2nd

2nd

RM Machinery has partnered with Standard and Horizon— the world leader in finishing solutions including folding, binding, stitching and cutting—to provide fully integrated finishing solutions that take your print products from the pressroom to the marketplace. Get ahead of the fold by contacting RM Machinery at 855-RMGT-123 or visiting us online: www.rmmc.ca.

The Standard Horizon BQ-500 Perfect Binder features the quickest set-up and changeover for variable book production in its class, especially for book-of-one.

• PUR-friendly design with gentle delivery system for 5mm drop and low temperature setting

• Easy glue changeover, between PUR and EVA

• Automated controls for adjusting roller height, nipping height, and amount of side glue

Equipping Canada to cut, fold, stitch and print.

RM Machinery Inc.

905-238-9797 • 1-855-RMGT-123

5250 Satellite Drive, Unit 9 Mississauga, ON L4W 5G5 www.rmmc.ca

With dual magnetic cylinders, the RD-4055DMC Rotary Die Cutter is designed to simultaneously die-cut and crease/score short-run product from both sides of the sheet. It can also perforate, slit, hole punch, and round corners in one process for digital and o set printed sheets.

• Crack-free creasing and clean, sharp creases

• Multiple-up applications from single-up die

• Handles complex creasing patterns and light packaging applications

PREMIER PRINTING TECHNOLOGY DISTRIBUTOR FOR

Four ways signs and graphics businesses can assist in the post-pandemic recovery

2nd Skin becomes Eastern Canada’s largest textile printing company

B.C. team earns Canadian title in 2019 Wrap Like a King Challenge

GAMUT

5 News, Calendar, People, Installs

TECH REPORT

18 Highlighting new offerings in the labelling segment

NEW PRODUCTS

19 Detailing new products and solutions from Kodak and Uteco, Boston Industrial Solutions, Appvion, Rotocon and Flint Group

SPOTLIGHT

22 Nicole Rycroft, founder and executive director of Canopy

COLUMNS

FROM THE EDITOR

4 Kavita Sabharwal-Chomiuk

A sales strategy fix

CHRONICLE

9 Nick Howard Stroke of genius

Robert Miehle established the Two-Revolution press as an industry standard

INSIDER

16 Bob Dale and Gord Griffiths

The third party

Print management and the corporate customer relationship

Now that we’ll be moving into fall very soon, we’re seeing an even greater focus on the COVID-19 recovery. But even though the world is working on reopening and our governments are doing what they can to get Canadians back on their feet, the pandemic is still a daily concern, every time we leave our homes, or decide to stay inside.

As many of us enter our sixth (!) month of modified business practices, including working from home for some (like me), I’ve started thinking about how sales have started to pick back up.

The Global Business Barometer found that 8.1 per cent of respondents “strongly agree” that their country is ready to reopen.

According to the Global Business Barometer, which is based on a survey and analysis conducted by The Economist Intelligence Unit and supported by SAS, as of late June, the possibility of a U-shaped recovery (that is, a swift decline, a moderate low period and a swift recovery) following the COVID-19 pandemic remains possible.

The overall barometer reading for the global economy reached -16.8. That may not sound good, but it is the closest result to positive yet. The most optimistic respondents were in Latin America and the Asia Pacific region, with +18.5 and +4.0 improvements, respectively. In North America, however, the sentiment surrounding the global and regional economies barely increased from the previous business barometer survey, rising by +1.5 and +0.2 points, respectively.

The Global Business Barometer found that 6.7 per cent “strongly agree” that their company is ready to return to business as usual.

Meanwhile, when it comes to getting back to normal, the Global Business Barometer found that only 8.1 per cent of respondents “strongly agree” that their country is ready to reopen, while a meager 6.7 per cent “strongly agree” that their company is ready to return to business as usual.Those numbers certainly don’t instill much confidence. For these figures to improve, the survey organizers said it will require more leaders and policymakers around the world to demonstrate that they can be more effective in containing the virus.

As far as returning to business as usual, according to a recent McKinsey survey of B2B companies across 11 countries in seven sectors, three emerging sales themes were highlighted during COVID-19:

• As many companies limit their spending, a growing number are increasing or at least maintaining their spending, with rates depending on company size, sector and, most importantly, location.

• Digital interactions are now seen by B2B companies as two to three times more important than traditional sales interactions, and will continue to be, looking forward.

• Nearly 90 per cent of sales are now being conducted over Zoom/other

videoconferencing program, phone or email. While some remain skeptical, more than 50 per cent of respondents believe these methods are at least as effective, if not more effective, than face-to-face sales models common prior to the pandemic.

McKinsey & Company also recently published some strategies to raise morale and position a sales team for a swift recovery during this time of uncertainty.

Rather than increasing sales targets, which can further demoralize already low sales teams due to unrealistic expectations and dealing with the switch to virtual selling, McKinsey encourages leaders to focus on the big picture, rather than short-term performance. By this, they mean investing in a sales team’s morale and training now, so the team is ready to clobber the competition as the economy recovers.

McKinsey recommends five actions for leaders to support their teams and get ready for the recovery ahead. Those actions include: adjust expectations to acknowledge that meeting original targets may be nearly impossible, so it is best to set new expectations; provide immediate financial security to sales staff and realign the company’s incentives for the longer term; invest in skills to succeed in the new reality of digital sales, including retraining sales staff to succeed at remote selling; identify successful sales strategies to help staff learn quickly and immediately use what works to make sales, and realign sales processes so they can be replicated at scale; and provide strong leadership that communicates what the organization needs to do, while demonstrating a commitment to employees by being transparent and sharing and celebrating wins. A strong and happy sales team will likely be a sales team to be reckoned with.

Speaking of sales, Mike Cline explains how signs and graphics businesses can assist in a company’s recovery, post-pandemic (p. 8). This issue also features an interview with Rémy Vézina, the owner of direct-to-garment printer 2nd Skin, about his company’s acquisition of textile printer Id pro (p. 12). We also spoke with Nicole Rycroft, founder and executive director of Canopy, about the NGO’s Pack4Good initiative, which aims to save the world’s ancient and endangered forests by partnering with companies that vow to make positive environmental changes in their own supply chain (p. 22).

Until next time, stay well.

Editor Kavita Sabharwal-Chomiuk kchomiuk@annexbusinessmedia.com 437-220-3039

Contributing writers

Mike Cline, Bob Dale, Gord Griffiths, Nick Howard

Associate Publisher

Stephen Longmire slongmire@annexbusinessmedia.com 416-510-5246

Media Designer Lisa Zambri lzambri@annexbusinessmedia.com

Account Coordinator Alice Chen achen@annexbusinessmedia.com 416-510-5217

Circulation Manager

Beata Olechnowicz bolechnowicz@annexbusinessmedia.com 416-510-5182

Circulation bolechnowicz@annexbusinessmedia.com Tel: 416-510-5182

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Group Publisher Diane Kleer dkleer@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Subscription rates

For a 1 year subscription (10 issues): Canada — $43.00 +Tax Canada 2 year — $70.50 +Tax United States —$98.00 Other foreign —$191.00

All prices in CAD funds

Mailing address

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 printaction.com Tel: 416-442-5600

Fax: 416-442-2230

Annex Privacy Officer Privacy@annexbusinessmedia.com 800-668-2384

PrintAction is printed by Annex Printing on Creator Gloss 80lb text and Creator Silk 70lb text available from Spicers Canada. ISSN 1481 9287 Mail Agreement No. 40065710 KAVITA

SABHARWAL-CHOMIUK Editor

support the transportation market and convey a message of hope and gratitude.

