FEATURES

14 Print 18 highlights

Celebrating its 50th year, the annual tradeshow recognizes print transformation and innovation

Celebrating its 50th year, the annual tradeshow recognizes print transformation and innovation

Conference session illustrates how inkjet technology can power the new customer communications delivery hub

GAMUT

5 News, People, Installs, Globe, Dots, Calendar

TECHNOLOGY REPORT

18 New plate and imaging hardware innovations

NEW PRODUCTS

22 Exploring new solutions from Agfa Graphics, CGS, EFI, Epson, Fujifilm, Highcon, Mimaki, Ricoh and Uflex Chemicals

SPOTLIGHT

26 Richard Kouwenhoven, Board Chair, Canadian Printing Industries Association (CPIA)

COLUMNS

FROM THE EDITOR

4 Alyssa Dalton

The catalogue comeback

SALES

10 Dave Fellman

Pitching versus storytelling

The more one person talks in a sales conversation, the less the other person is likely to listen

TRENDS

11 Lawrence Lee

The 2025 forecast

Making the world a smarter place

CHRONICLE

12 Nick Howard

Built like a tank

How digital is reinventing the printing press

Sears, Roebuck and Co., commonly known as Sears, was once the world’s largest retailer. Often credited for driving consumer culture over its 130-plusyear history, the company began as the R.W. Sears Watch Company in 1886 and published its first mail-order catalogue in 1888 to advertise watches and jewelry. Over the years, the catalogue expanded to showcase the breath of its merchandise, such as sewing machines, musical instruments, bicycles, sporting goods, firearms, baby carriages, and men’s and children’s clothing.

With 203 million copies distributed globally, the Ikea catalogue joins the Bible, the Quran and the Harry Potter series as one of the most distributed books in the world, according to Quartz.

In 1933, Sears added the Wish Book, an annual holiday gift guide, to its array of mailed materials. The 87-page catalogue showcased 25 pages of toys and 62 pages of gifts for adults, including Miss Pigtails dolls, a Mickey Mouse watch, fruitcakes, Lionel electric trains and live singing canaries. Fast forward to 1968 –the iconic guide totalled 605 pages, with 225 pages devoted to children’s toys and 380 pages to gifts for adults.

While Sears retired the Wish Book in 2011 in an effort to focus on online sales, the company astonishingly announced in October 2017 it would bring the guide back for the season due to overwhelming customer demand.

“Our members told us they missed the Wish Book, so we had to bring it back, but in a special way that lets you share more joy wherever you are,” Kelly Cook, then-Chief Marketing Officer for Sears and Kmart, said.

Earlier this year, news outlets reported Amazon.com Inc. would go conventional and publish a printed holiday toy catalogue ahead of the holiday season, instead of relying on all-digital advertising. Taking a page out of the traditional marketing playbook, the catalogue would be mailed to U.S. households and handed out at Whole Foods Market locations, the grocery chain Amazon bought last year, Bloomberg reported.

The strategy would represent another move from the e-commerce giant to incorporate classic engagement tools used by brick-and-mortar stores, perhaps capitalizing on the recent closure of U.K. and U.S. operations of Toys “R” Us.

Multi-channel shopping and buying is on the rise, and today’s savvy retailers understand that customers who use more than one of their channels are the most valuable, brand leadership author Denise Lee Yohn notes

“Nordstrom reports that customers who have a multi-channel relationship with the brand spend four times as much as those who do not. Bonobos shares similar results, with Craig Elbert, vice

president of marketing, reporting that 20 percent of the website’s first-time customers are placing their orders after having received a catalogue and are spending one and a half times as much as new shoppers who didn’t receive a catalogue first,” she writes in Why the print catalog is back in style in Harvard Business Review

A 2015 Canada Post survey found that 40 percent of consumers who receive printed catalogues keep them for at least a month, while 20 percent say they keep catalogues for at least four months.

After nearly a decade of not publishing a print catalogue, Canadian Tire decided to launch the Wow Guide in April 2016, an impressive 200-page catalogue that was mailed to 12 million homes across the country. Designed to integrate the digital and print media, the catalogue required customers to download the retailer’s mobile app and use their smartphone or tablet camera to hover over the pages for additional content, such as how-to videos or to check product inventory, for example.

In a 2016 interview with Media in Canada, TJ Flood, then-Senior VP Marketing at Canadian Tire, explained the “paper catalogue had to be the gateway to a robust digital representation.”

And it appears it worked. Michael Medline, CEO at the time, said the company saw its weekly e-commerce transactions double following the mailout, describing it as “the single biggest impact lever we have ever pulled to generate more online sales.”

For many, the printed catalogue, especially those filled with the latest must-have toys, gadgets and holiday whimsy, evokes a sense of nostalgia and comfort.

“There was something magical triggered in our brains when as a child we received that giant catalogue in the mail, or even by the few pages of toys in the back of the Sears catalogue,” writes contributor Curtis Silver in a July 2018 Forbes article. “Kids, as inundated as they are in their handheld technology, still like to flip through a book full of nothing but toys. We are still somewhat interested in the physical visual media, not totally overtaken by the digital world just yet.”

As a recent Canada Post blog explains, “A catalogue is a tangible presence that’s available at the moment of truth — when a shopper is considering a purchase. A convenient, inspiring source of reference to enjoy during a peaceful moment in an otherwise busy life. It presents so many opportunities for brand engagement.”

ALYSSA DALTON, editor adalton@annexbusinessmedia.com

Editor Alyssa Dalton adalton@annexbusinessmedia.com 416-510-5225

Contributing writers

Zac Bolan, Wayne Collins, David Fellman, Victoria Gaitskell, Martin Habekost, Nick Howard, Neva Murtha, Abhay Sharma

Associate Publisher

Stephen Longmire slongmire@annexbusinessmedia.com 416-510-5246

Media Designer Lisa Zambri lzambri@annexbusinessmedia.com

Account Coordinator Alice Chen achen@annexbusinessmedia.com 416-510-5217

Circulation Manager Barbara Adelt badelt@annexbusinessmedia.com 416-442-5600 ext. 3546

Circulation apotal@annexbusinessmedia.com

Tel: 416-510-5113

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Group Publisher Diane Kleer dkleer@annexbusinessmedia.com

President & CEO Mike Fredericks

Subscription rates

For a 1 year subscription (10 issues): Canada — $42.00 Canada 2 year— $69.00 United States — CN$74.00 Other foreign — CN$144.00

Mailing address

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 printaction.com

Tel: 416-442-5600 Fax: 416-442-2230

Annex Privacy Officer Privacy@annexbusinessmedia.com 800-668-2384

PrintAction

ISSN 1481 9287 Mail Agreement

Heidelberg’s acquisition of MBO Group is expected to be completed by the end of the year.

Heidelberger Druckmaschinen AG (Heidelberg) is taking over MBO Group in a bid to further expand its offerings in postpress operations for digitally printed products. The move, the company explains, is another step in its continuing growth in the digital and packaging segments and will help Heidelberg gain new customers in the pharmaceutical industry and add mailing system offerings to its offset portfolio. The acquired operations account for a sales volume of around €50 million, which amounts to roughly C$74 million. The acquisition involves, among other things, taking over the sites in Oppenweiler and Bielefeld, Germany, and the production site in Perifita, Portugal, which employ a total of approximately 450 staff.

Contrary to a widespread myth, forest harvesting is not synonymous with deforestation and doesn’t threaten the sustainability of Canadian forests, which are under-harvested, according to a report by public policy think tank The Montreal Economic Institute “It can seem counterintuitive to some, but the profit motive protects our forests. By this logic, forestry companies make substantial investments to reduce waste and get the most out of each tree harvested in the forest,” says Alexandre Moreau, Public Policy Analyst at the MEI and author of the publication. Canada’s forest cover has remained relatively stable since 1990 despite harvesting activities, and innovation has a lot to do with that, the institute says. For one thing, the volume of softwood roundwood needed to produce a given quantity of boards fell by

means access to an impressive array of latest-generation inkjet presses for short-run book printing,” says the company. The acquisition will enable Marquis’s team to grow from 400 to 600 employees. “This acquisition attests to our confidence in the future of printed books,” Serge Loubier, Marquis President and CEO, says. “It will help us better handle the new challenges of the publishing and book printing industry, which is undergoing a transformation.”

publishers to alternatively publish their work while controlling its distribution, the company explains.

nearly a quarter between 1990 and 2017. For another, recycled sawmill products accounted for 20 per cent of pulp and paper mills’ supply four decades ago, whereas it’s over 80 percent today. “Today’s technology and methods allow the forest to be harvested in a way that respects the environment, meeting both social expectations with regard to respecting biodiversity and the economic needs of the workers and communities that depend on the forest,” Moreau says.

