Calgary biofuels player’s patented tech is both feedstock and product agnostic

The winners of the 2024 Canadian Biomass Awards are unveiled

The opioids crisis: How to respond to a poisoning at your workplace

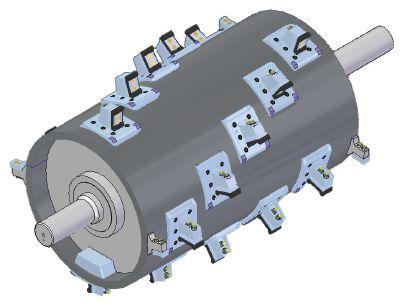

» 40” diameter capacity

» Heavy-duty 50” diameter x 66” wide hammermill

» 20 hammer inserts

» Caterpillar C32, 1,200 horsepower engine

» Standard impact detection system If you haven’t tried a Bandit unit for your operation, please contact a local Bandit dealer, email marketing@banditchippers.com or visit our website www.banditchippers.com and we will be

SixRing, a Calgary-based company, is redefining biomass technology with its pioneering chemical delignification process. Led by president Scott Treadwell, the company has developed a method that offers exceptional flexibility in converting non-food biomass into valuable products like biofuels and specialty chemicals.

WPAC’s Gordon Murray brought an entourage to Taiwan on a trade mission. “After the trip, I can say for certain that Taiwan is emerging as a market of interest for Canadian wood pellet producers and has the potential to reach a similar scale to South Korea and Japan,” he says.

We unveil the three industry legends who took home the hardware at the 2024 Canadian Biomass Awards. Hint: One is a “grandfather.”

Gordon Murray, Jesse Douglas and Joe Webster honoured.

Read the stories of Liezl van Wyk, Benjamin Patton, and Jamie Stephen.

Congratulations to the Village of Fort Simpson, Arctic Energy Alliance, Belledune Port Authority, Ecostrat, Fink Machine, and BSB.

Forestry workers are second only to construction when it comes to opioid poisonings. Find out how to respond to an overdose.

Markus Weissenberger, chief technology officer at SixRing, operates

chemicals. Photo: SixRing

by Todd Humber

n a perfect 10 degree Celsius Sunday afternoon in April, my partner and I took our two dogs for a walk in the woods. We were looking for a new spot to explore and settled on Holland Landing Prairie Provincial Park, located not far from our home north of Toronto.

We loaded up Athena, our four-year-old Bernese Mountain Dog, and Scout, our two-year old Labradoodle, into the car and set off. It’s not your typical provincial park, in that there are no staff and no facilities. “Currently, much of the reserve is planted to Red Pine, but future plans include restoring the native prairie ecosystem,” the Ontario Parks description reads

I’m not a tree hugger, nor am I devout forestry aficionado who takes joy in clear-cutting. If nothing else, I’m a pragmatist. Do we need wood? Yep. Lumber is one of the most practical (and renewable) resources we have. My house is framed with wood. The desk I’m typing this column on is wood. The floor under my feet is wood. It provides well-paying jobs for Canadians.

We saw some of the “future plans” in action, with part of the park fenced off and evidence of recent tree-clearing. In one open section, we ended up walking on top of what essentially looked like mulch — aka woody biomass.

This was just a few days after Canadian Biomass recognized the winners of its first awards program — so things like pellets and biofuels were a little more top of mind than usual. I also heard Gordon Murray’s voice echoing in my head.

Murray, executive-director of the Wood Pellet Association of Canada (WPAC), was named 2024 Champion of the Year. In a panel discussion on the challenges facing the industry, one thing jumped to mind for him. “We’ve attracted some vocal critics who tend to ignore science and twist facts to their own purposes to show biomass in bad light. Often, these folks are skilled communicators who’ve succeeded in getting through to the regulators and are causing some stress.”

As we walked through the forest, the dogs darting around through the underbrush, I looked at the piles of woody biomass and thought about something Jamie Stephen, managing director of Torchlight and winner of honourable mention for 2024 Thought Leader of the Year, said: “Last year, our wildfires emitted 2.4 billion tons of CO2, which is 50 per cent more emissions than the entire history of the oil sands.”

Murray’s point on communication is worth repeating. The biomass industry will always have detractors, aggressively scouring for weak points and poor practices. Is the industry perfect? No. Are there bad apples? Sure, just like in any industry.

In an era where sustainability matters, where fully using resources and not wasting anything should be applauded and not skewered, this sector has a positive story to tell. Ensuring the industry’s voice is just as loud as the critics, and more accurate, can defuse a lot of the arguments. •

Volume 24 No. 2

Reader Service Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Ph: (416) 510-5113 Fax: (416) 510-6875 Email: apotal@annexbusinessmedia.com Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

Senior Editor - Todd Humber Ph: (289) 264-4883 thumber@annexbusinessmedia.com

Contributors - Gordon Murray and Maria Church

Group Publisher - Anne Beswick abeswick@annexbusinessmedia.com Ph: (416) 510-5248 Mobile: 416-277-8428

Account Coordinator - Shannon Drumm Ph: (416) 510-6762 sdrumm@annexbusinessmedia.com

National Sales Manager - Rebecca Lewis Ph: (519) 429-5196 rlewis@annexbusinessmedia.com

Quebec Sales - Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexbusinessmedia.com

Western Sales Manager - Tim Shaddick twshaddick@gmail.com Ph: (604) 264-1158 Fax: (604) 264-1367

Audience Development Manager - Serina Dingeldein Ph: (416) 510-5124 sdingeldein@annexbusinessmedia.com

Media Designer - Svetlana Avrutin

CEO - Scott Jamieson

Canadian Biomass is published four times a year: Winter, Spring, Summer and Fall. Published and printed by Annex Business Media.

Publication Mail Agreement # 40065710

Printed in Canada ISSN 2290-3097

Subscription Rates: Canada - 1 Yr $58.14; 2 Yr $104.04 Single Copy - $9.00 (Canadian prices do not include applicable taxes) USA – 1 Yr $123.93 CDN; Foreign – 1 Yr $140.76 CDN

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Canadian Biomass magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2024 Annex Business Media, All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Ontario’s Renfrew County, located near Ottawa, has been issued a BDO Zone ‘AA’ rating — the first such distinction for pulpwood in the province and an indication of a robust outlook for its woody biomass sector.

It’s also the second highest rating available under the initiative, which ranges from “AAA” (highest quality) to “CC” and “NR” (High risk and no rating).

Located in Pembroke, Ont., the newly rated zone can handle up to 485,000 green metric tons of woody biomass annually. According to the BDO Zone Initiative, such ratings are given based on the projected capacity of a region to support biobased plant operations without significant risk of default.

David Wybou, business development officer for the County of Renfrew, emphasized the historical importance of forestry to the region and expressed eagerness to collaborate with biobased companies to explore new markets.

“Forestry has always been a foundational pillar within Renfrew

Congratulations to Premium Pellet’s Buddy Berg and Cody Braun, the first Safety Heroes to be recognized by the Wood Pellet Association of Canada (WPAC) for their significant contributions to workplace safety.

Both Berg and Braun are members of the safety-centered team at Premium Pellet who consistently step-up to help the wood pellet industry and other frontline workers to ensure leading safety practices are implemented and embraced.

Berg, plant operator, walks the talk and his can-do attitude led to a leading role in WPAC’s safety video, The Power of Pellets: Innovating Our Way to a Safer Better Product, while he was working as the plant’s interim production supervisor. Berg also served as a key member of the bow tie analysis workshop team for WPAC’s critical control management project.

Braun, plant operator, played a key role in providing input into WPAC’s and BC Forest Safety Council’s e-learning platform. In order to have a smooth rollout of the program, operators were needed to review the modules and identify gaps in content and subject matter that needed clarification. Along with operators from facilities across Canada, including Berg, Braun completed the review of four important plant operator modules and recommended several key improvements.

“Cody has become a very safe and diligent Plant Operator,” said Wall. “Cody makes great efforts to run the plant to design protocols and manages his crew well in the safety and cleanliness programs, along with the operational functions.”

County and we are eager to engage with biobased companies to expand and diversify our biomass into new markets. We take great pride in the sustainable management of our forests and the BDO Zone rating underscores our commitment to advancing biobased economic development and fostering job creation,” said Wybou.

