turfandrec.com

turfandrec.com

DECK WIDTH • 21"

CUTTING HEIGHT • 1 – 3.4"

GRASS CATCHER • 70 L

The RM 655 YS gas lawn mower with low-maintenance Hydrostatic Drive and variable speed adjustment is equipped to tackle demanding lawn maintenance. With a cutting width of 21”, the RM 655 YS offers fast and precise mowing. The bladebrake clutch allows the operator to disengage the mowing blade during operation, whether to remove objects from the mowing path or to empty the grass catcher, there is no need to stop and restart the engine. The Dual purpose multi-blade handles both cutting & mulching applications and ensures a precise cutting pattern. The RM 655 YS features a single point height adjustment with 7 settings from 1" to 3.4". A heightadjustable, folding mono-comfort handlebar with rubberized soft touch handle provides comfort and easy access to the 70-litre grass collection box. This includes a fill-level indicator making it easy to see when it needs to be emptied.

PRO-FLEET COMMERCIAL LANDSCAPE PROGRAM

STIHL’s Pro-Fleet Commercial Landscape Program is designed to provide commercial landscapers a volume discount on purchases of five or more landscaping power tools. Receive additional savings on STIHL battery products until June 28, 2024. Visit your STIHL Dealer today to learn about our power, performance and durability difference.

By Mike Jiggens

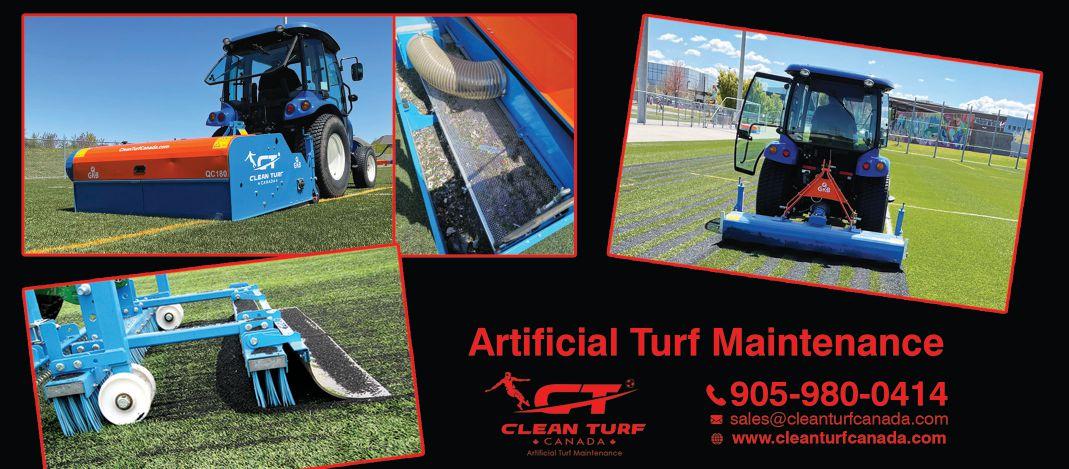

There’s been a growing trend in recent years – mainly among school boards – in which artificial turf sports fields are being installed at high school campuses. This is something happening right across the country. We’ve posted dozens of articles on our website the past several years about one school or another replacing an existing natural grass field with a synthetic turf playing surface, or a newly constructed school opting for a shiny, new artificial field.

Artificial turf fields aren’t cheap, and their lifespans are limited in comparison with their natural counterparts. Nevertheless, artificial turf is the preferred surface in many cases.

Several of these recent installations are collaborations between school boards and municipalities so that they can share the costs of construction and upkeep with an understanding that use of the fields isn’t limited to the site-specific school and that the community at large can compete on the fields if they cough up the requisite user fees. In our April/May issue, we published a detailed comparison of the two types of playing fields. The story was part of our ongoing series of research articles provided by the Guelph Turfgrass Institute.

There are pros and cons asso-

ciated with both turf types, and the municipalities and school boards that have chosen to jointly invest in artificial turf fields are usually basing their decision on several factors, such as:

• the surfaces’ ability to be game-ready following significant rain events

• artificial turf fields’ ability to avoid traditional wear and tear patterns associated with natural turf fields

• maintenance crews not having to rely on fertilizer and chemical inputs Although there is merit to these recognized advantages, there is more to consider. We’re living in an era of climate change, and our summers aren’t getting any cooler. Artificial turf doesn’t respire and therefore doesn’t provide a natural cooling effect. The surface temperature of synthetic turf is also noticeably warmer than that of natural grass.

playing surface.

Owners of professional sports franchises are often swayed by artificial turf’s glamour appeal. With their crisp lines and numbers – which are usually stitched in place – the white-on-green contrast “pops” that much more than lines and numbers painted onto natural grass, making artificial turf fields more TV and fan friendlier. This is even more apparent when as a game progresses, wear patterns can obliterate painted-on lines and numbers.

Television isn’t a factor in the decision-making process of school boards and municipalities. Understanding that an artificial turf field’s lifespan is limited to 10 to 12 years, those footing the bills want the most bang for their buck. Figuring there is no real difference in player safety between the two types of surfaces, those who choose the synthetic option are counting on increased user fee revenue as they can extend their seasons and can allow for more billable hours daily.

www.turfandrec.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Tel: 416-510-5113 apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

Editor Mike Jiggens mjiggens@annexbusinessmedia.com

Advertising Manager Rebecca Lewis 519-400-0322 rlewis@annexbusinessmedia.com

Account Coordinator Farwa Siddiqui 416-510-5118 fsiddiqui@annexbusinessmedia.com

Audience Development Manager Anita Madden 416-510-5183 amadden@annexbusinessmedia.com

Group Publisher Anne Beswick 416-410-5248 abeswick@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada ISSN 1186-0170

PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Published 7 times a year – Jan/Feb, March, Apr/May, June/July, Aug/Sept, October, Nov/Dec

Canada – 1 year $35.70 CDN; 2 year $45.90 CDN; 3 years $56.61 CDN (plus applicable taxes; single-copy$7.00 CDN USA – 1 year $48.96 CDN HST 86717 2652 RT0001

provide a cooling effect

Player safety is arguably the most important consideration. There’s no question that today’s generation of artificial turf surfaces is much safer to play on than the synthetic fields of yesteryear. Yet professional athletes – especially football players –are adamant that natural turf remains the safest possible

It’s vital that decision makers think ahead toward the end of an artificial turf field’s lifespan. What is to become of that field once it’s seen its last game? There can be an afterlife for portions of the surface to avoid its outright disposal at a landfill.

Artificial turf fields have their place and can be an important addition to a municipality’s inventory of playing facilities. But they aren’t the be-all and endall. There is considerable homework to be done before making a multi-million-dollar decision on which road to take.

Occasionally, Turf and Recreation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2024 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

City council in Barrie, Ont. is considering the construction of a new multi-use sports field.

The proposed facility is a combined sports field and parade ground that would measure 100 metres by 154 metres, and would be used for soccer, football, rugby and lacrosse.

Estimated to cost $4.6 million, the field would include an artificial turf surface. The project would take a minimum of 16 months to complete.

Not everyone in the community is on board with the project, however

Metro Vancouver is moving closer to outlawing the use of gas-powered, small engine landscaping equipment, including leaf blowers, mowers and pressurewashing equipment.

The municipality’s climate action committee has instructed staff to seek public input, including industry and local government, about ways to eliminate pollution from gas-powered equipment. The goal of the campaign is to create a shift toward battery and electric power..

A lack of funds needed to ensure its clubhouse can operate safely might mean the Petawawa Golf Club’s days are numbered.

The golf course is located on the base at Canadian Forces Base Petawawa, Ont. and is the only golf facility in town. The civilian-operated golf course was recently told its clubhouse would have to shut down by April 2025.

Estimated time for construction

The National Day of Mourning was observed April 28 to honour those who have lost their lives, have been injured, or suffered an illness due to their work.

