FEATURES

14 The wide-format experience

Exploring six popular consumerengagement trends that are driving the wide-format business

FEATURES

Exploring six popular consumerengagement trends that are driving the wide-format business

Exhibitors of the upcoming tradeshow share booth highlights attendees should focus on

GAMUT

5 News, People, Installs, Calendar, Globe

SPOTLIGHT

26 Patrick Kerrigan, President, Alpha Poly Corporation

COLUMNS

FROM THE EDITOR

4 Alyssa Dalton

Authentic connections

SALES

9 Dave Fellman

Rose-coloured bifocals

Successful print selling requires good near vision, far vision, and a fair share of optimism

CHRONICLE

10 Nick Howard

The ‘Little Wonder’

The story of how the two Harris brothers rocked the printing world

Sharing stories is one of the most – if not the most – innate forms of communication; the retelling of experiences and narratives as a means of inspiring thought-provoking perspectives, teaching life lessons and connecting people.

Deloitte’s 2015 research paper, Print is alive and well — at least for books, finds the sale of printed books is four times higher than e-books.

“Science has finally confirmed what we’ve long known to be true — we’re hardwired for stories,” Sujan Patel, growth marketer and entrepreneur, writes in the article, Nine companies that are killing it with brand-driven storytelling. “They lead to better understanding, trust, comprehension, receptivity and more. We teach important ideas to our children via fables and fairy tales. We share episodes from the lives of important religious and historical figures via dialogues and stories. We connect, engage and are moved…to tears, to laughter, to anger, to sympathy, to action.”

A recent design and social impact project highlights the power of human connection. Organizers collected untold, anonymous stories in Toronto and Atlanta, and wrote them into reclaimed, second-hand books; visitors of the art exhibit could then reply to these stories by sending a postcard. Titled What is your story?, the exhibit looks at the struggles and secrets hidden deep within ourselves and our peers, and how these unknown stories connect us more than we realize. Designed by Spark Corps and Orange Sparkle Ball, in collaboration with BooknBrunch, the interactive installation quickly became an outlet for untold stories.

“There are very few burdens greater than carrying the weight of an untold story. People constantly have trouble finding their voice and sharing their story for fear of being judged. Books are the silent storyteller,” the organizers explain.

“This interaction makes the storyteller feel heard and responded to. The vulnerability of what people share under anonymity is astounding and powerful.”

The collection of books was put on display as part of DesignTO in January 2019, a city-wide cultural celebration of design in Toronto, and is now on exhibit in Atlanta. The installation is expected to travel to additional locations in Canada, the United States and Colombia in the future.

“Stories create community, enable us to see through the eyes of other people, and open us to the claims of others,” Peter Forbes, photographer and author, once famously said.

Life on the line is an art project that saw 100 posters take the place of typical subway advertisements from November 17, 2018, to January 6, 2019. Launched

by Toronto-based not-for-profit organization Twentytwenty Arts, the pieces were created by artists who have been affected by mental health issues, either directly or through their loved ones, and aim to reflect their diverse experiences.

The 20 winning pieces – selected from roughly 350 submissions – vary in design and media, ranging from lithographs, digital works, screen prints, photography, oil paintings and collages.

“Art has an opportunity to communicate experiences that might be incommunicable,” Megan Kee, executive director for Twentytwenty Arts, told The Globe and Mail

Displayed on Toronto Transit Commission’s Lines 1 and 2 subways for nearly two months, the prints are also available for purchase, with 80 percent of sales going toward the Canadian Mental Health Association Toronto.

In today’s fast-paced society immersed in digital technology, we’ve seen a return to creating simpler, authentic connections. Think classic board games, vinyl record players, Polaroid cameras, retro-inspired television shows, even print catalogues and direct mail pieces — what’s old is new again.

“The Internet constantly rewards us with convenience and instant gratification, making the human touch increasingly more scarce and coveted,” writes Celinne Da Costa in the article, Three reasons why brand storytelling is the future of marketing “In this environment, businesses can no longer afford to be faceless entities. To survive, businesses need to connect with audiences, pull at their heartstrings, and engage with them on a much deeper level than seen before.”

While the article focuses on crafting and executing an effective brand marketing strategy, the bottom line – “humanity is becoming the new premium” – remains true. Effective storytelling will continue to evoke an emotional, memorable response.

“Your audience may forget what you say, but they will not forget how you made them feel,” Da Costa notes.

As Jimmy Neil Smith, founder and president emeritus of the International Storytelling Center in Jonesborough, Tenn., puts it: “We are all storytellers. We all live in a network of stories. There isn’t a stronger connection between people than storytelling.”

ALYSSA DALTON, editor adalton@annexbusinessmedia.com

Editor Alyssa Dalton adalton@annexbusinessmedia.com 416-510-5225

Contributing writers

Zac Bolan, Wayne Collins, David Fellman, Victoria Gaitskell, Martin Habekost, Nick Howard, Neva Murtha, Abhay Sharma

Associate Publisher Stephen Longmire slongmire@annexbusinessmedia.com 416-510-5246

Media Designer - Team Lead Lisa Zambri lzambri@annexbusinessmedia.com

Account Coordinator Alice Chen achen@annexbusinessmedia.com 416-510-5217

Circulation Manager Barbara Adelt badelt@annexbusinessmedia.com 416-442-5600 ext. 3546

Circulation apotal@annexbusinessmedia.com

Tel: 416-510-5113

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Group Publisher Diane Kleer dkleer@annexbusinessmedia.com

President & CEO

Mike Fredericks

Subscription rates

For a 1 year

subscription (10 issues): Canada — $43.00 +Tax Canada 2 year — $70.50 +Tax United States — USD$75.50 Other foreign — USD$147.00

Mailing address

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 printaction.com

Tel: 416-442-5600

Fax: 416-442-2230

Annex Privacy Officer

Privacy@annexbusinessmedia.com 800-668-2384

PrintAction is printed by Annex Printing on Creator Gloss 80lb text and Creator Silk 70lb text available from Spicers Canada.

ISSN 1481 9287 Mail Agreement No. 40065710

Thunderbird Press has switched to chemistry-free Azura plates to help achieve greener outcomes as part of the Agfa Graphics GreenWorks program.

Hillside Printing has closed its production facility at 3050 Nanaimo Street and has announced a strategic relationship with ARC Document Solutions Canada. A provider of print services and document management solutions, ARC has two locations on Vancouver Island, Saanichton and Nanaimo. Through this relationship, ARC will provide Hillside Printing with production capabilities to support its customers going forward. “We are confident that this change will benefit our customers and allow us to continue to offer the quality and service level they have come to expect, proudly produced on [Vancouver] Island,” writes Barbara Isman, President of Hillside Printing, in an open letter published on the company website.

“ARC offers some additional services, like document scanning and managed print, that will be extended to our customers, expanding the scope of what we can offer you in the future.” The company’s new location will be 6691 Mirah Road, Victoria, B.C.

Mitchell Press is the only Canadian printing company out of 13 winners recognized in the 2018 Kodak Sonora Plate Green Leaf Award. The program, now in its sixth year, celebrates print service providers that adopt sustainable practices and offer their customers eco-friendly options for their printing needs. In addition to integrating Kodak Sonora Process Free Plates into their operations, each of the winning companies demonstrated an ongoing commitment to investing in sustainable business practices. This is the

direction,” Marc Giroux, President of Pazazz, said in an email dated Feb. 5 to PrintAction. This is the second time in less than a decade the Quebec printing company has filed to restructure.

second consecutive program win for Mitchell Press. Award entrants were judged on a range of criteria, including management practices to improve energy and water efficiency, participation in local community sustainability initiatives and the use of eco-conscious materials and supplies.

Pazazz Printing of Ville Mont-Royal, Que., filed a Notice of Intention in January and has submitted a proposal for restructuring, with Richter Advisory Group appointed the proposal trustee. On January 14, Pazazz filed a Notice of Intention in accordance with Section 50.4(1) of the Bankruptcy and Insolvency Act, R.S. C. 1985, c. B.-3, and Richter Advisory Group was appointed as Proposal Trustee under the NOI. On January 24, Pazazz filed a Motion for the Authorization and Approval of Interim Financing, Certain Charges, A Sale and Solicitation Process and Other Relief. The DIP, SSP and Extension Motion was scheduled for hearing on January 29. “Operations continue as normal and we thank our suppliers for working with us. Nothing else has changed in any way in terms of operations, services, employees and our

Following a successful partnership in Canada, a distribution agreement has been finalized with Graphic Whizard Inc., Graphic Whizard USA Inc. and Xerox sales channels in the United States selling the PT335 SCC Multi slit/ cut/crease finishing system. Introduced to the North American finishing industry in 2015, the PT335 SCC Multi all-in-one finishing system converts digitally printed work into finished products with operator intervention. Now Xerox customers will be able to pair their Xerox production devices with Graphic Whizard finishing to streamline production and increase efficiency, Graphic Whizard explains. In 2016 Graphic Whizard signed a full-line distribution agreement with Xerox Canada. The success in Canada was the driving force behind the interest from Xerox USA, according to the parties. Graphic Whizard is a Burlington, Ontario-based company with dealers located throughout Canada, the United States and in more than 40 countries abroad.

