Celebrating Canadian packaging

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 printaction.com

Tel: 416-442-5600 • Fax: 416-442-2230

TC Transcontinental is selling its paper and woven polypropylene packaging operations to Hood Packaging for US$180 million (about C$239 million). Hood Packaging is a North American manufacturer of plastic film and bags, woven polypropylene bags, coated and laminated materials, and paper packaging, with head offices in Burlington, Ont., and Madison, Miss. The corporation anticipates using the net proceeds from this transaction to reduce debt in line with its goal to bring its net indebtedness ratio below 2.0x, as well as to continue its transformation through targeted acquisitions. The transaction is subject to regulatory approvals and is expected to close in the first quarter of fiscal 2020.

Hood Packaging will acquire the following paper packaging

operations and buildings of TC

Transcontinental: Transcontinental Sibley, Iowa;

Transcontinental Hanford, California; Transcontinental Hazleton, Pennsylvania; and Transcontinental Tifton, Georgia. In addition, Hood Packaging is acquiring the paper and woven polypropylene packaging operations at the Transcontinental Spartanburg, South Carolina plant; TC

Transcontinental will retain ownership of this building and continue operating from this location, which also manufactures plastic flexible packaging. About 415 employees will transfer to Hood Packaging after the closing of the transaction.

ProMach has acquired Jet Label & Packaging, a move that will expand its labelling and coding

capabilities and provide customers across Canada with enhanced sales and support, it says. Founded in 1998 and headquartered in Edmonton, Alta., Jet Label manufactures labels and printed tape for a range of industries, including food and beverage, consumer packaged goods, pharmaceuticals, forestry, transportation, and mass-market retailers. Jet Label provides sales, service and support from seven offices throughout Western Canada, from Vancouver to Winnipeg. ProMach’s ID Technology product brand has six existing label converting facilities through- out North America, with locations in California, Texas, Wisconsin, Georgia, New Hampshire, and Ontario that provide flexographic labels, blank and shell labels, digital labels, synthetic labels,

Rod Froment, VP and COO, and Darrell Friesen, President and CEO, last year as they celebrate Jet Label’s 20th anniversary with uniquely labelled cans. by a local team of labelling and coding personnel. Darrell Friesen, President and CEO of Jet Label, along with Rod Froment, Vice President and COO of Jet Label, will continue leading the Jet Label team, spanning over 80 employees across its multiple locations. Also joining ProMach is Jet Label’s sister company, Jet Marking Systems, a provider of label applicators, industrial printers, tracking and traceability solutions.

and more. ID Technology also provides various labelling and coding systems, offering customers ranging from small local startups to national retailers with a solution that includes both labels and machinery, supported by a network of more than 15 sales and service offices. The addition of Alberta-based Jet Label now adds a seventh flagship converting facility as well as additional sales and service offices so customer needs can be met

UPM Raflatac says it is the first label material producer to bring a new wood-based polypropylene film material into the market. The UPM Raflatac Forest Film label material was developed in collaboration with UPM Biofuels using UPM BioVerno naphtha, a 100-percent wood-based solution originating from sustainably managed forests, it explains. The film, it says, will answer brand owners’ needs to replace traditional fossil-based virgin materials with renewable ones, offering companies a way to “reach beyond their sustainability goals without

compromising on product performance.” “At UPM Raflatac, we support the circular economy by innovating circular labeling solutions, but that is not enough. We are aiming higher by making sure that the raw materials we use are as sustainable as possible. By replacing fossil-based raw materials with renewable ones we can ensure a truly sustainable packaging solution,” says

Antti Jääskeläinen, Executive Vice President,

UPM Raflatac.

TC Transcontinental has acquired a 60-percent participation in Industrial y Commercial

The label material is a 100-percent wood-based solution originating from sustainably managed forests, UPM Raflatac says.

