The proof is in the data: Why perceptions about the paper industry are wrong

Canadian print executives share their business strategies and how they have stayed successful through industry evolutions

Limited-edition beer cans and packaging mimic the unique eye and saddle patches of killer whales

GAMUT

5 News, People, Installs, Calendar

TECHNOLOGY REPORT

19 Exploring the latest in print consumables

NEW PRODUCTS

22 Introducing new products and solutions from Bobst, Color-Logic, EyeC, HP Indigo and Agfa, Kodak, Mark Andy, MGI and Konica Minolta, Roland and Solimar

SPOTLIGHT

26 Ward Stewart, Director of Production Operation, StickerYou

FROM THE EDITOR

4 Alyssa Dalton

Market convergence will lead to new growth opportunities

STAFFING

8 Marc Gordon

Five proven ways to attract and keep great team members

CHRONICLE

9 Nick Howard

Why we must learn from the past and keep an emphasis on creative typography and unique designs

Change is on the horizon — an adage that holds truer today than most sayings. Last month PrintAction attended the inaugural Printing United tradeshow in Dallas, Texas, and within a few hours of walking the show floor, there are an undeniable observation: OEMs and printers alike are embracing convergence, the concept of researching and strategically entering market segments outside of their traditional core offerings.

that they [have been] outsourcing or offering new applications to their customers.”

Thirty-eight percent of respondents of the SGIANAPCO Convergence in the print industry survey say they plan to grow their operations through merger and/or acquisition activity in the next five years.

Built on the foundation of the Specialty Graphic Imaging Association (SGIA) Expo, Printing United featured the latest solutions for apparel, graphics/ wide-format and functional printing applications, while also extending into the commercial, packaging, and in-plant printing segments. Ford Bowers, CEO and President, SGIA, explains the show’s new direction is in response to market demands for a single exhibition that provides “one-roof” access to all printing technologies. From October 23 to 25, over 650 exhibitors and tens of thousands of attendees gathered to explore a broader, more comprehensive range of leading print technologies across 720,000 square feet of the Kay Bailey Hutchison Convention Center.

“The industry has asked, and we are delivering,” Bowers said. “In 2017, when SGIA and NAPCO came together with a vision to meet the widespread need for an invigorated tradeshow and educational format to address the convergence of industry verticals, we immediately got to work. The fact that we sold out of our exhibitor booth space in our inaugural year is a testament to our idea of bringing together all printing disciplines under one roof.”

“There are so many different variables in print and I think this shows the future [of the industry],” Jason Hamilton, Solutions Architect, North America for Agfa, said. “Sometimes we make printing more difficult than it needs to be. I think this [convergence] really helps people understand that with the right tools, the right partners, new [technology and solutions] can impact their business in a positive way.”

SGIA and NAPCO in January 2018 surveyed nearly 500 commercial, graphics, in-plant, garment, packaging and industrial printers about the changing market dynamics. “Printers, across all segments, see the opportunity to better serve their customers with an expanded set of offerings. An overwhelming 95 percent see opportunity, are researching it, or have taken steps to expand their offerings,” according to the Convergence in the print industry report. “As one printer stated, ‘those that deliver value are the ones that grow and get the opportunities.’ Some of the reasons printers see such strong opportunity is because of increasing customer expectations – whether directly within the printing industry or from their perspective as consumers (e.g., Amazon two-day delivery) – which, in turn, raises the bar for all.”

Meanwhile, 93 percent of respondents say they are experiencing some or a significant degree of expansion. “In addition to expansion in their own businesses, the perception of widespread expansion occurring within the industry as a whole is significant: 80 percent of printers see it as accelerating,” states the report, with the most interest in the areas of commercial printing, graphics and signage, and printed product applications within packaging. As well, the survey finds there is strong interest expressed by both graphics and garment printers in each other’s segments, in addition to commercial’s interest in packaging, and graphics’ interest in commercial.

“The next few years for the printing industry are likely to be just as challenging as the recent past, with the changes in technology, customer needs, and the seemingly ever-shrinking amount of time to get an ever-increasing amount of work done. However, it also promises to hold substantial opportunity for those printers savvy enough to stay connected to the opportunities within their own market and to explore opportunities that exist within adjacent markets,” SGIA and NAPCO conclude.

As Greek philosopher Heraclitus once said, the only constant in life is change. Can you afford to sit on the sidelines?

Heather Poulin, Senior Director, Marketing, Commercial Printing Business, Ricoh USA, notes that print shops are becoming all-encompassing solutions providers. “A lot of our customers want to bring in new and different technology — we have wide-format printers that want to bring in production sheetfed products so they can provide shorter run jobs, and we also have commercial printers and in-plants that are looking at wide-format, either it’s bringing those jobs in-house ALYSSA DALTON, editor adalton@annexbusinessmedia.com

Editor Alyssa Dalton adalton@annexbusinessmedia.com 416-510-5225

Contributing writers

Zac Bolan, Wayne Collins, Victoria Gaitskell, Martin Habekost, Nick Howard, Neva Murtha, Abhay Sharma

Associate Publisher Stephen Longmire slongmire@annexbusinessmedia.com 416-510-5246

Media Designer - Team Lead Lisa Zambri lzambri@annexbusinessmedia.com

Account Coordinator Alice Chen achen@annexbusinessmedia.com 416-510-5217

Circulation Manager Beata Olechnowicz bolechnowicz@annexbusinessmedia.com 416-442-5600 ext. 3543

Circulation apotal@annexbusinessmedia.com Tel: 416-510-5113

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Group Publisher

Diane Kleer dkleer@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Subscription rates

For a 1 year

subscription (10 issues): Canada — $43.00 +Tax Canada 2 year — $70.50 +Tax United States — USD$75.50 Other foreign — USD$147.00

Mailing address

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 printaction.com

Tel: 416-442-5600

Fax: 416-442-2230

Annex Privacy Officer

Privacy@annexbusinessmedia.com 800-668-2384

PrintAction is printed by Annex Printing on Creator Gloss 80lb text and Creator Silk 70lb text available from Spicers Canada.

ISSN 1481 9287 Mail Agreement No. 40065710

During her 10 years at Ryerson University, Mary Black was the driving force behind the creation of GCM’s new home, the Heidelberg Centre.

TC Transcontinental has acquired Holland & Crosby Ltd., a manufacturing company specializing in in-store marketing product printing, including advertising display and signage, for North American retailers. Located in Mississauga, Ont., Holland & Crosby Ltd. employs 85 people and has expanded consistently through organic growth and acquisitions. Founded in 1932, the company specializes in a range of visual marketing solutions from design to manufacturing, including distribution, installation and storage. It also specializes in the printing of large-format advertising display, semi-permanent or permanent in-store promotional material, adhesive décor in various sizes. As TC Transcontinental explains, the transaction will expand TC Transcontinental Printing’s presence in the in-store marketing product market and broaden its manufacturing capabilities. Scott Crosby, Co-owner of Holland & Crosby Ltd., will continue in his role with the TC Transcontinental Printing team.

Canopy’s fifth annual Blueline Ranking reveals that four of the top five ranked printers actively supporting the development of next-generation solutions, such as agricultural residue and wheat

straw papers in North America, are Canadian printers: The Printing House (TPH), Hemlock Printers, Mitchell Press and TC Transcontinental Printing. Domestic production of straw pulp, paper and packaging is set to hit the North American market within the next six months with the opening of the Columbia Pulp mill in Washington State, Canopy explains. With wheat straw pulp carrying half the ecological footprint of conventional wood fibre pulps, top ranked printers understand that next-generation papers will help reduce the impacts of their operations, as well as those of packaging and paper, on the world’s forests and natural systems, Canopy notes, adding that today’s top printers are actively fostering the development of these papers, which promises a new environmentally friendly shift in paper production. This year’s top ranking Blueline printers are The Printing House with a new all-time high score, followed closely by Hemlock Printers in second place, and Mitchell Press in third. All three of these companies secured coveted dark green ink drops, indicating their commitment to sustainability, ancient and endangered forest conservation and next-generation solutions, Canopy explains. TC Transcontinental Printing, the seventh largest printer

Canopy’s 2019 Blueline Ranking reveals that four of the top five ranked printers actively supporting the development of next-generation solutions are Canadian.

in North America, also took action on conservation and innovation and is ranked fourth, moving up from ninth place in the previous edition. Other Canadian printers featured in the ranking and their respective positions are: 6. MET Fine Printers; 8. Marquis Book Printing; 9. Friesens; 11. The Lowe-Martin Company; 16. RR Donnelley; 17. St. Joseph Communications; and 19. Vistaprint (a Cimpress business).

