Building brand trust

Effective brand marketing is a result of personalized packaging, print and digital communications, and a swift social media strategy

By Alyssa Dalton

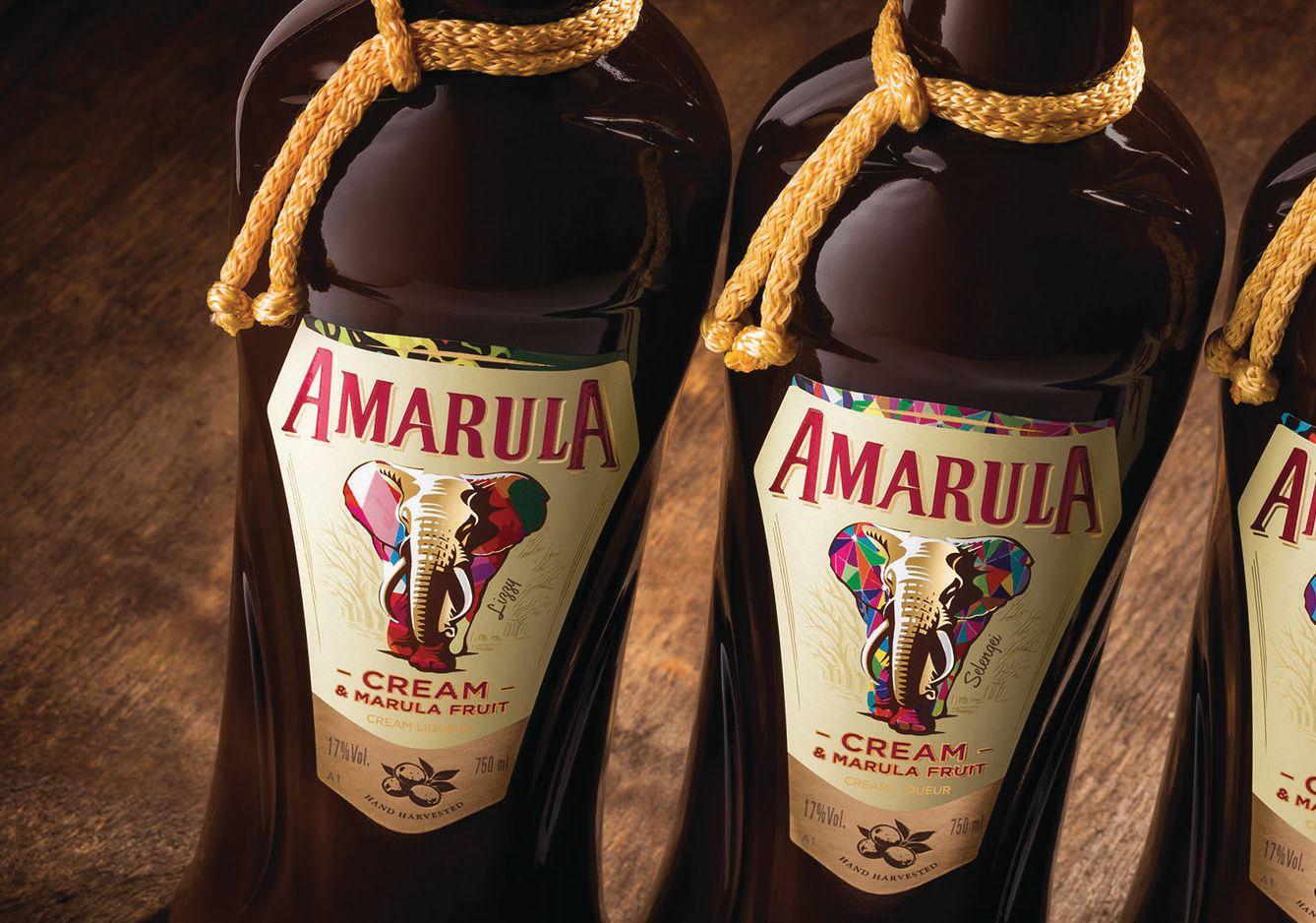

Earlier this year Amarula Cream Liqueur released a special edition bottle collection with its wellknown elephant branding individualized by HP Indigo digital printing. The first stage of the ‘Name Them, Save Them’ campaign raised awareness of the African elephant as an endangered species by letting consumers visit a virtual African savannah where they could design and name a one-of-akind African elephant. In turn, these consumer-produced designs were used to decorate individualized labels on 400,000 Amarula bottles — one bottle for every African elephant still surviving in the wild.