Turbo Images has created a ‘rolling tribute’ to frontline workers in the form of vehicle wraps on trucks travelling across North America.

The Printing United Alliance has announced the recipients of the 2020 Student Scholarship Award program, which grants a total of $50,000 in educational assistance to students studying graphic communications in the 2020-2021 academic year. Among the winners are seven students from Ryerson University.

The awards program is supported by donations from endowment investors and industry leaders through the Printing United Alliance Foundation. It provides support to students in the field that are seeking a career in the printing industry.

To qualify for a scholarship, students must be enrolled to attend a Printing United Alliance Educational Institution Member college or university for the Fall 2020 semester; be registered as a full-time student (12 or more credits); must be committed to pursuing a career in graphic communications, printing technology or printing management; and maintain a cumulative 3.0 grade point average or higher (on a 4.0 scale).

The 25 recipients of the 2020 Printing United Alliance Scholarship Program include Ryerson University students Jessica Huynh, Winnie Lee, Leen Bokr, Nathan Evangelista, Georgia Graham, Prudence Villanueva and Kaleigh Lueske.

Inx International Ink has announced it will increase the prices of all solvent inks and coatings for its North American customers, effective Sept. 1, 2020.

The company made the decision despite efforts to absorb costs. The

expense to manufacture solvents, especially alcohols used to produce sanitizers and medical initiatives to fight the COVID-19 pandemic, has risen dramatically this year.

The company has said its focus is to ensure it has an uninterrupted supply of solvents in order to continue to supply its customers. Inx will continue to monitor the situation, but expects the price of solvents will “likely continue to increase”.

The company noted that customers should expect communication from their Inx representatives to discuss specifics, including answering questions and providing market data that justifies the company raising its solvent inks and coatings prices.

Turbo Images has created a ‘rolling tribute’ to frontline workers in the form of 15 vehicle wraps on trucks travelling across North America, in an effort to thank truck drivers and other essential workers amid the COVID-19 pandemic.

The wraps appear on trucks that are owned and operated by Turbo Images’ customers including SGR Trucklines, Penner International, C.A.T., Groupe Morneau, Highlight Motor Freight, Salvation Army, Manac, Parmalat and Fruit et Legumes Gaetan Bono. Turbo Images partnered with Big Rig Wraps and 3M to create the vehicle wraps. The wraps feature colourful imagery and messages, including, “We appreciate you. We see you. We thank you for your contributions,” and, “Thank you, drivers!”

The designs were dreamed up by Turbo Images, featuring different themes for the variety of frontline workers. The goal was to

Cascades Inc. has announced that it will close its Etobicoke, Ont. containerboard packaging facility as part of a strategic repositioning of its containerboard platform in the province and the corporation’s continuing global optimization initiatives.

The company says its strategic plans includes gradually redeploying production from the Etobicoke facility to its other units within the region. The Etobicoke containerboard packaging facility will permanently close no later than Aug. 31, 2021, and the property will be put up for sale. The coming weeks and months will see Cascades working to minimize the impact of this announcement on the 125 employees working out of this facility. The facility’s existing business will be transitioned to the company’s other plants.

Cascades notes that this announcement has no impact on the activities of its Recovery+ facility and offices that are also located in Etobicoke.

Central National Gottesman Inc. (CNG)’s Kelly/Spicers division has acquired Northern California’s American Packaging, furthering its packaging business throughout the western United States. American Packaging has a portfolio in markets such as medical devices, food processing, pharmaceutical and technology products. It also has an expertise in packaging equipment, including sales, servicing, maintenance and line integration design.

This acquisition strengthens Kelly/Spicers’ growing industrial and retail packaging business, which is anchored by Southern California’s Premiere Packaging Industries (PPI).

American Packaging’s president, Kaye Leedham Herning, will continue on in the role following the acquisition. The business, which will be renamed Kelly/ Spicers later this year, will continue to operate out of its 72,000-square-foot San Leandro, Ca. warehouse.

Rootree Inc., a Canadian company specializing in sustainable digital flexible packaging, has opened a second location in Montreal, Que., and has moved its company head office from Hamilton, Ont. to a larger space in Burlington, Ont.

These moves follow what the company calls significant growth of their North American customer base over the past year. The second location in Montreal serves Rootree’s French-speaking and Quebec-based clients more effectively, providing clients with access to bilingual sales representatives; access to the company’s offices and showrooms from a more central location; and the ability to receive sample deliveries in less time.

In order to keep up with demand for sustainable digital flexible packaging, Rootree has also relocated its head office from Hamilton, Ont. to a new 50,000-square-foot facility in Burlington, Ont., a move which more than doubles its capacity. The move allows all manufacturing, creative services, co-packing, shipping and receiving to take place at the new Burlington facility. The space increase also allows Rootree to continue to grow its team and acquire additional HP Indigo digital presses. Rootree also plans to bring in three additional converting lines by the end of 2020.

Fujifilm Canada Inc. has signed a strategic agreement with Focus Pre-Press Systems Ltd., a full-service dealer with more than 27 years of experience in the graphics communications industry. Under the terms of the agreement, Focus Pre-Press Systems will act as a distributor of Fujifilm, covering sales in Western Canada.

Fujifilm products supported by Focus Pre-Press Systems will include thermal Superia ZD Processless and Superia LH-PL/PJ plates.

In an effort to help the print community profit more from selling custom printed apparel, SinaLite recently launched its Apparel Resource Center, a web page that provides downloadable guides to help businesses and individual resellers get the most out of selling custom apparel. The site contains a number of educational guides with topics such as how to get apparel customers, how to prepare print-ready files, how to select the right type of apparel and more. All resources on the site are free to download, even without a SinaLite account. To access the SinaLite Apparel Resource Center, visit the website. SinaLite plans to continue adding resources to the page.

Lorenzo DeCicco has joined MET Fine Printers as its new chief commercial officer. In this role, Lorenzo will work closely alongside MET’s executive leadership team as it moves forward with significant investments in technology, innovation and customer experience.

Lorenzo brings several decades of experience as a senior executive to the role, including 21 years at Telus, where he served as vice president for Telus Business in western Canada. He has an extensive background in B2C and B2B marketing and team member engagement.

Canon Canada Inc. has announced that company veteran Naoki “Mike” Sannomiya has been appointed senior vice-president and general manager for the Business Information Communications Group. In this role, Naoki will will be responsible for the Business Information Communications Group’s various channels, sales groups and product lines, including all small, medium and large office printers; production printing presses; large format printers; software solutions; and IT services.

Most recently, Naoki served as senior vice-president of enterprise services & solutions (ESS) marketing and strategy for Canon Solutions America.

Domino has hired Shane Govert as product manager, Digital Printing North America. In this role, Shane will be responsible for supporting the Label and Corrugated markets, as well as aftermarket.

Shane comes from Fujifilm Graphic Systems where he spent five years in product management for the commercial/offset, flexographic and digital printing markets. Shane has been a member of the printing industry for 13 years, has experience in colour management and has G7 certification.

Durst North America has announced that Steve Lynn, director and GM of New Markets, will be leading its label and packaging division. In this role, Steve will work with the Durst Label Sales team to focus on sales strategies to ensure growth in the North American label market.

This role will also see him build on relationships with finishing equipment and substrate partners.