Alpha Poly Corporation, a manufacturer of flexible packaging, has been certified to print film for product companies that require a Graphic Measures International (GMI) designation. Receiving the GMI certification means that Alpha Poly’s flexographic printing processes and capabilities provide customers with the colour accuracy and consistency needed for printing critical brand colours. Based in Brampton, Ont., the company manufactures and sells flexible packaging for customers in Canada, the United States, and other international markets.

Marquis Book Printing, headquartered in Montmagny, Que., has acquired Webcom, a move that will create an annual production capacity of over 100 million books in three printing plants. “Our combined strengths will help book publishers successfully navigate changing supply chain dynamics with POD, automatic stock replenishment, and complete “life of title” management solutions. For publishers in North America and Europe, this “joining of forces

Agfa Graphics says it intends to close its offset printing plate manufacturing facility in Branchburg, N.J., by the end of this year as part of a strategic plan to optimize its global production capacity and supply chain for printing plates. “While our volume of printing plates sold in North America remains strong, this action is being taken to better meet the current and future expectations of our customers, and the competitive pressures of today’s market for offset printing plates,” says Gunther Mertens, Regional President – North America, noting that 45 percent of the company’s offset printing plate volumes in North America are already sourced from other factories in the Agfa network.

Quebec company Scenarex has launched the Beta version of its first solution, Bookchain. Based on the Ethereum network, Bookchain is an online e-book distribution platform that enables authors, publishers and content creators to publish and sell books on the blockchain. Built to be cryptocurrency free, Bookchain brings innovation to the publishing industry by providing a flexible, secure way to manage digital books and empowering authors and

The Specialty Graphic Imaging Association (SGIA) in August purchased the printing tradeshow Graphics of the Americas (GOA) from the Florida Graphics Alliance (FGA), formerly the Printing Association of Florida. Following a transition period, GOA will relaunch in February 13-15, 2020, in Miami Beach, Fla. Over the next 18 months, SGIA and FGA say they will transition GOA to its new ownership and redefine it as an integral part of the calendar of events in the printing industry with high value for attendees and exhibitors.

TC Media has purchased Somabec, owned by Stéphan Rhéaume, a distributor of French-language specialty and trade books, whose offices are located in Saint-Hyacinthe, Que. Founded in 1968, the company represents more than 100 Canadian and European publishers and offers more than 50,000 titles spanning the fields of technical training, science, medicine and social science. The transaction, the parties say, also includes the acquisition of publishing house Edisem, also owned by Rhéaume, which specializes in the publication of medical books.

in 1996, Ultra Ink is located in Bois-des-Filion, Que.

International supplier of printing inks Siegwerk has expanded its Canadian business with its recent acquisition of Ultra Inks, a move that will help strengthen its local service, infrastructure and portfolio for label and packaging printers, it says. Located in Bois-des-Filion, Que., Ultra Inks focuses primarily on water-based flexo inks for narrow web, and paper and board applications. The integration of Ultra inks into Siegwerk’s offering will enable customers to benefit from a more comprehensive product portfolio and wider technological expertise, the companies explain.

Transcontinental has appointed H. Peter Brues to its Board of Directors. With a career spanning over 20 years in the Americas and Europe, he most recently served as a senior executive in the packaging industry at Amcor, a US$9.1-billion multinational company that develops and produces packaging for a variety of end markets. Additionally, he has a solid financial expertise and is recognized for his ability to maximize and drive performance across global network operations, Transcontinental explains.

The Board of Directors of Electronics For Imaging (EFI) has named William (Bill) D. Muir as its new Chief Executive Officer. Muir was most recently the Chief Operating Officer of Jabil, a product solutions company. On October 15, he took over the position and also joined the Board of Directors. Muir succeeds Guy Gecht, who informed the Board he intended to step down as CEO upon the appointment of his successor, as the company announced on July 30, 2018. Gecht will remain a member of the Board of Directors and will be an advisor to the CEO.

Print Digital Solutions (PDS) has sold Data Communications Management (DCM), a provider of business communication solutions, a Multigraf Touchline CP375 Duo and TCF375, enabling stop perforation in both directions, creasing, folding, and positive and negative creasing all in one operation.

Sun Chemical has appointed Myron Petruch President and CEO, effective January 1, 2019. Petruch assumes leadership of Sun Chemical after serving as President of Sun Chemical Performance Pigments and General Manager of the Pigments Products Division since 2008. He succeeds Rudi Lenz who will transition to the new role of Vice Chairman of the Board at Sun Chemical.

SA International (SAi), a provider of software solutions for the signmaking, digital printing and CNC machining industries, has promoted Michelle Johnson to Director of Worldwide Marketing. Johnson, who previously held the role of Marketing Manager at the company, will lead the development and continued expansion of the SAi brand and proposition. This will see her head up the implementation of global communication campaigns as well as strengthen SAi’s relationship with its partners and the media via digital marketing, says the company.

HP Canada is welcoming Steve Daigle to its General Commercial Sales team. Responsible for HP Indigo’s full product line in Eastern Canada as well as the HP PageWide web press solutions, he brings 25 years of experience in the industry. Daigle was previously at Cansel/Cobalt where he served as the Wide-Format Sales Specialist for Quebec. During that time, he was responsible for all digital flatbed, roll-to-roll and workflow solutions. Prior to that, he was the Executive Business Manager for Nustream Graphic.

Memjet has hired Dave Gelvin as Senior Vice President of Customer Success. In this newly created role, Gelvin will oversee the training and support of Memjet OEM partners to make sure they have the resources needed to build Memjet-powered printers.

Edmonton-based Jet Label and Packaging has purchased an HP Indigo 8000 Digital Press, saying the investment will double its digital capacity and allow for longer digital runs. Jet Label says it is currently printing at full capacity on its two HP Indigo WS6600 digital presses, running 24 hours, five days a week.

Mountain View Printing & Graphics says it will double its revenue over the next five years as a result of two new Xerox digital presses. The Calgary firm bought a Brenva HD Production Inkjet Press to help streamline production and an Iridesse Production Press for spot embellishments and metallic hues.

Illinois-based MAR Graphics recently installed a Ricoh VC60000 colour inkjet web press. The twin-engine press is configured with options to print up to 250 gsm and coated stocks up to 1200 x 1200 dpi.

King Printing Co. Inc. has completed the second phase of its expansion on its high-definition digital book manufacturing platform. The first print service provider in North America to adopt the commercialized High Definition Nozzle Architecture (HDNA) technology with the HP PageWide Web Press T240HD, King Printing of Lowell, Mass., says it is investing in HDNA across its fleet of colour inkjet presses to help meet the needs of publishers looking to migrate offset level work to the digital arena.

With 2,400 nozzles per square inch, HP PageWide Press HD printing is described as producing smoother colour fills and transitions, increased shadow detail and better skin tones.

King Printing specializes in print technology and book manufacturing.

“This upgrade has made our high-definition platform one of the most resilient and flexible in the book manufacturing industry by offering a digital option for quality sensitive work,” says Adi Chinai, President of King Printing.

T’Hooft is continuing its growth curve with its recent purchase of a second Compacta 818 from Koenig & Bauer. The system – its third Koenig & Bauer press – will go into operation next spring in Aalter, Belgium, alongside a Compacta 106 and a Compacta 818.

The system will be engineered for a cylinder circumference of 1,156 mm (45.5 inches) and a maximum web width of 2,270 mm (89.4 inches). Able to print up to 45,000 80page copies per hour, the press line will be equipped with an automatic paper reel feeder, a Pastomat RC reelstand, pneumatic roller locks, four printing units with automated plate changers, a high-performance dryer from Contiweb with integrated afterburning, and a P5 pin folder for vertical-page production and delta fold products. An inline colour measuring and control system aims to ensure high process stability and a LogoTronic production management system for the digital flow of job and presetting data, production monitoring and evaluation.

Established nearly 70 years ago, family-owned T’Hooft prints magazines, catalogues and posters. As well, it offers online marketing services in addition to its printed products to keep up with the digital shift.