Jordan Solomon, chairman of the BDO Zone Initiative, pointed out that Renfrew County’s longstanding tradition of sustainable forestry positions it well within the sector.

“Building on their rich history of sustainable forestry through generations, Renfrew County’s ‘AA’ rating positions them as a frontrunner in the province,” he said. “The rating will serve to unlock new markets and opportunities for woody biomass utilization, and spur biobased economic growth for the region.”

Renfrew County, Ontario’s largest county covering 7,645 square kilometers, is home to 108,000 residents with Pembroke as its central hub. It is strategically connected by Trans-Canada Highway 17 and Highway 41.

Maryland-based Enviva, which bills itself as the world’s largest producer of industrial wood pellets, has filed for Chapter 11 bankruptcy protection in Virginia. The company said it has debts exceeding $2.6 billion (all figures U.S.).

That includes $780 million owed to a bank in Delaware; $348 million to an energy company in Germany; and more than $353 million in bonds from development authorities in Mississippi and Alabama.

Enviva said it has entered into two Restructuring Support Agreements (RSAs): One RSA with an ad hoc group of holders representing about 72 per cent of its senior secured credit facility, approximately 95 per cent of its 2026 senior notes, approximately 78 per cent of bonds related to its Epes, Alabama plant currently under construction, and about 45 per cent of bonds related to its greenfield project near Bond, Mississippi; and a second RSA with certain holders representing more than 92 per cent of bonds related to the Bond project.

The RSAs have broad support across the company’s capital structure and are designed to support an expedited restructuring to reduce the debt by about $1 billion, as well as improve profitability, strengthen liquidity, and better position the business for long-term success as the world’s largest producer of industrial wood pellets, it said in a press release.

It has also secured commitments for $500 million in debtor-in-possession (DIP) financing and other financing accommodations from the ad hoc group. The DIP facility is expected to provide, subject to court approval, sufficient liquidity to support continued operations across its business throughout the restructuring, as well as help fund the completion of the Epes plant.

At the Wood Pellet Association of Canada (WPAC) we are constantly seeking ways to be ahead of the curve. That’s why we expend a significant amount of our time building partnerships that leverage our collective strengths and collaborate on R&D to position our sector for long-term success.

We’ve been fortunate over the years to have strategic and mutually beneficial partnerships across the country, as well as support from provincial and federal governments for our research and development activities.

In 2023, we spent considerable effort to develop proposals that will enhance our reputation as a reliable and responsible supplier of wood pellets both globally and domestically. I’m proud to say that because of this work, we are advancing five major research and development projects in 2024.

Increasingly, global markets and governments are asking for further proof that the products they purchase come from well-managed forests. The EU’s Deforestation Regulation will require new approaches to traceability including geolocation. In the Canadian context this may be impractical and therefore a market barrier for our products. As such, approaches to traceability will need to be tailored to address some of Canada’s unique attributes: vast forests, species and its public land model, and that the fibre from pellets can come many different areas and suppliers.

With funding from Natural Resources Canada’s Forest Innovation Program,

By Gordon Murray

Pellet plants receive millions of tonnes of residuals each year; determining their exact source location is impractical. The 2024 traceability research project will investigate and test potential and practical approaches to traceability, including geolocation.

Courtesy WPAC

WPAC will work with its members to investigate and test potential and practical approaches to traceability including geolocation and develop tools and systems for reporting on traceability to demonstrate compliance with emerging regulations such as the European Union Deforestation Regulation (EUDR). We will also work with the Sustainable Biomass Program to test the feasibility of linking our traceability approach with their data transfer systems.

As with the rest of Canada, Ontario’s wood pellet sector has grown by using sawmill residues. In the future, there will be an increasing reliance on forest biomass in the form of left-over tree-tops, branches, low quality logs and fire-dam-

aged timber which is often contaminated with rocks and sand which creates wear and tear on mill equipment and increases safety hazards.

With funding from Ontario’s Ministry of Natural Resources and Forestry, we have partnered up with BioPower Sustainable Energy Corp which owns and operates a wood pellet plant in Atikokan, Ont. Key activities include an economic analysis of using a combination of an in-woods portable chipper and triple deck screening plant to produce wood chips as pellet feedstock as well as testing feedstock samples for contaminants and testing finished pellets against the CAN/CSA-ISO 17225-2 pellet standards.

If successful, we will be able to increase utilization of forest biofibre, create new

revenue streams for companies, encourage Indigenous participation in the sector, and reduce forest waste and fire hazards.

With funding from BioFuelNet Canada which manages the Biomass Canada Cluster, WPAC is partnering with the University of British Columbia’s Biomass and Bioenergy Research Group (BBRG) to undertake a multi-year study to determine strategic locations and capacity of agri-pellet production facilities.

The cluster is focussed on de-risking and commoditizing agricultural biomass using complete value chains for rural and remote applications, using emerging technologies that improve the profitability of production, pre-processing, handling and storage.

This work will be led by Dr. Shahab Sokhansanj at UBC. He and his team will:

• calculate the number and sizes of potential farm- based agri-pellet plants and their geographical coordinates;

• quantify cumulative GHG reduction for fuel switching to agri-pellets and calculate the savings in BECCS (bioenergy with carbon capture and storage) for electricity generation at later years ;

• evaluate the investment criteria to identify the biomass development opportunity zones .

With support from the Global Forest Leadership Program, International Standards Organization, and approval from the Standards Council of Canada, WPAC will represent Canadian wood pellet interests on ISO Technical Committee 238. Through this support we will assist in the drafting, reviewing, and commenting on solid biofuel standards as well as participating in international laboratory testing. Our key goals in this project are to:

• Standardize terminology, specifications and classes, quality assurance, sampling and sample preparation and test methods of wood pellets.

• Establish internationally recognized safety standards for wood pellets.

• Establish testing standards for internationally accredited testing facilities for

physical and mechanical testing methods of wood pellets.

In turn, we are optimistic we will have internationally recognized standards that allow for safer international trade of wood pellets including handling, transportation and storage with all accredited testing facilities use the same standard to ensure consistency.

Often harvest residues are contaminated with sand, gravel and tramp metals; content of ash is high, moisture content is variable, and heterogenous lignin content between solid wood and bark is problematic.

To address this issue, WPAC and UBC’s BBRG have applied for funding to examine the potential to increase the use of forest and harvest residuals using near-infrared radiation (NIR) spectroscopy. This technology can be used to predict the chemical composition, density, structural change, and morphological characteristics of lignocellulosic biomass. Our goal is to develop a blend that produces

durable pellets and meet the specification of graded wood pellets for commercial, residential, and industrial applications as listed in ISO standard 17225-2.

The study will take place at BBRG’s lab as well as at Premium Pellet in B.C., Shaw Renewables in Nova Scotia and BioPower Sustainable Energy Corp in Ontario.

In closing, I want to acknowledge the tireless effort and vision of my colleague Dr. Fahimeh Yazdan Panah, Director of Research and Technical Development. On behalf of WPAC and all our members, she has led the development of these proposals alongside partners nationally and internationally. I also want to recognize the support of our funding partners who share our vision that investments in R&D are critical not only to the long-term success of our sector but hold the key to unlocking a world of possibilities and a better future for all. •

Gordon Murray is the executive director of the Wood Pellet Association of Canada.

By Maria Church

If asked for the elevator pitch, Scott Treadwell, president of Calgary-based SixRing, will say they are offering infinite optionality on the inputs and outputs of their biomass technology, a rare feat in the industry.

SixRing has been operating under the radar for many years now while quietly developing more than 40 patent families (filing some in over 130 countries), scaling the technology and optimizing the downstream refining and associated end products to ensure commercial viability prior to entering the market. The core of the technology is a chemical delignification process that’s low-cost, scalable, and offers high conversion rates of non-food biomass to a multitude of end products. The company’s pilot plant has a 20,000-li-

tre reactor that can process around three to five tonnes a day of biomass, along with many other technical support systems used in their process.

As Treadwell will tell you, SixRing’s advantage is in its flexibility. Their processes and methods can take any source of lignocellulosic biomass and turn it into high-value feedstocks for biofuels, speciality chemicals and advanced biomaterials.

