Canada’s aggregates and heavy construction associations share their New Year’s resolutions

Popular

Leaders across the aggregates and roadbuilding sectors share strategies for the industries' carbon future

Winter

In the third quarter of 2023, our population increased by 430,000 people. According to Statistics Canada, this population increase was higher than in any other year, including 2022 when there was record growth.

The last time we experienced a similar level of growth was in the second quarter of 1957. Canada’s population then was 16.7 million people. Today, our population is at more than 40.5 million people.

Back in 1957, that increase was mainly a result of the baby boom. Today, immigration is responsible for a significant rise in our population. This is important for our country as new Canadians are helping us grapple with an aging workforce and a low birthrate. We are already dealing with labour shortages in key sectors of our economy. Without immigration, the problem could be significantly worse.

However, this growth is not without its challenges. A population increase so quickly can have all kinds of unintended consequences.

As the father of two, I can tell you that growth spurts are painful, awkward and generally unpleasant experiences. But once a growth spurt is over, we are often better for it (I don’t know about you, but most days I’m happy to no longer be 12 years old).

Of course, a country’s growth spurt is not the same as an adolescent's, although the pains can be oddly similar.

For Canada, these pains can be felt most acutely in our housing industry. The cost of housing is soaring as there is not the supply to meet the demand. Municipal, provincial and federal governments are investing heavily in tackling the problem.

Yet it’s not just housing we need more of. We require more infrastructure to meet our growing population’s needs. There are neighbourhoods to build, pipes to lay, schools and hospitals to construct, roads to pave and bridges to erect.

And that’s just new infrastructure. Our

existing infrastructure is also in need of repair. That will increase even more as we place greater demands on the roads and bridges we travel on or the pipes that carry water to and from our homes.

And this all requires aggregate. Lots and lots of aggregate.

Michael McSweeney, executive director of the Ontario Stone, Sand and Gravel Association, says Ontario alone will need to produce 190 million tonnes of aggregate to meet the demand.

For nations, growth spurts can bring not only pain, but also conflict. There are (and will continue to be) concerns over the environmental, cultural and generational impacts of this growth. Those companies that can effectively manage those concerns will benefit. Those who try to get by through ignoring those concerns, well, they will have a more difficult time.

We have a thriving, healthy country, one that is envied around the world. It doesn’t often feel like it, but it’s true. Yes, Canada has its challenges, but by most measures, there is much to admire about our country. It’s the reason why so many people come here.

As we grapple with the demands of this growth spurt, it’s important we don’t lose sight of that fact.

Final thought: 2024 sure is starting off with a bang. The calendar is full of events over the first few months of the year. There are several conferences happening. If you see me around, please make sure to say hello.

Upcoming events

- Canadian Concrete Expo

- OSSGA conference

- World of Asphalt/AGG1

- National Heavy Equipment Show

- Good Roads Conference

- BC Stone, Sand and Gravel Conference

JAN/FEB

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep. Tel: (416) 510-51132

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor MIKE LACEY 416.510.5115 mlacey@annexbusinessmedia.com

Associate Editor JACK BURTON 289.259.1408 jburton@annexbusinessmedia.com

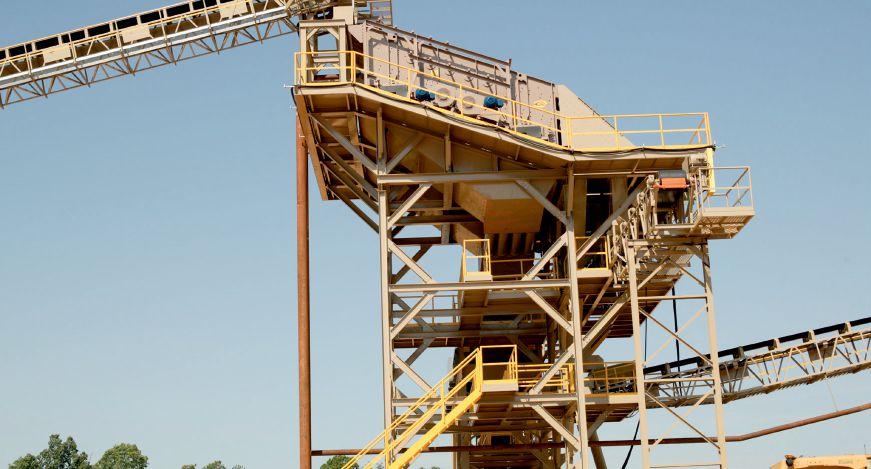

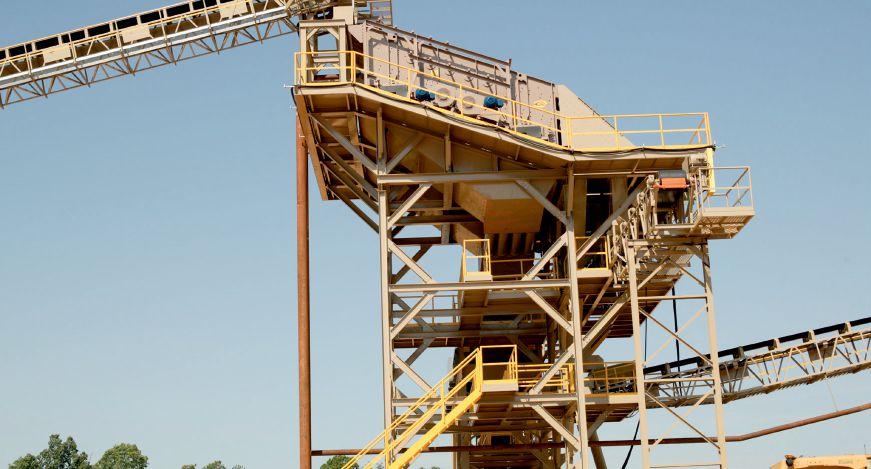

Astec’s commitment to its customers extends beyond making the sale.

From the beginning, our service team has provided construction services for the equipment we build. Astec construction and relocation services for asphalt plants include plant and equipment installs, plant tear-downs and moves, silo repairs, and industrial piping and tank farm installs.

Efficient planning minimizes downtime, local regulations and permits also play a key role. Astec has an extensive history and experience with permitting and regulations. Safety, efficiency, and compliance are paramount throughout the process.

CRH and Caterpillar have signed a strategic agreement for developing and deploying electric off-road vehicles and charging solutions in the aggregates and building materials sectors.

Through this partnership, CRH will test and validate Caterpillar’s 70- to 100-ton-class battery-electric off-road truck across its North America operations, advancing sustainable equipment integration across CRH’s operations while providing Caterpillar with applied insights on its electric equipment’s usage in the aggregates industry.

CRH is North America’s leading aggregate producer, with operations in both Canada and the U.S. With this partnership, CRH is the first company in the sector to sign an electrification agreement with Caterpillar.

CRH has previously collaborated with companies including Shell and Volvo to support the development of new transport

R.W. Tomlinson Ltd. has successfully appealed a zoning bylaw from the Town of Greater Napanee that previously prevented the construction of a permanent hot mix asphalt plant at the company’s Napanee quarry.

The decision, dated Dec. 22, 2023, was delivered by Ontario Land Tribunal member Dale Chipman, and allows the property to be used as the site of a permanent asphalt plant and a ready-mix concrete plant.

