission-controlsystemwarrantyon2013through2015off-roaddiesel engines.InCalifornia,newoff-roadenginesmustbedesigned,builtandequippedtomeettheState’sstringentanti-smogstandards.JohnDeere mustwarranttheemissioncontrolsystemonyourenginefortheperiodsoftimelistedbelowprovidedtherehasbeennoabuse,neglector impropermaintenanceofyourengine.

Youremissioncontrolsystemmayincludepartssuchasthefuelinjectionsystemandtheairinductionsystem.Alsoincludedmaybehoses,belts, connectorsandotheremission-relatedassemblies.

JohnDeerewarrantstotheultimatepurchaserandeachsubsequentpurchaserthatthisoff-roaddieselenginewasdesigned,built,andequipped soastoconformatthetimeofsalewithallapplicableregulationsadoptedbyCARBandisfreefromdefectsinmaterialsandworkmanshipwhich wouldcausethefailureofawarrantedparttobeidenticalinallmaterialrespectstothepartasdescribedinJohnDeere'sapplicationforcertification foraperiodoffiveyearsfromthedatetheengineisdeliveredtoanultimatepurchaseror3,000hoursofoperation,whicheveroccursfirstforall enginesratedat19kWandgreater.Intheabsenceofadevicetomeasurehoursofuse,theengineshallbewarrantedforaperiodoffiveyears.

EMISSIONSWARRANTYEXCLUSIONS:

JohnDeeremaydenywarrantyclaimsforfailurescausedbytheuseofanadd-onormodifiedpartwhichhasnotbeenexemptedbytheCARB.A modifiedpartisanaftermarketpartintendedtoreplaceanoriginalemission-relatedpartwhichisnotfunctionallyidenticalinallrespectsandwhich inanywayaffectsemissions.Anadd-onpartisanyaftermarketpartwhichisnotamodifiedpartorareplacementpart.

InnoeventwillJohnDeere,anyauthorizedenginedistributor,dealer,orrepairfacility,oranycompanyaffiliatedwithJohnDeerebeliable forincidentalorconsequentialdamage.

JOHNDEERE'SWARRANTYRESPONSIBILITY:

Whereawarrantableconditionexists,JohnDeerewillrepairorreplace,asitelects,youroff-roaddieselengineatnocosttoyou,including diagnosis,partsorlabor.Warrantycoverageissubjecttothelimitationsandexclusionssetforthherein.Theoff-roaddieselengineiswarranted foraperiodoffiveyearsfromthedatetheengineisdeliveredtoanultimatepurchaseror3,000hoursofoperation,whicheveroccursfirst. Thefollowingareemissions-relatedparts:

AirInductionSystem

• Intakemanifold

• Turbocharger

• Chargeaircooler

FuelMeteringsystem

• Fuelinjectionsystem

ExhaustGasRecirculation

• EGRvalve

CatalystorThermalReactorSystems

• Catalyticconverter

• Exhaustmanifold

Emissioncontrollabels

ParticulateControls

• Anydeviceusedtocaptureparticulate emissions

• Anydeviceusedintheregenerationofthe capturingsystem

• Enclosuresandmanifolding

• SmokePuffLimiters

PositiveCrankcaseVentilation(PCV)System

• PCVvalve

• Oilfillercap

AdvancedOxidesofNitrogen(NOx)Controls

• NOxabsorbersandcatalysts

SCRsystemsandureacontainers/dispensing systems

MiscellaneousItemsusedinAboveSystems

• Electroniccontrolunits,sensors,actuators, wiringharnesses,hoses,connectors,clamps, fittings,gasket,mountinghardware

Anywarrantedemissions-relatedpartscheduledforreplacementasrequiredmaintenanceiswarrantedbyJohnDeerefortheperiodoftimeprior tothefirstscheduledreplacementpointforthepart.Anywarrantedemissions-relatedpartnotscheduledforreplacementasrequiredmaintenance orscheduledonlyforregularinspectioniswarrantedbyJohnDeereforthestatedwarrantyperiod.

OWNER'SWARRANTYRESPONSIBILITIES:

Astheoff-roaddieselengineowneryouareresponsiblefortheperformanceoftherequiredmaintenancelistedinyourOperator’sManual.John Deererecommendsthattheownerretainallreceiptscoveringmaintenanceontheoff-roaddieselengine,butJohnDeerecannotdenywarranty solelyforthelackofreceiptsorfortheowner’sfailuretoensuretheperformanceofallscheduledmaintenance.However,astheoff-roaddiesel engineowner,youshouldbeawarethatJohnDeeremaydenyyouwarrantycoverageifyouroff-roaddieselengineoraparthasfaileddueto abuse,neglect,impropermaintenanceorunapprovedmodifications.

Theoff-roaddieselengineisdesignedtooperateondieselfuelasspecifiedintheFuels,LubricantsandCoolantssectionintheOperatorsManual. Useofanyotherfuelmayresultintheenginenolongeroperatingincompliancewithapplicableemissionsrequirements.

Theownerisresponsibleforinitiatingthewarrantyprocess,andshouldpresentthemachinetothenearestauthorizedJohnDeeredealerassoon asaproblemissuspected.ThewarrantyrepairsshouldbecompletedbytheauthorizedJohnDeeredealerasquicklyaspossible.

Emissionsregulationsrequirethecustomertobringtheunittoanauthorizedservicingdealerwhenwarrantyserviceisrequired.Asaresult,John DeereisNOTliablefortravelormileageonemissionswarrantyservicecalls.

Emission_CI_CARB(19Sep12)

Continuedonnextpage

DX,EMISSIONS,CARB-19-12DEC12-2/4

Continuedonnextpage

DX,EMISSIONS,CARB-19-12DEC12-3/4

DX,EMISSIONS,CARB-19-12DEC12-4/4

Introduction

FCCNotificationstoUser

FCCNotification

ThesedevicescomplywithPart15oftheFCCRules. Operationissubjecttothefollowingtwoconditions:(1) Thesedevicesmaynotcauseharmfulinterference,and (2)thesedevicesmustacceptanyinterferencereceived, includinginterferencethatmaycauseundesiredoperation.

ThesedevicesmustbeoperatedassuppliedbyJohn DeereAgManagementSolutions.Anychangesor modificationsmadetothesedeviceswithouttheexpress writtenapprovalofJohnDeereAgManagementSolutions mayvoidtheuser’sauthoritytooperatethesedevices.

ModularTelematicsGatewayandSatelliteModule

Thisequipmenthasbeentestedandfoundtocomplywith thelimitsforClassBdigitaldevices,pursuanttopart15 oftheFCCRules.Theselimitsaredesignedtoprovide reasonableprotectionagainstharmfulinterferenceina

residentialinstallation.Thisequipmentgenerates,uses, andcanradiateradiofrequencyenergy,andifnotinstalled andusedinaccordancewiththeinstructions,maycause harmfulinterferencetoradiocommunications.However, noguaranteeshallbemadethatinterferencewillnotoccur inaparticularinstallation.Ifthisequipmentdoescause harmfulinterferencetoradioortelevisionreception,which canbedeterminedbyturningtheequipmentoffandon, theuserisencouragedtotrytocorrecttheinterferenceby oneormoreofthefollowingmeasures:

• Reorientorrelocatethereceivingantenna.

• Increasetheseparationbetweentheequipmentand receiver.

• Connecttheequipmentintoanoutletonacircuit differentfromthattowhichthereceiverisconnected.

• Consultthedealeroranexperiencedradio/TV technicianforhelp.

MM16284,000196F-19-26JUL12-1/1

ServiceADVISOR™Remote(SAR)—SOFTWARETERMSANDCONDITIONS

IMPORTANT--READCAREFULLY:THISSOFTWARE LICENSEAGREEMENTISALEGALCONTRACT BETWEENYOUANDTHELICENSOR("LICENSOR") IDENTIFIEDBELOWANDGOVERNSYOURUSEOF THESOFTWAREDELIVEREDTOYOURMACHINE (THE“MACHINE”).

BYINDICATINGYOURACCEPTANCEONADISPLAY ONTHEMACHINE,BYINSTALLINGSOFTWARE TOTHEMACHINE,ORUSINGSOFTWAREONTHE MACHINE,YOUAREACCEPTINGANDAGREEINGTO THETERMSOFTHISLICENSEAGREEMENTWITH RESPECTTOTHESOFTWARE(THE"Software")THAT ISDELIVEREDTOYOURMACHINE.YOUAGREETHAT THISSOFTWARELICENSEAGREEMENT,INCLUDING THEWARRANTYDISCLAIMERS,LIMITATIONSOF LIABILITYANDTERMINATIONPROVISIONSBELOW, ISBINDINGUPONYOU,ANDUPONANYCOMPANY ONWHOSEBEHALFYOUUSETHESOFTWARE ASWELLASTHEEMPLOYEESOFANYSUCH COMPANY(COLLECTIVELYREFERREDTOAS "YOU"INTHISSOFTWARELICENSEAGREEMENT). IFYOUDONOTAGREETOTHETERMSOFTHIS AGREEMENT,ORIFYOUARENOTAUTHORIZED TOACCEPTTHESETERMSONBEHALFOFYOUR COMPANYORITSEMPLOYEES,PLEASECLICKTHE [Decline]ICONONTHEDISPLAYONTHEMACHINE TODECLINETHESETERMSANDCONDITIONS. THISLICENSEAGREEMENTREPRESENTSTHE ENTIREAGREEMENTCONCERNINGTHESOFTWARE BETWEENYOUANDTHELICENSOR.

1.DeliveryofSoftware. Softwaremaybedeliveredto yourMachinebyLicensorwirelesslyorviaanagentof Licensor,suchasadealer.Ifitisdeliveredwirelessly, youmayberesponsibleforanydatatransmissionfees incurredduetosuchdelivery.

2.License. Licensorherebygrantstoyou,andyou accept,anonexclusivelicensetousetheSoftwarein machine-readable,objectcodeform,onlyasauthorized inthisLicenseAgreementandtheapplicableprovisions oftheOperators'Manuals,whichyouagreetoreview carefullypriortousingtheSoftware.TheSoftwaremay beusedonlyontheMachinetowhichitwasinitially delivered.Youagreethatyouwillnotassign,sublicense, transfer,pledge,lease,rent,orshareyourrightsunder thisLicenseAgreement,exceptthatyoumaypermanently transferallofyourrightsunderthisLicenseAgreement inconnectionwiththesaleoftheMachineonwhichthe SoftwarecoveredbythisAgreementisinstalled.

3.Licensor'sRights. Youacknowledgeandagreethat theSoftwareisproprietarytoLicensorandisprotected undercopyrightlaw.Youfurtheracknowledgeandagree thatallright,title,andinterestsinandtotheSoftware, includingassociatedintellectualpropertyrights,areand shallremainwithLicensor.ThisLicenseAgreementdoes notconveytoyouanytitleorinterestinortotheSoftware, butonlyalimitedrightofuserevocableinaccordance withthetermsofthisLicenseAgreement.Youagree

thatyouwillnot:(a)reverseassemble,reversecompile, modify,orotherwisetranslatetheSoftware,orattemptto defeatthecopyrightprotectionandapplicationenabling mechanismstherein;(b)copyorreproducetheSoftware; or,(b)removeorobliterateanycopyright,trademarkor otherproprietaryrightsnoticesfromtheSoftware.You alsoagreenottopermitanythirdpartyactingunderyour controltodoanyoftheforegoing.

4.LicenseFees. Thelicensefeespaidbyyou,ifany,are paidinconsiderationofthelicensesgrantedunderthis LicenseAgreement.

5.LimitedWarranty. Licensorwarrants,foryour benefitaloneandnotforthebenefitofanyotherparty, thatduringthe"WarrantyPeriod"definedbelow,the Softwarewilloperatesubstantiallyinaccordancewiththe applicablefunctionalspecifications("Specifications") setforthintheOperators'Manuals.If,priortoexpiration oftheWarrantyPeriod,theSoftwarefailstoperform substantiallyinaccordancewiththeSpecifications,you mayreturntheMachinetotheplaceofpurchasefor repairorreplacementofthenon-performingSoftware. TheWarrantyPeriodisninety(90)daysfromthedateof installationoftheSoftwareorthedurationofthewarranty periodofthecomponentoftheMachineonwhichthe Softwareisinstalled,whicheverislonger.TheSoftware WarrantyPerioddoesnotaffectthewarrantyperiodofthe Machineitselforanycomponentthereof.

6.DISCLAIMEROFWARRANTIES. YOUHEREBY AGREETHATTHELIMITEDWARRANTYPROVIDED ABOVE(THE"LIMITEDWARRANTY")CONSTITUTES YOURSOLEANDEXCLUSIVEREMEDYFORANY PROBLEMWHATSOEVERWITHTHESOFTWARE. EXCEPTASPROVIDEDINTHELIMITEDWARRANTY, THESOFTWAREISLICENSED“ASIS,”AND LICENSOR,ITSAFFILIATESANDTHIRDPARTY SUPPLIERSEXPRESSLYDISCLAIMANDYOU EXPRESSLYWAIVE,RELEASEANDRENOUNCEALL WARRANTIESARISINGBYLAWOROTHERWISE WITHRESPECTTOTHESOFTWARE,INCLUDING, BUTNOTLIMITEDTO:ANYIMPLIEDWARRANTYOF MERCHANTABILITYORFITNESSFORAPARTICULAR PURPOSE;ANYIMPLIEDWARRANTYARISING FROMCOURSEOFPERFORMANCE,COURSEOF DEALINGORTRADEUSAGE;ANYWARRANTYOF TITLEORNON-INFRINGEMENT;AND,ANYOTHER WARRANTYARISINGUNDERANYTHEORYOF LAW,INCLUDINGTORT,NEGLIGENCE,STRICT LIABILITY,CONTRACTOROTHERLEGALOR EQUITABLETHEORY.NOREPRESENTATIONOR OTHERAFFIRMATIONOFFACTINCLUDING,BUTNOT LIMITEDTO,STATEMENTSREGARDINGSUITABILITY FORUSE,SHALLBEDEEMEDTOBEAWARRANTY BYLICENSORORANYOFITSAFFILIATESORTHIRD PARTYSUPPLIERS.LICENSORDOESNOTWARRANT THATTHESOFTWAREISERROR-FREEORWILL OPERATEWITHOUTINTERRUPTION.