$2 MILLION

Every year, thousands of workers in Canada are injured or killed on the job. According to the Association of Workers’ Compensation Boards of Canada (AWCBC), in 2022, there were 993 workplace fatalities recorded in Canada, 33 of which were young workers aged 15-24. Additionally, 348,747 accepted claims were reported for lost time due to work-related injuries or diseases. These statistics only include what is reported and accepted by the compensation boards. It is predicted that the total number of workers affected is even greater.

“The National Day of Mourning is an opportunity to create awareness about workplace safety

and reminds us to renew our commitment to ensure every worker goes home safe and healthy at the end of the workday,” Anne Tennier, president and chief executive officer, Canadian Centre for Occupational Health and Safety (CCOHS), said.

“Everyone can participate in the National Day of Mourning by taking a moment of silence at 11 a.m. on April 28 to remember those who lost their lives or experienced a life altering injury or illness due to their work.”

More information about the National Day of Mourning, including resources to help spread awareness in the workplace, is available on the CCOHS website: www.ccohs.ca/events/mourning.

Milwaukee Tool Canada, a subsidiary of Techtronic Industries Co. Ltd. (TTI), recently commemorated its centennial with a tree planting event on May 10, in partnership with Tree Canada. The event was in keeping with the company’s commitment to its sustainability stewardship, not only with its manufacturing capabilities but with the environment.

“I am incredibly proud to commemorate our 100th year by planting 100 trees,” Craig Baxter, group president of TTI Canada, said. “We are thrilled to be planting a tree on behalf of every year we have been in business, and it serves as a reminder of our

steadfast commitment to the environment as well as what we can accomplish when we work as one team.”

By planting native, non-invasive species, the heavy-duty tool manufacturer aims to provide essential habitat for wildlife, birds, mammals, and pollinating insects. Once planted, the area will be left to naturalize, reducing the need for harmful mowing practices and mitigating climate change, which will help to absorb carbon dioxide from the atmosphere.

Baxter added, “It’s been an honour to lead a talented team of colleagues and we would like to thank our team of partners,

customers and colleagues for their support in helping us achieve 100 years of business”

The partnership with Tree Canada is part of Milwaukee’s “Partners in Planting” program, which offers companies a way to deliver a team-building opportunity and foster good corporate citizenship where their employees live and work. Tree Canada secures trees, a planting site and all the logistics, allowing company teams to enjoy the event while doing something positive for their community.

The 100-year anniversary tree planting event took place at Cedar Grove Park in Markham, Ont., contributing to the future of the environment and the Markham community.

A look at the ways a small-to-mid-sized Ontario municipality tends to its sports fields

By Mike Jiggens

Management of sports fields and other significant green spaces varies from municipality to municipality. Larger cities, towns and counties generally have bigger budgets than smaller municipalities. Communities of similar size may not have the same number of fields to care for, nor the same number of maintenance staff.

Geography, soil types, climate and availability of land are other factors that can differentiate sports field management from one municipality to another. Some communities have multicultural populations that have precipitated the need for additional soccer fields or cricket pitches.

Turf & Rec, a publication of Annex Business Media, based in Simcoe, Ont., has profiled the parks operations of Norfolk County, of which Simcoe is its largest urban centre. Norfolk County, whose 2021 population was just shy of 68,000, is ranked 87th in size among Canada’s municipalities, according to Wikipedia.

Following is a look at sports field and parks management operations of

a small-to-mid-sized Canadian municipality..

How many sports fields (and other significant green spaces) are regularly maintained in Norfolk? And how many of these fields are categorized as Class A facilities? There are 35 sports fields and significant green spaces with 10 Class A facilities.

What specific maintenance practices do you employ to ensure the quality and safety of sports fields in Norfolk County?

Rolling, aeration, dethatching, topdressing, and overseeding annually. Fertilizing is done two to three times annually along with irrigation and maintenance of irrigation systems. Also, Infield grooming is done daily, infield dust control is done as needed, as well as pitching mound and batter’s box repairs. Fence, bench, bleacher repairs and other various maintenance are done as well. This is a combined effort from county staff, contractors, and user group volunteers.

How do you prioritize maintenance tasks across different sports fields, considering factors like usage frequency and upcoming events?

The majority of the grounds work is completed pre- and post-season. For anything required during the season, we rely on communication and co-ordination with user groups regarding any service disruptions or shutdowns. For irrigation of our lar-

gest sports parks, we co-ordinate cycles with the booking schedule. Infields are groomed daily whenever the facility is booked.

Can you describe the process of turf management, including aeration, fertilization, and pest control, for maintaining sports fields?

The majority is completed pre- or post-season, depending on location and equipment availability. Any mid-season maintenance is scheduled around usage and clearly communicated with user groups. Fertilizer is irrigated in as required or scheduled based on weather for our non-irrigated facilities.

What strategies do you use to conserve water while still keeping sports fields lush and playable?

All irrigation systems are fitted with rain sensors. Whenever possible, irrigation is scheduled for overnight and early mornings when wind and evaporation are typically low. All systems are regularly monitored and routinely inspected for proper operation.

How do you address issues such as drainage problems or uneven surfaces on sports fields?

Infield drainage issues are addressed by invasive, off-season turnover of screenings to break through hardpan layer. Grading infields, regular maintenance of the infield lip, and topdressing assists with both drainage and uneven surfaces. Rolling, routine inspection and manual work on problem areas help maintain level sports fields. Drainage and grading

are always taken into consideration during any facility upgrades.

Are there any ongoing or upcoming projects related to improving sports field infrastructure or amenities in your municipality?

Currently in our 10-year capital plan, we are continuing our sports field lighting replacement program, our fieldhouse refurbishment program, and other various amenity replacements and upgrades. We also have a condition assessment planned for all sports fields which will provide insight and recommendations for future capital improvements.

What measures are in place to monitor and maintain the safety of sports fields, including equipment inspections and surface testing?

We are members of ORFA (Ontario Recreation Facilities Association) and PRO (Parks and Recreation Ontario) where we continually review and adopt industry best practices. Staff complete weekly inspections and maintenance, and we have regular com-

munication with user groups on conditions and maintenance needs.

How do you collaborate with local sports organizations or leagues to ensure that their needs are met regarding field maintenance and scheduling?

All scheduling is handled by the recreation department. Collaboration with organizations and leagues takes place at our annual, pre-season user group meetings. We also keep open communication at both the management and operational levels with main points of contact within the user groups.

In what ways do you involve the community or volunteers to help with sports field maintenance tasks?

We rely heavily on user group volunteers and continue to maintain great working relationships with them. They regularly assist with basic maintenance functions such as mound repairs, line chalking and painting, and field set-ups. We meet annually with minor sports associations to dis-

cuss needs and future capital or operational projects. These volunteers are vital to providing quality facilities, and their assistance is always appreciated.

Can you discuss any challenges or obstacles you face in maintaining sports fields and how you address them to ensure optimal playing conditions?

Some challenges include:

• Recreational usage during maintenance windows. This is typically dealt with through quality customer service from frontline staff; communicating alternative locations, negotiating maintenance time, adjusting work schedules to accommodate.

• Misuse of baseball diamonds as dog parks. This is addressed through communication with owners, improved signage, creation of actual dog parks and bylaw enforcement, if required.

• Demand for early spring and late fall usage. Transitional seasons are always a challenge as our parks operations staff maintain both our arenas and our

Visit one of these participating Exmark Dealers to learn more about the full line of professional Exmark models.