Print Three Franchising Corporation has recently undergone a series of strategic partnerships and acquisitions to better serve the Canadian market — rounding out its offering, the company has brought Prime Data of Aurora, Ont., on board. Effective immediately, Prime Data will offer its services, such as inkjet printing and automated direct mail, through Print Three’s 45-plus locations.

Canon Inc. and Océ Holding B.V. have announced the official corporate name change of Canon Group company Océ to Canon Production Printing. After joining the Canon Group in 2010, Océ continued to develop and manufacture its printing products under the Océ brand. By renaming Océ to Canon Production Printing and integrating the Océ products under the Canon brand, there will be brand unity across all areas of the printing business, improved synergies across the portfolio and a clear end-to-end, go-to-market approach, the company notes. Through further integration with the Canon Group, Océ will continue to develop its core technologies and grow its market share as Canon Production Printing, in order to accelerate the growth of the Canon Group’s commercial printing business worldwide, it explains. Its product offering includes continuous-feed and cutsheet printers for high-volume printing and publishing, and large-format printers for display graphics and CAE/GIS applications. The change comes into effect January 2020.

On October 10, Ryerson University’s School of Graphic Communications Management (GCM) hosted a celebration of life for Mary Black The event saw a turnout of about 100 guests, with a mix of industry colleagues and former students who knew her. The print industry veteran and trailblazer passed away on July 5, 2019, at 80 years of age.

For more than 40 years, she was a champion of the industry as well as an inspirational leader, role model, mentor and friend to many. “People who haven’t seen each other for a long time got reunited through Mary’s spirit,” Martin Habekost of Ryerson University says, adding that her daughters thanked everyone for coming to the event and noted that she is still a force in the industry even after her passing. During the event, the GCM boardroom was renamed to the Mary Black boardroom in her honour. “Without Mary, the Heidelberg Centre would not be there and GCM would not have its own building,” Habekost explains.

The Toronto Club of Printing House Craftsmen, a division of the International Association of Printing House Craftsmen (IAPHC), is closing after 100 years of service. President Bill Kidd recently issued a statement explaining the “difficult” decision to close: “The age of social and information clubs in the graphic industry appears to be on the decline in certain sections. The Toronto Craftsmen’s social and competitive events have been declining drastically. Previously, (10 years ago) the Toronto membership and active participation of companies was at a height of over 60. Membership is now at an all-time low. A decision has been made to close The Toronto Club of Printing House Craftsmen in October of this year. This means that all activities will end. All assets will be forwarded to the Canadian Printing Industry Association which has a Canadian Print Scholarships program.”

Paragraph, StickerYou and Beneco Packaging are just some of the Canadian printing companies and packaging converters among Canada’s most prosperous and dynamic companies named in the 2019 Growth 500 ranking of Canada’s fastest growing companies. Formerly known as PROFIT 500, Growth 500 ranks Canadian private and public companies based on five-year revenue growth. The list of Canadian printing companies, packaging converters, suppliers and agencies featured in the 2019 ranking and their respective position include: 60. T-Shirt Elephant; 197. StickerYou; 340. Les Emballages Box Pack; 418. Beneco Packaging; 431. Paragraph; 438. Kimbo Design; and 447. Label Source

Martin Bachant has been appointed President of Xerox Canada Ltd., reporting to Mike Feldman, President of Americas Operations for Xerox. A 30-year Xerox veteran, Bachant will be responsible for Canada’s go-to-market strategy, operations, sales and delivery of document technology, solutions and services for small, medium, large enterprise, graphic communications, and public sector clients across all business channels. Prior to his appointment, Bachant was Senior Vice President of Xerox’s Canadian sales operations, responsible for the overall technology and services growth strategy, national business development and strategic investments. He also served as Vice President and General Manager of eastern regional operations and Quebec.

TI Group welcomes Toni Giancola to its team as Account Director, leading the team for a key client. Ken Wheeler also joins the company as Account Director with a specific focus on servicing consumer packaged goods companies.

Print industry veteran Ken Freek has a new role at Heidelberg Canada. Joining the company as Subscription Sales Support, he says he looks forward to using his print industry experience to support the team as it introduces Heidelberg Subscription to Canadian printers. He brings 35 years of printing industry experience to the role, including senior positions with printing and supplier companies as well as experience with various industry organizations and associations. In February, The Canadian Printing Industries Scholarship Trust Fund (CPISTF) Board of Trustees appointed Freek to the position of Executive Director, Outreach and Partner Relations.

Electronics For Imaging (EFI) has named tech finance executive Grant Fitz as its new Chief Financial Officer. Fitz replaces long-time EFI executive Marc Olin, who will assume the COO role at EFI. Fitz, who assumed his new CFO duties in September, brings nearly 30 years of financial and operational experience overseeing accounting, business support, and financial planning and analysis in the print marketing, tech and automotive fields. Fitz comes to EFI from Valassis, a print and digital marketing technology and consumer engagement company, where he also served as CFO. Prior to that, he was Corporate Vice President and CFO at Xerox Technology.

Robert Buongiorno has been appointed President of BST North America. Having worked in the press manufacturing industry for almost 40 years, he brings extensive experience to the role, which includes positions in sales, service, business development and leadership. Buongiorno succeeds Mark Lambrecht, who leaves the company for personal reasons.

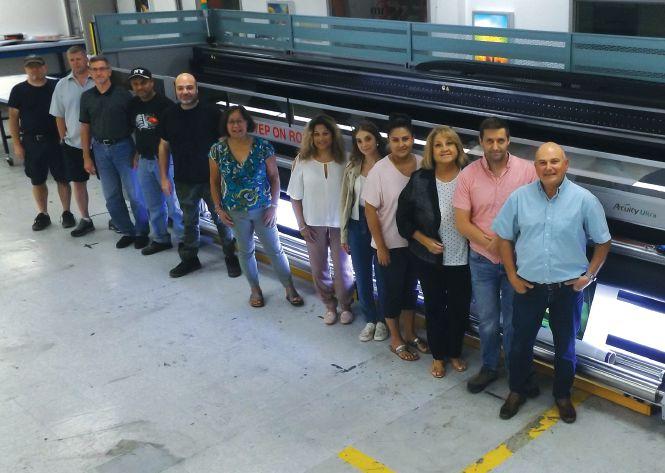

Impulse Graphic & Display Solutions of Mississauga, Ont., has expanded its wide-format portfolio with Fujifilm’s Acuity Ultra, a 5-metre superwide UV press for interior and exterior applications. With the new press, Impulse says it will be able to maintain printing in-house with reduced setup costs and prep time.

Solucan is installing the world’s first Tonejet Cyclone direct-to-can digital printing system at its new facility in Quebec for short-run can decoration. The system will be used to produce unique customized cans for local craft brewers and other beverage manufacturers.

Minuteman Press of Kitchener, Ont., has purchased Canada’s first Duplo DC-618 slitter/cutter/ creaser through Print Digital Solutions (PDS). The addition of the DC-618 is expected to increase the accuracy and efficiency of its print finishing, it explains.

November 7, 2019

Canadian Printing Awards Palais Royale, Toronto, Ont.

November 13, 2019

Canadian Print Scholarships

Launchpad Reception @ Ryerson University Toronto, Ont.

November 25-28, 2019

Shanghai World of Packaging Shanghai, China

December 11-12, 2019

Digital Textile Printing Conference Durham, N.C.

June 16-26, 2020

drupa 2020 Düsseldorf, Germany

September 15-17, 2020

Labelexpo Americas 2020 Rosemont, Ill.

By Marc Gordon

According to one Gallup poll, 50 percent of employees leave their job because of their bosses. However other studies have shown that employees can leave for a number of other reasons, such as opportunity, better pay, or more responsibility.

Regardless, attracting and retaining quality staff is not only good for the bottom line, it’s good for customer service. Here are five ways to best attract and retain great staff.

According to CareerBuilder, 56 percent of U.S.-based companies have paid for employees to get skills-based training outside the office, so they can move up to a higher-skill job within their organization.

• Be a coach, not a dictator. We all know being a manager is not an elected position. Maybe that’s why so many managers are prone to bark orders and rely on negative reinforcement. Instead, become a coach. Team coaches are still the boss, but understand that like athletes, staff need to be instructed, encouraged, praised, appreciated, and when necessary, disciplined. The key is to prioritize your energy towards the positive tasks first.

