Product: WHEEL SCRAPER

Model: 637D WHEEL SCRAPER 20W

Configuration: 637D SCRAPERS 20W00001-00494 (MACHINE) POWERED BY 3306 ENGINE

Disassembly and Assembly

C9 Engines for Caterpillar Built Machines

Media Number -RENR9579-20 Publication Date -01/02/2015 Date Updated -15/08/2018

Valve Mechanism Cover - Remove and Install

SMCS - 1107-010

Removal Procedure

NOTICE

Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life.

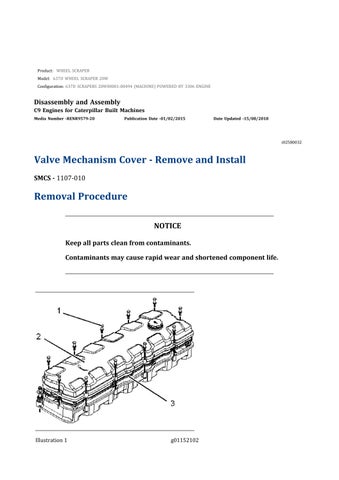

1. Removebolts(1)

2. Removevalvemechanismcover(2)andseal(3).

Installation Procedure

Table1

Required Tools

Tool

A 4C-9612 SiliconeSealant 1

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened component life.

Illustration3 g01138382

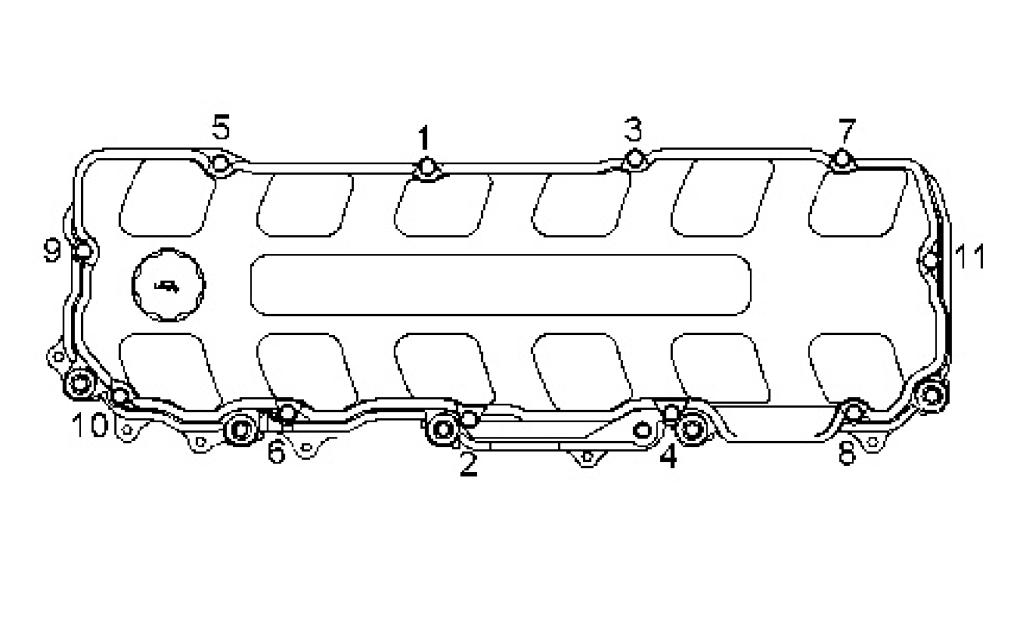

1. Positionseal(3)invalvemechanismcover(2) ApplyTooling(A)tobothsidesofthe seal joint Positionvalvemechanismcover(2)andseal(3)onthevalvecoverbase.

2. Installbolts(1).Tightenbolts(1)inanumericalsequencetoatorqueof20±3N·m(1 5± 2lbft).

Product: WHEEL SCRAPER

Model: 637D WHEEL SCRAPER 20W

Configuration: 637D SCRAPERS 20W00001-00494 (MACHINE) POWERED BY 3306 ENGINE

Disassembly and Assembly

C9 Engines for Caterpillar Built Machines

Media Number -RENR9579-20 Publication Date -01/02/2015 Date Updated -15/08/2018

Valve Mechanism Cover Base - Remove and Install

SMCS - 1120-010

Removal

Procedure

Start By:

a Removethevalvemechanismcover RefertoDisassemblyandAssembly,"Valve MechanismCover-RemoveandInstall".

NOTICE

Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life.

Illustration1 g01140735

1. Disconnectsensor(4)andharnessassembly(6)fromvalvecoverbase(5).

2. Removebolt(1)andtheclipthatholdstheharnessassembly.

3. Disconnectharnessassemblies(3).

4. Removebolts(2),thewashers,andthesprings

5. Removevalvecoverbase(5)andtheseal.

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened component life.

