“Hand-scooped” by Vemag

Watch live demonstrations of our Vemag Cookie Dough Depositor

n Go from hand-scooping to automated production without sacrificing product quality or eye appeal

n Increase production of exact-weight, pre-formed, ready-to-bake portions

n Gently handles dough, inclusions are not damaged

n Fast, easy changeovers

Vemag 500 Cookie Dough Depositor

BY COLLEEN CROSS

GETTING SOCIAL

Are you telling your story effectively?

Our bakery is producing high-quality, consistently delicious goods. Are you communicating closely with your fans and potential customers? If you’re not telling your story, you may be missing a chance to draw in new customers and lure back lapsed customers.

It’s important to have your website as a touchpoint. That will give you independence from social media platforms that can be sold or change algorithms and affect your operation. Once that’s set up, you can post a regular blog on any topic, people to sign up for a weekly, biweekly or monthly enewsletter, and encourage them to follow you on social media.

Your social media posts will remind them what’s on your menu, guide potential customers to your website or tempt them directly into your bakery. A single highly interesting post, such as an announcement you’re adding cinnamon buns to your roster, can get a like or comment and start a dialogue that makes your bakery or brand feel more like a friend than a business.

After an hour on our Bakers Journal Facebook feed, I learned that bakeries have plenty to say and their communities and customers are cheering them on. Here’s a glimpse of what I found.

Bakeries proudly showed off their creations, including Duchess Bake Shop’s latest Nostalgia Week feature, the St. Honoré; a delightful tuxedo cake by Sugar and Spice Bakery in Paris, Ont.; and new cheesecake flights with four different flavours from the Sweet Hereafter in Halifax, N.S.

We saw reminders about hours of operation and products for the day, about pop-up sales at fairs and farmers markets and about daily specials, including ube matcha cheesecake slices from Martinique Desserterie in Musquodoboit Harbour, N.S.

Your socials are a place to announce the not-so-good news that you must close early because you’ve sold out of product (also good news, depending on your point of view), suffered vandalism or have a family emergency. Customers understand life doesn’t always go as planned. If you maintain a long-term relationship with them over time, they will rally with you during the down times.

When you need to announce new terms for pickup and delivery such as payment in advance, social media platforms are the place to get the word out before people call in or set foot in your store. A few words of explanation in advance prevent misunderstandings and snags in service.

We saw posts inviting people to apply for jobs and posts celebrating the talents and achievements of their teams. Anniversary announcements are easy for followers to like and feel good about, as in The Hive Coffee House and Café’s special of a cake latte and honeycomb mocha macaron for $6.99 to mark a business milestone.

Some bakeries set out to share their knowledge, as with Kozak Ukrainian Eatery in Vancouver clarifying the difference between unbleached flour and their house-milled organic flour and Neme’s Kitchen discussing hydration.

The Iron Kettle in Comber, Ont., used social media to tell the story of how an influencer’s post drew long lineups to taste-test their Supreme Croissant. The owners told 20,000 Facebook followers about their bump in sales, need to increase production while short-staffed and measures put in place to move the line swiftly.

Social media is just one way to tell your story. It’s immediate, it’s effective and it’s a way for your business to develop a meaningful, win-win relationship with your customers. What’s more, in an age where artificial intelligence turns marketing messages into bland, cookie-cutter text, expressing yourself in an authentic voice has never been so important. The more your personality and values shine through, the more customers will remember there’s a human behind the business and products. / BJ

SEPTEMBER 2025 | VOL. 84, NO. 4

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep. Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | Colleen Cross ccross@annexbusinessmedia.com 519-429-5227

TECHNICAL

EDITOR | Julie Istead, Puratos Canada jistead@puratos.com

NATIONAL ADVERTISING MANAGER | Stephanie Jewell sjewell@annexbusinessmedia.com 705-826-2254

ACCOUNT COORDINATOR | Trish Ramsay tramsay@annexbusinessmedia.com 416-510-6760

MEDIA DESIGNER | Curtis Martin

GROUP PUBLISHER | Adam Szpakowski aszpakowski@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER | Beata Olechnowicz bolechnowicz@annexbusinessmedia.com 416-510-5182

CEO | Scott Jamieson sjamieson@annexbusinessmedia.com

Mailing Address P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710.

ISSN 0005-4097

Published six times per year (Feb, Apr, June, Sept, Oct, Nov) by Annex Business Media.

Subscription Rates Canada — 1 Year $ 32.64 USA — 1 Year $74.97 Foreign - 1 Year $86.19 Single Copy Canada - $5.00 All prices in CAD funds.

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2025 Annex Business Media. All rights reserved. Printed in Canada.

Bread is shaped by over 250 generations of bakers. Every generation tried out new recipes, new ingredients and a string of baking techniques. All to bake even better breads.

At Puratos, by getting the most from our heritage and respecting its three cornerstones - health, taste, texture - we intend to help bakers accomplish just that: better breads.

To learn more about our bakery solutions visit www.puratos.ca

¦ industry news ¦

briefly | Blossom Bakery brings fresh flavours and local fruit to downtown Thorold, Ont.; Study suggests reusing sunflower seed flour can make bread more protein-packed and rich in antioxidants | for more news in the baking world, check out our website, bakersjournal.com

Hearth breads achieve 40% of 2025 sodium reduction target; overall processors make ‘modest progress’: report Health Canada

Overall, only "modest progress" has been made toward the revised sodium reduction targets that were set in 2020, according to a July report by Health Canada summarizing the results of its assessment of progress in select processed food categories.

Hearth breads have made the most progress toward the sales weighted average, achieving 40 per cent of the 2025 target reduction.

The revised voluntary sodium reduction targets aim for an average daily sodium intake of 2,300 milligrams by the end of 2025.

To assess progress toward the 2025 targets, Health Canada surveyed nine processed food categories:

• white pantry bread and rolls, bagels, croissants, and flatbreads

• whole wheat and mixed grain pantry bread and rolls, bagels, croissants, and

flat breads

• pizza crust

• hearth bread

• hearth and non-hearth bread with savoury additions

• ready-to-eat cereals

• processed cheese and other cheese products

• ready-to-serve soups

• tomato sauce

According to Health Canada’s study results on its website, a category was chosen for one or more of the following reasons: its targets were revised in 2020, it is a staple food category, or it is an important contributor to the intake of sodium in the diets of people living in Canada.

Sales data were used to design a food label sampling plan to collect a representative number of foods from each of the nine categories which would cover about 80

per cent of the market for each category, Health Canada says in the report. Information from the food labels including the Nutrition Facts table values, ingredients, and product description were coded and the data was verified to ensure accuracy and to minimize transcription errors.

Sodium information from the food labels was converted to milligrams of sodium per 100 grams. This information was combined with sales data (kilograms) to calculate the SWA sodium levels in each food category. This data was compared to baseline data collected by Health Canada in 2017 and to 2025 targets to determine the progress made by industry in reducing sodium in these categories.

In total, 1,283 food labels were sampled from grocery stores across Canada between October 2023 and July 2024. The collected sample represented about 80 per cent of market sales (kilograms), except for pizza crust, which was about 60 per cent.

Overall, the results indicate that only modest progress has been made toward the 2025 sales-weighted-average sodium targets.

Hearth breads (for example, baguettes, crusted bread, artisan breads, rye bread, and pumpernickel bread) made the most progress toward the sales-weighted-average, achieving 40 per cent of the 2025 target reduction.

White bread products, breads with savoury additions (for example, olives, garlic, onion, and cheese), processed cheeses, and ready-to-serve soups made less progress, Health Canada said.

Four categories had higher sodium levels compared to 2017: pizza crust, tomato sauce, ready-to-eat cereals, and whole-wheat and mixed-grain bread products.

To learn more background about the sodium reduction targets and to read the full report, visit Health Canada’s website, canada.ca.

Food and Beverage Atlantic speakers announced

Food and Beverage Atlantic has announced speakers, workshops and panels for its 2025 Annual Conference and Awards Oct. 6-8 at the Delta Beauséjour in Moncton, N.B. The industry event will bring together food processors, suppliers, innovators, retailers and stakeholders from Atlantic Canada for three days of networking, education and inspiration.

Speakers include business leaders in all facets of the food industry:

• Lisa Genovese challenges how you think about brand value in her session, The customer decides your value, not you!