Thunderbird Press of Richmond, B.C., has switched to chemistry-free Azura plates in a move to achieve greener outcomes as part of Agfa Graphics GreenWorks, a program that accredits environmentally sustainable North American print service providers. Azura is described as a chemistry-free thermal plate for low- to medium-volume commercial printers seeking a safer work environment without chemical processing. It is designed to preserve high-quality imaging without press changes and offers reduced waste and disposal costs associated with chemicals, Agfa says, noting that Azura offers simplified platemaking with advanced ThermoFuse technology. Depending on press conditions, Azura can provide up to 100,000 impressions.

Xerox announced during its 2019 Investor Day that it has acquired Vader Systems, a New York-based metal additive manufacturing company, a move that is expected to help Xerox offer low-cost metal additive manufacturing with more

metals to its customers. Founded in 2013, Vader Systems is a machine tool manufacturer and developer of liquid metal additive manufacturing technology. Its offerings include the Magnet-o-Jet Subsystem for hybrid manufacturing equipment integration, the Vader Polaris liquid metal AM system and the Ares Microsphere Production System for the production of spherical metal powders.

HP finds the expected value of the personalized product market to be valued at US$31 billion by 2021, up 55 percent from 2016.

HP in January unveiled its framework, The Personalization Pinwheel, to help brand owners tap into the growing personalization market. Informed by insights from more than 45 million online conversations across the globe, the framework hones in on what motivates consumers to personalize – from photo books to magazine covers to consumer packaged goods – and how brands can capitalize on those motivations.

“Personalization is a powerful tool to create meaningful experiences with consumers. It increases brand loyalty and engagement and at the same time accelerates business growth and speed to market,” says Nancy Janes, Global Head of Brand Innovation, HP Inc.

ISA International Sign Expo 2019 and Xplor19 will co-locate in Las Vegas, bringing together the sign, graphics and visual communications industry with the electronic document systems industry. The International Sign Association and Xplor International have partnered for the past few years in educational sessions, but 2019 will mark the first time the two have co-located their complete events. Both will be held at Mandalay Bay Convention Center in Las Vegas. ISA Sign Expo is set for April 24-26; Xplor19 takes place April 23-25.

Quark Software has promoted John Friske, Senior Vice President of Global Sales and Services, to the role of President and Chief Operating Officer, where he will be responsible for the delivery of products, service and support to the company’s global network of customers. Friske joined the company as part of Quark’s acquisition of In.vision Research Corporation in 2008; the company’s flagship product is the foundation of Quark XML Author for Microsoft Word.

JM Heaford is welcoming Nick Myaard as Service Engineer for the Canadian, U.S., and Latin American markets. Based in Michigan, he was previously engaged in a similar role for a flexo press manufacturer. “I really relish the opportunity to expand my knowledge in the industry and indulge my practical problem-solving to the fullest,” he says.

Mike Wildbore has joined Konica Minolta Business Solutions (Canada) as Director, Business Development Wide Format Printing Systems, bringing more than 15 years of print-related sales experience. Prior to this role, Wildbore was a Digital Solutions Manager with Fujifilm Graphic Systems, overseeing Canadian sales of the company’s J-Press inkjet press, Acuity flatbed wide-format printers, and CTP and XMF Workflow software solutions. He also has prior experience as Vice President Sales at Drytac Canada, where he oversaw expanded adhesive coating and converting operations within the Toronto area.

Le Groupe Stylex du Progrès of Laval is the first in the province of Quebec to acquire Konica Minolta’s MGI JETvarnish 3D Evolution for the production of embellished images, text, data and brand designs using spot varnish, 3D raised varnish and digitally embossed foil in a single pass.

Rutger Jansen (right) has been appointed Chief Executive Officer of Contiweb, effective January 1, 2019, succeeding Bert Schoonderbeek who recently announced his retirement from the position. During his tenure as CEO, Schoonderbeek played a “pivotal role in establishing Contiweb as an industry leader” and driving the expansion of the company’s offering in the digital market along with the label and packaging sector, Contiweb says. Jansen joined the company in 1990, when the business was known as Stork Contiweb, and served as Director of Sales and Service prior to the Goss International acquisition in 2004. During Goss’s ownership, Jansen held various positions and was promoted from Director of Customer Service to Service Director EMEAR.

Hemlock Printers has appointed Amanda Chor to the role of Sustainability Coordinator, where she will work to maintain, develop and promote initiatives that reduce the company’s impact on the environment. She recently completed her Bachelor of Business Administration at SFU Beedie School of Business, along with a certificate from the SFU Corporate Environmental and Social Sustainability program.

Kurt Schlichting has been named BST North America’s new Customer Service Manager. With a degree in electrical/electronic design, he brings experience within the printing press industry, including managing press assembly, installation and press commissioning and coordinating customer training and supporting tech services.

Jet Label & Packaging has installed an RFID inserting system with an existing Mark Andy flexo press and a Tamarack RFID application unit. The single-pass RFID insertion sees label stock briefly opened for RFID inlay, then relaminated via finishing operations. The system verifies RFID function with a reader system after die-cutting.

Ellis Packaging of Pickering, Ont., has installed a new Komori GLX 6-colour 41-inch press from Komcan Inc. The highly automated GLX 18,000 iph machine sits beside a GLX 8c installed three years ago. Komcan explains The Ellis Group now has the largest number of GLX presses in Canada and a total of six Komori presses.

April 9-11, 2019

InPrint USA 2019 Louisville, Ky.

April 11-13, 2019

Graphics Canada

The International Centre, Mississauga, Ont.

April 24-25, 2019

AICC Canada Trade Show and Conference Toronto, Ont.

May 28-30, 2019

Packaging Première

Milan, Italy

May 30, 2019

Gala Gutenberg Montreal, Que.

June 13, 2019

PrintForum 2019

The International Centre, Mississauga, Ont.

October 3-5, 2019

Print 19 Chicago, Ill.

October 23-25, 2019

Printing United 2019 Dallas, Texas

November 7, 2019

Canadian Printing Awards Palais Royale, Toronto, Ont.

November 25-28, 2019

Shanghai World of Packaging Shanghai, China

June 16-26, 2020

drupa 2020

Düsseldorf, Germany

Just-Us Printers, a family-owned commercial print and packaging firm serving the Arkansas community, has installed InkZone Ink-Presets and Closed-Loop colour control technology through CMYK Distributors.

Having launched its packaging capabilities this past January, Just-Us Printers says InkZone brings a competitive advantage by increasing its capacity to control colour, and to measure and monitor the quality of its work.

“We’ve only been using the InkZone solution for about a month, but we are already realizing measurable benefits,” Brett Justus, President of Just-Us Printers, says. “We are seeing a significant reduction in colour variation during the print run and from job-to-job. In addition, our makeready waste is down 30 percent on average. While reducing makeready was not a driving factor in our decision to invest in InkZone, with these results, we are on course to realize a return on our investment much faster than we anticipated.”

The InkZone solution at Just-Us Printers features an X-Rite IntelliTrax spectral scanner for measuring the colour bar now with standard M0/M1, M0/M3 or M1/ M3 with a small aperture for colour bars that have patches greater than 2.0 mm in height x 3.0 mm in width. By measuring a colour bar, the collected data is sent directly into the InkZone Loop software to automate the process. The X-Rite IntelliTrax comes standard with the Pantone digital library.

“The pharmaceutical industry is our packaging business’ largest customer-base. With the combined forces of InkZone and Intellitrax, we can provide our pharma clients with exceptional quality. We now have the technology and tools to print folding cartons, as well as packaging inserts, with precise colour consistency across the varying substrates of carton and peripheral materials,” Justus adds.

Just-Us Printers’ services include wide-format, packaging, offset and digital printing, vehicle wraps, race wraps and fulfillment. The firm employs 36 people at its 37,000-square-foot facility in northeastern Springdale.

Nearly six months after installing an Océ VarioPrint i300 inkjet press, commercial printer Goodway Group is reporting uptimes above 95 percent, “decreased operating costs and new opportunities for business growth.”

Said to be the first commercial printer in the Boston, Mass., metropolitan area to install an Océ VarioPrint i300, the system has allowed Goodway Group to nearly triple its capacity. Prior to installing the inkjet press, the company says it landed a large project for a national client, but were limited by the speed and capacity provided by older toner devices in the company’s print fleet.

“As one of Boston’s early adopters of digital technology, we are

A leader in chocolate production, Belgium is home to many chocolate packaging printers that produce and package these delicious treats for customers around the world. Imprepack, based in Brussels, is a family-run business founded in 1928, with 20 employees. Specializing in luxury packaging, the company has been producing the ‘ballotin’ – a decorative cardboard box with slightly larger at the top and broad flaps, and other chocolate packages – for the past decade.

In order to meet its business development targets and market needs, Imprepack recently installed a new Roland 705 LV Evolution press.

“The start-up of the new press was very successful thanks to a structured pre-installation plan by Manroland Sheetfed’s technical team,” CEO and Owner Filip Winderickx says, a third-generation member of the family-run company, emphasizing that print quality is of paramount importance to the business. “We would like to thank Manroland Benelux for the intensive training provided to our staff for production to run smoothly and quickly.”

More than 10 years ago, Imprepack obtained the Certificate of Global Standard for Packaging and Packaging Materials, an accreditation that endorses the packages produced are food-safe.