Through comprehensive public and agency consultation, the tribunal determined the proposed asphalt plant to be compatible with the applicable planning and land use policies. The tribunal also concluded that potential impacts regarding dust, odour, noise and traffic can be minimized with best practices and proper provincial and municipal requirements.

Arguments for and against this project and the required amendments were presented on Aug. 14, 2023, with closing submissions received Sept. 22, 2023 by video hearing.

electric off-road vehicles across its aggregate operations.

technologies and sustainable equipment within the aggregates and building materials sector.

Following a busy 2023 filled with acquisitions and organizational growth, Superior Industries continued their momentum in December of last year with the addition of Kyle Donaldson as sales manager for conveyor components in the territories of Ontario and Canada’s Maritimes.

Located west of Toronto, Donaldson will be the primary point of contact across the regions for selling, training and supporting the industry on Superior’s conveyor parts.

“Kyle’s energy level is tremendous, and he’s very well respected in the region,” said Mike McFerren, manager of conveyor components sales at Superior. “Additionally, he’s very experienced: experienced in aggregates, experienced in the local market and experienced with our products.”

Donaldson joins Superior after 14 years at ELRUS Aggregate Systems, where he most recently served in their sales department.

Rock to Road magazine is circulated free of charge to qualified individuals holding management and supervisory positions with companies engaged in the aggregate, roadbuilding, ready-mix concrete and asphalt production industry in Canada. The Publisher reserves the right to determine qualification.

BY JACK burton

Canada’s aggregates and heavy construction associations share their New Year’s resolutions

> While some may still be struggling to avoid writing ‘2023’ on their cheques or considering dusting off that gym membership after a holiday turkey binge – we don’t blame you – Canada’s aggregates, roadbuilding and heavy construction associations have already hit the ground running on the busy year ahead.

We checked in with provincial associations across the country to get a sneak peek on what to expect from 2024, including infrastructure initiatives, moves to improve government relations and regulations, supply chain struggles and improvements to the sector’s persistent labour shortages.

The Alberta Sand & Gravel Association (ASGA) sees 2024 as an opportunity to reposition the industry and its relationships with

the province’s government and communities for success, with ASGA hoping to tackle a number of policy changes to remove growth ceilings and create the space for the aggregates industry to thrive.

One significant step is ASGA’s involvement in stakeholder advisory committees at the municipal level, making reviews and recommendations on their aggregate resource plans. Its first municipal collaboration began in fall of 2023, with ASGA hoping this partnership to have laid the foundation to forge similar relationships across the province.

“It’s been good to hear concerns from the citizens on the committee, but also to see their ‘I had no idea’ faces when presented with the facts of aggregate development and consumption: they’re realizing the value of aggregate, how regulated the industry currently is and learning some facts about things like land reclamation,” said Rob Fragoso, ASGA’s executive director.

A unique aspect of Alberta’s aggregates industry is the bylaw-mandated truck registry, which ASGA helps to manage and maintain. Certain municipalities require gravel trucks to be part of this registry for

accountability and feedback, but ASGA is looking to make changes to the registry and its requirements this year due to rising compliance issues.

“If a truck is not in the registry where mandated and attempts to haul gravel, the owner-operator will be warned or ticketed through local bylaw enforcement. Some operators won’t even allow hauling by trucks that are not part of the registry, regardless of location,” said Fragoso.

“It’s worked well in many instances, but has been problematic at times for various reasons. At ASGA, we’re looking at some potential changes, as we have seen a marked decrease in the number of registered trucks since the beginning of the pandemic.”

The Community Aggregate Payment Levy struck between ASGA and the province is another target of the changes the association is looking to make in 2024. The initial intention, Fragoso said, was to give municipalities a direct financial benefit from local aggregate producers based on a percentage of hauled tonnage, providing operations with a way to show their direct benefit to the communities

they work in and potentially ease municipal permitting and public opposition.

“That was the intent,” said Fragoso. “What’s happened, though, is many municipalities used the levy funds as general income, which they then used as wished without crediting the industry. In other words, communities are not seeing the positive impact operators have in improving local infrastructure and other projects. The agreement expires in December 2024, and I will be working with municipalities and the government on a solution that benefits all sides.”

Foundational to all these initiatives, though, is ASGA’s commitment to ensuring that the aggregate industry’s role in the provincial supply chain of infrastructure and commerce is properly recognized and accommodated at all levels, from key stakeholders to the general public.

“Without sand and gravel, you can’t have concrete, asphalt or other major infrastructure materials,” said Fragoso. “The government has infrastructure plans in place and sees its importance as the province and country continues to grow, but I’m not convinced they have a similar view

of aggregates, and the risks that sterilization and over-regulation poses. Part of the plan for 2024 is to press on these issues and create awareness of it.”

In Manitoba, the new provincial leadership’s priority on continuing the previous administration’s focus on infrastructure and heavy construction as a collaborative pathway to economic prosperity has left members of the industry with something to be excited about.

“We’re optimistic, given Premier Wab Kinew’s commitment to our industry being the economic horse that pulls the social cart and his view that the country needs a nation-building Canada Trade Infrastructure Plan,” said Chris Lorenc, president &

CEO of the Manitoba Heavy Construction Association (MHCA).

Kinew’s commitments have introduced several initiatives into the industry, including acting on his plans to establish a blueribbon advisory panel for infrastructure investments, early indications to build up Manitoba’s extraction and mining sector, improving relationships with stateside trade hubs and building up the City of Winnipeg as an economic and infrastructural leader.

“I think it’s been made very clear, with both the outgoing and new administrations, that the role of Manitoba’s transportation and infrastructure sectors need to be recognized for what they should be, which is an economic growth enabler,” said Lorenc.

“We’re optimistic, given Premier Wab Kinew’s commitment to our industry being the economic horse that pulls the social cart.” – Chris Lorenc, president & CEO of the Manitoba Heavy Construction Association.

The plans to reposition Winnipeg as an infrastructure hub both within and beyond Canada’s borders include the adoption of a specification review working group process, a collaborative change to how the city’s road projects will be introduced, designed, constructed and updated.

With this change, the review process for Winnipeg’s road projects is now a collaborative affair between key stakeholders including the city’s Public Works Department, the Association of Consulting Engineers, the Urban Development Institute, and the MHCA. The alignment this change has brought across key players in the city’s roadbuilding projects has the MHCA now advocating for it to be adopted at the provincial level.

“On the surface, one might say, ‘well, who cares?’ Well, we should all care. If we can streamline products from our aggregate industry, and produce it in greater volume, this volume reduces the cost of the final product, with the volume and consistency of designs reducing risks for both manufacturers and contractors during the construction or reconstruction process,” said Lorenc. “All of that has very, very positive implications on lowering costs, not just maintaining them.”

This big-picture approach to infrastructure and heavy construction gives Lorenc confidence the provincial administration is on the same page as industry leaders when it comes to viewing heavy construction as a key player on the path to developing Manitoba’s profile as a global trade hub.

“The Department of Transportation and Infrastructure should not be simply viewed as an asset manager that fixes potholes or repaves surfaces – those are aspects, certainly, but it needs to be seen as part of a larger strategy to harness investments in transportation, grow the Manitoba-U.S. economy, and enhance our trade profile not just in Western Canada, but domestically, continentally and globally,” he said.

As an association, Lorenc shared that these commitments, along with meetings between the MHCA and key figures within Manitoba’s Ministry of Transportation and Infrastructure, have positioned the association – and the province’s industries – in a beneficial vantage point heading into this year.