• Claire Brown dives into why sustainability and quality matter more than ever in today’s competitive market.

• Francis Gallant explores the critical connection between leadership, culture, and performance.

• Jason Hunt shows how to blend AI-powered advertising with human creativity for effective marketing.

• Will Yang leads a workshop on pocket production photography tailored to food and beverage businesses.

• Cédric Bélanger shares the latest Atlantic Canada market insights from Nielson IQ.

• Kristina Proulx delivers a key update on Food & Beverage Canada’s advocacy work, tariffs, and trade.

• Crystal MacGregor facilitates a mustattend panel on how to move your product after it hits the shelf, with real-world insights from producers Sarah Bennetto O’Brien, Laura Richards and Jenna Ross.

Attendess also will hear from three featured keynotes Suzie Yorke, founder of Love Good Fats, on building a $100-million brand from the ground up; Mike Fata ,

co-founder of Manitoba Harvest, on growing with purpose; and Graham Sherman, co-founder, Tool Shed Brewing, on breaking barriers and building buzz.

Through presenter sessions the event will explore how Atlantic Canada’s food and beverage sector can innovate, collaborate, and lead with resilience in a rapidly evolving economy.

The FBA Conference is open to professionals in the food and beverage industry, including business owners, entrepreneurs, government representatives, academia, retailers and service providers. Visit atlanticfood.ca for details.

The Baking Association of Canada’s Farmer-Miller-Baker Summit will take place the next day, Oct. 9, at New Brunswick Community College.

For more information and to register, visit the FBA event website.

For more information on the Farmer-MillerBaker Summit, visit farmer-miller-baker.org.

Golf tournaments raise funds for student scholarships

In June, BAC chapters hosted golf tournaments where golfers and sponsors raised significant funds to help fund scholarships for baking and pastry students. Some 150 dedicated BAC members hit the links at The Club at Bond Head near Beeton, Ont. The event raised more than $29,000.

Ontario sponsors were Barentz and Reiser (gold); Ireks, Malabar Ingredients, Mulitvac Fritsch and U-Pak (silver); and Burnbrae Farms, Con Eng Design Build, Embassy Ingredients, Preventive Controls and Compliance and Tielman (bronze).

The B.C. chapter tournament raised funds for scholarships at Vancouver Community College, Vancouver Island University and Okanagan College. Nearly 100 participants and almost 30 generous sponsors made the day a standout success. B.C. sponsors were AB Mauri – Fleischmann’s Yeast, ADM Milling, Ardent Mills, BakeMark Canada, Caldic North America, Cascades Containerboard Packaging, Cavendish Farms, Classic Cuisine Foods, COBS Bread, Dawn, Eggsolutions – Vanderpols, Gay Lea Foods, Hon’s Wun-Tun House, IMCD Canada Limited, JVR Food Packaging Solutions, Lesaffre Yeast Corp, Malabar Ingredients, Mark-Crest Foods, Nana’s Kitchen & Hot Sauce Ltd, Okanagan College, PB Bakery Group – Island City Baking, PB Bakery Group –Stuyvers, Portofino Bakery, Richardson Food & Ingredients, Rise Baking Company, Rogers Foods, Sara Lee Desserts, Snow Cap, Sugarplum Desserts, Sustainable Bioproduct Innovations, Trupack Enterprises, Unitrend Packaging, VCC and VIU.

Nova Scotia Community College, New Brunswick Community College, College of North Atlantic – Newfoundland and Holland College – PEI received scholarship funding through the Atlantic

Thomas Lowry and Jennifer Denomme, Olympic Wholesale, Kelly Teeter, Burnbrae Farms, and JC Madour, Lallemand, were among Ontario golfers who raised above $29,000 toward student scholarships.

chapter’s tournament.

Atlantic sponsors were AB Mauri, AMCA Sales & Marketing, Ardent Mills, Aucoin Bakery, Bakemark, Capital Foodservice, Dawn Foods, Farnell Packaging, Gennoe Baking Supplies, Lallemand, Lantic Sugar, Lesaffre Yeast Co, Maritime Pride Eggs, Mrs. Dunsters, P&H Milling and Reiser Canada.

The BAC extends a big thank-you to all sponsors and participants!

FDA to revoke 52 obsolete standards for food products

The U.S. Food and Drug Administration is revoking, or proposing to revoke, 52 food standards after concluding they are obsolete and unnecessary. The 52 standards are for canned fruits and vegetables, dairy products, baked goods, macaroni products and other foods.

These actions are the result of the agency’s ongoing analysis of its portfolio of more than 250 food Standards of Identity to make sure they are useful, relevant and serve consumers in the best possible way, the FDA said in a news release. The removal of these standards is in alignment with broader efforts to ensure that HHS is directing resources to where they’re most needed.

They include publication of the following:

• a direct final rule revoking standards for 11 types of canned fruits and vegetables that are no longer sold in U.S. grocery stores, including seven standards for fruits artificially sweetened with saccharin or sodium saccharin

• a proposed rule that would revoke standards for 18 types of dairy products – including certain milk and cream products, cheeses and related cheese products and frozen desserts

• a proposed rule that would revoke standards for 23 types of food products, including bakery products, macaroni and noodle products, canned fruit juices, fish and shellfish and food dressings and flavourings

For more information, visit the FDA’s website.

IBIE to host new competitions and extensive education for retail and wholesale bakeries

IBIE 2025, the Baking Expo, will present the latest baking trends and new business strategies, featuring unique, industryfocused education, products and opportunities as part of the key industry show held every three years.

New this year, registration now includes access to the expo, show floor demos, and IBIEducate sessions for one flat rate, organizers shared in a news release.

For the first time, registration includes full access to IBIEducate, the expo’s comprehensive education program. Attendees may participate in their choice of more than 100 sessions, workshops, and demonstrations – covering essential industry topics such as production efficiency, ingredient innovations, and retail strategies. The program offers practical, relevant learning experiences.

This year’s show lineup includes the following highlights:

IBIEducate: With more than 250 sessions, hands-on workshops and live demonstrations, there’s training for every job function and market segment.

Wholesale Bakers Center, sponsored by

Dawn Foods, is a new platform featuring expert-led talks on sustainability, workforce development, operational efficiency and more. With tailored sessions and peer connections, it delivers insights to help commercial bakeries tackle today’s challenges and elevate performance.

RBA Retail Bakers Center, sponsored by Lesaffre, is a space that brings together decorated cake pros, retail bakery innovators and the biggest names in baking. Watch live demos that fuel your creativity and leave with fresh ideas to take back to the bench.

Be sure to watch the Coupe de Monde de la Boulangerie, Americas Selection, in which North American bakers, including Canadians, will compete in four categories: baguette and world breads, viennoiserie, artistic bread showpiece and savoury baking. Winners will represent the Americas at the World Cup of Baking global final in Paris.

For the first time, the show will have Chef Talks, sponsored by Mexipan featuring top baking voices from Mexico and Latin America. This speaker series

explores innovation, flavour trends and entrepreneurship. It will be presented in Spanish and open to all attendees on the show floor, with real-time translation in many languages.

In the Panettone World Cup, Americas Selection, top bakers across North America – including Eric Goeury of Viva Panettone in Montreal, who will defend his title as Canadian winner in 2022 – will compete for a chance to represent their country at the global finals in Milan.

The Creative Cake Decorating Competition, sponsored by Pillsbury, will see six teams of elite decorators go head to head to win glory for their baking business. This two-day showdown spans four categories: wedding cake, rolled fondant, sculpted cake and buttercream. Enjoy a front-row view along with celebrity and master baker judges and live commentary.

Bakers Journal will attend the conference and trade show, and the BAC will have a booth at the show. IBIE is scheduled for Sept. 14-17 at the Las Vegas Convention Center. For more information and to register, visit bakingexpo.com.

B.C.’s Vibrant Health Products to open first U.S. manufacturing location in

Tennessee

Tennessee governor Bill Lee and officials announced July 25 Vibrant Health Products Inc., headquartered in Abbotsford, B.C., will expand by opening its first U.S. manufacturing operations in Rossville, Tenn.

Vibrant Health Products will create 394 new jobs and invest $48.5 million over the next five years in Fayette County in the former Kellogg’s Eggo facility, which closed in 2024, the municipality said in

a news release. The company will begin operations with bread production for its U.S. customers with plans to expand its manufacturing capacity for additional products as the project progresses.