“We are very satisfied with the outstanding performance and print quality of this new press, particularly its fantastic print effects, such as, embossing to provide flexibility with customization.”

Imprepack explains the press will help meet its business development targets and market needs.

proud to now be the first in the region to acquire this groundbreaking technology,” says Mike Jenoski, President and CEO of Goodway Group of Massachusetts. “It has brought great value to our business and our customers in a short time. The feedback from our customers on the quality of the prints has been overwhelmingly positive and our capacity to print a high volume of impressions has increased exponentially.”

According to Jenoski, the Océ VarioPrint i300 enabled Goodway Group to plan and be confident in its ability to take on high-volume requests and complex applications.

“In a short amount of time, the Océ VarioPrint i300 has demonstrated its capabilities and we are confident it will help Goodway Group of Massachusetts to remain competitive in the marketplace and improve its daily print operations,” says Francis McMahon, Executive VP of Canon Solutions America’s Production Print Solutions.

Chinese packaging company Hubei Guangcai Printing is investing in a Koenig & Bauer 9-colour Rapida 106 with coater and kit for UV-mixed operation.

By David M. Fellman

When I was a kid, you must need glasses, was a pretty common insult. I remember saying it to other kids, and once to a Little League Baseball umpire. That got me thrown out of the game. It turns out, though, that printing salespeople do need glasses. Specifically, they need rose-coloured bifocals, because success in the modern marketplace requires good near vision, far vision, and a fair share of optimism.

Near vision

It has been my experience that most salespeople do not focus very well on what is right in front of them. There is usually some opportunity to gain more value from current customers. Notice that I didn’t say gain more business, but rather gain more value. As I have written before, I believe every current customer provides you with three levels of value: The value of what they are buying from you now, the value of what they could be buying from you, and the value of influence. Working backwards, the value of influence is all about testimonials and referrals. When was the last time you asked one of your customers for a testimonial or a referral? When was the last time you got a real referral out of whatever networking group(s) you belong to?

The value of what they could be buying from you is mostly about the breadth of your product line. Have you talked to every customer about every element of your product line? I am not talking about that one conversation where you blasted out a list of everything you sell. I am also not talking about the time you said, “Think of me for anything that involves printing.” I am talking about having specific conversations about each individual element of your product line. It’s my experience that the more you try to cover in any one conversation, the less likely it is they will hear most of it, let alone all of it. We also need to talk about protecting the value of what they are buying from you now. The most obvious way to lose a

customer is a quality or service failure, but more customers are lost because of something less obvious, even though it should not be. You know your competitors are calling on your customers, right? That means you have to be calling on them too! But more than that, it means you have to be calling on them and bringing value. “Do you need any printing today?” is not a value-based selling strategy.

You know your competitors are calling on your customers, right? That means you have to be calling on them too!

We live in an age of near immediate gratification. As an Amazon Prime member, for example, I can order just about anything from Amazon and have it shipped to me for free within two days. They are even talking about using drones to make same-day deliveries. But while you can buy very quickly, you cannot always sell very quickly, especially when that involves building trust to the point where someone is willing to take the leap of faith and place a custom order with a new supplier. And make no mistake, that is a significant leap of faith.

With better far vision, you might realize it is going to take time to get people to the point where they will seriously consider buying from you. You will also realize that, while there are no shortcuts, there are accelerators. For example, do not just talk about your quality and service — provide some evidence to support your position. And please understand that a handful of hand-picked samples is not going to accelerate the process. But how about supporting the samples with a de-

scription of your quality control processes and procedures, and then some testimonials from current customers? Any one of those may have some effect, and any two are almost certainly better, so why not all three?

I read a study recently which noted that optimists tend to be more successful than pessimists. I hear a lot of pessimism from printing salespeople, though. Now maybe this is coloured by the fact that most of my business involves working with underachievers, but I am hearing a lot more about what is not working than what is. Here is a fact. There are people doing very well in printing sales, even in highly competitive markets in a difficult economy. Why? I think better vision – near and far – is probably a big part of it.

Are you experiencing the kind of success I’m talking about? If not, could the problem be that you need a new pair of glasses?

DAVE FELLMAN is the president of David Fellman & Associates, a graphic arts industry consulting firm based in Raleigh, N.C. He is a popular speaker who has delivered keynotes and seminars at industry events across the United States, Canada, England, Ireland and Australia. He is the author of “Sell More Printing” and “Listen To The Dinosaur.” Visit his website at www.davefellman.com.

By Nick Howard

n the sleepy Ohio town of Niles, brothers Alfred and Charles Harris owned a small jewellery store. The year was 1890 and after several blunders, including an ill-fated attempt inventing an automatic nail-feeder, both swore off any more financial fiascos. The 1972 book The Harris Story tells us what happened next. It seems Charles couldn’t help himself when he got to talking to the next-door neighbour — the owner of the Niles Independent newspaper. Mr. Smith boasted he had just purchased a new state-of-the-art cylinder printing press that was still fed by a boy.

“You mean you’ve actually got to feed that press by hand?” exclaimed Charles. “Of course, but I can feed 25 sheets a minute,” said Smith. Unimpressed, Charles shot back, “No wonder you haven’t finished our handbills.” “Well, if you’re so damned smart, why don’t you build one,” Smith shouted back.

“This first working Harris automatic press was not an improvement, it was a breakthrough.”

So they did. After years of toil with liberal amounts of cussing and at times complete hopelessness, the two brothers succeeded in fashioning a crude feeding device that actually worked — well, sort of. Needing refinements, they sent it to the Carter machine shop in Niles to be built of iron. Charles took another job in town as the small jewellery shop wasn’t going to support two men with an expensive inventing habit. While Alfred ran the store, Charles continued improving the little feeder. By 1893, they had managed to save up enough money to send Charles to the Columbian World’s Fair in Chicago, Ill., where anyone who was anybody in the printing industry showcased their wares. Charles came back pumped. “There’s nothing there we can’t skin, Al, but you’d best go look too.”

Alfred was more methodical compared to Charles and he returned from Chicago with a lot of notes and sketches. This was when they also made another monumental decision to not only construct the feeder but also design a brand-new FAST printing press. This had to be revolutionary, for the Harris brothers were witness to the lethargic speeds and excessive manpower needed to print anything. Harris would

create a printing press no longer inhibited with a flatbed. The concept they came up with was a revelation. Machinery of this era was either platen (hand-fed) or cylinder with reciprocating beds — slow as molasses. Bed machines wasted so much energy having to stop and return. Rotational designs could run incredibly fast with less moving parts and even less energy. Today’s offset presses are a prime example of the rotary principle. There would be no limit on how fast they could go, provided the press had an automatic feeder. E.C. Fuller and Dexter was already experimenting with feeders using negative air via a piston pump but Harris would do it all without any air, and for the first time, on a printing press automatically.

In late December 1895, the Harris Automatic Press Company was incorporated. The fledgling affair was relocated to two rooms of the clapboard house where President William McKinley was born. On a spring night in 1896, a group of men huddled around a lamp-lit contraption and watched as Charles threw the drive belt onto a pulley. The damn thing worked!

“This first working Harris automatic press was not an improvement, it was a breakthrough,” according to The Harris Story. “At a time when printers were feeding 25 sheets per minute, the Harris automatically-fed press was able to print 250 per minute, 15,000 per hour.”

“We may starve to death in a gold mine. Cut it to 5,000 per

hour.”

The little press with a sheet size of 11 x 12 inches could feed envelopes, tags and cards only with a thickness of no less than 0.009 inches. As the first machines were

built, Charles headed for Cleveland to start selling what was now designated the E1 card press. One call was made to the J.B. Savage Co. After ending his sales pitch with the statement that the press would run 15,000 per hour, Savage burst out laughing. “When my new stock of leather medals comes in, you get the first one for champion romancer! Look, I’m very busy.”

On subsequent calls, laughter didn’t subside even when Charles started to roll back the claim. Now he was telling folks 12,000 impressions per hour. Dejected, Charles returned to Niles. “We may starve to death in a gold mine. Cut it to 5,000 per hour.” At this point the brothers reluctantly agreed to modify the press without the watershed automatic feeder, turning it into a hand-fed press! Harris would now offer two versions of the E1.

Finally a prospect — Brooks Printing in Cleveland, Ohio. Brooks would later be purchased by Bowne and eventually closed in 2011. The two Brooks brothers promised an order if Harris would put on a demonstration of the E1 running 5,000 per hour. Plus, they wanted Harris to pay for any wasted stock and keep the sale secret for six months. While Alfred contemplated the offer, Charles readily accepted, “Agreed!” On the press’s arrival, Charles struggled to set it up. There was a 12,500 run of government postcards waiting. Finally it was show time. The cards were flying out so fast, one of the owners hurried to call in his brother. Minutes later they both came back to discover over half of the run was finished. “How fast is that press running?” asked Brooks. “About fourteen thousand an hour,” the brothers replied. “I thought you said it would do five thousand an hour!” Shocked beyond

A MUST-ATTEND CONFERENCE FOR ALL PRINT PROFESSIONALS LOOKING TO BUILD THEIR BUSINESS

WHY YOU SHOULD ATTEND:

• Explore new technology trends and revenue streams

• Participate in engaging panel discussions

• Hear inspiring keynotes from print leaders

• See demos of new technologies and solutions

• Engage in valuable networking opportunities

Silver sponsor Founding sponsor

belief, Brooks forgot about the exclusivity agreement and ran off to get two competitors who happened to be visiting their office. History was made that day.