Chuck Pemble has joined Xaar as its new business development manager for the Americas. In this role, Chuck will be responsible for building and growing OEM and integration channels in the Americas to deliver a range of digital print solutions using the company’s piezo printhead technology.

Chuck has over 30 years of experience in sales and business development. Prior to joining Xaar, he was VP of global business development at DataLase Ltd. and spent 12 years at Domino Printing Sciences

Cameron Advertising has purchased its second Agfa Jeti Tauro H3300 LED, which was installed in June at its Scarborough, Ont. facility. The new addition will allow Cameron Advertising to continue to improve productivity and efficiency for sustainable growth.

Brampton, Ont.’s Flora Graphics has installed the first Konica Minolta AccurioLabel 190 Digital Label Press in Ontario, along with a Scorpio 3500 Label Finisher. Flora Graphics says the AccurioLabel 190, which was designed for narrow web applications, will help the shop produce up to 200,000 labels per day.

Mississauga-based Premier Markings recently installed a Xeikon PX3000 to combine UV inkjet technology with existing Xeikon dry toner presses to further develop its digital label printing business. The purchase replaces the shop’s existing Xiekon 3030.

October 5-26, 2020

Printing United Digital Experience Online

March 9-12, 2021

FESPA Global Print Expo 2021 Amsterdam, The Netherlands

March 23-25, 2021

Labelexpo Americas 2021 Chicago, Ill.

March 23-25, 2021

Brand Print Americas 2021 Chicago, Ill.

April 15-17, 2021

Graphics Canada Mississauga, Ont.

April 20-30, 2021

drupa 2021

Düsseldorf, Germany

June 10, 2021

DIA Annual Golf Tournament Aurora, Ont.

August 12, 2021

OPIA Toronto Golf Classic Brampton, Ont.

Sept. 9-11, 2021

Sign Expo Canada 2021 Mississauga, Ont.

Editor’s note: Please note, we’ll be postponing the Canadian Print Awards until further notice. However, we’ll still be accepting your submissions produced from August 31, 2019 to August 31, 2020! Please stay tuned for more information.

Four ways signs and graphics businesses can assist in the post-pandemic recovery

By Mike Cline

The closely connected ecosystem of a local business community is never more evident than during economic challenges. Small businesses need to stand together and find ways to support their neighbours. As restrictions lift and businesses begin to reopen and rebuild, local signs and graphics businesses will have a vital role to play in our national recovery. With that in mind, I want to share some of the strategies we’ve seen being used by Alliance Franchise Brands’ franchisees and other independent signs businesses across the country. Here are four ways signs and graphics businesses can keep driving recovery post-pandemic.

It’s no secret that the economic impact of COVID-19 has been vast. Businesses are struggling to pay bills and employees. But even in the middle of these challenges, a local business community survives and thrives together. It might make sense to donate expertise, products or services as a gesture of goodwill to the broader community as part of your recovery readiness.You may be

Business relationships are built on trust, dependability and fairness. The payout may come a little later than you would like, but it is more likely to manifest in long-term loyalty.

able to leverage tactics that are specific to your local market that neighbouring businesses are finding useful. This kind of giving back shows the values of your business, and it’s a gesture of goodwill that your community will remember long after the current crisis is over.

The reality is that some of your best customers may be unable to buy right now or spend what they typically would. Use this time to strengthen your ties by offering sound advice. Business relationships are built on trust, dependability and fairness. The payout may come a little later than you would like, but it is more likely to manifest in long-term loyalty. The makeup of many businesses’ marketing and allocation of marketing dollars is likely to evolve in the coming months. Be a resource that can adjust, and you will maintain the value you can provide.

A network of like-minded professionals is invaluable during times of crisis. Many independent signs and graphics companies felt isolated during the beginning of the pandemic and may still feel the strain of going it alone. Our franchise owners have a network to depend on, and independent owners can create their own support systems, made up of professionals in the visual arts as well as other small business owners. Sharing best practices, troubleshooting issues, figuring out together the best way to access government resources – these are just a few ways signs businesses can use local part-

nerships to continue powering one another’s economic recovery. Now is the time to come together as an industry, so we can all thrive together.

There may never be a true “return to normal” in how we conduct business face-to-face. Now is the time to make sure the platforms and technologies you use make doing business with your company as easy – and contact-less – as possible. Do you offer online ordering? There is no time like the present to make your business more valuable by removing barriers to working with you. Diversifying your services to enable cross-selling, like adding promotional or branded visual products, will also allow you to deliver more solutions to your existing and prospective clients.

These are just a few strategies we’ve seen our franchise owners employing during the last several months. There are many other ways for your signs and graphics business to support local businesses that are specific to your community. Together, our industry can be a driver of economic recovery. As the saying goes (and it remains true no matter how many times we hear it), we’re all in this together.

Mike Cline is vice president of franchise development at Alliance Franchise Brands. He works with independent print and sign businesses interested in accessing the many benefits of franchise network participation. He can be contacted by phone at 800-445-5172 or by email at mikec@ alliancefranchisebrands.com.

Robert Miehle established the Two-Revolution press as an industry standard

By Nick Howard

No one ever said business is fair; it never was, and never will be. The best and worst of our humanity often surfaces under the guise of “doing business.” It was during the wild days of the 1880s in Chicago that a 23-year-old finished his apprenticeship and graduated to the rank of pressman at the famous Poole Brothers Printing Company. Frustrated with the constant clanging and banging of his two-revolution cylinder press, Robert Miehle spent hours on his back under his press, observing how the “Mangle-Drive” functioned to move the type-bed back and forth. The mechanical movement, first adopted by Germany’s Koenig & Bauer, was instrumental in Koenig’s Times of London press of 1814. Although hi-tech engineering in 1814, the Mangle continued to be used well into the late-1900s.

Armed with a small notepad, Miehle began drawing sketches of potential design improvements. Without an engineering background, Miehle spent his off-hours studying books and learning the art of mechanical principles. He spent countless hours crawling under his press during the day, intently observing the drive and bed mechanisms. By 1884, Miehle had a solution; one that would drive the bed and cylinder in perfect harmony and, more importantly, eliminate the jarring that occurred with the Mangle! That same year, Miehle was issued his first patent, followed quickly by two other revisions.

Most improvements don’t last for 60 years, but Miehle’s did

What Miehle was able to accomplish would resonate for the next sixty years. Using a novel mechanical movement called “The Scotch Yoke”, Miehle then discovered Englishman Joseph Whitworth’s alteration known as “The Whitworth Quick Return Mechanism”, the imparting of a rotational force (gear) into a linear force (bed) with the bed increasing speed upon its return. Miehle’s design provided a much smoother, and ultimately superior, printing result. These mechanical principles were also finding their way

into many other new technologies, including machine-tools and reciprocating engines. Large pipe organs were also early adaptors of the Scotch Yoke principle. Miehle claimed that, “a pica em quad standing on the bed would not be tumbled over even at a speed of 4,000-bed reversals an hour”. However, what was even more remarkable was that Miehle’s design displaced the cylinder gear, which removed the jarring effect of typical printing presses of the day.

During the late 1800s, our industry primarily used two design systems: the “Single-Revolution” (characterized by a massive impression cylinder and Mangle) and the “Stop-Cylinder”, favoured by the Germans. Robert Miehle had now surpassed both earlier methods and did it in just a matter of months. Miehle established the “Two-Revolution” as an industry standard; however, Miehle didn’t invent the Two-Revolution, which had the impression cylinder take two full turns on each printing cycle. David Napier, a Scot, developed it in the 1820s. Napier is also considered the inventor of the first metal “gripper”, which eliminated silk bands or string to transfer the sheet.