Founded in 1989, Vibrant Health Products produces sprouted and certified organic, gluten-free, grain-free, plant-based, paleo and keto baked goods for its own brands and for private label.

Canadian Food Innovation Network funds food-tech projects

The Canadian Food Innovation Network (CFIN) is awarding $1.2 million to 13 food technology projects through its Innovation Booster Program. CFIN’s industry partners will match these funds, resulting in a total investment of $2.4 million.

The following companies received Innovation Booster funding:

• Ag-Tronic Control Systems – Developing compostable, trade-compliant produce stickers to replace plastic labels in global markets.

• DeepSight Réalité Augmentée – Creating a real-time 3D scanning tool to support remote troubleshooting in industrial food settings.

• Food Cycle Science – Enhancing its commercial food waste recycling units with IoT-enabled sensors for real-time tracking and reporting.

• Genuine Taste – Scaling cultivated fat production to improve flavour and texture in plant-based foods.

• Lite-1 – Producing 100% bio-based pigments through microbial fermentation as a sustainable alternative to synthetic dyes.

• Lovingly Made Ingredients – Improving processing methods for Canadian-grown pea and faba proteins to boost performance in plant-based products.

• Miraterra Technologies Corporation –Designing a compact, fluorescence-free Raman spectroscopy probe for real-time food quality testing.

• New Protein International – Scaling a Canadian-made, hexane-free soy protein isolate for use in infant formula, bars, and other foods.

• Predhomme Strategic Marketing – Developing an AI-powered compliance tool to streamline interprovincial beverage alcohol label approvals.

• PULR Technologies – Advancing an AI platform that uses biopeptide colourants to predict food freshness and reduce waste in retail.

• Régéthermic Canada – Building an AI system to automate food placement in hospital kitchens, improving speed, accuracy, and ergonomics.

• Stocky AI – Creating an AI-based platform to automate agri-food procurement and sales workflows for SMEs.

• Sustainable Bioproduct Innovations –Scaling production of Zr0Fat, a plant-based fat replacer for baked goods, spreads, soups and meat alternatives.

“These 13 innovative projects directly address key food industry challenges like volatile input costs, labour shortages, food waste, and rising demand for healthy, clean-label ingredients. CFIN is proud to support the creative and ambitious companies doing transformative work that will fuel productivity, drive economic growth, and contribute to a more resilient, sustainable, and competitive Canadian food economy,” said Dana McCauley, CEO, CFIN.

CFIN’s Innovation Booster provides funding and support to SMEs to help them accelerate product development, overcome innovation hurdles, and validate market fit. During this 12th round of funding, CFIN received 66 applications from across the country.

“Tthese thirteen projects show that Canadian innovators are at the forefront of the industry, and helping the sector thrive,” said Heath MacDonald, agriculture minister.

DRIVEN BY PURPOSE

Bakers are a passionate bunch. Combining that passion with your everyday work, for many, is a dream come true. What if you could further build your values – a deeper purpose –into your business?

We spoke with bakeries and social enterprises that are living their values.

Joy Bakery Café in Simcoe, Ont., has made sustainability a non-negotiable tenet of its operation. Joy Allgood, co-owner with sister Judith Holditch, sees a lot of value in weaving her desire for zero-waste sustainability into the nine-year-old business that serves a bevy of bespoke beverages, unique cookies, bars, muffins, scones, catered cakes and focaccia sandwiches from a peaceful space that features natural décor.

Positions as national sales manager for Brita and Burt’s Bees sparked Allgood’s interest in advocating for environmental responsibility, especially eliminating or drastically reducing the use of plastic in packaging, smallware and other aspects of operation. It’s a complicated proposition and depends on your local standards, Allgood says. Early on, she checked with her recycling authority to make sure what the team are putting in the boxes is actually what the authority accepts and what will actually be recycled. She learned that, in her municipality, fast food packaging is not recyclable. "Certified compostable and reusable is the best we can do right now when it comes to packaging,.” she says.

}“The businesses or brands we interact with can become a reflection of who we are. There’s never been a better time to show your values.” –Melanie Côté, Do Good Donuts

she says, adding that Holditch now spends hours each week sourcing sustainable products and packaging.

They have never sold plastic water bottles and their bamboo reusable trays with “Please return” written on the back help offset their carbon footprint.

Their environmental commitment is not mere lip service. On their days off, for example, they plant 600 trees per year on participating local farms and properties. Allgood has educated herself and her team and shares that knowledge freely. They have helped extend local woodlands, and, in one of several projects, arranged for local church camp to work with Alternative Land Use Services, or ALUS, which paid for 4,000 trees. The Joy team paid for and helped plant 600 trees as part of the initiative.

“Milk bags are the hardest to reduce,” she says. “We use about 200 a week. We wash them as per the instructions and we recycle them.”

Compostable cups are expensive, more so since tariffs were announced and their regular distribution chain was disrupted. “The 50-cent cup became an 80-cent cup,”

Prioritizing local ingredients is their biggest focus. They work with more than a dozen local farms and producers in Norfolk County, a farming community known as “Ontario’s Garden.” By prioritizing local produce and products, supporting community events and making local residents feels welcome, Allgood says, you are supporting your neighbours, and encouraging them to stay close, use less gas and in turn support your business.

They focus on and support a different cause every year. This year they raised money toward the Long Point Biosphere turtle hatchery program, which collects eggs and relocates turtle hatchlings safely. They created themed cupcakes and taught classes about the process to local children during their “Environmental March.”

Walking the talk helps with marketability. “The concept and practices are 100 per cent marketable,” Allgood says without hesitation, citing social media ads shot at

local farms as one example. Her marketing background has helped the café draw new customers and convert them to loyal fans. They’re already planning their 10th anniversary post. “We need to show the activities of a full season,” she says.

“Staying focused on your business and not getting pulled aside is important –staying on your path,” Allgood advises bakeries starting out. It’s important to avoid what she calls the Walmart effect of trying to be all things to all people. “If there is something important to you in life, it has to be important in your business. We made local food our focus.”

“Everyone on our team is in the mindset now,” she says proudly.

DO GOOD DONUTS

Do Good Donuts is a non-profit social enterprise that aims to stretch the boundaries of what people with intellectual and developmental disabilities can do, provide workers with meaningful work, confidence and a sense of purpose and challenge other people’s perceptions in the process.

In 2021, Melanie Côté founded the enterprise, which bakes at a community kitchen, caters corporate and community events and sells doughnuts, cookies, cinnamon buns and other goods at Toronto’s Leslieville market.

The idea formed a few years ago, after she and her husband learned their five-month-old daughter, Alma, was born with a rare genetic syndrome. Doctors told them parenting this child would be different and advised adjusting expectations. “It was a lot of statements to make about a person who just born,” Côté said.

Côté hires and trains youth with developmental disabilities to build a world where everyone belongs at work. She has a college pastry diploma and employs a lead and a sous baker to ensure things run smoothly. At the time of writing, they have five trainee employees living with developmental disabilities working on prep and front-of-house duties.

“I thought there could be a way to give kids a ‘job before a job’ – so they could take a sideways move once they gained some skills and confidence and experience.” The goal was to make it easier for employers to say yes to hiring these young people and increase the chances of retaining their new hires.

Offering the kind of product people want

to buy, quite apart from their community appeal, is high on the list of Côté’s priorities. “It’s important for us to have an excellent product. For us to succeed as a social enterprise, the “profit” we make is invested back into the business,” she says.

On May 16, 2021, their first day, they sold all of their 100 doughnuts in 20 minutes. These sales, together with merchandise, earned $710. A few weeks later they added cookies. Now, they generally bring about 300 doughnuts on a Sunday, six kinds of cookies, cinnamon buns, scones, lemonade and can take in up to $1,500 on a sunny market day.

They also provide corporate catering and build connections in the community. The goal is to build a brick-and-mortar café and they plan to get there via food truck. They currently rent time in a shared community kitchen, but to grow, need access to production bakery equipment and unlimited access through the week. “A food truck will give us the ability to install a full-size commercial doughnut fryer and commercial oven. It will serve as both commissary kitchen where we can scale up production and mobile retail space,” she says.