“All of this gives us a reason to be optimistic and excited about the prospects for economic growth in this province heading into 2024 and beyond,” he said.

On the east coast, Prince Edward Island (PEI) faces many of the same factors that have been affecting roadbuilding and

heavy construction professionals over recent years, with one notable exception regarding aggregate cost and supply.

“Like most provinces, our industry struggles with labour shortages, rising costs, and availability of materials and equipment,” said Melissa Paquet, executive director of the PEI Roadbuilders & Heavy Construction Association (PEIRB). “One unique challenge to PEI, though, is that a very high percentage of our aggregates are shipping in from out-of-province, due to there being no local sources.”

The lack of close-to-market solutions across the Island means current obstacles common to the country’s heavy construction sector, such as supply chain issues and inflated material and transportation costs, are especially pronounced in the province.

“With almost no local sources, it has become a challenge to co-ordinate due to strained transportation resources and increased aggregate and shipping costs –even imported products are harder to get,” Paquet said.

These availability issues have made it more difficult for roadbuilding projects to have the resources necessary to be completed on time, while also making it more expensive for projects to effectively source these materials in the first place.

“There has been limited transportation resources available which can sometimes make it challenging to get the aggregates we require, when we need them,” said Paquet. “With aggregate being so far from our markets, we’ve seen larger transportation costs than most other provinces: trouble with gravel ships, trucks, and sources. We’re seeing increased costs to get these products there and back.”

One resource that the association is focused on making available across the province’s roadbuilding and heavy

construction industry, however, is labour. With labour crunches affecting all provinces, the PEIRB is committed to making it known to the province’s workers of tomorrow that there are viable career paths within the roadbuilding and heavy construction industries.

To achieve this, the association has developed the Essential Skills Pathway, a collaborative program developed alongside the province’s Department of Education. The program connects high school students with ground-breaking technology that showcases the wide array of opportunities that a career in the province’s roadbuilding and heavy construction sectors presents.

“One of our major initiatives is our investment in the Vortex Edge Max, which simulates six different pieces of heavy machinery as part of our Essential Skills Pathway program,” said Paquet. “The end goal is to draw more youth to our industry, by showing them the great opportunities and careers available in PEI’s roadbuilding and heavy equipment operation sectors.”

The Essential Skills Pathway program is just one of several ways the association is addressing industry’s labour issues. Between participating in local job fairs, consulting with Charlottetown’s Holland College on their construction technology program and showing Canadian newcomers the viability of heavy construction as a career, the PEIRB’s commitment to addressing labour gaps is a core value informing their goals for years to come.

“Recruiting more qualified people into our industry, to fill those vacancies, is our association’s most pressing longterm goal,” said Paquet. “We want to let as many people know as possible that there are great opportunities and careers available in the roadbuilding and heavy equipment fields.”

MICHAEL mcsweeney

This year has potential to be very good for Ontario's aggregate industry, says Michael McSweeney.

The Ontario Stone, Sand and Gravel Association (OSSGA) has a new man at its helm.

Michael McSweeney took over as executive director in November of 2023, replacing Norm Cheesman who had guided the organization for nearly eight years.

McSweeney brings a wealth of experience to the role.

Most recently he was executive director of the Ontario Road Builders Association. Prior to that, he served for as president and CEO of the Cement Association of Canada. McSweeney has worked in the private and public sector for more than 35 years, which includes nearly a decade as a city and regional councillor in Ottawa.

Rock To Road recently spoke with McSweeney about the aggregate industry’s outlook for 2024, his background and his vision for OSSGA moving forward.

When you look at the challenges and opportunities across the industry, how would you describe the current state of Ontario’s aggregates sector heading into 2024?

McSweeney: You could say the aggregate industry is at a crossroads. All levels of government are spending unprecedented amounts of money in public infrastructure. They are spending money on social infrastructure — hospitals, schools and long-term care homes — on above ground infrastructure — roads and bridges — and on below ground infrastructure — wastewater treatment infrastructure and above and underground transit. It’s an unprecedented investment, but none of it can be built without aggregates. More roads and infrastructure mean that we need more aggregate. A lot more. It is estimated that to meet the challenges of Ontario’s growing population we will need an average of 190 million tonnes of aggregate a year.

However, while this demand is growing, the timeline to bring new aggregate sites into production is increasing. NIMBYism and the misinformation that is so prevalent about aggregate is the root cause of the problem. In 2024 and beyond, we need to pull out all of the stops and help educate and persuade Ontarians about the need for aggregate – and that close-to-market aggregate is the environmentally-smart solution to building Ontario’s infrastructure. This outreach will

include active meetings with First Nation Communities, environmental groups and other decision-makers and influencers in our province.

Could you tell me about your past roles and experiences, and how this will inform your decisions and approach in your new position as executive director of OSSGA?

McSweeney: I bring with me a wealth of experience right across the supply chain. I was the CEO of the Cement Association of Canada for 15 years, as well as most recently the CEO of the Ontario Road Builders Association, so aggregate seemed the next logical place for me to land. You could say that I’ve done it backwards – I’m going down the supply chain to the raw material that makes it all happen, because without stone, sand or gravel, nothing gets built in Ontario.

The specific experience I bring to OSSGA is around sustainability and a vision for a net-zero industry by 2050. We have an engaged board and membership, and we will continue to map out a plan for the aggregate industry to address climate change and I’m very much looking forward to bringing my vision, experience and passion for the environment to the aggregate business.

When it comes to events, advocacy and organizational plans, what does 2024 have in store for OSSGA?

McSweeney: OSSGA is pleased to be hosting our conference and AGM in February. In 2024, we’re pleased to be launching our inaugural Queen’s Park Lobby Day, which will be held this spring. It is important to have a constant, consistent and co-ordinated presence at Queen’s Park along with a compelling story to tell legislators and civil servants. This presence will create opportunities for our members to showcase not only the importance of stone, sand and gravel to building Ontario but how the industry plays such an important role to the economy of virtually every riding in the province. It is also important for OSSGA to create stronger ties with municipal governments who are charged with developing Official Plans for their communities.

In addition to attending the Association of Municipalities of Ontario's annual meeting, we look forward to sponsoring and hosting the mayors and councillors

of the province in a reception in Ottawa, as well as visiting them in their cities and towns. To tell the story of aggregate, we need to be out speaking to the politicians and helping them work with their constituents to demonstrate the need for aggregates in all aspects of their daily lives.

I’ll be spending a lot my time with these communities explaining why aggregates are so important. But I will also try to understand their fears.

The reality is, we don’t have a choice where to locate our pits and quarries. We have to locate business where the Creator put the aggregate. But where we can have an impact is how we extract aggregate in a socially and community minded way. It’s a process of education and building relationships so that we can better understand what is at the root of people’s concerns.

With the Ontario government planning to build 1.5 million homes by 2031, what will the province's aggregate industry need to do to meet this demand?

McSweeney: Each home in Ontario takes approximately 250 tonnes of aggregate to build, not including the aggregate needed to build all of the roads, transit, shopping malls, schools and other infrastructure to support the people who will live in those homes. So that’s likely close to a billion tonnes of aggregate to put that new infrastructure in place.

