Never produce concrete at a temperature below 0°C.

Use Portland cement rather than blended cement

Use insulating blankets to help retain the heat produced by the curing process

In cold weather periods try to produce concrete when the ambient temperature is at its daily peak.

(around 5°C) but concrete production has been scheduled or is required, there are several possible courses of action that will help keep production going

Temperature is the biggest factor in the ability of concrete to develop enough strength (more than 5MPa) to resist the effects of freezing weather conditions The timing of the production is key During cold periods, production should be scheduled close to midday, to ensure maximum ambient temperature

To give extra help with concreting during cold weather:

Use an accelerator

Use water-reducing admixtures

Increase the strength class of the concrete

Use or change to Portland cement

Warm/heat moulds or formwork

Use insulation on moulds or formwork

Leave curing concrete in the mould or formwork for longer

If possible use enhanced curing techniques like steam curing or autoclaving

Winter - a great time to keep up with your mould maintenance.

During the quieter season take time to review your moulds' condition and stock levels. Get yourself ready for a busy Spring with new moulds and ideas, surprise your customers with a new range of products and be prepared for new trends

If you're not sure what you need or you'd like to speak with someone and get some inspiration, contact our Precast specialists who will help you with any kind of enquiry

Armcon Thermal Blanket –

An insulated cover to assist in curing cast concrete It is quilted, stitched and welded, to ensure not only durability, but also flexibility.

GPH, a leading Scottish Builders' Merchant Recently bought their second volumetric concrete mixer from Armcon, with the purchase being a fulfilment of GPH’s business strategy and objectives to become the one-stop shop for customers.

Sean Warburton, Armcon's Managing Director, visited Grant Shewan the GPH Managing Director and Fraser Bruce, one of the volumetric operators, to witness for himself the benefits that the Duralight and Armcon had brought to GPH and its clients

As part of this visit, Sean met with Grant to discuss how the product might be enhanced and how Grant felt about the entire Armcon experience.

The clear message from GPH was that Armcon had been supportive from the very first meeting Grant commented:

“Armcon are a really easy business to work with and are great at listening to and reacting to the feedback we provide on the mixer From the start, Derek has been great to deal with and the aftermarket support and customer service have both been excellent I also like the fact that every member of the Armcon team is available to us, and this was a really key factor for our business"

Sean also went out with Fraser and the truck to see what the Duralight was like to live with on a daily basis and find out what Fraser thought about Armcon. Out in the field, (to a local caravan park just outside of Aberdeen) the customer wanted two different mixes, one wet and one dry and after the hard work was done by Fraser, he commented:

“ The Armcon Duralight is just so easy to operate and all the staff at Armcon are so helpful but I have to give a special shout-out to Derek and Phil who have both gone out of their way to help us"