“We hire young adults who self-identify as having a developmental disability or autistic youth, aged 18-28, who have a self-determined desire to work at a job in the community but need the opportunity to learn and practise work skills and gain confidence to be prepared to succeed at another job.”

Do Good Donuts hires trainees into three-month contracts at 15 hours a week, with the potential to extend the contract. “Trainees learn in a group setting and work

with staff or peers, with a focus on independent skill development. When hiring, the key things for me are emerging math and reading skills. We can adapt the way a recipe is presented to suit a trainee’s learning strengths, but in baking, you need to have some math and reading skills to be successful.”

To get started, they raised $17,000 through a GoFundMe campaign. Since then, they have received a $1,000 community grant from Meridian; then won first prize in the “Small business, big impact” award for Ontario and received other project grants. Their new food truck will funded by a donation from the Doane Grant Thornton Foundation. “We do get funding, but it’s hard to get investment or loans, so it has been challenging to scale up,” she says.

The skills trainees gain are transferable and can translate to independence. One of the people Do Good hired also works at the St. John’s (social enterprise) Bakery as a volunteer. Another works at a local school as part of the kitchen team, preparing the hot lunch program. “We didn’t find them the jobs. They went out and submitted resumés,” she says.

The goal is slow and steady growth with a committed customer base. Côté hopes to have the truck operating by the spring of 2026, and they are launching a long-planned e-commerce site to sell across Canada this fall.

“I think that, especially now, the line between businesses and the everyday customer is becoming blurred. The businesses or brands we interact with can become a reflection of who we are. There’s never been a better time to show your values.” / BJ

¦ concepts for success ¦

BY DIANE CHIASSON

EIGHT EASY IDEAS TO BRING FALL FLAVOURS TO YOUR BAKERY MENU

Creating a successful bakery menu requires careful planning and strategic thinking

Apple, pumpkin, plum, cinnamon, caramel, and maple pies and cakes are featured heavily during this peak produce season. Get your bakery ready for your customers’ fall favourites with a well-designed fall menu that makes it easier for them to choose, helps increase average order size and distinguishes you from the competition. Here are eight easy ideas to bring fall flavours to your bakery menu.

1. LIST YOUR FALL ITEMS

}Familiarize yourself with the fall produce available in your region. Streamline your items, then write out all the dishes you want on your menu, including breads, pies, cakes, pastries, cookies and beverages. A fall menu should be carefully curated to include ingredients at their peak freshness and availability. Showcase ingredients that are abundant, such as apples, pumpkins, cranberries, pears, sweet potatoes, grapes, chestnuts and figs. Use a spreadsheet, a Google Doc or pad of paper. Grouping similar menu items will help your customers find what they are looking for quickly.

3. USE APPEALING DESCRIPTIONS

Provide brief, enticing descriptions for each item, highlighting key ingredients and flavours. Proper menu descriptions are a key factor in your customers deciding what to order. Instead of just listing ingredients, describe the taste, texture and overall experience. Include words such as gooey, creamy, crispy, fresh, melty, zesty, home-style, hand-made crust, rich, warm, decadent or velvety.

4. EMPLOY MENU ENGINEERING

When customers are looking at a standard two- or three-fold menu, their eyes typically move in a triangular motion. They start in the middle of a page, then move to the top right, then to the top left. So, where you place your items on your

Well-designed menus aren’t just for guests: they also help staff take faster, more accurate orders.

menu matters greatly. Many customers notice when high-margin items are spotlighted at the top, centre and upper-right corner of your menu, and most particularly if these items are bolded, boxed or visually isolated. Consider highlighting your “signature,” “seasonal specials” or chef’s recommendation” using icons or coloured fonts.

5. FOCUS ON PRICING STRATEGIES

2. ORGANIZE INTO CATEGORIES

Don’t overwhelm your customers with choices. Make sure your menu is easy to read, clear, concise and visually appealing. Organize your sections into clear and easy-to-understand categories and group your food items accordingly. For example, categorize all your breads, pastries, cakes, cookies and drinks. The layout of your menu will impact what guests order. Always highlight and place high-profit items, such as drinks, desserts, and add-ons, in prime locations where eyes naturally focus first.

Stick to a consistent and reasonable pricing strategy. Developing your pricing structure will undoubtedly take the bulk of your time. Pricing isn’t just about profit: it’s about psychology. Guests will always compare prices before making a purchase. Think of offering small, medium and large sizes, and bundle your items into meal deals. First, identify your food cost percentage. This is the percentage of a menu item’s price allocated to purchasing and preparing it. The average food cost percentage rate is anywhere from 28 to 35 per cent. Always place premium items near high-margin products for contrast.

6.

INFLUENCE WITH VISUALS

Adding photos to your menu can increase sales by up to 65 per cent. Experiment with the best angle and maintain a consistent style. Use natural lighting and avoid flash. Food stylists employ various techniques to make baked goods appear appetizing in photographs. They use fresh, high-quality ingredients to achieve a natural look, add textures such as sprinkling spices, sugar or salt, and often apply a glycerin-water mix to create droplets and enhance visual appeal. Including garnishes like fresh berries, toasted nuts and coconuts, chocolate shavings or seasonal candies in your menu will add visual interest and boost customer engagement and sales.

7. USE SOCIAL MEDIA TO PROMOTE

Use social media to showcase your new menu. Post high-quality photos of your new menu, showcasing your special and signature bakery items, and share customer stories. Create interesting content and engage with your audience. Ask guests to tag you in their social posts.

8. TRAIN STAFF TO SELL, UPSELL

Once your menu is ready, it’s time to promote it. Well-designed menus aren’t just for guests: they also help staff take faster, more accurate orders. Make sure your staff is thoroughly familiar with your menu and give them the opportunity to sample all menu items so they can make informed recommendations to undecided customers. Your staff should also be able to answer any questions a customer might have about the menu. / BJ

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping foodservice, hospitality and retail operators increase sales for over 35 years by providing innovative and revenue-increasing food service and retail merchandising programs, interior design, branding, menu engineering, marketing and promotional campaigns. Contact her at 416-926-1338, or send her an email at chiasson@chiassonconsultlants.com, or visit www.chiassonconsultants.com.

EMBRACING HERITAGE AND ANCIENT GRAINS

As professional bakers, you know your flours. How much thought do you give to the farmers, fields and mills that produce them?

Farmer-Miller-Baker Summit Edmonton, hosted by the Baking Association of Canada June 17 at the Northern Alberta Institute of Technology, provided a rare chance for professionals who are different links in the supply chain to bake, learn and get to know one another by sharing their unique but compatible perspectives.

The scent of freshly baked bread and the sight of a table laden with eye-catching and innovative strawberry-striped and cream-filled croissants, potato-flour cinnamon rolls and other delights greeted the highly motivated group of farmers, millers, bakers and baking students.

}Alan Dumonceaux, baker of the morning’s delicious pastries, led a comprehensive hands-on demonstration that taught participants about flavours developed from preferments, including pain meunier, which translates to bread for the miller; whole-grain pizza dough; whole-grain sourdough; and sprouted grain.

Dr. Michael Gänzle concluded we are getting to the ideal of clean-label slowly, but the products likely will look and taste different from the standard sliced pan bread.

bakery’s customers are looking for.

This seemed to be the biggest takeaway for several participants – that even a small amount of preferment can add a lot of flavour and nutrition to any dough.

Bakers labelled their doughs and Dumonceaux called up each person to score their doughs and watch as they went into a large Bongard oven with a hand-cranked system that lowered and raised the platform of bread doughs to align with each of its multiple decks.

Dumonceaux, academic chair of both the baking and pastry arts program at NAIT and the BAC’s education committee – not to mention a coach and World Skills Expert in sourdough for Skills Canada –prepared four types of yeasted preferments (biga, sponge, poolish and prefermented dough) and two non-yeasted preferments (stiff levain and liquid levain). Over two-and-a-half hours, he taught participants about the characteristics of the different preferments and how to incorporate them into their baking to add the flavour and nutrition many of your

Dumonceaux invited participants to touch the preferments and then set to work folding, stretching and shaping a variety of doughs, including pain meunier, which incorporates all parts of the wheat kernel, including the bran, germ, and endosperm, into the dough.

