BY JAY KOBLUN

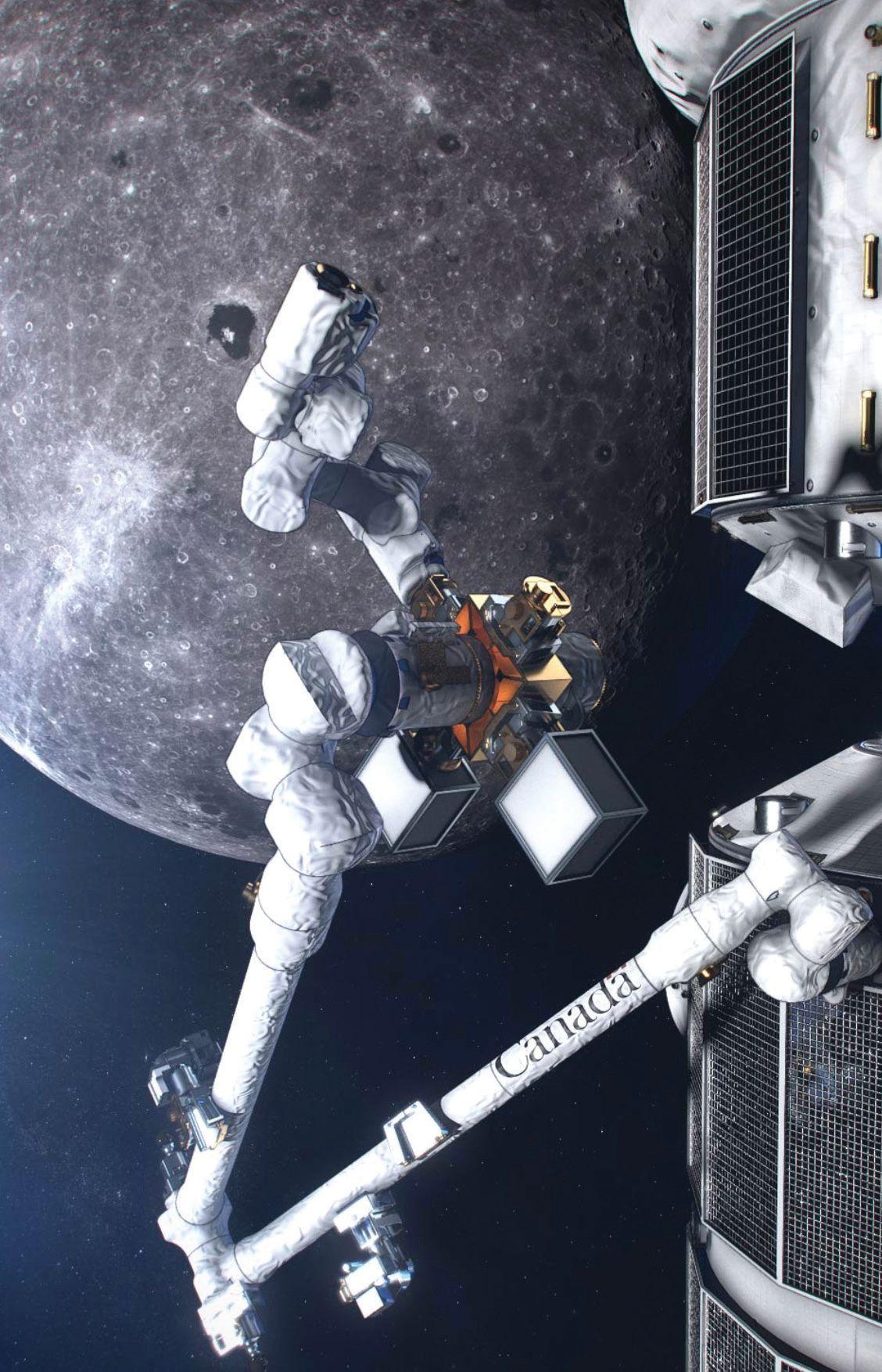

TThe Canadian Space Agency is taking another important step forward in space exploration by managing the development of Canadarm3, which in its most basic form— is possibly the smartest crane in the Milky Way.

“The original Canadarm and Canadarm2 are smart cranes. Canadarm3—you could call it a crane—but it is indeed much, much more. It is very smart, very artificially intelligent, and has the same function as the human arm,” said Gilles Leclerc, director general space exploration at the Canadian Space Agency (CSA).

This smart robotic system is Canada’s contribution to the United States-led Lunar Gateway for the Artemis program, the next major international collaboration in human space exploration, which forms the cornerstone of Exploration, Imagination, Innovation: A New Space Strategy for Canada.

The development of Canadarm3 will extend and strengthen Canada’s well-established global leadership in space robotics. It will also help grow the economy, create jobs of tomorrow, and help young Canadians interested in pursuing studies and careers in STEM disciplines (science, technology, engineering and mathematics).

Canadarm3 will be composed of a next-generation smart robotic arm, a small dexterous arm and a set of specialized tools. Using advanced machine vision, cutting-edge software and advances in artificial intelligence, this highly autonomous system will be able to perform tasks without human intervention. Navdeep Bains, Minister of Innovation, Science and Industry, announced Canada intends to enter into a contract with MacDonald, Dettwiler and Associates Inc. (MDA), based in Brampton, Ont., to build Canadarm3.

Crane and Hoist Canada editor talked with Leclerc about the similarities and differences between Canadarm3 and a modern terrestrial crane, what’s new and interesting on Canadarm3, and what its overall function on the Gateway space structure will be. Check out page 14 and 15 for a Q&A, pictures, and more information.

Publications Mail Agreement #PM40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor – Jay Koblun

jkoblun@annexbusinessmedia.com • 519-410-0600

National Account Manager – Laura Goodwin lgoodwin@annexbusinessmedia.com • 289-928-8543

Media Designer – Mark Ryan

Regular Contributors

Saul Chernos, Doug Younger, Nelson Dewey, Matt Jones, Judy Mellott-Green Group Publisher – Todd Humber thumber@annexbusinessmedia.com

COO – Scott Jamieson sjamieson@annexbusinessmedia.com

Audience Development Manager / Subscriptions – Urszula Grzyb ugrzyb@annexbusinessmedia.com • Tel: 416-510-5180 Fax: 416-510-6875 or 416-442-2191 • www.craneandhoistcanada.com

Annex Privacy Officer – Privacy@annexbusinessmedia.com Tel: 800-668-2374

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher. A subscription to Crane & Hoist Canada (six issues) is $37 + Tax per year in Canada. For subscriptions in the USA the price is $37 USD. Send cheque or VISA/ Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO:

Crane & Hoist Canada. CIRCULATION DEPT.

111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1 ISSN 1923-788X

Next Advertising Deadline: Oct. 2, 2020

Don’t miss the opportunity to be part of this exciting new industry publication. For more information, or to reserve space in the next issue, call Laura Goodwin at our Advertising Department Tel: +1-289-928-8543 • lgoodwin@annexbusinessmedia.com

Next Editorial Deadline: Oct. 2, 2020 For writers’ guidelines and submission requirements get in touch with the editor, Jay Koblun, at +1-519-410-0600 Email: jkoblun@annexbusinessmedia.com

This has been a year for the record books no matter how much or how little you’ve been affected by COVID-19. I consider myself a pretty good writer, but I don’t think even I could have predicted how 2020 would pan out—and its only September.

I read an article online titled, “Why 2020 Sucks” and it’s easy to see why it may. Here’s a few of the reasons the author came up:

• Talks of WWIII in early 2020

• Kobe Bryant died

• Canada had the worst mass shooting in its modern history

• Beirut explosion

• Australian bushfires

• All music festivals and concerts were cancelled

• The Olympics were postponed

• Professional sports were cancelled

• Coronavirus

• And—Trump has been threatening to ban TikTok

It’s been quite the year and at this point no one really knows what to expect next. I guess one more thing to throw into the mix right now that may immediately affect the global crane industry is the ongoing investigation being conducted by the U.S. about crane imports.

BY JAY KOBLUN

The U.S. Secretary of Commerce Wilbur Ross announced the department will initiate an investigation into whether the quantities or circumstances of mobile crane imports into the U.S. threaten to impair the national security.

But that’s not to say things aren’t looking up for the Canadian economy and plans for renewal and growth in the wake of the pandemic. The Canadian government has been quick to inform and educate the public as it sets up new plans and protocols from the latest COVID-19 rules to things like construction updates and plans for new infrastructure.

For example, Canada and Ontario are investing in roads and bridges, connecting rural communities; there’s plans for tourism as travel becomes more available; and there’s been significant changes to the Canada Emergency Wage Subsidy (CEWS) since July (which is further explored on page 17). So things are happening. A lot of companies have been announcing increased revenue the last few months and despite working form home and some provinces implement mandatory masks in public, the country is hopeful.