It wasn’t long before competitors were to discard previous prior-art and embrace (copy or reverse engineer) the Miehle design. German manufacturers, including Koenig & Bauer, quickly came up with identical machines, as did the majority of American builders. Plenty of court cases ensued in the United States, with one particularly nasty fight that played out in a Cook County courtroom and the public press. In 1899, the Campbell Printing

Press Company was sued by the Miehle Printing Press & Manufacturing Company, with Miehle citing patent violations used by Campbell. Miehle lost and Campbell took out full-page ads touting their win and superiority over the Miehle Two-Revolution design, even though Robert Miehle’s DNA was all over Campbell’s machines. In the case, the Judge concluded that Miehle had used a version of the Scotch Yoke principle and could, therefore, not sue to stop others using something considered in the public domain.

By November 1885, Robert Miehle finally completed wood patterns and had the parts cast in iron at Tarrant Foundries. Once completed, the castings were taken to a Chicago Avenue printing shop where Miehle’s brother, John, was employed. After assembling the first press, word spread quickly through Printer’s Row saloons and a steady stream of industry types, from pressmen to owners, paraded through Miehle’s shop, all praising the design. Now all Miehle needed was something he never had: money. The old saying, “he doesn’t have a pot to pee in, nor a window to throw it out off,” summed up many inventors’ financial situations in the nineteenth century. Robert Miehle had to find someone to fund his new printing press.

“Mr. Miehle, I have a proposition for you.”

Samuel K. White would become that money source for Miehle. White already had a going concern at a building on Market Street, between Washington and

Madison. Although known for his paging and numbering machines, White also dabbled in machine-tools and occasionally tried his lot as an inventor. White had even designed and constructed a paper cutter. It wasn’t long before White realized the significance of Miehle’s invention. In short order,White rustled up two business friends to form a partnership of what would become the iconic Miehle Printing Press & Manufacturing Company. On December 8, 1890, the three men convened for the first meeting of the new company. However, Robert Miehle wasn’t invited. Miehle had no way of coming up with his share of the $50,000 seed money ($1,415,000 today). Instead, Miehle cut a deal directly with White that would have his patent rights assigned to White in exchange for a royalty on all presses sold and a ten-year contract as chief designer. The company that bore Miehle’s name would ironically never have Robert Miehle as a shareholder; a blunder he would come to regret.

The first press produced by the newly incorporated company would leave the White factory in March of 1891, and to the surprise of Robert Miehle, would not bear the name “MIEHLE” on its side-frame, but instead, the name “S.K. WHITE,” in bas-relief. Our Howard Iron Works Museum has one of these early S.K. White machines. Business became so brisk that the factory expanded later in the year and moved to the corner of Clinton and Fulton Streets in Chicago. With profits rolling in, the three partners were making substantial returns on their investments. Robert Miehle, stung by his gullible mistake, left the company in 1892 only to return later that year after his compensation was increased, and the “S.K. WHITE” moniker was replaced with “The MIEHLE P.P. & MFG CO.”

During Chicago’s World’s Columbian Exposition of 1893, Miehle showcased their press and walked away with a medal and a prize diploma, and was chosen to print The Book of the Fair. It was about this time that a lawyer hailing from Canada set eyes upon the Miehle Company, who just happened to be across the street

from his thriving sash and door weights factory. Canadian John Hewitt emigrated to the United States, but not to practice law, as it turned out. Hewitt began his American dream selling lightning rods to farmers across the country until he settled down in Chicago. Eventually buying into Miehle, Hewitt would ultimately force White out and ascend to the Miehle Company’s presidency.

Miehle advertisements from 1924 (left) and 1901 (right).

By 1919, Miehle was manufacturing 23 models, including an earlier introduction of a massive 7/0 that handled a sheet size of 49 ½” x 73 ½”. Robert Miehle continued developing technologies, obtaining patents, and with his improved financial remuneration, soon found himself living in a large home on the North Side while being driven to and from work in his prized Stanley Steamer automobile.

At the beginning of the twentieth century, there seemed little fear that Robert Miehle might find himself ensconced in front of Chicago’s Wrigley Building, selling used pencils from a tin cup for a penny apiece.

The company’s early foray into Europe also proved surprisingly lucrative. In 1899, Hewitt traveled to England, where he consummated a deal with the Printing Machinery Company Limited (later renamed Linotype & Machinery) to manufacture Miehles under license in Great Britain and Ireland. This deal alone brought in £20,000 (an astounding £2,586,000 today!).

An early advertisement for a Miehle press, from 1892.

Quickly the Miehle Printing Press Company gained a substantial share of the world market, which positioned them at the pinnacle of a burgeoning sheetfed printing industry. A timely encounter with a Milwaukee inventor in 1920 would provide another milestone for the company. Edward Cheshire had designed a new little 13 x 19-inch printing press that ironically used the “Stop-Cylinder” principle long discarded by Miehle. Instead of a normal horizontal plane of the type bed, this machine held the bed and type vertically.The Miehle Company soon latched onto this concept as they were looking for a small “jobber” to complete their offerings. In 1921, Miehle purchased Cheshire’s “Milwaukee Automatic Press Company,” and the now renamed “MIEHLE-VERTICAL” would quickly become a top seller; remaining in production until 1974! After some research, I estimate well over twenty-two thousand MIEHLE-VERTICALs were manufactured.

“You never hear of a Miehle press

being scrapped.”

Considering the length and breadth of the Two-Revolution Miehle success, including Europe, Scandinavia, South America,

China, Japan and most of Southeast Asia, Miehle would reign as the undisputed leader in its field. The Chinese even printed currency on a Miehle, and the Swiss loved the Miehle, especially for printing Bibles. American and Canadian printers would also purchase the lion’s share of Miehle presses for generations to come. Robert Miehle would live until 1932, but his legacy and name would remain at the forefront of the North American printing industry until 1990, when Rockwell International (who had purchased MGD in 1969) discontinued what had been a 39-year relationship with Germany’s Faber & Schleicher, now known as Manroland. Since 1951, every Roland press that arrived in Canada and the USA was emblazoned with the MIEHLE name. It wasn’t until several years after Manroland’s arrival that the Roland name would supplant that of Miehle to Americans and Canadians alike. Ironically, I have one of those “six degrees of separation” tales concerning Miehle. The Toronto Type Foundry represented the Miehle Company for decades, going back to before 1912. My father worked for TTF, and I remember when he came home and told the family TTF was closing their doors. Miehle (which was now part of a triumvirate of three businesses – Miehle, Goss, and Dexter) decided that they (MGD) wouldn’t renew TTF’s contract and would instead sell directly in Canada. In 1966, TTF simply closed shop after being in business since 1887. The TTF owner was Mr. W.J. Palmer, whose family roots went back to San Francisco in 1878 and a type foundry and press builder known as Palmer & Rey. MGD’s destruction of an 80-year-old sales partner remained an invaluable business lesson I have never forgotten. When you work for, or represent a manufacturer, nothing is assured, and you might go to bed a peacock, but awaken as a feather duster. My father’s abrupt unemployed status resulted in our company, Howard Graphic Equipment Ltd. Perhaps had it not been for Robert Miehle, I may never have written this article.