Experienced bakers worked alongside the less experienced, providing advice, encouragement and having a few laughs along the way. “Elbows out,” Dumonceaux advised as the diverse baking class folded their doughs, which were made using freshly milled flour provided by Gold Forest Grains and Midmore Farms.

Some of that dough Dumonceaux transported to the culinary department’s kitchen, like the Pied Piper leading the bakers on a 10-minute walk. In the kitchen, bakers took turns stretching and topping their pizzas then watching them bake in the high-temperature dome oven as the instructor monitored, turned and pulled them out using a long pizza paddle.

IDENTIFYING CONSUMER TRENDS

Reid McEachran, associate marketing director at Ardent Mills, discussed three of five broad trends driving customer purchases as laid out in the flour company’s Trend to Table report.

McEachran said many consumers are eager to explore new cultures through

flavours and formats. We see this trend in fusion food and different ethnic cuisines. Expanding your menu is an opportunity to reach those customers, he said. “If you’re not offering diverse options on your menu, you may be missing out.”

The report identified the trend of not removing ingredients but adding value to your products, referred to as “adding with intent.” This might mean adding ingredients to improve gut health or to meet a GLP-1 diet and sprouted powder is an example of this trend.

“Desire to do good” is about environmental social governance, or ESG, and encompasses organic and regenerative farming. A lot of people are starting to pay attention to the sustainability of businesses they support, McEachran said. Businesses such as bakeries and suppliers can help customers understand sustainability terms such as CO2 equivalence and what they mean, thereby helping them decide where to spend their dollars.

U OF ALBERTA RESEARCH

Dr. Michael Gänzle, professor and Canada Research Chair in food microbiology and

probiotics at the University of Alberta, explored a question of great interest to bakeries of all sizes regarding sourdough fermentation and bread quality: Can we produce clean-label bread?

Dr. Gänzle said the term “sourdough” means different things to different people. “Today, we are concerned with producing a great loaf of sourdough that has a reasonable shelf life,” he explained, noting that manufacturers need about a threeweek shelf life when shipping across Canada. The food scientist’s presentation emphasized that over the centuries, sourdough has been used for leavening, acidification and, in today’s knowledge economy, to help with cost reduction, bread quality and product diversification.

Dr. Gänzle concluded we are getting to the ideal of clean-label slowly, but the products likely will look and taste different from the standard sliced pan bread. He and his team’s highly interesting research will be published soon through the U of Alberta.

PANEL TALK

BAC executive director and longtime

professional baker Martin Barnett moderated the panel of six:

Ward Middleton, proprietor of Midmore Farms with his wife, Jo-Anne, grows certified organic grain, oilseeds, forage and sea buckthorn.

Cindy Kozak and son Garreth have been operating Gold Forest Grains, a small farm 10 minutes north of St. Albert, growing ancient and heritage grains and milling fresh flour using a stone mill. They’ve been selling out of Strathcona farmers market for 15 years. They sell directly to consumers as much as possible and also supplement their supply with grain from other organic farmers.

Wendy Neudorf and her two daughters mill fresh flours for individual orders at Fallen Timber Creek Flour Mill, a farm that has been certified organic for more than 20 years. “We mill using a stone mill and we also do baking and sell baked items.

Kevin Pettersen, owner of Black Flox Flour in Prince George, B.C., flew in for the Summit and was excited to share his perspective. “I took it as a challenge: how do you remove that whole shelf-life concept and get the freshest milled flour

into the hands of consumers? I believe freshly milled flour is what flour should be.” He mills hard red spring, the durum wheat, ryes and also the ancient and heritage grains. They are all organically grown and in the hands of consumers the day after or a few days after they’re milled.

Austin Hohn of ADM Milling is a baker by trade who has worked for major companies like Puratos and BakeMark in technical and sales roles before joining ADM Milling.

Christian Redois hails from France originally, has travelled widely in Europe, Australia and New Zealand, and has been in Canada for 15 years where he operates his bakery-café, EpiCanmore.

Kozak, Pettersen, Neudorf and Redois have stone mills. Kozak chose stone because it mills at a lower temperature, which is supposed to preserve nutrients. “We like the texture it provides as well."

Neudorf did a lot of research on celiac disease, flour and mills, and discovered, to her surprise, that some of her customers who are extremely sensitive to wheat could eat bread made with her stoneground flour. She said, “It’s so exciting to have somebody say, ‘I have my life back.’ ”

Pettersen said he fell in love with his stone mill made in Austria. It has a sifter to extract the courser parts of the bran to help gluten form better, he said, adding that the courser parts of the bran don’t cut the strands of gluten.

DIVERSE CHALLENGES

What have been the biggest changes in Canadian cereals development over the

last 10-15 years?

Middleton talked about changes in seed regulation over the years that impact farmers. He said seed development used to be within the purview of the government, but seed regulation has changed. Governments have made it easier for private companies to take over the development of new varieties of seed. “Unfortunately, with that come royalties and changes in regulations where farmers are not necessarily allowed to retain their own seed if it is of a variety owned by a private company,” he said. “Even if you buy the seed and grow the crop, you are not allowed to keep that seed and replant it unless you pay a royalty. That’s just the environment that we’re in. For our farm, we have found that organic farming has exposed us to a farm-direct market where people prefer to have older varieties anyway. We have found it’s easier to grow some of the older varieties that keep us free of some of the royalties and some of that larger corporate involvement in the ownership of seed.”

Baker Redois shared his perspective on challenges of baking with fresh-milled and heritage grains. “For me, Canadians are used to a white loaf of some sort. One of the challenges is to introduce whole-grain to customers who are used to white bread. I don’t do 100 per cent whole-grain breads. I try to go 50-50. For an einkorn or khorasan loaf, for example, I use 50 per cent wheat and 50 per cent of an ancient grain or heritage grain.”

“In the bakery, it’s challenging in terms of fermentation control. Fresh-milled

grain, in general, ferments a bit faster, the hydration might differ, there are a few challenges. In terms of cost, as a business, it takes extra time for me and my staff . . . even though the mill does its job by itself, you still have to fill the hopper and monitor it, so it takes a bit of extra time on top of our business schedule”

Kevin Pettersen weighed in on the challenges of growing and milling on a small scale. “You don’t know how niche you are until you dip your toe in the water,” Pettersen said. He didn’t expect there to be a large local market in his community of some 80,000, so his first priority was to make sure the flours were accessible across Canada. This meant figuring out the market, shipping, logistics and ecommerce. “It’s a very different customer than is looking for supermarket flour,” he said.

Pettersen said his customers are interested in the grains for a variety of reasons, including health requirements like diets tailored for diabetes or an auto-immune deficiency. “It’s transformational for their lives,” he said.

Neudorf’s biggest challenge is educating customers. “People say, ‘It tastes so good, I wish it was healthy.’ It blew me away how people don’t think bread is healthy. We’re getting more and more educated. In the city, it seems people who come to markets have educated themselves prior to coming. In the country markets, people still don’t always know what organic flour is.”

Kozack and son Garreth sell at Strathcona market. She finds educating customers a challenge sometimes too. “It’s apples to oranges, as far as I’m concerned,” she said. “There’s taste, nutrition, all those things, so we have conversations about that.”

CONSUMER TRENDS

How are consumer trends driving the changes in cereal crops both in growing, processing and in food manufacturing?

Hohn of ADM Milling said, “We’re experiencing today on a small scale interest in artisan, organic and heritage grains. Working in the large-scale side of things, we see clean-label being a big trend. . . . In the end, people always want consistency when going clean-label.”

Following the panel, Farmer-MillerBaker participants left with their own handmade bread. / BJ

Sunflower kernels are:

available raw or roasted

an excellent alternative to nuts

mild in flavour and add a pleasant crunch to food

a good source of fibre, Vitamin E, zinc and folate

ideal for a variety of foods including: bakery products, granola, snack bars, salad toppings and plant-based foods

THE BAKING ASSOCIATION OF CANADA NEWSLETTER SEPT 2025

Technical Report

A DISCUSSION OF AUTOLYSE VERSUS FAST INDUSTRIAL MIXING IN YEAST PRODUCTION

I usually leave the technical writing to others with more expertise, but I was intrigued by a discussion started recently on the Bread Bakers Guild of America forum.