This issue isn’t full of bad news for the industry and only negative talk on “what could possibly come next,” we’ve got some great content in this issue. Take a look inside, I can promise you Crane and Hoist Canada won’t be on the list of what contributed to 2020 sucking.

The crane, rigging, and specialized transportation industry relies on people with technical skills, but faces a shortage of qualified workers. In order to promote the career opportunities in this fast-paced, high-tech sector, Lift & Move USA connects students and educators with the people, equipment, and companies that work in crane, rigging, and specialized transportation operations.

A new website, launched in May 2020, now showcases the careers, industries, and types of work related to this specialty field. Additional resources available on the site include information on where to get training, certifications that are needed, and scholarships. Industry professionals can also find ideas for engaging with students, parents, and educators in your local area, best practices for planning in-person events, and an archive of relevant research and toolkits related to workforce development.

“Lift & Move USA supports workforce development efforts that are aligned with construction, equipment, manufacturing, and related fields,” said Tracy Bennett, director. “We seek to join forces with other like-minded organizations in promoting the skilled trades and careers that serve crane, rigging, and specialized transportation operations.”

With the massive economic impact of COVID-19, the need for full food banks is more important than ever and asset management and disposition company Ritchie Bros. has stepped up to help.

Over the past several weeks, Ritchie Bros. has made $187,500 in donations to 52 different food banks around the world, including organizations in the U.S., Canada, Australia, India, Japan, Spain, Germany, Italy, France, the Netherlands, and the United Kingdom.

“Right now, there are tens of millions of men and women out of work, worried about how they are going to continue putting food on the table for themselves and their families—we are just trying to do our small part to help,” said Ann Fandozzi, Ritchie Bros CEO. “We hope our donations will inspire our employees and customers to give back to their community—with their time and/or their money. Please join us in supporting food banks around the world.”

One of the company’s larger donations was a $25,000 grant made to the Greater Vancouver Food Bank in British Columbia, Canada, where Ritchie Bros.’ head office and several hundred of its employees call home.

“We are incredibly grateful to Ritchie Bros. for gifting $25,000 to the Greater Vancouver Foodbank during the current COVID-19 crisis, meaning those in need can continue accessing healthy food,” said Elizabeth Charing, philanthropy officer for the Greater Vancouver Food Bank. “This wonderful donation, along with our strong buying power, means that your support could provide three months’ supply of rice to all our clients—that’s a huge amount! On behalf of all our clients, volunteers, and staff, thank you so much.”

The AED Foundation (AEDF) has developed a plan to stimulate growth in the industry and address the technician shortage, titled Vision 2024. Goals of this plan include:

• 100 Accredited College Programs • 500 Certified Managers

• 50 Recognized High School Programs • 10,000 Tests Administered

• 10,000 Skilled Technicians Entering the Workforce • 5,000 Certified Technicians

Vision 2024 is a call to action for high school students and established industry technicians alike to develop skills through AEDF recognized programs and certifications. With an increase in highly skilled employees entering the industry, equipment dealerships will be able to hire top applicants that require less training and add profitability and customer satisfaction to dealerships.

A $300,000 grant from The Caterpillar Foundation will aid in Vision 2024’s development as it will provide scholarships for students attending AEDF recognized high schools who are moving on to an AEDF accredited college.

“Vision 2024 is the AED Foundation’s commitment to solving the skills gap issue. We’re excited about the increased resources that we are receiving from our business partners to accelerate this goal,” said Jason Blake, executive vice president AEDF.

This will not only provide incentives for students to enter the program but also for high schools and colleges to become AEDF recognized or accredited.

The AED Foundation offers certification courses for roles throughout the dealership to help interested employees gain the skills they need to advance their careers. Employees can earn certifications in a matter of weeks, providing the opportunity for quick and efficient learning. Certifications provide employees with an opportunity for skill development as well as increase their industry knowledge, while dealers benefit from having a top qualified employee on their team. Both employees and dealers have the chance to be recognized by the Foundation for putting their time and efforts into a certification course.

Crane Industry Services (CIS) expanded its services to include certain programs of the National Commission for the Certification of Crane Operators (NCCCO).

As of April 2020, CIS is authorized to deliver re-certification and written exam testing for NCCCO Mobile Crane Operator, Tower Crane Operator, Overhead Crane Operator, Digger Derrick Operator, and Rigger Level 1 and Rigger Level 2.

“CIS is pleased to offer customers a choice of certification options, all of which are OSHA recognized and ANSI accredited, to meet OSHA crane operator certification requirements,” said Debbie Dickinson, CEO of CIS. “Certification is a national requirement that sets a base line for crane operators.

Qualification specific to machine types and work is also necessary. Crane operators should be certified by an accredited, OSHA recognized provider, and qualified. National certification is not required for riggers, but at a minimum, riggers and all members of the lift crew, must be qualified.”

Recertification is required every five years. NCCCO recertification candidates may take their recertification written exams up to one year prior to the certification’s expiration. “CIS will also offer NCCCO practical exams in the near future.” said Noel Whelchel, trainer and inspector.

Manitex has made two improvements to its CD4430R, a 30-U.S.-ton capacity cab-down rough terrain crane designed to meet the needs of the rail industry.

Manitex has updated the CD4430R with a Cummins B6.7 Liter 325-hp Tier 4/Stage V diesel engine that meets current emission standards while also delivering more power, more torque, and easier maintenance. The simpler maintenance comes from having all the exhaust emission systems in one container mounted atop the engine.

The second major improvement is an all-new touchscreen display that is easy for operators to use and that gives them more information and controls in one interface. It also lets the operator easily select and control operation.

Manitex said that all of the improvements are based on input from customers. The Manitex CD4430R offers a two-section 53’ formed boom with integrated rail gear system. It is designed for the rugged environment of railroad work.

Ritchie Bros. makes $187,500 in donations to food banks around the world

With the massive economic impact of COVID-19, the need for full food banks is more important than ever and asset management and disposition company Ritchie Bros. has stepped up to help.

Over the past several weeks, Ritchie Bros. has made $187,500 in donations to 52 different food banks around the world, including organizations in the U.S., Canada, Australia, India, Japan, Spain, Germany, Italy, France, the Netherlands, and the United Kingdom.

“Right now, there are tens of millions of men and women out of work, worried about how they are going to continue putting food on the table for themselves and their families—we are just trying to do our small part to help,” said Ann Fandozzi, Ritchie Bros CEO. “We hope our donations will inspire our employees and customers to give back to their community—with their time and/or their money. Please join us in supporting food banks around the world.”

One of the company’s larger donations was a $25,000 grant made to the Greater Vancouver Food Bank in British Columbia, Canada, where Ritchie Bros.’ head office and several hundred of its employees call home.

“We are incredibly grateful to Ritchie Bros. for gifting $25,000 to the Greater Vancouver Foodbank during the current COVID-19 crisis, meaning those in need can continue accessing healthy food,” said Elizabeth Charing, philanthropy officer for the Greater Vancouver Food Bank. “This wonderful donation, along with our strong buying power, means that your support could provide three months’ supply of rice to all our clients—that’s a huge amount! On behalf of all our clients, volunteers, and staff, thank you so much.”

Terex Corporation announced Matt Fearon, the current president of its AWP brand Genie, is leaving on August 1 after 25 years with the company. John L. Garrison, Jr., chairman and CEO of Terex Corporation, will take on additional responsibilities as Terex AWP president immediately.

A statement from Genie said Simon A. Meester, vice president, global sales and marketing administration for AWP (aerial work platforms), will be promoted to COO, Terex Aerials. Meester and Clint Weber, general manager of Terex Utilities, Terex’s other business in the AWP segment, will both report directly to Garrison in his role as president, Terex AWP. The Terex executive leadership team will continue to report to Garrison in his role as chairman and CEO of Terex Corporation.

“We thank Matt Fearon for his many contributions to Terex,” Garrison said. “Matt has been a dynamic and much-admired leader who helped Genie grow from a regional brand to a global powerhouse. He arrived as an engineer 25 years ago and went on to key roles including vice president operations, vice president and managing director of EMEAR, vice president and general manager, Americas, and ultimately president of AWP.”

Meester joined Terex in 2018 from Eaton Corporation, where he was vice president and general manager of the Industrial Control Division. Earlier, he spent 14 years in progressively senior roles at Caterpillar, before becoming president of Sandvik Mining and Construction in India. He has managed global teams and operations for 20 years, based in seven countries, including eight years in the U.S. He holds an MBA from the University of Surrey, England and a Bachelor of Science in Automotive Engineering, Apeldoorn, Netherlands.

“I look forward to working closely with Simon and Clint, and their terrific teams at Genie and Utilities,” Garrison said. “We congratulate Simon on his expanded responsibilities, and we send best wishes to Matt for continued great success in the years ahead.”

CCrane Industry Services (CIS) in partnership with CM Labs Simulations, expands simulation training for cranes, earthmoving equipment, and maritime and port equipment.