• Be flexible — to a point. Regardless of what some bosses think, employees do not live to work. They have lives outside of the company. A sick parent, a dentist appointment, or a child’s class field trip can all conflict with a pre-set work schedule. Setting policies that give freedom within established boundaries can reduce stress and allow staff to better focus on their jobs when at the office.

• Understand the job. Managers often have a hard time understanding what employees go through on

Attracting and retaining quality staff is not only good for the bottom line, it’s good for customer service.

a daily basis, especially if it’s a job they’ve never held themselves. Being yelled at by customers, meeting tight deadlines, hard physical labour — these can all impact mood and productivity. Understanding how daily tasks can affect staff well-being will result in more empathetic and thoughtful bosses.

• Be a problem solver. Managers need to understand that they and their staff are all on the same team. And anyone who feels part of a team naturally wants to contribute more. Helping staff solve work related problems not only reduces down time, it can present opportunities for ineffective processes and procedures to be updated.

• Empower others. An employee who is not sure what they are allowed to say, will always say no. This can result in angry customers, lost sales, or missed opportunities. Staff that are empowered to make decisions within a framework of guidelines will usually make the right ones. Empowerment will also lead to pride and ownership of their positions. Two traits that employees will likely not want to give up.

Marc Gordon is a recognized marketing expert, speaker and strategist. His articles appear in over 200 publications worldwide. Visit marcgordon.ca or his online show at marctv.net for more business tips. This article was originally published in Bakers Journal, a sister publication of PrintAction at Annex Business Media.

By Nick Howard

As a kid growing up in Montreal, Que., my parents had a good friend who owned a French-made Citroën DS. Almost every time Mr. Hagen would come over, I’d run out of the house and plead with him to show me how his car would magically go up then down. The whole body of the car would slowly rise and descend with the turn of a knob. It was magic! There was nothing like that 1960 model DS anywhere, and with how it was designed, it looked like a rocket ship. Even Flash Gordon’s spacecraft never looked this cool. Citroën called the self-levelling feature ‘Hydropneumatic Suspension’ and boy, did it make my dad’s 1959 Chevy look drab in comparison.

As I learned later in life, there were many more unique features in that Citroën, but rarely do I see one anymore. What crawls out of the minds of designers and engineers astounds me. Ironically using the Citroën DS as an example, few ideas that seem like a winner on the drawing board become a success.

Case in point is the earliest development of what we today call lenticular printing. In the February 25, 1964 issue of LOOK magazine, a small postcard insert displayed what was then described as a parallax panoramagram. The initial process was said to have been patented by Dr. Edgar Fuller in 1938, but it wasn’t until LOOK ’s Vice President Marvin Whatmore turned his eye to it to boost the circulation of the magazine. In 1950, the parent company of LOOK, Cowles Magazines & Broadcasting Inc., worked to design a special 3D camera and a plastic substrate that would adhere to an image. Later Eastman Chemical Products Inc. (Kodak) and Harris-Intertype Corp. were roped in to add their knowhow and research labs to the effort. These early results, although promising, still required viewers to wear special glasses to see the 3D effect.

Fourteen years of testing and modifying came to fruition with that insert in LOOK . The first three-dimensional printing ever achieved went to the homes of several hundred thousand people.

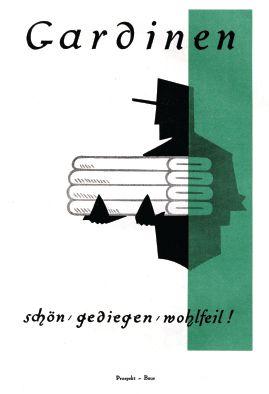

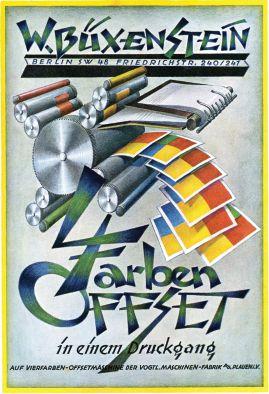

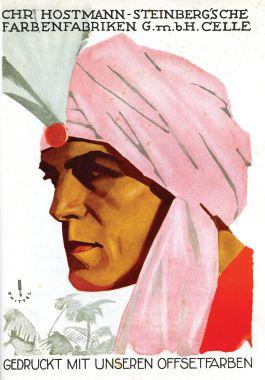

Above: Printing Magazine/National Lithographer, 1964 - 03, vol. 88, page 63. Below: Book of Art Printing, 1930.

Epoline hot-melt plastic was applied to a specially built Harris offset press, which when cooled against a corresponding mold, provided the prismatic lines to create the 3D effect.

I happen to have one of those 3D cards. It is a paperback piece with the newly developed Kodak polyester fibre lens material – Kodel – and features a black and white photo of Thomas Edison surrounded by five of his most notable inventions. Looking at this sample today, I can’t see what the fuss was all about — the sample is at best amusing; comparisons to modern lenticular material are stark at best.

The printing industry has always jumped at any opportunity to differentiate themselves from mass media. The unique offerings of print had no competition. The 1920s to 1970s were the boom years where design trumped just about everything else. Typography was prolific, but before phototypesetting, every printer had to ‘buy’ his fonts or matrices to draw customers. With the arrival of phototypesetting, the cycle of expenditures would begin all over again. The music industry would replicate this agony when vinyl records made way for 8-track tapes then cassettes, which led to CDs and now MP3s. Each time, the customer bore the brunt of a technology that forced obsolescence.

Print seems to have forgotten the lessons of early 3D printing, even though lenticular substrates are genuinely fantastic. The problem is that what Mr.

Whatmore assumed would be a significant breakthrough, never lived up to the promise of 1964. Lenticular is often used today but is relegated to a very tiny segment of what you can do for your customers.

Ultraviolet printing arrived in great fanfare in the 1960s. Small research laboratories all over the U.S. and western Europe were diligently experimenting with drying systems and inks that cure and not oxidize as with conventional oilbased inks. The possibilities were mind-blowing: Instant dry, higher gloss, and no spray powder.

The U.S. firm Royal Zenith was so enthusiastic that it installed a few of the crude UV lamps on its 26-inch half-web. By doing so, large hot-air dryers and chillrolls wouldn’t be needed — except UV turned out to be a disaster. One company ripped out the UV after it ran into every imaginable flaw possible, including trapping and colour variation issues. Furthermore, the whole plant was covered in a brownish coating from ink misting. Early UV was plagued by everything from extreme heat and constant fires to unstable inks, tremendous power draws, and slow ramp-up times. Word quickly spread, and during most of the 1970s and 1980s, UV went nowhere fast.

Today, it’s an entirely different story. Inks have improved, lamp technology and performance are a given, and ‘instant-on’ means what it says on the label. Since 2009, 100-percent UV has taken a back seat to underlying newer technology, often referred to as low energy curing. Whether it be LED or doped UV lamps that operate on very little electricity, this technology is the culmination of over 50 years of research and failures and can be retrofitted to any offset press. Long perfectors are an excellent example. They

need only two Low-E lamps to completely cure inks on both sides of the sheet and at any speed. Low-E/LED is a blessing for perfectors.

Offset presses with tower coaters, and now even digital presses, can apply coatings without the worry of drying. This ability has helped to create new forms of coatings that the majority of printers use everyday. Strike-through and reticulating varnishes provide stunning results, as does the often seen soft-touch effect. These enhancements have done marvels for our industry since being introduced about a decade ago.

But…just imagine you’re at the Frankfurt Book Fair and find yourself despondent because almost every book cover or jacket you pick up has one of these three effects. Although we love the effect and our customers love them, the euphoria won’t last. Same as Mr. Whatmore’s experiments with his early parallax panoramagram postcard — there’s not much head-turning over lenticular today. Once clients get used to soft-touch, it quickly becomes passé. If everybody has the same car or similar furniture tastes, it becomes a fad and fads don’t last. Harvest Gold appliances or Scandinavian Teak are fads that quickly come to mind.

Consumer indifference is already incubating, and perhaps your company hasn’t noticed yet. Possibly the enhancement effects of off-line digital polymer equipment is close behind. Everyone is using this technology, and when repeated continuously, customers grow weary.

One thing that never goes out of fashion is design and typography. With all the exciting new tools available on our equipment, we may be forgiven for not putting as much effort into the design itself. Pretty much any printer can use UV and the amazing varnishes and coatings, but not everyone can design a bespoke piece of print. Some because they don’t have to and still get work handed to them, others because they see no need to ruffle feathers and waste time when all their client wants is what they have created, or perhaps, they simply don’t have the talent.