Onalaska, Wisconsin-based Empire Screen Printing says its newly installed Fujifilm North America Graphic Systems Division’s Graphium UV digital hybrid inkjet press is opening the door to new markets and additional revenues.

Within the first three months of going live with Avanti Slingshot, we had saved as much as eight hours/day just in order input, tracking, and managerial tasks.“

Armando Pena, COO of Printing and Marketing Group, Inc.

Graphium, Fujifilm explains, is designed to help print service providers embrace complex label, packaging and specialty jobs that aren’t achievable with standalone conventional or inkjet presses. As well, the Graphium is designed to make converting short to medium print jobs profitable, as it aims to streamline workflow, require less setup material, use less ink/varnish/laminate, and minimize overruns, it adds. Furthermore, Fujifilm says the Graphium is one of the only modular digital inkjet presses offering the option to integrate true flexo and finishing stations for hybrid production and conversion in a single pass.

Founded in 1960, Empire began in La Crosse, Wisc., as a one-man operation. Though its roots are in screen printing, it has expanded into flexographic and digital printing with the Graphium. Empire Screen Printing provides print products for industries within the automotive, aircraft, electronics, food and beverages, sporting goods and retail sectors.

“The print quality on the Graphium extends our capabilities of our screen printing when it comes to printing four-colour process, fine lines, and perfect register jobs. The Graphium allows us to work with designers and companies looking for perfect registration,” explains Empire Screen Printing President John Freismuth.

Avery Dennison Graphics Solutions recently announced 10 vehicle graphics installer teams from around the world have been named Regional Wrap Kings in the Wrap Like a King Challenge featuring Avery Dennison Supreme Wrapping Film, the Conform Chrome and ColorFlow Series and MPI 1105 Supercast Digital film. Taking the title for North America –Canada is The Warrior, installed by Ben Bieber, Dan Desroches, Charles Brossard and David Boily of Team Canadian Wrap Masters of Georgetown, Ont.

A panel of eight industry judges evaluated the submissions based on the visual transformation (difference between the before and after pictures submitted), quality and skill level of installation, overall public look and appeal and uniqueness of the design, and chose 10 Wrap Kings from North America and Europe. The regional winners would then go on to compete for the title of Continental Wrap King, and then King of the Wrap World at the 2018 SEMA Show in Las Vegas.

Eight other teams entered the North America – Canada category alongside Canadian Wrap Masters, including: Graphiki of Ottawa, Ont., Empire Graphics of Langley, B.C., Wraptors King based in Ontario, Wrap Meisters of Aurora, Ont., CK Wraps of Unionville, Ont.,Yourcarwrap of Orangeville, Ont., Complex Auto Designs of Whitby, Ont., and ChuckyCourty Wrap Installs of Fenelon Falls, Ont.

“We are insanely blessed to have a team of some of the best wrappers in Canada and we feel like the combined efforts of our members played a huge part in the success of this build. Each member gave a tremendous amount of time and effort and brought their own unique skills to the table and the results, we hope, speak for themselves,” according to a statement from Canadian Wrap Masters. “The inspiration for the design came from one of our members who, working alongside our designer, came to fruition entirely raw. The design was drawn by hand and meticulously converted to vector in Illustrator for both the print layer and the three graduated cut layers underneath the print. Nothing on this design is stock.”

The wrap consists of over 1,300 square feet of cut vinyl broken into three layers of embossing, followed by a printed layer of Avery Red Chrome with DOL1370z Satin overlaminate, Canadian Wrap Masters explains. Total design, production and installation topped out around 425 hours.

“Our biggest challenge was of course matching three layers of embossed material with the print layer above, as 85 percent of the truck is embossed. We hope you enjoy our wrap as much as we did bringing it to the wrap world,” Canadian Wrap Masters says.

Canadian Wrap Masters of Georgetown, Ont., was named Regional Winner for North America – Canada for its work on The Warrior. The team used Avery Dennison digital overlaminate films and Conform Chrome wrapping films on the Ford pickup truck.

November 12-16, 2018

IS&T Color and Imaging Conference Vancouver, B.C.

April 11-13, 2019

Graphics Canada The International Centre, Mississauga, Ont.

April 24-25, 2019

AICC Canada Trade Show and Conference Toronto, Ont.

October 3-5, 2019 Print 19

Chicago, Ill.

October 23-25, 2019

Printing United 2019 Dallas, Texas

November 25-28, 2019

Shanghai World of Packaging Shanghai, China

June 16-26, 2020 drupa 2020 Dusseldorf, Germany

The

more one person talks in a sales conversation,

the less the other person is likely to listen

By David M. Fellman

This is the third instalment in my series on The top 5 ways to talk yourself out of a sale. The topic for today is Pitching versus Storytelling The official rules of baseball describe a pitch as a ball delivered to the batter by the pitcher. In North American slang though, we often refer to the words a salesperson uses to try to get someone to buy something as a sales pitch, and it is usually not considered a complimentary term.

Most salespeople employ a presentation style as opposed to a consultative style. What is the difference? In a presentation style, the seller tells the buyer all about the products, services or capabilities. In a consultative style, the seller asks the buyer about their wants and needs. In a presentation style, the seller is saying, “Here is what I think you need to know, now please make a decision.” In a consultative style, the seller is saying, “By asking the right questions and providing you with specific answers, I think I can help you make the best possible decision.” Which of these selling styles would you rather be on the buying side of?

There is more to this than just style.The more one person talks in any selling conversation, the less the other person is likely to listen. Think back on the last time your customer dominated any part of the conversation. Did you really listen to everything that was said, or were you thinking more about what you wanted to say?

I had a salesperson call me just this morning. The phone on my desk has a timer, and when it got to 60 seconds, I could remember thinking only eight words. Rather than listening, I was thinking, “Is this guy ever going to shut up?”

OK, I know I covered this issue in the first instalment, Too much talk, not enough listen, but it is important enough that I think it needs repeating.

Even in a consultative style, there

comes a point where the seller must present a proposal. There is a difference though, between starting with a presentation and finishing with one.

In a consultative style, the tailored presentation comes after the needs analysis: “Based on what you’ve told me about your wants and needs, this is what I think you should do.”

According to SiriusDecisions Inc. research, it takes an average of eight cold call attempts to reach a sales prospect.

Here is where the storytelling comes in. With all due respect to the Star Trek franchise, very few humans really want to go where no one has gone before. We do not want to take chances, we prefer the tried and true. I will grant you that many of us will take chances personally in search of recreation or entertainment, which can be anything from trying out a new restaurant to skydiving. I hope you will grant me, though, that buying printing has very little thrill potential attached to it. Print buyers want to make safe choices.

So how do you convince a buyer that you and your company are a safe choice?

The salesperson who called me this morning told me his company has been in business for 35 years. He also told me they invest heavily in new manufacturing technology. He then hit several more bullet points before asking me if I would meet with him.

Let me suggest an alternate strategy: “Mr. Fellman, I have a story I would like to tell you. John Smith founded this company almost 35 years ago on a shoestring, like a lot of other small businesses. He was undercapitalized and underequipped and because of that, he

had to do pretty much everything the hard way, but he always paid attention to what was going on in the industry. When he started getting a little bit ahead, he started investing in technology that would let him do things the right way, with greater efficiency, producing better quality. He also likes to say he made every possible mistake during those early years, but he thinks he learned how not to make them again. So, I guess I am asking you, do we sound like the kind of company you would like to work with? And if so, would you agree to meet with me?”

Yes, ultimately this is a sales pitch — a set of words used by a salesperson to get someone to buy something. So maybe the question is this, does the storytelling element make it a better pitch, one more likely to get the desired result? Obviously I think so, and I hope you will start thinking about incorporating storytelling into your own selling.

DAVE FELLMAN is the president of David Fellman & Associates, a graphic arts industry consulting firm based in Raleigh, N.C. He is a popular speaker who has delivered keynotes and seminars at industry events across the United States, Canada, England, Ireland and Australia. He is the author of “Sell More Printing” and “Listen To The Dinosaur.” Visit his website at www.davefellman.com.

By Lawrence Lee

Digital printing’s introduction sparked colossal change, but it is a drop in the big blue ocean compared to what’s on the horizon. Digital graphics printing, functional printing, and 3D structural printing are the future of printing – covering everything from smart packaging to on-demand manufacturing – and the benefits will be felt across our society.