7.LIMITATIONOFLIABILITY. EXCEPTASSET FORTHINTHELIMITEDWARRANTY,UNDERNO CIRCUMSTANCESSHALLLICENSOR,ITSAFFILIATES ORITSTHIRDPARTYSUPPLIERSBELIABLETO YOUORTOANYTHIRDPARTIESFORDIRECT, INDIRECT,INCIDENTALORCONSEQUENTIAL DAMAGESOFANYKIND,INCLUDINGANYLOSS ORDAMAGECAUSEDBYTHESOFTWARE;ANY PARTIALORTOTALFAILUREOFTHESOFTWARE; PERFORMANCE,NONPERFORMANCEORDELAYS INCONNECTIONWITHANYINSTALLATION, MAINTENANCE,WARRANTYORREPAIRSOFTHE SOFTWARE,DAMAGESFORCROPLOSS,DAMAGE TOLAND,LOSTPROFITS,LOSSOFBUSINESSOR LOSSOFGOODWILL,LOSSOFUSEOFEQUIPMENT ORSERVICESORDAMAGESTOBUSINESSOR REPUTATIONARISINGFROMTHEPERFORMANCE ORNON-PERFORMANCEOFANYASPECTOFTHIS AGREEMENT,WHETHERINCONTRACT,TORTOR OTHERWISE,ANDWHETHERORNOTLICENSOR, ITSAFFILIATESORITSTHIRDPARTYSUPPLIERS HAVEBEENADVISEDOFTHEPOSSIBILITYOF SUCHDAMAGES.INNOEVENTSHALLLICENSOR’S CUMULATIVELIABILITYTOYOUORTOANYOTHER PARTYFORANYLOSSESORDAMAGESRESULTING FROMANYCLAIMS,LAWSUITS,DEMANDS,OR ACTIONSARISINGFROMORRELATINGTOUSEOF THESOFTWAREEXCEEDYOURTOTALPAYMENT FORTHEMACHINEANDFORTHELICENSEOFTHE SOFTWARE.

8.TerminationofLicense. Licensormayterminatethe licensegrantedunderthisAgreementuponwrittennotice ofterminationprovidedtoyouifyouviolateanymaterial termofthisAgreementpertainingtoyouruseofthe SoftwareorLicensor'srights,including,withoutlimitation, theprovisionsofSections2and3above.

9.CompliancewithLaw. Youagreethatyouwillusethe SoftwareinaccordancewithUnitedStateslawandthe lawsofthecountryinwhichyouarelocated,asapplicable, includingforeigntradecontrollawsandregulations.The Softwaremaybesubjecttoexportandotherforeign tradecontrolsrestrictingre-salesand/ortransfersto othercountriesandparties.Byacceptingthetermsof thisAgreement,youacknowledgethatyouunderstand thattheSoftwaremaybesocontrolled,including,but notlimitedto,bytheExportAdministrationRegulations and/ortheforeigntradecontrolregulationsoftheTreasury DepartmentoftheUnitedStates.Anyotherprovision ofthisAgreementtothecontrarynotwithstanding,you agreethattheSoftwarewillnotberesold,re-exportedor otherwisetransferred.TheSoftwareremainssubjectto applicableU.S.laws.

10.Indemnification. Youagreetodefend,indemnify andholdLicensor,itsaffiliatesandthirdpartysupplier, andtheir,officers,directors,employees,agentsand representatives(eachan"IndemnifiedParty"),harmless

fromandagainstallclaims,demandsproceedings, injuries,liabilities,losses,orcostsandexpenses(including reasonablelegalfees)broughtbyanythirdpartyagainst anysuchpersonsarisingfromorinconnectionwithyour useoftheSoftware,regardlessofwhethersuchlosses arecaused,whollyorpartially,byanynegligence,breach ofcontractorotherfaultofanIndemnifiedParty.

11.CostsofLitigation. Ifanyclaimoractionisbrought byeitherpartytothisLicenseAgreementagainsttheother partyregardingthesubjectmatterhereof,theprevailing partyshallbeentitledtorecover,inadditiontoanyother reliefgranted,reasonableattorneyfeesandexpenses oflitigation.

12.SeverabilityandWaiver. Shouldanytermofthis Agreementbedeclaredvoidorunenforceablebyany courtofcompetentjurisdiction,suchdeclarationshall havenoeffectontheremainingtermshereof.Thefailure ofeitherpartytoenforceanyrightsgrantedhereunder ortotakeactionagainsttheotherpartyintheeventof anybreachhereundershallnotbedeemedawaiver bythatpartyastosubsequentenforcementofrightsof subsequentactionsintheeventoffuturebreaches.

13.LanguageClause. IfyouarearesidentofCanada atthetimeyouacceptthisAgreement,thentheparties herebyacknowledgethattheyhaverequiredthis Agreement,andallotherdocumentsrelatinghereto, bedrawnupintheEnglishlanguageonly.Lesparties reconnaissentavoirdemandéqueleprésentcontratainsi quetouteautreententeouavisrequisoupermisàêtre concluoudonnéenvertudesstipulationsduprésent contrat,soientrédigésenlangueanglaiseseulement.If youarearesidentofanycountryotherthantheUnited States,Canada,GreatBritain,AustraliaorNewZealand thenyouagreeasfollows:theremaybeatranslated versionofthisAgreement.Ifthereisaninconsistency orcontradictionbetweenthetranslatedversionandthe EnglishversionofthisAgreement,theEnglishversionof thisAgreementshallcontrol.

14.AssignmentbyLicensor. Licensormayassignthis Agreementwithoutyourpriorconsenttoanycompany orentityaffiliatedwithLicensor,orbyanassignment associatedwithacorporaterestructuring,mergeror acquisition.

15.GoverningLawandForum. ThisAgreementwill begovernedbyandconstruedinaccordancewiththe substantivelawsidentifiedinthetableinSection18,below Therespectivecourtsofthevenueidentifiedinthetable inSection18,below,forthelocationoftheMachineshall havenon-exclusivejurisdictionoveralldisputesrelating tothisAgreement.ThisAgreementwillnotbegoverned bytheconflictoflawrulesofanyjurisdictionortheUnited NationsConventiononContractsfortheInternationalSale ofGoods,theapplicationofwhichisexpresslyexcluded.

16.SpecificExceptions.

16.1LimitedWarrantyforUsersResidinginEuropean EconomicAreaCountriesorSwitzerland. Ifyou obtainedtheSoftwareinanyEuropeanEconomicArea countryorSwitzerland,andyouusuallyresideinsuch country,thenSection6doesnotapply,instead,Licensor warrantsthattheSoftwareprovidesthefunctionalities setforthintheOperatorsManuals(the"agreedupon functionalities")fortheWarrantyPeriod.Asused inthisSection,"WarrantyPeriod"meansone(1) year.Non-substantialvariationfromtheagreedupon functionalitiesshallnotbeconsideredanddoesnot establishanywarrantyrights.THISLIMITEDWARRANTY DOESNOTAPPLYTOSOFTWAREPROVIDEDTO YOUFREEOFCHARGE,FOREXAMPLE,UPDATES, ORSOFTWARETHATHASBEENALTEREDBYYOU, TOTHEEXTENTSUCHALTERATIONSCAUSEDA DEFECT.Tomakeawarrantyclaim,duringtheWarranty Periodyoumustreturn,atourexpense,theSoftwareand proofofpurchasetothelocationwhereyouobtainedit. IfthefunctionalitiesoftheSoftwarevarysubstantially fromtheagreeduponfunctionalities,Licensorisentitled --bywayofre-performanceandatitsowndiscretion-torepairorreplacetheSoftware.Ifthisfails,youare entitledtoareductionofthepurchaseprice(reduction) ortocancelthepurchaseagreement(rescission).For furtherwarrantyinformation,pleasecontactLicensorat theaddresslistedinSection18.

16.2LimitationofLiabilityforUsersResidingin EuropeanEconomicAreaCountriesorSwitzerland.

(a)IfyouobtainedtheSoftwareinanyEuropean EconomicAreacountryorSwitzerland,andyouusually resideinsuchcountry,thenSections7and10donot apply,Instead,Licensor'sstatutoryliabilityfordamages shallbelimitedasfollows:(a)Licensorshallbeliableonly uptotheamountofdamagesastypicallyforeseeable atthetimeofenteringintothisAgreementinrespect ofdamagescausedbyaslightlynegligentbreachofa materialcontractualobligationand(b)Licensorshall

PlaceofPurchase Address

UnitedStatesofAmerica

JohnDeereSharedServices,Inc. OneJohnDeerePlace Moline,IL61265U.S.A.

Argentina IndustriasJohnDeereArgentina,S.A. CasilladeCorreo80 Rosario(SantaFe),2000,Argentina

notbeliablefordamagescausedbyaslightlynegligent breachofanon-materialcontractualobligation.

(b)Theaforesaidlimitationofliabilityshallnotapplytoany mandatorystatutoryliability,inparticular,toliabilityunder theGermanProductLiabilityAct,liabilityforassuminga specificguaranteeorliabilityforculpablycausedpersonal injuries.

(c)Youarerequiredtotakeallreasonablemeasuresto avoidandreducedamages,inparticulartomakeback-up copiesoftheSoftwareandyourcomputerdatasubjectto theprovisionsofthisAgreement.

17.RepresentationsofLicensee. BYACCEPTING THISAGREEMENT,YOU:(A)ACKNOWLEDGE THATYOUHAVEREADANDUNDERSTANDTHIS AGREEMENT;(B)REPRESENTTHATYOUHAVETHE AUTHORITYTOENTERINTOTHISAGREEMENT;(C) AGREETHATTHISAGREEMENTISENFORCEABLE AGAINSTYOUANDANYLEGALENTITYTHAT OBTAINEDTHESOFTWAREANDONWHOSEBEHALF ITISUSED;AND,(D)AGREETOPERFORMTHE OBLIGATIONSOFTHISAGREEMENT.

18.IdentificationofLicensorandNotices.The Licensoristheentityidentifiedinthetablebelow.All noticestoLicensorshallbesentbycertifiedorregistered mailtothecorrespondingaddressfortheLicensorgiven below.Ineachcaseacopyofthenoticeshallalsobe senttoJohnDeereIntelligentSolutionsGroup,ATTN: Legal,4140114thStreetUrbandale,IA50322U.S.A.All noticestoLicensorshallbeeffectiveuponreceipt.All noticesrequiredtobegiventoyoushall,inLicensor’ssole discretion,eitherbesentviacertifiedorregisteredmail totheaddressgiventoLicensorinconnectionwithyour purchaseoftheMachine.Eithermethodofnotification usedbyLicensorshallbeeffectiveupondispatch.You agreetonotifyLicensorofanychangeinyouraddressin themannersetforthabove.

GoverningLaw Venue

StateofIllinois,USA RockIslandCounty,Illinois,USA

ProvinceofSantaFe,ArgentinaProvinceofSantaFe,Argentina

AustraliaorNewZealand JohnDeereLimited(Australia) P.O.Box2022 Crestmead,Queensland,Australia4132

Canada JohnDeereLimited 295HunterRoad P.O.Box1000 Grimsby,ONL9K1M3

Chile JohnDeereWater,S.A. CerroSantaLucia9990 Quilicura,Santiago,Chile

Mexico IndustriasJohnDeere,S.A.deC.V. BoulevardDiazOrdaz#500 GarzaGarcia NuevoLeon66210,Mexico

StateofQueensland,AustraliaStateofQueensland,Australia

ProvinceofOntario,CanadaProvinceofOntario,Canada

ProvinceofSantiago,ChileProvinceofSantiago,Chile

StateofNuevoLeon,MexicoStateofNuevoLeon,Mexico

Introduction

Europe ETIC Strassburgerallee5 67657Kaiserslautern,Germany

Other

TheJohnDeereentityidentified forthelocationofyourMachine onwww.JDLink.com.

TechnicalInformationFeedbackForm

Weneedyourhelptocontinuallyimproveourtechnical publications.PleasecopythispageandFAXormailyour comments,ideasandimprovements.

SENDTO: JohnDeereDubuqueWorks 18600SouthJohnDeereRoad Attn:Publications,Dept.324 Dubuque,IA52004-0538 USA

FAXNUMBER: 1-563-589-5800(USA)

PublicationNumber:

PageNumber:

Ideas,Comments:

Name:

Phone:

EmailAddress:

THANKYOU!

FederalRepublicofGermanyKaiserslautern,Germany

TheJohnDeereentityidentified forthelocationofyourMachine onwww.JDLink.com.

TheJohnDeereentityidentified forthelocationofyourMachine onwww.JDLink.com.