There was an old slogan Miehle often used: “You Never Hear of a Miehle Press Being Scrapped.” Robert Miehle was no doubt proud of that phrase and, more importantly, of how, as a young man of twenty-three, lying on his back in a noisy and hot Chicago pressroom, he discovered such a breakthrough that would change the face of print for almost 60 years!

HOWARD, a partner in Howard Graphic Equipment and Howard Iron Works, is a printing historian, consultant and Certified Appraiser of capital equipment. nick@howardgraphicequipment.com

AVAILABLE EXCLUSIVELY FROM VERITIV

OFFERT EXCLUSIVEMENT PAR VERITIV

HI-BRITE C1S BOARD, C2S BOARD AND C2S HI-BULK BOARD

Features include:

• Highly versatile, bright white boards that are ideal for numerous applications

• Strong folding endurance and stiffness

•

•

•

•

Please contact your Veritiv sales professional to learn more and place your order.

HI-BRITE C1S BOARD, C2S BOARD AND C2S HI-BULK BOARD

• Carton blanc brillant très polyvalent, parfait pour de multiples applications

•

•

•

• Large éventail de poids de base et d’épaisseurs

•

Pour en savoir plus et pour passer une commande, communiquez avec votre professionnel des ventes Veritiv.

C1S 15, 18, 24 pt C2S 8, 10, 12, 14, 16, 18, 24 pt

2nd Skin becomes Eastern Canada’s largest textile printing company

By Kavita Sabharwal-Chomiuk

Quebec City-based textile printer 2nd Skin last year reported investments of over $600,000 in advanced technology to help the company serve the Ontario and Maritime regions. Following this announcement, 2nd Skin announced that it had acquired the textile division of Id pro, a major screen-printing company, making it the largest textile printer in Eastern Canada. Now, 2nd Skin is looking to expand beyond Eastern Canada, to the rest of the country.

2nd Skin offers direct-to-garment printing, vinyl transfer, sublimation printing and

Following the acquisition of Id pro, 2nd Skin is now able to run nine automatic screen-printing presses out of its new 17,000-square-foot plant.

laser engraving divisions. The acquisition of Id pro significantly increased 2nd Skin’s production capacity, allowing the printer to run nine automatic screen-printing presses out of its new 17,000-square-foot plant. Now the company is able to produce 25,000 prints per shift, compared to its previous capacity of 5,000 pieces per day. Plus, following the acquisition, its range of services improved upon what Id pro was able to offer its distributor clients before the acquisition.

”Our goal was to become one of the biggest screen printers in Canada,” says Rémy Vézina, the owner of 2nd Skin. “With this acquisition, we will do direct sales and sales for distributors with Id pro. With our nine presses, we will be able to manage a huge capacity of production.”

In addition to the acquisition, 2nd Skin also purchased new embroidery equipment to enhance the services offered, increasing the number of embroidery heads from 13 to 19. The company has also started introducing automation of its processes, in an effort to optimize production and provide employees with a more advanced work environment.

Vézina says that the company plans to maintain all staff from both companies, a total of 42 employees. The move to the new building coincides with the consolidation of locations where employees do screen printing, embroidery, vinyl transfer and direct-to-garment work.

2nd Skin, like all businesses operating out of Quebec, had to close its doors in March for the COVID-19 lockdown, but the company only stayed shuttered for 12 days. The business was allowed to reopen because it had contracts with grocery stores to produce social distancing t-shirts. They also started working on the sale of face masks when they reopened.

Now that the company is back at work, running at full capacity following the COVID-19 shutdown, Vézina says that they’re doing more work related to social distancing, including the aforementioned t-shirts.

“We got a big contract of 45,000 t-shirts for grocery store staff, asking people to

keep their distance,” he says. “We will also be doing some floor graphics, banners and things like that.”

Now that the worst of COVID-19 may be (hopefully) behind us, Vézina says the company has undergone several steps to prepare for the recovery. For one, Vézina says all of 2nd Skin’s sales and administrative staff has been working from home since the start of the shutdown. Meanwhile, production staff have been able to work staggered shifts to limit interaction while at work and on break or mealtimes.

In addition, Vézina says the company has deployed signs to remind employees to wash their hands, and has provided extra sanitizing materials to keep areas clean and germ-free.

Vézina is hopeful about what the pandemic’s hygienic necessities mean for businesses in the future, however. “When you have over 40 employees, and you have a flu epidemic, you have three weeks where you’re short-staffed or some staff is overworked,” he says. “With this, this new normal with washing our hands and signs, maybe there will be fewer epidemics in the future, and more productivity.”

Looking forward, Vézina believes the pandemic will impact sales long-term. “I think everybody wants a shortcut, but you need three things for sales: the deals, the quality and the price. The bigger printers have the capacity to offer the best deals. If you offer the best deal, you can provide better prices or better quality with better equipment,” he explains. “We’re offering all three, while most businesses only offer two. If you offer quality and deals, you don’t have the price. I think that the future is going to see that big business can offer the best deals and respectable quality for a good price.”

The company recently launched a sales platform online in January, and plans to invest more in its web solution. Currently, 2nd Skin’s website is only offered in French, but the company plans to launch an English site soon.

“We want to take the markets in all of Canada, not only in Quebec,” says Vézina. It looks like 2nd Skin is well on its way.

“Our goal was to become one of the biggest screen printers in Canada.”

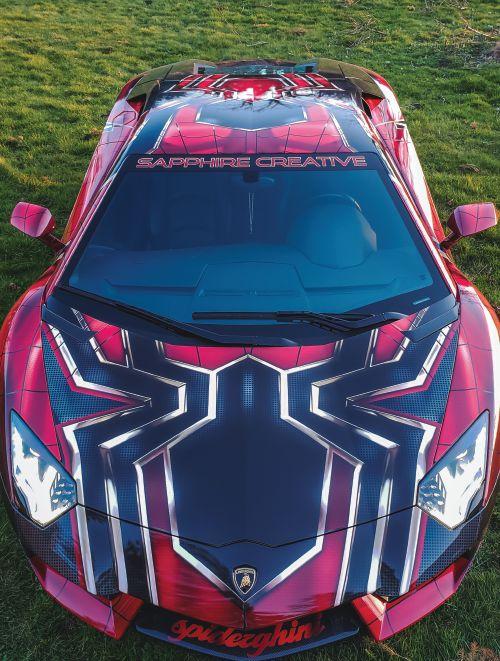

By Kavita Sabharwal-Chomiuk

Avery Dennison Graphics Solutions’ annual Wrap Like a King Challenge names 10 vehicle graphics installer teams as Regional Wrap Kings. B.C.’s Sapphire Creative was named the Regional Wrap King for Canada for Spiderghini, a full vehicle wrap on a Lamborghini Aventador installed by Sapphire Creative’s Jeremie Webber, Peter Den Uyl and Dave Benedict.

To be named a winner, projects must have used Avery Dennison vehicle wrap products, such as Supreme Wrapping Film or MPI 1105 to wrap a four-wheel passenger vehicle.

Spiderghini took the team one week to design, and one week to install. The intent of the project, according to the company’s entry form, was to emulate Spider-Man’s Iron Spider suit design from the movie Avengers: Endgame, because the team describes itself as “huge Spider-Man fans”.