We will see rapid advancements in digital colour printing in graphic communications, including new types of inks and toners that can create higher image quality and specialized effects. But there is another large new growth opportunity beyond document printing that will come from the ability to digitally print on a wider range of materials. Digital printing enables converters and manufacturers to offer more value to their customers, including late-stage customization, personalization and shelf-ready displays. Technology advancements will help deliver the benefits of digital with the image quality and run-cost of analogue printing on longer runs and a wider range of packaging media from foils and films to plastics and metals. By 2025, we will see inline digital presses in distribution centres and plants, and specialized printers and kiosks in retail stores that offer on-demand personalized printing.

Beyond graphics printing, the next frontier is functional printing. Today we see active functional inks that can change colour or structure depending on environmental factors, such as temperature. We also see early prototypes of printed electronics that enable sensing and monitoring at the individual package level. By 2025, we will see a more mature printed and hybrid electronics ecosystem, with software that will simplify electronics design and digital manufacturing systems that produce sensors, memory, com -

munications and power options on flexible, low-cost smart tags or print them directly on products. Functional printing will give us the ability to extend intelligence pervasively to documents, products and packages. This will radically enhance existing services, from cold-chain logistics to environmental monitoring, enabling a host of new services that connect the physical and digital worlds. Print providers will deliver printed materials and analytics that result in outcome-based pricing models and greater value.

Today 3D printing of parts, or structural printing, is mostly limited to rapid prototyping or specialized low-volume production. Even with current limitations, we see the value of specialized 3D printed parts. Artificial implants, for instance, can be customized to each patient and have highly specialized structures that mimic biological forms. Over the next few years, we will see new advances in highspeed 3D printing of plastics, metals and even composites, enabling large-scale manufacturing of production parts with advantages in design, weight and material properties over traditional processes. As these technologies mature, we will also see significant changes in supply chains. Sending off parts to be made in factories can be inflexible and time-consuming; structural printing allows parts to be made in an integrated process that reduces components and production steps.

Smithers Pira estimates the worldwide printing industry will increase 0.8 percent year-on-year, reaching US$814.5 billion by 2022.

Perhaps the most exciting potential is the combination of structural 3D printing and digital functional printing, where we will be able to create personalized smart products on demand. This value proposition is especially compelling in the consumer health and fitness industry. We have already seen smart clothing with embedded sensors and in the future, we will see even more personalized applications combining structural and functional properties. Take 3D-printed orthopedic inserts – with a 3D scan, it will be possible to print a custom insert and make it “smart” by embedding printed electronics to provide analytics and communicate with your smartphone.

Print providers will be faced with new opportunities that are too good to miss, becoming one-stop-shops that provide everything from initial designs to finished products and analytics. While this may seem a bridge too far for some, new printing innovations will work with smarter software to make the market more accessible over time. AI-enabled design software will help designers and operators use these new technologies and Cloud-based software will help collect data, perform analytics, and close the loop on marketing communications and new IoT applications we can only dream about today.

LAWRENCE LEE is Vice President, Incubation and Strategy, Xerox.

By Nick Howard

If you take a drive west from the city of Quebec and cross the St. Lawrence River, you come across an unusual site. Two bridges come into view. The Quebec Bridge (Pont de Quebec) is starkly dissonant from its neighbour only 200 metres to the east. Completed in 1919, it’s a massive steel truss structure with a tragic past. Today it remains the largest cantilever bridge in the world. Originally conceived in 1903, the first attempt saw the bridge collapse during construction in 1907. Seventy-five workers lost their lives. A second attempt in 1916 met a similar fate when a large section, being hoisted into place, broke loose and fell into the river. That section remains at the bottom of the St. Lawrence to this day. Thirteen workers died during this incident. The bridge was finally completed in 1919 and although no longer used for cars, it is still in service for rail.

Next to it is the Pierre Laporte Bridge (Pont Pierre-Laporte). Completed in 1970, it is a sleek, modern looking bridge and is the longest suspension design bridge in the country. The striking difference in designs stayed with me ever since I crossed the Pierre Laporte in 1981. Oh how technology and engineering have advanced in the 51 years between 1919 and 1970. One is a massively overbuilt behemoth – the other less pythonic and demonstrates the advancements in design, construction and materials. The same can now be said of the printing press.

One can assume that getting a piece of paper precisely through an offset machine requires stability above all else. For over 100 years, the answer to this problem was to build platforms super heavy and with thick cast-iron side-frames and cylinders that look as if the press is going to be printing on quarter-inch steel plates. Over the century, presses have continued to be constructed this way with only the occasional nod to increased use of aluminum and magnesium castings to reduce the heft. Other than the infamous all-aluminum West Berlin Kiekebusch

A photo of the Heidelberg CD 102-6+LX Howard Graphic Equipment had rebuilt, now in its plant.

back in the 1950s have press makers dared to deter from a common path of massive construction. That is until the advent of digital equipment.

Just as others in the offset world, I too understood the advantages of massive construction. But over time and with much lighter digital presses elbowing their way into more and more pressrooms, I must say the industry needs to reconsider how they design and build legacy offset presses in an ever-shrinking landscape. With a typical transfer gear on a B1 40-inch press weighing at roughly 500 pounds, a typical single printing unit tops out at about 7.5 tonnes. A six-colour without coater 40-inch BI has a weight of roughly 59 tonnes. Compare this to a somewhat similar digital press, such as the HP Indigo 12000. The HP handles a maximum sheet of 29 x 20 inches and has a weight of just 11 tonnes all in.

Although a smaller sheet size, the construction differences are startling. Perhaps a more relevant comparison would be the HP 20000 roll-fed version. With an image area closer to that of a 40inch offset, the 20000 weighs in at only 15 tonnes. More weight translates into more costs in everything from raw materials, freight, rigging, power and pressroom infrastructure.

Digital equipment seems to have ignored the hallowed approach of the offset builders. Almost all digital have instead taken a different route and this further exacerbates the line between the old and new approaches to print. With offset, you

need three massive cylinders and a full ink and dampening train just to get a dot onto paper. Then repeat that for every colour. Digital requires just one cylinder for all six colours. In the mid-1980s, one press maker redesigned its ink train using hollow rubber rollers. The results were catastrophic and it quickly returned to heaver solid core rollers. You can tell the offset guys are scared to death of tinkering with what is now a proven process. Embracing the very latest engineering technologies has encouraged younger minds to take a fresh look at how to build a printing press, which will most likely have a shorter lifespan compared to offset. They are feeding and transferring substrates using modern approaches without the bias of the older mature offset industry. Instead of bulky feeders that can hold 5,000+ sheets, they have simplistic feeding devices akin to long forgotten duplicating era. Plenty of punched steel sideframes, delrin gears and plastic!

However there are exceptions. Konica Minolta teamed up with Komori to slap its inkjet technology onto a staid traditional Komori offset platform. Landa has done the same, choosing Komori for its feed and transfer elements. Heidelberg teamed up with Fujifilm recently, installing the first 41-inch Primefire 106 Speedmaster in the U.S. and Koenig & Bauer’s VariJet 106 is a joint-venture with Xerox. All four designs are complimentary in that the proven technology of a modern offset press coupled with inkjet can offer an assured outcome of sorts. But this may

be temporary. Advances with pretty much all digital suppliers are happening at almost lightning speed and the new digital kids may simply disregard the old timers and go it alone. For the likes of Konica Minolta, Canon and Fujifilm et al are fully aware it is they who now make the rules.

Lighter weights also open the door to easier installations. Long vanished from most downtown city cores, offset presses are now generally found in outer industrial areas where they can get more power and in ground-level buildings. Digital presses can be installed virtually anywhere and with much smaller footprints. Arguments for such hybrid offset/digital presses are understandable. Speed is the most obvious. Light-duty machinery currently will not stand up to the punishment of daily use at offset-like press speeds so why not eliminate that factor? This is true and traditionalists will defend that position out of common sense.

“We make and sell printing presses — we don’t rent them!” But

something will have to be done to get around the high costs of manufacturing

offset machinery. Until then and with metal prices skyrocketing – especially aluminum alloys – press makers will keep collaborating with digital up-andcomers as they have no choice. One approach that is rather unique is the Heidelberg Prescription program of charging per sheet. Over 20 years ago, a colleague – who ran sales for a major press maker – pushed his company to create a program that basically rented a press to a printer for a fixed period of time. The concept was quickly shoved into a trash bin and the comments were, “We make and sell printing presses — we don’t rent them!” It wasn’t the right time.