OUT4001,00006C5-19-08NOV10-4/4

TX,TM,FAX-19-03JUL01-1/1

Safety—SafetyandOperatorConveniences

SafetyandOperatorConvenienceFeatures.....1-1-1

Safety—GeneralPrecautions

RecognizeSafetyInformation...........................1-2-1

FollowSafetyInstructions..................................1-2-1

OperateOnlyIfQualified...................................1-2-1

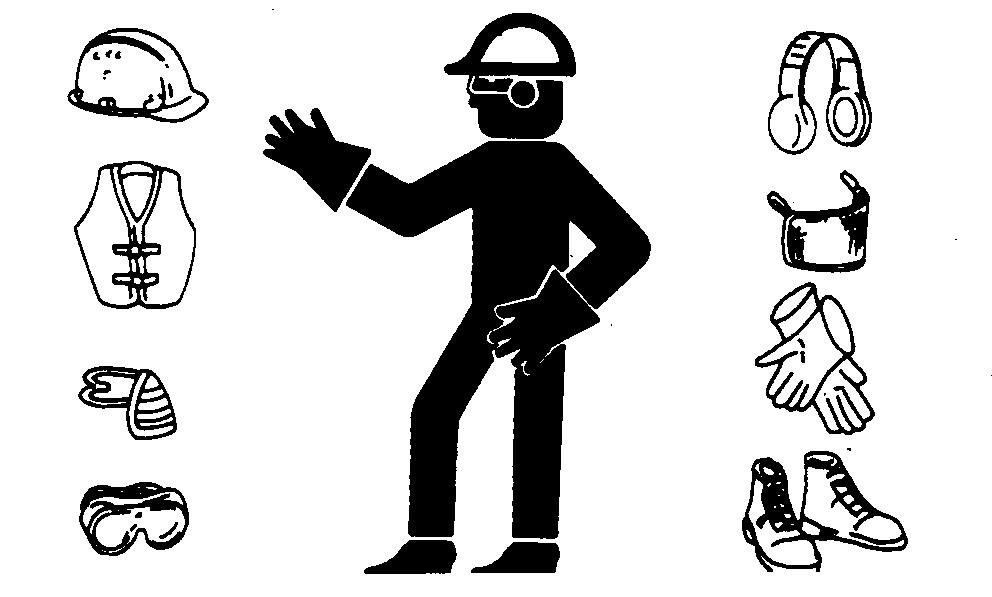

WearProtectiveEquipment...............................1-2-2

AvoidUnauthorizedMachineModifications.......1-2-2

InspectMachine................................................1-2-2

StayClearofMovingParts................................1-2-2

AvoidHigh-PressureFluids...............................1-2-3

AvoidHigh-PressureOils..................................1-2-3

WorkInVentilatedArea.....................................1-2-4

PreventFires.....................................................1-2-4

CleanDebrisfromMachine...............................1-2-5

PreventBatteryExplosions...............................1-2-5

HandleChemicalProductsSafely.....................1-2-5

DisposeofWasteProperly................................1-2-6

ExhaustFilterAshHandlingandDisposal........1-2-6

PrepareforEmergencies...................................1-2-6

AddCabGuardingforSpecialUses..................1-2-6

Safety—OperatingPrecautions

UseStepsandHandholdsCorrectly.................1-3-1

StartOnlyFromOperator'sSeat.......................1-3-1

UseandMaintainSeatBelt...............................1-3-1

PreventUnintendedMachineMovement..........1-3-2

AvoidWorkSiteHazards...................................1-3-2

UseSpecialCareWhenOperatingLoader.......1-3-3

KeepRidersOffMachine..................................1-3-3

AvoidBackoverAccidents.................................1-3-3

AvoidMachineTipOver....................................1-3-4

OperatingonSlopes..........................................1-3-4

OperatingorTravelingOnPublicRoads...........1-3-5

InspectandMaintainROPS..............................1-3-5

AddandOperateAttachmentsSafely...............1-3-5

Safety—MaintenancePrecautions

ParkandPrepareforServiceSafely.................1-4-1

CleanExhaustFilterSafely...............................1-4-2

ServiceCoolingSystemSafely.........................1-4-3

ServiceTiresSafely...........................................1-4-3

RemovePaintBeforeWeldingorHeating.........1-4-4

MakeWeldingRepairsSafely...........................1-4-4

DriveMetalPinsSafely.....................................1-4-4

Safety—SafetySigns

SafetySigns......................................................1-5-1

Operation—Operator’sStation

Levers—TwoFunctionHydraulicControl..........2-1-1 Levers—ThreeFunctionHydraulicControl.......2-1-2 Levers—FourFunctionHydraulicControl.........2-1-4 Levers—JoystickSteeringControl....................2-1-4 Pedals................................................................2-1-5

SealedSwitchModule(SSM)............................2-1-6 SwitchModuleFunctions...................................2-1-7 AdvancedDisplayUnit(ADU).........................2-1-10 DisplayUnitFunctions.....................................2-1-11 DisplayUnit—NormalDisplay.........................2-1-16 DisplayUnit—MainMenu................................2-1-17 DisplayUnit—MainMenu—Codes..................2-1-18 DisplayUnit—Main Menu—Codes—ActiveCodes....................2-1-18 DisplayUnit—Main Menu—Codes—StoredCodes....................2-1-19 DisplayUnit—MainMenu—Settings...............2-1-20 DisplayUnit—MainMenu—Settings—ReverseFanCycle..........................2-1-21 DisplayUnit—MainMenu—Settings—CourtesyLights................................2-1-21 DisplayUnit—MainMenu—Settings—QuickShift........................................2-1-22 DisplayUnit—MainMenu—Settings—JobTimer.........................................2-1-22 DisplayUnit—MainMenu—Settings—Stopwatch........................................2-1-23 DisplayUnit—MainMenu—Settings—RideControl—IfEquipped...............2-1-23 DisplayUnit—MainMenu—Settings—Counters..........................................2-1-23 DisplayUnit—MainMenu—Settings—CameraMode..................................2-1-24 DisplayUnit—MainMenu—Settings—OperatorConfiguration....................2-1-24 DisplayUnit—MainMenu—Diagnostics..........2-1-25 DisplayUnit—MainMenu—Diagnostics—MachineID.........................................2-1-26 DisplayUnit—MainMenu—Diagnostics—BatteryMonitor...................................2-1-26

OriginalInstructions.Allinformation,illustrationsandspecificationsinthis manualarebasedonthelatestinformationavailableatthetimeofpublication. Therightisreservedtomakechangesatanytimewithoutnotice.

Continuedonnextpage

COPYRIGHT©2013 DEERE&COMPANY Moline,Illinois Allrightsreserved. AJohnDeereILLUSTRUCTION®Manual PreviousEditions Copyright©2010,2011

DisplayUnit—MainMenu—Diagnostics—EngineSensors..................................2-1-27 DisplayUnit—MainMenu—Diagnostics—Transmission/Axle..............................2-1-27 DisplayUnit—MainMenu—Diagnostics—HydraulicSensors..............................2-1-28 DisplayUnit—MainMenu—Diagnostics—MachineSensors...............................2-1-28 DisplayUnit—MainMenu—Diagnostics—FNRSelector......................................2-1-29 DisplayUnit—MainMenu—Diagnostics—CabSwitches.....................................2-1-29 DisplayUnit—MainMenu—Diagnostics—SwitchModule....................................2-1-29 DisplayUnit—MainMenu—Diagnostics—JoystickSteering—IfEquipped..........2-1-30 DisplayUnit—MainMenu—Diagnostics—TirePressure—IfEquipped................2-1-31 DisplayUnit—MainMenu—Diagnostics—ObjectDetect—IfEquipped................2-1-32 DisplayUnit—MainMenu—Diagnostics—AutoDiffLock—IfEquipped...............2-1-32 DisplayUnit—MainMenu—Diagnostics—PayloadScale—IfEquipped..............2-1-33 DisplayUnit—MainMenu—Diagnostics—JDLink™SystemInfo.........................2-1-33 DisplayUnit—MainMenu—Diagnostics—ParkBrakeTest..................................2-1-34 DisplayUnit—MainMenu—Payload Scale—IfEquipped.....................................2-1-35 DisplayUnit—MainMenu—Payload Scale—LongTotal.......................................2-1-35 DisplayUnit—MainMenu—Payload Scale—DisplayUnits...................................2-1-36 DisplayUnit—MainMenu—Payload Scale—AutoAdd.........................................2-1-36 DisplayUnit—MainMenu—Payload Scale—Diagnostics.....................................2-1-36 DisplayUnit—MainMenu—Payload Scale—Setup..............................................2-1-36 DisplayUnit—MainMenu—Security...............2-1-37 DisplayUnit—MainMenu—Security—Security...............................................2-1-38 DisplayUnit—MainMenu—Security—ChangeOwnerPIN.............................2-1-38 DisplayUnit—MainMenu—Security—ManageOperatorPINs.......................2-1-39 DisplayUnit—MainMenu—Security—ManageTransportPIN........................2-1-40 DisplayUnit—MainMenu—Security—DelayedOperatorLogout...................2-1-41 DisplayUnit—MainMenu—ExhaustFilter......2-1-42 DisplayUnit—MainMenu—Exhaust Filter—AutoCleaning..................................2-1-43 DisplayUnit—MainMenu—Exhaust Filter—ParkedCleaning..............................2-1-44

DisplayUnit—MainMenu—Software Delivery.......................................................2-1-45 DisplayUnit—MainMenu—Software Delivery—SoftwareUpdate.........................2-1-46 HornButton.....................................................2-1-47 TurnSignals....................................................2-1-47 NeutralLock....................................................2-1-48 JoystickSteeringArmrest Adjustment—ifEquipped............................2-1-48 AirConditionerandHeaterOperation.............2-1-49 CounterSwitch................................................2-1-50 OpeningandSecuringSideDoor....................2-1-51 OpeningSideWindow/SecondaryExit............2-1-52 OpeningRearSideWindow............................2-1-52 SeatAdjustment..............................................2-1-53 FireExtinguisherMountingLocation...............2-1-54

Operation—OperatingtheMachine BeforeStartingWork.........................................2-2-1 InspectMachineDailyBeforeStarting..............2-2-1 CheckInstrumentsBeforeStarting....................2-2-1 SecuritySystem.................................................2-2-2

BatteryDisconnectSwitch.................................2-2-2 EngineBreak-InPeriod.....................................2-2-3 StartingtheEngine............................................2-2-4 EngineBlockHeater—IfEquipped....................2-2-6 StartingFluid(ColdWeatherStarting Aid)—IfEquipped..........................................2-2-6 Warmup.............................................................2-2-7 ColdWeatherWarmup......................................2-2-7 ParkBrakeSwitch.............................................2-2-8 ShiftingtheTransmission..................................2-2-9 AutomaticIdleandAutomaticShutdown.........2-2-11 JoystickBucketandBoomControl..................2-2-12 TwoLeverBucketandBoomControl..............2-2-13 AuxiliaryControl..............................................2-2-14

JoystickSteeringControl—IfEquipped...........2-2-15 RideControl—IfEquipped...............................2-2-17 SecondarySteering—IfEquipped...................2-2-19 DifferentialLockOperation..............................2-2-19 ExhaustFilter...................................................2-2-20

ServiceADVISOR™Remote(SAR) SoftwareDeliveryProcess..........................2-2-22 RearCameraandRadarObject Detection(ROD)System—IfEquipped.......2-2-23 CounterSwitchOperation...............................2-2-25 EmbeddedPayloadScale—IfEquipped.........2-2-26 BoomHeightKickoutAdjustment....................2-2-30

Return-to-CarryKickoutAdjustment................2-2-30

Return-to-DigAdjustmentforZ-BarLinkage...2-2-31 Return-to-DigAdjustmentfor Powerllel™Linkage—IfEquipped...............2-2-33 OperatingLoaderCoupler—IfEquipped.........2-2-34 UsingtheLoaderBucket.................................2-2-35 Backdragging...................................................2-2-36 ForkAttachment..............................................2-2-37

ParkingtheMachine........................................2-2-39 Continuedonnextpage

LoadingMachineonaTrailer..........................2-2-40

TowingProcedure............................................2-2-42

LiftingtheMachine..........................................2-2-44

Maintenance—Machine

DieselFuel.........................................................3-1-1

DieselFuelSpecifications.................................3-1-1

LubricityofDieselFuel......................................3-1-2

HandlingandStoringDieselFuel......................3-1-2

BiodieselFuel....................................................3-1-3

TestingDieselFuel............................................3-1-4

MinimizingtheEffectofColdWeather onDieselEngines.........................................3-1-5

AlternativeandSyntheticLubricants.................3-1-6

MixingofLubricants...........................................3-1-6

LubricantStorage..............................................3-1-6

JohnDeereBreak-InPlus™EngineOil............3-1-7

DieselEngineOil—InterimTier4and StageIIIBEngines.......................................3-1-8

EngineOilandFilterService Intervals—InterimTier4andStage IIIBEngines..................................................3-1-9

Transmission,ParkBrake,andAxleOil............3-1-9

HydraulicSystemOil.......................................3-1-10

Grease.............................................................3-1-10

HeavyDutyDieselEngineCoolant.................3-1-11

DrainIntervalsforDieselEngineCoolant........3-1-11

JohnDeereCOOL-GARD™IICoolant Extender......................................................3-1-12

SupplementalCoolantAdditives......................3-1-12

OperatinginWarmTemperatureClimates......3-1-13

AdditionalInformationAboutDiesel EngineCoolantsandJohnDeere COOL-GARD™IICoolantExtender...........3-1-14

TestingDieselEngineCoolant.........................3-1-15

DisposingofCoolant.......................................3-1-15

Maintenance—PeriodicMaintenance

ServiceMachineatSpecifiedIntervals..............3-2-1

CheckHourMeterRegularly.............................3-2-1

PrepareMachineforMaintenance....................3-2-2

FrameLockingBar............................................3-2-3

BoomLock.........................................................3-2-4

PinRemoval—IfEquippedWith Powerllel™Linkage......................................3-2-5

EngineServiceDoorsandSideShields............3-2-6

CoolingSystemDoors.......................................3-2-7

FuelTank...........................................................3-2-8

FluidAnalysisProgramTestKitsand 3-WayCoolantTestKit..................................3-2-8

ServiceIntervals................................................3-2-9

RequiredParts.................................................3-2-11

Maintenance—AsRequired

ServiceExhaustFilter........................................3-3-1

InspectTiresandCheckPressure....................3-3-2 TirePressures...................................................3-3-3

Page

CheckWheelBoltTorque..................................3-3-5 InspectEngineAirCleanerElements................3-3-6 ReplaceFastFillFuelBreather Filter—IfEquipped........................................3-3-7 InspectAirConditionerCompressor andAlternatorBelt........................................3-3-7 CheckEngineCoolant.......................................3-3-8 CleanCoolerCores...........................................3-3-9 CheckRearCameraandRadarObject Detection(ROD)System—IfEquipped.......3-3-10 CheckWindshieldWasherFluidLevel............3-3-11 DrainWaterFromPrimaryFuelFilter..............3-3-11 CheckandCleanorReplaceCab FreshAirFilter.............................................3-3-12 CheckandCleanorReplaceCab RecirculatingAirFilter.................................3-3-13

Maintenance—Every10HoursorDaily CleanAirCleanerDustUnloaderValve............3-4-1 CheckCoolantLevelinSurgeTank..................3-4-1 CheckEngineOilLevel.....................................3-4-2 CheckHydraulicSystemOilLevel....................3-4-2 CheckTransmissionOilLevel...........................3-4-3 InspectOuterPinSeals.....................................3-4-4