The question was posed: Does oxygen have any materially negative effects on bread dough beyond its bleaching action? Benzoyl peroxide is known to bleach flour without impacting dough performance, while chlorine alters flour properties – it’s beneficial for cakes but detrimental to bread. This relates to the purpose of autolyse, often seen as a way to shorten mixing time and limit oxygen incorporation. Traditionally, oxygen is thought to degrade flavour by bleaching carotenoids, but the question remains: is its impact merely cosmetic, or does it truly affect dough strength and taste?

There were two responses: the first, technical. Here is a synopsis.

Oxygen incorporation during dough mixing influences both flavour and gluten structure. It bleaches carotenoids like lutein, reducing aroma precursors and leading to a blander crumb. Raymond Calvel’s work emphasized this loss of flavor due to intensive mixing. Simultaneously, oxygen promotes disulfide bond formation

in glutenin proteins, increasing elasticity. This is beneficial in moderation but harmful when overdone, reducing dough extensibility and oven spring. Unlike benzoyl peroxide and chlorine gas, oxygen actively engages enzymatic and protein oxidation pathways. Autolyse counters these effects by minimizing mechanical input and oxygen exposure, preserving flavour and dough integrity. Thus, oxygen’s role is pivotal, with both positive and negative implications for bread quality.

The second response was penned by our colleague and mentor Jeffrey Hamelman and left in the first person for context:

“I don’t pretend to understand the science behind this question – my comments come strictly from personal experience. Back when I was first learning, I was taught that high-speed mixing incorporated excess oxygen, bleaching the ‘good guys’ –carotenoid pigments that lend crumb its yellow hue and signal intact flavour.

“My first baking job was in Massachusetts in 1976. The bread baker was from Grenoble, the pastry chef from Paris, and the German owner always closed the shop for August so they could each have a proper vacation in France. She had it arranged so I’d fill in wherever needed: pastry when Marcel was away, bread when Michel took his leave. I wasn’t exactly qualified for either role, but I learned by doing – fast.

“Michel taught me his way, which was

classic pétrissage intensifiée. No scaling the flour, water, or yeast – just dump in a full 100 lb bag, then a portion of another, throw in broken blocks of yeast, fill buckets with water by eye, and let the oblique mixer run. Only the salt was weighed. First speed was 40 rpm, second speed was 80 – and once the dough came together, it was a full 20 minutes on 2nd at 1600 rpm. (I’m willing to submit to a polygraph if you doubt my honesty.) The dough came out white, shiny, and warm. Bulk fermentation lasted no more than 30 minutes. Those baguettes had impressive volume, but they lacked soul. Back then, they passed as ‘good’ because we had no point of comparison, but looking back, they had structure and no flavor.

“Fast forward several decades: one of my favorite classes to teach was ‘Baguettes Six Ways.’ It gave students the chance to mix, shape, score, and bake different styles –and taste them side by side. The intensifée baguette consistently stood out for its weakness: pale, bland, and over-aerated. No question, it had been oxygenized to death. At the top for flavor and texture? Pointage en bac and, unexpectedly, the six-fold unkneaded baguette– impractical in a production bakery, but enlightening in the classroom.

“I may not have lab results to prove these observations, but years of mixing dough have taught me this: flavor lives in restraint, not in horsepower. And bread, like memory, carries its lessons in the crumb.”.

THE BREAD BAKERS GUILD OF AMERICA

Did you know that BAC membership comes with a complimentary membership to the BBGA? Also, BBGA members have access to BAC benefits.

WHAT IS AUTOLYSE?

Autolyse is a bread-making technique in which flour and water are mixed together and allowed to rest before adding other ingredients like salt or yeast. This simple pause unlocks a world of magic in your dough.

JEFFREY HAMELMAN

Jeffrey Hamelman’s Bread: A Baker’s Book of Techniques and Recipes is a revered guide that melds artisanal passion with professional expertise. Drawing on Hamelman’s extensive experience as a Certified Master Baker, the book offers over 100 detailed recipes – from rustic sourdoughs and hearty ryes to enriched brioche and artful decorative loaves – while teaching foundational techniques like fermentation, kneading and shaping. Enhanced with practical charts and visuals, it caters to both home enthusiasts and professional bakers. Throughout, Hamelman’s thoughtful reflections infuse the text with warmth and reverence for the craft, making it as much a philosophical meditation on bread as a technical manual.

RAYMOND CALVEL’S INFLUENCE

Raymond Calvel, a French bread expert, showed that intense mixing harms dough flavour by oxidizing carotenoids like lutein. In The Taste of Bread, he advocated gentle techniques like autolyse to preserve aroma and balance dough strength. His ideas led to widespread adoption of slow, lowoxidation methods.

Notes from the Executive Director

I would like to acknowledge Alan Cohn for posting the original discussion starter, Pepe Fields for the technical comments and Jeffrey for his personal observations.

My own baking experience, also dating back to the 1970s, mirrors Jeffrey’s in many ways and I shall share those in a future update. If any of our readers would also like to share their own technical evolution over the decades, please send in your submissions; the best will be published in a future issue.

BAC LAUNCHES CANADIAN BAKERY EXECUTIVES COUNCIL TO LEAD INDUSTRY STRATEGY AND ADVOCACY

The Baking Association of Canada has announced the formation of the Canadian Bakery Executives Council, a dynamic national advisory body composed of Canada’s most respected leaders from SMEs, commercial bakery, pastry and confectionery manufacturing sectors.

The Council has been established by the BAC to address critical gaps in industry intelligence, provide strategic guidance and sharpen the association’s focus through a non-competitive, collaborative forum. It will serve as a unified voice for the sector at the highest levels of policy and government, while fostering growth, influence and innovation both nationwide and globally.

BAC also announced the election of Carmelo De Luca, president of Premium Brands Bakery Group, as the council’s inaugural chair,

bringing decades of leadership, vision and expertise to this important role. Council mandates include the following:

• Strategic intelligence sharing: Creating a collaborative space for sharing best practices, sector challenges and data to build industry credibility and drive growth.

• Sector alignment and advisement: Identifying and aligning common priorities, standards and issues that affect the bakery sector.

• Policy and advocacy direction: Shaping policy engagement strategies to ensure the sector’s voice is consistently represented.

• National presence and representation: Strengthening the industry’s visibility and influence at regional, national and international levels.

• Independent governance: Constituted as an independent advisory body with elected leadership, facilitated by BAC.

This council marks a major milestone in the evolution of Canada’s bakery industry – a leap toward greater influence, sector unity and strategic growth.

“I’m deeply honoured to serve as Chair of the Canadian Bakery Executives Council,” De Luca said in a news release from the BAC.

“Our sector needs a unified voice – not only to drive innovation and excellence within our businesses, but to ensure we’re heard at the highest levels of government. This council is about bridging that gap: shaping smart policy, advocating for practical regulations, and building relationships with decision-makers that will define the future of baking in Canada.”

Martin Barnett, Executive Director Baking Association of Canada mbarnett@baking.ca

COLLEEN CROSS

BIG IDEAS FROM GERMANY

Bakers Journal, attended the IBA baking show in May where an abundance of big ideas were presented

Over five days, 985 exhibitors from 46 countries showcased their wide range of products attracting nearly 50,000 visitors from 149 countries to Duesseldorf.

PLANT-BASED OPPORTUNITIES FOR BAKERY

Thomas Kunte, head of research and development for Ireks, delivered an interesting talk on plant-based ingredients and products. Kunte proposed grain as the ideal foundation for creative, plant-based snack baked goods and dishes that add variety, while discussing exciting raw materials such as buckwheat or green spelt that can be processed sustainably and reliably.

In “What does the future taste like?” Kunte said five per cent of Europeans identifying as vegetarian, three per cent as vegan and a whopping 27 per cent as flexitarian. Kunte said the flexitarian customer represents a significant opportunity for bakeries and food service. In Germany that number is higher, represents about 40 per cent of the population. Flexitarians don’t seek to ban meat products from their diet but to maintain a healthier lifestyle. There are the usual two options that appeal to different customers: mimicking existing meat products or developing plant-based alternative products.