Heidelberg’s reasoning is spot on. In an era of shorter runs, why spent three to four million on a 40-inch press when you can only pay for what you print? Backing all this up Heidelberg owns or controls a host of consumables under the brand Saphira and rolled that into the program too. The printer has no upfront financing and no costs of ownership. The company gets to concentrate on finding more work for the press, not finding finance partners. The

digital industry, led by Xerox, invented the “click” charge and finally a legacy press maker has embraced it. I think this is an excellent idea whose time has come in an industry that is constantly changing. The average printer is already used to clicks versus costs with its digital machines and most don’t have the lemming-like desire to own technology that have a shorter and shorter technology lifecycle.

When and until someone figures out how to raise the production speeds of digital platforms, the reliable over-built offset press will remain the stop-gap. Run lengths continue to fall and will accelerate the offset demise. As throughput increases, the two technologies will differ as much as the two bridges crossing the St. Lawrence.

Your older equipment can look—and perform—like new. Now you can empower your bindery with new technologies that help enhance performance and throughput. Certified Rebuilt by Muller Martini restores a variety of equipment, including stitching heads, feeders, glue pots, pockets, and entire machines—to their original factory specifications in our conveniently located Allentown, Pennsylvania facility. What’s more, it costs considerably less than a new machine purchase.

Call your Regional Sales Manager or 1.888.2MULLER today for more information about Muller Martini Certified Rebuilt.

1.888.2MULLER

In its 50th year, the annual tradeshow celebrates print transformation and innovation

By Alyssa Dalton

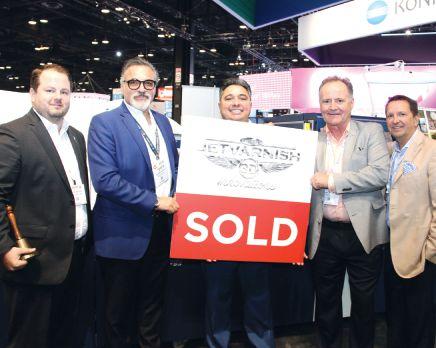

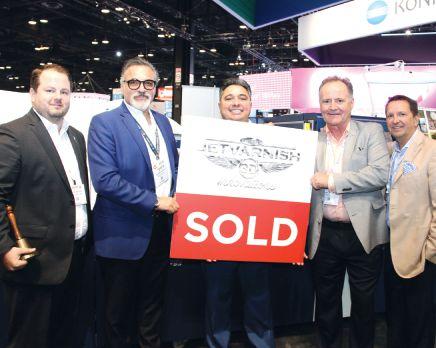

Running September 30-October 2, Print 18 featured new technologies and services from more than 350 exhibitors and brought together nearly 17,000 print professionals to learn about personalized print, the growth of direct mail, shop connectivity, augmented and virtual reality, and emerging revenue streams, among many other topics.

“Digital embellishment is going mainstream ,” Kevin Abergel, MGI VP of Marketing and Sales, said during a Konica Minolta/MGI press conference, explaining one of his customers regularly sees a 400-percent increase in response rates any time it features tactile finishing on its mailed postcards. “[Printers] are taking advantage of personalized foil, whether it’s invitations, agendas or [customized] packaging...it’s turning them into collector’s pieces.” He noted today’s companies are

maximizing their equipment investments by pursuing niche applications to create new business models

At the Learning Experience Theater, Noel Ward, Managing Director at Brimstone Hill Associates , discussed how augmented reality can make print products more valuable by incorporating dynamic digital technology to present information. “Be creative. The more ways you can connect your customers with their customers, the better. [The goal is] for them to come back to [the product] more than once. When that happens, it increases the connection with the end-customer and leads to brand extension.”

After chatting with a number of print experts at the show, one thing is certain: A wave of disruptive technologies is hitting the industry and print providers must ensure their business strategies enable them to be agile and cost-effective.

This year APTech introduced the inaugural Red Hot Technology Vanguard Awards to recognize innovative products and services.

Attendees and exhibitors

Conference session illustrates how inkjet technology can power the new customer communications delivery hub

By Susan Cotter

ThINK 2018, held September 5-7 in Boca Raton, Fla., demonstrated once again the power of bringing together the print community to share innovations and best practices. With Canon Solutions America as the executive sponsor, thINK is an independent community of Canon Solutions America Production Print customers, vendors and print experts. This year’s conference featured 25 sessions and valuable networking time, providing educational opportunities and hands-on learning for newcomers and veterans alike.

As inkjet technology matures, utilization opportunities are growing at a rapid pace. Technology advancements are allowing for continued migration of new

applications to cost-effective colour communications. These advancements, paired with strategic investments in customer communication management (CCM) technologies, are opening up new growth opportunities for enterprise users and print service providers.

As senior analyst, program manager at Madison Advisors, I partnered with Jason Fonner of HM Document Solutions (HMDS) to present how HMDS transformed its traditional in-plant print operation into a true customer communications delivery hub and centre of excellence in a session titled, The new customer communications delivery hub, powered by inkjet technology

Session highlights

Production inkjet technology is becoming the latest catalyst for digital transforma-

tion for traditional print operations. The session focused on best practices for a CCM journey and how HMDS is using new CCM tools, advanced workflow management software, and leading-edge document delivery systems to transform its print operation into a dynamic full-service CCM centre of excellence.

The session focused on digital transformation and a shift in corporate leadership and strategies to adapt technology to better meet customer communication needs in both print and electronic communications. A CCM strategy focusing on a comprehensive approach to outbound communications results in higher levels of customer satisfaction and new client acquisition.

As demonstrated by HMDS, the print operations team has in-depth business and organizational knowledge that assist in streamlining the development of customer communications, while maintaining the security, compliance and quality controls that must be established to protect member/client information. Print operations are oftentimes an organization’s final line of defence for brand compliance, becoming a key element of a successful communications strategy.

Developing a digital approach requires an organization to think like the customer. What information does the customer want, and when and how do they want it? This includes the ability to bridge the gap between online and offline channels. As HMDS demonstrated, creating a centre of excellence that includes representatives from multiple business units affords a single source of truth for all customer communications. HMDS utilizes Canon’s PRISMA technology to increase efficiencies in its production and to provide input for reporting and overall program governance.

Madison Advisors and HMDS partnered in the CCM journey by creating a transformation roadmap based on six vital steps.

The first step is to review, clarify and document customer communication goals relative to revenue enhancement, cost and risk reduction, customer experience, and retention by:

• Preparing a comprehensive current state of operations,

• Mapping out the desired future state,

• Identifying barriers, and

• Setting improvement priorities. To achieve these goals and outcomes during this step, HMDS engaged with Madison Advisors to gather data on the scope of CCM in the healthcare and insurance markets, including potential revenues and recommendations. After completing the documentation of current state and future state, the improvements were identified and priorities were set.

Before moving forward, a high-level return on investment analysis was developed to gain organizational buy-in.

The goal here is to collect key data elements, including an inventory of all current communications, related work activities, volumes and overall cost to produce. The desired outcomes of this step were:

• Prepare a comprehensive inventory of all communications,

• Assess workflow processes and outline pros and cons, and

• Establish the total cost of data collection and documentation. This step was critical for HMDS as it utilized a number of document management tools. Reviewing the capabilities and costs of each tool presented options for routing and load balancing for multiple locations using PRISMA. HMDS was able to also identify opportunities for template consolidation. Another important part of this step was identifying future services and the enterprise goals for CCM.

At this stage, we developed an optimized operating model based on the company’s specific output requirements.The desired outcomes of this step were:

• Build a production model,

• Assess the technology platform,

• Develop a pro forma financial statement,

• Construct a governance model, and

• Create market best practices and benchmarking.

The creation of the HMDS Target Operating Model identified a CCM technology platform compatible with PRISMA that promoted load balancing and the ability to print within any location. This model was also used to create a pro forma with savings opportunities.

At Step 4, a strategic roadmap was created for implementing the optimization initiatives that are consistent with the overarching business goals and strategy by:

• Documenting all requirements,

• Finalizing the Target Operating Model, and

• Identifying internal and external resource requirements. This important step included preparing request for proposal (RFP) requirements and specific use cases for the planned partner technology summits. Use cases for user self-service and load balancing were set as priorities. HMDS engaged enterprise resources to identify the appropriate business units that would participate in the partner technology summit in order to gain acceptance across all interested parties.