“If we advertised until doomsday!”

Continual improvements were made to the E1 over the next few years including attachments to feed multiple-up tags, diecut paper box blanks and paper bags. One unusual modification allowed the feeding of milk bottle (round) stoppers. Harris devised a second unit for numbering and perforating in one pass. But all was not well at Harris; strange things were occurring to their presses. Parts would mysteriously fall off, nails somehow fell from the ceiling and emery dust would find its way into the bushings on a lot of the sold presses. Sabotage was a worry — this revolutionary press had pressman, and especially feeders, fearing they’d be out of a job.

Then the marketing of the E1 turned out to be a nightmare slog through heavy bitumen. Word of mouth was slow to spread with most of the early purchasers mum about leaks to competitors. Even though Harris started spending a fortune on ads, few believed the claims. Many Harris ads took to chastising printers for being so narrow-minded they couldn’t see

what a revolution the E1 was. One advertisement, appearing in The Inland Printer, of 1900 railed: “If some people were not slow to catch on, there would be small chance for the more intelligent to get ahead in the race.” Topping that off with the heading: “If we advertised until doomsday!”

The Harris boys screamed it was so obvious the E1 would not only run like a banshee but eliminate gang-runs and multiple-ups on larger sheets. The savings on composition was mouth-watering. Oneup on the ‘Little Wonder’ equalled eight-up on a cylinder — wake up printerdom!

It wasn’t long before two roadblocks percolated to the surface with the E1. First it could only feed substrates with a minimum thickness of .009 inches. This was soon solved in 1900 with a new feeder that was specifically adaptable for thin paper.

But by far the biggest hurdle was something neither Harris brother considered — few of their customers used or had the equipment to make Stereos or copper Electros. Stereos were developed in the early 1800s and were a lead plate made from a Flong mat mold of foundry type. Large shops and large web/newspapers had the casters for this revolutionary plate but small-town printers, notoriously cheap, would not invest in casters, shavers

A photo from Harris Automatic Press Company in Niles, Ohio, demonstrating how simple it was to hand-feed the E1.

and routers. Without plates, the E1 was useless. Harris started offering equipment for plate-making as well as a curving device for electros. But that meant more money when the industry was still haunted by the Panic of 1893 depression.

Back at the Niles factory, the Harris brothers fashioned together a crude ‘type box’ which would replace the plate cylinder and hold normal foundry type. But with the E1 cranking out at 15,000, the type would jar loose and spray out like a burst steam pipe. The type box wasn’t a success and created the biggest downfall in massive sales to jobbing printers.

Regardless, spurred by some early E1 successes, Harris built a larger press in 1897 called the S1, or ‘Big Brother.’ The press would feed carton and paper with a larger sheet size of 16 x 20 inches. The S1 was almost as fast as the E1 too. In fact, a confidential company specification sheet notes that the E1 could even reach 18,000 sheets per hour. All told, Harris would build just 617 E1’s (1896-1932) and 449 S1 and S2’s (1897-1926) before ending production.

The S1 would open up an even bigger door when in 1904, Harris happened upon the

Muller Martini’s manufacturing philosophy, trademarked Finishing 4.0., does just that with machines and systems that are designed and engineered to help you compete within the variable world of today and tomorrow. Our forward-thinking finishing solutions efficiently and expeditiously accommodate offset, digital and hybrid printed products by creating end-to-end workflows, from file through finished product, that achieve the greatest quality—and even greater efficiencies. These efficiencies include reduced makeready and manpower, less waste, and faster speed to market, all the while significantly improving the experience of the product’s end user.

There is a demand for innovative print-finishing solutions for the digital and offset printing of long and short runs.

With Finishing 4.0 Muller Martini will underline the major importance of digital networking and end-to-end touchless workflow, from printing to distribution. Muller Martini is leading the way in finishing with the seamless integration of its solutions. Muller Martini – your strong partner.

magic of offset. During an installation of an E1 at the Enterprise Printing Company in Cleveland, Alfred would be witness to a commotion between a pressman and feeder girl over her misfeeding a sheet on a lithographic stone press. On examination, Harris noticed how much sharper the reversed image was compared to what was printed directly from the stone. Harris hurried back and by 1905, had modified the S1 with an additional blanket cylinder to become its first offset press: model S4L (L for litho). At the time Harris employed a German immigrant named Casper Hermann. Having arrived from Königsberg, Germany, in 1889, Hermann bounced around print shops in Baltimore and Richmond before ending up in Niles. Being witness to the new letterpress/offset S1, Hermann returned to Germany in 1907 where he would become the first German to build what was a copy of the Harris offset press – the Triumpf. Germany’s first offset press was a Harris! I only saw one Harris E1 and that was in 1982. I didn’t know what it was and was quite surprised to learn Harris ever made letterpresses. This ‘Little Wonder’ fascinated me. How could it be that such a trailblazing design had been forgotten in time? During the last few years, I tried to find another. Luckily I did, but in terrible

Harris print advertisements from The Inland Printer, a U.S.based printing magazine that first published in the early 1880s.

shape. Out of the blue I received a call from Richard Foley from Dayton. He had worked for Harris-Intertype and was a fountain of knowledge. He connected me with the Smithsonian Institution in Washington, who not only had the oldest E1 (in storage) but all the early records of the Harris Automatic Press Company. I spent two days rifling through documentation and original parts drawings, all drawn in ink on fabric. The museum was very gracious and is a big reason why today we have restored #259 manufactured in 1899. We’ll be printing on it too! A recreation of a Harris postcard franked in 1898 at Niles. The press doesn’t have any ball bearings or a vacuum pump. All it needs is a ½ HP drive motor. There are only five taper pins — everything else is keyed with set screws. The ‘Wobble Gear’ for oscillation of the inker drum started with this E1 as did patented feed-rolls for sheet register. The press could be tripped off impression if it missed a sheet — unheard of then, taken for granted today.

All of these Harris construction methods remained to the very last Redaelli Tecna Offset Aurelia that rolled off the line around 1996. Harris had sold off its sheetfed offset business to the Italians in 1975. The shuttle feeder remains the real piece of brilliance. If you have a mailing depart-

ment, take a look at the feeder. That device is thanks to Harris. Today’s manufacturers – Morgana, Kirk-Rudy, Sitma, Buhrs and Cheshire to name a few – use the Harris principle top-load-bottom-feed device. Groundbreaking as the ‘Little Wonder’ was, even though being proven, it still attracted naysayers and killjoys. Today’s current environment shows not much has changed since 1896; we often times refuse to open our eyes to new technologies even when they are staring right back at us. Harris would enter electronics in the 1950s and are now L3 Harris Technologies Inc., with sales of US$16 billion dollars — all with fond respect for the two jewellers in Niles who started it all.

A special thank you to Richard Foley, Harris, and Joan Boudreau, curator of the Graphic Arts Collection, National Museum of American History, Smithsonian Institution, Washington. She was patient and instrumental in assisting us to bring back a part of print’s history.

NICK HOWARD, a partner in Howard Graphic Equipment and Howard Iron Works, is a printing historian, consultant and Certified Appraiser of capital equipment. nick@howardgraphicequipment.com