ALBERTA FOREST & GARDEN FUTURE AG INC

EDGE EQUIPMENT LTD

HORIZON FOREST AND GARDEN LTD

SAVOY EQUIPMENT

SAVOY EQUIPMENT

C & L SUPPLY (1988) LTD

PILON TOOL RENTALS 1972

B & L SMALL MOTORS LTD

ALTONA FARM SERVICE LTD

HEPBURN ENTERPRISES INC

B.M. MARINE INC

THE TRACTOR DOME INC

WPE LANDSCAPE EQUIPMENT

BRADFORD RENTAL SALES & SERIVCE

GREEN TRACTORS INC (BRAMPTON)

BLUE WEST EQUIPMENT INC

NORTHSHORE TRACTOR

HURON TRACTOR LTD

HURON TRACTOR

LOCATION LE GARDEUR INC

SERVICE MECANIQUE MOBILE ENR.

HURON TRACTOR LTD

BOBCAT OF BRANTFORD INC

B.R. DICKSON EQUIPMENT INC

CHATHAM OUTDOOR POWER

MARTIN’S SMALL ENGINES LTD

CAMPEAU OUTDOOR POWER EQUIP. LTD

ZEHR’S SALES AND MANUFACTURING

CURRENT POWER MACHINERY INC

WPE LANDSCAPE EQUIPMENT

CAMPBELL’S OUTDOOR POWER EQUIP.

HURON TRACTOR LTD

M.R. BLAIS SALES & SERVICE INC

VEHICLE VENTURE

D-MINI MOTEURS INC

G.H.L. DISTRIBUTION INC

LOCATION LE GARDEUR INC.

WICKHAM

403-248-0878

403-343-6101

780-455-3343

780-542-4446

sports fields and parks. Once staff are on their arena operations shift schedule, time allotment for sports fields and parks maintenance is substantially impacted. This is addressed through limiting weekday programmable hours in the arenas, creative and prioritized work plans, and increased usage of contractors.

Is there a particular user group that is growing and requesting additional fields to accommodate its growth?

Like all sports, membership numbers ebb and flow. Currently, the busiest organizations are good at getting creative with their time and work well with other groups to utilize other local facilities as much as possible.

Has there been any feedback from user groups about a shortage of baseball or soccer fields in Norfolk?

Not that we’re aware of.

905-628-3055

905-775-7101

905-846-2511

519-688-0909

705-248-2208

519-235-1115

519-285-3845

450-581-6345

819-564-6623

519-666-2300

519-752-7900

905-331-5040

519-354-3990

519-669-2884

519-727-5031

519-595-7579

905-822-4211

905-569-2055

519-245-2428

519-285-3845

613-443-1230

519-966-8642

450-687-9171

450-467-5459

450-581-6345

306-825-3262

Has Norfolk ever been approached about installing an artificial turf field somewhere in the county?

Not that we’re aware of.

How many seasonal workers are hired each year to tend to the county’s fields/green spaces, and are you facing any challenges related to labour shortages?

Our many sports fields, parklands and facilities are maintained by 17 permanent, full-time staff. They are complemented with 13 seasonal, full-time, student hires, from May to August. Our biggest challenge is attracting qualified candidates. The recruitment process takes months and can include multiple position reposts and advertising.

Are there any projects coming up that might include significant renovations to existing fields?

The only significant project we have in the 10-year capital plan is infield resizing at the Delhi baseball diamond. This will include shrinking the infield, installing drainage, and grading. Other various projects include fence replacements, irrigation installation, sports park lighting upgrades, and fieldhouse refurbishments.

We thank Adam Kannawin and Mark Bouw, respectively, the supervisors of parks operations, west and east, Norfolk County, for their assistance into this profile.

By Dr. Sara Stricker

Research conducted by John Watson & Eric Lyons, University of Guelph, in partnership with the National Turfgrass Evaluation Program.

In the realm of landscaping and sports turf management, selecting the right plant for the right purpose is key. Among the turfgrass species available, tall fescue grass stands out as a resilient and adaptable choice, finding its place in lawns, sports fields, and parks around the world. But what exactly sets tall fescue apart from its counterparts, and what are the pros and cons of embracing this specific species?

Tall fescue (Festuca arundinacea) is a cool-season perennial grass native to Europe and widely naturalized in North America. Its robust nature makes it a favourite among turf managers seeking a grass species that can withstand various environmental stressors. Tall fescue exhibits remarkable drought tolerance, making it a great choice for regions with erratic rainfall patterns or tightening water restrictions. Its deep root system allows it to access moisture from lower soil layers, ensuring survival during dry spells, and making this species a great choice for erosion prevention on slopes. While Kentucky bluegrass (Poa pratensis) will struggle in shaded environments, tall fescue thrives in partial shade conditions, making it ideal for urban settings where sunlight may be limited. Tall fescue does not always produce underground rhizomes, which means it’s not likely to be sold as a pure stand from a sod farm. Seeded tall fescue will germinate and establish quicker than Kentucky bluegrass, so it is an ideal species to use in overseeding or repairing previously established stands. When mature, tall fescue can stand up to intense foot traffic, even under relatively low inputs. One of the primary historical drawbacks of tall fes-

cue is its coarse texture, which can be less aesthetically pleasing. This is exemplified in one of the first commercially available cultivars of tall fescue called Kentucky-31 (K-31). This cultivar was developed in the 1940s and was initially used as a pasture and forage grass, but the resilience under low inputs made it appealing to the home lawn market. K-31 generally has a lighter, lime-green hue when compared to Kentucky bluegrass and a much coarser texture which may not be desirable. However, over eight decades of selective breeding has created multiple varieties of “turf-type” tall fescue. The new, improved turf-type varieties have finer leaf texture, denser growth habit, darker colour, and may produce weak rhizomes.

If you’ve tried tall fescue in our northern climates, you may be aware of the one major drawback preventing this species from becoming the fan-favourite for lawn care and

sports field use: WINTER DAMAGE. Tall fescue is well known to be susceptible to grey snow mould, pink snow mould, Microdochium patch, ice encasement, and desiccation under cold air currents. Tall fescue is also susceptible to gray leaf spot, a disease that hasn’t yet become prevalent in Canada.

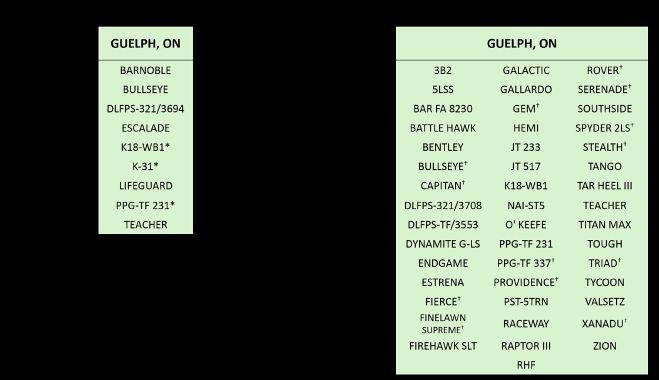

A turf-type tall fescue cultivar trial was seeded with 132 cultivars in 2018 at the Guelph Turfgrass Institute through the National Turfgrass Evaluation Project (NTEP) and data was collected from 2019–2023. NTEP is a non-profit program, sponsored by the Beltsville Agricultural Research Center and the National Turfgrass Federation. The data from test trials can be used by extension specialists for making recommendations, and turf managers can access the reports on the different turf species online to compare the performance of the cultivars in their geographic regions. Density, colour, spring green-up, leaf texture, and overall quality

Table 1. NTEP tall fescue cultivars with rating highest rating for spring green-up and summer quality. Cultivars are listed alphabetically and are in the same statistical grouping. Names with * or † were rated best for the average of all testing sites and at Guelph for either green-up or summer quality. This data is averaged from the 2019–2022 seasons.

were assessed using previously established methods. This trial included 23 other locations across the United States, some of which conducted multiple trials. Spring green-up data wasn’t gathered for all locations due to the absence of a winter season in those regions.