Clockwise from top left: Book images from Klimschs Jahrbuch, 1927, vol. 20; Archiv Fur Buchgewerbe Und Gebrauchsgraphik, 1925, vol. 62; Zeitschrift, 1926, vol. 38; Zeitschrift, 1926, vol. 38 - A; Penrose Annual, 1937, vol. 39; Penrose Annual, 1937, vol. 39; and Zeitschrift, 1926, vol. 38 - B.

As these new printing effects start to lose interest, and they will, consider what our industry has always known: Good design stands out more than anything else. Probably the best example of standing out occurs each year when the industry assembles to judge the best of print and award commendations. Want to see plenty of use of coatings, varnishes and UV inks? Check the submissions for these awards. Unfortunately, they also start looking the same.

We enjoy a steady stream of visitors at our Howard Iron Works Museum, from all walks of life and levels of interest, but the majority are artists and designers. Plenty of historically unique machinery on display, but you know what these folks want to see? Our library and type collection. Designers are searching for unique typography, and if it’s going to be printed, preferably letterpress on heavy uncoated paper, with ‘Lettra’ a particular favourite for stationery and invitations. I want to talk about this or that press, but they head for our type, and eyes light up. Searching our books from the ’20s and ’30s is a pleasure that makes them feel invigorated again. Masterful bookbinding perhaps, or perhaps the Swiss-style Akzidenz Grotesk? The early 20th century unleashed such beautiful periods of design. The Inter-

national Typographic Style movement of the 1920s made way for Bauhaus and Art Deco. Jan Tschichold’s revolutionary New Typography period opened up a design style that felt clean, bold and uncluttered. The use of Grotesk and creative silhouettes spread throughout Germany, eventually reaching Britain and North America. There is a lot you can do in black and white.

Creative typography and unique designs have no expiry date. That’s the beauty of design — not everyone can do it. The Citroën caught my attention but quickly faded away. I am no longer excited to see lenticular, and soft-touch bores me. I still enjoy reticulating varnish effects though, but for how long? The same is happening with the vast array of coating effects today. We must learn from the past and keep moving forward with an emphasis on design and not just applications — don’t always follow the herd.

NICK HOWARD, a partner in Howard Graphic Equipment and Howard Iron Works, is a printing historian, consultant and Certified Appraiser of capital equipment.

nick@howardgraphicequipment.com

AVAILABLE EXCLUSIVELY FROM VERITIV

PROVIDING A PERFECT BALANCE OF PERFORMANCE AND AFFORDABILITY

Features include:

• Gloss and Silk finishes in a wide range of standard weights and sizes

• Available in matching digital basis weights and sizes

• Smooth, even print surface for excellent print results

• High opacity for superior image sharpness

• Excellent print contrast leads to crisp imagery

• PEFC Certified

60, 70, 80, 100 and 115 lb. Text

80, 100, 111 and 130 lb. Cover

To learn more and see the full offset and digital range, please visit: Pour en savoir plus et pour voir tout l’éventail de papiers offset et numériques, rendez-vous sur : veritivcorp.com/proprint

OFFERT EXCLUSIVEMENT PAR VERITIV

L’ÉQUILIBRE PARFAIT ENTRE LA PERFORMANCE ET L’ABORDABILITÉ

Principales caractéristiques :

• Finis brillant et satiné, large éventail de formats standard, versions édition et couverture assorties

• Poids de base et formats digital assortis

• Surface d’impression lisse et uniforme pour d’excellents résultats

• Opacité élevée pour une netteté supérieure des images

• Excellent contraste pour des images précises

• Certifié PEFC

120, 140, 160, 200 et 230 M Édition

160, 200, 222 et 200 M Couverture

The proof is in the data: Why perceptions about the paper industry are wrong

By Mariana Sandin

The paper industry is dead. Or at least that’s what consumers are led to believe. As the world digitized, the news was filled with projected declines in paper consumption and subsequent revenue. Not only that, as more North Americans believe climate change is real, the pulp and paper industry has become a target of energy consumption, sustainability and deforestation concerns.

While such apprehensions are valid for any product category, visions of printed paper piled high in the recycle bin often leave the pulp and paper industry’s reputation in tatters. And it’s time to reverse the stigma.

Here are four myths about paper and how the new, data-driven pulp and paper

industry really stacks up.

Myth: Paper is a dying industry

Fact: Sales are up and the industry is thriving

According to reports, paper is a 19th-century industry on the wane — and 25 years ago, that was correct. However, paper prices are higher than they’ve been in years and specialty packaging is up. Additionally, as anti-plastic sentiment continues to grow, new opportunities will continue to arise. Today, about 60 percent of paper waste is recycled compared to just 9 percent of plastics, putting paper firmly in the position to replace single-use plastics, such as straws. These opportunities are paving the way for a new paper industry, allowing innovative mills to reposition themselves to produce fresh types of packaging products and increase

As part of its efficiency efforts, Verso has dramatically reduced the amount of water consumed per tonne of production, which in turn dramatically reduces the amount of energy consumed at the plant. Simultaneously, it has increased the number of tonnes per day produced.

Graph courtesy of OSIsoft.

When consumers think of paper, many think of excessive waste and environmental damage, but that’s simply not the case.

return on capital.

In 2010, Fortress Paper purchased a closed pulp-based paper production mill with the goal of converting it to a dissolving pulp production facility. Dissolving pulp is manufactured in the mill and is then sent to textile customers where it is converted to rayon. To produce this pulp, Fortress installed completely new cooking equipment and a cogeneration plant, but the company found itself in uncharted terrain. Fortress decided to leverage a data infrastructure to monitor all assets and, with the influx of real-time data, it gained visibility into processes and overcame many challenges. By defining, measuring, analyzing, improving and controlling all parts of the plant floor, the plant now produces 170,000 tonnes of dissolving pulp per year.

Myth: The paper industry is antiquated Fact: It’s ripe with new processes, new products and machines

When tablets became widely available, many predicted paper books, magazines and even greeting cards would fall by the wayside. However, there’s a sensory aspect to books and cards, and physical book sales are on the rise. While many mills are producing new items to meet changing demands, others are finding innovative ways to manufacture the products consumers know and love.

For one mill, reducing variability in pulp viscosity was critical to maintaining its product quality. However, it lacked visibility into the digester, which affected

downstream quality. Using operational data, it analyzed 8,000 cooks and 450 million data points within a data infrastructure, and used that information to build a model that predicted outcomes based on current viscosity. Its goal is to provide operators with enough information to comply with product quality requirements before the furnish goes into the digester.

Myth: The paper industry is not environmentally friendly Fact: Resource usage is down and the industry is very efficient

When consumers think of paper, many think of excessive waste and environmental damage, but that’s simply not the case. Certified wood promotes sustainable forest management policies. Inventories on private timberlands, which provide more than 90 percent of the domestic wood and paper products, have increased nearly 7 percent since 2008. Waste products, such as lignin, are used to generate power in paper mills, and close to 70 percent of waste is turned into energy. In addition, an estimated 65 percent of the fibre brought to recycling centres gets reused.

For every paper mill, energy consumption and conservation are imperative to operate profitably. Due to paper grade changes, production rates and time of year, Verso Paper’s Androscoggin mill experienced wide variances in water and energy pricing. With over 2,000 tonnes per day of freesheet and groundwood coated paper, even small energy pricing changes resulted in hefty energy bills. By

connecting the water and energy meters into a data infrastructure, the mill analyzed information to gain an understanding of present and future consumption. Management reconfigured the water system to use water and energy when prices were optimal, resulting in a 20-percent reduction in cost. With the help of these insights, 80 percent of Verso’s mill energy requirements are now generated onsite using renewable resources.

Fact: It’s incredibly sophisticated

For years, the pulp and paper industry operated using antiquated systems and lacked data to gain operational visibility. However, changing demand and shifting consumer preferences have changed how mills operate.The first and most common production problem mills attempt to tackle is predictive maintenance. Reactive maintenance, or maintenance performed after equipment fails, can be 60 to 90 percent more expensive than predictive methods. After maintenance strategies, many mills work toward extracting more product from the same production footprint. While this can be more profitable, it’s far more challenging.

Klabin’s recently opened Puma plant, the largest ever industrial investment in the state of Parana, Brazil, and produces 1.5 million tonnes of pulp per year. Klabin created a digital twin of plant operations, providing complete visibility into the entire production line. Using models within the data infrastructure, Klabin stimulates production changes and schedules stops to improve production forecasts and process stability. By tweaking processes, Klabin has increased output by 3,400 dry tonnes a year.