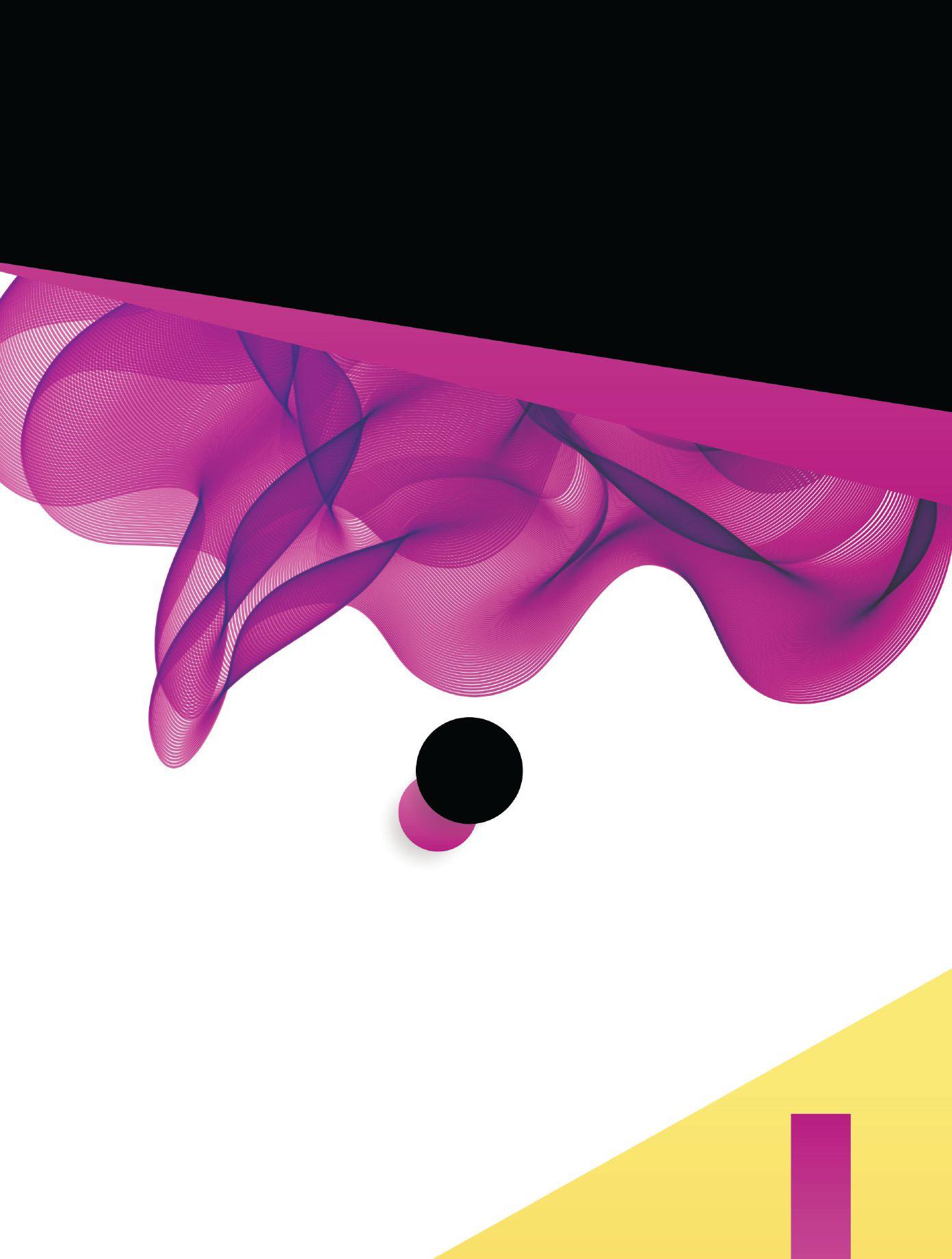

Digital cutting at an industrial level .

Over Cutter Camera OCC system: now available for all Zünd cutter series (G3/D3/S3)

– Powerful 3.6 kW RM-L with auto tool changer for exceptional routing productivity

– Fully automated BHS150 Board Handling System

PNH Solutions supplied thousands of wall-mounted Silicone Edge (SEG) fabric frames and lightboxes for Swatch stores across North, Central and South America, from 2013 to 2015.

By Victoria Gaitskell

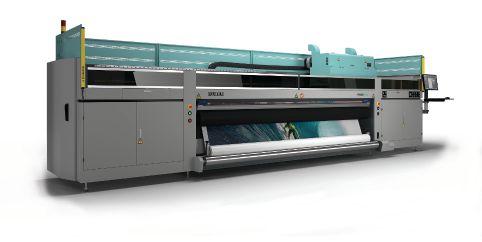

Whether it’s an event poster, indoor or outdoor signage, vehicle wrap, storefront decal, tradeshow graphic, wall mural or architectural drawing – to name a few – we can find wide-format printing all around us. Also known as large-format printing, it is a print application that remains a top marketing solution. In this report, Simpson Print and PNH Solutions explain how printing companies can leverage wide-format technologies to keep pace with six top marketing trends.

“Marketing is becoming increasingly complex, and you must become fluent in omni-channel marketing to be able to

explain to clients how they benefit from print,” Carla Johanns, President at Simpson Print of Bloomingdale, Ont., says.

“Our company understands that today’s brands are aiming to attract shoppers to both their online and physical retail environments. Recent studies show consumers who shop both online and in-store have a 30-percent higher lifetime value than those who shop using only one channel. This concept has prompted our acquisition decisions over the last 12 months.”

In February 2018 the company installed a new swissQprint Nyala 2 LED wide-format inkjet system and just 12 months later in February 2019, a Nyala 3 to complement its arsenal of screen printing presses, a 40-inch Komori LS640 UV press, and digital presses, including a 6-colour HP Indigo. The range of products currently coming off the Nyalas in-

PNH Solutions supplied dyesublimated fabric banners for the stage backdrops used in both the opening and closing ceremonies of the 2016 Invictus Games in Florida.

cludes displays, temporary and permanent signage for retail environments, packaging, hoarding (temporary fencing used on construction sites), and custom installation work.

“For 50 years we were strictly a sheetfed environment, so it is quite a dramatic shift for us to be exploiting the new equipment’s option of printing roll to roll,” Johanns says. “In my opinion, brand owners will still want to align themselves with a traditional screen printer for their evolving wide-format requirements. Screen printing will remain a viable production method for at least another five to 10 years and is still more cost-effective for quantities above 250 pieces.”

“We want to fill the demand for customers who want more unique displays that are different from what have been done before.”

Johanns observes that new trends in retailing are leading to shorter, higher-priced runs more suited to digital wide-format equipment. “In 2012 customers were coming with a plethora of brick-and-mortar stores and would place an order for 300 T-stands and 300 banners or 1,500 kits sent to 1,500 stores, but now retail is changing. There is more customization and interest in enhancing the retail experience for consumers. Retailers are spending more money on fewer locations, as major brands like Lululemon and Under Armour enter the pop-up space.”

Pop-up retail is the trend of temporary sales establishments that emerge for a few hours, days or weeks, creating a new touchpoint for brands to engage with customers. This opportunity allows businesses to experiment with short-term sales strategies without having to invest in a permanent location.

Johanns says the other feature that attracted her to digital wide-format technology is its ability to print on a virtually unlimited number of substrates, including plastics, metals, fabrics and composite materials. Additionally, digital colour-management systems enable 100-percent matching of Pantones to meet the exacting requirements of major brand

owners, she adds. Inks for digital wide-format applications have also improved substantially; Johanns says the most robust digital inks are now better for outdoor applications because of their sun-fast properties. She explains Simpson Print is “very much a coatings company,” so she was attracted to the fact that special effects, such as deep glitter, lenticular or raised UV, can be accomplished through prepress manipulations on her swissQprint equipment.

“From an ecology perspective, UV LED is important because the process is highly efficient and generates half the energy footprint of screen printing, while still mimicking the same high-quality ink saturation as screen,” Johanns says. “Environmental sustainability is where you need to be now.You need to show how much you care about your green footprint. Brands are telling us it’s important, and when players like Carlsberg are eliminating beer six-pack rings to tackle plastic pollution, you need to be concerned as a vendor.”

In particular, it is the younger generations of consumers who have or are now growing up in a scary world with a struggling economy, and tend to prefer environmentally or socially responsible businesses that make the world a better place.

PNH Solutions supplies wide-format print and custom hardware for events, retail stores, museum exhibits and tradeshows. Its past jobs include scenic elements for Toronto’s 2015 Pan American Games; the 2016 and 2017 Invictus Games; the 2016, 2017 and 2018 Toronto Honda Indy; the 2017 Victoria’s Secret Fashion Show; and the 2018 and 2019 Super Bowl.

The last two years have been especially big years for PNH with the expansion of both its Dorval, Que., and Concord, Ont., production facilities to serve bigger contracts and more complex custom work. The expansion included the introduction of three new departments – metalwork, woodwork and electrical – in its Dorval location.

“Our business is moving toward more custom work. We want to fill the demand for customers who want more unique displays that are different from what have been done before,” Katherine Hudon, PNH Solutions Marketing Coordinator, says. “We’re not the cheapest. We’re well aware of that, but we market our products as high quality — not a single-use tent frame with plastic parts that you can buy cheaply. Our other value-added propos-

ition is that we can be a lot more flexible in what we offer, and we are able to customize products fully in-house.”

She adds that customized printed flooring is a product that has boomed lately. “It used to be popular to print on carpet, but the disadvantages are that it is heavy to transport and relatively hard to clean, so it’s not the most practical thing — especially in Canada where people come inside wearing slushy boots in the winter. Polymer flooring has become really popular because it is lightweight, cleans easily, and lasts for long durations of time. For example, we covered the floor of a big lounge in Montreal’s Saputo Stadium with the branding of the company that sponsored the lounge. The flooring stood up to frequent cleaning and the foot traffic of everyone attending games twice a week for a full season and is still in really good condition.”

Hudon says it is becoming increasingly common for agencies to organize pop-up brand activation events in shopping malls and in other public areas as a way to attract customers. “People say retail is in decline because of online shopping, so brands are trying to encourage customers with interesting types of promotions and incentives to come back into physical retail environments.” Accordingly, PNH’s projects in the recent past have included booths for pop-up brand activation events for Money Mart, Polly Pocket, Pizza Pizza, McDonald’s, Tropicana and Hyundai.

Another goal of today’s approach to marketing is not just to place information in front of consumers, but rather to inspire them or provoke their thoughts and feelings to the point that they will engage with or share the brand’s content.The resulting two-way communication is regarded as crucial for building trust, genuine relationships, and enhanced experiences that today’s consumers are thought to be seeking.

“One booth we did last year was for a video game company introducing a new game in Las Vegas. The interior of the booth had screens built into it that brought visitors inside the booth to test the game. The exhibit left a much stronger impression on people because they had that experience,” Hudon recounts.

She says 3D installations are also huge for promoting interactive consumer experiences. Last year for Cineplex, PNH built two giant 3D pieces – a soda can and popcorn bag – that were installed in malls across Ontario and used enthusiastically by moviegoers as selfie props. Another of its past successes for Emporio Armani involved creating a huge 3D backdrop with part of a car emerging from it. Consumers could take photos with stylish brand ambassadors in front of the backdrop to share on social media

Exhibitors of the April 11-13 tradeshow provide their best booth highlights for attendees to focus on

*For a complete listing of Graphics Canada exhibitors, please visit www.graphicscanada.com.