Trilex C.A., a plastic packaging supplier located in Guayaquil, Ecuador, employing about 170 people. Trilex specializes in the production and sale of packaging materials and banana farm plastics for protection and pest control. “Trilex expands our already well-established footprint in Latin America with a second location in Ecuador, in addition to our plants in Guatemala and Mexico, and our sales office in Costa Rica,” says François Olivier, President and CEO of TC Transcontinental. “Thanks to Trilex, we will bolster our product offering for the agricultural market, namely with banana tree bags and box liners, and strengthen our position as a key supplier to the banana industry in Latin America,” Thomas Morin, President of TC Transcontin-

ental Packaging, adds. “This market is the perfect example of how active ingredients in films can lead to better harvests and how important food protection is to extend product shelf life for export.” This is TC Transcontinental’s eighth flexible packaging acquisition since entering the industry in 2014. TC Transcontinental Packaging has over 4,000 employees. Sustainably sourced packaged material is becoming increasingly important in Canadians’ purchasing decisions, with 62 percent of Canadians willing to pay more for such products, according to a new survey conducted by Asia Pulp & Paper (APP) Canada. According to APP Canada’s third annual Attitudes Towards Sustainability report, 74 percent of

Canadians consider sustainability an important factor when making purchases. This trend was particularly reflected in food packaging where a majority of Canadian adults (62 percent) were willing to pay more for products packaged in sustainable materials, with 40 percent saying they would be open to paying up to 10 percent more. The sustainability survey was administered online in August 2019 among a representative sample of 1,003 Canadian adults by Engine Caravan Surveys. While the survey indicated sustainability is most important to Canadians when making purchasing decisions related to food packaging (63 percent), it is also important to over half of consumers when buying retail goods (56 percent) and office goods (53 percent).

– Zünd Board-Handling System BHS150 for industrial-level automation – Ultimate non-stop productivity with 1.5m stack height, automatic job retrieval, D3 dual-beam production capacity – Find out more at www.zund.com/en/bhs 1.5 m Click

Solucan says it is installing the world’s first Tonejet Cyclone direct-to-can digital printing system at its new facility in Quebec to produce “millions” of unique customized cans that are 100-percent recyclable. “Currently, beverage producers wanting to avoid labels have to purchase from the major can manufacturers, whose minimum quantities are far too large for any microbrewer or craft beer producer that we are working with. With the Cyclone, these issues are addressed – the system allows us to keep up with changing consumer habits, transforming packaging as we know it,” says Sebastien Baril, President at Solucan.

Canpak, run by President Eric Fok, is a family-operated business serving the trade industry for over 30 years in the Greater Toronto Area in Ontario, specializing in packing and folding carton applications, commercial collaterals and printing applications with unique finishing requirements. Canpak recently invested in a new folder gluer, die-cutting system supporting existing offset presses up to 40 inches and digital cutsheet sizes with its new Xerox Iridesse production press.

Canadian short-run offset packaging specialist SoOPAK has bolstered its internal systems by earning the International Featured Standard (IFS) certification and Hazard Analysis Critical Control Point (HACCP) certification, making its facility compliant with HACCP food safety regulations. The two new certifications join SoOPAK’s existing ISO 9001:2015 certification, an advanced upgraded standard highlighting the firm’s commitment to quality management and customer satisfaction. With operations in Mississauga and Scarborough, Ont., SoOPAK is a manufacturer of short-run packaging production starting at 500 pieces.

M o re p ro fi t f ro m your cur rent fl ex o p ress ?