}Kunte said the vegan market has grown by 18 per cent over the last 10 years. He acknowledged the challenge of delivering suitable baked products, which, in part, relates to the multiple ingredients and elements involved in the baking process. Kunte said the word “vegan” is sometimes viewed as synonymous with healthy eating. Grains and cereals are a good

Repeatloaf was exhibiting its automated high-precision fermentor that processes waste or returned bread within 24 hours

solution, he said, because they provide significant protein, minerals, and vitamins, and are natural. The food scientist encouraged bakers to use wholemeal as it can make EFSA-backed claims. Examples you can use for plant-based products include green spelt,

which is dried over beechwood and has a smoky flavour. “It’s an interesting raw material and a big crop in Germany,” he said, reminding the audience that it has no gluten to bind ingredients and, therefore, may best be used as a sourdough starter, preferment or as groats with their crunchy texture.

The second example is oats, which have grown in popularity by 130 per cent since 2008. With their nutty, mild flavour, they are well suited for use in a mild pre-

dough or sourdough.

Buckwheat is another great option, Kunte suggested. A late-flowering non-cereal, it is a long-flowering crop that doesn’t need much water, he said. “It has an intense flavour: you either love it or hate it.” The challenge is the many weeds and byproducts that grow alongside it.

With buckwheat you must first preferment it, Kunte advised. With its earthy flavour, the ingredient is well-suited to savoury recipes.

FOOD WASTE CONCERNS ADDRESSED

Repeatloaf was exhibiting its automated

high-precision fermentor that processes waste or returned bread within 24 hours. The fermentation process is influenced by time, movement, temperature, type and volume of incoming product, starter and moisture. The final product, a dry powder with three months’ shelf life, is released after a final sieving step.

The machine has 500-kilogram recycling capacity and can be scaled up. Representatives said there is future potential to scale the machine down for use by smaller bakeries, pizzerias or restaurants – or even by the public directly – but that’s not practical at the moment. There is also potential for shared use between small businesses someday.

NEW PRODUCTS

Thermo Future Box, made by Cambria, can keep foods at a constant temperature for six to eight hours. Reusable and hygienic, the boxes come in three sizes. A key feature is the non-slip surface, which ensures cakes won’t slide during transport.

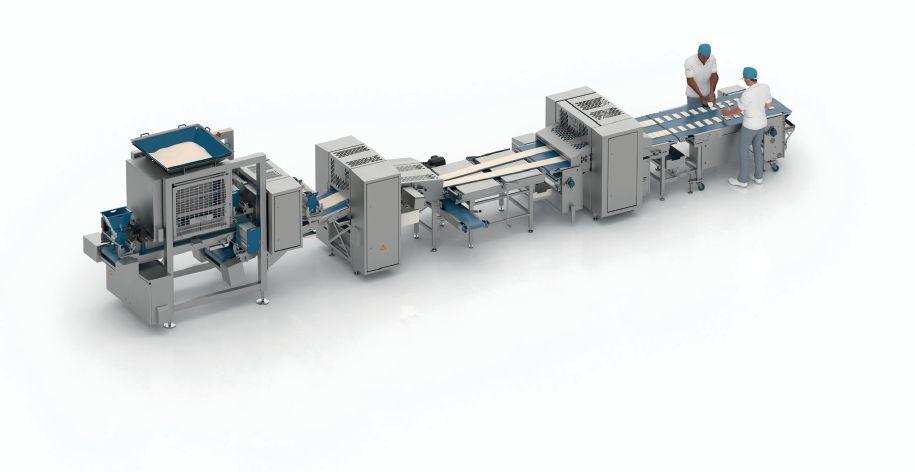

JAC Machines exhibited its Divimax container loading divider, which produces a maximum number of containers in

25_007032_Bakers_Journal_SEP_CN Mod: June 26, 2025 11:02 AM Print: 07/23/25 page 1 v2.5

a minimum of space, provides ergonomics on a physically demanding workstation, groups and folds up to seven dough pieces of 1,580 grams each directly onto the output conveyor., producing up to 327 containers per hour.

Bizerba’s self-serve bakery vending concept allows customers to serve themselves from a many-doored glass case while staff monitor quantity, keep the case looking full throughout the day and upsell by reducing prices as stock dwindles at the end of the day.

Dieter Waldner had Waldner wooden hand mills, commercial mills, flake presses and other products on display. The grain mills and combination mills are handcrafted exclusively from locally sourced solid pine wood and the mills can be adapted to the technical requirements of different countries.

Cashmaster representative Lisa-Marie Kujović showed us the company’s clever machine that counts your till by weight, making that task faster and easier for team members closing your pizzeria. It accommodates at least 25 currencies, including Canadian dollars. It will accept

up to 30 bills at a time, automatically scanning the bills and integrating into many POS systems.

Lukas Mueller of MHS demonstrated various models of bread-cutting machines, including a model that has a drawer underneath it, allowing busy staff – possibly running the bakery singlehandedly – to face customers while slicing. Mueller, the grandson of company founder Rudi Siller, also showed us a self-serve cutter that allows customers to have their loaves sliced and bagged safely and quickly.

Bizerba’s self-serve bakery vending concept also allows customers to serve themselves from a many-doored glass case while staff monitor quantity, keep the case looking full throughout the day and upsell by reducing prices as stock dwindles at the end of the day.

Via Delle Arti’s Velly and Matty Spray food colouring lines were on display in a rainbow of colours. Matty Spray gives a matte effect that is ideal for colouring any surface, a company rep told me. It’s available in dark and pastel colours and in alcohol-free versions. The company

has been manufacturing for 30 years, providing white-label products for other companies; a year ago it decided to sell directly to the market under its own brand.

COMPETITIVE CREATIVITY

Congratulations are in order for Corentin Molina and Yannis Thouys from France, the winners of The IBA UIBC Cup of Bakers. Teams from six countries competed for the gold medal over two days. Second place went to Johanna Lenhardt and Lea Wagner from Germany and third were Mike Onase and Gerrit Huckriede from the Netherlands.

Six nations competed against each other, represented by the best bakers from Germany, France, Iceland, Jordan, the Netherlands and Sweden. Within six hours, the teams of two had to produce bread, miniature products, party and Danish pastries as well as one baked showpiece.

On each competition day, the baked goods were rated and evaluated by international experts Urs Röthlin (Switzerland), Jimmy Griffin (Ireland)

and Josef Schrott (Austria) as well as jury chairman Andreas Schmidt (Germany). The evaluation of the fully edible showpiece masterpiece took place in the bakery before it was set up at the presentation table.

“To succeed in this competition, bakers have to perform outstandingly. Every move has to be perfect. Over the two days, the IBA audience could witness live how these talented bakers created true masterpieces under tension and time

pressure. This is artisan bakery at top notch level,” said jury chairman Schmidt.

INNOVATIVE STARTUP AWARDS

In the start-up lounge, young companies had two minutes each to present their innovative ideas, pitches were posted online where registered attendees could vote for their favourites. Fonte Ingredientes from Brazil received IBA’s start-up award for its Maximus SP30+ mould inhibitor, which helps keep baked goods fresh for longer with a liquid anti-mould product containing more than 80 per cent organic substance.

Czech company 369 Sonic presented the world’s first kitchen knife with ultrasonic technology in the handle. Snaggit from Aachen, Germany, presented an app for a rapid ordering process designed to eliminate waiting times and make the ordering process more efficient. Swiss company ProSeed demonstrated how, thanks to stabilization technology, brown barley byproducts can be used to generate barley flakes, which in turn can then be processed into flour or protein concentrate.

The next IBA will take place from Oct. 24- 28, 2027, in Munich. / BJ

Innovators Supporting Innovators.

KAREN BARR

SWEET THAI BITES

Thailand is rich with historic temples, gorgeous beaches and a tempting selection of exotic foods. Classic Thai desserts end many meals, but there is also a new array of sweets inspired by local ingredients.

Blue Elephant Cooking School and Restaurant in Phuket Town on the island of Phuket offers Thai cooking classes. On this day, Molly teaches the group how to make coconut milk soup with chicken and mushrooms, grilled aubergine eggplant salad with chicken and prawns, stir-fried prawns with

tamarind sauce and jungle curry with sea bass. For dessert, there are traditional taro dumplings in coconut milk.

“Has anyone tried taro before?” asks the chef, then continues, “It’s like a sweet potato, yet it’s creamier.”

To make the dumplings the taro is peeled, steamed and mashed. Glutinous rice flour, rice flour, arrowroot flour and coconut milk are combined to make the dough. The difference between rice flour and glutinous rice flour is that rice flour is made from long-grain rice, and glutinous rice is made from a combination of short-grain glutinous rices,

such as sticky rice.