CIS designed a new simulation training and demo room located at the CIS Centered on Safety Training Center in the Atlanta area. The showroom features a variety of portable and full-scale models with operator seats and controls.

“Simulation training using CM Labs’ Vortex simulators allows CIS the flexibility to scale training to the needs of the employer or operator. Vortex simulators are effective at helping operators develop skills that transfer to real equipment, making them an efficient and objective method for training and qualifying operators,” said Debbie Dickinson, CEO of CIS.

“We have been using Vortex simulators since 2016. As CM Labs’ products have evolved, CIS has increasingly integrated simulation training into operator qualification and certification programs,” said Dickinson. “CIS subject matter experts quickly recognized that simulations add great value when part of a well-planned, disciplined, integrated training system.”

“We’re delighted to work with CIS experts to make simulation-based training available to a wider audience,” said Drew Carruthers, CM Labs’ director of product strategy. “We know from experience that Vortex simulators result in operators that are better prepared for today’s work sites.”

The simulation training and demo room will open in July with a variety of Vortex simulators, including the Vortex Advantage full immersion 5-display system, and the Vortex Edge Plus, an affordable desktop simulator that is ideal for introductory training.

“These simulators have the added benefit of enabling crew training exercises for team learning, such as multiple crane operators for tandem lifts, signal person and crane operator communications, or excavator and articulated dump truck scenarios where operators of both pieces of equipment must work together,” said Dickinson.

Simulators provide the most cost-effective way to train groups of new operators or to keep skills sharp. Employers interested in exploring how simulators can be used for inhouse employee evaluation, qualification, and training can schedule a demo with CIS and CM Labs. In addition, Vortex simulators are available for purchase from CIS.

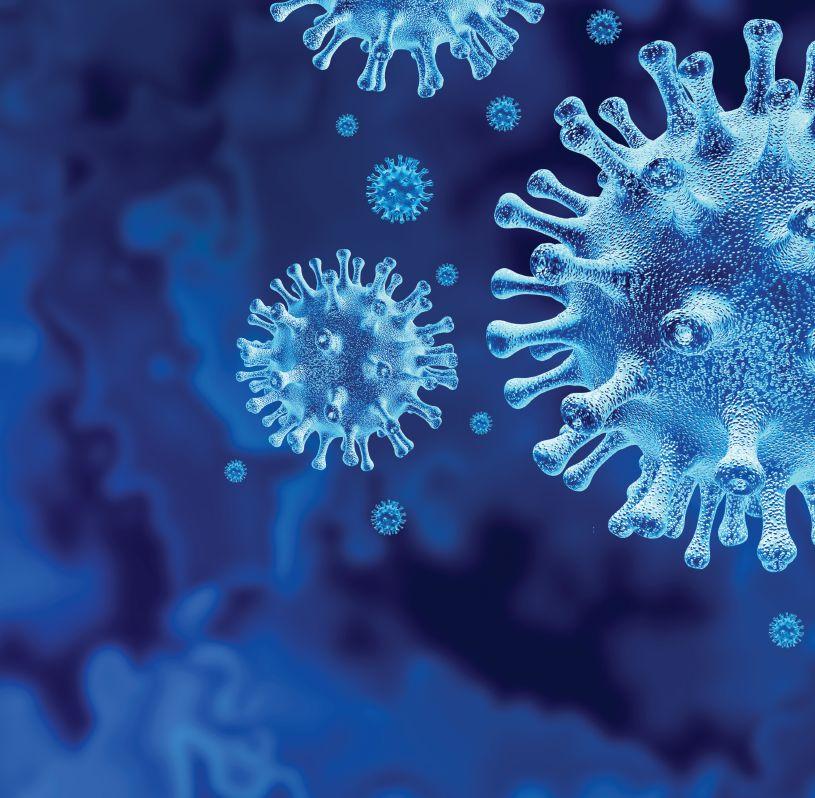

Activist shareholders, altruistic employees and an increasing focus on good citizenship has put corporate social responsibility at the forefront for many organizations.

BKT, a global manufacturer of tires based in India with employees around the world including Canada, recently created a 28-page document that explained, in detail, steps it is taking to be a positive force in the world.

“Life is made up of different events. Some happy, others sad,” wrote Arvind Poddar, chair and managing director at BKT. “Each of us questions and reflects, wondering how to react. And so it is for the situation we are living through due to COVID-19.”

A truly global effort

The document outlines some of the efforts BKT embarked on around the world, including India, Italy and the U.S.

More than 2,000 employees donated one day’s salary to the “solidarity projects of the BKT foundation.”

In real dollars, that amounted to nearly $200,000 (Canadian) in support. In India, some of these resources were steered towards food, clothing and housing for vulnerable people.

“In India, there are many people who are earning their livelihood by doing some short term/odd jobs and many are earning their wages daily,” the report said. “Due to the lockdown imposed as a result of the COVID-19 pandemic, these people could not earn their wages and furthermore due to various restrictions, could not get the food items needed for daily living.”

BKT arranged for cooked food and grain packets for the lockdown period, provided to jobless workers at various construction sites and agricultural farming areas. That included:

• 60,000 packs of food assistance

Liebherr is developing “climate-friendly” injection solutions for the use of hydrogen and synthetic fuels. As the internal combustion engine is still the dominant form of propulsion for mobility today, Liebherr’s Components Division sees it as a logical step to also advance the internal combustion engine for the use of CO2-neutral fuels.

The way forward has been paved for new mobility systems. Climate change and environmental policy requirements mean that this form of mobility needs to undergo further improvements.

In the development of climate-friendly injection solutions Liebherr focuses on new injector concepts using alternative fuels. In terms of costs and conversion, these can be integrated into existing engine platforms for heavy-duty applications with reasonable effort.

As a fuel in the combustion process, hydrogen is an attractive solution with its absolute CO2 neutrality. Of course, the premise that hydrogen is produced exclusively using renewable energy sources must be considered. In the field of injection systems, Liebherr is currently working on solutions for direct hydrogen injection that is ready for series production in correlation with the binding CO2 targets for trucks introduced in 2019. Liebherr is announcing the first engine tests before the end of the year.

An additional alternative is offered by synthetic fuels. Electricity-based fuels, the so-called e-fuels, contain significantly more oxygen than diesel fuels. Consequently, synthetic fuels burn much cleaner and generate fewer emissions. However, as a result of the higher oxygen content, energy density is lower, so more fuel is needed to generate the same engine power as a diesel engine.

• 300,000 kilograms of flour

• 60,000 kilograms of salt

• 60,000 litres of cooking oil

• 60,000 kilograms of lentils

• 120,000 kilograms of rice

• 60,000 kilograms of sugar

• 60,000 spice bags

• 60,000 bottles of soap

BKT also donated 25,000 personal protective equipment (PPE) kits to medical staff who were treating COVID-19 patients.

The single-use kits included a protective suit with a hood, a face shield, a mask, a pair of gloves and shoe cover. It also included a biowaste bag to dispose of it safely after use.

Italy was one of the nations hit hardest by the pandemic. BKT worked with Cesvi, an Italian humanitarian organization, on a “We’ll come to you” project to support the most vulnerable elderly residents.

“By activating home social assistance services, it manages the primary needs of thse people, supporting them so that they do not remain alone and emarginated due to the Coronavirus emergency,” it wrote.

While the U.S. was hit in the later stages of the pandemic, all 50 states were eventually impacted.

“The U.S.A. has had the highest level of contagion and deaths worldwide,” the report noted. Employees in Akron, Ohio, donated one month’s travel allowance to Samaritan’s Purse, an international relief agency. It helped set up a field hospital in New York’s Central Park, and also a respiratory care unit. In Cremona, Italy.

“We want to get involved, to do something concrete for ourselves and for our loved ones, to help our friends, to offer assistance to those who are suffering, to help support those who are in the front line fighting this insidious and invisible enemy,” said Poddar. “We know that it is not finished and that the virus is still not beaten. But we also know that this challenge that we have faced together has made us even stronger and ready to act, once again, all together.”

BY: MARK LEYDEN

Many owners of small and large family businesses are reluctant to undertake succession planning and end up doing so as a result of other personal planning. Whether the owner or owners are addressing their estate or their retirement, neither can be adequately structured without having made plans for what is most likely the owner’s largest asset, the family business.

According to PwC’s 2019 U.S. Family Business Survey, 58 per cent of family businesses report having succession plans. However, most are informal, and only 18 per cent claim to have robust plans in place.

The reluctance to plan is understandable given the number of emotional decisions which need to be made. An owner can’t simply think about the future of the business. He or she also needs to consider personal involvement and the potential involvement of other family members. Is there a time the owner plans to step back and cede responsibility to others? If so, who are those ‘others’? What happens to the business if the owner dies or becomes disabled? Is there a plan to eventually sell the business? Are there plans for key personnel, including those who are non-family members, for not only instances of death or disability, but also to retain and reward?