We kn ow i t ’s ha rd to believe . It really is as amazing as it sounds. The Illumina UV-LED retrofit curing system from Fujifilm expands production capabilities while reducing energy costs up to 94% – all on your existing flexo press. With the rapidly growing number of installations, the system has increased running speeds up to 70%. And, when

Celebrating Canadian packaging

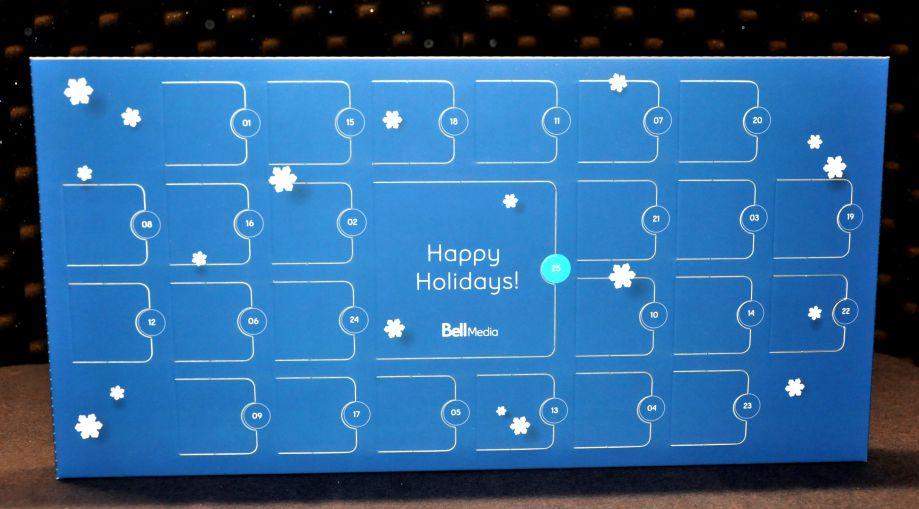

More than 230 people from across the country attended the 14th annual Canadian Printing Awards on November 7, organized by PrintAction and parent company Annex Business Media. A 12-person independent judging panel, working from a blind scoring system, evaluated more than 230 submissions to determine Gold, Silver and Bronze awards across 28 Print Design and Printing categories. Here we highlight this year’s award-winning packaging projects.