Web-to-print software and website provider Amazing Print Tech will be presenting live demos of its ePrintDesigner software. The Canadian solution aims to save users time from preflight, data entry and billing, while letting print end-users design online and upload their artwork directly. The solution also enables users to print in-house or outsource to trade providers, the company explains. The customizable ordering technology can be used as an add-on to an existing website or as a stand-alone website.

Arrow Systems is highlighting the Anyjet, describing it as a new system that allows users to print labels in 1600 x 1600 dpi, laminate and die-cut them in-line on a tabletop system. The Anyjet uses the Memjet platform for high-resolution printing and pairs it with the Anycut laser technology, designed for a simplified workflow. In addition to the Anyjet, Arrow Systems will also show the Any-002, a LED toner-based printer. The Any-002 allows users to print high durability GHS labels in full colour. The Any-002 also allows for the use of pre-cut labels or continuous labels to be cut after printing. The system utilizes a variable heat fuser to allow printing on a variety of substrates, including PP and BOPP.

From order entry through to production and billing, the goal of Avanti Slingshot is to help users work more efficiently, control their costs and move more jobs through their shop with ease. In addition to providing an integrated MIS platform, Avanti describes its staff as experts in connecting best of breed software (i.e. prepress, production automation software) to Avanti Slingshot, with the goal of enabling reduced breakpoints in workflow and lower costs, while helping to get customers the information they want.

Cambridge Label will debut its new laser die-cutting capabilities for die-cutting special shapes without the need for cutting dies or tooling. Additionally, Cambridge Label will be featuring a new sample package that showcases high-quality digitally printed labels, long-run flexo labels, foil-stamped labels and more. The Ontario-based trade printer says the selling piece is a “great tool” for label resellers to use when selling overthe-counter or in a face-to-face environment.

Canon Canada intends to have over 100 applications on display with its diverse portfolio of flatbed printers, sheetfed presses, web presses and wide-format roll printers, as well as UV gel and LED curing print technologies. Also present at the 4,500-square-foot booth will be the company’s imagePROGRAF PRO-6000S, imagePROGRAF TX-3000 MFP T36, Color imagePRESS C10000VP, Prisma Solutions, Color imagePRESS C850, Océ Arizona Series, Océ Colorado 1640 and Océ ProCut Series.

The DocketManager System is a Cloud/Software-as-aService (SaaS)-based print management solution with a fully integrated web-to-print system. DocketManager boasts unlimited portals designed exclusively for the printing and graphic arts industry and is integrated with the MIS system. DocketManager explains the solution includes a complete suite of modules for customer management, estimating, production, accounting and e-commerce, all combined in a single integrated solution, and features a browser interface that doesn’t require installation of a software locally.

Founded in 1978, Domino is a manufacturer and distributor of digital printing and product identification solutions. The group operates a global network of 25 subsidiary offices with 200+ distributors, employing over 2,500 people worldwide with manufacturing facilities situated in the U.K., China, Germany, India, Sweden and the United States. In June 2015, Domino became an autonomous division of Brother Industries Limited.

Epson will be showcasing the Epson SureColor S-Series solvent-based printers, introducing the Epson SureColor F-Series Dye Sublimation printers, and demonstrating the Epson SureColor T-Series printers, all of which leverage the MicroPiezo TFP printhead. Other products on display include: Dye sublimation solutions – SureColor F6200 (44 inches) and SureColor F9370 (64 inches); solutions for proofing, production, indoor signage – SureColor P5000 (17 inches), SureColor P9000 (44 inches), SureColor P20000 (64 inches) and SureColor T5270 (36 inches); solvent solutions – SureColor S80600; and solutions for colour labels – ColorWorks C7500G and ColorWorks C3500.

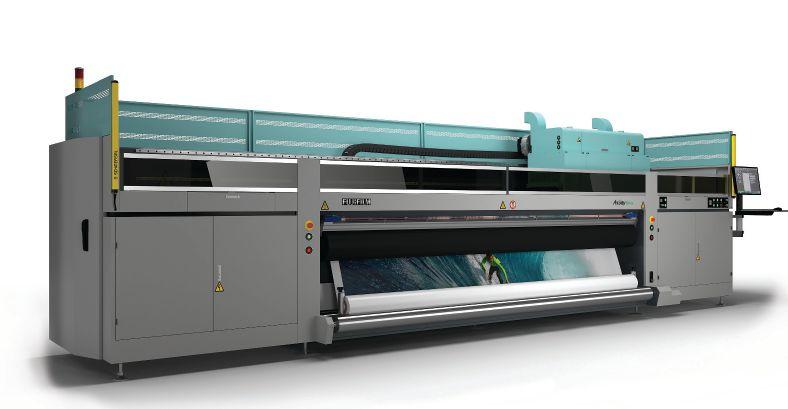

Making its Canadian debut is the new Acuity Ultra, a highspeed, superwide UV roll-to-roll press for the production of high-end interior graphics and outdoor signage. The Acuity Ultra Series is available in 126-inch and 197-inch versions. With a 3.5 pl drop size, the Acuity Ultra is best suited for the indoor display market, especially for luxury brands, with the quality comparable with litho and water-based ink systems, Fujifilm says.

GMG will show its range of colour management tools, featuring GMG OpenColor which it describes as an easy-to-use multi-channel profiling software to characterize offset, flexo and gravure printing processes with 10+ ink colours without extensive fingerprint data. GMG OpenColor can create GMG DotProof profiles with spot colours for special substrates, such as foil or metal, and aims to achieve reliable colour matching. GMG SmartProfiler is a supporting software-wizard developed to calibrate, recalibrate and profile digital, large-format and traditional printing systems without advanced knowledge. With centralized colour management, different front ends, RIPs and printing processes no longer need to be individually configured and synchronized, the company explains. The GMG ColorProof solution comes pre-loaded with colour profiles of all common standards, so users can get started right away.

GVDirect will display the Komfi Amiga 52 FK. Fully equipped with sheet preheat, flying knife sheet separation, and an over-toner foil option, the Komfi Amiga 52 FK features a deep pile suction feed that allows for unattended laminating on sheets of up to 20.5 x 31 inches in size.

The new HP Latex R-Series aims to help users achieve “amazing colours” on rigid and flexible substrates with the vibrant HP Latex colour gamut on rigid, and prints with no smell, HP explains. The HP Latex 335 Print and Cut solution was developed to work two times faster with an end-to-end solution that enables printing and cutting at the same time. Meanwhile, the HP Designjet z9+ printer with vertical trimmer prints up to 2.5 times faster without losing quality, with high-definition printheads, HP says, noting that the integrated vertical trimmer reduces post-processing time by up to 20 percent.

Konica Minolta’s recently launched AccurioWide 160 and 200 wide-format printers will be on display for the first time in Canada. The AccurioWide printers employ a hybrid technology platform that can print on most roll-toroll, flexible roll and rigid media, enabling the production of traditional signage and displays as well as more niche applications. Also premiering at the show is the new digital label AccurioLabel 190 and PLS-475i and packaging PKG-675i printers. The AccurioLabel 190 boasts “outstanding productivity, exceptional image quality and ease of use for personalized and print-on-demand jobs.” The Precision Label Series PLS-475i offers continuous roll and pre-die-cut media printing up to 9.0 inches on a variety of materials. The PKG-675i prints on flexible packaging, as well on corrugated materials, such as cartons, displays and traditional boxes.

Esko will present solutions designed to make packaging and label print production workflows more productive while connecting everyone in the supply chain. Automation Engine, Esko’s workflow server, aims to automate prepress tasks, speed up the process, reduce the error rate and the need for operator intervention. Automation Engine automates workflows for various printing technique (digital, flexo and offset), and as such, one production workflow can feed all presses, Esko says. WebCenter brings all stakeholders together on a web-based platform to help streamline and control print projects from specification and execution to design and content management. It manages approval and project lifecycle for brands and printers alike. Meanwhile the Kongsberg portfolio consists of two types of digital cutting tables based on the type of work produced: Flexibility for versatile jobs (Kongsberg X) or productivity for efficient production runs (Kongsberg C).

At Graphics Canada, miip, a manufacturer of vision systems for the printing industry based in Saint-Hubert, Que., will exhibit its flagship viewers: The miipCam and the miipCam Mini. The company explains all products are designed and assembled in Canada.

Attendees can see Mimaki’s array of digital printing solutions for the sign and graphics, textile and apparel, and industrial segments. This includes the UCJV300-160 that offers in-line cutting capabilities and layered print technology. In addition, the JFX200-2513 UV-LED flatbed, the UJF-7151 plus direct-to-object flatbed, the CF22-1225 wide-format cutting plotter, the UJV55-320 superwide UV-LED printer will also be on display. Attendees can learn about Mimaki Microfactory complete application workflows and receive hands-on experience with the company’s products.