The process of creating and implementing a business succession plan often means having honest and sometimes brutal discussions with other family members (and with employees). For example, imagine having to tell a son or daughter who has struggled working in the business that he or she is not fit to take over. It’s no wonder so few family businesses have followed through to a formal plan, which involves not only a written strategy, but also the ability to fund all the liabilities uncovered to make sure the future vision for the business is realized and not knocked off course.

Approaching succession planning in distinct steps makes it clear to the business owner what needs to be accomplished. Here are the seven steps to create a formal succession and continuity plan for a family business.

1. DEFINE THE VISION FOR THE FUTURE OF THE COMPANY AND AN OWNER’S INVOLVEMENT

An owner of a business must know where the business is headed. The plan might be as simple as shutting down the company someday which—if the company is reliant upon the unique skills of the owner or the company is not readily transferable—may be the most realistic outcome. The company could be transferred to the next generation or other family members. Employees or outsiders could purchase the company. Hand-in-hand with considering the disposition of the company is the need to understand the exit plan for an owner and what that means to continued operations.

2. IDENTIFY SUCCESSORS

This just doesn’t mean identifying future owners. It also involves knowing of those currently employed, who could be a key manager or executive. Methods for training, retaining and rewarding will need to be implemented. If the current employee pool lacks leadership potential, a plan to recruit that talent should be a priority.

3. PLAN FOR CONTINGENCIES

This means planning for “what if” scenarios. What if an owner or other key employee dies or becomes disabled? What if a key employee leaves the company? What if an owner gets married or divorced or has other family members they want to have working for the company? Closely linked to all these scenarios involving personnel are questions about the shares of the company any of these individuals might hold and what happens to those shares.

4.

For a succession plan to be effective, it must be shared with those on whom it has an impact. Successors should know the opportunity ahead. Family and non-family members alike need to understand their roles with respect to the company. These conversations can often be difficult, and many companies bring in professional facilitators, often attorneys, to help.

“The more communication, the better,” says John Olivieri, a partner in the Indianapolis and New York offices of Barnes & Thornburg, LLP, whose practice focuses on estate and business succession planning. “In the absence of communication, family members will have expectations which may be unrealistic and can lead to disharmony and litigation. When everyone knows the plan, some may not be happy, but no one is surprised. As a result, a smoother succession can take place.

An independent appraisal to determine the fair market of the company is useful for both personal and business purposes. From a business perspective, the value to each owner is important for buy-sell and key person provisions and for funding any liabilities which arise from having to apply those agreements. Personally, the business value enables the estate and retirement plans of an owner.

“When interest in a family business is to be transferred to the next generation, it may be necessary to start by reorganizing the capital structure of the company,” says Dan Rosio, ASA, the partner-in-charge of Katz, Sapper & Miller’s Valuation Services Group in Indianapolis. “This often involves classifying a small number of shares as controlling so that a majority of the shares, which are non-controlling, can be gifted or sold to other family members. There are similar considerations for transfer or sale to non-family members.”

6. FORMALIZE THE PLAN BY CREATING OR UPDATING SUPPORTING DOCUMENTATION

This includes:

• Shareholder agreements

• Buy-sell agreements, including trust agreements where there are intra-family transfers

• Key-person agreements

• Key-person compensation arrangements

• Power of attorney(s)

In addition, the following records should be collected, well-organized and easily accessible when needed:

• Legal will

• Property deeds/titles, leases, rental agreements, etc.

• Mortgages and notes payable

• Tax returns, financial records and financial statements for the last five years

• Bank account information

• Contact listing of all professional service advisors

• Life insurance and property & casualty policy information

7. IMPLEMENT LIFE INSURANCE TO FUND IDENTIFIED LIABILITIES ARISING FROM THE SUCCESSION PLAN

Life insurance provides the liquidity to make good on promises made in various of the planning agreements at any time. Under a buy-sell agreement, funds are readily available to purchase the shares of a deceased owner. The same policy can also be used to provide additional proceeds to the family of the deceased owner. Many key person executive compensation programs are funded with life insurance and include non-qualified deferred compensation plans, split-dollar arrangements and executive bonus agreements.

Additionally, life insurance can be useful to a business owner in order to equalize the disposition of the company. Where a business is left to one or more family members to the exclusion of others, life insurance can ‘equalize’ not inheriting the family company. Learning a parent has selected another sibling other than you to own the business is easier to accept if the value of the company in cash can be expected.

Perhaps the most important thing a business owner should understand when faced with creating a succession plan is that the plan will not be set in stone. Just about any element of the plan can be changed as conditions demand. A company thought to be carried on for years and passed to children could suddenly be sold the next month if an attractive offer was made. Identified successors might turn out to not be a fit, while others thought to be lacking in leadership potential blossom.

Changes should be expected and usually do not create complications as long as they are well documented and communicated. Often growth of a business creates imbalance in the succession plan.

Agreements, valuations and life insurance funding can become obsolete in a company that is expecting growth. Most importantly, any liabilities impacted by changes to a succession plan should be evaluated along with the life insurance funding solution in place to see if existing coverage should be re-positioned, or if additional policies are needed.

3

This is the second in a series of four articles discussing considerations around succession and continuity planning for family businesses leading to how life insurance strategies are utilized to achieve many of the goals for such planning. This article discusses the first three steps a business owner should undertake when beginning the process.

Many business owners today simply do not adequately plan their succession. Reasons for procrastination vary and include not wanting to leave or let go, not wishing to face their own mortality and an apprehension about creating family disharmony with tough discussions and decisions. In effect, most justifications for not planning an exit are emotional, and a business owner must set aside emotion and plan strategically.

“The owner must have a clear vision of where they are going and how they are going to get there,” says Mike Hutson, CPA, CEPA, the founder of Edge Business Strategies in Indianapolis and a Professional EOS Implementor. Hutson routinely works with familyowned businesses to help them align operations to reach defined goals. “There are two components in any vision for the future – a business part and a family and personal piece. The owner must decide what they want to get out of the business for themselves and consider how this impacts the future of the business, which may include other family members.”

DEFINE THE VISION OF THE FUTURE OF THE COMPANY AND AN OWNER’S INVOLVEMENT

The process must begin with the owner having an honest conversation with themselves. How long does the owner want to stay in the business, either running it or in some other capacity? By answering this question, the owner can first consider their own needs and how long the business might satisfy those needs – financially and otherwise — as the first building block in planning.

A family business owner must honestly and accurately answer these four questions to set the rest of the foundation for a succession plan:

1. Should the owner keep the business or sell it?

2. If the business is to remain within a family, who will lead it?

3. Will the selection of a new leader create interpersonal ill will and bitterness?

4. If the business is to be sold, will that happen in the near future or in the long term?

A family business owner does not have to consider the path set by answering these questions to be inflexible. For instance, choosing to keep the business within the family does not mean selecting a specific heir. It may mean choosing more than one and, through a development program, being able to eventually make the selection. Also, choosing the family succession path does not mean the business could not be sold someday if conditions warranted.

Although there is flexibility on carrying out the succession plan, there are elements that cannot wait. If the business is to be sold, there are vastly different goals to plan for depending on whether the sale is in the near future or not. Selling the business sooner rather than later calls for short-term actions which would quickly enhance the value of the business. Conversely, if the sale of the business is off in the future, the current operating strategy should at least preserve shareholder value if not increase it.

IDENTIFY SUCCESSORS

Unless the owner has chosen to sell the family business in the short-term, the next step is to identify one or more successors. “The earlier the process for choosing a successor is started, the better the outcome,” says Dan Luther, an attorney and partner with the Chicago office of Mayer Brown, LLP. “Many business owners are focused solely upon growing their business and they need to take steps to make sure the business will thrive past their involvement. Selecting the next generation of leadership is a critical element of this process.”

In a situation where the succession plan calls for an eventual sale, identifying a successor can mean hiring a future potential buyer and grooming them just as would be done for a family member. An outsider may also be chosen as the successor in situations where the business will remain within the family but there are not family members interested or qualified to operate the company.

For some family businesses, there are easily determined successors from within the family and the process for transition is clear. In many instances, though, there may be a need to ‘wait-and-see’, especially where members of the next generation are still in school or have other careers and have not yet decided whether or not to join the business.

“I find that the children of owners who have first worked elsewhere after college for at least a few years and gain experience outside of the family business make the best successors,” notes Luther. “In addition to the obvious advantages of learning skills in a different environment, there are subjective benefits to not joining the company right away such as the other employees in the family business having more respect for a son or daughter who appears to have earned their place in the company instead of just being dropped in.”