PRINT DESIGN

Packaging

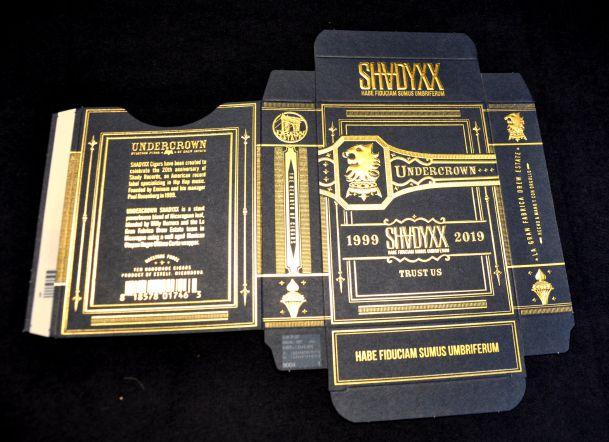

Gold: Undercrown, Gravure Choquet

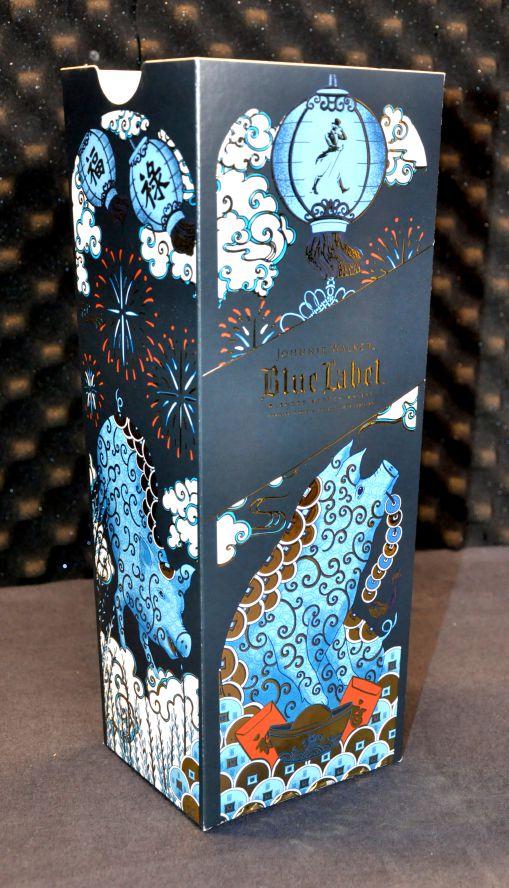

Gold: Johnnie Walker Blue Label Carton, CJ Graphics

Silver: Revolution 81 Carton, CJ Graphics

Bronze: J.P. Wiser’s Gift Pack Carton, CJ Graphics

This year 113 Gold, Silver and Bronze Awards were presented in five program sections: Industry Achievement, Print Design, Printing, Technology and Environmental.