In collaboration with HP, SA Litho, a Cape Town-based label producer, transformed the bottles into unique pieces using an HP Indigo WS6800 press with HP SmartStream Mosaic variable design technology, leveraging two seed patterns in a variable design software algorithm. In less than a week, SA Litho completed the printing of

the 400,000 labels, HP explains, which was produced on a metallic substrate using ElectroInk CMYK and white.

saving our elephants.”

77%

A 2018 Cone/ Porter Novelli

Purpose study found 77 percent of respondents feel a stronger emotional connection to purpose-driven companies over traditional companies.

“Individualizing Amarula bottles is a powerful way to reinforce the message that every elephant is an individual with a unique personality,” said Saramien Dekker, Global Marketing Manager for Amarula.

“This campaign is about creating a connection between humans and elephants, and becoming actively involved in raising awareness and

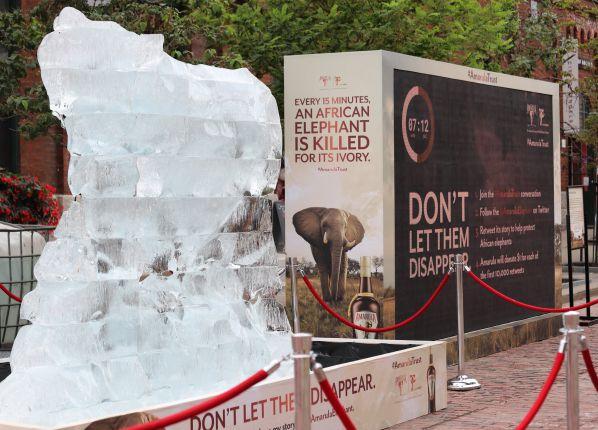

In partnership with conservation group WildlifeDirect, Amarula recently launched its latest campaign initiative, ‘Don’t Let Them Disappear,’ in countries around the world, including South Africa, the United States, Brazil, Germany and Canada. On August 12, World Elephant Day, a life-sized elephant ice sculpture – consisting of roughly 103 blocks of ice and weighing an estimated 9,344 kilograms – appeared in Toronto’s Distillery Dis-

“Companies that lead with purpose will stand to build deeper bonds with existing consumers, expand the consumer base and enlist those brand advocates to share the brand message.”

trict. Over the course of the day the ice sculpture slowly melted in the summer heat, symbolizing the rate at which African elephants are being killed for their ivory.

A week prior to World Elephant Day, the @AmarulaElephant Twitter account and hashtag #AmarulaTrust launched, giving a voice to the elephant ice sculpture so it can share its story and spread the word about the disappearance of its brothers and sisters in Africa in real time, before disappearing itself.

The liqueur company’s wildly popular, global campaign on African elephant preservation and protection is a testament to the brand’s effective marketing tactic, promoted through a mixed media campaign supported by personalized packaging, print and digital communications, and a swift social media strategy.

Branding not only drives consumer sales, it also serves as a powerful company differentiator. A recent Cone/Porter Novelli Purpose study found 77 percent of survey respondents feel a stronger emotional connection to purposedriven companies over traditional companies, while 78 percent believe companies must do more than “make money” — they need to positively impact society as well.

“In fact, companies that lead with purpose will stand to build deeper bonds with existing consumers, expand the consumer base and enlist those brand advocates to share the brand message,” states the research report.

A July 2018 article published by Kantar TNS, a U.K. research and market information group, looks at how brands can inspire trust in to-

According to OnBrand research, building an audience is more valuable than direct sales for more than 70 percent of brand managers. 70%

day’s evolving environment with the three i’s framework: Integrity, identification and inclusion.

“The concept of trust has usually been associated with stasis more than change. It brings up images of age-old, time-tested, large, solid brands and organizations with large and loyal user bases,” Anjali Puri, Global Director, Qualitative Offer and Expertise, at Kantar Insights Division, writes.