Nine cultivars stood out among the rest for the best average green-up in Guelph, as averaged over four years (Table 1). One of these is K-31, the historical cultivar with a wider leaf texture. The average summer quality for this trial identified 46 cultivars, and this did not include K-31. ‘Bullseye’ by Burlingham Seeds and ‘Teacher’ by Columbia Seeds performed well in both spring green-up and summer quality in Guelph, but these two cultivars didn’t make the cut for top ratings when averaged across the other locations tested. This underscores the significance of conducting research tailored to specific locations, emphasizing the need for more research focused specifically on Canada’s unique conditions. Important note: Although these cultivars were rated the highest for spring green-up, that does not mean that they are completely resistant to winter diseases and damage!

Although they aren’t entirely infallible, some tall fescue cultivars show promise for use in Canadian turf stands. Consider overseeding an existing Kentucky bluegrass field with tall fescue to boost mid-summer colour and durability but also understand that there may be some loss and damage due to severe winter conditions. Refer to the online Turfgrass Trial Explorer at NTEP.org and choose a nearby location to get cultivar data that applies to your region.

You can contact the Guelph Turfgrass Institute at GTI@ uoguelph.ca or follow @GuelphTurf on social media. Visit www.GuelphTurfgrass.ca for more information.

Dr. Sara Stricker is the communications and outreach co-ordinator at the Guelph Turfgrass Institute.

Benedict

As we transition to the summer season, landscape contractors, municipal ground managers, and groundskeepers are resetting after a busy spring. However, work isn’t slowing down as summer arrives and, for owners and operators, it’s important to refresh yourself with machine maintenance best practices before the second half of the mowing season.

One of the key factors in maintaining lawn health is ensuring your mower is operating at peak performance. Due to the warmer climate in the summer, performing the proper maintenance on your zero-turn radius (ZTR) becomes more important for the health of your property, the lifespan of your machine, and your safety.

Whether you’re mowing lawns or maintaining a golf course, proper maintenance is key. The following tips will help maintain the health of your ZTR this summer.

Become familiar with your ZTR maintenance schedule and how to perform tasks

Much like a car, routine maintenance is essential to keeping your ZTR running, even in challenging conditions. Becoming familiar with your ZTR is important for maximizing your machine’s efficiency, minimizing downtime, and ensuring safe operation. Every operator should start by reading the owner’s manual. Not only does the owner’s manual include operation instructions, but it also features a maintenance schedule for the specific machine, along with proper instructions.

Routine maintenance is important in the summer when it may have to be done more often because of the heat and increased usage. The manual will often include directions for engine maintenance, lubrication, deck maintenance, tire maintenance, battery maintenance, and safety inspections.

Owners should also lean on their dealer for support. The dealership where you

purchased your mower staffs those who will be able to assist with maintenance work or allow you to purchase the proper materials to perform maintenance yourself. The dealers will know what is best for your specific mower and can provide best practices that can save you time and ensure your ZTR is operating at peak performance.

Don’t overlook these summer factors

In the summer, operators need to carefully monitor their ZTR for issues. Continued usage combined with hot and dry climates lead to more dust and debris, which can cause various parts like filters and bearings to experience more wear and tear. These parts may need to be replaced or serviced more often to maintain optimal performance.

The combination of high temperatures and debris can cause a mower’s engine to overheat, leading to mechanical issues and reduced performance. If not addressed properly, this can cause permanent damage.

A dirty air filter can also affect the performance of a ZTR because it will cause limited airflow to the mower’s engine.

In hot weather, fuel in the mower’s tank can evaporate more quickly, leading to issues such as vapor lock or fuel degradation. Use high-quality fuel and fuel stabilizers, and store the mower in a shaded, well-ventilated area. This will help to minimize fuel evaporation, maintain fuel quality, and preserve engine performance.

Examine your tires before every use to ensure there are no punctures. In the summer the ground can become hard and dry, and it is easier for tires to be punctured by rocks or debris. It is also key to regularly monitor tire pressure to ensure proper inflation.

Soaring temperatures can also dry out the machine belts, leading to cracking and splitting. Like other parts of ZTRs, belts need to be inspected more frequently. Heat also affects the flexibility of belts, causing slipping. All these issues can impact the mower’s operation. To avoid these problems, monitor the mower belt regularly and replace it when there are signs that the belt is failing or about to break.

During the summer, dry ground can cause the mower blades to dull faster. Dull blades can leave strands of grass uncut, resulting in streaks or an uneven lawn appearance. Sharpen or change mower blades after

every 25-30 hours of use. Additionally, wash the blades after every use. Dry clumps of grass built up around the blades can speed up the degradation of blades.

Cleaning your machine is key to the health and performance of the mower. After every use, clean the machine to help decrease the chance of operational issues and to ensure safety and performance. Spotting issues on a clean mower is easier because you can see every part of the machine.

After every use, hose down your machine including the undercarriage. If the mower deck is packed with grass clippings, it can accelerate aging of the mower or affect cut quality, potentially damaging the lawn. This is more likely to happen in the summer since dry grass is more likely to kick up in the air and accumulate around the engine and across the mower deck.

In dry climates, grass, dust, and debris can build up around different parts of the mower. Dry grass is flammable, so it is not ideal to have it build up around parts of the mower that generate heat when the mower is being used. Debris buildup can also cause engine failure and affect other moving parts of your machine. It is important to inspect and clean and replace, if necessary, the engine’s air filter regularly.

Operators should always think about safety when operating and performing maintenance on their machines. Like other heavy equipment, there are hazards to consider.

It is important to look over your mower before each use to address any visible issues promptly. Always use the proper jack stands and wheel clocks to prevent accidents or damage to the mower. Additionally, make sure you are doing maintenance on level ground to prevent the ZTR from tipping over.

Never try to perform maintenance on your machine while it is on. Before beginning work, make sure the blades are disengaged. Mower blades and other moving parts like belts and pulleys can cause serious injuries if handled improperly.

If you need to perform maintenance after using your ZTR, allow the mower to cool down first. The engine and other parts of the mower can get extremely hot during operation. Letting the mower cool down is the best way to avoid burns.

Something that operators overlook when choosing equipment is operator fatigue. Long days in the summer heat can lead to an operator becoming tired, which can be a safety hazard.

Steven Benedict is product line manager (turf) for KIOTI Tractor.

It may be early, but getting snow equipment serviced soon ensures winter readiness

Submitted by the Outdoor Power Equipment Institute.

Although winter is still months away and snow isn’t expected to fall in most parts of Canada until at least November, it’s never too early to start thinking about preparing snow removal equipment for the season ahead.

The Outdoor Power Equipment Institute (OPEI) encourages lawn and landscaping business owners to ready their snow throwers and other winter equipment before snow flurries and winter storms arrive. Clearing driveways, sidewalks and parking lots is no small job, and you rely on your outdoor power equipment to make these big jobs easy, but it’s also important to keep safety in mind when using snow throwers, often referred to as snow blowers.

“Get your snow thrower serviced now, before repair shops are busy,” OPEI president and CEO Kris Kiser advises. “Weather is more unpredictable than ever, so you want to be ready before the first flakes fall. Review your owner’s manual now so you can use your equipment safely and have the right fuel on hand. Remember, protect your power. Gasoline-powered snow throwers should use E10 or less.”

OPEI offers the following questions to get ready for old man winter:

Have you read your owner’s manual? Read up for safe handling procedures. (See additional tips below.) If you lost your manual, you can look it up online (and store a copy on your computer so you have the manual available to reference in the future). Review how to operate the con-

trols. You should be able to shut off your equipment quickly.

Have you checked your equipment since storing it? Make sure all equipment is completely powered off when checking it over. If you forgot to drain the fuel last winter before storing your snow thrower, drain the gas tank now. Adjust any cables and check the auger –again when the equipment is powered off.