To transform all of that aggregate into the concrete, cement, bricks, glass, asphalt, subway lines and road bedding that we need – while being environmentally smart – it’s imperative that we embrace the use of close-to-market aggregate. That means reducing the lead time it takes to bring new pits and quarries online. We can always get aggregate further north, but should we be extracting aggregate and trucking it across dozens of municipalities further south?

Industries across Canada are facing difficulty in finding and retaining labour. What are the unique challenges Ontario’s aggregates sector faces on this front and what are some of the initiatives OSSGA has announced or is planning around this issue?

McSweeney: Working in the aggregate industry is a great career opportunity. A lot of people who work in the aggregate industry come from the community, so they are our ambassadors. They are the ones who should be talking about the benefits of employment in the aggregate

sector. The biggest barrier we have as an industry is that opportunities in the sector are not well known. For that reason, OSSGA has been attending career fairs and working with sector partners to better showcase the career opportunities especially in the area of heavy equipment, mechanics and environmental scientists. We really encourage anyone who is interested to visit GravelFacts.ca where they can see a wide variety of career opportunities described by the people currently in those jobs. From plant operator to field worker, the opportunities are endless.

With the prevalence of both construction opportunities and labour issues, what role can emerging technologies, such as automation and artificial intelligence, play in the aggregate industry? Are there any other technological solutions you are excited about? McSweeney: There are definitely sites in the United States that are starting to implement some automation with respect to loaders and trucks. That technology hasn’t made its way into Canada yet, but there’s no question it’s coming. With respect to artificial intelligence, there are many opportunities in the not-too-distant future. An obvious one is enhancing

equipment performance by using sensors to monitor performance and then using AI to optimize the operation of that equipment. Augmented reality will play a crucial role in training and maintenance programs with workers using smart glasses to obtain real-time instructions. Predictive analytics will help better optimize production, schedules, anticipate equipment failures and make data-driven decisions for continuous improvement.

When looking beyond 2024, what are your long-range plans and goals for OSSGA?

McSweeney: It’s an exciting time. I would say our long-range plans and goals are focused on building relationships: with governments, First Nations, environmental groups and with Ontarians in general. OSSGA wants everyone to know the world is built with stone, sand and gravel, and that our members are here to do that in the most responsible way possible. We can’t build homes, hospitals and public transit without aggregates. We can’t build roads without aggregates. Aggregates are the fundamental foundation of our communities and Ontarians need to understand that better.

>It’s late fall in the Cariboo Region of central B.C. Two operators have set up a drill rig near a stand of fir trees at the end of a dirt road close to Highway 20 at Hodgson and Dog Creek roads, southwest of Williams Lake.

Lengths of metal pipe are stacked nearby. One of the operators, in blue coveralls and a white hard hat, is at the controls of the heavy equipment. The other is a few feet away, keeping a watchful eye on the operation.

The area has been affected by a slowmoving landslide and the operators are there to do geotechnical drilling of up to 74 metres below the surface. Instruments will then be installed in the holes to measure the characteristics of the slide and provide engineers with the data they need to develop mitigation measures.

In 2021, multiple historic landslides were reactivated in the area. Sections of Highway 20 and portions of provincial side roads were damaged by the ground move-

BY GRANT cameron

ment and were repaired. Since then, the Ministry of Transportation and Infrastructure has been investigating how to mitigate further slides in the area.

The venture is one of 10 slide mitigation projects along the Highway 97 corridor between Williams Lake and just north of Quesnel, known as the Cariboo Road Recovery Projects (CRRP). The work being done includes research on soil and water, environmental reviews and on-site inspections and interim drainage and slope improvements.

John Babineau, deputy director of the CRRP at the B.C. Ministry of Transportation, says drilling at the Hodgson and Dog Creek roads will provide engineers with the detailed information they need to come up with solutions.

“It’s a unique slide, it’s very large, it’s very deep-seated and is one that is particularly challenging,” he says. “The geotechnical investigation has been going on for the last two years. There was some additional investigation this fall to continue to inform the project team of the characterization of the slide.

“It allows us to get a good sense of what’s going on, what are the driving forces, how we could actually attack and try to stabilize the slide.”

The investigation will assess the amount of groundwater, gauge if movement has occurred and get a sense of where the failure plane is, how it’s changing over time and

how the groundwater is interacting with the slide.

“We’ve learned you can’t have too much technical information,” says Babineau. “That level of investigation is a really important piece in making sure that when we deliver a solution, we’re confident it is the best solution. Our goal here is to slow down the slide and stop the slide if we can, and that will have a benefit to not just highway infrastructure but to municipal infrastructure, private utilities and homes as well.”

Work on mitigation options at the Hodgson and Dog Creek roads has been ongoing since spring 2021. The risk to public safety is considered low and roadways are still open. However, a potential fix is not easy.

Engineers will examine data that will be collected from instrumentation in the bore holes and look at information collected from past investigations. The details will provide the project team with a sense of forces driving the slow-moving slide and what measures need to be put in place to stop it from causing further damage.

“We know that surface water and groundwater are always problematic for landslides and managing that will always have a benefit to the slide, so we’ve undertaken ditching improvements, culvert improvements, moving standing water and surface water into public rights of way to get it into the ditches and get it down off the slide as efficiently as they can,” notes Babineau.

Indeed, crews have updated existing infrastructure and are clearing and widening ditches and installing a new culvert to move rain and snow melt from the upslope to downslope area.

The project team hopes to formulate specific options to stop the slide next year and present the measures to the public at meetings.

An idea for the Hodgson slide includes upgrading existing drainage infrastructure. On the Dog Creek slide, an option may include flattening the top of the slide, construction of a berm at the bottom to prevent movement, and placement of large rock in seepage areas. The slide is too big to stabilize mechanically.

Changing weather patterns have hit the Cariboo Region particularly hard in recent years. The province is restoring access where feasible while designing and building transportation infrastructure that will be more resilient.

In all, 10 sections of road in the Cariboo along the Highway 97 corridor between Williams Lake and just north of Quesnel were significantly affected and are slated for mitigation measures. Fixes for each area are different.

“We see some slides that are on major routes, and we’ve got some slides on very low volume sideroads,” says Babineau. “Some slides have been moving for a very long time but were certainly moving much more quickly in 2020 and 2021, and we

have some that we’ve never known about before and have come out of nowhere.

“Our approach on each of them, apart from using a thoughtful, technically-based approach, is that all projects are on their own path.”

The design and construction of two other projects along the route have been approved at a cost of $538 million. They are expected to move to the construction phase next year.

At Highway 97 and Cottonwood Hill, about 15 kilometres north of Quesnel, a historic slide reawakened in 2020 and ministry contractors have installed groynes along the Cottonwood River adjacent to the highway. The groynes, built with large rock material, redirect river flows away from the slide area.

Interim works have also reduced the force of the river on the bottom of the slide while the highway will be reconstructed and stabilized through the slide area. The stabilization work includes removing weight from the top of the slide and improving slope stability. Final details of the project are being confirmed and construction on the highway realignment is scheduled to start in the spring.

The project team is working with partners to ensure the protection of aquatic habitat and wildlife while working on the area.

At Blackwater and Knickerbocker roads, meanwhile, construction is expected to start in summer 2024, with installation of pumping wells to reduce groundwater pressure. Future phases of work will include the realignment of 1.4 kilometres of Blackwater Road, beginning in spring 2025, and armouring a section of the riverbank to withstand the river forces and ensure materials are held in place, starting in summer 2025.