About the author: Mark Leyden, CLU is the CEO and founder of Mark Leyden & Associates, an Indianapolis-based firm specializing in assisting businesses and families in the acquisition and management of life insurance assets. He specializes in assisting business owners and families, including some members of the Forbes 400, in design and funding of wealth transfer and business succession plans. This is accomplished working closely with clients and their advisors. The objectives commonly achieved include: tax-efficient wealth transfer, business succession, asset protection, and management team retention plans

No matter how challenging your needs, AIROMAX AM 27 is your best ally for mobile cranes in industrial applications. The tire is particularly suitable for road usage. Thanks to its All Steel casing and the special tread design, AIROMAX AM 27 provides extraordinary traction along with high load capacity.

AIROMAX AM 27 is BKT’s response to withstand the toughest conditions in the construction industry. For

PX532, one of the latest Jekko mini cranes, arrived in Latin America for the first time and was recently delivered to Guindaste Aranha. The new model adds to other Jekko mini cranes already owned by Guindaste Aranha, who has been Jekko products’ representative in Brazil for two years.

SThis mini crane became known thanks to the important innovations it incorporates: a cutting-edge stabilizing system, a sophisticated electronic and hydraulic system, greater ease of use, increased lifting capacity (3.2 tonnes), an updated design and a new and userfriendly radio remote control. Important new features include also the 1 tonne hydraulic jib, the maximum height of which, at 17.3 metres, can be compared to that of a higher category of crane. The jib can be stored in three ways, either at rest on the column, on the ground or resting under the main arm.

“Thanks to the compact dimensions and footprint, smaller than in the previous SPX527 and SPX536 models, and the excellent lifting capacity and maximum reachable height, SPX532 is positioned between the small size and the big size mini cranes and is the right answer to both rental and sale market needs” says Jefferson Candeo, Guindaste Aranha’s director.

Davis Company with first Hup M 28-22 self-erecting tower crane in North America

Davis Company purchased the first Potain Hup M 28-22 self-erecting tower crane in North America.

The company first invested in a Potain in 2005, when it purchased the first Igo MA 21 in North America. A decade and a half later, the 2 USt capacity, 85.3 ft jib radius crane continues to work consistently on job sites.

“We’re excited about our new Hup M 28-22 and its new features. We’ll put it to work building apartments, retirement housing and motels as soon as it is delivered. Its small footprint and easy operation make it perfect for the projects we undertake,” said Dennis Davis, founder and owner of Davis Company.

The Hup M 28-22 is the third model from the Hup self-erecting crane range and the first to prioritize mobility — symbolized by the M in its name. Showcasing its mobility, the crane is configured with an integrated transport axle (North America compliant), which allows transportation by 5-wheel or two bar over the road. Once on the job site, the transport axle can maneuver the crane into position by wireless remote. The new maneuverability opportunities of the Hup M 28-22 enable work in narrow, restricted job sites, as well as making it easy to transport from site to site.

“The Hup M 28-22’s features are impressive. It offers a long radius, strong capacities and a tall height under hook for a crane that is completely self-contained,” said Kelly Hadland, CEO at Compass Equipment, the Gilbert, Arizona-based dealer that will supply the crane to Davis Company. “This new crane demonstrates Manitowoc’s commitment to listening to customers and putting their needs into manufacturing practice.”

The Potain Hup M 28-22 features two load charts, each with 16 configurations, which is unique to this category of self-erecting cranes, enabling it to be easily adapted for a wide range of job site applications. The crane has a maximum capacity of 2.4 USt and can impressively lift 1,874 lb at its 92 ft jib end.

Canadian construction company Eagle Builders is specializing in the design, engineering, fabrication and building of precast concrete structures. It’s subsidiary Quickline Crane is serving all the heavy lift requirements for the parent company.

As project requirements are getting more complex and higher load capacities are demanded, the company has purchased a Liebherr mobile crane LTM 1250-5.1. The 300 ton (250 metric tonne) crane meets the demands of Eagle Builders. Quickline Crane turned to Liebherr.

“We looked at the market projection and what we had coming up for projects and decided now was a good time to purchase a larger crane,” said Craig Haan, director of Quickline Crane and Eagle Builderse. “We looked at many options but ultimately decided that a 300-tonne mobile crane was the right choice. From both a lifting capacity and mobility within seasonal road bans—this crane checked off the requirements.”

The new LTM 1250-5.1 is the largest crane in the Quickline Crane fleet and will be utilized on major Eagle Builders projects.

As Eagle Builders turns 20, they take pride in the quality of service the company delivers on projects.

“We stand behind every project throughout its lifecycle so we expect the same from our suppliers, trades or service companies. Therefore, service of equipment is of the utmost importance and not taken lightly” said Haan.

Eagle Builders employees 273 personal with four dedicated staff members for Quickline Crane, now operating two Liebherr Cranes in its growing fleet.

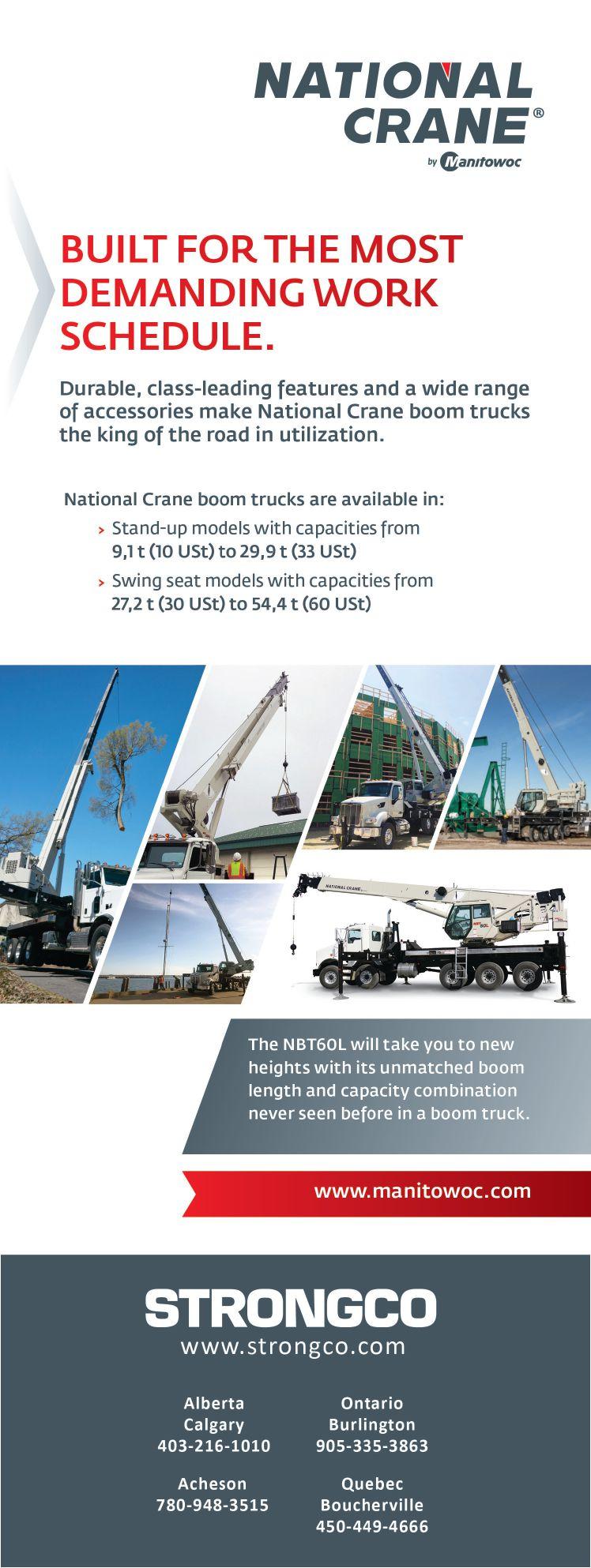

Sarens Canada adds three new National Crane boom trucks to fleet

Sarens Canada just added three National Crane boom trucks to its fleet, further strengthening its repertoire of dependable, durable truck-mounted cranes that serve Canada and beyond.

“We’d like to thank Lee Rowe and his team at Sarens Canada for the recent acquisition of two new National Crane NBT30H-2s and a new long-reach NBT55L,” said Chris Gray, territory manager at Strongco, which supplied the boom trucks to Sarens Canada at the handover ceremony in early June. “We look forward to supporting Sarens Canada as they continue to grow in the country and other regions.”

Manitowoc filed a petition last year requesting an investigation into mobile crane imports and asked the U.S. Commerce Department to investigate whether this is a fair-trade environment. Several companies have since spoken out against the petition, for more information and to view Manitowoc’s full petition visit, craneandhoistcanada.com.

The U.S. Secretary of Commerce Wilbur Ross announced the Department will initiate an investigation into whether the quantities or circumstances of mobile crane imports into the United States threaten to impair the national security.

This decision follows a petition filed by Manitowoc in December, requesting that the Department of Commerce launch an investigation into mobile crane imports under Section 232 of the Trade Expansion Act of 1962, as amended. The investigation, to be conducted by the Department’s Bureau of Industry and Security, will provide the opportunity for public comment once the rule is posted in the Federal Register.