Step 5 identifies resources and partner screening, creates scorecards and implements techniques needed for the proper selection and negotiation of service and technology providers. The desired outcomes of this step were:

• Schedule technology summits,

• Execute RFI/RFP with scoring and evaluations,

• Perform site visits, and

• Request proofs of concept from the short list of partners.

The HMDS team identified the partners selected for the RFP and attended technology summits to include solving for specific use cases. Each participant submitted their score cards for partner analysis and finalists were selected for a second meeting. HMDS selected to utilize the Océ Color Stream 3900 supported by PRISMA and a decision was made afterwards for a CCM software partner.

In this final step, documentation that supports the business case for change was outlined, including expert analysis and the desired impact to various stakeholder organizations within the company. Here, we:

• Created a detailed statement of work based on RFP requirements and required service level agreements (SLAs),

• Developed a project plan with assigned resources, and

• Formulated a Cost Benefit Analysis/ ROI to provide guidance and governance for the project team.

To achieve these goals and outcomes during this step, HMDS’ investment in a CCM platform was key to providing the benefits of a superior communication platform for members/clients using multiple channels with consistent messaging. The investment in Canon technology allows HMDS to bring 20 percent of the work previously outsourced back inhouse, along with the ability to provide new services to both internal and external clients.

Technology leaders must be prepared for disruption. HMDS’ strategy is a prime example of how to be successful during a digital transition and the importance of adopting a customer service mindset.

SUSAN COTTER is a senior analyst, program manager at Madison Advisors with over 20 years of experience in consulting in the business communications and business process outsourcing (BPO) industries. She is well-versed in customizing solutions for business process re-engineering and the outsourcing of business-critical back office functions using technology to achieve automation.

At Labelexpo Americas 2018, Xitron introduced Navigator Flexo Suite, comprised of several productivity tools designed specifically for flexo imaging. The company describes the modular workflow as being fully compatible with any flexo CTP engine that accepts one-bit TIFF files, such as Amsky, Cron and Xeikon. Navigator Flexo Suite starts with the Navigator RIP platform, of which more than 35,000 have been sold in commercial, in-plant, digital, screen printing, inkjet and flexo markets around the world. It’s coupled with the Client-Server properties of the Navigator workflow, which gives prepress operators and artists independent submission, modification, pixel-level preview and throughput control of jobs from their own workstations. This allows them to work independently and without interruption from anywhere on the network, Xitron says. Finally, all the colour separated job plates are collected by Navigator Plate Controller, which helps the operator assemble the final flexo plate for output with as little material waste as possible, the company explains. The optional screening engine gives users the ability to specify FM to AM crossover points between highlights/ shadows and mid-tones while also letting them determine minimum dot size through nine levels of sustainable “smart dots.” Users are able to customize the screening based on platesetter exposure accuracy and the print results of each individual press.Those customized setups are retained as screening templates for repeated use.

CRON-ECRM last September debuted and demonstrated the Blackwood Digital-UV plate. The CRON Blackwood Emerald-UV low chemistry plate, explains the company, is designed to

Kodak describes Prinergy Tools as an Adobe Illustrator software-based suite of design tools for packaging printers and digital, flexographic and offset print applications.

minimize the consumption of chemicals and water for UV exposed plates. With a wash-out bath, CRON explains the plates are press-ready in a matter of seconds, with dot reproduction from 1-98 percent for either stochastic screening (20 micron) or conventional screening up to 200 lpi. Run length is rated for up to 50,000. For UV ink printing, Blackwood offers UV double coating plate, HUV whose run length is over 50,000 and dot reproduction 1-98 percent at 350 lpi. For normal ink printing, HU-PXX offers the highest value in terms of price performance, states the company. Run length can go up to 100,000 and dot reproduction 1-98 percent at 350 lpi.

Fujifilm North America debuted the Superia ZD offset plate technology, a new addition to its processless plate portfolio for the commercial market, last year at Print 17. It was demonstrated with the existing Superia Ecomaxx-T plate. The company describes the Superia ZD as a true no-process thermal plate, with no effluent to dispose of and no additional consumables to contend with. Superia ZD performance is maximized with Fujifilm Hunt fountain solutions, including Superia PressMax JRDC-AB, compatible with UV/LED-UV/H-UV or conventional inks; along with the single-step Superia PressMax PPF-DC, a fountain solution with calcium control additive, also suitable for UV/LED-UV/H-UV or conventional inks.

Trelleborg’s printing solutions operations in October announced the signing of agency agreements with Pamarco and Bingham Flexo Services (BFS) for the distribution of the Axcyl flexographic

product line in Canada and the U.S. The three companies, they explain, will work together to promote Trelleborg’s Axcyl plate mounting sleeves, bridges and adapters for flexographic press applications. Damien Leterrier, Flexo Sales and Application Manager, explains the three companies have complementary products and strengths and as a result, the arrangement will create “exciting opportunities” for the North American flexo industry. Trelleborg’s Axcyl plate mounting sleeves are designed to offer better functions to flexo printers, in particular in printing speeds and tolling life span, the company says. Combined with dedicated services, such as Fast Track, the offering aims to provide flexo printers with improved performance and accelerated time to market.

Agfa Graphics in September launched Avatar V-ZH, describing it as a chem-free violet newspaper CtP plate that does not require pre-heating. As well, it boasts a “very high image contrast” after clean-out, allowing a visual image inspection to avoid mix-ups on press, Agfa explains. Avatar Z-VH is suited for high-quality Arkitex Sublima screening. Using it with Arkitex OptiInk software, the company explains, will result in a more economical use of ink, higher colour fidelity, and improved makeready time with less paper waste. Other features include daylight compatibility, high scratch-resistance, and robustness on press (run length, dot gain and press startup). The plate is intended to be flexible and can be used with either conventional or UV inks for semi-commercial or special applications. Meanwhile in March, Agfa Graphics released a new chemical-free plate line called Adamas. The company states Adamas will be the most durable chem-free plate available on the market, in terms of plate throughput and run length. Agfa says the plate system will require zero

water and provide up to 75 percent less waste when compared to similar products. Adamas leverages new Agfa-patented ThermoLink technology which, according to the company, provides run lengths as long as 350,000 copies. Adamas can be used in various print environments like sheetfed and cold-set to heatset printing.

In October Burnishine Products announced the immediate availability of a new flexo cleaner formulated specifically for use on plates and anilox rolls. Designed to safely clean plates, anilox rolls and more, the Burnishine Flexo Cleaner is described as containing low-phosphate biodegradable surfactants and being environmentally safe. Burnishine Products explains the flexo cleaner has been tested on water-based and UV-based inks and varnishes, and may be used full strength or diluted as much as 1:8 with water.

Mark Andy, a technology developer for the label and packaging industries, in March announced it had acquired Presstek, a global supplier of direct imaging (DI) offset plates and presses and CTP solutions. With the acquisition, Mark Andy explains it now serves as one of the only full-complement solutions providers to the global graphic arts and print industry. Presstek’s Zahara waterless plates division, which is not being acquired by Mark Andy, will be spun into a new company, Verico Technology, led by former Presstek CEO Yuval Dubois.Verico Technology will focus on expanding its market share for cut sheet aluminum waterless plates and coating technologies in the printing industry as well as venturing into new market segments. Presstek’s team of more than 60 technical professionals will be integrated within Mark Andy’s service infrastructure, which the company states makes it the largest, regionally staffed service organization in North America. Certified technicians will support equipment service for

brands such as Presstek, ABDick, Ryobi, Heidelberg, Xerox, Koenig & Bauer, Epson and more.

Kodak Prinergy Workflow Solutions recently unveiled its Prinergy Tools for Packaging and new Ink & Plate Usage Services. Prinergy Tools is an Adobe Illustrator software-based suite of design tools for packaging printers and all print applications – digital, flexographic and offset. Kodak also recently demonstrated its Ink & Plate Usage Service, which it says will deliver “ground-breaking ability” to automate the process of estimating and analyzing usage of inks and coatings in the pressroom for precise job quoting and inventory control for inks and coatings.

The Burnishine Flexo Cleaner is designed to safely clean plates, anilox rolls and more, the company says.

The new Kocher+Beck TecScreen processing unit is designed to be compact and economical and is suitable for fully automated washing and drying of nickel-based screen printing plates, the company explains. Kocher+Beck says the unit guarantees consistently high results in the prepress stage. “We are very happy to present the newest Kocher + Beck innovation. The new processing unit enables time savings and an optimization of costs to our customers,” says John Fehrenbacher, Product Manager at TecScreen.