Consumers are seeing new, sustainable product options from the pulp and paper industry that span far beyond traditional perceptions. And it’s all thanks to the right combination of capital investments and data. As data has permeated mills, pulp and paper companies are finding new and innovative ways to meet consumer demand, increase sustainability and drive bottom line results.

Mariana Sandin is industry principal for the forest and paper products sector at OSIsoft.

It’s undeniable that the print industry is in a state of constant transformation, so how can today’s printing companies best navigate these turbulent times? We ask print executives from across Canada about their business practices and how they stay successful.

Compiled by Alyssa Dalton

Burke has been able to continue to lead in our market by investing in technology and new equipment purchases, but our greatest asset by far is our staff. We consistently promote from within and encourage our staff members to grow their departments by bringing new ideas to the table to better develop or expand our service offerings.

Ian Burke, Owner/CEO Burke Group, Edmonton, Alta., est. 2005

To remain relevant in the print industry over the past three decades, our business has had to continually invest in new technology, training and product offerings. We are always looking for the next piece of technology or software that will help give us that extra edge relative to our competitors. We are never scared to invest in something. It doesn’t always pan out, but it’s the only way we have stayed relevant.

Bhadresh Bhatt, President

PrintPro Digital & Offset Printing, Winnipeg, Man., est. 1989

We have stayed competitive by investing in technology and our people. We strongly believe that if you are not embracing new technological advancements to improve your product offerings and speedup your production processes, then you are moving backwards. We also believe in investing in our people, because without our amazing team, we would not be where we are today.

Deanne Sinclair, Owner/ Vice president

Cambridge Label, Cambridge, Ont., est. 1998

Simpson Print has weathered many key shifts in the printing industry. The first key shift – desktop publishing – eliminated the film and storyboard era and transformed design and prepress. The second key shift was the advance of digital print and as early adopters in wide-format, our commitment has always been in highquality digital acquisition. Ensuring we are on the leading edge of digital ink and equipment technology is essential to our core capabilities. We look to the emerging economics of sustainability and its impact on the industry moving forward. Investment in a greener process and preparation for the regulation of plastics is where we will seek to drive our competitive edge as an organization.

Carla Johanns, President

Simpson Print, Bloomingdale, Ont., est. 1964

Print Panther was first in Canada with the Konica Minolta MGI JETvarnish and Konica Minolta AccurioWide. Rather than lose ground as many printers experienced, we chose to break new ground as a truly digital print shop. We built Print Panther with a progressive, gutsy mindset – always expanding, fine-tuning and augmenting our core offerings with the newest emerging technologies.

Christine Yardley, President

Print Panther, Oakville, Ont., Trigger Communications T/A Binders Galore & Print Panther est. 1997

CJ Graphics Inc. started as a boutique printing company, challenging itself on every project. We were the print shop that others sent the complex and difficult projects to. This helped align us with the best of the best designers and agencies and allowed our skilled staff to win numerous awards. We pride ourselves on hiring the best craftsman and investing in the newest technology. We always owned our real estate and did not buy a new piece of equipment until the others were paid. Our goal was to be a one-stop solution and keep everything under one roof.

Jay Mandarino, President/CEO

CJ Graphics Inc., Mississauga, Ont., est. 1981

Throughout our 51-year history, we have always strived to be better — this is a never-ending process driven by a desire to do great work for our clients and to always look for ways to add value to the services we provide. This drive inspires our continued technology investments, product and service innovations, sustainability initiatives and expansion into new markets.

Richard Kouwenhoven, President/COO

Hemlock Printers, Burnaby, B.C., est. 1968

Our hot-foil stamping and embossing processes are still competitive even if cold foiling (to replace hot stamping) and raised UV (to replace embossing) processes are offered in the industry. Our process offers better productivity and pricing on medium and large runs, better shine than cold foil, less foil usage than cold foil and digital foil. We are closely watching the evolution of these competitive processes and we are very active in the commercial, collectibles, packaging and high security markets.

Patrick Choquet, President Gravure Choquet, Montreal, Que., est. 1973

PDI adopted a strategy many years ago based on diversification, with a strong focus on adding value to both existing product lines and all new initiatives aimed at growing our sales. We determined our customers would be favourable to us taking on more of their business if we could provide more turnkey services that enable print and justify an ROI on marketing spend.

Jamie Barbieri, President

PDI Group, Kirkland, Que., est. 2007

Ingersoll Paper Box has been in the paperboard packaging industry for 97 years. We have stayed competitive for all those years by providing the highest quality packaging on every single package, which is why our tagline is, The proof is in the package. Investing in state-of-the-art equipment, staying abreast of market trends, and innovative structural designs also keeps us on the cutting edge of business.

Sarah Skinner, President

Ingersoll Paper Box, Ingersoll, Ont., est. 1922

There are four key principles that have helped Friesens navigate the evolutions of the print industry: 1) Be responsive to your customer’s evolving needs; 2) Link every employee’s interests to the same outcomes; 3) Invest relentlessly in technology; and 4) Embrace change and continuous improvement.

Chad Friesen, CEO Friesens Corp., Altona, Man., est. 1907

Proceeds from sales of the Pod Pack went towards the Pacific Salmon Foundation’s effort to preserve the wild B.C. salmon stocks, a critical food source for killer whales.

Limited-edition cans and packaging mimic the unique eye and saddle patches of killer whales

By Victoria Gaitskell

Vancouver Island Brewing of Victoria, B.C., recently raised greater awareness for the population decline of British Columbia’s southern resident killer whales (SRKW) and its own company brand through an eye-catching, limited-edition promotional pack of beers. Unlike other resident communities, the SRKW is only one clan that consists of three pods or family groups. Dubbed the Pod Pack, the mix pack consisted of four different beers, each one created in collaboration with a different local brewery on Vancouver Island and named after a specific animal in the critically endangered SRKW population.

The four specialty brews in the Pod

Pack are: Mystic, a dry-hopped sour beer from Ile Sauvage Brewing named after L-115, a male born in 2010; Deadhead, a hazy session India pale ale from Land & Sea Brewing named after K-27, a female born in 1994; Ocean Sun, a double India pale ale by White Sails Brewing named after L-24, a female born in 1928; and Rainshadow, a blackberry-raspberry sour beer from Twin City Brewing named after K-37, a male born in 2004.

Available the last week of July in British Columbia and Alberta until it sold out, proceeds from sales of the Pod Pack went towards the Pacific Salmon Foundation’s effort to preserve the wild B.C. salmon stocks, an important food source for killer whales, also known as orcas.

Each Pod Pack beer is housed in a 16-oz tall can decorated with reproductions of the unique eye- and saddle-patch mark-

Colour Graphical Interface

Operators are guided through job setup with detailed graphics that can provide step-by-step guidance. Getting professional results has never been easier.

The all NEW Morgana BM5000 series is the latest member of the Plockmatic Group booklet making family. Engineered for mid-to-high volume customers with the highest quality and functionality requirements.

With an increasing number of printing systems available to handle larger cut-sheet sizes, Letter landscape and oversize booklets can now be produced easily and cost-effectively. The new BM5000 Series delivers these new applications by handling up to 24.4” long sheets.

Lower cost per copy can be achieved with the BM5050S, with its 4 stitching heads, you can finish jobs up to 50 sheets that have been imposed 2-up on a sheet; this functionality offers you higher productivity and efficiency.

Hand Feed Capability

This standard feature allows operators to easily drop complete collated sets into the Booklet Maker.

Finishing Module - Now Standard

BM5035/BM3050 Production Booklet Makers

VF602 High Capacity Feeder

The VF602 high capacity dual bin feederr gives the ability for long uninterrupted runs of booklets. The bins can be loaded on the run with pre-collated sets from multiple print engines.

The Finishing Module now places both SquareFold and Face Trim capabilities in one single moduleand comes as standard. It adds the finishing touch with a square folded edge and printable spine.

The BM5050 can staple and fold up to 50 sheets of 20lb Bond, which creates booklets of up to 200 pages. The BM5035 is capable of 35 sheets creating 140 page booklets.

The Booklet Maker can be specified with either two staples or up to four stitching heads. This gives customers the ability to further tailor their systemand finish a wider variety of booklet sizes. The system can also provide edge stitching in one or two locations for even more flexibility.

CST Crease/Side Trimming Module (optional)

The System 5035/5050 can be enhanced by adding the CST creasing and side slitting module. It creates bleed trimmed booklets “on the fly’ eliminating the need for a guillotine prior to production.