“We will conduct this review thoroughly and expeditiously,” said secretary Ross. “This investigation will help determine whether mobile cranes are being imported in such quantities or under such circumstances as to threaten to impair U.S. national security.”

Manitowoc alleges that increased imports of low-priced mobile cranes, particularly from Germany, Austria, and Japan, and intellectual property (IP) infringement by foreign competition, have harmed the domestic mobile crane manufacturing industry. The Department of Homeland Security has identified mobile cranes as a critical industry because of their

Ingo Schiller, chief executive of Tadano America has given a statement coming out against the tariffs proposed by Manitowoc.

“The situation is an unusual one for our industry in that the manufacturers are divided on this issue with Manitowoc requesting tariffs be applied—but not to its cranes, which include German built telescopic crawlers—while most of the rest of the industry appears to be against it. As manufacturers we are all naturally fiercely competitive and we fight each other to win every deal, but if you lose a deal you move onto the next one. We are competitors—not enemies,” Schiller stated. “When it comes to issues concerning what is best for the industry as a whole, we are usually all in agreement. This is the first time that I recall where we are so divergent on an issue.”

“We have some issues with inaccuracies and misrepresentations in the petition which appear to be an attempt to mislead, and will be submitting some private and confidential attachments to our submission alongside the public material in order to illustrate that fact,” he stated. “I hope that the department gives this the time and attention that it requires and then reaches the right decision based on all the evidence and comments submitted.”

extensive use in national defense applications, as well as in critical infrastructure sectors.

Manitowoc says that without import relief the armed forces and their contractors would become largely dependent on foreign producers of mobile cranes and also claims the low-priced imports and IP infringement resulted in the closure of one of its two production facilities in the United States and eliminated hundreds of skilled manufacturing jobs in Wisconsin.

Manitowoc cites the U.S. International Trade Commission’s (USITC) Dataweb to note that imports of mobile cranes increased 152 per cent between 2014 and 2019, and a 2015 finding that a Chinese manufacturer misappropriated six trade secrets and infringed on a patent, resulting in the USITC banning the sale of a Chinese crane in the United States.

Manitowoc executive vice president Aaron Ravenscroft, wrote to Manitowoc staff stating the company’s reasons for its petition for an investigation into crane pricing in the U.S. Here is the report in its entirety.

July 20, 2020

Dear Team:

As you know, Manitowoc recently filed a petition with the U.S. Department of Commerce to investigate the surge in U.S. mobile crane imports. Manitowoc is the last remaining 100% Americanowned crane company, and we have been supplying cranes to all branches of the U.S. military since 1961. Over the last couple of years, we have been supplying cranes for the FOATC (Family of All Terrain Cranes) program – these are Allterrain cranes that are deployed to combat zones to retrieve equipment damaged in battle, such as a military truck or a Humvee. FYI, we currently supply 100% of All-terrain cranes and nearly 66% of Rough-terrain cranes to the U.S. military. No other domestic U.S. manufacturer could supply these cranes if we were unable to meet that demand.

In addition to being a critical military partner, our cranes are integral to the construction and repair of our country’s infrastructure, and cranes play a vital role at nuclear plants, dams, roads, and bridges. Just to name a few, Manitowoc cranes have been integral in building the following important projects:

• Ground Zero in New York City after the 9/11 terror attacks and remained present and visible there for years.

• Reconstruction of the levee system in New Orleans after Hurricane Katrina.

• Soo Locks operated and maintained by the U.S. Army Corps of Engineers, which enable ships to travel between Lake Superior and the lower Great Lakes.

• Major bridge and railway projects across the country. If you visit Washington D.C., our products supported the construction of the new Silver Line of the Metrorail project extending the line out to Ashburn, VA.

• The NASA and SpaceX space projects.

Over the past decade, we have seen a tremendous change in the business landscape, primarily driven by foreign imports. As the U.S. dollar has strengthened, so has the competitive nature of the market. During this period, we have seen cost increases, such as wage increases, while pricing for products has remained constant or down. For example, the MLC300 Crawler-crane was launched seven years ago at the same price point as the legacy 300-ton crane, which was roughly $2.5 million. If you recall, we had record orders at the launch at ConExpo in 2014. As foreign competition has fought hard to take market share, the price of this crane classification has fallen 25%. This is one of many examples we can cite as issues related to foreign competition. Many of our foreign competitors benefit from their local government policies that give them a competitive advantage in the U.S. while concurrently creating barriers for imports to enter their home markets. Existing trade dynamics make it very difficult for Manitowoc to compete fairly in our home market, let alone export U.S.-made products to foreign markets. When I compare our U.S. exports from 2006-2009 versus 2016-2019, our shipments of American-manufactured products to foreign markets has dropped over 80%. We asked the U.S. Commerce Department to investigate whether this is a fair-trade environment, not to create an unfair advantage. The investigation will proceed over the next several months and ultimately there will

be a recommendation report from U.S. Commerce. So far, the public (including members of the crane industry) have had the opportunity to submit their opinions. We will have the opportunity to post rebuttals to these comments. Naturally, we have our supporters and our detractors. In total, I believe that the U.S. Government has a good process to ensure that everyone’s voice is heard and that all the relevant data are collected for a decision. Thus far, there has been much industry chatter both domestically and abroad regarding our filing, but the government has not yet begun evaluating possible remedies. Please note that tariffs are not the only solution – the U.S. President has wide discretion in determining what remedies may be most appropriate to address the threat presented by the surge in imports. As this process moves forward, we will continue to update you about important milestones along the way.

Please appreciate that this is a very complicated matter, and it can be emotional. Nevertheless, our organization cannot be distracted by the investigation. We need to stay focused on the things that we can control to manage the business through these turbulent times –develop, engineer and build great cranes, service our customers, and responsibly manage our spending.

If you have any questions or comments, please feel free to contact me at aaron.ravenscroft@manitowoc.com.

Thank you, Aaron

AMCS Technologies - Collégien, France

Arsenal Engineering Ltd. - Abbotsford, BC, Canada

Bow City Crane Service Ltd. – Calgary, AB, Canada

Capacity Truck & Crane Service – Abbotsford, BC, Canada

Fulford Harbour Consulting Ltd. – Vancouver, BC, Canada

Lift Source Machinery Ltd. – Houston , TX, USA

Morrow Equipment Company LLC. - Brantford, ON, Canada

Radius Crane & Rigging Inc. Crane & Rigging – Leduc, AB, Canada

Revolution Crane & Transport - Nisku, AB, Canada

Zero Gravity Crane & Rigging Inc. – Lethbridge, AB, Canada

BY JAY KOBLUN

Ever wonder if cranes are used in space exploration? Crane and Hoist Canada editor talked with Gilles Leclerc about the similarities and differences between Canadarm3—a crane designed for assembling space structures in space—and a modern terrestrial crane, what’s new and interesting on Canadarm3, and what its overall function on the Gateway space structure will be. Leclerc is director of general space exploration at the Canadian Space Agency.

Jay: What’s your role at the Canadian Space Agency?

Gilles: I’m the director of general space exploration. Responsible for human space flight and robotic exploration which covers planetary missions and other projects.

Jay: What were the original Canadarm and Canadarm2 used for?

Gilles: Canadian astronaut Chris Hadfield famously said, “Canada built the Canadarm2 that built the International Space Station” and that’s very true. We provided a service to assemble structures in orbit.

The first arm is retired and has been for almost 10 years. You can find the original Canadarm at the Canada Aviation and Space Museum in Ottawa. Canadarm1 is a series of robotic arms that were used on NASA space shuttle orbiters to deploy, manoeuvre, and capture payloads. The original arm was launched and brought back by a shuttle.

In Canadarm2’s case, we launched it into space in 2001 and its been there ever since

with no plan to recover it. Once the lifetime of the ISS is deemed over, the station itself will be dismantled, but there’s no plan to recover or retrieve the Canadarm2. So, you can imagine it’s an extraordinary piece of engineering and has been in space for almost 20 years, we’ve changed some parts of the Canadarm2 but it’s still in perfect working order.

Editor note: The Shuttle’s Canadarm wrapped up 30 years of successful operations when it was retired along with the Space Shuttle program after mission STS135, which marked the robotic arm’s 90th flight. The arm’s legacy lives on, though, since it established Canada’s international reputation for robotics innovation and know-how and generated the family of Canadian robotics on board the International Space Station, as well as future generations to come. Its excellent performance record has inspired several generations of scientists and engineers as they develop new technologies for industry, medicine, and other applications. Source: Government of Canada

Jay: What is the main function of Canadarm3?

Gilles: Canadarm is a space robotics system. Canadarm3, the third “arm” is going to be sent to a lunar orbiting station called the Gateway. The purpose of all these space robotics devices is to assemble space structures. Also, to support activities by astronauts, and attach more parts as they may be sent into space.