Maintenance—Every100Hours LubricateLoaderLinkageandCylinder Pivots—Z-BarLinkage..................................3-5-1 LubricateLoaderLinkageandCylinder Pivots—Powerllel™Linkage.........................3-5-2

Maintenance—InitialService-250Hours DrainandRefillFrontandRearAxleOil...........3-6-1 ReplaceAxleOilFilters—IfEquipped...............3-6-2

Maintenance—Every250Hours TakeEngineOilSample....................................3-7-1

Maintenance—Every500Hours LubricateDrivelineUpperandLower SlidingJointsandLowerU-Joints.................3-8-1 CheckFrontandRearAxleOilLevel................3-8-2 LubricateFrontandRearAxleShaftSeals.......3-8-3 CheckBatteryWaterLevelandTerminals........3-8-4 CheckAirIntakeHosesandCharge AirCoolerTubeCouplings............................3-8-6 ReplaceFastFillFuelBreather Filter—IfEquipped........................................3-8-6 TakeFluidSamples...........................................3-8-7 DrainandRefillEngineOilandReplaceFilter..3-8-7 ReplaceIn-LineFuelStrainer............................3-8-8 ReplacePrimaryFuelFilter...............................3-8-9 ReplaceFinalFuelFilter..................................3-8-10 ReplaceHydraulicReservoirBreatherFilter...3-8-10 CheckParkBrakeOilLevel.............................3-8-11

LubricateFrontandRearShaftSeals onParkBrake.............................................3-8-11

CheckRideControlAccumulator—If Equipped.....................................................3-8-12

Maintenance—Every1000Hours

CleanHydraulicFanDriveCaseDrain In-LineScreen...............................................3-9-1

ReplaceAirCleanerDustUnloaderValve.........3-9-3

ReplaceEngineAirCleanerElements..............3-9-3

CheckCoolant...................................................3-9-4

ReplaceFuelTankBreatherFilter.....................3-9-4

ReplaceAxleOilFilters—IfEquipped...............3-9-4

LubricateFrameHingePivots...........................3-9-5

DrainandRefillParkBrakeOil..........................3-9-5

Maintenance—Every2000Hours

ReplaceOuterPinSeals.................................3-10-1

DrainandRefillTransmissionOiland

ReplaceFilter..............................................3-10-1

DrainandRefillFrontandRearAxleOil.........3-10-3

CleanFrontandRearAxleOil RecirculationScreens—IfEquipped...........3-10-4

AdjustEngineValveLash(Clearance)............3-10-4

RerunTransmissionClutchCalibration...........3-10-4

Maintenance—Every4000Hours

CleanHydraulicPumpCaseDrain In-LineScreen.............................................3-11-1

ReplaceHydraulicSystemReturnFilter..........3-11-3

Drain,Flush,andRefillHydraulic SystemOil...................................................3-11-4

CleanHydraulicSystemFillStrainer...............3-11-5

Maintenance—Every5000Hours CheckDrivelineDamperForCracks...............3-12-1

Maintenance—Every6000Hours DrainCoolingSystem......................................3-13-1 RefillCoolingSystem......................................3-13-2

Miscellaneous—Machine TireRemovalWithTirePressure Monitor(TPM)System—IfEquipped............4-1-1 CheckAirInletCover.........................................4-1-1

BleedFuelSystem............................................4-1-2 DoNotServiceControlValves, Cylinders,Pumps,orMotors.........................4-1-2 PrecautionsforAlternatorandRegulator..........4-1-2

Handling,Checking,andServicing BatteriesCarefully.........................................4-1-3 UsingBoosterBatteries—24-VoltSystem.........4-1-4 UsingBatteryCharger.......................................4-1-5 ReplacementBatteries......................................4-1-5 RemoveandInstallBatteries.............................4-1-6 12-VoltAuxiliaryPowerOutlet—IfEquipped.....4-1-7 JDLink™MachineMonitoringSystem (MMS)—IfEquipped......................................4-1-7

ReplacingFuses................................................4-1-8

RemoveandInstallHalogenBulbs.................4-1-10

FluidSamplingTestPorts—IfEquipped..........4-1-10 AirConditioningSystemService.....................4-1-12

ExternalServiceBrakeInspection...................4-1-13

BleedingBrakes..............................................4-1-14 ServiceRecommendationsFor Snap-To-Connect(STC®)Fittings..............4-1-15 WeldingOnMachine.......................................4-1-16

WeldingNearElectronicControlUnits............4-1-16 KeepElectronicControlUnit ConnectorsClean.......................................4-1-16 KeepROPSInstalledProperly........................4-1-17 HardwareTorqueSpecifications......................4-1-17

MetricBoltandScrewTorqueValues..............4-1-18

UnifiedInchBoltandScrewTorqueValues.....4-1-19

Miscellaneous—OperationalCheckout OperationalCheckout........................................4-2-1

Miscellaneous—Troubleshooting

TroubleshootingProcedure...............................4-3-1 Engine...............................................................4-3-2 Transmission.....................................................4-3-5

DifferentialandAxle..........................................4-3-8

ServiceBrake....................................................4-3-9 Driveline...........................................................4-3-10

ParkBrake.......................................................4-3-10

HydraulicSystem.............................................4-3-11 Steering...........................................................4-3-13

AirConditioningSystem..................................4-3-14

HeaterSystem.................................................4-3-16 SoftwareUpdate..............................................4-3-16

Miscellaneous—Storage PrepareMachineforStorage............................4-4-1 MonthlyStorageProcedure...............................4-4-2

Miscellaneous—MachineNumbers

RecordProductIdentificationNumber(PIN).....4-5-1

RecordEngineSerialNumber...........................4-5-1

RecordTransmissionSerialNumber.................4-5-1

RecordHydraulicPumpSerialNumber.............4-5-2

RecordFrontandRearAxleHousing SerialNumbers.............................................4-5-2

KeepProofofOwnership..................................4-5-2

KeepMachinesSecure.....................................4-5-3

Miscellaneous—Specifications

EngineSpecifications........................................4-6-1

DrainandRefillCapacities................................4-6-1

StandardZ-BarSpecifications...........................4-6-2

HighLiftZ-BarSpecifications............................4-6-4

Powerllel™Specifications.................................4-6-6

TravelSpeeds...................................................4-6-7

Pleaseremember,theoperatoristhekeyto preventingaccidents.

1. ROPS,FOPS,andOPS. Structuresdesignedtohelp protecttheoperatorarecertifiedtoISOandOSHA. Enclosuresalsodeflectsunandrain.

2. PressurizedCabwithHeaterandDefroster. Positivepressureventilationsystemcirculatesboth outsideandinsideairthroughfiltersforaclean workingenvironment.Builtindefrosterventsdirectair flowforeffectivewindowdefogging/deicing.

3. Mirrors. Largeexteriormirrorsonbothsidesand aninsidemirroroffersoperatorabroadviewofarea behindmachine.

4. LargeWindshieldWiperwithWasher. Extralong wipercleanslargewindshieldarea.

5. LoaderBoomServiceLock. Loaderincludesa mechanicallockforsecuringboomintheraised positionbeforeworkisstartedonoraroundthe machine.

6. HalogenLightsandTurnSignals. Highintensity halogendrive/worklightsandhigh-visibilityturn signalsarestandardequipment.

7. ArticulationLockingBar. Aself-storingmechanical lockisprovidedfortransportorservice.

8. Handholds. Large,convenientlyplacedhandholds makeiteasytoenterorexittheoperator'sstationor servicearea.

9. Horn. Standardhornisusefulwhendrivingor signalingcoworkers.

10. IndependentParkingBrake. Electronicallycontrolled andengageswhenevertheengineisstopped.

11. SeatBeltRetractors. Seatbeltretractorshelpkeep beltscleanandconvenienttouse.

12. BypassStartProtection. Shieldingoverthestarter terminalshelpspreventdangerousbypassstarting.

13. EngineFanGuard. Asecondaryfanguardinsidethe coolingcompartmenthelpspreventcontactwiththe rotatingfanblades.

14. BackupAlarm. Alertsbystanderswhenreversetravel directionisselectedbyoperator.

15. StopandSignalLights. Highlyvisiblestoplightsand turnsignallightsarestandardequipment.

Safety—GeneralPrecautions

RecognizeSafetyInformation

Thisisthesafetyalertsymbol.Whenyouseethis symbolonyourmachineorinthismanual,bealert forthepotentialofpersonalinjury.

Followtheprecautionsandsafeoperatingpractices highlightedbythissymbol.

Asignalword—DANGER,WARNING,orCAUTION— isusedwiththesafetyalertsymbol.DANGERidentifies themostserioushazards.

Onyourmachine,DANGERsignsareredincolor, WARNINGsignsareorange,andCAUTIONsignsare yellow.DANGERandWARNINGsignsarelocatednear specifichazards.GeneralprecautionsareonCAUTION labels.

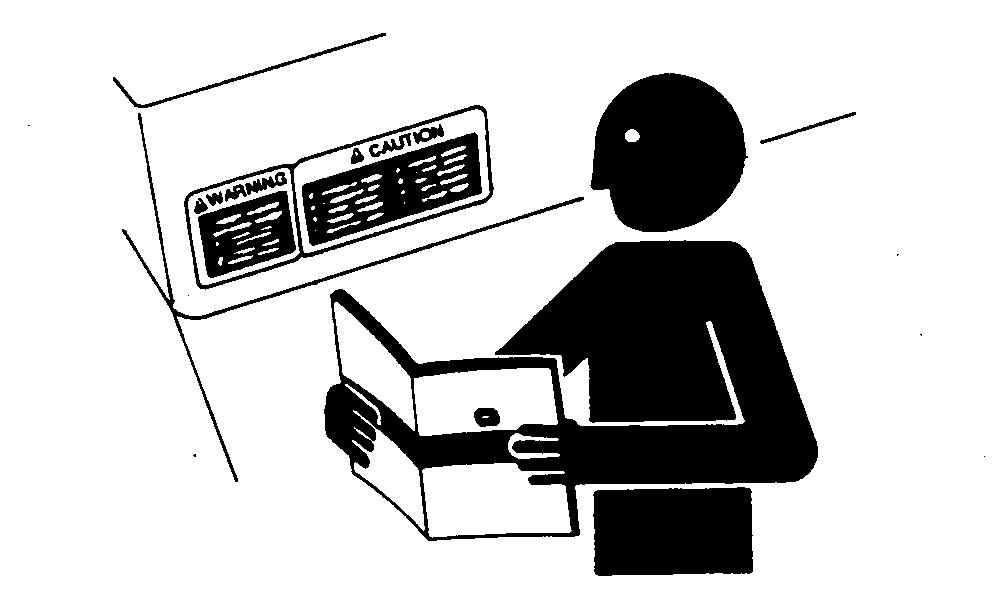

FollowSafetyInstructions

Carefullyreadallsafetymessagesinthismanualandon yourmachinesafetysigns.Keepsafetysignsingood condition.Replacemissingordamagedsafetysigns.Use thisoperator’smanualforcorrectsafetysignplacement. Besurethatnewequipmentcomponentsandrepairparts includethecurrentsafetysigns.Replacementsafety signsareavailablefromyourJohnDeeredealer.

Therecanbeadditionalsafetyinformationcontainedon partsandcomponentssourcedfromsuppliersthatisnot reproducedinthisoperator'smanual.

Learnhowtooperatethemachineandhowtousecontrols properly.Donotletanyoneoperatewithoutinstruction.

Keepyourmachineinproperworkingcondition. Unauthorizedmodificationstothemachinecouldimpair thefunctionorsafetyandaffectmachinelife.

OperateOnlyIfQualified

Donotoperatethismachineunlesstheoperator'smanual hasbeenreadcarefully,andyouhavebeenqualifiedby supervisedtrainingandinstruction.

Operatorshouldbefamiliarwiththejobsiteand surroundingsbeforeoperating.Tryallcontrolsand

TX,RECOGNIZE-19-28JUN10-1/1

Ifyoudonotunderstandanypartofthismanualandneed assistance,contactyourJohnDeeredealer.

TX,FOLLOW-19-20JAN11-1/1

machinefunctionswiththemachineinanopenarea beforestartingtowork.

Knowandobserveallsafetyrulesthatmayapplytoevery worksituationandworksite.

TX,QUALIFIED-19-18JAN11-1/1

WearProtectiveEquipment

Guardagainstinjuryfromflyingpiecesormetalordebris; weargogglesorsafetyglasses.

Wearclosefittingclothingandsafetyequipment appropriatetothejob.

Operatingequipmentsafelyrequiresthefullattentionof theoperator.Donotwearradioormusicheadphones whileoperatingmachine.

Prolongedexposuretoloudnoisecancauseimpairment orlossofhearing.Wearsuitablehearingprotectionsuch asearmuffsorearplugstoprotectagainstobjectionableor uncomfortableloudnoises.Radioormusicheadphones arenotsuitabletouseforhearingprotection.

AvoidUnauthorizedMachineModifications

JohnDeererecommendsusingonlygenuineJohnDeere replacementpartstoensuremachineperformance. NeversubstitutegenuineJohnDeerepartswithalternate partsnotintendedfortheapplicationasthesecan createhazardoussituationsorhazardousperformance. Non-JohnDeereParts,oranydamageorfailuresresulting fromtheirusearenotcoveredbyanyJohnDeerewarranty.

Modificationsofthismachine,oradditionofunapproved productsorattachments,mayaffectmachinestabilityor

InspectMachine

Inspectmachinecarefullyeachdaybywalkingaroundit beforestarting.

Keepallguardsandshieldsingoodconditionandproperly installed.Fixdamageandreplacewornorbrokenparts immediately.Payspecialattentiontohydraulichosesand electricalwiring.

TX,WEAR,PE-19-22SEP10-1/1

reliability,andmaycreateahazardfortheoperatoror othersnearthemachine.Theinstallerofanymodification whichmayaffecttheelectroniccontrolsofthismachineis responsibleforestablishingthatthemodificationdoesnot adverselyaffectthemachineoritsperformance.