This past summer, crews were doing environmental and geotechnical testing and research work at the site, including drilling to collect soil and water samples.

Seven more projects along the corridor are moving through the design and funding approvals stage and will require significant investment:

Quesnel-Hixon Road: The road is closed to traffic as the slide remains active and unsafe for vehicles. Geotechnical investigations have been completed and crews did visual environmental inspections along Quesnel-Hixon Road, Cottonwood River Canyon Bridge and Cinema-Old/ Ahbau Creek Bridge crossing locations, and Naver Creek.

Quesnel-Hydraulic Road: The road is open to single-lane alternating traffic. In September, a geotechnical drilling program was carried out in the area to collect soil and water samples. A substantial amount of armouring and bank protection work was also done.

Kersley-Dale Landing Road: A temporary, single-lane gravel road is open for local traffic and the ministry is in the final stage of determining long-term restoration options.

Bastin Road at Bastin Hill: The road has been reduced to single-lane traffic. Construction work, including drainage improvements, slope repair and stabilization and debris removal was completed in 2022 and long-term restoration options are being explored.

Durrell Road: The road is closed. Engineers are doing technical work and looking at restoration options.

Highway 97 at Cuisson Creek: In 2021, cracked pavement and other surface damage was repaired and geotechnical drilling was done.

Soda Creek-MacAlister Road: The road is closed at the slide area. A geotechnical drilling program was carried out and

long-term restoration options are being explored.

While B.C. is always susceptible to landslides due to the mountainous terrain in many parts, persistent wet seasons in 2020 and 2021, combined with snow melts, triggered the deluge. Meanwhile, major wildfires damaged vegetation in the area, making it less effective at absorbing moisture and holding soil together.

“That really gave the groundwater a chance to saturate and come up into the slide and reactivate a number of slides,” says Babineau. “Since that we event, we haven’t seen that level of movement in the Cariboo Region.”

Each landslide is different and requires an individual fix, according to Babineau.

“They’ve all got their own characteristics. We see some slides that are on major routes, we’ve got some slides on very low-volume sideroads, some slides have been moving for a very long time, but were certainly moving much more quickly in 2020 and 2021, and we have some that we’ve never known about before and have come out of nowhere and had a really big impact on infrastructure.

“No two landslides are the same, nor is

Popular industry trade show runs March 25 to 27 in Nashville

World of Asphalt and AGG1 Aggregates Academy & Expo returns to Nashville, Tenn. from March 25 to 27.

More than 400 exhibitors will be on display at the popular show, which features a lineup of the top manufacturers and service providers of the asphalt industry.

Below is a small sampling of what visitors will see.

BKT USA INC.

Booth: 353

BKT, one of the world’s leading manufacturers of off-highway tires, will have various promotional giveaways at its booth, including baseball caps, Bik & Tik coloring supplies, EARTHMAX keychains and soccer balls.

The following products will be featured:

• EARTHMAX SR 41: An all steel radial tire for articulated dump trucks, loaders and dozers. Thanks to its all-steel structure and special block pattern, EARTHMAX SR 41 provides excellent resistance against punctures and an extended service life. In addition to long working hours without downtime, the tire ensures extraordinary comfort.

• EARTHMAX SR 45: An all steel radial tire specially designed for rigid haul trucks. EARTHMAX SR 45 is the ideal tire for all operations requiring high traction.

• EARTHMAX SR 53: An all steel radial tire specially designed for loaders,

dozers and low profile dump trucks (LPDT) operating in severe rocky conditions, including underground operations and scrap yards. The deep L-5 tread and the cut-resistant compound provide an extended wear life in addition to excellent traction and stability.

Haver & Boecker Niagara’s Niagara F-Class vibrating screen features new technology for simplified maintenance combined with maximum performance and longevity. The updated design retains the technical benefits the original F-Class is known for, such as improving performance in material stratification and reducing blinding and pegging.

The vibrating screen is primarily manufactured with vibration-resistant lockbolts instead of the traditional welding. Lockbolts are more effective at maintaining structural integrity during operation while making vibrating screen maintenance more convenient, safer and cost-effective. Additionally, the company redesigned the flat

deck models to create the largest amount of open area possible.

Haver & Boecker Niagara have also redesigned the flat deck models of the new F-Class to create the largest amount of open area possible for modular screen media. Featuring replaceable polyurethane anchors, the new high open area modular deck is suitable for virtually any pin and sleeve modular screen media.

The F-Class is available with a variety of configurations and upgrades, and can be used in both stationary and portable applications.

MAJOR offers FLEX-MAT Modular PLUS, which is specially designed to withstand harsh screening conditions with the most abrasive materials, such as granite and basalt. The advanced screen media offers all the benefits of FLEX-MAT — high open area, efficient stratification, no blinding or pegging — combined with a new and improved wear life comparable to polyurethane screen media. Additionally, the media offers up to five times longer wear life than traditional woven wire and produces a

No matter how challenging your needs, BKT is with you offering a wide range of OTR tires specifically designed for the toughest operating conditions: from mining to construction sites. Sturdy and resistant, reliable and safe, able to combine comfort and high performance.

BKT is with you, even when work gets tough.

“World of Asphalt is a great place to bring together new technology, along with industry ambassadors to highlight the future of asphalt.” — Earl Roberts, W-L Construction & Paving

March 25-27, 2024 | Nashville, Tennessee

Use promo code PARTNER20 to save 20% off admission

ASPHALT TRADE SHOW AND CONFERENCE

• 400 Exhibitors

• 120 Education Sessions

March 25-27, 2024 | Nashville, Tennessee

Use promo code PARTNER20 to save 20% off admission

cleaner retained product.

The efficiency-enhancing design of all FLEX-MAT screen media, including the modular PLUS series, allows the wires to vibrate independently from end to end under material contact. The high frequency of the wires — 8,000 to 10,000 cycles per minute — adds to the vibration of the screen box — 800 to 900 cycles per minute — to speed up material separation and passing.

The new PLUS series is available in the D, S and T series. FLEX-MAT Modular PLUS screen media panels are available in either the patented OPTIMUMWIRE or 304 stainless steel wire.

Booth: 305

Martin Engineering delivers tough, tested and innovative material handling solutions, backed by ndustry experience. Specializing in belt cleaning, belt support, belt alignment, belt sealing, dust management, flow aid solutions and more, Martin offers products specifically suited for the aggregate industry.

Products on display include:

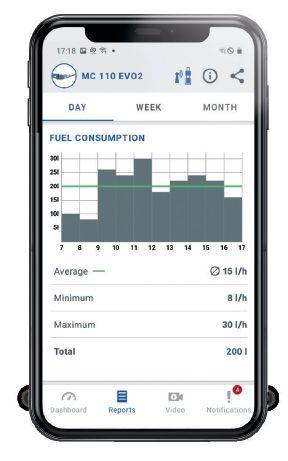

• Martin Engineering N2 Position Indicator: Martin Engineering’s intuitive N2 Position Indicator allows for remote monitoring of the belt cleaner blade via Martin’s proprietary mobile app, indicating remaining blade life, notifying when re-tensioning or replacement is required and warning in the event the blade is no longer in contact with the belt. The N2 Position Indicator will collect data and provide information on any belt cleaner utilizing a Martin blade.