On the Gateway, Canadarm3 will be deploying scientific experiments, capturing

visiting vehicles and maintaining the structure itself, which is an assembly of modules, that forms the Gateway. The Gateway is more modest than the ISS, but Canadarm3 will be as busy as Canadarm 2 is right now on the ISS. So, if go by the ISS, Canadarm 2 contributed to assembling the ISS. Now most of the work we do is simply maintaining it. For example, during the past month there has been several robotic operations involved in changing the batteries on the ISS. We’re still extremely busy maintaining the ISS and will likely be just as busy on the Gateway structure.

Jay: Can we call it a crane?

Gilles: The original Canadarm and Canadarm 2 are smart cranes. Canadarm 3— you could call it a crane—but it is indeed much, much more. It is very smart, very artificially intelligent, and has the same function as the human arm. It would be a disservice to the engineers and researchers behind the development of Canadarm3 to simply call it a crane, and I would be careful to call it equal to a terrestrial crane in terms of design. There are similarities but it is also very different.

It’s going to be able to work autonomously, as well as being remotely controlled from the ground station, as well as by as astronauts on board the Gateway itself. But when you look at the architecture of the arm, it’s the same form and function as a human arm. It has three joints in the shoulder, one joint in the elbow, three joints in the wrist, seven degrees of freedom—you don’t find that in many terrestrial cranes.

Each joint can move 360 degrees. It’s a very sophisticated crane.

Jay: Who is going to manufacture the arm?

Gilles: The Canadian Space Agency announced MacDonald, Dettwiler and Associates (MDA), based in Brampton, Ont., has our intention to give them the contract. MDA is the same company that designed and built the original Canadarm as well as Canadarm2. MDA is a Canadian owned company and is going to work with a large array of suppliers to complete the arm. The role of the Canadian Space Agency is to essentially manage the project. We give the contract, MDA will have the responsibility to manufacturer it and include all our new technologies. The Canadian Space Agency is responsible to deliver the Canadarm3 to NASA for the Gateway

Jay: What’s unique about the third arm?

Gilles: Artificial intelligence, the ability to be autonomous, a 3D vision sensor that will map objects around it, a sense of touch— which was already on Canadarm 2—automatic collision avoidance, and it will have a high definition 4k camera, that’s important. The colour camera will give us an interesting vantage point from the Gateway to earth, and will help immensely with operation on the arm but also just will be great to be able to look at the universe around the gateway. Just as the second arm was to the first, the third arm will again be almost a quantum leap forward in terms of development compared its predecessors. The company

will have to integrate all these new features and they will also have to work with subcontractors to provide the hardware, but also with centres of expertise in A.I. in Canada and universities.

We’re also going to be asking MDA to commercialize some of these technologies for space robotics. We want MDA to continue to take these technologies and put a spin on them for surgical robots, so they can be involved in medical surgery too. We want to see that kind of transfer; from the very exotic, specific space project, into terrestrial application and ground robotics.

Jay: What are some challenges involved in operating a crane, or arm, in space?

Gilles: The space environment is very harsh. You have radiation to consider. Thermal shock, going from exposure to the sun, to security and temperature. The extremes out there are, well—extreme. Also, the time that it takes for communications from command to get to the robotic system is also a challenge. But that is taken into consideration with the fact that the arm will be autonomous, so we will program it to perform a series of operations from earth so it can operate on its own.

Going to the lunar orbit will cause additional challenges, with the main challenge being exposure to cosmic rays and radiations. The Gateway is going to be outside of the belt protecting the earth from solar flares and cosmic radiation. An additional challenge for space robotics is obviously the interaction with astronauts. We need both astronauts and robots to explore these very dangerous areas outside the reach of the earth.

The ISS is at roughly 400 kilometres altitude, the Canadarm3 on the gateway will

be at 400 thousand kilometres. That’s going to be interesting but not impossible. NASA and other nations have robots and rovers on Mars for example, which is much farther than the Gateway will be. We’ve learned to manage all of these challenges and technical issues but are also learning as we go. That’s the essence of the challenge of space exploration.

Jay: What’s something about the arm crane operators would find interesting?

Gilles: What’s interesting about Canadarm2 and 3 is that they don’t have a fixed base. They can move from one attachment, what we call robotic interfaces, to another— they don’t have a fixed base. The other thing is it’s a complete 3D environment, so they can move around 360 degrees. I’m not an expert in terrestrial cranes, but the mobility features of the arms are completely different in space compared to the environment on the earth.

Another interesting aspect is there is no weight. Only mass. So, there’s no gravity pulling it down. We can only test the arm— crane—once we’re in orbit, because by itself the arm would not be able to support itself. In space we’re able to manipulate objects that are 10, 50, 100 tons, because there’s only mass, no gravity or weight.

Jay: Any last thoughts on the project?

Gilles: Canada’s progress in space, and Canadian space technology, is almost defined by the Canadarms. Canadian Space Robotics has been identified as an iconic contribution that we keep giving to the world of space exploration. We can be very proud of not only our current achievements but what the Canadian Space Agency will continue to achieve.

The Shuttle’s robotic arm has performed many kinds of tasks over the years. It has set satellites into orbit and retrieved others for repair. The first time Canadarm was used in one of many International Space Station (ISS) assembly missions was for Mission STS88, December 1998.

Canadarm has always performed flawlessly. It supports astronauts during spacewalks. Its elbow and wrist joint cameras have provided visual inspection of the Shuttle and its payload. It has knocked ice off the Shuttle’s wastewater dumping vents and loosened a jammed solar array panel.

And it has had two IMAX cameras attached to its lower boom so the experience of space could be brought to the movie theatre for everyone to enjoy.

The robotic technology used in Canadarm provides humanlike dexterity here on Earth in a variety of environments. These may include servicing nuclear power stations, remote servicing of utility power lines, or cleaning up radioactive and other hazardous wastes.

For example, MacDonald, Dettwiler and Associates Ltd. (MDA), which developed Canadarm, has also designed a Light Duty Utility Arm system to inspect and analyze radioactive waste in underground storage tanks. This system consists of a modular, seven-joint manipulator attached to a telescopic vertical positioning mast. A mobile system deploys the manipulator in the tank.

Remotely operated robotic systems have enjoyed wide application in industry and other fields. In medicine, Canada has been a leader in the development of techniques involving robotic surgery operated from a remote location.

The Seaman Magnetic Resonance Centre in Calgary has teamed up with MDA Space Missions to adapt space robotics for use in surgery. The benefits are improved accuracy, efficiency, and the quality of patient care. “NeuroArm” uses miniaturized tools such as laser scalpels with pinpoint accuracy and it can also perform soft tissue manipulation, needle insertion, suturing, and cauterization.

The Centre for Minimal Access Surgery at McMaster University’s St. Joseph’s Hospital in Hamilton, Ont., is a telesurgery pioneer. In a successful pilot project, the surgeon directed medical staff from a remote, high technology, operating console and conducted robotic surgical operations on patients hundreds of kilometres away in a hospital in North Bay, Ontario.

The Canadian Space Agency (CSA) has promoted the application of this medical technology for missions here on Earth involving Canadian astronauts Robert Thirsk (Neemo 7) and Dave Williams (Neemo 9).

Comfortable

Operator

Finance Minister Bill Morneau announced proposed changes to the Canada Emergency Wage Subsidy (CEWS) program to provide support to employers for employees wages since March 15 as part of the government’s overall COVID-19 Economic Response Plan. Originally in place until June 6, the CEWS was extended to August 29 and is now being proposed to be extended to December 19 – four additional 4-week claim periods (Periods 5-9). The proposal released Friday has details related to the July 5 to November 21 claim periods, with the November 22 – December 19 period details to be released later. All claims must now be submitted before February 2021.

For most of the claim periods to July 4, an employer must have experienced a revenue decrease of at least 30 per cent in order to qualify, and all employers meeting the eligibility criteria receive the same level of maximum subsidy funding per employee (75 per cent of $1,129, or $847 per week). The subsidy maximum was triggered regardless of how significant the revenue decrease was below 30 per cent, and no subsidy was received if the threshold was not met. This rigid 30 per cent threshold was seen as a disincentive to growth as employers may forgo opportunities for potentially increased business operations – which would normally include hiring more staff and expanded economic activity for their suppliers – if it meant they would rise above the 30 per cent threshold and therefore lose the CEWS funding.

Providing continued support to the economy as it continues to recover, removing an employers’ disincentive to grow revenue, and focusing additional funding on industries most adversely affected by COVID are the stated goals for the proposed changes. However, the government also wants to reduce their cost of the CEWS so they are implementing a gradual reduction in the maximum subsidy claim over the next five 4-week claim periods

(starting July 5 and ending November 21) with details for the November 22 – December 19 period not released yet. The maximum weekly amount of wages eligible for the subsidy remains at $1,129/week.