A new optional Convenience Feeder is available with a capacity of up to 800 sheets. It can either feed covers or functions as a feeder to make a simple, compact landscape booklet maker without the need for an additional feeder module.

ings of the beer’s titular orca. Differences in the shape of these markings, located above and behind an orca’s eyes and behind its top or dorsal fin, help researchers identify each orca individually.

“The markings form such beautiful patterns that it was a no-brainer to use them in the package design,” says Eric Seymour, Art Director and Designer at One Twenty Three West, based in Vancouver, B.C., who conceived and designed the Pod Pack. He first fell in love with orcas during frequent childhood trips with his parents to Vancouver Island and the nearby Gulf Islands. “The first second you see an orca is an awe-inspiring, life-changing experience,” he recalls.

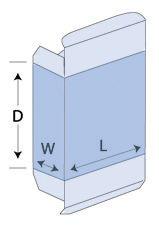

Westkey Graphics of Burnaby,

B.C., which produced the labels for the cans, applied a soft-touch laminate to the labels after they were printed on a Nilpeter flexographic press. Bob Adams, National Account Manager at Westkey, explains the laminate gave the labels a tactile quality that made the cans feel rubbery, similar to the skin of a living marine mammal. As well, Great Little Box Company of Richmond, B.C., which produced the Pod Pack cartons, worked closely with the One Twenty Three West team to create a finish for the carton that would replicate the labels.

“For a packaging project, we always do a competitive analysis up front to make sure we are not stepping on any competitor’s toes and that our packaging will stand out from everyone else’s on the shelf,” Seymour continues. “The dorsal fin on top of the Pod Pack carton is a unique feature that definitely makes it stand out.” He recounts that one of the biggest challenges was to ensure the structural integrity of the carton.

Shari Guest, Packaging Specialist – Folding Carton at Great Little Box Company notes that figuring out

how to shape the fin to mimic the orca’s anatomy while also being a functional closure was a challenge that required multiple mock-ups and tests. Finding a suitable solution, Seymour explains, took at least four or five trial runs of walking around the office carrying a mock-up carton full of beer cans.The earliest of these experiments ended with the cans dropping all over the floor.

“Vancouver Island Brewing’s brand involves being part of and supporting the Vancouver Island community and lifestyle. People love the whales and the locale and were attracted by the compelling story the Pod Pack tells,” Seymour says. Research finds the SRKW population has declined over 20 percent, from 98 orcas in 1995 to only 73 orcas in 2019, a 30-year low. Resident killer whales are only one of three distinct ecotypes of killer whales found in Canadian Pacific waters and are further subdivided into northern and southern populations. It is not all killer whales but only the specific SRKW population that is endangered. Historically these endangered whales spend from May to October feeding on salmon in the waterways

off the coast of British Columbia and Washington, but scientists fear these animals now face nutritional and health challenges and are not returning to their summer residence because of too much vessel traffic and sound pollution and not enough fish. Accordingly, one dollar from the sale of every Pod Pack was donated to the Pacific Salmon Foundation (PSF), a non-profit Vancouver-based charitable organization dedicated to protecting, conserving and restoring wild Pacific salmon and their natural habitat in British Columbia and the Yukon.

The goal of the Pod Pack was to raise $20,000 for PSF, but public support for the cause proved to be so high, the team doubled its production run.

“The orca is a majestic mammal and an iconic symbol of Vancouver Island, so it’s vitally important for us to do what we can to keep the population thriving. We hope that this Pod Pack collaboration will not simply raise funds, but also help raise awareness for our B.C. resident killer whales,” says Chris Bjerrisgaard, Marketing Director of Vancouver Island Brewing.

APP Canada is celebrating 20 years of growth and success in a market segment that has undergone significant transformation. To mark this milestone, the company looks back at its strategy of evolution and its ability to respond to more informed consumer choices especially with a growing trend of moving away from plastics. In our conversation with David Chin-Bing, president of APP Canada, we track the company’s journey and innovative products that will guide its future.

A BRIEF TIMELINE OF APP’S EARLY YEARS IN CANADA:

Two decades ago APP Canada, an independent subsidiary of an Asian company operating in Canada, was established with one small location in Mississauga, two sales offices in Montreal and Vancouver, and the strong hope that the printing industry would respond favourably to its offering.

During the early years, the company focused on sales of coated and uncoated Riviera paper, photocopy paper and stationery and in 2005, APP introduced its coated paper and board products to the Canadian market.

“Twenty years ago, the industry was somewhat resistant to Asian paper, with concerns over its quality and how it will affect the machines and the finished products,” said David Chin-Bing, president of APP Canada. “But the printing industry soon realized the benefits of paper from Asia and how competitive it was with North American or European alternatives.”

In 2007, APP Canada moved to its current location on Hereford Street in Brampton for added space to accommodate its 50-person staff and the need for a larger warehouse for its expanding product lines that now also included Paperline photocopy paper. The company also opened additional sales offices in Calgary, Winnipeg and Edmonton.

“The market became more competitive with the merger of vendors and several key acquisitions. There were also newer players, like ourselves, looking to service wide customer segments and meet demands for faster turn- around times, online functionality and the desire for collaboration, ”said Chin-Bing.

Over the next decade, APP Canada continued to reach new milestones. It received PEFC certification, introduced thermal paper and stationery products to the market and expanded its sales network nationwide.

The company invested in increased support for the paper packaging segments for consumables, household items and logistics.

In 2019, APP Canada is known for far more than photocopy and printing paper. With a looming ban on single use plastics in Canada, the company is leading the way in innovation with the recent announcement of a completely biodegradable foopak line of disposable cups and food containers. This year, it also announced the production of one of the first paper straw alternatives on the market fully capable of performing as well as its plastic alternatives.

Today’s market is also prioritizing sustainable development at the local level and once again, the company is at the forefront. In Indonesia and China it focuses on best practices for training, education, poverty alleviation for famers working and living within their forests. Pay-it-forward programs integrating community engagement, NGOs and local governments are as much a part of APP’s business strategy as the technology invested in the paper production itself.

Asia Pulp & Paper (APP) is a trade name for a group of pulp and paper manufacturing companies in Indonesia and China. APP is responsible for delivering quality products to meet the growing global demand for tissue, packaging and paper, with an annual combined pulp, paper, packaging product and converting capacity of over 19 million tons per annum. On any given day, APP’s products find their way into the hands of consumers in various branded forms from all over the world.

Ensuring supply chain integrity and commitment to the Sustainable Roadmap Vision 2020 are crucial to APP’s operations. Learn more about APP’s path to operational excellence by reading our Sustainability Reports and Forest Conservation Policy at www.asiapulppaper.com.

DuPont Advanced Printing has received Eco Passport by OEKO-TEX certification from the Hohenstein Institute in Germany across the DuPont Artistri textiles digital inks and pretreatments portfolio for both roll-to-roll and direct-to-garment textiles printing applications and specifically apply to pre-treatments, acid, reactive, disperse, pigment and dye-sublimation inks. Eco Passport by OEKO-TEX is an independent testing and certification system for textile chemical suppliers to demonstrate their products are safe and can be used in a sustainable textile production.

Highcon in October 2018 introduced a new range of consumables for its digital cutting and creasing machines: DART Premium and DART Economy consumables. The consumables, it says, have been developed to suit paper, folding carton and corrugated boards. The Highcon DART technology, implemented in the DART resin, DART foils and DART counter, aims to open up a range of digital potential to the previously analogue process. The digitally driven rule shape (geometry – cross-section) and dimensions (height versus width) can now be automatically adapted, and if necessary by grain direction, depending on the application or substrate thickness, Highcon explains. Also, since there is no die-cut-

ting form and the two processes of cutting and creasing are separated on Highcon machines, there is no restriction to cutting or etching on a crease, it adds. DART Premium Consumables boast reusable foil that can be reused three to five times, rapid writing of rules (~10 minutes for the first job), a substrate gamut – paper or folding carton up to 600μ and corrugated up to 3mm (Euclid IIIC only), and savings of up to 80 percent in consumables cost.