AlwayscontactanauthorizedJohnDeeredealerbefore makingmachinemodificationsthatchangetheintended use,weightorbalanceofthemachine,orthatalter machinecontrols,performanceorreliability.

AM40430,00000A9-19-14JAN08-1/1

TX,INSPECT-19-08SEP10-1/1

StayClearofMovingParts

Entanglementsinmovingpartscancauseseriousinjury. Stopenginebeforeexamining,adjusting,ormaintaining anypartofmachinewithmovingparts.

Keepguardsandshieldsinplace.Replaceanyguard orshieldthathasbeenremovedforaccessassoonas serviceorrepairiscomplete.

TX,MOVING,PARTS-19-20JAN11-1/1

AvoidHigh-PressureFluids

Inspecthydraulichosesperiodically–atleastonce peryear–forleakage,kinking,cuts,cracks,abrasion, blisters,corrosion,exposedwirebraidoranyothersigns ofwearordamage.

Replacewornordamagedhoseassembliesimmediately withJohnDeereapprovedreplacementparts.

Escapingfluidunderpressurecanpenetratetheskin causingseriousinjury.

Avoidthehazardbyrelievingpressurebefore disconnectinghydraulicorotherlines.Tightenall connectionsbeforeapplyingpressure.

Searchforleakswithapieceofcardboard.Protecthands andbodyfromhigh-pressurefluids.

Ifanaccidentoccurs,seeadoctorimmediately.Anyfluid injectedintotheskinmustbesurgicallyremovedwithin afewhoursorgangrenemayresult.Doctorsunfamiliar

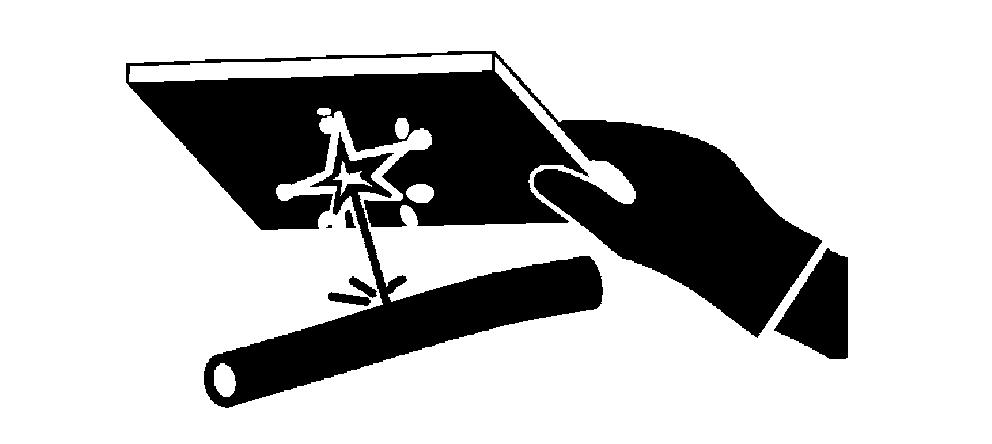

AvoidHigh-PressureOils

Thismachineusesahigh-pressurehydraulicsystem. Escapingoilunderpressurecanpenetratetheskin causingseriousinjury.

Neversearchforleakswithyourhands. Protecthands. Useapieceofcardboardtofindlocationofescapingoil. Stopengineandrelievepressurebeforedisconnecting linesorworkingonhydraulicsystem.

Ifhydraulicoilpenetratesyourskin,seeadoctor immediately.Injectedoilmustberemovedsurgically withinhoursorgangrenecouldresult. Contacta knowledgeablemedicalsourceortheDeere&Company MedicalDepartmentinMoline,Illinois,U.S.A.

withthistypeofinjuryshouldreferenceaknowledgeable medicalsource.Suchinformationisavailablein EnglishfromDeere&CompanyMedicalDepartmentin Moline,Illinois,U.S.A.,bycalling1-800-822-8262or+1 309-748-5636.

DX,FLUID-19-12OCT11-1/1

TX,HPOILS-19-20JAN11-1/1

WorkInVentilatedArea

Engineexhaustfumescancausesicknessordeath.If itisnecessarytorunanengineinanenclosedarea, removetheexhaustfumesfromtheareawithanexhaust pipeextension.

Ifyoudonothaveanexhaustpipeextension,openthe doorsandgetoutsideairintothearea.

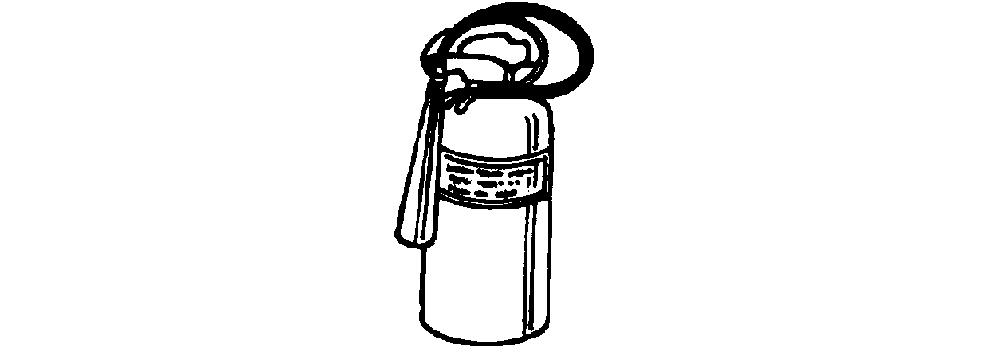

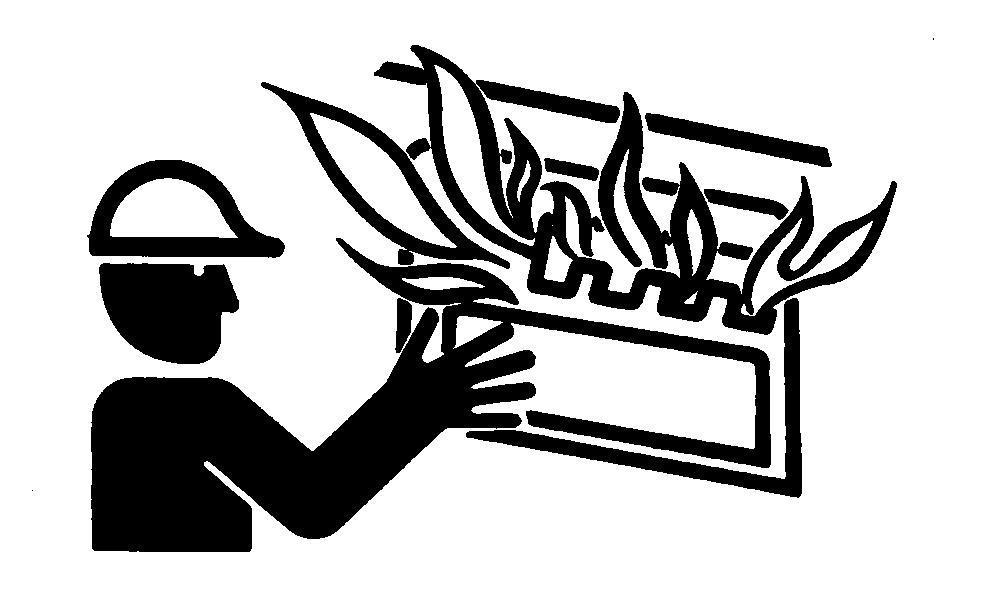

PreventFires

HandleFuelSafely: Storeflammablefluidsawayfrom firehazards.Neverrefuelmachinewhilesmokingorwhen nearsparksorflame.

CleanMachineRegularly: Keeptrash,debris,grease andoilfromaccumulatinginenginecompartment,around fuellines,hydrauliclines,exhaustcomponents,and electricalwiring.Neverstoreoilyragsorflammable materialsinsideamachinecompartment.

MaintainHosesandWiring: Replacehydraulichoses immediatelyiftheybegintoleak,andcleanupanyoil spills.Examineelectricalwiringandconnectorsfrequently fordamage.

KeepAFireExtinguisherAvailable: Alwayskeepa multipurposefireextinguisheronornearthemachine. Knowhowtouseextinguisherproperly.

TX,PREVENT,FIRE-19-20JAN11-1/1

T133553—UN—07SEP00

T133554—UN—07SEP00

CleanDebrisfromMachine

Keepenginecompartment,radiator,batteries,hydraulic lines,exhaustcomponents,fueltank,andoperator's stationcleanandfreeofdebris.

Cleananyoilspillsorfuelspillsonmachinesurfaces.

Temperatureinenginecompartmentcouldgoup immediatelyafterengineisstopped.BEONGUARD FORFIRESDURINGTHISPERIOD.

Openaccessdoor(s)tocooltheenginefaster,andclean enginecompartment.

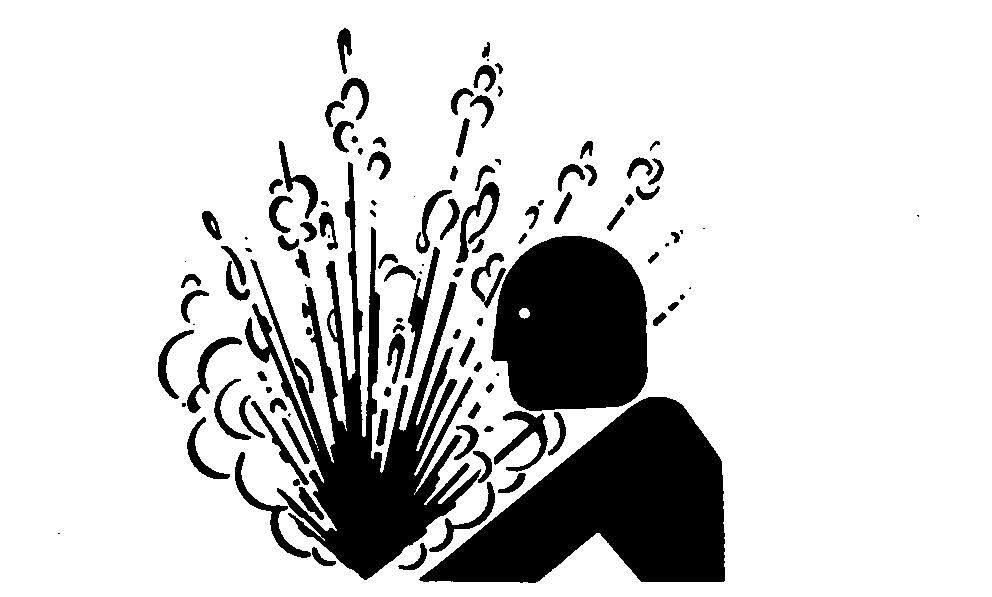

PreventBatteryExplosions

Keepsparks,lightedmatches,andopenflameawayfrom thetopofbattery.Batterygascanexplode.

Nevercheckbatterychargebyplacingametalobject acrosstheposts.Useavolt-meterorhydrometer.

Donotchargeafrozenbattery;itmayexplode.Warm batteryto16°C(60°F).

HandleChemicalProductsSafely

Directexposuretohazardouschemicalscancause seriousinjury.Potentiallyhazardouschemicalsusedwith JohnDeereequipmentincludesuchitemsaslubricants, coolants,paints,andadhesives.

AMaterialSafetyDataSheet(MSDS)providesspecific detailsonchemicalproducts:physicalandhealthhazards, safetyprocedures,andemergencyresponsetechniques.

ChecktheMSDSbeforeyoustartanyjobusinga hazardouschemical.Thatwayyouwillknowexactlywhat therisksareandhowtodothejobsafely.Thenfollow proceduresandrecommendedequipment.

(SeeyourJohnDeeredealerforMSDS’sonchemical productsusedwithJohnDeereequipment.)

TX,DEBRIS-19-20JAN11-1/1

DX,SPARKS-19-03MAR93-1/1

DX,MSDS,NA-19-03MAR93-1/1

DisposeofWasteProperly

Improperlydisposingofwastecanthreatenthe environmentandecology.Potentiallyharmfulwasteused withJohnDeereequipmentincludesuchitemsasoil,fuel, coolant,brakefluid,filters,andbatteries.

Useleakproofcontainerswhendrainingfluids.Donotuse foodorbeveragecontainersthatmaymisleadsomeone intodrinkingfromthem.

Donotpourwasteontotheground,downadrain,orinto anywatersource.

Airconditioningrefrigerantsescapingintotheaircan damagetheEarth’satmosphere.Governmentregulations mayrequireacertifiedairconditioningservicecenterto recoverandrecycleusedairconditioningrefrigerants.

ExhaustFilterAshHandlingandDisposal

CAUTION:Underfederal,state,andlocallawsor regulations,exhaustfilterashcanbeclassified asahazardouswaste.Hazardouswastemust bedisposedofinaccordancewithallapplicable federal,state,andlocallawsorregulations

PrepareforEmergencies

Bepreparedifafirestarts.

Keepafirstaidkitandfireextinguisherhandy.

Keepemergencynumbersfordoctors,ambulanceservice, hospital,andfiredepartmentnearyourtelephone.

Inquireontheproperwaytorecycleordisposeofwaste fromyourlocalenvironmentalorrecyclingcenter,orfrom yourJohnDeeredealer.

DX,DRAIN-19-03MAR93-1/1

governinghazardouswastedisposal.Onlya qualifiedserviceprovidershouldremoveashfrom theexhaustfilter.Personalprotectiveequipment andclothing,maintainedinasanitaryandreliable condition,shouldbeusedwhenhandlingand cleaningexhaustfilter.Seeyourauthorizeddealer forexhaustfilterashhandlinganddisposal.

TX,ASH,DISP-19-20JAN11-1/1

DX,FIRE2-19-03MAR93-1/1

AddCabGuardingforSpecialUses

Specialworksituationsormachineattachmentscould createanenvironmentwithfallingorflyingobjects. Workingnearanoverheadbank,demolitionwork,using ahydraulichammerorwinch,workinginaforestry applicationorwoodedarea,orworkinginawaste managementapplication,forexample,couldrequire addedguardingtoprotecttheoperator.