She describes the perception of integrity as “doing what you promise, and owning and making up for it when promises are broken.” Identification, she explains, is the ability to have access to one’s real, authen-

tic self; for brands, this means creating a human face to represent the set of values it stands by.

Inclusion, the final ‘i,’ rests on building a sense of kinship, whether by virtue of being family, community, country or even people with shared values, Puri writes. “At its best, inclusion means that the brand cedes some control to its customers, and asks them to invest something of themselves in the brand’s world. We trust our kin because they are an extension of us –we are invested in them.”

As Steve Jobs once famously proclaimed, “A brand is simply trust.”

Success and Security for the Label Printer.

Redefining Digital Labels.

digital

was meant

The Gallus Labelfire 340 is a one-of-a-kind industrial-strength digital label converting solution best inkjet image quality at native 1200 dpi – fully integrated with flexo printing processes. www.gallus-group.com

THE DIGITAL CHANGE

The vast possibilities of digital label printing continue to drive growth in the flourishing

market segment

By Victoria Gaitskell

For a better understanding of the directions in which digital label printing is growing and evolving, PrintAction spoke to Griffin Schrack, HP’s Labels and Packaging Specialist for Canada and the Northeastern U.S.

A recent report by Future Market Insights forecasts a significantly

high growth rate for the digital label segment, estimating it will increase in revenues at 16.7 percent CAGR from over US$7.1 billion in 2016 to US$38.4 billion in 2026. The report further predicts that during the same 10-year period, digital label production will grow its global market share of digital packaging printing from 64.1 percent to over 70 percent.

Schrack, who has worked at HP

Bottles from Amarula Cream Liqueur’s ‘Name Them, Save Them’ campaign to save the African Elephant, which saw 400,000 individualized labels launched in global markets.

for 12 years, points out that digital label production is a post-mature market for which his company has been supplying technology for two decades.

He clarifies that many of the same trends that prompted the rise of digital label printing in the first place still remain among its major driving forces. Factors such as the decline of print warehousing and demand for just-in-time manufacturing and personalization using variable data all continue to exert a

“You must be able to see no difference between two SKUs of the same product when both are placed side by side on the shelf...if one looks different, consumers won’t buy either one because they think one is counterfeit.”

formative influence on the digital label market – although these factors have now metamorphosized and intensified into the latest trends and applications outlined below.

Avoiding obsolescence

Schrack says in the old days, a major brand owner would develop a new product, then create a few million labels for it, stockpile the labels in a warehouse, and pull them out of storage as required for use on the packaging line. Back then, he says, the cost per label was the main thing everyone worried about. He recalls in 2008, digital label production grew almost 60 percent in six months because it was the only way to effectively avoid warehousing by producing labels fast and truly just in time.

He says the trend has since continued to escalate as companies become increasingly vigilant about reducing not only warehousing costs but also such other expenses as inventory management and especially the disposal of labels that have become waste through obsolescence (still the fate of 15 to 25 percent of printed labels).

“If you have a warehouse full of labels for 12-ounce jars of peanut butter, and when things get tight you decide to reduce the jar size by several ounces, what do you do with all that obsolete printing?” he asks. “Or if you make vitamins in the U.S. (where vitamins are not as regulated by the government as they are in Canada) and you strike a better deal to produce a new batch in China that changes the ingredient panel, your conventional printer has to make a completely new plate. But with digital printing all you have to do is send the printer revised digital artwork.”

Rising cost of substrates

“Across the board, the prices of substrates, both paper stocks and polyester film, are rising globally, especially in the last 90 days,” he says. “I’m hearing that prices are rising about 5 percent each time, and that two to three increases are expected in 2018.

“In digital printing there’s no makeready, but in conventional printing every four-colour job requires initial adjustments that produce trash. For this reason, the higher the cost of substrates, the more lucrative digital printing looks.”

Because stocks for digital printing need the application of a primer that promotes adhesion of ink to the substrate, Schrack notes HP Indigo and other manufacturers build in-line priming (ILP) units into their digital presses.