“You’ve got these fundamental building blocks coming out of the SixRing process that doesn’t lock you in to a downstream or end-use market. And what’s coming in as feedstock doesn’t lock you in to an upstream market, greatly de-risking the deployment of our technology versus alternatives, most of which are very capital intensive,” Treadwell says.

SixRing’s technology evolution began more than a decade ago when current CEO Clay Purdy founded Fluid Energy Group Ltd. to offer chemical solutions to the oil and gas industry. The company’s aggressive R&D efforts led them to a solution for treating biomass to produce a very high purity cellulose and a liquid organic mixture that seemed to be reflective of a crude oil.

Chief technology officer Markus Weissenberger understood quickly there was a strong technology differentiator and business development opportunity in the delignification of biomass using their fairly simple chemical mixture, Treadwell says. Last year, serial entrepreneur Purdy and his team sold its petroleum-based tech-

nology portfolio (numbering over 300 patents) to focus solely on commercial opportunities with SixRing technology, now a wholly owned subsidiary of Chemical Evolution Ltd. With some seed capital from the sale and around 40 staff, half of which are scientists, the company continued scaling up its pilot plant in Calgary that has been humming along for more than four years.

Treadwell, a chemical engineer by education with a corporate finance and capital markets background, joined the SixRing team in 2022 as the company was executing the sale of its energy industry business. The leadership team is well-rounded with legal, commercial, financial and business development expertise across the group.

“One of the things you sometimes see with startups is the cliché that they are run out of a garage with guys in lab coats. They typically have very innovative technology – and we saw this all the time in oil and gas – but a lot of that technology doesn’t make it to the mainstream for lack of a vision and a strong corporate team to bring it to market,” Treadwell says.

With the corporate team in place and the technology proven at small commercial scale under the direction of Weissenberger, SixRing is nearing the finish line and ready to broadcast their story with the help of key employees such as Ron Hoffmann, a former Canadian ambassador whose rolodex has been critical to much of the federal and provincial support the technology has garnered.

Lignocellulosic biomass has three chemical components: lignin, cellulose and hemicellulose. In the breakdown process, Treadwell likens lignin to three-dimensional barbed wire.

“It’s incredibly tough to get through, being difficult to break in any meaningful sense, so typically the only way it’s been done is through brute force – lots of chemical energy or lots of heat and pressure – but that can have negative impacts on the chemical composition of the end products,” he says. “We’ve found a way to take the chemical equivalent of very small wire cutters and cut very specifically through the barbed wire and basically peel it back to access the inside, very pre-

cisely, retaining the high value molecules typically degraded in other processes. The high value components inside can now be taken out separately with very little impact to their chemical composition.”

The SixRing delignification process has a low energy input and a high yield – 99 per cent delignification occurs with minimal losses. The ambient temperature and pressure process creates two product streams: a liquid lignin hemicellulose depolymerized organics (LHDO), and a solid cellulose.

The resulting lignin remains in liquid form and does not repolymerize or reform as a solid, making it suitable as a chemical feedstock as well as a fuel solution, already proven to be refined into gasoline, diesel and, maybe most importantly, SAF or sustainable aviation fuel. The other original components – cellulose and hemicellulose – both exit the process as mainly unaltered chemicals, which have a multitude of uses in dozens of industries including chemicals, fuels and pharmaceuticals.

“Over 80 per cent of the incoming mass of that biomass is turned into saleable products,” Treadwell says.

Many downstream processes are in place to expand the potential end products

of LHDO and cellulose. Biofuels, biochemicals and biomaterials are all pathways to market.

SAF is one potential that has both scalability and a growing pool of motivated investors as regulatory changes become law with heavy non-compliance penalties coming into effect. SixRing’s technology can provide two different feedstocks for SAF production, first through ethanol production from cellulose to feed alcohol-to-jet (ATJ) conversion, and secondly through the refining of its LHDO, which has shown very high conversion to the lightweight fuel products required for aviation uses.

“The fact that we use non-food based biomass is a huge enabler for SAF growth,” Treadwell says. “There is still some downstream technology that needs to be brought to market, fully commercialized and optimized to get cost down to where it makes sense – to be economically sustainable for the end-user. The SixRing technology is a pathway to assist heavy industry with decarbonization now that there is a viable technology that can provide the required feedstocks for these already proven catalytic methods which produce the final fuels.”

“Over 80 per cent of the incoming mass of that biomass is turned into saleable products. ” –Scott Treadwell

On the feedstock end, being agnostic plays well into the agricultural trend towards regenerative farming. As farmers rotate crops to maintain soil integrity, SixRing’s technology can process whatever feedstock is produced each year, and at whatever amounts exceed what is needed to keep healthy organic material in the soil.

“We can work to make sure enough is left and farmers get a revenue stream no matter what crop it is they are growing,” Treadwell says.

SixRing’s pilot plant in its current iteration can process up to five tonnes a day

“In 10 years we would like to be a global example in how you solve humanity’s challenges with bio-based solutions that are both costeffective and fundamentally sustainable.” –Scott Treadwell

of biomass. The plant has mainly processed agricultural residues including cereal straws, oilseed straws, rice hulls, and corn stover. Other interesting trials have included sugarcane bagasse, date palm tree cuttings, as well as hardwood and softwood fibre, including hogfuel and salt-contaminated woods, most of which were supplied by partners across four continents. These partners are all in discussions with the company for licensing of its technology, direct investment or another commercial relationship. The team has been working with major pulp and paper companies for almost three years now.

Aside from the reactor and its delignification process, all other downstream technology in the pilot plant is off the shelf, yet accounts for around 90 per cent of the capital for a commercial facility, Treadwell says. “We’re really only scaling up that first 10 per cent and I would say we’re now there. Essentially we’re at the finish line and now raising capital to deploy an asset we own as our licensees do the same in their respective jurisdictions.”

SixRing’s Phase 1 of its first commercial plant is set to process 25 tonnes a day with six to eight reactors of a similar size to the pilot plant. The company is working with Gas Liquids Engineering in Calgary for initial work on future commercial facilities, and has engaged with some OEMs in the biofuels industry for scaling up to commercial production.

Last year, SixRing signed a memorandum of understanding with the Edmonton International Airport to explore a commercial facility that would advance the use of biofuels, including SAF, in the Edmonton region and has since signed and formed key relationships around the world with refiners, biomass asset owners, end users and government entities.

Strategically, Treadwell says, Edmonton is flush with both industrial refining infrastructure and agricultural and forestry feedstock supply. “Having a partner like Edmonton airport that’s looking to push sustainability forward and be one of the first major entities through the door is a great advantage for us to bring global attention and build the consortium to deliver that facility,” he says.

SixRing’s leadership is proud of its Canadian roots, but operating in Canada – a highcost jurisdiction – comes with unique challenges. Labour is one part of that challenge, as is the dwindling supply of made-in-Canada materials, and long hauling distances to bring in feedstocks.

“Canada has done a lot to try and valorize biomass, not just in forestry but in agriculture as well,” Treadwell says. “But in a global sense, thinking of biofuels, you’re trying to chase $80 a barrel oil and $5 a gallon diesel, and if you are starting with feedstock that’s $150 a tonne, you’re on the back foot economically.”

Despite these challenges, the fundamental conditions to succeed in the biomass industry at scale are as good in Canada as in any other jurisdiction, Treadwell says. There are some policy gaps, he acknowledges, but these policies must be balanced to ensure taxpayer money is invested sensibly.

And most importantly, Treadwell says he believes the majority of Canadians are wiling to support new solutions, even those that come at a small price increase, if it’s the right thing to do, especially when they save or create new jobs.

“I think Canada is a country where people are open to doing things better. If there is a slight incremental cost, people are willing to at least evaluate it on its benefits before saying, ‘No, I don’t want to pay another nickel for my litre of gas or plane ticket.’ So I think there is an opportunity here to build markets and build end uses. There are enough people with enough good will for Canada to be a leader.”

Similar to the energy industry, Treadwell says the biomass industry at times struggles to marry technical expertise with sales expertise. “Sometimes the good technology and the good story aren’t the same thing. You have good technologies out there that suffer because the story is not being told properly. And you have some really good stories, but when you dig into them they’re not as shiny as you once thought. And that’s true in any industry,” he says. “I do think as the industry matures you will start to see a movement of talented people.”