AdditionallevelIIFOPS(fallingobjectprotective structure),forestryprotectionpackages,andspecial screensorguardingshouldbeinstalledwhenfalling orflyingobjectscouldenterordamagethemachine. Arearscreenshouldalwaysbeusedwithawinchto protectagainstasnappingcable.Beforeoperatinginany specialworkenvironments,followtheoperatorprotection recommendationsofthemanufacturerofanyspecialized attachmentorequipment.ContactyourauthorizedJohn Deeredealerforinformationonprotectiveguarding.

TX,CABGUARD-19-12FEB13-1/1

Safety—OperatingPrecautions

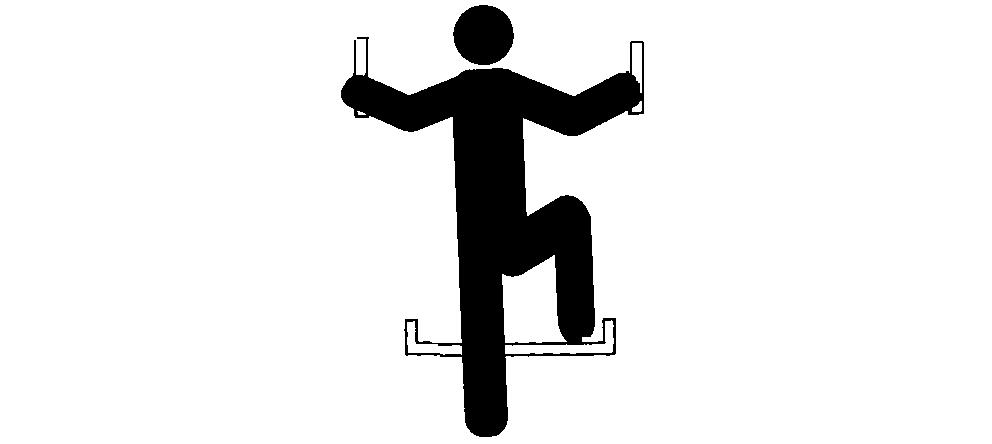

UseStepsandHandholdsCorrectly

Preventfallsbyfacingthemachinewhenyougetonand off.Maintain3-pointcontactwithstepsandhandrails. Neverusemachinecontrolsashandholds.

Useextracarewhenmud,snow,ormoisturepresent slipperyconditions.Keepstepscleanandfreeofgrease oroil.Neverjumpwhenexitingmachine.Nevermountor dismountamovingmachine.

StartOnlyFromOperator'sSeat

Avoidunexpectedmachinemovement.Startengineonly whilesittinginoperator'sseat.Ensurethatallcontrolsand workingtoolsareinproperpositionforaparkedmachine. Neverattempttostartenginefromtheground.Donot attempttostartenginebyshortingacrossthestarter solenoidterminals.

UseandMaintainSeatBelt

Useseatbeltwhenoperatingmachine.Rememberto fastenseatbeltwhenloadingandunloadingfromtrucks andduringotheruses.

Examineseatbeltfrequently.Besurethatwebbingisnot cutortorn.Replaceseatbeltimmediatelyifanypartis damagedordoesnotfunctionproperly.

Thecompleteseatbeltassemblyshouldbereplaced everythreeyears,regardlessofappearance.

TX,STEPS-19-09FEB11-1/1

TX,SOFOS-19-20JAN11-1/1

TX,SEAT,BELT-19-20JAN11-1/1

PreventUnintendedMachineMovement

Lowerallequipmenttothegroundduringwork interruptions.Placetransmissioncontrolinneutral,press parkbrakeswitch(1)toengageparkbrake,presspilot enable/boomdownswitch(2)todisablethehydraulics, andstopenginebeforeallowinganyonetoapproachthe machine.

Followthesesameprecautionsbeforestandingup, leavingtheoperator'sseat,orexitingthemachine.

1—ParkBrakeSwitch 2—PilotEnable/BoomDown Switch

DP99999,00000A3-19-28JUN12-1/1

AvoidWorkSiteHazards

Avoidcontactwithgaslines,buriedcablesandwater lines.Callutilitylinelocationservicestoidentifyall undergroundutilitiesbeforestartingwork.

Prepareworksiteproperly. Avoidoperatingnear structuresorobjectsthatcouldfallontothemachine.Clear awaydebristhatcouldmoveunexpectedlyifrunover.

Avoidboomorattachmentcontactwithoverhead obstaclesoroverheadelectricallines. Nevermove machinecloserthan3m(10ft)plustwicethelineinsulator lengthtooverheadwires.

Keepbystandersclearatalltimes. Keepbystanders awayfromraisedbooms,attachments,andunsupported loads.Avoidswingingorraisingbooms,attachments,or loadsoverornearpersonnel.Usebarricadesorasignal persontokeepvehiclesandpedestriansaway.Usea signalpersonifmovingmachineincongestedareasor wherevisibilityisrestricted.Alwayskeepsignalpersonin view.Coordinatehandsignalsbeforestartingmachine.

Operateonlyonsolidfooting withstrengthsufficient tosupportmachine.Beespeciallyalertworkingnear embankmentsorexcavations.

Avoidworkingunderover-hangingembankmentsor stockpiles thatcouldcollapseunderoronmachine.

Reducemachinespeed whenoperatingwithtoolonor neargroundwhenobstaclesmaybehidden(e.g.,during snowremovalorclearingmud,dirt,etc.).Athighspeeds hittingobstacles(rocks,unevenconcreteormanholes) cancauseasuddenstop.Alwayswearyourseatbelt.

DP99999,0000113-19-19AUG10-1/1

UseSpecialCareWhenOperatingLoader

Neverusetheloadertoliftpeople.Donotallow anyonetorideinthebucketorusethebucketasa workplatform.

Operatecarefullywithraisedloads. Raisingtheload reducesmachinestability,especiallyonsideslopesoran unstablesurface.Driveandturnslowlywitharaisedload.

Ensurethatobjectsinthebucketaresecure. Donot attempttoliftorcarryobjectsthataretoobigortoolongto fitinsidethebucketunlesssecuredwithanadequatechain orotherdevice.Keepbystandersawayfromraisedloads.

Becarefulwhenliftingobjects. Neverattempttolift objectstooheavyforyourmachine.Assuremachine stabilityandhydrauliccapabilitywithatestliftbefore attemptingothermaneuvers.Useanadequatechainor slingandproperriggingtechniquestoattachandstabilize loads.Neverliftanobjectaboveornearanotherperson.

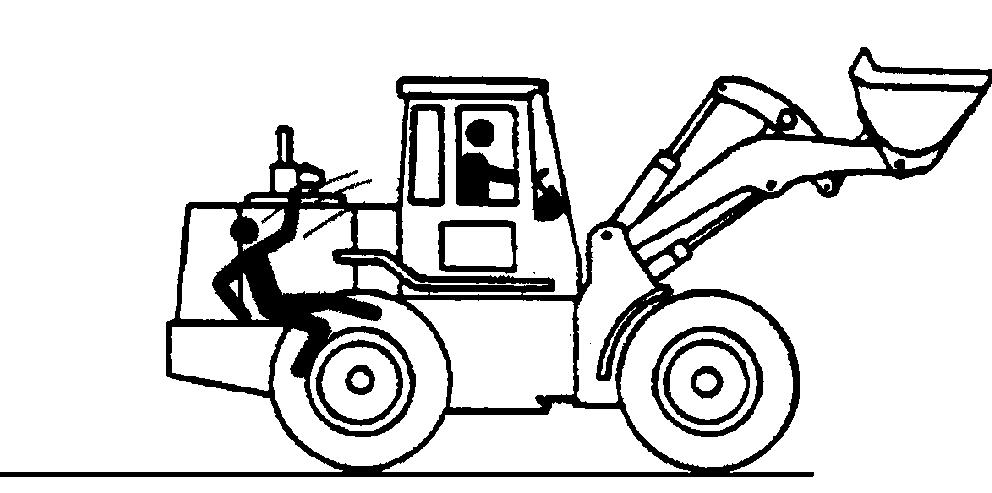

KeepRidersOffMachine

Onlyallowoperatoronmachine.

Ridersaresubjecttoinjury.Theymayfallfrommachine, becaughtbetweenmachineparts,orbestruckbyforeign objects.

Ridersmayobstructoperator’svieworimpairhisability tooperatemachinesafely.

AvoidBackoverAccidents

Beforemovingmachine,besurethatallpersonsare clearofmachinepath. Turnaroundandlookdirectlyfor bestvisibility.Usemirrorstoassistincheckingallaround machine.Keepwindowsandmirrorsclean,adjusted,and ingoodrepair.

Becertainreversewarningalarmisworkingproperly.

Useasignalpersonwhenbackingifviewisobstructed orwheninclosequarters. Keepsignalpersoninviewat alltimes.Useprearrangedhandsignalstocommunicate.

Donotrelyontherearcameraandradarobjectdetection systemstodetermineifpersonnelarebehindthemachine. Thesystemhaslimitationsduetomaintenancepractices, environmentalconditions,andoperatingrange.

TX03768,0000B70-19-14MAY01-1/1

TX03679,000179B-19-20APR01-1/1

TX,AVOID,BACKOVER-19-25OCT10-1/1

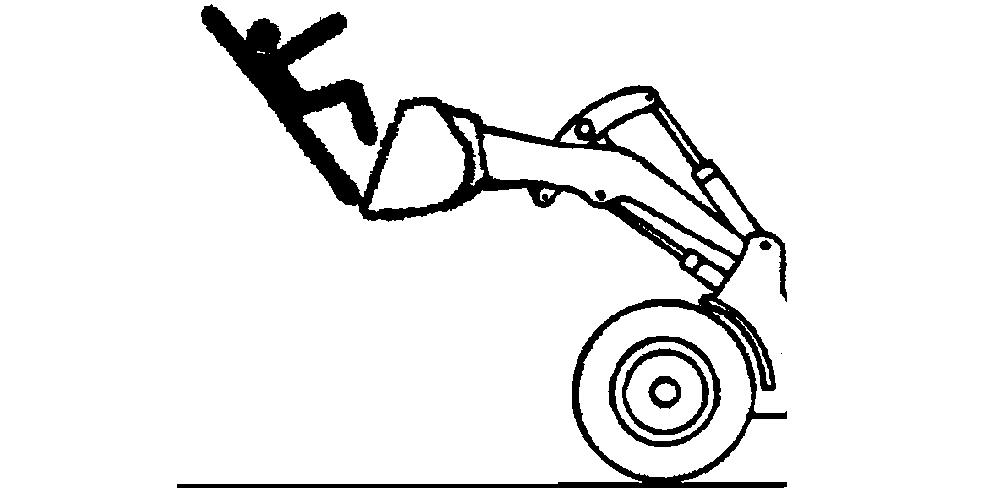

AvoidMachineTipOver

Useseatbeltatalltimes.

Donotjumpifthemachinetips. Youwillbeunlikelyto jumpclearandthemachinemaycrushyou.

Loadandunloadfromtrucksortrailerscarefully. Be suretruckiswideenoughandonafirmlevelsurface.Use loadingrampsandattachthemproperlytotruckbed.

Becarefulonslopes. Avoidsharpturns.Balanceloads soweightisevenlydistributedandloadisstable.Carry toolsandloadsclosetothegroundtoaidvisibilityand lowercenterofgravity.Useextracareonsoft,rockyor frozenground.

Knowthecapacityofthemachine. Donotoverload.Be carefulwithheavyloads.Usingoversizebucketsorlifting heavyobjectsreducesmachinestability.

Ensuresolidfooting. Useextracareinsoftground conditionsthatmaynotuniformlysupportthewheels, especiallywhenraisingtheboom.Donotoperatecloseto banksoropenexcavationsthatmaycaveinandcause machinetotiporfall.

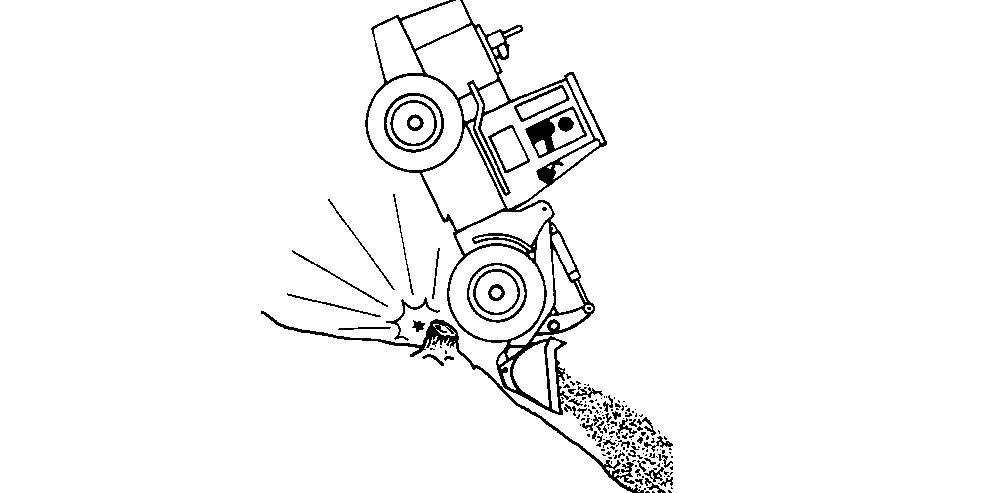

OperatingonSlopes

Avoidsideslopetravelwheneverpossible.Driveupsteep slopeinforwardanddowninreverse.

Selectlowgearspeedbeforestartingdownslope.The gradeoftheslopewillbelimitedbygroundconditionand loadbeinghandled.

Useservicebrakestocontrolspeed.Suddenbrake applicationwithaloadedbucketondownhillsidecould causemachinetotipforward.

TX03679,000179D-19-02MAY01-1/1

TX03679,000179E-19-14MAY01-1/1

OperatingorTravelingOnPublicRoads

Machinesthatworknearvehicletrafficortravelslower thannormalhighwayspeedsmusthaveproperlighting andmarkingstoassuretheyarevisibletootherdrivers.

Installadditionallights,beaconlights,slowmovingvehicle (SMV)emblems,orotherdevicesanduseasrequiredto makethemachinevisibleandidentifyitasaworkmachine. Checkstateandlocalregulationstoassurecompliance. Keepthesedevicescleanandinworkingcondition.