PRINTING

Variable Data Printing

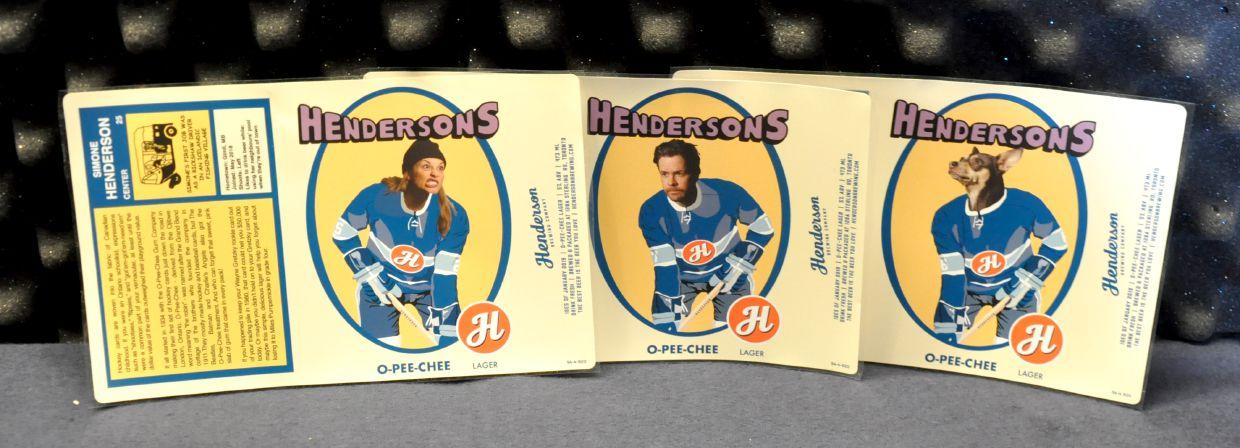

Gold: Henderson’s O-Pee-Chee

Lager, Lorpon Labels

Silver: CJ Look Book, Special Effects, CJ Graphics

Bronze: Railway City Brewing

ArtsCrawl, Lorpon Labels

Labels, Digital

Gold: Rise from the Ashes Amber Ale

(Dog Island Brewing), Jet Label & Packaging

Silver: Prairie Fire Rauchbier

(Town Square Brewing), Jet Label & Packaging

Bronze: Organic Jasmine Pearl White Tea

(Tea Leaves), Jet Label & Packaging

Labels, Flexography/Gravure

Gold: Henderson’s Ides of September 2018

– Lanny 2018 West Coast IPA, Lorpon Labels

Silver: Evazione Chardonnay, Multi-Color

Corporation Montreal Canada

Bronze: Diabolica, Multi-Color Corporation

Montreal Canada

Flexible Packaging

Gold: Jim Beam Barbecue – Cooking Wood Pellets, Energex, Farnell Packaging

Rigid Packaging

Gold: Bell Media Advent Calendar, CJ Graphics

Silver: Martell Blue Swift Gift Carton, CJ Graphics

Bronze: Crown Royal Vanilla Gift Box, CJ Graphics

Finishing

Gold: Coromandel P, Chopsticks box, Pacific Bindery Services

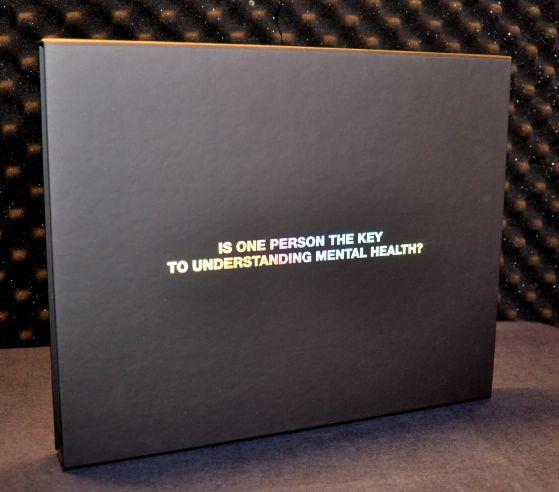

Silver: CAMH Sean Hill Box, CJ Graphics

Bronze: CJ Look Book, Special Effects, CJ Graphics

For now, the Vision CI is offered as an 8-colour press, while the option for 10 colours is expected to launch next year.

Bobst Vision CI flexo press

Bobst in October 2019 announced the launch of the Bobst Vision CI flexo press designed to deliver efficient performance for all production lengths on a wide range of substrates. Described as being fast to setup and change over, the press is available as an initially 8-colour press and aims to provide consistent and repeatable printing quality with solvent-based and water-based ink printing. Developed with sustainable benefits in mind, the press contains smartHEAT technology, which enables the machine to use its own heat as an internal and useful energy source, while its smartCLEAN technology is designed to save on ink and solvents.

Mark Andy Evolution Series

Mark Andy’s Evolution Series made its global debut in September at Labelexpo. Described as a scalable, full servo flexo press, the series is available in 13- and 17-inch web widths with production speeds up to 750 fpm. “Full servo flexographic printing is now within reach for all converters,” says Tom Schelmbauer, Chief Business Officer, Mark Andy Flexo, “this technology, with the highest possible quality and engineering, has been a longstanding – and noticeably absent – request in the industry.” Available for immediate order, Evolution Series will join Mark Andy’s newest digital offerings, Digital Pro and Digital Series HD, on stand 4C45 at Labelexpo Europe. Deliveries of Evolution Series will be ready as early as October 2019 globally.

Cascades recyclable cardboard tray

The series is available in 13- and 17-inch web widths with speeds up to 750 fpm.

Cascades has introduced a fully recyclable cardboard container for fresh food packaging, describing it as an alternative to traditional solutions that do not have a recyclable interior coating. Certified to Forest Stewardship Council (FSC) standards, the made-in-Canada tray is made from 100-percent recycled fibres. It uses a waterbased barrier coating that protects against humidity and helps to preserve the freshness of foods. Cascades says the patented coating does not affect the recyclability or compostability of the cardboard, and can replace traditional waxor plastic-based applications in cardboard food packaging.

The tray is made from 100-percent recycled and recyclable material.

Roland DG VersaUV LEC2-300

Roland DG Corporation has launched the VersaUV LEC2-300 30-inch UV printer/cutter for on-demand production of custom labels,packaging prototypes and bespoke POS and signage. The LEC2-300’s UV ink is designed to adhere to the surface of a material, making printing possible on a range of media, from adhesive sheets for stickers and labels to PET or PVC-based substrates, and textiles, thin paper, canvas, tarpaulin and more. In addition to CMYK ink, the LEC2-300 can be used with clear (gloss) and white ink configurations, including full-colour prints with matte or gloss finishes, simulated embossing and other custom-textured effects.

Meanwhile the automated process, the company explains, is designed to eliminate the need for platemaking and die punching for trimming adhesive decals, labels and stickers.