Visualizing 10 years from now, Treadwell sees success for SixRing as a multi-billion-dollar company with 100 or more employees that has licensed its technology

globally. The company has evolved from one that develops processes to one that is solving downstream, final-product problems. SixRing will continue to invest heavily in R&D, he says, but that will ideally shift from tech commercialization to prod-

uct development and licencing support.

2023-06-15 4.875in x 4.75in-Detroit Comb Equip-Canadian Biomass copy.pdf 1 6/16/2023 10:57:34 AM

“In 10 years we would like to be a global example in how you solve humanity’s challenges with bio-based solutions that are both cost-effective and fundamentally sustainable,” Treadwell says. •

By Gordon Murray, executive director, Wood Pellet Association of Canada (WPAC)

Last month, the Wood Pellet Association of Canada (WPAC) and some of its members visited Taiwan on a trade mission, visiting prospective customers and their facilities and participating in a oneday conference on exploring the potential of the Taiwanese market. WPAC, the Canadian Trade Office in Taipei and the Taiwan Bio-energy Technology Development Association organized the mission.

After the trip, I can say for certain that Taiwan is emerging as a market of interest for Canadian wood pellet producers and has the potential to reach a similar scale to South Korea and Japan.

The Taiwan Ministry of Economic Affairs (MOEA) has set a target of 20 per cent renewable energy generation by 2025. Taiwan’s Greenhouse Gas Reduction and Management Act mandates a 20 per cent reduction in annual carbon emissions by 2030 and a 50 per cent reduction by 2050, based on 2005 levels. This translates to a reduction of 53 million tonnes of CO2 equivalent by 2030 and 133 million tonnes by 2050.

Currently, renewables account for less than 10 per cent of Taiwan’s total energy output. The government aims to install 778 megawatts (MW) of biomass energy capacity by 2025, enabling the generation of 4.1 billion kilowatt hours (kWh).

Taiwan recently held an election, resulting in a change in government. This has temporarily stalled progress on several previously announced bioenergy projects and how the government intends to support

them. Nevertheless, mission participants observed that coal power station operators were enthusiastic about phasing out coal in favour of clean, low-carbon, renewable wood pellets.

Taiwan is expected to import significant quantities of wood pellets to meet its green energy production goals. The Taiwan authorities’ commitment to generat-

ing sustainable bioenergy by using wood pellets could create a $450 million CDN wood pellet trade opportunity.

One of the projects of most immediate promise is with the state-owned Taiwan Power Company (Taipower), which is planning to convert 500-megawatt (MW) Number 1 coal-fired boiler in its Kaohsiung Hsinta Power Plant into a low-carbon biomass energy generation system specializing in burning wood pellets. Although with the recent change in government, the

timing of this project is uncertain, when it does proceed, it will mark the first domestic case of transforming a decommissioned coal-fired unit into a biomass energy generation facility, serving as a technology demonstration for the transition of largescale coal systems to clean energy in Taiwan. Taipower will seek to purchase 1.7 million tonnes of industrial-grade wood pellets annually for the updated facility.

There are also many independent power producers using coal boilers to produce electricity, especially for plastics, petroleum and paper manufacturing, who are interested in transitioning to renewable energy.

Ho-Ping Power Company is a coal-firing sub-critical pressure thermal plant with a gross generating capacity of 1,320MW (2x660MW). All of the electricity generated by the Ho-Ping Power Plant is sold to Taipower Company. This helps Taipower Company improve the power supply situation in the eastern region and slow down the 345kV ultra-high voltage north-south main line transmission in the western region, thereby improving the stability of Taiwan’s power supply system. Ho-Ping Power is looking at marine energy development, unit upgrading and a renewable plan that could include solar and a carbon reduction plan with wood-pellet co-firing and SRF gasification syngas co-firing.

Cheng Loong Corp., a paper and packaging company, has a biomass CFB boiler system at its Chupei Mill and will have one at its Houli Mill in 2026. The conversion at the Houli Mill is estimated to reduce GHG by 50k tCO2e/year. Cheng Loong Corp’s wood pellet demand is estimated at 54,000 – 56,000 tonnes in 2026.

While Formosa Petrochemical Corporation primarily refines crude oil, sells refined petroleum products and produces and sells olefins from its naphtha cracking operations, the company also provides electricity, steam, and other utility products generated from its co-generation power plants to plants in their area. Formosa’s Utility Department has four cogeneration plants with 16 boilers (11,580T/H) and 15 generators (2,750MW). To comply with ESG carbon reduction goals, it will plan a small amount of wood pellet co-firing (5 per cent) with three of its 600MW coal-firing boilers. It is estimated Formosa will need 560,000 tonnes of pellets per year.

Vietnam surpassed Canada as the second-largest producer in the world in the past year. The country now accounts for 21 per cent of global pellet supply compared to 12 per cent for Canada. Given the country’s proximity to Taiwan, Vietnam is well-positioned to be a leading wood pellet supplier. It has low labour costs, paying salaries of just $400 to $500 USD per month, and has abundant raw material from domestic forest plantations. On the other hand, Canadian pellet producers are known for their high product quality and strong sustainability credentials. Nevertheless, the potential market should be large enough for Vietnam, Canada, and many other countries to supply Taiwan.

More than 170 people from Southeast Asia, North America, and Europe attended the 2024 Taiwan Solid Biofuels Conference, hosted by Taiwan’s Bio-energy Technology Development Association and co-organized with Canada’s Trade Office in Taipei.

Ed Jager, senior trade commissioner/ director of trade and investment with Canada’s Trade Office in Taipei, opened the session. “The benefits of wood pellets and solid biofuel as a replacement for coal and other fossil fuels are clear. By embracing these sustainable energy sources, we not only safeguard our planet for future generations but also pave the way for a more prosperous and resilient society,” he said.

Keynote speaker Dr. William Strauss, president of FutureMetrics, explained that the consequences of climate change are

not only environmental and ecological but also economic.

“The increasing frequency and severity of the consequences of climate change will accelerate decarbonization policies in most nations,” Strauss said. “Sustainably sourced biomass is the foundation for several decarbonization pathways. The market for industrial pellet fuel could reach 55 million tonnes by 2030.”

Fiona Matthews, director of Hawkins Wright, provided an outlook for global solid biofuel markets in 2025 and beyond. Pellets are the largest type of traded biomass at more than 27 million tonnes/year. There has been significant growth in pellet demand from Japan, mainly from new builds. She believes that there will be a wider uptake of co-firing in the future.

Tony McRae, director of Sales with Drax, provided an overview of the wood pellet supply chain and quality considerations. He explained that supporting global customers requires world-class logistics; with transportation costs making up 70-80 per cent of the delivered price. “Canada has a highly sophisticated supply and logistics chain from the transportation from Western Canadian pellet plants via train to two ports on the west coast and onto vessels to Asia,” said McRae.

Canada is well-positioned to become a reliable supplier of high-quality, sustainably-produced, climate-friendly wood pellets to Taiwan. We can offer Taiwan advice on several fronts, including safe transportation and storage of pellets, logistics solutions, and policies supporting further uptake of wood pellets. •

From the bustling urban landscapes of Singapore to the rugged natural beauty of British Columbia, Rob McCurdy has shaped an industry and spearheaded the global biomass movement. As a visionary whose career has spanned continents and cultures, McCurdy’s story is not just about professional success but a profound commitment to environmental stewardship.

He began his career with a simple yet profound mission: to influence climate change positively through sustainable industrial practices. His leadership at Pinnacle Renewable Resources from 2012 to 2020 was transformational, as he grew the organization from a relatively modest operation into the world’s third-largest producer of industrial wood pellets.

“We took a small two-plant operation in British Columbia and built the company into one of the largest biomass producers in the world,” he said. Under his guidance, Pinnacle not only expanded its capacity but also cemented its status as a key player on the global stage, particularly in the Asian markets. Throughout his tenure, McCurdy’s strategic vision led Pinnacle through significant global expansions, including into new markets like Japan and Korea. Since stepping down as CEO, McCurdy has not slowed down. As the principal consultant at McCurdy Consulting, he continues to play a role in the industry, offering expert advice on everything from site selection to corporate restructuring.