Did you put your equipment where you

can get to it easily? Move your equipment to a convenient and accessible location, so you can get to it easily when you need it. Have you purchased the right fuel? Due to power outages, gas stations may be closed after a storm, so have some on hand. Be sure to use the correct fuel, as recommended by your equipment’s manufacturer. Place gasoline in a fuel container and label it with the date purchased and the ethanol content of the fuel. Use fresh fuel in your snow thrower as fuel that is more than 30 days old can phase separate and cause operating problems. Make sure fuel is stored safely and out of the reach of children.

Are you fueling safely? Before you start the engine fill up the fuel tank on your snow thrower outside while the engine is cold. Never add fuel to a running or hot engine.

Are batteries charged? If using a battery/ electric-powered snow-thrower, make sure batteries are fully charged, in case electricity goes out during a winter storm. Is the area you intend to clear free of obstructions or hidden obstacles? Snow can hide objects. Doormats, hoses, balls, toys, boards, wires, and other debris should be removed from the areas you intend to clear. When run over by a snow thrower, these objects may harm the machine or people.

Are you dressed properly for winter weather? Locate your safety gear now, and place it in an accessible closet or location. Plan to wear safety glasses, gloves and footwear that can handle cold and slippery surfaces.

Do you have a clean-out tool or stick? NEVER put your hands inside the auger or chute. Use a clean-out tool (or stick) to unclog snow or debris from your snow thrower.

Do you turn off your snow thrower if you need to clear a clog? Always turn off your snow thrower and wait for all moving parts to come to a complete stop before clearing any clogs or debris.

Do you use your snow thrower in visible

conditions? Never operate the snow thrower without good visibility or light.

Can you aim your snow thrower with care? Never throw snow toward people or cars. Do not allow anyone to stand in front of your snow thrower. Keep children or pets away from your snow thrower when it

is operating.

Will you use extreme caution on slopes and hills? Do not attempt to clear steep slopes and use caution when changing directions on slopes or inclines.

More safety tips and information are available at https://opei.org.

@ReistIndustries

The Reist 3PH mounted or towable AeraSeeder is the ideal tool for the discerning professional who demands quality in groundskeeping. Ideal for all experience levels this unit provides optimal seeding in just 3 steps.

Creates perforations for optimizing seed contact with the ground increasing germination.

Internal agitator and bearing assembly delivers smooth consistent flow of seed.

Ensures seed makes contact with the ground by brushing it off grass blades and gently pressing it in.

Many questions need answers before choosing the ZTR mower that best fits your needs.

By Justin Parrott

Looking for a new mower can be a daunting task, with numerous styles available in the industry. While all of them cut grass, some perform better in certain applications. Even within a manufacturer’s mower lineup, there can be a variety of mowers that have very similar specifications, but not all may fit your needs. When deciding on a new mower, there are a few questions that can help narrow down the offering.

• How large are the properties that you mow?

• How many hours per week do you anticipate putting on the machine?

• How often do you plan on trailering?

• What kind of terrain will you have to cover with your new mower? Lots of slopes, rough ground, ditches?

• Are there any other task outside of mowing you wish to perform?

In addition to these questions, it’s import-

ant to also weigh the pros and cons of specific mower configurations and setups to assess which type of commercial mower will work best for you. The three most common rideon commercial mowers seen are the traditional ride-on zero turn, stand-on zero turns and front mount mowers. These three machines all cut grass, but each have unique advantages that should be considered.

The ride-on zero turn is your Swiss army knife for commercial mowing. They find the right balance between maneuverability in tight areas, operator comfort for large properties and a variety of mower deck and chassis sizes. These three-season machines can be outfitted with attachments, such as grass catchers, and can usually pull small tools on the rear, allowing you to expand services being offered.

<sh>Stand-on zero turn</sh> Stand-on mowers have been gaining

strong popularity in recent years amongst contractors. Compared to a traditional zero turn, their smaller wheelbase makes them more maneuverable in tight areas and allow for more machines to fit on a trailer. Getting on and off the machine is a lot quicker and requires less effort which is beneficial for smaller residential properties where debris needs to be picked up or gates opened. Some operators also have a greater sense of confidence on hillsides with stand-on mowers, as they allow an operator the ability to lean with the bank. Attachments are usually limited for stand-on mowers, making them more of a “grass cutting only” machine.

As the name suggests, front-mount mowers place the mower deck ahead of the operator. For long operating days, this increases overall operator comfort by reducing the need to consistently look towards the sides of the

machine. Additionally, the mower deck ahead of the machine provides the ability to trim underneath obstacles such as park benches, shrubs or fences. For added hillside stability, some machines come with 4WD, delivering better traction when climbing or descending slopes. For a business that needs to operate in all seasons, a front-mount mower may be an attractive option, as you can easily take the mower deck off the front of the machine and attach a variety of snow attachments in the winter months.

The types of contracts a business will bid on can also impact mower purchase decisions. Safety is often top of mind for public contracts, where rear discharge mower decks may be an advantage, as they eject grass clippings under the rear of the machine where it can safely drop. This reduces the risk of accidentally ejecting grass or debris compared to a side discharge configuration that can eject clippings in an un-

wanted direction. Adding a rear discharge mower to your fleet may give you a leg up on the competition when bidding on these contracts.

After selecting the mower type that is right for you, it’s also important to select a mower deck size that’s the right fit for the types of properties you will be working on.

When assessing mower deck size, it’s important to consider the smallest opening the machine must travel through. Do you have narrow passageways or entrance gates to properties that the machine must pass through? If passageways aren’t a concern, contractors will often opt for a 54-inch or 60-inch mower deck width, as these sizes find the balance of high productivity while reducing potential scalping on uneven lawns. For large flat areas where acreage mower per hour is important, mower deck sizes of 72 inches or more can be opted for to maximize acreage per hour.

Once you’ve landed on the optimal mower deck size and your new mower has been purchased, it’s vitally important to familiarize yourself with the machine in a safe operating environment as you get used to its characteristics and controls. Before starting up the engine, read the owner’s manual to understand all machine controls and safety features unique to that particular model. Take the time to adjust the seat, armrest, control levers and parking brake in a position that is natural and comfortable. In an urgent situation, knowing and being able to quickly disable the machine can prevent potential harm.

With these questions and considerations in mind, you’ll be well on your way to selecting a new mower that will help maximize productivity for your commercial mowing business for many years to come.

Justin Parrott is Kubota Canada’s turf and RTV product manager.

Peak power for 10 sec

Continuous power

The era of batteries chasing gas engines is over. Now, it’s their turn to try and catch up with Kress.

Ultra-fast on-site charge

At just 8 minutes, batteries power up faster than they wind down. Even better, they charge on the go—no AC outlet in the field needed.

Elevate your bottom line with the only system that delivers substantial savings over gas. Pro landscapers

Extreme longevity

Guaranteed for 3,000 cycles, Kress 8-minute are the only batteries to outsave two-stroke mix.

Your only choice to replace gas

In the ever-evolving world of commercial landscaping, the choice between gas and battery-powered equipment has never been more critical. As we strive for greater efficiency, sustainability and environmental responsibility, it’s essential to consider the impact our tools have on the earth and our communities. At Kress Commercial, whose products are California CORE eligible and American Green Zone Alliance certified, we’re proud to champion the transition to battery-powered landscaping equipment, offering a host of benefits that go beyond mere convenience.

When considering environmental impact in Canada, the statistics speak for themselves. According to Environment and Climate Change Canada, operating a gas-powered lawn mower for one hour produces eight times the pollution of a car engine1. With Kress Commercial, these harmful emissions become a thing of the past. By eliminating exhaust, Kress Commercial equipment delivers cleaner power than their gas-powered counterparts.

The benefits don’t stop there. With a longer lifespan than traditional lithium-ion batteries, Kress Commercial batteries last approximately 10 times longer than traditional Lithium-ion batteries2. This means that professionals need to replace their batteries less frequently than other battery-powered equipment, significantly reducing their environmental footprint.

Beyond environmental considerations, Kress Commercial battery-powered equipment also brings tangible benefits to local communities. Wafting zero emissions3 into the environment, Kress products mitigate the fumes and odors that accompany traditional gas-powered tools.