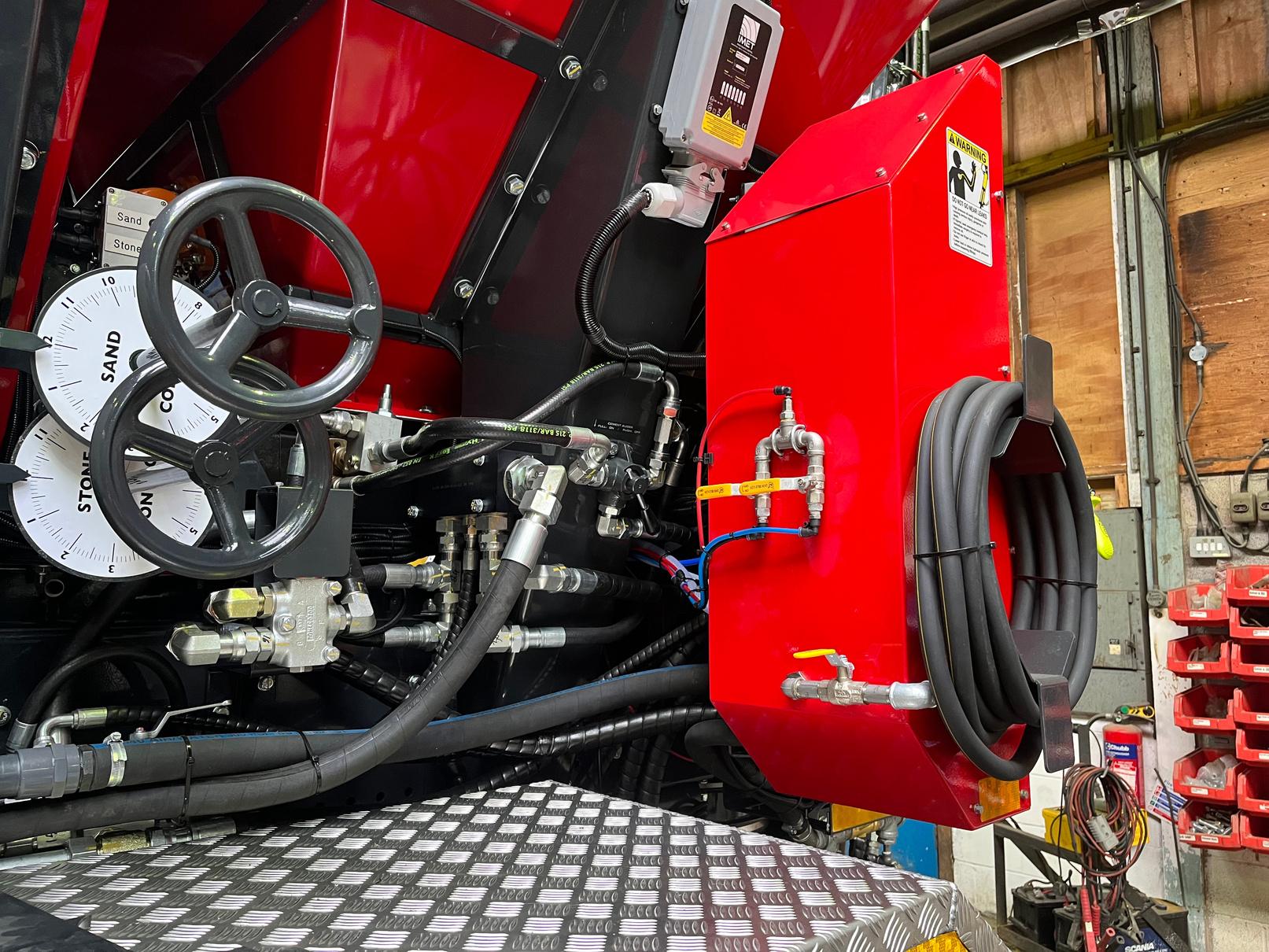

The winter season is when your mixer can suffer the most harm Although winter may be the slowest season for your business, it is critical to carefully maintain your mixer in order to keep it operating and pouring without issue

It is vital to ensure that you are properly prepared and equipped for the winter season

Worn-out valves, for example, make draining maintenance difficult. This invariably results in liquids freezing in your mixer

By the next morning, you may have to deal with a possible mixer malfunction that might have been avoided!

By contacting our skilled engineers and parts specialists, they can advise you on how to avoid winter failures

The key things are to drain the water pump, flow meter and water valve This ensures that liquids do not freez and hinder your mixer in extreme conditions

Specific instructions vary from model to model so the manual you have is best to refer to - better yet our Technical Team and engineers are always available to assist Whether it's carrying out simple winter maintenance or a free engineer mixer health check, your mixer can be ready for the busy concrete season to start in Spring!

Ben Gregg joined Armcon in 2012 straight from school as a fresh faced 16 year old with very little knowledge or skills Having signed up to the Armcon apprenticeship scheme Ben started his career as an engineer and it was clear early on that Ben was destined for greater things. Ben quickly showed his abilities and with our first class engineering team

providing comprehensive training married to his college apprenticeship he soon became very proficient in assembling and repairing our equipment Ben’s skills truly developed when Armcon became a manufacturer - he was heavily involved in the prototype of the Duralight, working closely with the team on all aspects of the machine from initial design right through to the intricacies of the hydraulics

A taste for the open road came next Having attended a few customer breakdown calls, Ben decided he wanted to develop his skills even further and become customer facing which led to him becoming a Field Service Engineer

Everything he had learned so far was really put to the test in this new role but as we expected customers started to comment on not only the great job that he did but also his knowledge and helpfulness

In October we welcomed yet another Apprenticeship Scheme participant to our team. Jack Chignell joined the Parts Team and under Kevin's knowledgeable eye he'll soon be up to speed so he can help support our customers

When the business became employee owned in February 2021 there was a restructure of the business to align with the fact it was a manufacturer and not a dealer anymore and this presented new opportunities for the team One of these opportunities was a new operations manager with responsibility for manufacturing and after market support The advert had been on the job board less than five minutes when Ben walked in to the Managing Directors office and stated his case for the role which was subsequently supported by numerous colleagues From Apprentice to Operations Manager, it really is a success story

Commenting on his latest role at Armcon Ben said “With an incredibly supportive team, it has not been hard to settle into the role and I have enjoyed every minute! As an employee owned business now , the team spirit and work ethic at Armcon are outstanding. We have made incredible steps this past couple of years to ensure we are delivering top-quality products followed up by exceptional customer service, and I’m thrilled to be a part of it

Last month Fred Bolton participated at the National Masters Swimming Championships in two team races Fred and his team took gold in both races and broke the British record! Congratulations to Fred and his team for the extraordinary achievement and we wish them further success!