In the realm of commercial and institutional biomass heating systems, Burkhard Fink is a name synonymous with innovation and resilience. With a career spanning two decades, Fink’s groundbreaking work has not only shaped the industry but has also established a sustainable pathway. Fink began his foray into biomass heating out of necessity and ingenuity. Originally a builder of log homes, Fink was vexed by the inefficiencies and costs associated with traditional energy sources.

‘THE

John Swaan is not just an industry pioneer — he also has a cool moniker: “The grandfather of North American wood pellets.”

Swaan’s journey began in 1994 when he founded the Pacific BioEnergy Corporation in Prince George, B.C.

“Desperation during the ‘Livestock Feedmill’ era made pelletizing low-value fibre resources such as sawdust seem like a fix for our financial woes,” he said. “Little did I know, it would set the stage for a multibillion-dollar industry.”

Indeed, Swaan’s venture marked a key shift in the industry when, in 1998, he orchestrated the first trans-ocean shipment of wood pellets from Western Canada to Sweden. This not only established Canada as a leader in wood pellet export but also signaled the birth of a global industry now renowned for its role in CO2 reduction. “Negotiating that first off-take contract was not just a highlight of my career but the beginning of what we know today as the industrial wood pellet market,” said Swaan.

Beyond his entrepreneurial spirit, his tenure as the executive director of the Wood Pellet Association of Canada (WPAC) from 2005 to 2009 underscored his commitment to nurturing the industry. In 2013, he continued his mission by joining FutureMetrics, where he shared invaluable insights with stakeholders.

Swaan’s philosophy on success in the biomass industry emphasizes both historical lessons and forward-thinking strategies.

“I had been building log homes for a number of years and I was frustrated with how we were paying for natural gas as well as paying to get rid of our wood waste. I decided to build my own boiler,”

Fink said. This initial step into biomass heating was just the beginning of what would become a transformative journey in the energy sector. That pragmatic approach led him to look overseas for inspiration, which in turn crystallized his vision for Canada’s biomass potential.

“After operating it for a short while I quickly realised that a better solution was out there in Europe,” he said. This realization paved the way for the development of the first small-scale, for-profit biomass district heating system in Canada — a project accomplished without the aid of grants. This pioneering system became a model, validating the feasibility and efficiency of small-scale district heating systems and inspiring similar initiatives. Fink has installed more than 170 heating systems, collectively generating over 58 megawatts of energy.

Gordon Murray’s path from a forestry operations manager to an acclaimed leader in the bioenergy sector as executive-director of the Wood Pellet Association of Canada (WPAC) reflects a career marked by significant transitions and a passion for sustainability.

After graduating in 1982 with a Bachelor of Science in Forestry and qualifying as a registered professional forester, Murray’s early career revolved around forest operations for leading lumber manufacturers in British Columbia.

His entrepreneurial spirit soon led him to establish a forestry contracting business, cultivating a team that would grow to more than 20 employees, which he managed until he decided to become a chartered professional accountant (CPA) in 2003.

This financial expertise transitioned him into a pivotal role at WPAC in 2008. It wasn’t long before he was at the helm as the executive director, a role he has held for the past 16 years.

Turning waste into energy was a “revelation” for Jesse Douglas, the CEO and founder of Green Impact Partners, and a big reason why he was drawn into the biomass sector.

Douglas has been recognized with an Honourable Mention in the Champion of the Year category at the 2024 Canadian Biomass Awards, a testament to his significant contributions and visionary approach in the industry. Douglas started on his journey in the bioenergy sector driven by a desire to enact meaningful change. Raised in Alberta, a province dominated by energy, he was naturally drawn to the industry. “Growing up in Alberta, where energy is the heartbeat of the province, I’ve always felt this pull to make a real impact in the energy sector,” Douglas said, adding that using waste to create energy “offers immediate benefits that resonate deeply with my values and aspirations.”

Douglas has founded, and sold, multiple businesses throughout his career and has been at the helm of numerous engineering, procurement, and construction projects. He has also held executive, board, and senior leadership roles where he has honed his expertise in driving teams to achieve greatness, he said.

In 2021, Douglas founded Green Impact Partners — a “standout” moment for him.

“I didn’t deliberately seek this position, but I rapidly grew an enormous passion for bioenergy and have been thrilled to be part of our industry’s growth and success,” he said. Under his leadership, WPAC has not only seen substantial growth but has also embraced rigorous safety and sustainability standards.

“I am very gratified to have been part of the movement to demonstrate the sustainability credentials of our industry,” he said. Safety initiatives have been another cornerstone of his tenure. Starting with a focus on personal health and safety and evolving to sophisticated process safety management, these initiatives have placed WPAC at the forefront of industry standards.

Murray remains optimistic about the future of bioenergy, acknowledging both its necessity and the challenges it faces.

“The world needs bioenergy. It is a vital part of the tools needed to combat global warming,” he said, ready to continue to advocate for bioenergy’s role in sustainable practices.

Joe Webster’s career began in the woods of B.C. In 1991, he entered forestry as a truck driver — hauling logs and building roads for Pioneer Logging. Webster, now operations manager at Tŝideldel Biomass, won Honourable Mention at the 2024 Canadian Biomass Awards for Champion of the Year. Webster’s career in biomass began unexpectedly at 4 a.m. on a Thursday in 2008, amidst economic uncertainty and mill closures. Atlantic Power was short on fibre, and he had been summoned into his supervisor’s officer. It took 15 minutes for him to alter the course of his career as he consented to head out to the woods with a grinder. In short order, he was running a 24-7 operation, overseeing six contractors. Using two Cats, ploughing snow ahead of four grinders yielding 80 loads a day, Atlantic Power had a yard full of fibre.

Pioneer Biomass changed hands several more times before Webster landed at Tolko Industries in 2013. Even when laid off in 2019, opportunity was literally waiting just outside the door; Philippe Theriault of Tsi Del Del Enterprises was standing in the parking lot and was ready to bring him aboard Tŝideldel Biomass.

As an operations manager, Webster does not see his role as merely overseeing logistics but as fostering a collaborative environment where innovation can thrive.

FROM NAMIBIA TO CANADA: LIEZL VAN WYK’S

JOURNEY TO BIOMASS LEADERSHIP

In a world increasingly attentive to sustainable energy solutions, Liezl van Wyk stands out not just for her expertise but also for her visionary approach to biomass energy.

As the vice-president of Northern Operations at Drax Group Canada, van Wyk has been instrumental in steering Canada’s largest pellet plant grouping toward a carbon-negative future. Born in Namibia and educated at the University of Stellenbosch in South Africa, van Wyk’s academic roots in electrical and electronic engineering laid the groundwork for her career. Her professional path spanned across the power utility industry in the SADEC region before an MBA from IMD in Switzerland pivoted her focus towards mining and ,subsequently, renewable energy. “When Drax approached me to join them as the VP for their Northern Operations, I was ecstatic. I was not too familiar with the industry at the time,” she said. “I decided to join… because of Drax’s values as a company and their

vision for a carbon negative future through their sustainability and carbon capture and storage programs.”

van Wyk’s leadership has not only enhanced operational efficiencies but has also foregrounded safety and sustainability. “One of the highlights, for sure, is how we are making our pellet mills safer through further investments in process safety,” she said. “You don’t ever do operations well without a very solid safety foundation to build on.”

Her broad international experience, working in more than 10 countries, has enriched her perspective, a diversity that she deems vital for personal and professional growth. “This has afforded me great personal and professional growth and allowed me to work on very interesting projects with very interesting people,” van Wyk said. Looking ahead, van Wyk is optimistic about the future.

“The Biomass industry is developing and diversifying in new and complex ways,” she said. “Responsible resource management is a key them and central to the climate change discussion.”

High above the ground in the lush forests of B.C., a young Benjamin Patton first found his calling among the branches as a climbing arborist. Today, grounded in his role as the founder and CEO of TreeCycle Canada, he is pioneering sustainable solutions in the biomass industry, earning him an Honourable Mention in the Thought Leader of the Year category.