The base colour of the car was white at the start of the project. The hood and roof were embossed in order to register the webbing and logos with the printer layer, while the classic Spider-Man logo was embossed on the back of the car. Sapphire Creative used Avery Dennison Supreme Wrapping Film in Gloss White to emboss, and Supreme Wrapping Film in Diamond White for the digital print layout, along with DOL1360Z clear, high gloss laminate.

“We wanted to build a design that was both relevant for today as well as easily recognizable,” explains Jeremie Webber, president of Sapphire Creative, and installer on the project. “Having the design stand out by standing close to the car as well as having it stand out from a distance was one of our main goals. To do this, we

vehicle graphics installer teams were named Regional Wrap Kings.

The team used Avery Dennison Supreme Wrapping Film in Gloss White to emboss, and Supreme Wrapping Film in Diamond White for the digital print layout, along with DOL1360Z clear, high gloss laminate.

“We wanted to build a design that was both relevant for today as well as easily recognizable.”

had to make sure our general layout design was simple enough with a strong contrast of colours so that visually you could see and understand the artwork from 10 to 20 feet away from the car but also have some serious wow factor when you got up close and personal.”

In order to achieve this, the team printed the graphics on the Avery Diamond SW900 series so the prints would have a heavy metallic finish. In order to give the wrap some depth, the team laid down a cut vinyl layer of the webbing on the car prior to placing the wrap, so when the car was wrapped, the webbing of the car would have an embossed look and feel.

According to Webber, the major difficulty in the design of the project (in addition to actually building it) was taking a design concept that has been custom designed for the human body, and redesigning it to fit a Lamborghini.

“[We had] questions like ‘how do we made a design like this compliment the body shape of the car itself? How thick should the webbing be? How should the webbing curve around the body of the car? Where to place the iconic logos?’ This process took our designers multiple revisions and edits to get the layout exactly how we wanted it before print production was started,” notes Webber. “[We had] multiple revisions to make sure the webbing curved around the body lines of the car just the way we wanted, and making sure the Spider-Man symbols worked with the body of the car.”

Despite any challenges involved in the design, Sapphire Creative is grateful for both the experience and the exposure of the contest.

“Winning the Wrap Like a King contest for Canada helps set us apart as a company. It is not an award that is easy to win and each year the entries are getting better and more creative from every company that enters,” says Webber. “It shows our potential clients that they can trust our work and that our staff is more than capable to handle any of their wrap needs.”

B.C.’s Sapphire Creative was named the Canadian Regional Winner for its work on Spiderghini at the Wrap Like a King Challenge. The team used Avery Dennison Supreme Wrapping Films and DOL1360Z clear, high gloss laminate to complete a full vehicle wrap on a Lamborghini Aventador.

By Bob Dale and Gord Griffiths

There are many players in the “print management” market, including Innerworkings, HH Global, DCM (Data Communications Management), RR Donnelley, Xerox and others. They have negotiated a role with major corporations to manage print procurement and other aspects of creative and print management on behalf of the organization.

What do these companies do that printers don’t? From the website of Innerworkings, the largest print management firm with almost $1 billion in annual revenue, at the core, they: “… leverage our global expertise, certified supplier base, proven methods and proprietary technology. ...Services include creative, print, direct mail, branded merchandise, packaging, retail environments, and digital solutions”.

I’m sure if we check out most websites

value-added statements.

It was announced this summer that HH Global acquired Innerworkings. Both companies act as intermediaries between printers and their former loyal corporate customers. By combining print volumes from many clients, taking advantage of overcapacity in the industry, they have forced printers to accept unsustainable price reductions. The impact has been devastating for many printers.

While pricing has not been sustainable for printers, it appears that the ap -

$1B

Despite generating more than $1 billion in annual revenue, Innerworkings has not had a profit since 2017.

The key to success is owning the relationship with clients. The relationship is your asset – literally – and it’s called goodwill.

over $1 billion in annual revenue, they have not had a profit since 2017.

Print consolidation and bidding software were originally introduced as e-commerce tools with platforms like Impress, Print Café and Collaboria, and procurement tools like Ariba. With the exception of Ariba, the other platforms do not exist. The common premise for these tools was enter the print specifications and use the ecommerce platform to solicit bids from many different suppliers. The problem with that was that it takes expertise to write specifications and also efficiently plan a print order.

Ever wonder how Innerworkings or Xerox got the opportunity to provide print management services and you, the print expert, did not? Besides their brand image, they nurture client relationships at the executive level. Best practices used in large enterprises is to ensure that there is a senior executive relationship with their top-tier suppliers. These relationships are designed to understand current strategy and challenges, industry and technology changes, and together explore strategies to work together to address issues, improve efficiency and ultimately reduce costs. Make sure your sales rep is not the only person that the enterprise customer meets. Build relationships between senior people with the intent to really help and bring true added value to the relationship.

Enterprise executives and some senior procurement experts recognize that managing print is different, and there is a complex life cycle with hidden costs that need to be managed. Internal staff don’t have the same expertise and processes offered by major print management firms.

They do not understand the cost impact of the full supply chain, and

Joel Quadracci was interviewed and he was asked where Quad’s sales growth was going to come from. His response was, from Quads’ current customers! His advice was instead of providing a client one or two lines of business, leverage your relationship and sell two, three or four types of business services.

While customers don’t usually care about technology, offering litho and digital is a given, but of-

Best practices used in large enterprises is to ensure that there is a senior executive relationship with their top-tier suppliers.

instead focus on the purchasing function, searching for the lowest unit cost, instead of understanding the impact of creating and version management, warehousing, distribution and obsolescence.

Once the enterprise has outsourced the procurement function, they lose control. They lose visibility of the cost, since the data is now in the vendor’s control and the third party is not passing on all the savings promised. However, the initial problem of lack of expertise and formal process was solved, but often at considerable expense to the organization.

If your blue-chip enterprise client’s printing is now managed by a third party, here are some suggestions:

• Try to replace that customer with another to retain a direct client relationship.

• Provide full service – explore how you can become a provider for the total supply chain.

• Use your expertise to become a competitor to the print management firm. Can you also provide a full range of marketing solutions, either through internal capabilities or through a strategic relationship with another firm?

• Go online – develop an e-commerce platform and form direct relationships with customers.

• Diversify – explore if you can expand into other areas that your clients will benefit from, like labels, packaging or wide format.

The key to success is owning the relationship with clients. The relationship is your asset – literally –and it’s called goodwill. Recently,

fering on-site creative and production management support, installation for the wide-format products you produce, distribution and inventory management are all value-added services that many clients need.

The bottom line

• Look at your relationship and business offfering from your customers’ perspectives.

• Continually re-assess your value-add and services for your customers.

• Understand the life cycle of the printed product and cost impact at each stage.

• Train your team on “solution sales”.

• Invest in equipment and innovation!

We wish you continued success!

Bob Dale and Gord Griffiths are partners in Connecting for Results Inc. Their focus is to facilitate mergers and acquisitions that maximize results for all parties, and provide recruitment and consulting services. Both Bob and Gord have many years of experience, with Gord holding positions as the President of Quebecor Canada, and COO of Cenveo. Bob has over 15 years’ experience offering management consulting services, transition execution and support. He was a part-time faculty member of Ryerson University. Over the past 14 years, he was employed by RBC as a specialist to lead national and international efforts for effective print management. They can be contacted at info@ connectingforresults.com or by visiting https://connectingforresults. com.

FlexCon has launched a floor graphic product, Flexmark floor art 6610TF, which allows label printers to offer wayfinding and social distancing graphics as businesses continue to reopen amid COVID-19.