Proliferation of SKUs

Schrack says today’s manufacturers are trying to make their brands as personal to the end-consumer as possible, and one way they try to achieve this is to produce more pack sizes and varieties of a single brand, each with a different SKU (or inventory identification code).

For example, for a dishwashing liquid, these multiple SKUs might include different colours and fragrances, an extra-strength version for superior cleaning, a milder detergent for sensitive skin, and so on. Skippy Peanut Butter now comes in Creamy, Super Chunk, Roasted Honey Nut, Reduced Fat, Natural and Natural With Honey varieties. Pringles Potato Chips come in 37 different flavours and formats. Schrack expects digital label volumes will continue to rise as the trend toward SKU proliferation becomes more pronounced in consumer packaged goods.

“Digital printing makes it faster and more economical than flexography to get 20 SKUs of 5,000 or 50,000 each on the shelf immediately, while also ensuring the labels appear identical to the ones on the brand’s standard packaging,” he says. “You must be able to see no difference between two SKUs of the same product when both are placed side by side on the shelf. They must look identical because, if one looks different, consumers won’t buy either one because they think one is counterfeit. For hitting brand colours, automatic digital

Jet Label & Packaging recently celebrated its 20-year anniversary with uniquely labelled refreshments, accomplished with HP SmartStream Mosaic printing, showcasing two decades of labelling evolution.

colour calibration and matching processes can provide extreme accuracy and consistency.”

He continues: “Once the brand owner finds out which SKUs are really popular, they can print them more economically on a conventional flexographic press, but the others that didn’t take off and have a much shorter product lifecycle are only printed using short-run digital.”

Shorter shelf appeal

“When I was younger, major brands would tell advertising trade publications they would never change their brand colours or look so that consumers could always find their products in supermarkets,” recalls Schrack. “But now the major brands tend to think they have to change their look relatively often because people get bored. Research by industry associations suggests the current length of a package’s shelf appeal is around 120 days, whereas before it used to be three or four years.”

Smithers Pira reports digital printing accounted for 16.2 percent of the global print market value and 2.9 percent of the volume in 2017, noting that growth is accelerating to 3.9 percent of volume by 2022.

He says cause marketing, such as promoting breast cancer awareness, has become a popular way for brands to change the look of their product label just a little.

Other approaches include regionalization in which, for example, brand owners will decorate their labels with references to winning teams in major national or international sports tournaments immediately after their victories. Schrack says in many cases, an item will appear on the news –such as a study showing a particular supplement is effective in reducing flu symptoms – and vitamin producers will want to reference the news item on their labels before the end of day tomorrow. He recounts after the

Boston Marathon bombing in April 2013, all his customers in the local area were inundated with orders for labels to add the phrase “Boston Strong” to the product packaging. He says the quick turnaround required for these types of applications is something that only digital printing can accomplish.

Mass customization

In recent years major brand owners have been experimenting with ways to forge deeper, more personal connections with consumers, often millennials, by offering unexpected, customized and sharable brand experiences that make them feel special by catering to their desire for individuality.

“Major brands tend to think they have to change their look relatively often because people get bored. Research by industry associations suggests the current length of a package’s shelf appeal is around 120 days, whereas before it used to be three or four years.”

An early, much-publicized example was Coca-Cola’s international ‘Share A Coke’ campaign, reportedly the largest print job of colour digital consumer labels ever produced. Launched in 2011 and extended over several years across 32 countries, the campaign used HP Indigo presses to print individually customized labels, each bearing a popular name found in each respective market.

Coke credited the campaign with gains of 2.5 percent in sales – following a decadelong decline – and 1.14 billion hits on social media.

In 2015, Bud Light became the first brand in the United States to use HP SmartStream Mosaic software for mass customization, producing 200,000 unique, limited-edition beer cans for distribution at Mad Decent Block Party music festival events in cities across Canada and the U.S. HP SmartStream Mosaic creates huge numbers of one-of-a-kind graphics by automatically generating millions of unique designs based on core patterns.

Diet Coke’s 2016 ‘It’s Mine’ campaign used the same software to generate 900,000 one-of-a-kind sleeves for its bottles and cans. “Consumers thought ‘Nobody in the world has that container but me.’ And if they really liked the pattern, they could order a shirt with the same design on the Diet Coke website. The only way to produce this type of print run of one is digitally,” says Schrack.