InspectandMaintainROPS

Adamagedrolloverprotectivestructure(ROPS)should bereplaced,notreused.

TheprotectionofferedbyROPScouldbeimpairedif ROPSissubjectedtostructuraldamage,isinvolvedin anoverturnincident,orisinanywayalteredbywelding, bending,drilling,orcutting.

IfROPSwasloosenedorremovedforanyreason,inspect itcarefullybeforeoperatingthemachineagain.

AddandOperateAttachmentsSafely

Alwaysverifycompatibilityofattachmentsbycontacting yourauthorizeddealer.Addingunapprovedattachments couldaffectmachinestabilityorreliabilityandcouldcreate ahazardforothersnearthemachine.

Ensurethataqualifiedpersonisinvolvedinattachment installation.Addguardstomachineifoperatorprotection

TX,ROADS-19-20JAN11-1/1

TomaintaintheROPS:

• Replacemissinghardwareusingcorrectgrade hardware.

• Checkhardwaretorque.

• Checkisolationmountsfordamage,looseness,or wear;replacethemifnecessary.

• CheckROPSforcracksorphysicaldamage.

TX,ROPS-19-20JAN11-1/1

isrequiredorrecommended.Verifythatallconnections aresecureandattachmentrespondsproperlytocontrols. Carefullyreadattachmentmanualandfollowall instructionsandwarnings.Inanareafreeofbystanders andobstructions,carefullyoperateattachmenttolearnits characteristicsandrangeofmotion.

TX,ATTACH-19-20JAN11-1/1

Safety—MaintenancePrecautions

ParkandPrepareforServiceSafely

Warnothersofservicework. Alwaysparkandprepare yourmachineforserviceorrepairproperly.

• Parkmachineonalevelsurfaceandlowerequipment totheground.

• Engageparkbrake.

• Stopengine.

• Installframelockingbar.

• AttachaDONOTOPERATEtaginanobviousplacein theoperator'sstation.

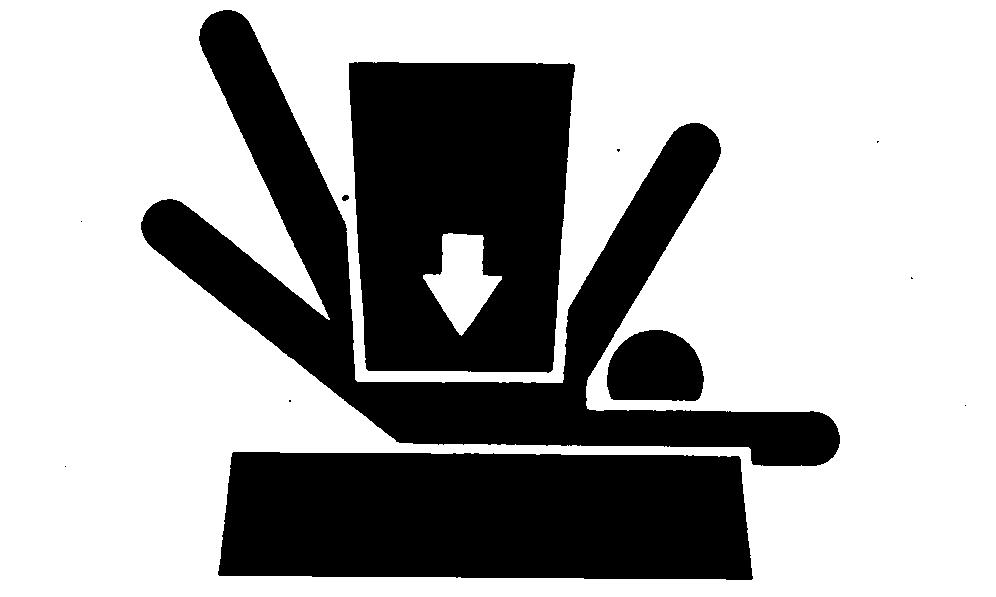

Securelysupportmachineorattachmentbeforeworking underit.

• Donotsupportmachinewithboom,bucket,orother hydraulicallyactuatedequipment.

• Donotsupportmachinewithcinderblocksorwooden piecesthatcancrumbleorcrush.

• Donotsupportmachinewithasinglejackorother devicesthatcouldslipoutofplace.

Understandserviceproceduresbeforebeginningrepairs. Keepserviceareacleananddry.Usetwopeople whenevertheenginemustberunningforservicework.

TX,PARK,4WD-19-28JUN10-1/1

CleanExhaustFilterSafely

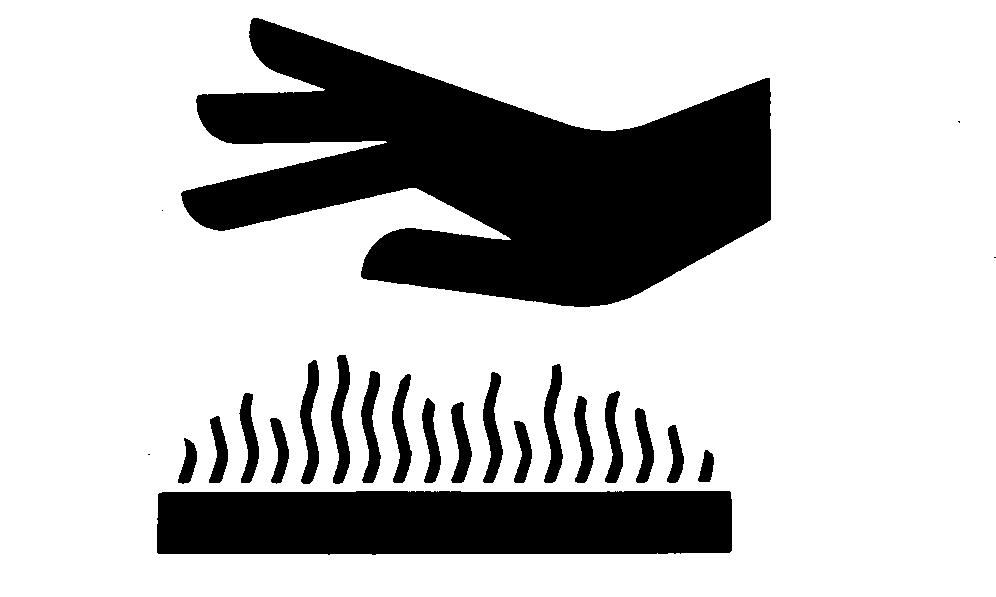

Duringexhaustfiltercleaningoperations,theengine mayrunatelevatedidleandhottemperaturesforan extendedperiodoftime.Exhaustgasesandexhaust filtercomponentsreachtemperatureshotenoughtoburn people,origniteormeltcommonmaterials.

Keepmachineawayfrompeople,animals,orstructures whichmaybesusceptibletoharmordamagefromhot exhaustgasesorcomponents.Avoidpotentialfireor explosionhazardsfromflammablematerialsandvapors neartheexhaust.Keepexhaustoutletawayfrompeople andanythingthatcanmelt,burn,orexplode.

Closelymonitormachineandsurroundingareafor smolderingdebrisduringandafterexhaustfiltercleaning.

Addingfuelwhileanengineisrunningcancreateafire orexplosionhazard.Alwaysstopenginebeforerefueling machineandcleanupanyspilledfuel.

Alwaysmakesurethatengineisstoppedwhilehauling machineonatruckortrailer.

Contactwithexhaustcomponentswhilestillhotcanresult inseriouspersonalinjury.

Avoidcontactwiththesecomponentsuntilcooledtosafe temperatures.

Ifserviceprocedurerequiresenginetoberunning:

• Onlyengagepower-drivenpartsrequiredbyservice procedure

• Ensurethatotherpeopleareclearofoperatorstation andmachine

Keephands,feet,andclothingawayfrompower-driven parts.

Alwaysdisablemovement(neutral),settheparkingbrake ormechanismanddisconnectpowertoattachmentsor toolsbeforeleavingtheoperator’sstation.

Shutoffengineandremovekey(ifequipped)before leavingthemachineunattended.

ServiceCoolingSystemSafely

Explosivereleaseoffluidsfrompressurizedcooling systemcancauseseriousburns.

Donotserviceradiatorthroughtheradiatorcap.Onlyfill throughthesurgetankfillercap.Shutoffengine.Only removesurgetankfillercapwhencoolenoughtotouch withbarehands.Slowlyloosencaptorelievepressure beforeremovingcompletely.

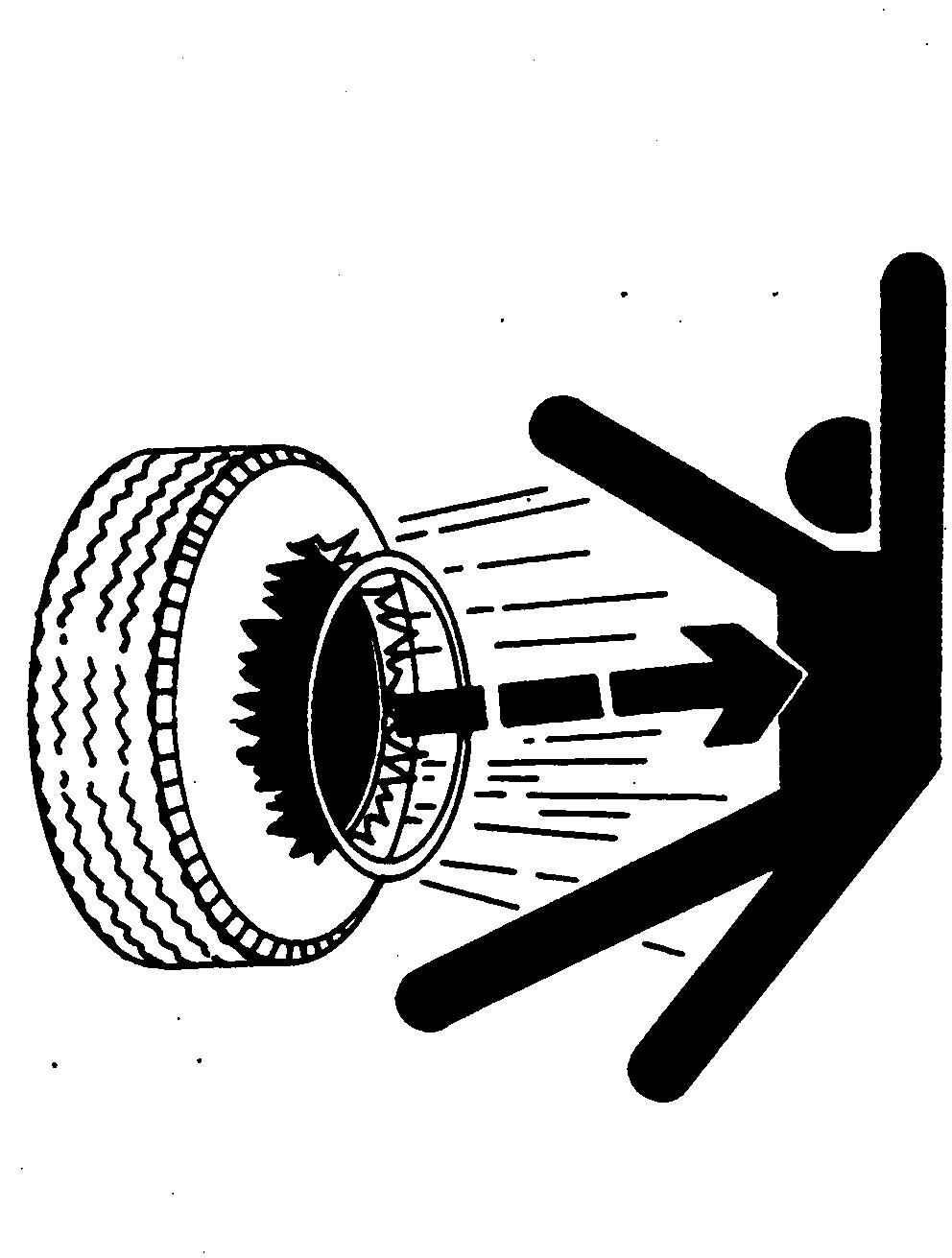

ServiceTiresSafely

Explosiveseparationofatireandrimpartscancause seriousinjuryordeath.

Donotattempttomountatireunlessyouhavetheproper equipmentandexperiencetoperformthejob.

Alwaysmaintainthecorrecttirepressure.Donotinflate thetiresabovetherecommendedpressure.Neverweld orheatawheelandtireassembly.Theheatcancause anincreaseinairpressureresultinginatireexplosion. Weldingcanstructurallyweakenordeformthewheel.

Wheninflatingtires,useaclip-onchuckandextension hoselongenoughtoallowyoutostandtoonesideand NOTinfrontoforoverthetireassembly.Useasafety cageifavailable.

Checkwheelsforlowpressure,cuts,bubbles,damaged rimsormissinglugboltsandnuts.

DX,RIM-19-24AUG90-1/1

RemovePaintBeforeWeldingorHeating

Avoidpotentiallytoxicfumesanddust.

Hazardousfumescanbegeneratedwhenpaintisheated bywelding,soldering,orusingatorch.

Removepaintbeforeheating:

• Removepaintaminimumof100mm(4in.)fromarea tobeaffectedbyheating.Ifpaintcannotberemoved, wearanapprovedrespiratorbeforeheatingorwelding.

• Ifyousandorgrindpaint,avoidbreathingthedust. Wearanapprovedrespirator.

• Ifyouusesolventorpaintstripper,removestripperwith soapandwaterbeforewelding.Removesolventor paintstrippercontainersandotherflammablematerial fromarea.Allowfumestodisperseatleast15minutes beforeweldingorheating.

Donotuseachlorinatedsolventinareaswherewelding willtakeplace.

MakeWeldingRepairsSafely

IMPORTANT:Disableelectricalpowerbeforewelding. Turnoffmainbatteryswitchanddisconnect positiveandnegativebatterycables.

Donotweldorapplyheatonanypartofareservoiror tankthathascontainedoilorfuel.Heatfromweldingand cuttingcancauseoil,fuel,orcleaningsolutiontocreate gaseswhichareexplosive,flammable,ortoxic.