Additionally, Kress equipment operates quieter than its gas counterparts, creating a more peaceful environment. With Kress, operators and their clients can enjoy the tranquility of their natural environment without the disturbance of loud lawn care equipment. Even the Kress Commercial backpack blower, one of the loudest pieces of equipment, has a maximum decibel level at full power of 62.5dB4, roughly the same as an air conditioner, compared with gas powered blowers that range from 75-100dB5, or roughly the volume of a blender or garbage disposal.

Experience the difference that Kress Commercial battery-powered landscaping equipment can make for you and your crew. Visit kress.com to explore our full range of products and discover why operators everywhere are choosing Kress. Interested in seeing for yourself? Register with your local dealer for a free 10-day trial. Locate your nearest dealer at kress.com.

By Mike Jiggens

Growing people is a lot like growing grass, attendees at February’s Canadian Golf Course Management Conference in Montreal were told. Both must be right for the existing conditions and must be nurtured to thrive.

James Beebe, who recently retired as golf course manager at Alberta’s Priddis Greens Golf Club, compared the strategies of growing turf and people to achieve the best of both worlds.

“To grow the right turf, you’re not going to put tall fescue or bermudagrass on our greens in Canada,” he said. “If you choose the wrong species, it’s not going to thrive. If you choose the wrong species, it’s going to be way harder to get performance out of your greens. You’ll have to work harder, and the rewards are going to be less.”

Selecting the right species of turfgrass will result in a better fit for that culture. People are no different, he said, adding the right type of people must be hired. Difficult people can fracture a culture.

“If you get the right people on the bus, and they’re the right type of people for your culture and you set the bus in the right direction and you put the right people in the right seats, you can dominate any industry.”

Beebe spent 30 years at the Calgary-area

golf property as superintendent, overseeing two 18-hole courses named Hawk and Raven. His final day at Priddis Greens was March 16 which marked 30 years to the day since he was hired. His address to his industry peers included a reflection of how he personally grew as a leader and featured sound advice for other superintendents to grow their employees, teams and themselves.

“The leader is the most important person

who sets the direction of the ship,” he said. “At the end of the day, it’s not about you. It’s about your people.”

Beebe said that as he grew his leadership, he also started to think more about growing people, acknowledging how rewarding it became. The process could be frustrating at times, though, he added, noting there were periods of personal stress he dealt with during his younger years when producing the best-conditioned golf course possible

was foremost on his mind.

“The weight of that burden takes its toll, but I was young and figured I could handle it. In hindsight, I was totally crushed. I remember being so stressed.”

As he learned to delegate certain responsibilities, thereby decreasing his own stress levels, he felt some burnout still existed but found a corner was turned following the COVID-19 pandemic.

“It wasn’t just about growing people. It wasn’t just about creating great conditions. It was really about creating an environment of wellness for my team and making sure they were healthy, and I was healthy so that we could create a good culture so that we could perform.”

Trying to perform without a good culture and without team members being healthy helped bring on stress.

“As I flipped that narrative, it really seemed to prove dividends.”

The 2023 season saw Priddis Greens earn its highest ever member survey rating, and Beebe said he experienced 100 per cent engagement from the 84 employees on his grounds maintenance team.

There can be a burden to leadership, no matter how strong or resilient one is to stress. Burnout is job-related stress, characterized by exhaustion, depersonalizing and a lack of accomplishment.

People working with those they can trust and who are willing to ask for help tend to deal with stress better than others. Burnout is more common among younger people who are unmarried and don’t have families of their own and who have no one to lean on when experiencing stress.

Beebe said superintendents of his generation were taught to “grind” when they began in the business.

“Burnout and the number of hours we put in was a badge of honour. I hope those days are gone. It’s really hard as an older person to get over that because you feel that you still need to do that.”

Beebe said that among the employees on his staff, about 15 individuals are career-oriented people.

“They’re the ones who really tend to get burned out, and we’ve seen a real difference in the energy.”

Although a leader’s objective is to “put the right people on the bus,” the wrong choices can sometimes be made. If the wrong people are “on the bus,” they must be removed quickly, Beebe said, noting that holding onto them had hurt him and others on his team in the past.

The best way to select good team members is to hire slowly with the right intent, he said.

“Hire slow and fire fast if you get the

wrong person.”

No one becomes part of the Priddis Greens team without proving its core values. Beebe said he looks for those who believe in people, want to work with others, are respectful, like to have fun on the job, and can work to a high level of excellence.

“That’s the type of people we’re looking for.”

Interview questions are specifically tailored to better the chances of hiring the right people, and the first impression a new employee has upon joining the team is important, he said. One of Beebe’s interns recalled a situation while working at another golf course where he was put on a fairway unit with only minimal training. When he returned to the maintenance shop afterwards, everyone had already left for the day without bothering to check on their new co-worker.

“Not a great first impression.”

Like new grass, new people need plenty of care and attention, he said. New grass can’t handle stress and must be “babied” to become acclimated. Ample time is spent learning how the grass is doing, how it’s behaving and how much water is requires.

“You can ask people what they need. How are you feeling? Are you getting enough information? Do you need to be retrained? Wouldn’t it be nice to be able to ask your grass that?”

New employees must be treated and prepared so that they can cope with stress once they’ve become competent, Beebe said.

Until new turf has had the chance to mature, it won’t be mowed at a traditional height and won’t see play until it has become resilient. It requires density, some matting and the ability to handle stress. Its roots must also be long enough to deal with drought.

“That’s kind of how we look at training our employees. Baby them until they can handle that stress and until they become competent enough to do that.”

Once new employees reach that level of maturity, they will require a growth plan, Beebe said, noting growth plans for turf include fertility and chemical programs aimed to achieve a desired state of health. A growth plan has been developed at Priddis Greens to ensure its employees continue to grow and thrive.

A mental health and culture performance coach has been helping with senior staff at Priddis Greens. Beebe said the involvement of the coaching professional has been a game changer and has allowed senior staff to acquire the necessary leadership training to potentially become a superintendent.

The superintendents overseeing the Hawk and Raven courses came from other clubs where they were inundated with stress and became disenchanted with the industry, Beebe said. Their lives have completely turned around over the past few years, however, due to the coaching program.

Stress isn’t necessarily a bad thing, he said.

“Stress is what makes you grow. You need to get out of your comfort zone to be able to do something different. You don’t want to be in too much stress and don’t want to be in stress for too long.”

The key to wanting staff to grow is that it leaves a superintendent saddled with less responsibility, Beebe said. Subordinates can take on more responsibility and can be placed in an environment where they can grow and feel challenged yet have the confidence to achieve more. Those who take on too much stress are likely to become tired, frustrated and have a shorter fuse.

Delegation of responsibilities is a component of Priddis Greens’ growth plan. Beebe said he delegates as much responsibility as possible to his superintendents, not simply to unload it from his plate but to help them grow and be able to take over in his absence.

Although there were 84 people on the Priddis Greens grounds maintenance staff, only five answered directly to Beebe.

“I don’t have to have the weight on my shoulders of what everyone else is doing. I get to delegate the burden to other people.”

Beebe said his responsibility was to ensure the five individuals directly below him understood their roles, had the necessary leadership skills and had the club’s vision in mind. He said his two superintendents were capable of doing everything he did.

Growing people is one thing, “but growing ourselves as leaders is altogether different.”

If a mower’s blades aren’t sharp, it takes more work to cut grass. The same principle is true with people, Beebe said.

“If you’re tired or burned out, it takes more work to get the results you want,” and means having to focus on wellness for oneself.

He pondered how a superintendent can help people grow if he doesn’t have what it takes for himself.

“Like growing grass, if the trees are tall and the shadows are on the green, your turf’s not photosynthesizing and not growing. In leadership, you have to be the best leader you can, but it’s about creating the best leaders around you.”