“Keep the taro dumplings small,” cautions Chef Molly, pointing to the recipe that suggests each be rolled into a round measuring one centimetre. “Otherwise, the dumplings will be too chewy after cooking.” The taro balls are dropped into boiling water. “You’ll know they are ready when the taro balls float to the top.”

Once the taro dumplings are placed in ice water to stop the cooking process, it’s time to make the coconut milk sauce. The coconut milk is brought to a boil, and then the spiky green-coloured pandanus leaf, prized for its

fragrance, is added. Palm sugar and a touch of salt are also a part of the ingredient list. After the coconut milk sauce is simmered for five minutes, the pandanus leaf is removed and fresh coconut is added along with the cooked taro dumplings.

Phuket Town is as much an architectural gem as it is a feast of foods and night markets. The Portuguese arrived in Thailand, formerly known as The Kingdom of Siam, in the 16th century. The island of Phuket became a hub for trade for adventurers all over Asia and Europe.

Portuguese home builders employed Chinese workers to

craft residences in bright, coloured hues, with shuttered windows to keep out the scorching sun. Intricately patterned tiles, imported from China, make up facades and courtyards – many feature Chinese symbols of good luck and prosperity.

Visitors to Phuket will find small egg custard tarts served for breakfast throughout the island. At first bite, one may imagine these are the traditional Portuguese pastel de nada, given Portugal’s fascination with Thailand. This isn’t quite right.

}According to an article in the Bangkok Post, while the Portuguese-style tart is based on the original, credit goes to a British baker who opened Lord Stow’s bakery in Macau. The Macau egg custard tart is a hybrid version of a Portuguese and English egg custard tart. With more decadent, richer crust and heavier cream-based filling, eating just one is impossible!

Surin Beach, a town in Phuket’s quieter northeast area, caters to a European crowd used to contemporarystyle desserts. Across from the beach, Nalu Bar & Grill, part of Outrigger Hotel and Resorts, offers an open restaurant with a seaside surf

theme. Here, the ever-popular mango with sticky rice gets a plated dessert upgrade.

Presented on a raised box platform, sliced mango is set in a small decorative skillet under a blanket of coconut gel. Tiny edible blossoms add colour, while sunflower seeds give crunch. The rice is wrapped into a cylinder shape, first in a banana leaf, then wrapped in a corn husk and

cultivation in Thailand,” explains Yanisa Wiangnon, the hotel’s executive pastry chef. “We wanted to craft an experience that celebrates Thai chocolate’s unique flavours and exceptional craftsmanship while supporting the local community and its farmers. We felt it was important to show our region’s remarkable talent and raise awareness and apprecia-

To make the dumplings the taro is peeled, steamed and mashed. Glutinous rice flour, rice flour, arrowroot flour and coconut milk are combined to make the dough.

steamed. The sweetened coconut milk is presented separately in a small, lidded round dish.

At the Four Seasons Hotel in Chiang Mai, in mainland northern Thailand, the pastry team proudly uses Thai chocolate. Not very long ago, all chocolate had to be imported from overseas. The hotel created a special Chocolate Afternoon Tea. It’s available from November to January, the high tourist season in Chiang Mai, which coincides with the festive holidays.

“The inspiration behind the Chocolate Afternoon Tea draws from Chiang Mai’s rising reputation as a vibrant hub for fine-quality chocolate

tion for all Thailand offers.”

What is the pastry chef’s favourite dessert on the Chocolate Afternoon Tea menu? It’s a toss-up between the chocolate mousse with blackberry caviar and the strawberry rhubarb with chocolate. “The blackberry caviar is made using an ingenious spherification technique. When you bite into the dessert, these tiny pearls burst with the taste of fresh blackberries. The dessert is as visually captivating as it is indulgent.”

Next is the strawberry rhubarb white chocolate, a nod to a traditional English dessert. “It’s the perfect balance of sweetness and

tanginess. The key is to slow-cook the rhubarb to preserve its vibrant colour and flavour, before pairing it with the creamy decadence of white chocolate.”

Beyond the Chocolate Afternoon Tea, other desserts on the menu are inspired by local ingredients. The team works closely to incorporate as many local ingredients as possible for guests’ dining pleasure at the Four Seasons. “One standout creation is the Khao Mak or fermented rice cheesecake, a twist on a classic favourite, paired with tart raspberries and the warm fragrance of Thai-grown vanilla,” she says.

Other favourite ingredients include Som Gliang, a tangy sour orange from Lampang province, and Phulae, a sweet and juicy baby pineapple from Chiang Rai province.

Bakers and pastry chefs across Thailand still make traditional Thai desserts and Asian favourites. An everexpanding list of local ingredients has led to new sweet experiences. Each shares the story of Thailand’s culinary heritage. / BJ

Karen Barr is an Ottawa-based writer and licensed chef who travels the world to explore topics about food and culture.

RISING STRONG

Every year, some bakery workers in B.C. experience injuries that require time away from work. Last year, there were 420 claims allowed from bakery workers due to injury. Of these, 296 were time-loss claims, with a median time away from work of 25 days.

In a hands-on industry like baking, even short absences can affect daily operations. For workers, being off work may temporarily affect income or disrupt routines. For employers, it can lead to adjustments in staffing and workflow, along with potential costs.

That’s why a safe and timely return to work (RTW) isn’t just a good idea – it’s essential. When planned well, RTW supports recovery, maintains business continuity and benefits everyone involved. While each province has its own requirements, this B.C.-specific guidance offers a strong starting point for your bakery to review and update its RTW policies and best practices.

WHY RETURN TO WORK MATTERS

Retaining skilled and experienced workers reduces the need for recruitment and retraining.

}“It’s important for employers to understand that by supporting workers and providing them suitable work during their recovery, both employers and workers benefit,” says Elise Kobylanski, Client Service Manager, Return to Work Services at WorkSafeBC.

The return-to-work plan includes what the worker is physically able to do, job duties and hours of work.

UNDERSTANDING THE LEGAL OBLIGATIONS: THE DUTY TO COOPERATE AND DUTY TO MAINTAIN EMPLOYMENT

Employers benefit from retaining skilled and experienced workers, and it reduces the need for recruitment and retraining. Employers also help ease the burden on co-workers and strengthen relationships with staff by showing workers they are valued. In addition, maintaining productivity and minimizing workflow disruptions can help reduce overall costs, including WorkSafeBC premiums.

For workers, returning to work while recovering – when it is safe to do so – can support both physical recovery and mental well-being. It also prevents disruption of their income, employment benefits, social contacts, routines and job security.

On Jan. 1, 2024, changes to the Workers Compensation Act came into effect to support a coordinated, safe and successful return to work following an injury, including two key provisions:

1. The duty to cooperate

2. The duty to maintain employment

The duty to cooperate

The duty to cooperate requires employers and injured workers to work together, and with WorkSafeBC, to support a timely and safe return to work.

Workers and employers have mutual obligations under the duty to cooperate. Employers and workers are required to cooperate by contacting each other and maintaining communication, identifying suitable work for the worker, and

providing WorkSafeBC with information required to support return-to-work efforts.

The duty to maintain employment

The duty to maintain employment applies if the employer regularly employs 20 or more workers and has employed the injured worker for at least one year before the worker’s injury. If a worker is fit to return to their pre-injury work, the employer is required to offer either that pre-injury work or a comparable alternative.

If the worker cannot perform their pre-injury job, but is otherwise fit to work in another capacity, the employer is required to offer the first suitable work that becomes available.

The legislation also requires employers to make any changes necessary to the work or workplace to accommodate an injured worker, unless the changes create an undue hardship for the employer.

“Making safe, suitable, and sustainable work arrangements for people who were injured at work takes cooperation and collaboration,” Kobylanski says.

COLLABORATE EARLY

Providing meaningful work during recovery helps workers feel valued, boosts confidence, and keeps them connected to their workplace, colleagues and skills. This makes it easier to return to their regular duties, which benefits both workers and employers.

To meet legal obligations and ensure a smooth RTW process, employers should establish clear procedures, maintain regular communication with injured workers and identify duties that support recovery. Ideally, they should also pre-assess job tasks to better accommodate modifications when needed.