MacDermid Graphics Solutions recently presented the new Lava NW-M Plate Processing System and the latest Lux InThe-Plate (ITP) product additions at Labelexpo Americas 2018. The product launch is MacDermid’s newest addition to its thermal platemaking technology. According to the company, the Lava NW-M intends to improve productivity and workflow in narrow web to mid web applications. The thermal processing system has a smaller footprint and the ability to output press-ready plates in less than an hour, it says. MacDermid also presented the Lux ITP 60 at the tradeshow. The Lux ITP 60 was recognized by the FTA in 2016 with the Technical Innovation Award for its low dot gain, low tack plate suited for long and clean run print jobs. The Lux ITP technology is offered in Lux ITP 60, Lux ITP M and Lux

ITP Epic, the latest addition to the line. Lux ITP M is a medium durometer plate that provides all the benefits of Lux ITP 60 but in a lower durometer, MacDermid states. Lux ITP M is suitable for paper stock, preprinted liner board and other applications where a “combination of high durability and excellent ink laydown is required.” Meanwhile, Lux ITP Epic offers a micro-rough surface for “excellent” ink transfer for challenging flexographic printing applications or unique ink requirements.

In September Flint Group’s Flexographic division presented the nyloflex Xpress Thermal Processing System with its latest plate addition, the nyloflex XVH Digital plate, a new hard durometer plate with a flat top surface. It can be used as is or further tailored with the use of surface screening. The thermally-processed printing plate provides “extraordinary detail” that rivals the quality of solvent-processed plates, Flint says. To expand the company’s offering for the label market, the nyloprint WF Sharp was launched at Labelexpo Americas 2018. The water-washable, film-based plate for the high-end label market is suitable for all types of processing equipment with a flexible polyester base, Flint explains. Also on display at the tradeshow was the rotec Eco Bridge, an adapter for use on flexographic printing presses and plate-mounting equipment. It features a breathable metal ring designed to create an air pillow around the entire circumference of the adapter for easy mounting of sleeves. Flint explains the adapter uses 90 percent less volume of compressed air, resulting in reduced noise and cost savings.

MacDermid says the Lava NW-M Plate Processing System has the ability to output press-ready plates in less than an hour.

Nilpeter’s new FA, Panorama Hybrid and FB-350 presses made their North American debut at Labelexpo Americas 2018 in September. The new offerings, according to Nilpeter, are designed for the next generation of printers and Industry 4.0 needs, through the automation of almost all processes. The new FA, for example, boasts complete clean-hand operation from wireless tablets, handheld or positioned anywhere on the front of the machine. All new machines offer total job store and recall, automated controls and full connectivity. The company’s digital product line, Panorama, is designed to cover a varied spectrum of requirements – from stand-alone to all-round, and value-added hybrid configurations. The company describes the FB-350 as the latest generation of highly efficient label printing, offering new features such as Automated Plate Positioning System (APPS), pre-register and re-register functionality.

Inspira Opaque is a premium opaque printing paper with 98 ISO brightness, high smoothness, excellent paper formation, opacity, and printability.

It is ideal for offset printing − both for high-speed web and sheet-fed − of financial documents, reference books, textbooks, directories, catalogs and commercial printing.

It provides crystal clear contrast for text and vivid imagery, especially when used together with the performance of high gloss inks.

1x Mitsubishi 40” 10 Colour Tandem with AQ

1x Mitsubishi 40” 8 Colour Tandem with AQ

1x Mitsubishi 40” 8 Colour Perfector with AQ

3x Mitsubishi 40” 6 Colour with AQ

2x Heidelberg Printmasters

3x Saddle Stitchers / 1 Perfect Binder / 10+ MBO Folders

Over 75,000 sq ft plant housing state-of-the-art nishing and bindery

Personalized account management and complete control over production

24/7 Production with fully automated and barcode controlled plant

FSC / PEFC / SFI certi ed

The Jeti Tauro H3300 UV-LED Inkjet Printing System from Agfa Graphics made its North American debut at SGIA 2018. Described as an UV inkjet system designed to support single or dual master rolls for uninterrupted printing, the Jeti Tauro H3300 LED boasts four levels of automation to choose from so printing companies can configure the engine to their specific needs: manual loading and unloading, master roll-to-roll, semi-automation, and full automation. Featuring a resolution of 635 x 1200 dpi in all print modes, Jeti Tauro H3300 LED produces prints up to 130 inches wide (3.3 m) at speeds up to 4,676 sqft/h (453 sqm/h).

At Print 18, Ricoh USA introduced a Cloud-hosted, vendor-agnostic solution developed to help printing companies better identify areas where automation can save time and money, and drive increased ROI on existing equipment. Designed to gather high-value data from across the printing operations, Supervisor collects, sorts and analyzes data from Internet of Things (IoT) endpoints and presents it in customizable dashboards. These dashboards can be tailored to measure various KPIs, while different dashboard views can be provided to different levels of users, so supervisors and managers at every level can access the necessary informa-

tion for their specific function. The solution provides breakdowns of KPIs, both in real time and historically, that can help businesses identify and address bottlenecks, uncover patterns and trends, and more intelligently estimate jobs, Ricoh says, adding that it analyzes key data, sourcing information from any device or software, including those not manufactured by Ricoh.

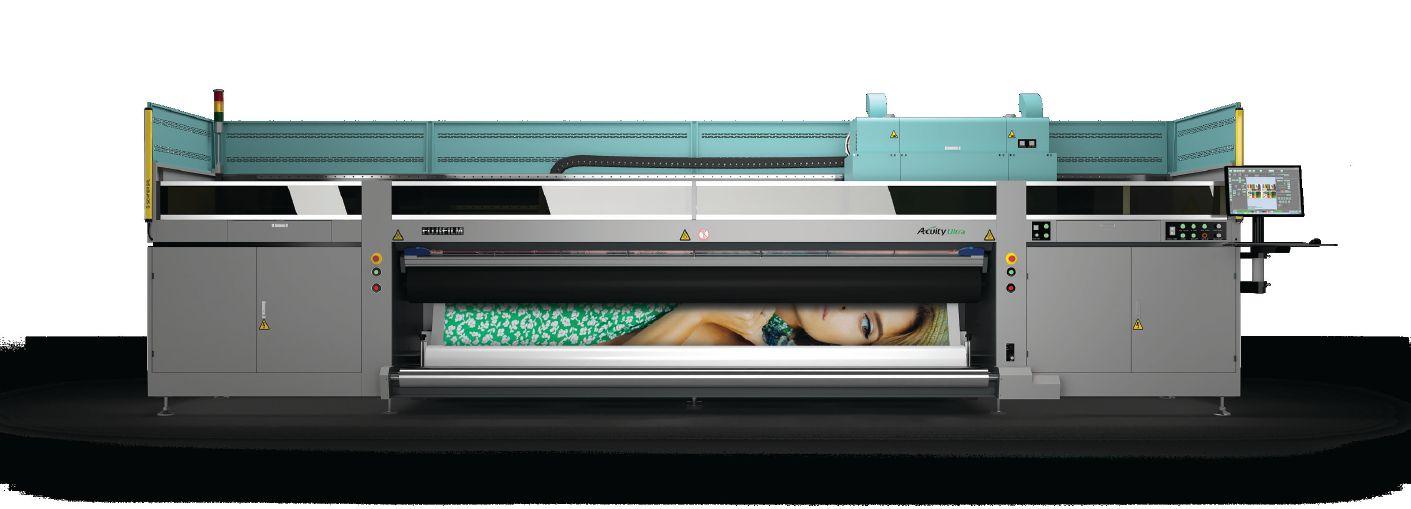

The superwide UV roll-to-roll Acuity Ultra printer from Fujifilm was recently presented at SGIA Expo 2018 in Las Vegas. Acuity Ultra boasts increased size and quality for the production of high-end interior graphics for interior and exterior applications, such as exhibition graphics, point-of-purchase displays, high-value graphic art and indoor backlit displays, says Fujifilm. The newest superwide UV printers from the company, the series utilizes Fujifilm’s new Uvijet GS inks and with a 3.5 pl drop size, the grand format Acuity Ultra is designed for the high-end indoor display market, especially for luxury brands, with quality comparable to litho, Fujifilm states. The Uvijet GS ink series, developed specifically for use with the Acuity Ultra series, produces a low-build ink film and is described as delivering “excellent coverage and adhesion, high density vibrant backlits, and a durable finish.”