• Canoe Liner: Installed inside conveyor transfer point skirtboards, Martin Manufactured Canoe Liners absorb impact and abrasion and creates a dam to shield the sealing system from the

weight of the material load, prolonging the life of the seal. Martin manufactured Canoe Liners feature a steel plate molded inside the urethane to prevent bond issues. Liners are also stackable to line higher drop chutes.

• Martin Air Cannons: When material is hung up in a hopper or head chute of a conveyor transfer point, it can force a shut down during shifts to get the process back online. Instead of using hammers or lances to clear material, Martin Air Cannons offer another approach. Air cannons provide a controlled blast of air to clear material blockages and maintain proper material flow.

McCloskey International leads the mobile aggregate screening and crushing industry with a complete line of equipment including crushers and screeners.

• J6 Jaw Crusher: Designed to thrive in the most challenging environments, McCloskey International states the J6 jaw crusher is not only resilient, but powerful and reliable. The company boasts the J6 has unmatched performance with its jaw chamber configuration and optimized material circulation, and the design not only ensures superior durability but also that the machine achieves high throughputs. The large chamber tackles some of the toughest materials and the J6 also features an optional factory fit rock hammer for added versatility.

• C3 Cone Crusher: The mobile C3 Cone Crusher has been designed to deliver superior performance while also achieving higher capacity, better product quality, optimum versatility and improved fuel efficiency. The C3 cone crusher is equipped with

a powerful and efficient cone with a hydraulic closed side setting (CSS) adjustment allowing for consistent and precise product sizing. The C3’s large feed opening allows the crusher to accept larger feed sizes, increasing throughput and reducing the risk of bridging, where material gets stuck in the crusher. This crusher can handle a wide range of materials and applications, including secondary and tertiary crushing. The C3 optimizes power utilization while maintaining high crushing efficiency. Its direct drive and variable speed reduce energy consumption and operational costs. The C3 also comes with features like a large high-resolution control panel display with full machine monitoring and remote monitoring with 365Connex Telematics, optimizing the crusher’s performance and ensuring efficient operation even in varying conditions.

Polydeck has distinguished itself as the leading provider of modular synthetic screening media and comprehensive screening solutions.

Visit the Polydeck booth to learn how the company will provide a free plant survey to anyone located in North America. The company’s screening experts will review your screen media along with wear and static parts. Their comprehensive analysis will equip you with the insights needed to enhance your screens for optimal performance, achieving higher throughput at lower costs.

Feature products on display include:

• RUBBERDEX ULTRAMAX: Ultrahigh open area modular rubber screen media.

• METALDEX ULTRACLEAN: Ultrahigh open area modular wire screen

media with integrated secondary movement to eliminate plugging and blinding.

• PROTEX UC: Urethane coating that fully seals steel to extend life of equipment, provide abrasion and tear protection, and reduce noise pollution.

Booth: 517

After acquiring CEMCO last year, Superior Industries rebranded the company name, but maintains the name and design of the 60-year-old CEMCO Vertical Shaft Impact Crusher.

A T80 single drive model of the pioneering VSI will be on display in Superior’s booth at AGG1. Notable features include an interchangeable crushing chamber that accommodates multiple rotor and anvil configurations, a hydraulic lid lifter, and an adjustable feed tube. Superior’s CEMCO VSI is available in seven models with production rates up to 450 tons per hour.

Booth: 1101

For 50 years, Techweigh has provided durable, accurate and reliable in-motion feeding, weighing and metering equipment for dry material handling needs. The following items will be featured at the company’s booth:

• WY10 Belt Scale: The Tecweigh WY10 Single Idler Conveyor Scale is the most dependable and rugged belt scale on the market. Weather-tight one-piece construction keeps your line rolling, even in the most extreme conditions: dust, dirt and harsh weather. The WY10 utilizes LVDT load sensor technology. LVDT load sensors simply can’t be overloaded and are far less susceptible to damage from lightning

strikes, reducing changes of blown load cells.

• HY15 Belt Scale: The HY15 Hybrid Belt Scale was designed to incorporate the Tecweigh electronics package with the less costly modular scale frame design. The compact, low-profile design is suitable for many conveyor applications, including mobile units. Made with heavy-duty cold rolled steel, the HY15 will withstand the harshest environments. Featuring two NTEP approved strain-gauge load cells, the HY15 offers a single-idler accuracy of one-half to 1 per cent. The dual-idler HY25 model provides an accuracy of one-quarter to one-half per cent. These scales come with a complete installation kit, mechanical overload protection, signal conditioning enclosure, calibration weight brackets, speed sensor, and Tecweigh’s standard five-year warranty. Tecweigh’s Hybrid Belt Scales can also be provided with optional features including wireless communication, multi-scale processor, printer, remote displays and more.

• WY15 Belt Scale: Keeping with Tecweigh’s tradition of unbeatable accuracy, dependability and ease of use leads the company to combine its unique time and labour-saving belt scale features with strain gauge load cell technology in its WY15 Conveyor Scale. The Tecweigh WY15 Single Idler Conveyor Scale utilizes two NTEP approved bending-beam load cells, features rigid all-welded construction. It is backed with a five-year warranty.

Booth: 357

Terex MPS is a leading provider in the crushing and screening industry. Comprising three legacy brands – Canica, Cedarapids and Simplicity – Terex MPS supplies a range of crushing and screening equipment across key industries, including mining, aggregates, demolition and recycling, and industrial minerals.

Terex MPS offers a diverse product line, including modular, portable and static equipment designed to produce the highest quality end products. The equipment caters to the processing needs of hard and soft rock, sand and gravel, ore, and industrial minerals.

The company’s team of product specialists will be on hand at AGG1.

The event supplies a platform to share insights, contribute to conversations and highlight the latest advancements shaping the future of crushing and screening. AGG1 presents an opportunity to collaborate directly with Terex MPS’ distribution network to discuss and address the evolving needs of customers.

Booth: 431

Weir ESCO is a developer, manufacturer and provider of components for mining, construction and industrial applications. The company’s booth will feature its latest products, including:

• Crusher wear parts

• Bucket GET, teeth and lip systems

• Construction excavator and wheel loader buckets and attachments

• Blades, end bits and cutting edges

Motion Metrics has recently joined Weir ESCO. Stop by the booth and learn how these smart products can provide data solutions that improve quarry safety and energy efficiency.

LoaderMetrics cameras will mitigate the risk of crusher obstructions caused by missing teeth. Motion Metrics LoaderMetrics cameras use artificial intelligence and thermal imaging to provide accurate missing tooth detection for all loader types. This alerts operators to missing teeth before the teeth travel downstream and obstruct crushers.

Motion Metrics' proprietary lens-cleaning system ensures accurate performance under the harshest environmental conditions. The hardware is built to meet or exceed military standards for temperature, shock, vibration and dust.

Weiler MTVs are designed with innovative features to increase productivity while reducing operating costs, and are available with front- and rear- mounted operating platforms.

Weiler commercial pavers bring reliable, heavy-duty design and components to the commercial paving market.

Weiler road wideners feature durable designs in the right size machine for the job. The S200 soil stabilizer provides high production in a variety of applications with both a soil and combination rotor option.

The D560 and D460 rock drills rely on a proven hammer design and are the only drill built in North America.

BY JACK burton

> Adaptation is on the agenda for the aggregates and roadbuilding industries.