Illustration2 g01140735

Illustration3 g01061297

1. Positionthesealandvalvecoverbase(5)onthecylinderhead.

2. Installthesprings,thewashers,andbolts(2).Tightenbolts(2)inanumericalseque nce

3. Connectharnessassemblies(3).

4. Installtheclipandbolt(1)thatholdstheharnessassembly.

5. Connectharnessassembly(6)tovalvecoverbase(5).Tightentheboltstoatorqueof 6±1N·m(53±9lbin).

6. Connectsensor(4)tovalvecoverbase(5).

End By:

a. Installthevalvemechanismcover.RefertoDisassemblyandAssembly,"ValveMechani sm Cover-RemoveandInstall".

Product: WHEEL SCRAPER

Model: 637D WHEEL SCRAPER 20W

Configuration: 637D SCRAPERS 20W00001-00494 (MACHINE) POWERED BY 3306 ENGINE

Disassembly and Assembly

C9 Engines for Caterpillar Built Machines

Media Number -RENR9579-20 Publication Date -01/02/2015 Date Updated -15/08/2018

Rocker Arm and Shaft - Remove

SMCS - 1102-011

Removal Procedure

Start By:

i02884496

a Removethevalvemechanismcover RefertoDisassemblyandAssembly,"Valve MechanismCover-RemoveandInstall".

NOTICE

Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life.

1. Placeidentificationmarksoneachoftherockerarmsinordertoidentifytheproperlo cation forinstallation

Illustration1 g00953116

2. Loosennuts(3)androckerarmadjustmentscrews(2).

3. Removebolts(1)androckershaft(4).

4. Removethepushrodsandthevalvebridges

Product: WHEEL SCRAPER

Model: 637D WHEEL SCRAPER 20W

Configuration: 637D SCRAPERS 20W00001-00494 (MACHINE) POWERED BY 3306 ENGINE

Disassembly and Assembly

C9 Engines for Caterpillar Built Machines

Media Number -RENR9579-20 Publication Date -01/02/2015

Rocker Arm - Disassemble

SMCS - 1123-015

Disassembly Procedure

Start By:

Date Updated -15/08/2018

a Removetherockerarmandshaft RefertoDisassemblyandAssembly,"RockerArman d Shaft-Remove".

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened component life.

Note: Placeanidentificationmarkoneachofthecomponentsoftherockershaftforinstallat ion purposes.

Illustration1 g01160012

Personal injury can result from being struck by parts propelled by a released spring force.

Make sure to wear all necessary protective equipment.

Follow the recommended procedure and use all recommended tooling to release the spring force.

1. Removeplug(2)fromrockershaft(1).

2. Removestand(6),inletrockerarm(5),spring(4),andexhaustrockerarm(3)fromro cker shaft(1).

Product: WHEEL SCRAPER

Model: 637D WHEEL SCRAPER 20W

Configuration: 637D SCRAPERS 20W00001-00494 (MACHINE) POWERED BY 3306 ENGINE

Disassembly and Assembly

C9 Engines for Caterpillar Built Machines

Media Number -RENR9579-20 Publication Date -01/02/2015 Date Updated -15/08/2018

Rocker Arm - Assemble

SMCS - 1123-016

Assembly Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened component life.

1. Lubricateallcomponentsoftherockerarmshaftwithcleanengineoil

Illustration1 g01160012

Improper assembly of parts that are spring loaded can cause bodily injury.

To prevent possible injury, follow the established assembly procedure and wear protective equipment.

2. Installexhaustrockerarm(3),spring(4),inletrockerarm(5),andstand(6)onrocker shaft (1).

3. Installplug(2)intorockershaft(1).

End By:

a Installtherockerarmandshaft RefertoDisassemblyandAssembly,"RockerArmand Shaft-Install".

Product: WHEEL SCRAPER

Model: 637D WHEEL SCRAPER 20W

Configuration: 637D SCRAPERS 20W00001-00494 (MACHINE) POWERED BY 3306 ENGINE

Disassembly and Assembly

C9 Engines for Caterpillar Built Machines Media Number -RENR9579-20

Rocker Arm and Shaft - Install

SMCS - 1102-012

Installation Procedure Table1

Required Tools

i04506590

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened component life.

1. ApplyTooling(A)tobothendsofthepushrods.

2. Lubricatethepushrodswithcleanengineoil Installthepushrodsandthevalvebridge s.

Illustration1 g00953116

3. Positionrockershaft(4)onthecylinderhead.Installbolts(1).

Illustration2 g02685496 Rockershaftholddownboltstighteningsequence

4. Tightenbolts(1)inthesequenceshown.Tightenbolts(1)tostandardtorque.

5. ApplyTooling(A)toeachofthebottomfacesoftherockerarms

6. Positionrockerarmadjustmentscrews(2)andtightennuts(3).Adjustthevalvelasho fthe rockerarms RefertoTestingandAdjusting,"EngineValveLash-Inspect/Adjust".

End By:

a. Installthevalvemechanismcover.RefertoDisassemblyandAssembly,"ValveMechani sm Cover-RemoveandInstall".