Avoidweldingorheatingnearpressurizedfluidlines. Flammablespraymayresultandcausesevereburnsif pressurizedlinesfailasaresultofheating.Donotletheat gobeyondworkareatonearbypressurizedlines.

Removepaintproperly.Donotinhalepaintdustorfumes. Useaqualifiedweldingtechnicianforstructuralrepairs.

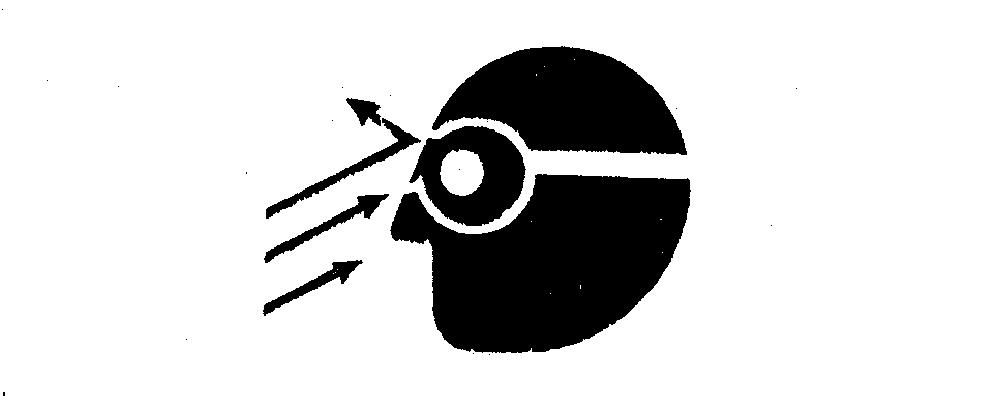

DriveMetalPinsSafely

Alwayswearprotectivegogglesorsafetyglassesand otherprotectiveequipmentbeforestrikinghardened parts.Hammeringhardenedmetalpartssuchaspinsand bucketteethcoulddislodgechipsathighvelocity.

Useasofthammerorabrassbarbetweenhammerand objecttopreventchipping.

Doallworkinanareathatiswellventilatedtocarrytoxic fumesanddustaway.

Disposeofpaintandsolventproperly.

DX,PAINT-19-24JUL02-1/1

Makesurethereisgoodventilation.Weareyeprotection andprotectiveequipmentwhenwelding.

MB60223,0000212-19-31MAY12-1/1

TX,PINS-19-20JAN11-1/1

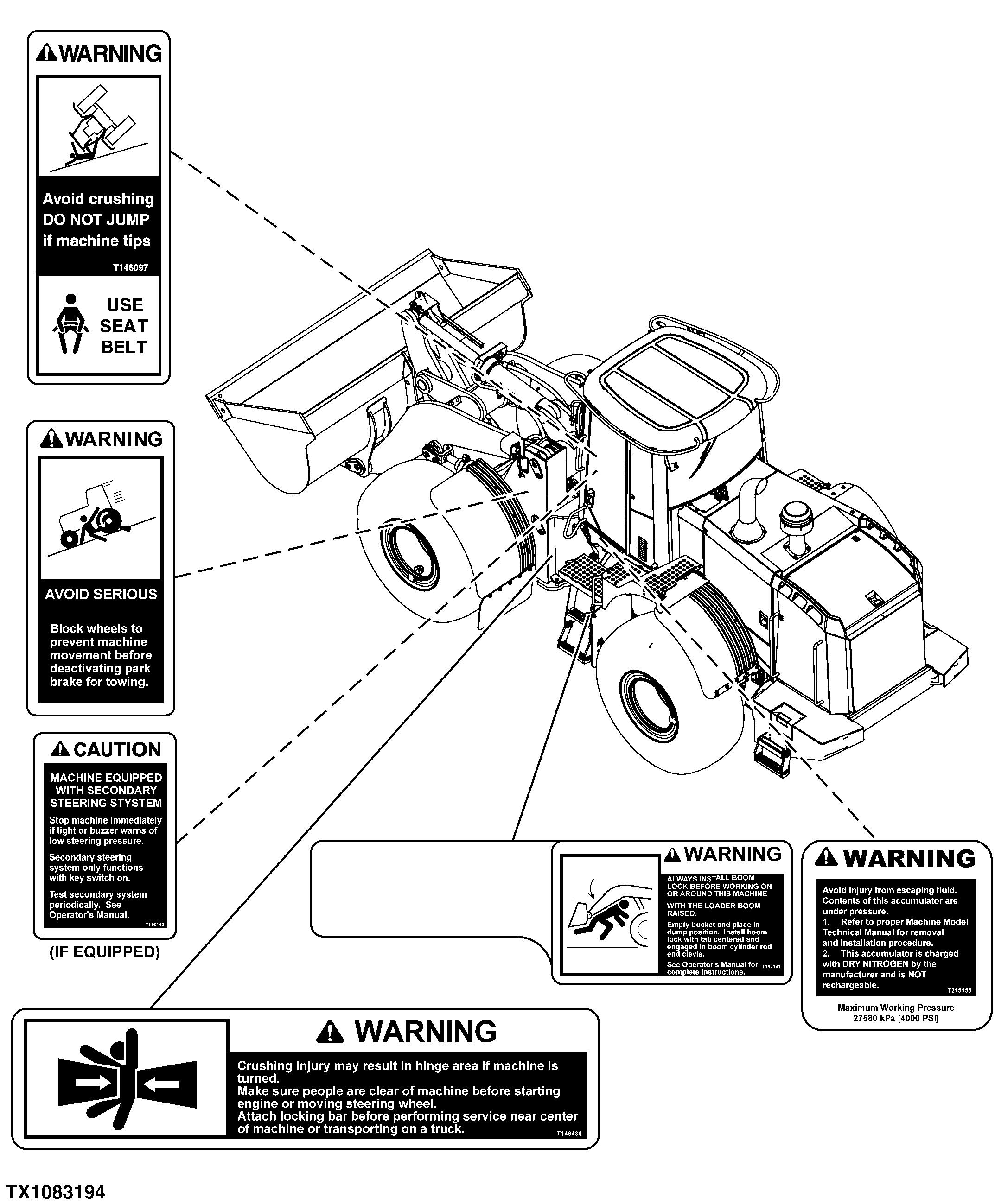

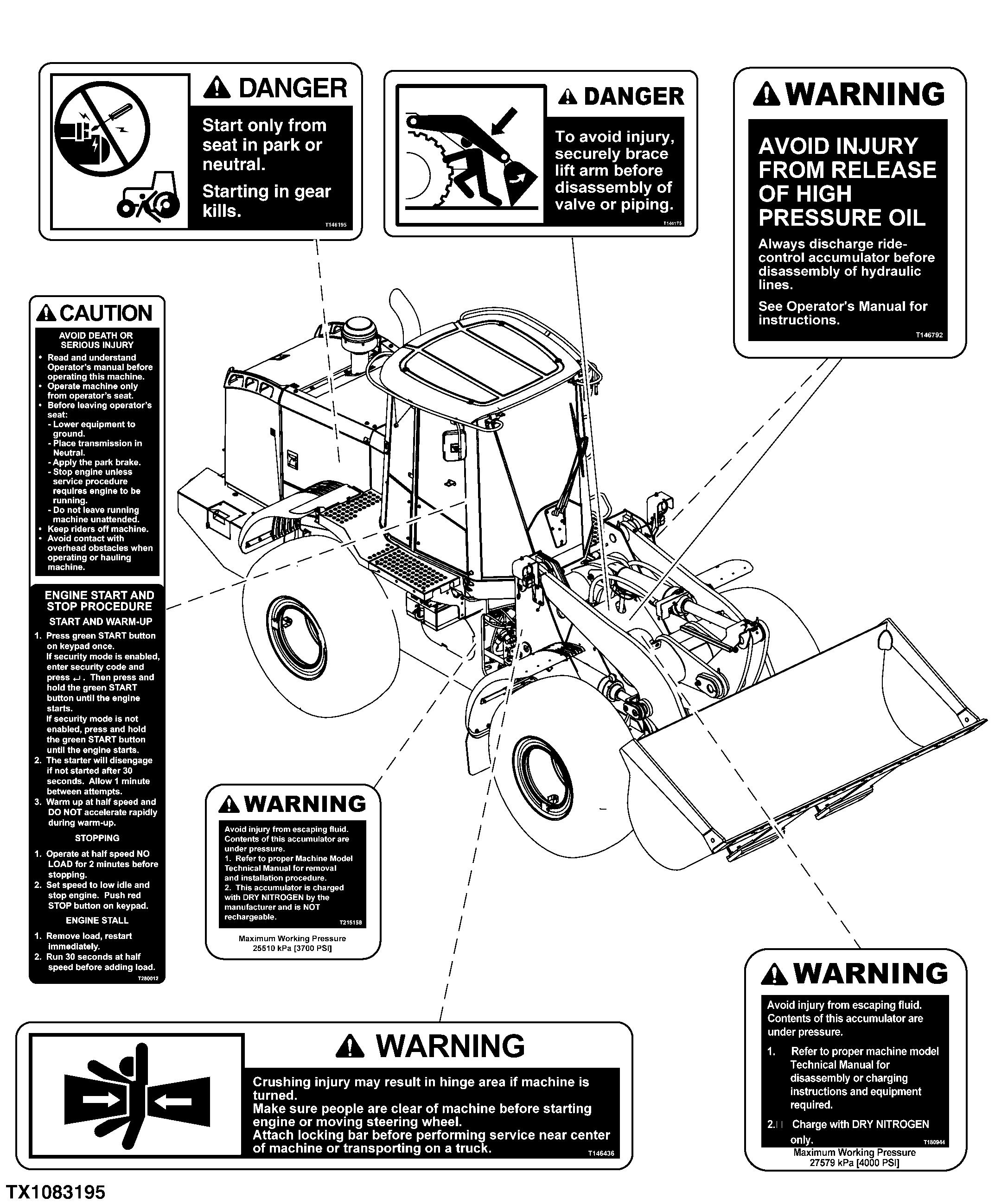

Safety—SafetySigns

SafetySigns

LeftSideShown

Operation—Operator’sStation

Levers—TwoFunctionHydraulicControl

NOTE:Thereareseveralcontrolleverconfigurations availableonJohnDeerefourwheeldriveloaders. Pleaseverifytheconfigurationofyourmachine beforereviewingoperatinginstructions.

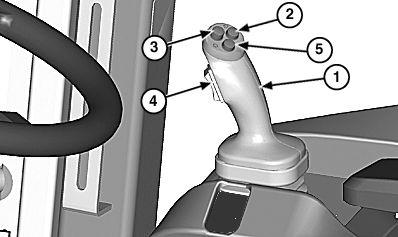

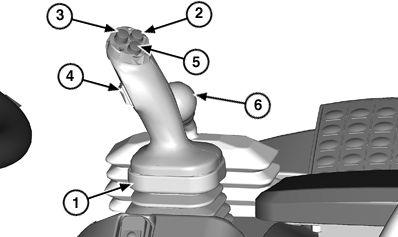

JoystickBucketandBoomControlwithGearshift, QuickShiftSwitch,andFNRSwitch

1—JoystickBucketandBoom Control

2—IncreaseGearButton

3—QuickShiftSwitch

4—Forward,Neutral,or Reverse(FNR)Switch

5—DecreaseGearButton

JoystickBucketandBoomControlwithGearshift,Quick ShiftSwitch,andFNRSwitch

JH91824,00006A4-19-20JUL11-1/2

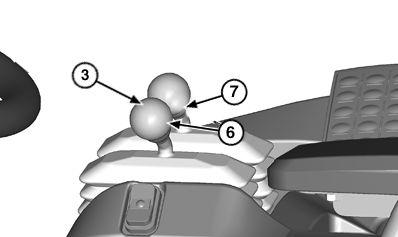

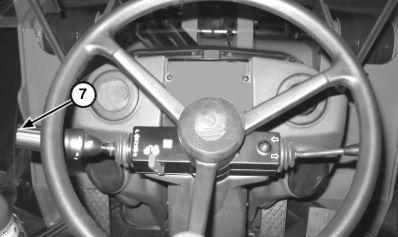

TwoLeverBucketandBoomControlwithQuick ShiftSwitchandSteeringColumnFNRLever

3—QuickShiftSwitch

5—SteeringColumnForward, Neutral,orReverse(FNR) Lever

6—BucketControlLever

7—BoomControlLever

TwoLeverBucketandBoomControlwithQuickShiftSwitch

SteeringColumnFNRLever

JH91824,00006A4-19-20JUL11-2/2

Levers—ThreeFunctionHydraulicControl

NOTE:Thereareseveralcontrolleverconfigurations availableonJohnDeerefourwheeldriveloaders. Pleaseverifytheconfigurationofyourmachine beforereviewingoperatinginstructions.

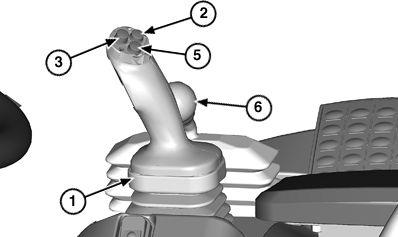

JoystickBucketandBoomControlwithGearshift, QuickShiftSwitch,FNRSwitch,andThird FunctionAuxiliaryControlLever

1—JoystickBucketandBoom Control

2—IncreaseGearButton 3—QuickShiftSwitch

4—Forward,Neutral,or Reverse(FNR)Switch

5—DecreaseGearButton 6—ThirdFunctionAuxiliary ControlLever

JoystickBucketandBoomControlwithGearshift,QuickShiftSwitch, FNRSwitch,andThirdFunctionAuxiliaryControlLever

JH91824,00006B9-19-30NOV10-1/3

JoystickBucketandBoomControlwithGearshift andQuickShiftSwitch,SteeringColumnFNRLever, andThirdFunctionAuxiliaryControlLever

1—JoystickBucketandBoom Control 2—IncreaseGearButton 3—QuickShiftSwitch

5—DecreaseGearButton 6—ThirdFunctionAuxiliary ControlLever

7—SteeringColumnForward, Neutral,orReverse(FNR) Lever