CEWS benefit based on current and historical declines in revenue with staged decline of maximum support amount

Under this proposal, the CEWS would have two components – a “base subsidy” for any employer with a decline in revenue in the claim period, and a “top-up subsidy” for employers with more significant declines in revenue over a longer time frame. The combined subsidy amount would apply to active employees, with furloughed employees subject to a separate calculation. As well, employees who are without remuneration from the employerclaimant for more than 14 days will no longer be excluded from the definition of “eligible employee” and their wages would be eligible for CEWS support.

The maximum base subsidy would be available to employers with revenue decline of at least 50 per cent in each claim period, but the amount of the base subsidy would decrease over time – 60 per cent in Periods 5 and 6, 50 per cent in P7, 40 per cent in P8 and 20 per cent in P9. Employers with less than 50 per cent decline in revenue would receive a subsidy percentage based on their specific decline. In P5 and P6, the maximum subsidy would be 1.2x the percentage decline, 1.0x in P7, 0.8x in P8 and 0.4x in P9. Therefore a 20 per cent revenue decline in July would result in a 24 per cent maximum wage subsidy – or $270 if the employee was eligible for the maximum subsidized wage amount. That same 20 per cent revenue decline in October would result in a 16 per cent maximum wage subsidy – or $181 of CEWS benefit.

In addition to the base subsidy, employers who experienced an average revenue decline of more than 50 per cent in the previous three month period would have their maximum CEWS subsidy rate increased by up to 25 per cent over the base subsidy amount. Employers with an average revenue decline of 70 per cent or more would receive the full 25 per cent addition, with average declines between 50 per cent and 70 per cent receiving a proportionate amount of the 25 per cent addition to any eligible base subsidy amount.

The proposal also include a “safe harbour” provision that would allow employers that would have qualified for the 75 per cent maximum subsidy amount in P5/P6 under the original 30 per cent revenue decline criteria will still receive that 75 per cent subsidy amount for those two periods. Claimants that would be able to receive more than 75 per cent through the base subsidy and top up subsidy would be able to receive the higher amount.

Going forward, the employer’s current period CEWS rate will be based on the greater of their current monthly revenue decline, and their previous month’s revenue decline, providing a more stable support amount and avoiding a sudden decrease in support when revenues increase. Employers will retain the ability to choose how they calculate their revenue decline – cash or accrual basis of accounting, current month comparison to either the prior year or their Jan/Feb 2020 average – but will have the ability to use different calculation methods in Periods 1-4 and Periods 5-9 if they wish.

The end result of the proposals would be to expand the CEWS support to more employers for a longer period of time, but also gradually reduce the amounts paid on behalf of each employee. The legislative changes will need to be passed by Parliament (introduction and First Reading were done today) and there is no definitive time frame for that process to be completed, however Period 5 will end August 1 so it will be important for employers to receive certainty on the potential benefits available when making their business decisions.

These proposals are complex and potential claimants should be sure they understand them fully before making a CEWS claim for any relevant claim period. More details on the proposed changes and example calculations are available in the Department of Finance release.

Provided by Virtus Group Auditing Firm of the Crane Rental Association of Canada

BY: MALA DEWAN, CM LABS

Due to increases in computing power as well as the rise of technology in construction equipment and applications, simulators continue to gain momentum as a smart and effective way to train heavy equipment operators. As the pandemic forces us to reconsider various aspects of our daily lives from entertainment to healthcare and education, simulator-based training has become more relevant than ever.

This should come as no surprise. Simulators, by their very nature, are well positioned to help construction companies and vocational schools overcome the training challenges brought on by COVID-19. Reduced classroom and crew sizes, on-site sanitation and designated travel paths are among the most common guidelines issued by officials to help mitigate the spread of the virus. A survey from the Associated General Contractors of America shows that 65 per cent of respondents have experienced laid-off or existing employees refusing to return to work, citing concerns over the coronavirus while teachers continue to worry about their health as plans to reopen schools are underway.

In this time of insecurity organizations need to demonstrate a commitment to a safe environment without compromising on the quality of training. Here’s how simulation-based training can help:

Simulation facilitates safe and hygienic hands-on training. Operators can train on any simulator and easily wipe down and disinfect the machine before and after every use. Multiple students can be placed on simulators that are physically distanced or separated by plexiglass while portable solutions like the Edge Plus enable remote training from any location.

In contrast, on-the-job instruction forces both the instructor and the student into a confined cab where they are breathing the same air, speaking loudly over noisy machinery and touching the same surfaces.

To provide an even greater level of safety, CM Labs simulators can be paired with an optional Instructor Operating Station (IOS). This remote workstation can be set up within the classroom or a separate room and allows instructors to control the training right from

their seat. The IOS empowers instructors with a real-time 3D view of the virtual work site and allows them to initiate exercises, inject faults and manipulate weather conditions. What’s more, the IOS tracks and benchmarks trainee progress and allows instructors to add bookmarks and notes to the training session that can be addressed with each student at any time.

Meet physical distancing requirements with the Instructor Operating station and enable a new form of hands-on instruction that maintains an unprecedented quality of training in heavy equipment operation.

Fewer workers on site means project delays. Optimizing your crew’s capabilities and making sure workers on the job have the necessary skills and training to operate equipment remain an important part of ensuring projects stay on track.

Simulation provides a 360-degree solution to the recruitment and training process from evaluating the skill-set of prospective operators to training them remotely as well as upskilling and cross-skilling them with no down-time to the real equipment. Keep your machines working and your operators training at the same time for maximum efficiency.

Simulation training means you always have the manpower you need to bid on jobs and remain competitive. The construction industry is dealing with a residual skills gap dating back to the 2008 financial crisis. Simulators can help curb that gap by investing in the career paths of operators and giving them a reason pursue a career in the industry and to stay.

According to Mckinsey & Company companies that came out ahead after the financial crisis of 2008 typically, rapidly reallocated resources, and made bold moves to prepare for the future. With recovery through infrastructure spending looming it’s important to plan today for tomorrow.

At the end of the day, simulators deliver where it really counts

This includes safety, flexibility, control and efficiency. If you’ve been considering simulationbased training, there’s never been a better time. Access our webinar on How simulation can help you get ahead of the pandemic to learn more about the benefits or contact us directly. Don’t let the effects of the coronavirus leave you behind.

BY MATT JONES

On September 15, 1773, a ship called Hector arrived in Nova Scotia in the Pictou harbour. While there were already Scottish settlers in the area, most had arrived via the United States, making the 189 Scottish Highlanders who travelled on the cargo vessel the first Scottish immigrants to travel directly to Nova Scotia. The original Hector returned to Scotland shortly afterwards, but a replica of the ship was finished in 2000.

20 years later, the replica is in need of restoration and the Ship Hector Society will take the opportunity to make enhancements as well, including adding motors to allow the Hector to be more than an attraction on the dock.

“[The replica Hector] was never a sailing vessel,” says Darlene MacDonald, a member of the Ship Hector Society board of directors. “There used to be a Hector festival and a couple of times we towed it into the harbour and did a

re-enactment of the landing. But it never sailed. With our restoration, we want to do harbour tours with it.”

In order to perform the restorations, the ship needed to be raised out of the water and placed on solid ground in what the Ship Hector Society dubbed “The Great Big Lift.” A.W. Leil Cranes and Equipment were tasked with the job. Operations manager Robert Fraser says that the company primarily utilized a Terex/ Demag CC 2400 with superlift for the operation because of the limited space on the land by the quay.

“If we tried to approach it with two cranes or tandem lifts, you didn’t have room to really work,” says Fraser. “The geometry was pretty close between the center of the ship and the center of the crane and the center of the superlift tray but we managed to get it all in there with a few inches here or there and got it where they wanted it.”

A T-250 Tadano was also utilized to put the large Terex together and another small crane that helped with loading and unloading the weight tray during the lift. Fraser says that the actual weight of the ship was something of an unknown, and they estimated it at 220 metric tons. Once they actually lifted the ship up they were able to take 40 tons off the tray.

“When you’re lifting with superlift, you’re forced to lift at 80 to 90 per cent capacity of your lift because if your tray is too heavy, you’re not going to pick it up off the ground,” says Fraser. “If you can’t pick it up off the ground, you can’t swing or crawl. Once we got it up closer to us, the tray was too heavy to pick up and crawl backwards. With any crane, you have to get that balance figured out.”

The initial plan had been to maneuver the ship to one side of the dock, to moor it off with anchors and boats and rig it in that position. That seemed extremely time-consuming however, so instead, they slinged it ahead of time at the dock where it was normally located.

“When we hooked on to it, we were only good for 15-20 tons out there because we had the boom down flat and no superlift tray,” says Fraser. “But that allowed us to rig the boat while it was still stable and tied off to the wharf, giving us an area to work off. Then we crawled back just enough to keep the slings tight and got into a lifting position where they loaded the tray up.”

The rigging for the lift was custom-made by Versalift out of Texas to the exact specifications needed.