The latest product from colour management developer CGS is Oris X Gamut, a fully automated software for expanded gamut printing on conventional and digital presses. Released during Labelexpo Americas 2018 and Print 18, Oris X Gamut aims to extend the full colour space and multicolour ink set of the press. CGS explains a specific spot colour can be reproduced without the need for a special ink formulation, an appealing feature to brand owners and the packaging and label industries. As well, Oris X Gamut is designed to increase the colour saturation of images, which is especially important in the production of pictures for photobooks and complex packaging designs, for example. Oris X Gamut, the company explains, extracts the DNA of the spot and CMYK/RGB colours in the print job and translates them into the expanded fixed colour palette (CMYK+n) of the press. Usually this expanded gamut is achieved at press by adding orange, green and violet to the standard process inks (CMYK+OGV). The process makes use of the included special colour reference tables, i.e. the Pantone colour library or a table created automatically from imported CxF data. CGS explains the software leads the user through the whole process, from reading in the test chart to output of the final, optimized print job – all done automatically.

Highcon in October introduced a new range of consumables for its digital cutting and creasing machines: DART Premium and DART Economy consumables. The consumables, it says, have been developed to suit paper, folding carton and corrugated boards. The Highcon DART technology, implemented in the DART resin, DART foils and DART counter aims to open up a wide range of digital potential to the previously analogue process. The digitally driven rule shape (geometry – cross-section) and dimensions (height versus width) can now be automatically adapted, and if necessary by grain direction, depending on the applica-

tion or substrate thickness, Highcon explains. Also, since there is no die-cutting form and the two processes of cutting and creasing are separated on the Highcon machines, there is no restriction to cutting or etching on a crease, it adds. DART Premium Consumables boasts reusable foil that can be reused three to five times when stored appropriately, rapid writing of rules (~10 minutes for the first job), a substrate gamut – paper or folding carton up to 600µ and corrugated up to 3mm (Euclid IIIC only), and savings of up to 80 percent in consumables cost. Meanwhile, DART Economy Consumables are suitable for short runs of up to 5,000 sheets, one-time use, and substrates up to 450µ.

Epson in September presented the SurePress L-6534VW digital label press, designed for converters investing in a digital label press for the first time or looking to expand production facilities. Joining the SurePress L-6034VW in the UV digital label press line, the new system offers three print speed modes from 49 to 162 feet per minute. Epson explains the SurePress L-6534W integrates all of the functions required for label production, including a Corona Treater, White ink, digital varnish and an additional UV curing unit. The printheads, inks, LED pinning and curing lamp units, media feeding, and control system are all developed and manufactured by Epson. Additional features include PrecisionCore Linehead for single-pass printing while a digital monitoring system uses Nozzle Verification Technology to automatically manage inkjet noz-

TECHNOLOGY — Die crease without a die, then fold and even glue all on the same machine, up to 30 pt.

3. INTEGRATED MODULAR UNITS — Combined in-line finishing: crease, fold, glue, tipping, envelope inserting, ink jetting (Duplex), clip seal (3 sides), mail prep.

4. SAVE ON POSTAGE COSTS —As a Certified Canada Post Direct Marketing Specialist, we get contract pricing reductions.

5. RETURN MAIL PRODUCTS — Customized “Return Mailers” created in-line with “U” or “BOX-shape” remoistenable glue, time perfed applications and envelope formation.

6. MINI-BOOKLETS — Saddle-stitch and trim 2-up booklets in-line to the size of a business card. No need to trim off-line, or do 2 passes.

7. HIGH SPEED EQUIPMENT — High speed Tipping, Folding, Saddle-stitching and soft folding ensuring on time delivery.

zles; digital varnish – gloss or matte finish can be selected for partial accents or the overall label; and variable web width to supports rolls from 3.15 to 13 inches wide up to 0.013 inches thick.

clogged nozzles, while the Nozzle Recovery System allows the operator to substitute unproductive nozzles to avoid poor image quality.

2018-09-14 11:33 AM

Mimaki explains its new TS551800, a 76.3-inch, dye-sublimation transfer inkjet printer, offers low running costs and unattended continuous printing for the mid-level and high-end markets. The TS551800 prints with the new Sb610 inks at a maximum output of 1,506 sqft/h. These inks hold the Eco Passport by Oeko-Tex certification, meeting sustainability, safety and compliance requirements. Additionally, two new optional units, a mini jumbo roll and a 10-kg ink supply have been introduced on the TS55-1800. The mini jumbo roll is a feeding unit to load the 64-inch Mimaki Vision Jet-X transfer paper, supplied by Neenah Coldenhove, with a length of about 8,202 feet Mimaki says the system ensures high-volume and unattended printing for longer production runs, noting it also decreases the running paper costs per square foot in comparison to the normal plotter rolls. The TS55-1800 is equipped with several of Mimaki’s Core Technologies, including the Mimaki Advanced Pass System (MAPS) for greater productivity and print quality by eliminating visible banding. As well, the Nozzle Check Unit automatically monitors the printhead performance and detects

Uflex Chemicals has introduced its new FlexGreen range of UV LED sheetfed inks for commercial printing and packaging. The company describes FlexGreen as a series of UV-LED process colours for sheetfed offset printing on coated paper, paperboard and MetPet Board, boasting “high colour strength and gloss, quick curing, excellent inkwater balance and press stability.” FlexGreen, Uflex Chemicals explains, is expected to bring substantial savings to printers by way of lower energy costs and reduced carbon footprint.

The new EFI Reggiani Terra solution is described as a high-performance digital production offering featuring a new pigment ink set and binder for sustainable industrial textile printing. The newly available offering, EFI says, uses an efficient in-line polymerization process that allows users to print designs using less water, less energy and in less processing time, with no steaming or washing needed on direct-to-textile applications. The new pigment inks are commercially available as a six-colour set of cyan, magenta, yellow, black, blue and red, with additional colours coming soon.

head and a high potential for growth. Located in Hamilton-Burlington area. Owner would like to retire after 39 years in business. For more information please contact 905printbizforsale@gmail.com Serious enquiries only.

Apel

Dave Fellman

Both

Heidelberg: K-Line/S-Line/Speedmaster/GTO/MO/KORD64

Komori: 1, 2, 4 or 5 colours & any size

Adast: 714/715/724/725

Mitsubishi: Any model

Ryobi: 2800CD/3200CD-MCD/640K

Itek: 960/975/985

Hamada: 600/700/800/E47/RS34

Shinohara/Fuji: 66/65 1,2 or 4 colours

Sakurai: 1, 2 or 4 colours and any size (newer model)

Polar: any size/older or newer models (66/72/76/78/82/90/92/107/115)

Horizon-BQ: 220/240/260/440/460

In October 2018, Canadian Printing Industries Association (CPIA) launched a newly restructured printing industry association in Canada. Proposed by its Board of Directors and ratified by its membership this past March, the CPIA intends to operate under a new membership structure to help unify the industry. Six regional print associations and one supplier association make up the CPIA members – PrintForward Printing and Imaging Association, Printing and Graphics Industries Association of Alberta (PGIA), Saskatchewan Printing Industries Association (SPIA), Manitoba Print Industries Association (MPIA), Ontario Printing Industries Association (OPIA), Quebec Association of the Printing Industry (AQII), and Printing Equipment and Supply Dealers of Canada (PESDA) – with one or two representatives from each association making up the Board. PrintAction spoke to Richard Kouwenhoven, President and Chief Operating Officer of Hemlock Printers Ltd. in Burnaby, B.C., who serves as Board Chair.

What does the relaunched CPIA hope to achieve?

RK: The association has continued to exist over the decades, but its activity has dropped off substantially in recent years and needed to take a new direction. When the relationship between the CPIA and the regionals started to break down, it became really challenging for the CPIA to succeed, and ultimately was the core of its problems. In late 2016, the new board picked up the leadership of the CPIA and began major restructuring of the association. The new structure focuses on the idea that the CPIA exists to connect the regional associations. One of the biggest changes is that the CPIA members are the regional associations themselves, and the printers become members of the national association through their respective regional association. With all active regionals on board, we look forward to adding an Atlantic Canada association, which we expect will be completed by the end of the year. We hope that by 2019, we will have true representation from across the country.