This is due to Canada’s pledge to reduce carbon emissions to 40 per cent below 2005 levels by 2030 and ultimately reach net zero by 2050. These goals, and the changes they will bring to the sector, were the topic of Rock to Road’s inaugural virtual event, the Road to Net Zero.

Presented alongside exclusive sponsor ASTEC, the event opened with a keynote speech from Crestview Strategy and was followed by the Navigating Net Zero roundtable, which explored the changes these carbon reduction goals will bring and the strategies producers can use now to prepare for what’s to come.

Rock to Road brought together leading voices on sustainability in the aggregates and roadbuilding sectors to discuss these changes, including Mac Carmichael, senior director of sustainability and environment at Green Infrastructure Partners (GIP); Bill Gowdy, technical director of aggregates at SLR Consulting; Dr. Jon Makar, low carbon materials lead at the National

Research Council (NRC); and Trevor Wagoner, product manager of sustainability at ASTEC.

Here is what the roundtable had to say:

RTR: Based on your experience, I’d like to try and get a snapshot of where you feel the roadbuilding and aggregate sectors currently stand when it comes to these goals.

BILL: Where we are in the aggregate industry is unique. We’re in the business

of moving materials – a lot of what we do is transportation. Most of the greenhouse gas contributions I’ve seen are associated with the transportation behind getting these materials to market.

Deposits close to market are being depleted very, very quickly, and that’s going to increase the demand for transportation. The ability to have as much material as possible close to the market is going to become really critical. There are a lot of issues around permitting, public opposition, and resistance, but what it actually

Left to Right: Bill Gowdy, technical director of aggregates at SLR Consulting, is a geologist with more than 35 years of experience in all facets of aggregate assessment, including environmental monitoring, reclamation and securing regulatory approvals; As ASTEC’s product manager of sustainability, Trevor Wagoner works alongside the company’s Infrastructure Solutions group to help in developing innovative products that are economically and environmentally sustainable.

ends up doing is increasing greenhouse gas contributions.

TREVOR: The opportunity I’m seeing right now for us in the industry is a chance to really stay ahead of things and lead the conversation as the rules are being written. At your company, especially if you’re a producer, put together a program to track and manage energy consumption. Having that baseline established can inform you how to achieve a 10, 20, even 50 per cent reduction in greenhouse gases or your carbon footprint.

JON: One of the things to pay attention to is not just legislation, but where the procurement requirements are coming

ning to make any reduction based off it.

JON: It really is important to start getting those baseline numbers and establishing where you are. You want to be measuring what you’re doing, because at some point, someone is going to ask about them, and if you can’t demonstrate that you’ve improved, or even started, then you’re going to run into trouble.

Tracking, ideally in a form that is thirdparty validated, is going to be critical, whatever your role in the construction industry is. You’ll need to demonstrate what your carbon impact is, and that’s only possible if someone is doing a calculation on the whole project.

from. That’s where you’ll see the initial impact, because that’s where they’ll be looking to have their suppliers demonstrate that they’re cutting GHGs.

In many cases, it’s going to be much more about what the local people want. What Vancouver does is going to be different from what Toronto does, so it becomes about engaging with the people that you’re working with. If they’re buying your products or services, you need to know what their specific requirements are going to be based on where their market is.

MAC: It’s important for the industry to adapt now to start down that road to decarbonization. These requirements are not onerous, and we’ve already woven some of these ESG and sustainability considerations right into our operations.

In the construction materials world, we often look at ourselves as the temporary steward of a project, but we need to understand that what we do impacts the climate goals of both our customers and our stakeholders. We have to collaborate: we’re part of a larger network, and getting

started with decarbonization now will keep us from being caught flat-footed and losing out on some opportunities for good work.

RTR: How do you see these changes affecting operations on a day-to-day level, and what are the consequences for professionals not sufficiently prepared for these changes?

TREVOR: When it comes to asphalt and concrete plants, operations can have an overwhelming impact on the energy consumed during production, and that directly correlates to any effort to decarbonize operations. However, efforts to control those variables can take time, so professionals should start preparing now.

That means establishing the hardware and software used to track these metrics. You can manage what you can measure, and in this case, that’s operations and performance.

If you’re going to demonstrate a reduction, there’s often a requirement to establish a baseline built from annualized data. For that, you need a year’s worth of data to establish that baseline before begin-

"The opportunity I’m seeing right now for us in the industry is a chance to really stay ahead of things and lead the conversation as the rules are being written." - Trevor Wagoner

MAC: The approach to when and how we decarbonize will impact how we procure equipment and upgrade our plant assets. We’re going to see an increase in cost just from carbon pollution pricing: it’s $65 a ton right now, but that will increase to $170 in 2030. So suddenly, your cost of operation and equipment changes, unless you get on the path forward right now. If you don’t, you’re going to be stuck behind the eight-ball in terms of cost increases, and it will be too pricey to make the necessary operational changes in such a short period of time.

BILL: As Jon mentioned, it’s also going to affect the procurement side of things. Those buying your product will want to know its associated carbon footprint, because they’re putting that product into a road or a building project, and they need to know the environmental impact of their project. You’ve got to do that accounting at an early stage of the game, otherwise you won’t be able to compete or sell into the market without having that information.

Where is the sector’s current level of knowledge and preparedness on these issues, and how far away are we from where you feel we should be?

JON: Trying to find the answer to that question is part of what I do. For this industry, it really comes down to what the material is, and what it takes to get it in terms of energy.

Even still, there’s knowledge that needs to be built up along the supply chain to make sure everyone is on the same page. It’s getting ahead of the curve that will close the gap, and make sure that organizations can discuss this topic from the same perspective.

MAC: It shouldn’t be surprising that we’re behind other industrial sectors. I don’t think that’s a negative thing, but to be expected. The major focus for decarbonization is on transportation, energy and building construction, but the thing is, we service those sectors.

That means we need to align our thinking with our customers and suppliers in those sectors, and that happens when we integrate sustainability and talks of decarbonization into our leadership. They need to be able to include decarbonization into their strategy and walk the talk, and from there, educate teams internally. I believe sustainability efforts have to be championed across the company, rather than being the responsibility of a single, specialized department.

TREVOR: A lot of PR efforts in this industry may lag behind others, but what’s been really impressive to me is how quickly I’ve seen producers latch onto this idea once they get a handle of what’s needed. I haven’t seen a lot of green-washing, so to speak, coming out of our industry. A lot of what we’re doing is grounded in data, and the folks talking about it know what they’re doing. There’s a lot of low-hanging fruit in our industry for reducing your carbon footprint that has direct and meaningful impacts on operating costs, and we’ve seen producers do that.

BILL: Change almost needs to look like a pyramid, where you’re getting all individuals across your operations involved, because it’s the incremental changes that make a difference.

For a lot of the work I’ve done with operations, these changes came from small, common-sense things, like turning down the temperatures on water heaters, or making sure conveyors aren’t running without a load on them. Don’t underestimate your operations people: they know these operations so well, quite often they’ll be the biggest source of your reductions.

RTR: So, to end us off, what do you all think is the single most important thing that producers should know or do to prepare for these changes?

MAC: We need to understand that no one has a crystal ball. Nobody’s truly going to know what the path for our industry is going to look like in 2030, 2040 or 2050 –the technology, economics and regulatory frameworks aren’t quite clearly in place yet. The road to decarbonization is not a

" It’s important for the industry to adapt now to start down that road to decarbonization. These requirements are not onerous, and we’ve already woven some of these ESG and sustainability considerations right into our operations."