Flexmark floor art 6610TF is a 3.4 mil flexible white opaque vinyl suitable for print with UV and water flexo equipment. It features an adhesive created for durability, with removability up to 180 days following installation. When paired with one of Flexcon’s approved overlaminates, it also meets industry standards for nonslip performance under UL 410.

“As more businesses start reopening around the country, we’re seeing an increased demand for directional and physical distancing graphics,” said Bekie Berg, product manager at FlexCon. “For non-essential retailers, hair salons, dentist offices and commercial office buildings, the idea of putting graphics on the floor may be new, so there’s an opportunity for label printers to support their needs with printed floor graphics. Such graphics are typically less than 18 inches wide – perfect for narrow format presses.”

Berg added that the sizes typically being produced for wayfinding and distancing makes flexo printing an “ideal medium” for their production.

UPM Raflatac has launched Rêverie 2, a new premium collection of high-end labeling materials for wines, spirits and craft beverages, developed in response to market trends. The collection was created in collaboration with the company’s partners to enable innovative printing techniques and finishes.

The collection features a variety of FSC-certified materials (FSC-C012530) from sustainably managed forests and materials made from 100 per cent recycled content and other controlled sources. The collection comes in five different styles, with additional features such as ice-bucket performance, iridescence and material suitable for high embossing or debossing.

Rotocontrol and Domino have partnered to offer label printers and converters expanded capabilities and value-added differentiation in hybrid label printing and finishing.

The new inline hybrid solution for the Rotocontrol DT-340 digital label finishing machine with integrated Domino N610i label press was featured at Rotocontrol’s new headquarters and demo centre in Siek, Germany during its grand opening that took place in June 2020. EMT/Rotocontrol’s new Green Bay, Wisconsin demo centre also featured this new inkjet hybrid finishing press at its grand opening in June.

The Rêverie 2 collection was designed for wines, spirits and craft beverages.

The N610i in the combined hybrid solution has up to seven colours including opaque white, 600dpi native print resolution and operating speeds up to 70m per minute (or 230ft. per minute). Compliance for food packaging is also offered with the new Domino UV95 ink set.

The DT-340 provides a highly modular machine with multiple die cutting (die stations capable of running full or semi-rotary mode with simple changeover) and printing stations (rotary flexo and flatbed screen printing), lamination, cold foiling, hot stamping, label inspection, small roll programmable auto turret winding and 100 per cent servo control from Bosch Rexroth. In addition, its open architecture allows easy operator access to the web and integrated modules for increased efficiencies in operation/ web handling and movement during production.

TE Connectivity (TE) has launched its new TTDS-245 thermal transfer printable adhesive-backed panel labels, which use high-performance adhesive foam, rendering the use of rivets or bolts in en-

The Rotocontrol DT-340 digital label finishing machine features an integrated Domino N610i label press.

The TTDS-245 uses high-performance adhesive foam to reduce installation time.

graving obsolete, due to lower material cost, ability to print on demand and reduced installation time.

TE’s panel labels are die-cut pieces on a liner in a roll offered in standard colours of white and silver, but custom colours and shapes are available. Typical applications are industrial control panels, data racks, switchgear and general industrial equipment labelling.

Panel labels have three layers – a printable topcoat that provides protection, a central film for stability and structure and an adhesive layer which can adhere to many surfaces, including low surface energy and powder coatings. Unlike traditional rigid metal or plastic engraving plates, the adhesive foam backing can conform and adhere to textured surfaces, uneven surfaces and rounded shapes, says the company. TE panel labels are suitable for both indoor and outdoor applications.

Mactac’s new cryogenic labels were developed to withstand ultra-low temperatures.

Mactac has introduced a new line of cryogenic products developed to withstand ultra-low temperatures, intended for harsh environment applications where labels can be exposed to ultra-low temperatures, liquid nitrogen, thaw cycles, chemicals and solvents.

Created for use in medical fields, such as research, clinical laboratories, fertility clinics and biobanks, the new line of products were designed for labeling lab identification substrates such as test tubes, ampules, vials, slides and more.

The products were created to offer strong adhesion to small radius containers for firm attachment to test tubes and ampules, as well as create easy identification of plastic and glass containers that are stored long-term in liquid nitrogen. The labels provide resistance to edge-lifting, even when repeatedly subjected to temperature changes.

Kodak recently launched a digital flexible packaging press, in partnership with Uteco. The Sapphire EVO W is the first flexible packaging press using Kodak’s latest continuous inkjet technology. The Uteco Sapphire EVO W is the company’s second product developed in partnership with Kodak for digital flexible packaging production.

Kodak first unveiled the flexible packaging press late last year, with the intention of launching at drupa 2020. The company says the Sapphire EVO W is now available worldwide, and the first installation will take place later this year for a U.S. customer.

The press can print flexible packaging applications on plastic films and paper. It prints CMYK inkjet at 600 x 1800 dpi across 49.2 in print width, at speeds of up to 500 feet/ minute. The press is available with in-line priming, flexo-white and post coating and a hot air/IR drying system. Used with the Sapphire EVO, water-based Kodak Prosper Press QD Packaging Inks have been certified for indirect food contact.

Boston Industrial Solutions has launched the Volta S150 Screen Printer, a single-colour automatic tabletop screen printing machine for printing tagless face masks, t-shirts, neck labels, uniforms, underwear, denim material, pants pockets, waistbands and other apparel.

The printer produces wash-resistant and vibrant tagless images on cotton, nylon, polyester, denim,

fleece, spandex and ribbed textiles, according to the company. Boston Industrial Solutions says the S150’s process is superior to tagless pad printing because of the ability to print bright white images on dark substrates at low cost. In addition, the company says the process is “superior to heat-transfer labels for jeans and denim materials at incredible speed and cost savings”, which it adds is impossible with the pad-printing process.

The Volta S150 can be used by both start-ups and heavy-duty industrial textile printers. Face masks can also be printed on S150, as well as flat, promotional products and industrial parts up to 4.2 inches high. The printer includes an easyto-use PLC and tool-less set-up for quick job changeovers, an adjustable x-y fixture holder table and variable inking. The printer also features print frequency controls that allow the operator to control print opacity, quality and speed. The printer can be used with Natron screen printing inks, including

3. INTEGRATED MODULAR UNITS — Combined in-line finishing: crease, fold, glue, tipping, envelope inserting, ink jetting (Duplex), clip seal (3 sides), mail prep.

4. SAVE ON POSTAGE COSTS

—As a Certified Canada Post Direct Marketing Specialist, we get contract pricing reductions.

5. RETURN MAIL PRODUCTS — Customized “Return Mailers” created in-line with “U” or “BOX-shape” remoistenable glue, time perfed applications and envelope formation.

6. MINI-BOOKLETS — Saddle-stitch and trim 2-up booklets in-line to the size of a business card. No need to trim off-line, or do 2 passes.

7. HIGH SPEED EQUIPMENT — High speed Tipping, Folding, Saddle-stitching and soft folding ensuring on time delivery.

silicone inks for both textiles and rubber, LED UV screen printing inks, water-based inks and solvent screen-printing inks.

Appvion Operations, Inc., has launched a new antimicrobial coating technology for a variety of substrates called SafeShield that prevents the replication of DNA and new cell formation.

According to Appvion, independent lab tests have been conducted, demonstrating up to 99.99 per cent reduction in non-pathogenic bacteria on the paper’s surface, even after printing and post processing. The product can be used in healthcare, food service, education, entertainment, transportation, office settings and government sectors.