His extensive background, which includes roles as an arborist technician, danger tree assessor, occupational first aider, and wildlands firefighter (and he’s only 31) has culminated in a focused commitment to environmental stewardship. Patton’s academic endeavors — spanning from BCIT’s Applied Biology Program to a Wood Kiln Drying Certificate from UBC’s Faculty of Forestry — have equipped him with a deep understanding of natural resource management and urban forestry.

Reflecting on his diverse career path, Patton finds resonance in the concept of ‘Ikigai’, a Japanese term meaning the “reason to live”, which aligns one’s passions and talents with what the world needs and is willing to pay for. “My career path could best be described by Ikigai. It’s about blending what we are good at and what we love, with the needs of the world and the opportunities to make a living.”

CURIOSITY FUELS CHANGE: JAMIE

STEPHEN OF TORCHLIGHT BIORESOURCES

“Curiosity and intellectual stimulation.” That’s what drove Jamie Stephen to pursue and embrace a career in the biomass sector. Stephen, managing director of Torchlight Bioresources, was recognized with Honourable Mention in the 2024 Canadian Biomass Awards’ Thought Leader of the Year category.

“I love complex systems and working to understand the relationships and interactions between the components in those systems,” Stephen said, highlighting his draw to the intricate dynamics of forest products and energy systems.

His approach to bioenergy integrates forest carbon dynamics, climate considerations, and socio-economic factors, positioning him as a critical and respected thinker. Under his leadership, Torchlight Bioresources has transitioned from a consultancy to a frontrunner in developing major bioenergy projects, such as Canada’s first bioenergy with carbon capture and storage (BECCS) initiative, Rocky Mountain Carbon, and the pioneering community-wide district heating system, Heat New Glasgow.

Looking ahead, Stephen sees both opportunities and challenges for the bioenergy sector in Canada. He believes in the potential for Canada to play a globally significant role, particularly in BECCS and in decarbonizing the nation’s heat market.

In the small, remote village of Fort Simpson, nestled at the confluence of the McKenzie and Liard Rivers in the Northwest Territories, an innovative approach to sustainable energy has revolutionized their infrastructure — and earned them national recognition.

The village was recently honored as the Winner of the 2024 Canadian Biomass Project of the Year, a testament to their pioneering efforts in integrating biomass heating systems into their community.

“Thank you to Canadian Biomass for recognizing the community of Fort Simpson,” said Mayor Sean Whelly in his acceptance speech. “We’re just a small community, but we’re certainly at the forefront of seeing climate change impact communities.”

Fort Simpson, population 1,200, has witnessed firsthand the harsh realities of climate change, underscored by severe wildfires in the surrounding regions, he said.

This has catalyzed a deeper commitment to environmental stewardship within the community.

“We recognize the importance of using alternative energy and

In the frostbitten reaches of the Northwest Territories, the Arctic Energy Alliance (AEA) is redefining community heating with sustainable solutions that have earned them an honorable mention at the 2024 Canadian Biomass Awards.

The AEA’s Biomass Program has been an example of innovation and sustainability. Through comprehensive projects ranging from supporting existing systems to implementing new community-scale biomass heating solutions, AEA has become synonymous with renewable energy education and advocacy in the N.W.T.

A crucial aspect of the program is its focus on the operational success of existing biomass systems. “Supporting these systems is essential,” said Michelle Leger, project coordinator at AEA. “It’s not just about building new infrastructures; it’s crucial to ensure that what is already built works well.”

Collaboration lies at the heart of the Biomass Program. AEA works closely with various stakeholders including community governments, indigenous governments, and local businesses to conduct prefeasibility studies and set up community biomass district heating systems.

“Our partnerships are designed to empower communities,” said Leger. “They are pivotal in transitioning from traditional fuel sources to biomass, which is not only more economical but also environmentally friendly.”

not contributing to the carbon issue. We want to reduce our impact as much as possible,” Whelly said.

The award-winning project involved the installation of biomass heating systems in two of the village’s main municipal infrastructure buildings, including a swimming pool and fitness center, which were connected to a district biomass heating plant run by the territorial government. Additionally, an entirely new system was set up for their water treatment plant.

Whelly highlighted the collaborative efforts that made these initiatives possible, particularly praising the Arctic Energy Alliance.

“Because we are a small community... to gain the knowledge and the skills to be able to do this kind of project, we engaged quite a lot with Arctic Energy,” he said. The alliance assisted in hiring an energy champion and undertaking an energy plan, which were pivotal in seeing the project through to completion.

This transition to biomass heating is not only a step towards environmental conservation but also a cost-effective solution for the community, he said.

FROM

BOOM: BELLEDUNE PORT’S SUSTAINABLE TRANSFORMATION

New Brunswick’s Belledune Port Authority (BPA) has captured Honourable Mention for Community Project of the Year. The Port of Belledune, under the stewardship of president and CEO Denis Caron, has emerged as Eastern Canada’s premier exporter of biomass, recording a sixth consecutive year of growth in wood pellet volume.

“This has been a journey of strategic foresight and robust partnerships aimed at enhancing our capacity for climate-friendly energy sources,” Caron said. The port’s shipment volume soared from 223,948 tonnes in 2018 to a projected 510,000 tonnes in 2024, driven by $15 million in investments to expand terminal capacities and storage facilities.

With its eye on the future, the port has not only increased its handling capabilities but also its resilience against global economic shifts. “Even during the global supply chain slowdowns brought by the pandemic, our focus on biomass helped sustain and grow our annual profits,” said Caron. The Port of Belledune’s success is closely tied to the global pivot away from fossil fuels, with much of its exported biomass destined for European power plants transitioning away from coal.

ECOSTRAT WINS 2024 CANADIAN BIOMASS COMPANY OF THE YEAR FOR PIONEERING BIOECONOMY SOLUTIONS

In an era increasingly defined by the urgent need for sustainable energy solutions, Ecostrat has emerged as a leader in innovation and efficacy in the biomass sector. The company has become synonymous with its groundbreaking Bioeconomy Development Opportunity (BDO) Zone ratings. These ratings serve as a rigorous risk assessment tool that evaluates the potential for bio-manufacturing in various regions based on biomass feedstock, supply chain, and infrastructure.

Over the past year, Ecostrat has made significant strides in enhancing the credibility and utility of BDO Zone ratings. In 2023, these efforts were bolstered by the support from the Standards Council of Canada and the Canadian Standards Association’s anticipated release of the BDO Zone National Standard of Canada in early 2025. “Our BDO Zone Initiative has transformed how regions attract and

The numbers tell an impressive story: Fink Machine has installed more than 180 systems across Canada, cumulatively generating more than 55 megawatts of energy. As a major supplier of commercial and institutional biomass boilers its portfolio includes Mawera and Schmid biomass boilers, along with custom-fabricated, plug-and-play heating plants, it said.

It was recognized with an honourable mention as the 2024 Canadian Biomass Company of the Year. The past year has been noteworthy, highlighted by several projects. One of the standout achievements was the development of the Sicamous District Energy System, where Fink Machine not only supplied the boilers but also spearheaded the design and construction of the entire plant. This project exemplifies their expertise, from managing construction to installing the boiler and heating lines, and successfully connecting clients to the new system.

Another significant installation was for the Saanich Commonwealth Games pool in Victoria. The successful implementation of a low-carbon heating solution in such a challenging environment underscores Fink Machine’s ability to handle demanding projects and provides a model for other urban centers looking to reduce carbon footprints.

accelerate bioproject development, making it a cornerstone of regional bioeconomic planning,” said CEO Jordan Solomon. The company’s achievements include facilitating more than $1 billion in capital for the development of advanced biorefineries, such as Velocys’ Bayou Fuels project in Natchez, Mississippi. “The BDO Zone Rating was instrumental in supporting this significant capital raise,” Solomon said.

Ecostrat’s influence extends beyond North America. With over 48 BDO Zone ratings issued and more than 100 expected by the end of 2024, the company’s standards are being recognized globally as essential tools for advancing the bioeconomy. This international acclaim is reflected in the recent U.S. Department of Agriculture’s report, which references the BDO Zone ratings four times as a key element in America’s bioeconomy framework. “We are proud to be at the vanguard of biomass supply chain innovation, helping to derisk and scale up the global bioeconomy,” Solomon said.