- Mac Carmichael

straight line; it’s going to have bumps and valleys. It’s important to get on that road and make those responsible choices now, in order to maximize opportunity when it arises and your value for your communities and customers.

BILL: The best thing you can do is keep an open mind. These changes are happening at lightspeed, so communication is going to be paramount, whether with governments, industry partners or consultants. Just trying to stay on top of what’s going on, let alone just running your operations, is going to be a challenge, so keeping that dialogue open is the best

thing you can do.

TREVOR: Data, data and data – it’s all about data collection, and establishing that baseline to have regardless of what happens in the future. Understanding where you are now is critical, and the sooner you can get on top of that, the better position you will be in for whatever environment we find ourselves in. So, track your energy consumption and use that data to establish a baseline – that’s really what it all boils down to.

This interview has been edited and condensed.

BY MIKE LACEY

>Each year, thousands of kilometres of ice and winter roads are built across Canada. These roads are a vital lifeline to remote communities in the country’s isolated, northern lands.

Here’s what you need to know about those roads.

Unlike a typical all-weather road that is constructed of aggregates, winter roads are constructed out of snow, ice and water. Dustin Dewar, regional highway manager with the Northwest Territories, says snow cats, graders, water trucks and loaders are used to construct and maintain the territory’s 900-kilometre winter road system.

Anita Tamrazi, with the Ontario Ministry of Northern Development, notes that in northern Ontario, some water crossings have pre-engineered bridges or culverts installed. This year, the Ontario government is spending $5 million for the installation of pre-engineered bridges or culverts and repairs to existing structures. As well, Tamrazi adds, other ‘ice bridges’ consist of logs and brush laid into a creek or stream with snow packed on top.

Tamrazi states that for 2023-24, the Ontario government will spend $6 million to fund construction and maintenance of the winter roads network to 32 remote Indigenous communities and the Town of Moosonee.

In northern Ontario, communities are responsible for building the roads and own or lease the equipment. While some communities have licensed mechanics on-site to repair and maintain equipment, Tamrazi says other communities may fly in skilled tradespeople to repair damaged equipment.

In the Northwest Territories, the work

is handled by eight different road contractors and about 60 people are involved in the construction each year.

According to the Ministry of Northern Ontario, its 3,200 kilometres of winter roads connect remote and First Nation communities in the far north to a permanent highway or railway system. This allows essential goods and services to more easily reach these communities. As a result of the winter road system, medical and construction supplies, food and fuel are shipped in at a lower cost. Winter roads also improve access to primary health care services. Many of these communities are only connected to the all-weather road system through winter and ice roads. As such, when winter roads are not in use, travellers in and out must do so through plane or, in some cases, train.

Sandy Lake, a remote, fly-in First Nations community in northern Ontario, is an example of this. That community notes the

winter road season lasts anywhere from six to 11 weeks and is vital for its residents.

“It is during this time that the community ships essential materials and equipment for the year that would not otherwise be economical or possible to ship by plane,” the community states on its website.

While weather dependent, typically these roads are open from mid-January until the spring thaw. According to Dewar, the roads in the Northwest Territories are closed by March to allow for spring freshet.

Tamrazi states that in north Ontario, the roads can open to vehicles within six to seven weeks of construction, but it is weather dependent.

Once spring hits, the roads disappear.

“The roads completely melt, leaving only the cleared rights-of-way visible through the forested section,” states Tamrazi, noting these rights-of-ways are inaccessible outside the winter season.

> FEBRUARY 20-22 Ontario Stone, Sand and Gravel Conference and AGM Toronto, ON www.ossga.com/ conference24

> MARCH 12-15 Canadian Construction Association Annual Conference

Punta Cana, Dominican Republic www.cca-acc.com/ events/cca-annualconference/

> MARCH 25-27 World of Asphalt Nashville, TN Worldofashpalt.com

> APRIL 11-12 National Heavy Equipment Show

Mississauga, ON www.nhes.ca

> APRIL 21-24 Good Roads Conference Toronto www.goodroads.ca/ conference/

> APRIL 25-26 British Columbia Stone, Sand and Gravel Association Tradeshow and Conference Victoria, BC www.gravelbc.ca/ events

ESG has become the buzzworthy acronym that you can’t escape. It permeates the news we read, echoes through the voices of our senior leadership and shapes our work. Despite the constant exposure, many are left wondering what it really means.

ESG stands for Environment, Social and Governance. It’s a financial term, introduced by the lending community to capture the long list of legacy and emerging investment risks that are relevant to borrowers and sponsors. These risks are not all that new, they have just been rebranded. You can think of it as sustainable development — growth that can be sustained, meeting the needs of the present without compromising the ability of future generations to meet their own needs. This term was introduced to us in the late 1980s through the World Commission on Environment and Development’s Brundtland report, which laid the groundwork for the first Earth Summit in Rio de Janeiro in 1992. However, operationalizing the idea of sustainable development on a global scale proved to be a challenge.

It just didn’t readily translate from boardrooms to projects. ESG is sustainable development in a new jacket. It packages societal risks into a set of imperatives that make sense for business. It breaks down global challenges like climate change, resource depletion, food insecurity and human rights into bite-sized solutions that businesses can readily understand and tackle.

The aggregates and roadbuilding industries have grappled with environmental and community issues since their inception, long before Brundtland even coined the term ‘sustainable development.’ The big difference now is that there are more issues to think about, and there is much greater demand from stakeholders for transparency, progress, and real, verifiable improvement to the health of the planet and its inhabitants. A check mark on legal compliance is no longer enough.

In the past few years, aggregate operations have had to quickly adapt to these heightened ESG requirements to meet the demands of their clients. This holds particular significance in dealings with government and large corporations, where adherence to specific ESG criteria can be the difference between winning or los-

ing work. You now need to know the answer to questions relating to your energy transition plans, your circularity strategy, your greenhouse gas footprint, and your policy on human rights. Where were those questions 10 years ago?

While this may sound daunting, staying ahead of the curve with a proactive ESG approach is surprisingly straightforward.

Whether you are just starting to think about your strategy, or you are already well along the way, a prudent step for any company is to undertake an ESG Materiality Assessment. This assessment looks critically and deeply at your business activities to identify the impacts that you have on the environment and society, and at the same time identifies and classifies the impacts that the environment and society do and will have on your business. It’s an important foundation for your risk management strategy, and it is the best way to thoroughly identify and prioritize those ESG risks that matter most to your operations. Like any part of your business, you always want to put resources where they add the most value, and a Materiality Assessment can help achieve this for ESG related issues.

An ESG Materiality Assessment can apply at any scale: a project site, a small business or a multi-national company. The risks (and opportunities) might look different, and the effort to figure things out will vary, but the overall approach is transferable and will set you up for long-term success in meeting the demands of clients, stakeholders, and the health of our planet.

Embracing a proactive ESG approach not only meets current demands but ensures a company’s resilience and success in the years to come. As an added bonus, senior leadership will consider you a superstar for figuring this ESG thing out!

James Hartshorn is an environmental scientist and ESG practice leader with SLR Consulting (Canada) Ltd.. James has worked in the environmental and safety field and on sustainability solutions for almost 30 years. That work has taken him all over the world to provide advice and support to organizations in manufacturing, mining, energy, power and infrastructure. He can be reached at jhartshorn@slrconsulting.com