1x Mitsubishi 40” 10 Colour Tandem with AQ

1x Mitsubishi 40” 8 Colour Tandem with AQ

1x Mitsubishi 40” 8 Colour Perfector with AQ

3x Mitsubishi 40” 6 Colour with AQ

2x Heidelberg Printmasters

3x Saddle Stitchers / 1 Perfect Binder / 10+ MBO Folders

Over 75,000 sq ft plant housing state-of-the-art finishing and bindery

Personalized account management and complete control over production

24/7 Production with fully automated and barcode controlled plant

FSC / PEFC / SFI certified

A wholesale distributor for graphic supplies with over 15 years of experience, OMZ Graphic Supplies specializes in wide-format digital printing media, laminates, tradeshow displays, banner stands and more. It maintains an inventory in Mississauga, Ont., and says it is dedicated to providing high-quality products with the latest print technology and applications.

The Touchline CP375/TCF is a creasing, folding and perforating system capable of performing up to 20 creases and 20 perforations simultaneously in a single run. Utilizing 600 x 600-dpi inkjet technology, UV lamp curing and camera image registration, the Duplo DDC-810 digital raised spot UV coater applies a gloss varnish to designated areas of the substrate. Equipped with Duplo’s air suction feed system, it handles maximum paper sizes of 14.33 x 29.13 inches up to 450 gsm. Anytron digital colour label printer Any-002 features a 600 x 1200-dpi colour laser engine for printing on continuous media up to 8.5 inches wide.

On display at the Racad Tech booth are W2P Cloud, W2P Shop Editor for Shopify, and W2P Shop uDRAW Editor. The W2P Cloudopen architecture circumvents design, functionality, workflow and template limitations as the system can integrate with multiple platforms, display multiple templates and communicate with any MIS/ ERP system, Racad Tech says. Its features include: easy setup and management of online stores; pre-approved templates that can be created, edited and stored; and automatic routing mechanisms to multiple production locations. W2PShop PDF Editor for Shopify combines an e-commerce system with web-to-print technology, letting customers add their own text and images to the product template, proof it and then order it. W2P Shop uDRAW Editor is an online HTML5 graphics editor that allows users to create and edit different products. Its capabilities include: editing text, size, font, colour and curvature; adding and manipulating images; controlling canvas and document sizes, bleeds, crop marks; and enabling QR codes.

The Ricoh product portfolio is expanding with its new graphics wide-format latex printer series. Suitable for signs, banners, vehicle wraps and indoor and outdoor displays, the Ricoh Pro L5160 wide-format roll-fed latex inkjet printer leverages Ricoh’s Greenguard-certified latex inks and printheads. It prints up to 473.6 b2/hour in outdoor standard mode and 270 b2/hour in indoor standard mode. The company will also display the Ricoh Pro C7200 Graphic Arts Edition, which features a fifth colour station for clear, white, neon yellow, neon pink and invisible red toner. It boasts outputs of up to 95 ppm colour and B&W, monthly volumes of up to 240,000 pages, and support for oversized sheets up to 13 x 49.6 inches and auto-duplex up to 13 x 27.5 inches. New to Canada is Ricoh Clickable Paper, an augmented reality solution that invites users to “go beyond” CMYK by transforming static printed materials into an interactive, crossmedia experience.

Roland DGA plans to unveil new additions to its TrueVIS and VersaUV printer lineups at Graphics Canada 2019. In addition to being among the first to see these next-generation devices in action, attendees can get a firsthand look at the recently launched VersaSTUDIO BT-12, the company’s first direct-to-garment printer which is designed to make printing detailed graphics directly to cotton apparel easier. Roland DGA will also be demonstrating its newest benchtop rotary engraving machine, the DGSHAPE DE-3.

Significans Automation, a Toronto, Ontario-based professional services company, aims to bring next-generation efficiencies to the graphic arts industry with custom automated workflow development, colour management, prepress training, and business integration services. It will debut a series of customizable software modules that aim to enhance productivity, boost business capacity, enable unmanned production capabilities, and bring efficiencies to business communications, project management, scheduling, estimating and systems integration. The following modules will enhance remote automation in production, it explains: Turbine – for automating without a data trigger; and Right-Art – for automated preflighting and artwork clean-up.

As part of SinaLite’s celebration of its 20 years in business, the Canadian wholesale trade printer will showcase new roll labels and specialty business cards, a move it says will help printing companies “earn more than ever before.” SinaLite now offers printed roll labels that come in paper, polyester and BOPP, as well as custom-shaped silver foil labels to waterproof clear labels with white ink printing. SinaLite will also present specialty business cards printed with gold and silver foil, 100-percent recycled kraft paper, shimmery pearl paper, and durable waterproof stock.

Southwest Binding Systems has changed its name to Southwest Business Products, describing it as an all-encompassing business brand that communicates its Canadian heritage and the fact that it offers multiple business products, not just document binding. At the show, it will highlight the Tornado EX AutoPunch Machine, an all-in-one punching machine that automatically feeds, collates and punches. It is designed to save up to 40 percent in process efficiency, helping to reduce overall costs, the company explains. Also on display is the Koilmatic Auto Inserter Crimper, a fully electric tabletop automatic coil inserter designed for the digital print market. The system binds up to 450 books an hour. Show visitors will also see the ICON Foil 1-sided 13-inch laminator for either hot or cold laminating, foil fusing, and single-sided laminating.

ONE-STOP SHOP — Die Cutting, Bindery, Data & Lettershop.

2. SUPERIOR TECHNOLOGY — Die crease without a die, then fold and even glue all on the same machine, up to 30 pt.

3. INTEGRATED MODULAR UNITS — Combined in-line finishing: crease, fold, glue, tipping, envelope inserting, ink jetting (Duplex), clip seal (3 sides), mail prep.

4. SAVE ON POSTAGE COSTS As a Certified Canada Post Direct Marketing Specialist, we get contract pricing reductions.

5. RETURN MAIL PRODUCTS — Customized “Return Mailers” created in-line with “U” or “BOX-shape” remoistenable glue, time perfed applications and envelope formation.

6. MINI-BOOKLETS — Saddle-stitch and trim 2-up booklets in-line to the size of a business card. No need to trim off-line, or do 2 passes.

7. HIGH SPEED EQUIPMENT — High speed Tipping, Folding, Saddle-stitching and soft folding ensuring on time delivery.

The En/Press Digital Multimedia Press aims to provide users with an affordable way to go digital. Driven by iQueue Simply Brilliant Workflow technology, it was designed to print envelopes but was eventually made to be an all-in-one solution for the digital print shop, Sydney Stone explains. The Morgana DigiBook 450 perfect-binding machine is suited for litho and digital printers that require medium to long runs of PUR perfect-bound books, and is equipped with a closed gluing system where the spine and side glue is applied by a slot applicator. Also on display is the InstaFoiler18 for single- and double-sided lamination, thanks to the built-in decurl bar, as well as mounting and foiling.

Making its Canadian debut is the Ultimate Impostrip 2019, which aims to revolutionize the way print service providers automate their impositions through its speed, flexibility, automation and intelligence, the Quebec-based company says. The new features and benefits expected in this version include Intuitive User Experience, Imposition Agent for flat and bound work, Advanced Dynamic Preview, Enhanced Mark Design Capability, and Speed Records.

With the Xerox Versant 3100 Press, businesses can lower costs and turn around jobs faster through automation, removing time-consuming tasks, Xerox says. Printing at speeds of up to 100 pages per minute on stocks up to 350 gsm, the Versant 3100 boasts high image quality and performance, along with advanced in-line finishing capabilities. Introduced last year, the Xerox Iridesse Production Press is described as a high-speed, six-station colour press that combines four-colour printing with up to two specialty dry inks in one printing pass (silver, gold, white and clear inks), and is described as the only digital press that can print six colours in a single pass.

Made in Canada, YUL Technologies will showcase its most recent electric paper cutter models available in four formats: 17 1/8 inches, 19 1/8 inches, 22 1/8 inches and 26 1/2 inches. Boasting a small footprint, low energy consumption and ease of operation, YUL cutters feature an intuitive interface designed to help shorten the learning curve for newly hired employees as well as various safety devices.

Zünd manufactures multifunctional digital cutters for sign and display graphics, packaging and other industrial applications. Its booth will feature some of the company’s latest developments, including the Zünd Over-Cutter Camera system OCC, a registration system that captures register marks in one shot instead of having to travel to each one. Also on display is the 3.6kW routing system RM-L with automatic tool/router bit changer, designed for little to no operator intervention. The G3/S3 and dual-beam D3 are described as modular, highly adaptable finishing solutions with multiple tool choices and easy-to-use workflow software. Set up for tandem operation, the system boasts a smart production workflow for non-stop operation with loading/unloading and processing of materials occurring on alternating halves of the cutting system.

Full time Press Operator required for busy print shop in Hamilton area. Must have the ability to run Heidelberg Inpress Controls and run a Heidelberg press with coater.

Successful operator must have the ability to operate machine without supervision and have excellent work habits. Wages + Benefits. Email resume to: printjobber@gmail.com

Skilled bindery operator required for busy Hamilton print shop. Must be able to lift heavy stock piles and run a Polar 78 Guillotine and run a Stahl 78 Baum folder. General knowledge of finishing requirements a must. Also must be self-motivated. Hourly wage + benefits.