With increasingly strict and regionally variable regulation of printing inks for food packaging, printers have been required to use a variety of inks in order to meet regulatory demands for North American and European markets. hubergroup in January said it had reinvented its MGA Natura sheetfed offset ink series with a single ink that complies with all FDA standards and EC regulations for folding-carton food packaging in one formula, in a move to help printers meet regulatory demands for different markets. The new inks are globally available and include both process and spot colour inks. hubergroup explains it developed and manufactured its own customized raw materials for the inks, saying chemists discovered a method for incorporating a “fully bio-compatible” yet unused raw material into the ink formula. The company says its own strict MGA guidelines

Now globally available, the new Natura series includes both process and spot colour inks.

for packaging printing inks guarantee the ink is produced in compliance with all relevant standards, including Good Manufacturing Practice (GMP) requirements for printing inks for food contact materials.

HP says HP Indigo digital printing inks are now certified for compostability. This latest sustainable initiative is designed to allow converters and brands to print smaller quantities, while reducing inventory waste and improving their overall environmental impact. HP Indigo supports packaging printing with its portfolio of presses, which includes the HP Indigo 20000, HP Indigo 8000 and HP Indigo 6900 for flexible packaging. “Demand for sustainable packaging solutions is driving converters to digital printing, allowing converters and brands to help significantly lower the environmental impact of printing,” says Alon Bar-Shany, General Manager, HP Indigo.

Printing inks provider Siegwerk has joined forces with INGEDE member Stora Enso, a provider of renewable solutions in packaging, biomaterials, wooden constructions and paper, to improve the deinkability of UV/LED-cured prints. First results of this cooperation have already marked a significant milestone towards more sustainable UV printing solutions in terms of deinkability in the paper recycling process, the parties explain. Based on these investigations, Siegwerk has developed a new UV/LED offset ink system with “impressive” deinking properties on various paper grades comparable to the deinkability of conventional oil-based sheetfed offset inks, they say. As they explain, paper that is printed with UV/LED inks shows poor deinkability as these inks form a solid, chemically and mechanically resistant layer after curing, comparable with adhesive plastic layers. UV/LED inks are strongly attached to the paper fibre and therefore, are very hard to remove during the recycling process resulting in big colour spots in the recycled paper. It is important that the cured ink film is fragmented into hydrophobic particles as small as possible during recycling in order to become detached and more easily separated from the paper fibre. As low-energy curing UV inks (iron-doped UV, LED-UV) gain more market share, the problem has reached new dimensions and has increased the need for further advancements of UV inks and the UV printing process. Since 2017, the partners have been investigating the deinkability of different ink formulations developed by Siegwerk and have examined the different inks’ behaviour with standard UV, LEDUV as well as iron-doped UV curing,

When you only have a few seconds to make that first impression memorable, Duplo’s

Raised Spot UV Coater gets the job done. Embellish your images and engage the senses with an eye catching layer of texture and depth that they can touch and feel!

such as LE-UV, H-UV, HR-UV and LEC-UV. The deinkability has been checked using the INGEDE method 11 (01/2018) and the EPRC scorecard, the officially-approved industry standards for deinking testing and evaluation. Based on their investigations, Siegwerk has succeeded in developing an enhanced UV/ LED offset ink system with good deinking properties on both high- and low-weight coated paper as well as on uncoated virgin fibre-based newsprint (iNP).

Eastman Kodak Company in May introduced its Kodacolor fabric inks, leveraging proprietary ink dispersion technology with a 20-year history of ink development and manufacturing. “The result is an exceptionally large colour gamut, a more reliable high-quality image with outstanding shelf life and a soft, natural feel, as well as better in-printer performance,” the company explains. Kodak partnered with ColDesi, Digital Ink Sciences and Resolute DTG, among others, to bring Kodak’s ink formulations to their respective hardware printing capabilities. Kodak has been producing and selling digital inks for thermal piezo and continuous inkjet systems since the 1990s. It plans to offer the Kodacolor fabric inks in all major markets by the end of the year.

Foxpak of Ireland recently opened a new manufacturing plant and uses the HP Indigo 20000 and HP Indigo WS6800 to produce compostable and recyclable packaging.

Uflex Chemicals has introduced its new FlexGreen range of UV LED sheetfed inks for commercial printing and packaging. The company describes FlexGreen as a series of UV-LED process colours for sheetfed offset printing on coated paper, paperboard and MetPet Board, boasting “high colour strength and gloss, quick curing, excellent ink-water balance and press stability.” FlexGreen, Uflex Chemicals explains, is expected to bring substantial savings to printers by way of reduced carbon footprint and energy costs.

Sun Chemical in September announced it has signed an exclusive agreement with German printing inks manufacturer Epple Druckfarben to combine their resources to make Epple’s series of sheetfed offset inks for direct food contact, BoFood Organic, available to a global audience. BoFood Organic is a worldwide patented sheetfed offset ink for printing on the inside of folding-carton food packaging that allows for direct food contact. All raw materials used in the manufacturing of the ink have been approved for use in foodstuffs, they note. Under the agreement, ownership of the intellectual property in BoFood Organic remains with Epple, which has granted Sun Chemical a licence to market BoFood Organic under the name of SunPak Organic, reflecting the ink’s food-safe qualities. The two companies have also agreed to work together to further develop the platform technology for other potential applications.

Printing inks provider Siegwerk has joined forces with Stora Enso to improve the deinkability of UV/ LED cured prints.

Mutoh America says its DH-21 dye-sublimation ink is designed to achieve highdensity colours with less ink consumption. Compatible with ValueJets 1948WX, 1638WX, 1938WX and 1624WX printers,

the ink boasts high transferability, consistent colours under various lighting conditions, versatility in media usage, and the ability to print on a range of media thicknesses.

INX International Ink Co. introduced a new series of EB flexo inks at Printing United last month. Described as the next generation of Gelflex series of EB flexo inks, INX Gelflex is a high-performance electron beam solution for food packaging that combines the technology of Technosolutions with INX’s expertise. INX says printers can expect low viscosity with high strength and stability, giving endusers an opportunity to achieve better print quality at a lower cost, as well as being safer for the environment with 80 to 90 percent less solvents.

DIC Corporation in August entered into a definitive agreement to acquire BASF’s global pigments business, known as BASF Colors & Effects (BCE). The acquisition, the parties explain, will broaden DIC’s portfolio as a global manufacturer of pigments, including those for electronic displays, cosmetics, coatings, plastics, inks and specialty applications, by creating a united pigments supplier that offers customers an “even wider range of versatile solutions.” DIC says the acquisition will offer customers a unique opportunity to combine complementary know-how and best practices to develop innovative solutions for the marketplace. In the immediate future, business for customers will remain the same as usual, DIC says, and a transition team will be put in place to ensure a smooth transition by the expected closing date in the fourth quarter of 2020.

After introducing SunLit Publish in a number of European countries, Sun Chemical is now extending the availability of its sheetfed offset process inks to printers throughout the rest of Europe and the world. Formulated for high-speed printing and high mechanical resistance on a variety of paper stocks, SunLit Publish is designed to improve both bindery handling and productivity, and reduce turnaround time, Sun Chemical explains. For commercial and publication print work, such as business reports, art catalogues, four-colour books and brochures, SunLit Publish aims to deliver balanced colour reproduction and high print gloss, especially on matte or semi-matte paper that does not require a water-based or oil-based coating. Sun Chemical explains SunLit Publish is compliant with ISO 2846-1 (colour and transparency standards) and helps to achieve ISO 12647-2 (Process Standard Offset) standard tolerances.

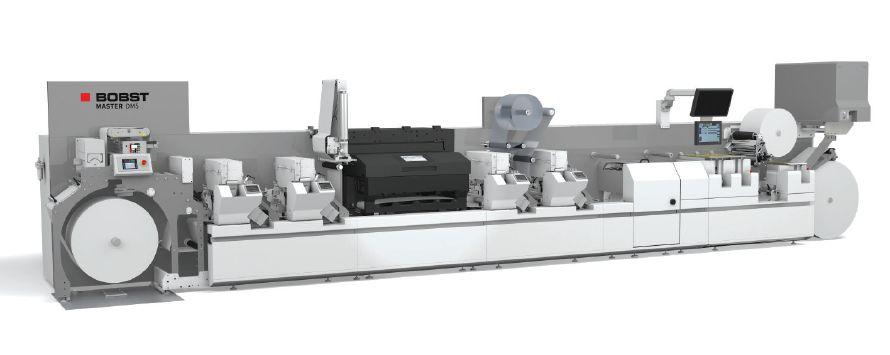

Featuring Mouvent inkjet digital technology, the Bobst Master DM5 is designed for high value-added labels, with short job setup and boasts fast return on investment.