Six of the 2026 FIFA tournament games will be played at the Toronto stadium. By Mike Jiggens

Canada is one of three host countries for the 2026 FIFA World Cup, and both Toronto and Vancouver are gearing up for soccer’s premier event. The quadrennial tournament will also be played at venues in the United States and Mexico.

Of the 104 matches scheduled for the World Cup, 13 will be played on Canadian soil. Seven games will be played at Vancouver’s B.C. Place while six matches are slated for Toronto’s BMO Field.

Robert Heggie, head groundskeeper at BMO Field, outlined the necessary preparations being made for the event during February’s Ontario Turfgrass Symposium in Guelph.

FIFA (Federation internationale de football association) demands field conditions and set-up at its host facilities are strictly adhered to in advance of the tournament to ensure playability is consistent from one venue to another. Foremost among its policies is that all games must be played on natural turf.

BMO Field has a hybrid playing surface, but its 95 per cent natural turf complies with FIFA regulations. In 2019, artificial turf fibres were stitched into the field to reduce the number of divots and produce a more consistent playing surface. The fibres account for only five per cent of the entire surface and are barely visible.

Heggie said at the time the hybrid system

was introduced, it was still unclear that Toronto would serve as one of the host venues for the World Cup.

The lion’s share of games at the 2026 World Cup – 78 of the 104 matches – will be played in the United States at 11 different venues. Games in Mexico will be played at three different sites. Participating teams will experience playing on both cool and warm-season grasses.

Heggie said having two types of grasses is irrelevant as long as ball roll remains consistent from one type to the other.

Like golf, a Stimpmeter-like device is used to measure soccer ball roll. Ball bounce is also measured with a computerized mechanism inside the ball. Measure -

ments are taken from the moment the ball hits the ground and then bounces again. Ball roll and bounce measurements at BMO Field comply with FIFA regulations, Heggie said.

BMO Field, which is home to both Major League Soccer’s Toronto FC and the Canadian Football League’s Toronto Argonauts, has been a suitable venue for the World Cup for several years. Built in 2006 along Toronto’s lakeshore, the original 20,000-seat stadium opened the following year and featured an artificial turf surface that was replaced with permanent natural grass a few years later. The transition to natural grass was prompted by the FC club’s desire to attract elite players who preferred playing on a natural surface. In 2009, a “friendly” match was played at BMO Field between the FC club and Real Madrid – a premier European team that wished to play on natural turf.

A temporary natural grass covering was installed atop the artificial turf to accommodate the match.

To avoid further transitions and to provide the home team players with its preferred surface type, a decision was made to remove the artificial turf in 2009 and replace it with natural grass.

“There are challenges with growing grass in Toronto,” Heggie said. “When you’re trying to recover grass for the winter and maintain grass quality through the summer and shoulder seasons, there’s a lot of investment that needs to go with that.”

BMO Field was originally owned by the Ontario Teachers’ Pension Plan before it was sold to the city in 2010 and became managed by Maple Leaf Sports and Entertainment. Heggie said the transaction was the best thing to happen for the field’s future. It freed up money for the necessary upkeep of the field’s ongoing conditioning as a natural grass venue, especially when the Toronto FC’s home opener was sometimes played in February with the season continuing into December.

To keep natural turf alive and able to cope with the rigours of play outside of the typical growing season, Heggie convinced the city to invest in the necessary infrastructure. A glycol heating system controls soil temperatures through conductive heat and allows turf to break dormancy earlier in the spring and later in the fall.

‘There are challenges with growing grass in Toronto’

The system was installed between layers of stone and 12 inches of USGA-specification sand. Four two-millionBTU boilers generate the necessary heat, yet only two are usually fired up at a time. Heggie feeds such information as root zone temperatures into a computer, allowing the system to regulate flow, heat and valve position to achieve the ideal temperature the plant requires.

A SubAir system was installed in 2010 that allows surface water to be sucked in without waiting for natural drainage to occur. If the field is aerated and is soft enough, suction can be applied to the lines to pull water through the soil profile, allowing percolation. When the system isn’t being used for suction, it can be pressurized, allowing air to blow through the profile and aerate the root zone without the need to pull cores and disturb the surface.

“It allows me to aerate my field without actually aerating my field and disturbing ball roll and disturbing play.”

Drainage lines are situated below the heating system lines, enabling air to be blown through the heat and the 12 inches of sand. When the field is tarped, a microclimate is created by trapping the heat.

“If the plant isn’t too confused why my roots are nine (degrees Celsius) and why the air is four and why the sun is 11 hours, everything we do is going against the evolution of the plant.”

Heggie said that when the heating system is activated, the plant wakes up but has limited carbohydrates and reserves to get through spring before it starts carb-loading again.

“If I start burning the candle too quickly on this end, I might not get to that point where it can start recovering itself. It’s a little bit of a balance pushing it hard enough but not burning the plant out because grow lights won’t necessarily recover those carbs in February or March.”

BMO Field’s grow lights, which Heggie quipped are Toronto Hydro’s “best friend,” was another major aspect of the city’s investment into the property. The field has nine large grow light rigs and six smaller rigs which can bathe about 65 per cent of the field in artificial light and heat.

Field preparations are especially challenging during late winter and early spring. Tarps are removed when it might be minus five degrees Celsius, yet the grass is mowed and fed even though it’s freezing and re-tarped.

“So, it’s one step forward, two steps back, one step forward, two steps back. I can turn it green, but it doesn’t mean I can grow roots. It doesn’t mean I can carb

load and doesn’t mean I can have a healthy plant.”

Heggie has dealt with other challenges since BMO Field’s conversion to natural turf. The NHL’s Centennial Classic game was played on the field in January 2017, allowing less than two months of remedial work to be done to have the field ready for the FC’s home opener in March. Resodding of the field was required following the hockey game at a time of year when sodding isn’t traditionally done. A year later, snow that had covered the tarp was itself encased in ice following a storm. Heggie said if it wasn’t for the infrastructure beneath the surface, it likely would have led to an unsuccessful recovery.

Season preparations include fraize mowing with different teeth and the removal of 15 per cent of the field’s organic matter at a

time. About 60 per cent of the field’s organic matter was removed last year and it was hoped 90 per cent will be offed this year, Heggie said.

“If you can remove 60 to 90 per cent of

the organic matter off the top of the surface every year and not have that clog up my system, I get to start winning.”

He said the process also helps to “flick” back up the artificial turf fibres which tend to sink into the soil from cleated foot traffic during play.

Traditional aeration isn’t done at BMO Field for fear of damaging the sub-surface array of infrastructure tubing. Heggie said even the stitching in of the artificial turf fibres, which was completed over the course of eight days and 24 hours a day, “gave me a heart attack with every movement.”

Heggie and the other head groundskeepers for the 2026 World Cup had spent time in Qatar – site of the 2022 World Cup – to get a first-hand look at field set-up and other pre-tournament considerations.

John Deere has introduced its John Deere Operations Center PRO Golf, a new addition to the John Deere Operations Center PRO suite. This all-new licence-based remote management system is designed to enhance golf course management by integrating comprehensive labour and fleet management capabilities, offering golf course professionals a unified solution for enhancing efficiency and decision-making.

“By integrating the capabilities of our OnLink golf course management software into the Operations Center, we’re providing our customers with a more tailored and efficient tool to manage their operations,” Dave Anderson, product manager, John Deere, said. “This not only ensures the improvement of day-today activities but also enhances the overall sustainability and profitability of their courses.”

John Deere PRO Golf leverages an adaptive web-based experience, allowing full access to its

features on any internet-enabled device. This flexibility ensures that golf course professionals can manage their operations anytime, anywhere, promoting a better work-life balance. Also, this solution was built specifically for the golf course professional requiring specialized labour and fleet management capabilities beyond what is currently provided with John Deere Operations Center.