BSB was founded in 2011 in New Brunswick by Jean-Claude Savoie, owner of Groupe Savoie, and Malcolm Fisher, owner of Compact Appliances. Fast forward a little more than a decade, and the company has been honoured with an Honourable Mention for 2024 Company of the Year, underscoring its growing influence and commitment to sustainable energy solutions across Canada.

Jonathan Levesque, BSB’s general manager, said the company has been on a growth spurt — broadening its horizons beyond the Maritimes to embrace opportunities across Canada, including ventures in the Northwest Territories and Quebec.

“We offer forced air, warm-hot water and steam systems ranging from 20 kW up to 20MW capacity,” said Levesque. “Some of our systems can use a variety of biomass, such as wood pellets, wood chips, demolition wood and agricultural waste.”

One of their flagship products is the Binder boiler — a solution that is designed according to customer specifications. “Tell me what you want to burn, and I’ll design a boiler for you,” Levesque said.

The genesis of BSB traces back to a transformative industry tour in Austria in 2011, which was a pivotal moment for the company. This experience highlighted the potential for local markets for biomass products, steering the company’s founding philosophy.

“Why export all our wood pellets overseas when there’s a market in our own country?” Levesque said.

By Todd Humber

Opioid-related poisonings are plaguing many parts of Canadian society, and workplaces aren’t immune from the issue. Data put together by the Institute for Work and Health shows that workers in the forestry, fishing, and trapping sector are at high risk.

Only construction workers are experiencing a higher rate of opioid poisonings, according to the data. And forestry workers who are in the 45 to 65 age range account for 60.3 per cent of all overdoses in the sector, it said.

With that in mind, Talent Canada and OHS Canada — sister media brands to Canadian Biomass — recently held an in-depth discussion on what to do if a worker overdoes on the job and how leaders can support their recovery long term.

Candace Plattor, an addictions therapist with Love With Boundaries, shared the story of “Dave” — one of her clients — as an example of how an opioid addiction can progress.

Dave was in his 30s and was a site supervisor at a construction site in British Columbia.

“He didn’t hurt himself on the job, he hurt himself playing football with friends,” she said. With a bad knee injury, he tried to continue working — but it became almost impossible because of the level of pain.

He went to the doctor, who prescribed him opioids to ease the discomfort, she said. The doctor also gave him a leave of absence to recover. At first, things were fine — he moved back home with his parents to save money while he focused on his recovery.

“But opioids are addictive, and his body became addicted to them,” she said. “Even though he really wasn’t in increased pain, he went to his doctor and said, ‘My pain is worse and I need more drugs. I need a higher dosage.’”

The doctor gave him additional medication, but soon scaled it back, she said. He wasn’t cut off completely, but he wanted more than what he was being given, she said.

“Dave went to the downtown eastside of Vancouver and he started buying the pills on Main and Hastings, but it got to be too expensive for him,” she said. “So, he went to heroin. He was even seeking out fentanyl because it could give him the hit that he wanted.”

His entire personality changed, he had volatile mood swings, and he even became violent at times, said Plattor. And that all stemmed from a simple injury to his knee while playing a game of football with his friends.

SAVE ME

Vicky Waldron, executive-director of the Construction Industry Rehabilitation Plan, is a fan of the acronym SAVE ME. It lays out, in a handy format, the steps that need to be taken in the case of a suspected opioid poisoning.

SAVE ME is “stimulate, airway, ventilate, evaluate, muscular injection, evaluate (whether a second dose is required).”

“The first thing you do is call 911, and then you begin the steps,” she said. That includes a sternum rub, to see if the person is awake.

“You don’t want to go straight in with the injection because naloxone puts people into what we call precipitated withdrawal,” said Waldron. “It’s a temporary reversal of the overdose, and it puts them into withdrawal right away. It’s a harsh, fast, and quick withdrawal.”

From size reduction to the perfect finished pellet, Schutte Hammermill has the system to meet your needs. From single units to complete turnkey systems, our custom configured hammer mills and pelleting equipment provide precision, energy efficiency and a superior finished product. Contact us today to find out how we can help you improve your process!

The risk is that people might get up and run away and try to overdose again, she said, because the withdrawal symptoms are immediate and painful.

“When that happens, they may go off and use again — but they won’t get the effects of the opioids because they’ve got naloxone in their system,” she said.

Naloxone has a half-life of about 90 minutes, while opioids have half lives ranging from four to eight hours.

“What that means is that, once the naloxone has disappeared, the opioids that were in the system are going to reattach to the receptor sites,” she said. Add in the new opioids the person ingested, and there is an increased risk of a fatality.

“In reversing an overdose, you do want to call 911 first because then you can say to them that we’ve administered naloxone, they know they’ve got to get there fast, and then they can get into a safe environment as they watch for the reversals,” said Waldron.

Mike Russo, president of WorkBright, said naloxone kits are critical in treating an overdose. Ontario has mandated that naloxone kits be made available in certain high-risk workplaces — a move he called “significant and groundbreaking.”

But just making the kits available isn’t enough, he said. There are specific compliance requirements in the legislation that

organizations need to take into account.

“The act sets out specific responsibilities for the employer to assign a person in charge of the naloxone kit, and that that person be trained,” he said. That includes recognizing the signs of an overdose and how to administer the product.

Another key consideration is where the naloxone is physically stored, because it needs to be kept in a strategic location so it’s easily accessible, said Russo.

“Many workplaces have multiple sites, they have multiple shifts,” he said. There are also climate considerations, because the kits are temperature sensitive to both extreme cold and extreme heat.

“I’ve spoken with workplaces that have handed out naloxone kits to their supervisors, and instructed them to lock them in the desk to avoid them from being misplaced or taken home,” said Russo. “You want to avoid that. It needs to be really accessible.”

Lilian Riad-Allen, senior director, workplace health, safety and wellness at the Liquor Control Board of Ontario (LCBO), said prevention can go a long way in preventing overdoses. One of the tactics it takes is to create a culture where people feel comfortable speaking up.

“How do we create safe spaces where people feel comfortable to come forward and identify risks,” she said. “It may be just

noticing when someone may not be themselves… and creating an opportunity to have those check-ins to connect with someone, to look for those signs of impairment.”

The goal is to treat an opiate overdose or poisoning in the workplace the same way any other medical event is treated, she said, just like a cardiac event or any other situation that required medical intervention.

“Our approach is to always have the person’s best interests at heart,” she said.

How the person is welcomed back to the workplace following an overdose is also critical, said Riad-Allen. Two things happen upon preparing for that return, she said.

“The first is a conversation with the affected individual, where we let them know in advance what the conversation with the team will look like — which is that we will always preserve people’s confidentiality and privacy related to any medical situation,” she said.

The second is what she called a “huddle” with the person’s manager to equip them and prepare them in advance.

“We provide them with scripts of things they can say, and things they can’t say,” said Riad-Allen.

But she stressed that the best opportunity for organizations isn’t how to respond to an event, it’s to prevent it in the first place.

“This goes back to that duty to inquire, but also created a safe psychological space for someone to come forward and share,” she said. “Whether it’s that they’re using opiates, or that they have any other kind of impairment that may affect them in the workplace.”

She also recommends implementing a “robust system” to prevent reoccurrence. That could include working with the person’s family — with the person’s consent, of course.

“We have had really good success working with collateral partners, whether that be family support partners but also bridging and creating those supports as part of a return to work plan,” she said.

The language Riad-Allen uses in these situations is always focused on safety, she said. “That’s the language we always use. Safety is the root and the anchor of everything we talk about,” she said. “People, intuitively, can appreciate that what we’re putting in place isn’t punitive. It is for their safety and the safety of their colleagues.” •

Steininger Sawmill / Rastenfeld Austria

Since December 2020, energy has been generated at the Steininger sawmill with a Schmid wood chip combustion. The new plant of Schmid energy solutions supplies the drying chambers and the pellet plant with heat.

„At the end of 2019, we learned that our neighboring heating plant would cease operations in December 2020. The plant supplied our pellet factory and our drying chambers with the necessary heat,“ explains Johann Steininger. It quickly became clear to the sawmill operators that they would invest in their own heating plant and become independent of others.