Email: info@pinnaclelitho.com Tel: 905-662-6724

Heidelberg: K-Line/S-Line/Speedmaster/GTO/MO/KORD64

Komori: 1, 2, 4 or 5 colours & any size

Adast: 714/715/724/725

Mitsubishi: Any model

Ryobi: 2800CD/3200CD-MCD/640K

Itek: 960/975/985

Hamada: 600/700/800/E47/RS34

Shinohara/Fuji: 66/65 1,2 or 4 colours

Sakurai: 1, 2 or 4 colours and any size (newer model)

Polar: any size/older or newer models (66/72/76/78/82/90/92/107/115)

Horizon-BQ: 220/240/260/440/460

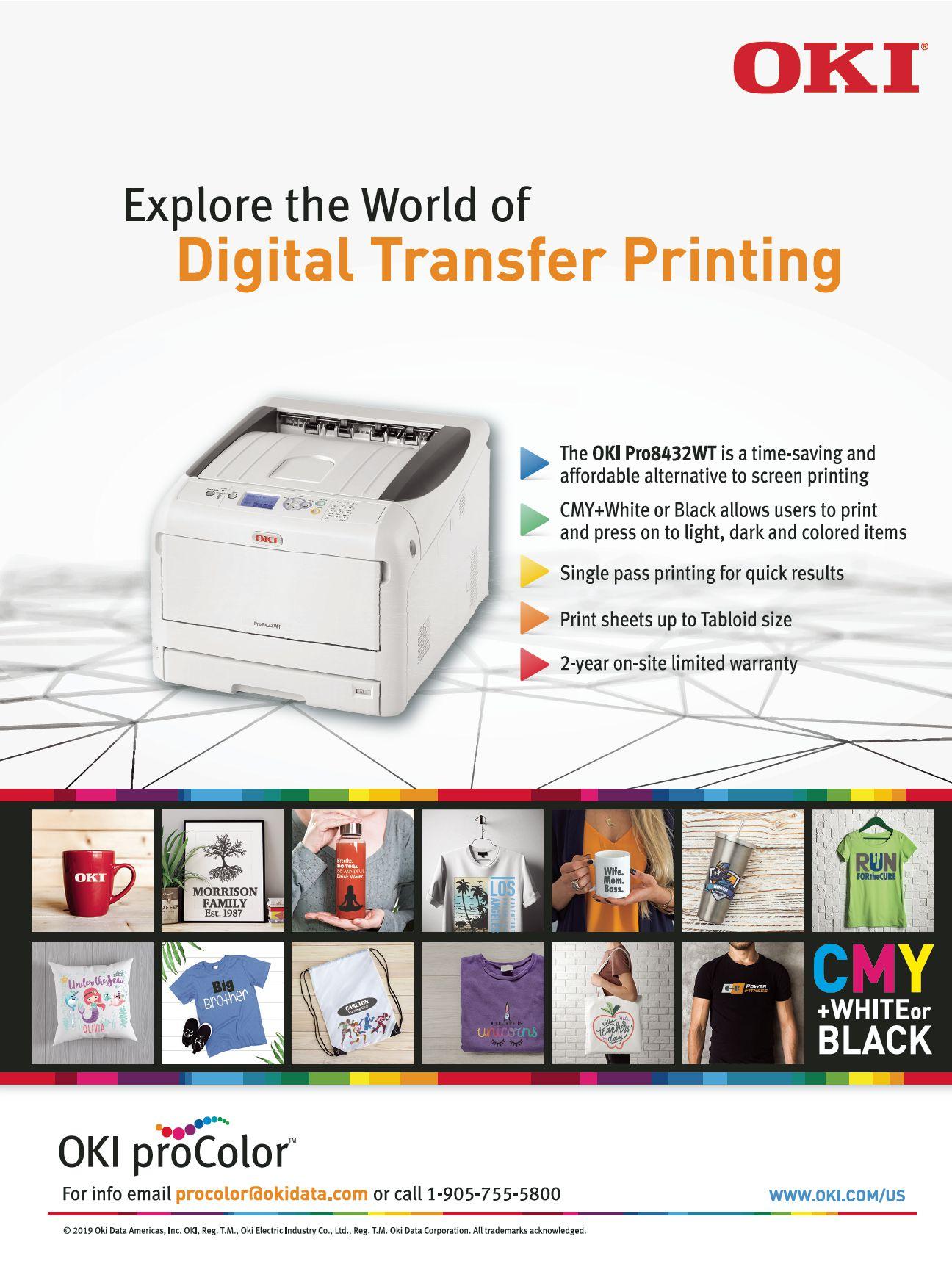

From its establishment in 1989, flexible packaging manufacturer Alpha Poly has focused its business on its commitment to customer service and quality, plus the use of up-to-date HD technology. A push for strategic investing led Alpha Poly to install a large 8-colour Miraflex AM from Windmöller & Hölscher in 2013. Then in December 2018, Alpha Poly ushered in a new wave of strategic investment with the installation of a Windmöller & Hölscher Miraflex II 10-colour press. PrintAction spoke with Patrick Kerrigan, President of Alpha Poly and successor to the business’ founder, his father Paul, to discuss this newest installation, his thoughts on the industry and the company’s strategic investment plan.

PA: What does the new installation mean for Alpha Poly?

PK: Number one for us is to always bring on more capacity and look for growth — strategic planning is important for us [and] allows us to continue to grow. It also adds greater capabilities by moving us from and being able to print up to eight colours. Now we can print up to 10 colours and capabilities wise, that’s great as designs get more complicated and the requirements for those stations. Also, bringing on more capacity as we look to grow as well. It brings us a huge amount of capacity as we look to grow our business.

PA: What is Alpha Poly’s long-term investment plan and vision?

PK: We have a pretty aggressive strategic plan over the next four years of imminent growth, and this is one asset of a multiasset capital purchase over the next four years. There is significant capital in other areas in pouch-making and lamination that we’ll look to in the next few years.

When we look at where we want to go and what we want to do, a big thing for us is we’ve moved into the markets of multi-laminate, rollstock, and stand-up pouches. We look to continue to grow that area and that segment because we see that as an area of growth where we traditionally had passed various focuses on print and poly bags. We find that the laminate market is the growth segment. That is, strategically, where we’re focusing on.

You hear about employee engagement, atmosphere and environment. For me, a big thing is that we’re a family business, but I look at it as it’s an overall family business for everyone who works here and their extended families. My dad’s always been a visionary and he’s always been looking at the next thing. Taking over from him and continuing in his vision is also important to me.

The North American food and drink market is expected to see a 19.6-percent increase in demand for packaging by 2022, according to Smithers Pira.

PA: Are commercial printers focused on packaging growth?

PK: Most of the people who play in our space, they’ve been set up to do this type of packaging. We’ve always done packaging from a flexible standpoint, it’s not like we were in corrugated and decided to move over into plastic. We’ve targeted an area of stand-up pouches as an area of growth. So that’s why we’ve invested assets that allow us to continue to sell to those segments. I don’t have experience with other converters that weren’t in this market that are moving into it — it’s more so adding capabilities to grow in that segment.

PA: Why should traditional commercial printers diversify into the packaging space?

PK: For us, as an example, we’re primarily in the food market and food manufacturers. We’re finding that a lot of companies are moving away from rigids – like glass and plastics – and moving toward more laminated and pouch, stand-up pouch or rollstock to help with shelf presence and reduce costs. Rigids can cost a lot of money in terms of their prices, but also their storage in their warehouse, storing the goods before they are packaged, and from a shipping standpoint. There are a lot of

advantages to moving toward that kind of growth.

PA: What growth do you see in the sector when it comes to flexible packaging?

PK: I think the number that we’ve thrown around is that the American market grows by about five percent a year, which is pretty significant. For us, we’re looking for growth in the range of 20-percent plus. That’s the kind of growth we’re looking for.

Another thing, in terms of strategic planning, is that the U.S. market is huge for us. We have sales representatives in the U.S. selling for us, that part of strategic planning where we see a lot of growth in the U.S. market.

PA: What are the key factors that are driving this growth?

PK: I think the U.S. economy is growing, they’re on a roll, and I think that helps. I think transitioning from rigids and such over to flexibles is big, as well as consolidation with our customers. What we find is when there is a lot of consolidation acquisitions happening, that opens up the door to get things moving.

By Stefano Ruccia

Visit our booth and see the unveiling of Ricoh’s New Graphics Wide Format Printers:

• New 64” Roll-to-Roll Latex Inkjet

• New 4’x8’ UV Flatbed Inkjet both featuring blazing speeds, versatile print applications, and outstanding image quality

There’s never been a better time to take your business further with Ricoh. Request more details by visiting info.ricoh.ca/BeyondCMYK Go Beyond CMYK with Ricoh at the 2019 Graphics Canada Expo

Come see our latest & greatest innovations designed for the Commercial and Industrial Print industry at Canada’s Largest Production Event.

Register now for your FREE exhibit pass by using promo code: RICOH19GC at info.ricoh.ca/graphicscanada2019 2019 Graphics Canada Expo April 11-13 | Booth #5300 Toronto International Centre

Unlike anything currently available, the Acuity Ultra produces almost photographic quality at unprecedented speeds of up to 236 sq. m. per hour, ideal for high-end interior graphics. And with a new low film weight and high-density UV ink, running costs are impressively low. Capable of printing on up to three 160 cm rolls simultaneously, as well as graphics up to 500cm wide, the Acuity Ultra is set to become the new superwide standard.