Bobst recently featured the world premiere of its latest hybrid label press, describing it as a combination of digital and DigiFlexo printing in a single press. Boasting Mouvent inkjet digital technology, the Master DM5 hybrid press is designed for high value-added labels, with short

job setup and boasts fast return on investment. According to the company, it is the most digitally automated press in the label market, with the highest print quality and productivity. The digital print engine inside the Master DM5 is made up of Mouvent’s Cluster Technology, integrating Fujifilm Dimatix

Samba printheads. The Mouvent Cluster heads, Bobst explains, are “super compact and simple to change for easy and accessible maintenance” and have all-in-one fully integrated inking, conditioning and electronic circuits for increased printhead reliability. Ink-on-Demand (IoD) is an optional extra for

DigiFlexo print units, a solution that replaces conventional inking reservoirs with a single rubber pipe that dispenses 30 grams of ink to the print unit. The system eliminates ink trays and chambered doctor blades and performs fully automated washing of the print unit in less than one minute, the company notes. It also includes a complete range of additional specialty capabilities, including coatings, varnishes, tactile effects, 3D effects, hot stamping, cold foil, embossing, die-cutting, punching, silk screen, flexo and digital variable data printing.

In a move to help streamline inspection processes, EyeC and Hybrid Software have launched the EyeC Driver, a new application that integrates EyeC’s PDF proofing technology – the EyeC Proofiler Graphic – into Hybrid Software’s CloudFlow. The EyeC Driver aims to help prepress studios reduce the time, effort and money spent on quality controls. The integration

triggers inspection procedures within the CloudFlow automatically, retrieving job data, files and inspection parameters from the workflow system, the companies explain. Prepress files are inspected and released automatically if they match the approved artwork, and prepress operators only intervene when deviations are detected. A task appears in their workspace that opens the EyeC Proofiler Graphic to review for discrepancies. The EyeC software verifies the entire content of prepress files against the approved artwork. Text, graphics, Braille, 1D and 2D codes are checked in a single inspection cycle. Users can create as many inspection procedures as needed to compare, for instance, prepress files against customer files, one-up against stepand-repeat files or different versions of a file.

Roland DG Corporation in September introduced the VersaUV LEC2-300 30-inch UV printer/ cutter for on-demand production of custom labels and packaging prototypes, as well as bespoke POS and signage. The LEC2-300’s UV ink is designed to adhere to the surface of a material, making printing possible on a range of media, from adhesive sheets for stickers and labels to PET or PVC-based substrates, and textiles, thin paper, canvas, tarpaulin and more. In addition to CMYK ink, the LEC2-300 can be used with clear (gloss) and white ink configurations, including full-colour prints with matte or gloss finishes, simulated embossing and other custom-textured effects. The contour cutting function has been further enhanced to cut out printed graphics to any shape with exceptional precision, Roland DG explains, saying the automated process is designed to eliminate the need for platemaking and die-punching for trimming adhesive decals, labels and stickers. A perforated cut function allows users to print out as many labels as required and then peel and apply as needed. Com-

Mark Andy

is

bined with the new Multiple Print function and a new precision media take-up system, high-volume jobs can be printed with unattended operation. As well, white ink density has been increased by up to 40 percent of the previous model to provide much higher opacity and coverage, the company says.

Solimar Systems has released Solimar Print Director Enterprise (SPDE) version 9.0, boasting new PDF optimization and secure printing capabilities. SPDE, the company explains, is a flexible enterprise output management system with “extensive” connectivity, datastream conversion, and workflow automation capabilities for high-volume variable data printing. SPDE 9.0 highlights include: ReadyPDF optimization and prepress module; Dispatcher Command-line Interface; Task Scheduling features; Regular Expression support; IPP Input and Output modules for secure IPP-based printing; and Windows Server 2019 support. The ReadyPDF module is designed to deliver critical resource and content optimization capability for high-volume printing and e-delivery including variable marketing and transactional workflows. ReadyPDF functionality includes font embedding, substitution, and consolidation; colour conversion; transparency flattening; image downsampling and more.

Mark Andy’s Evolution Series made its global debut at Labelexpo 2019. Described as a scalable, full servo flexo press, the series is available in 13-inch and 17-inch web widths with production speeds up to 750 fpm. Available for immediate order, Evolution Series joined Mark Andy’s newest digital offerings, Digital Pro and Digital Series HD, on stand 4C45 at Labelexpo Europe. According to the company, deliveries of the new Evolution Series will be ready as early as this fall.

30 pt.

3. INTEGRATED MODULAR UNITS — Combined in-line finishing: crease, fold, glue, tipping, envelope inserting, ink jetting (Duplex), clip seal (3 sides), mail prep.

4. SAVE ON POSTAGE COSTS

—As a Certified Canada Post Direct Marketing Specialist, we get contract pricing reductions.

5. RETURN MAIL PRODUCTS — Customized “Return Mailers” created in-line with “U” or “BOX-shape” remoistenable glue, time perfed applications and envelope formation.

6. MINI-BOOKLETS — Saddle-stitch and trim 2-up booklets in-line to the size of a business card. No need to trim off-line, or do 2 passes.

7. HIGH SPEED EQUIPMENT — High speed Tipping, Folding, Saddle-stitching and soft folding ensuring on time delivery.

The new JETvarnish 3D One digital embellishment press from MGI and Konica Minolta made its international debut at Printing United last month. An expansion of MGI’s JETvarnish 3D Series, the press offers a spectrum of 2D/3D spot coating and dimensional textures for commercial and in-plant printers. The automatic inkjet head cleaning technology – along with the onboard Image Editor and Job Cost Calculator software programs –boast a simple path for developing new digital finishing applications and diverse application-based revenue streams. The press also utilizes key components of the JETvarnish 3D Press Series, including the adaptive AIS SmartScanner registration system. The all-purpose varnish formula allows both flat 2D Spot UV highlighting and sculptured 3D raised special effects on a range of substrates and media, such as paper, synthetics and plastics. Sheet sizes range up to 14 x 29 inches and the 2D/3D effects reach 116 microns in a single pass. Special MGI substrate management processes are designed to deliver tactile sensory print treatments to be produced on stocks from 135 to 600 gsm on various printed materials.

To help printers who are considering changing their plates to process free, Kodak has developed the Sonora Plate Savings Estimator, a new online tool that allows printers to calculate their estimated savings if they were to switch from a traditionally processed plate to Kodak Sonora Process Free Plates. Traditional plate processing uses water, energy, and chemicals to prepare plates for the press after imaging on the CTP device, Kodak explains, adding that the processing step also adds variability that impacts efficiency and costs in the pressroom.

The Sonora Plate Savings Estimator provides a customized calculation of the savings a printer could see if they integrate Sonora plates into their operations. To get started, the

user enters information about their current plate volumes, type of plate processing used, plate price, and the location of their business. The Savings Estimator will then calculate the total estimated savings for several local currencies.

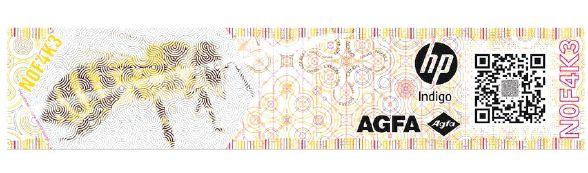

HP Indigo and Agfa announced at Labelexpo 2019 a unique variable design security solution for brand protection and security printing. The new solution, HP Indigo Secure Studio Powered by Agfa, is designed to create unique graphic designs with endless variations, the parties say, while also blending with the original design without compromising the look and feel of the original document or product. The first version of the solution is designed to create complex security and embellishment designs for label and packaging printing. The goal, they say, is not only to protect digital prints from counterfeiting, but also to improve their aesthetic appearance and shelf appeal as designer creativity can be elevated to give a high-end look to digitally printed packages, labels or documents, with security embedded in the design.

Color-Logic recently introduced

Touch7 Photo ECG, an extended colour gamut (ECG) tool designed to simplify the use of extended colour gamut in wide-format and digital presses. Touch7 Photo ECG, is a Photoshop plugin that enables the designer or prepress operator to quickly add one, two or three ECG separations into an image. As well, it aims to eliminate the need to create manual masks, thus any designer using Photoshop CC can do this kind of work. In addition, Touch7 Photo ECG does not require ICC profiles to create the ECG separations, enabling designers to create, at the design stage, five-, six- or seven-colour separations and then send the file to prepress for production, where ICC colour management is used to map the image to the ink set of the printer or press.

Place your own ad and view the latest postings:printaction.com/Marketplace

Heidelberg: K-Line/S-Line/Speedmaster/GTO/MO/KORD64

Komori: 1, 2, 4 or 5 colours & any size