2020 ist im Sägewerk Steininger ein neues Heizwerk in die Trockenkammern und das Pelletswerk mit Wärme der Coronapandemie konnte der straffe Zeitplan einge-

„We worked flat out to find the right system and the right partner. Schmid energy solutions offered us the best concept and guaranteed that we would be able to launch the new heating plant in December 2020,“ continues Steininger.

Tight schedule

Nöstler wir, dass unser benachbartes Heizwerk im DeBetrieb einstellen wird. Die Anlage versorgte aber unsere Trockenkammern mit der notwendiJohann Steininger. Er führt gemeinsam mit seiSteininger, das Sägewerk Steininger in Rastendie Verantwortlichen rasch klar, selbst in ein investieren. Bei der technischen Planung stand den Ramler zur Seite. Mit Hochdruck machte man sich einem geeigneten Heizkessellieferanten. Fündig Schmid Energy Solution in Lieboch. „Schmid bot das garantierte uns, dass wir im Dezember 2020 mit starten können“, führt Steininger aus.

Das Wasser wird je nach Temperatur dem Schichtwassertank an unterschiedlichen Stellen zugeführt und das heiße Wasser von oben entnommen

The collaboration with Schmid began in March 2020 - in the middle of the first lockdown. The fuel requirement for the new boiler was that mainly bark as well as cross-cut wood could be used and that the system would supply the sawmill with thermal energy from December 10, 2020. Schmid started installing the UTSR-8000 moving grate combustion system in October 2020 and the heating plant was put into operation on December 1, 2020.

The 27‘296 MBtu / 8 MW system is designed for a fuel moisture content of 10 to 60 % and is ideal for the requirements of the sawmill. From bark to wood shavings, everything can be used.

Straffer Zeitplan Im März 2020 – mitten im ersten Lockdown – trat man erstmals mit Schmid in Kontakt. Die Anforderung seitens Steininger an den neuen Kessel war, dass überwiegend Rinde sowie auch Kappholz verheizt werden können. Die Wahl fiel auf eine 8 MW-Anlage des Typs UTSR 8000. Zudem war Schmid als Generalunternehmen auch für die gesamte Elektro- und Wasserinstallation zuständig. „Wir wussten, dass wir am 10. Dezember vom benachbarten Heizwerk keine Wärme mehr bekommen. Damit wir aber sowohl die Pelletsproduktion als auch unsere Trockenkammern weiterbetreiben können, war eine zeitgerechte Inbetriebnahme unabdingbar“, sagt Steininger. Im Oktober 2020 startete die Montage, bereits am 1. Dezember konnte die neue Anlage in Betrieb genommen werden. Trotz der Coronapandemie schloss man alle wesentlichen Arbeiten sogar zehn Tage früher ab als geplant. „Das ermöglichte uns einen nahtlosen Übergang und wir hatten keinerlei Ausfall in der Pelletsproduktion beziehungsweise bei der Trocknung“, freut sich Steininger.

zember 2020 den Betrieb einstellen wird. Die Anlage versorgte aber unser Pelletswerk und unsere Trockenkammern mit der

gen Wärme“, erzählt Johann Steininger. Er führt gemeinsam mit seinem Onkel, Gerhard Steininger, das Sägewerk Steininger in Rastenfeld. Damit war für die Verantwortlichen rasch klar, selbst in ein Heizwerk zu investieren. Bei der technischen Planung stand den Steiningers Franz Ramler zur Seite. Mit Hochdruck machte man sich auf die Suche nach einem geeigneten Heizkessellieferanten. Fündig wurde man bei Schmid Energy Solution in Lieboch. „Schmid bot das beste Konzept und garantierte uns, dass wir im Dezember 2020 mit dem neuen Heizwerk starten können“, führt Steininger aus.

Remote maintenance and service around the clock

The control center for the entire system is located in the heating plant and can be reached around the clock via the remote maintenance module. Faults are reported to the heating engineer in accordance with the settings. Schmid also offers 24/7 support with its own service specialists. „This support is important to us and has been confirmed,“ confirms Steininger.

Im März 2020 –Schmid in Kontakt. Kessel war, dass werden können.

8000. Zudem war samte Elektro- und wir am 10. Dezember mehr bekommen. auch unsere Trockenkammern zeitgerechte Inbetriebnahme ber 2020 startete neue Anlage in Betrieb mie schloss man ab als geplant. „Das wir hatten keinerlei bei der Trocknung“, Per Lader wird Kessel eignet sich mit ideal für die Rinde bis Hobelspäne Er ist Geschäftsführer Ein Schubboden rial in den Kessel. Kessel ist mit einer zug-Wärmetauscher eine 100 mm dicke

die Heizanlage Elektrofilter

Per Lader wird das Restholz zum neuen Heizwerk gebracht. „Der Kessel eignet sich für eine Brennstofffeuchte von 10 bis 60 % und damit ideal für die Anforderungen des Sägewerks. Man kann also von Rinde bis Hobelspäne alles verheizen“, verdeutlicht Josef Strohmeier. Er ist Geschäftsführer von Schmid Energy Solutions in Lieboch.

The fuel is loaded into the 20‘482.5 ft3 / 580 m3 silo using a loader. The moving floor built into the silo can be driven over and the hydraulic pusher feeds the material into the boiler. All is controlled and monitored over the Schmid boiler control system with communication to BMS over Modbus. The boiler is equipped with a three zone combustion chamber and a three-pass heat exchanger. Steininger also decided to use a 10‘582 gal / 40‘000 l buffer tank to overcome the seasonal demands for peak and smaller load situations.

Ein Schubboden mit hydraulischem Einschieber bringt das Material in den Kessel. Sensoren überwachen dabei die Zuführung. Der Kessel ist mit einer Dreizonen-Brennkammer sowie einem Dreizug-Wärmetauscher ausgestattet. Die Brennkammerwand hat außen eine 100 mm dicke Wärmedämmung mit Verkleidungsblech. Es folgt

Product type Moving grate combustion UTSR8000.42-1 visio

Control PersonalTouch visio with remote maintenance option

Fuel Wood chips and forest maintenance wood

Power

Use

27‘296 MBtu / 8‘000 kW

Heat for operation, drying plant and pellet factory

Discharge / Silo Moving floor (Drive over)

Exhaust gas dedusting Multicyvlone

In operations since December, 2020

Owner Steininger Sawmill, Rastenfeld, Austria

As an innovative technology leader, we offer exciting energy solutions for an environmentally friendly and sustainable future.

The Schmid Group is a Swiss family business that has specialized in wood energy since 1936 and is one of the world’s leading manufacturers. Schmid combustion systems enable environmentally friendly heating and are in use around the globe.

We offer a wide range of products up to large-scale industrial plants with an output of 614 - 27‘296MBtu | 180 - 8000 KW. Our customers are in the field of agricultural, Sawmills, forestry sectors, the wood industry, real estate companies, energy service providers, commercial-, industrial Manufacturing companies and cities or municipalities.

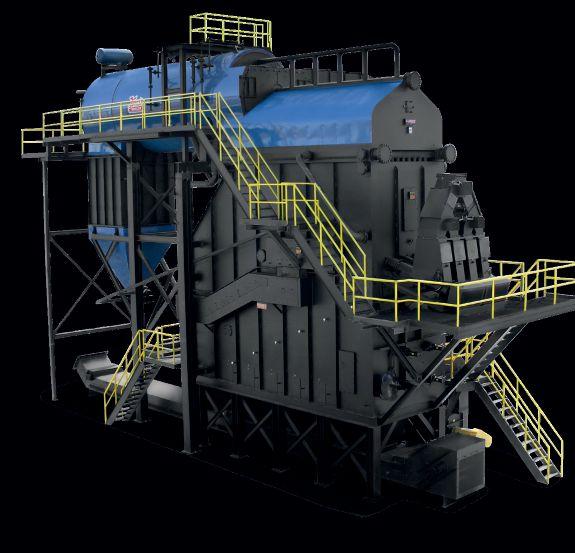

WOOD

for High Temperature Batch & Continuous Lumber

Hurst offers a full line of biomass combustion systems backed with fifty years of innovative clean-burn design. Diverse in every way with multi-fuel blending capability. Hurst stokers utilize hundreds of common and abundant solid biomass fuels.