To ensure the efficacy of the product, the antimicrobial coating is formulated with components that have gone through the United States’ Environmental Protection Agency (EPA)’s review and registration processes.

more affordable and efficient format. Additionally, a servo-driven motor enables ideal stripping tension, even in the presence of matrix coil diameter variations, which prevents any issues arising by special substrates or die-cutting complex label shapes.

The new machine also features a dual-turret slitter rewinder. It has two spindles that save converters time by allowing them to finish a roll of labels directly on the RDF 330 in one pass.The RDF 330 also includes the Ecoline branded UV LED curing system, which facilitates significantly lower operating costs due to energy savings, fewer consumable parts and lower maintenance costs.

Finally, the machine uses the latest servo motor and software enhancements available. The shape of the machine has been modified by rounding off any sharp edges and incorporating a sleek, modern colour palette of grey and red (rather than white and red, on the previous model).

1x Mitsubishi 40” 10 Colour Tandem with AQ

1x Mitsubishi 40” 8 Colour Tandem with AQ

1x Mitsubishi 40” 8 Colour Perfector with AQ

3x Mitsubishi 40” 6 Colour with AQ

2x Heidelberg Printmasters

3x Saddle Stitchers / 1 Perfect Binder / 10+ MBO Folders

Over 75,000 sq ft plant housing state-of-the-art nishing and bindery

Personalized account management and complete control over production

24/7 Production with fully automated and barcode controlled plant

FSC / PEFC / SFI certi ed

Rotocon has launched the next-generation Ecoline RDF 330 digital printed label converting and finishing machine. The enhanced version, upgraded following customer feedback, is now globally available through Rotocon, Rotocon Europe and Rotocontrol.

One major upgrade to the system is the addition of an automatic sheer knife slitting system that simplifies the normally time-consuming setup and tweaking needed when manually adjusting blades across more than three lanes. Now, the operator can enter the label sizes, gap sizes and number of slits, and the system will automatically move the blades into the right positions, with the correct gaps.

The second upgrade is a highspeed matrix stripping system, which ensures no web in between the stripping shaft and matrix, preventing waste breakage and machine downtime. This upgrade was highly requested by customers wanting a

Flint Group Paper & Board have launched TerraCode, a full range of bio-renewable water-based ink and coating range for paper and board packaging applications. Designed to support market demands for sustainable packaging, Flint Group presents an innovative bio-renewable product offering that can be tailored for converters’ individual needs.

The TerraCode range was designed to support a number of applications, including corrugated post and pre-print, food wraps, folding carton, cups, paper bags and aseptic packaging.

In addition to the sustainability aspect of the range, Flint Group says it also delivers the necessary requirements for premium packaging results, such as high print quality, product consistency and ease of use. The inks and coatings are bio-renewable content (BRC) certified and sustainably sourced. The range is also available as printready or through a building block package.

The TerraCode range has been developed using a combination of natural feed stock options – natural pigments, resins, additives and biomass balance materials – that the company says do not compete with food or facilitate deforestation. The company has also extended its strict raw material review policy to include renewable source information.

Heidelberg: K-Line/S-Line/Speedmaster/GTO/MO/KORD64

Komori: 1, 2, 4 or 5 colours & any size

Adast: 714/715/724/725

Mitsubishi: Any model

Ryobi: 2800CD/3200CD-MCD/640K

Itek: 960/975/985

Hamada: 600/700/800/E47/RS34

Shinohara/Fuji: 66/65 1,2 or 4 colours

Sakurai: 1, 2 or 4 colours and any size

(newer model)

Polar: any size/older or newer models (66/72/76/78/82/90/92/107/115)

Horizon-BQ: 220/240/260/440/460

Nicole Rycroft is the founder and executive director of Canopy, an organization that is working to protect the world’s forests, species and climate. Nicole launched the organization over 20 years ago, and she and the organization have received a number of environmental and business awards.

We spoke with Nicole about her goal to save the world’s ancient and endangered forests, and how Canopy’s Pack4Good initiative advances that goal.

How was the Pack4Good initiative started?

NR: We launched Pack4Good in October 2019. The background for it was that three billion trees disappear into packaging every year, and that number is expected to increase by at least another 20 per cent within the next five years. It’s already got a massive footprint, and that footprint is continuing to grow quite aggressively. Plus, of the 450 million tonnes of paper that’s produced, more than half of it disappears into packaging. It’s the largest footprint of the sector and its impacts are far-reaching in the landscapes that have been degraded, as well as the climate footprint that it has.

Packaging has been going through a bit of zeitgeist moment in recent years. As companies and governments have been grappling with the environmental impacts of plastic packaging, we want to ensure that as they tried to resolve that, they weren’t exacerbating the impacts on forests.

How did the companies involved with Pack4Good come on board?

NR: We launched with 44 brands. With the original cadre of brands, we reached out to some of the 320 brands that we’ve already been working with for the last six and a half years, [companies in] the fashion industry. The fashion industry is responsible for more than 50 per cent of B2C e-commerce. A lot of the fashion brands that we work with use just as much, if not more, fiber in the packaging that underpins their businesses as they do in the actual apparel that they sell. We started working with some of these brands to expand the commitments which have been focused on viscose and rayon fabrics to include packaging, so it was just a natural extension of relationships.

What are the main principles of the Pack4Good commitment?

NR: When a brand develops a Pack4Good policy, they are committing to ensure that none of their packaging comes from ancient and endangered forests. They are committing to prioritize the use of next-generation solution fibers; agricultural residues like straw that is leftover after the food grain harvest, or microbial cellulose, which can be

grown on food waste to make packaging. They are committing to using smarter design, both in terms of product and packaging systems. When virgin wood fiber does have to be used, ensuring that it’s Forest Stewardship Council (FSC) certified, and that they will advocate for conservation. Those are the primary tenets that are part of the Pack4Good commitment.

of the fiber they would have used, and they saved themselves $14 million in a single year.

$14M

A redesigned, reusable shipping box saved a company 80 per cent of the fiber it would have used, and $14 million in one year.

Our launch of Pack4Good was really to seek to ensure that we’re enabling brands to have a holistic approach to addressing their packaging impacts. Most of the brands that we work with already have plastic packaging commitments in place, and this is a complimentary strategy for them to ensure that they’re not trading in one environmental problem for another.

How have Pack4Good member companies already started to work towards the goals of the initiative?

NR: One of our really big European brand partners changed the system between their warehouse and their store that enables a box to be used up to six or seven times on average, rather than being a single-use product. They’ve redesigned the actual physical structure of the box, and in doing so, they are essentially saving 80 per cent

Some of our other brand partners, we’re already working with them to pull Columbia pulp, which is North America’s first modern day straw pulp mill. A number of our brand partners are starting to trial working with their packaging suppliers, to start incorporating it into their consumer-facing products or their B2B shipping boxes.

Do you have any requirements for the technology solution providers you work with?

NR: Our requirement of the next-generation technology entrepreneurs that we work with is that they are price competitive with conventional wood or wood-based technologies and that they’re at least equivalent in terms of the technical performance, tensile strength, printability or the other various requirements that there are, so those alternative fibers are performing equivalently.

Nicole’s responses were edited for length and clarity. For more Q&A Spotlight interviews, please visit www.printaction. com/profiles

The J Press 750S brings profitable short runs.

n

n