Furthermore, the enhanced partnership with John Deere dealers through the connected support feature enables closer collaboration on product issues, parts and service, thereby improving uptime and productivity. Customer-controlled access levels allow the dealer to work closer to their customers, helping to better support their needs on and off the course.

The launch provides tools and technologies that are efficient and integrated in a way to aid in golf course management. Explore.deere.com

Bobcat Company has commercialized its latest grounds maintenance innovation: the battery-powered, electric ZT6000e zero-turn mower.

Powered by a 20.4-kWh, lithium-ion battery, the ZT6000e produces zero emissions and delivers productive runtimes in commercial applications. It requires fewer components and less maintenance than gas-powered equivalents, costs less to operate and leaves behind a high-quality cut.

“The ZT6000e is designed for both lawn care professionals and other businesses that want to create their own professional-grade results in a more sustainable way,” Daniel Stibral, Bobcat grounds maintenance product specialist, said. “It’s highly maneuverable, efficient and takes on challenging mowing tasks with precision, ease and the perfect cut.”

On a single charge, the ZT6000e provides up to eight hours of run time and mows up to 23.8 acres, depending on conditions. This turf-taming machine can be fully recharged in 6.3 hours with a 240-volt connection, or in 12.6 hours using a 120-volt connection. Apart from routine recharge cycles, the powerful lithium-ion battery requires no maintenance for the life of the machine.

Built with heavy-duty, dual-tubed steel framing for maximum durability, the ZT6000e is loaded with performance-boosting features including three drive response modes, swift travel speeds and a comfortable command station with a high-back deluxe suspension seat and a smart, intuitive control layout.

Its three-drive response modes allow operators to choose how the ZT6000e responds to the movement of the lap bars. Whether operators like a more gradual response; quick, instant feedback; or a response somewhere in between, three drive response modes offer customization for greater productivity.

The ZT6000e is equipped with the AirFX cutting system. The cutting system’s deep profile and bullnose design creates a powerful vacuum that lifts grass to the blade for a razorsharp, uniform cut, resulting in a professional finish. The ZT6000e is available with either a 52-inch or 61-inch deck.

Three independent electric motors provide high and low blade speeds to make quick work of both heavy and light mowing conditions. Change the blade speed on the go to meet the mowing conditions to get more mowing done in less time.

The ZT6000e is an innovative solution for park districts, municipalities and other government entities, and landscape businesses that want to reduce their operating costs and maintenance downtime. Producing no emissions, the ZT6000e is also ideal for government agencies and commercial landscapers that are increasingly turning to eco-friendly work solutions for a more sustainable future. Bobcat.com

When outdoor workers are on their feet eight or more hours of the day, foot comfort is paramount. What may be surprising to many is that something as simple as shoelaces can greatly affect that level of comfort.

No-tie laces from Caterpy significantly reduce the amount of pressure on the top of the foot where traditional shoelaces are normally tied. The laces utilize elastic bump technology developed in Japan by a marathon runner. Like traditional laces, the Caterpy Run laces are inserted into a shoe’s eyelets, but allow for

customized tension without the need to be tied. The bumps prevent the laces from becoming undone and promote better circulation and ease of putting on and taking off.

Wearers of shoes equipped

with Caterpy laces also never have to worry about the possibility of tripping over their untied laces.

People may think that foot pain is caused by an ill-fitting shoe, but often it may be due to the laces. Caterpy laces are

approved by sports medicine doctors and podiatrists.

Tested by Turf & Rec, the laces were inserted into a pair of golf shoes and worn while walking 18 holes. Feet retained their flexibility through the elasticity of the laces. Not once did the laces pop out from the eyelets, and noticeably less tension and strain was realized at the tops of the feet.

The laces’ strong outer nylon sheath is designed to flex and last through the toughest of conditions. The inner rubber core provides the right strength tension. caterpy.com

Identify and control weeds with this colorful, expanded edition—with bonus CD.

For more than a decade, the Color Atlas of Turfgrass Weeds has been the leading authority for green industry professionals in their ongoing quest to control weeds and limit deleterious effects: the weed clumps, color variation, and unsightly patches that disrupt turf uniformity. The Second Edition of this essential resource has been expanded and updated to provide control information that professionals need to maintain the quality that is so vital to the golf, sports field, and managed landscape industries.

By CCOHS

The Canadian Centre for Occupational Health and Safety (CCOHS) promotes the total well being of workers in Canada by providing information, training, education, systems and solutions that support health and safety programs and injury and illness prevention. www.ccohs.ca

Much like a lawn or turf that requires routine maintenance to thrive, so, too, does your health and safety training program. In fact, it’s important to regularly evaluate your program to make sure the training you provide workers is effective at preventing incidents, injuries, illnesses, and diseases, and is updated when needed.

There are different types of training that can help build a culture of safety in your workplace. Orientation training for your new hires, for example, provides the necessary knowledge and skills to work safely, including the safe use of tools, machinery, and equipment. It should also cover their rights and responsibilities, how to report injuries or concerns, and how to wear and store personal protective equipment.

New and seasoned workers should also receive Workplace Hazardous Materials Information System (WHMIS) training if they work with hazardous products. This training should cover safe working practices, including checking safety data sheets before handling any hazardous substances and knowing how to respond to an emergency.

Refresher training can help workers stay updated on safety procedures and teach them how to use new equipment or perform new tasks safely.

Informal “crew talks” before a shift starts are brief but import-

ant touchpoints to communicate vital health and safety information to your workers, while also fielding their questions and concerns.

Whether you’re setting up your first health and safety training program or revising an existing one, you need to know the hazards your workers face to ensure it’s effective.

Working with tools and machinery and handling chemicals, including pesticides and herbicides, are among the more obvious workplace hazards. But overexertion and repetitive strain from digging or removing debris, working alone on a jobsite or in a confined space, and slips, trips, and falls from uneven or slippery grounds, are also risks to consider.

Conducting risk assessments can help you identify the unique hazards workers may encounter while performing routine work, as well as during non-routine

circumstances like an extreme weather event.

Inspect the jobsite and look for potential hazards, talk about risk factors with your workers, and review health and safety records to find issues that need to be addressed. A thorough review of the level of risk associated with each hazard can help to inform the elements of your health and safety training program.

Check the legislation in your province or territory for the health and safety training requirements in your specific industry. The requirements may vary, but many provinces, territories, and federal jurisdictions require worker training for emergency procedures, such as fire prevention, evacuation, and first aid protocols.

Beyond this, many jurisdictions also require workers to receive training on how to recognize and respond to violence

and harassment. Some also mandate ergonomic training for workers who are at risk of musculoskeletal injuries. This can include providing instruction on safe work procedures, like how to lift properly, and how to use mechanical lifting aids that can help prevent physical strain such as back injuries.

Knowing your local legislation will not only help ensure you are following the laws in your area to protect the health and safety of workers but can also help you set a baseline for training that you can expand upon in your workplace.

The goal of health and safety training is for workers to understand the nature of the hazards in their workplace, and to learn and retain information about how to work safely.

You can engage your workers by involving them in the development and implementation of health and safety training, and by inviting their suggestions to make the program better. Talk to them about how work gets done and encourage them to share their experiences and input.

When leading training sessions, it’s a good idea to break down jobs into steps and have training aids available. Describe the hazards a worker may face doing the job, and the protective measures available. This could include showing workers how to wear the right personal protective equipment, how to safely maintain equipment, or how to avoid repetitive strain. Always document and keep records.

Lastly, evaluate the results of your health and safety training program.

• 79.9 cc 2-stroke engine • 835 average CFM • 40N blowing force • 386 km/h max. air speed • Hip or tube throttle models available

The ECHO PB-7910 is engineered for professionals who demand top-tier performance. With a 79.9 cc engine, this backpack blower delivers a powerful 40N blowing force. Clearing leaves, debris, and grass clippings has never been this efficient.