Another campaign called ‘Name Them, Save Them’ by Amarula Cream Liqueur raised awareness of the African elephant as an endangered species by letting consumers visit a virtual African savannah where they could design and name a one-of-a-kind African elephant. In turn, these consumer-

Left to right: Rod Froment and Darrell Friesen, co-owners of Jet Label & Packaging.

produced designs were used to decorate individualized labels on 400,000 Amarula bottles — one bottle for every African elephant still surviving in the wild. “Brands don’t mind investing large amounts of money on a label when the label does most of the selling,” Schrack explains.

Longer runs with fewer process variables

“All these trends are never going away,” says Schrack. “They are going to accelerate. Ten years ago, when we were marketing our products, services and presses, some printers rejected digital processes because it was too expensive. But now they know if they’re going to be a full-service label and packaging provider, they must have a digital asset on the floor.

“In fact, in the last two or three years we find people printing digitally, even when it’s not the most economical choice,” he continues. “We see runs of 20,000 or 50,000 that might be done less expensively with flexography, but they’re being done digitally because the process lets them know how fast the printing time will be to the second and exactly how much the job will cost.”

Shrack says declining availability of conventional press operators is also a factor in promoting digital printing.

“We see that as a real problem in the graphic arts industry. Everywhere I go, from Montreal to New York City, people are buying digital presses because it’s easier to find and train someone to run a digital asset than a conventional press.”

ANNIVERSARY BASH SHOWCASES UNIQUE BEVERAGE CANS

Jet Label & Packaging recently celebrated its 20-year anniversary with uniquely labelled refreshments, showcasing two decades of labelling evolution. The feat was accomplished with HP SmartStream Mosaic printing, creating unique-to-unit labels from a finite number of original designs. Jet Label explains Mosaic printing has a two-fold function of “uniquifying” products to make consumers feel special and differentiating a brand’s product from competitors, while staying true to overall brand consistency.

Beginning as a single-press, single-client startup in 1998, in a space so small that the owner/ operator’s office was literally a closet, the company has grown into a label manufacturer with over 80 employees, manufacturing facilities in Edmonton, Alta., and Vancouver, B.C., and $25 million in annual revenue.

Today, Jet Label produces labels and printed tape for a range of customers, including grocery stores, international forest product companies, consumer product companies, and industrial application companies. It also supplies parking and boarding passes and baggage tags to the Toronto, Calgary, and Edmonton International Airports. It says digital printing, precision colour-matching capabilities and a commitment to total platform redundancy have all been key factors to gain and retain customers.

Jet Label’s growth has been largely investment-driven through the years. Last year, it acquired United Label Company of Coquitlam, B.C. – a move that secured additional space and production capacity by means of a second facility.

Giving surfaces the life

Established in Canada since July 2018, ICP Industrial Canada is a leader in the development, application, and technical support of specialty coatings and adhesives for the packaging, labeling, and graphic arts industry with leading brands Nicoat® and MinusNine Technologies.

ICP Industrial Canada’s strategic partner, DIVICOR, a manufacturer’s representative firm will support supplying its pressroom consumables to the Canadian market.

DIVICOR is represented by a Canadian team who have been leaders in the consumable sector for over 30 years and have a deep knowledge and expertise of the printing industry.

CAPACITY & QUALITY

Over 165,000 Square Feet of Manufacturing Space throughout North America with dedicated quality control to ensure product consistency for large and small scale customer requirements.

PASSION

Our passion lies in delivering high-quality consumer solutions, dedication to quick turnaround times and industry-leading product development at our two Innovation Centers.

surfaces they deserve

PORTFOLIO

Industry’s most comprehensive portfolio of high-performance UV/EB, aqueous, and specialty coating and adhesive technologies.

SERVICE

Dedicated R&D, Technical Service and Technical Sales teams that provide coating solutions and manufacturing support.

info@divicor.ca

THE INTERNET OF LABELS

Views from the 2018 FINAT technical seminar illustrate the future of self-adhesive labels

By Ann Hirst-Smith

The unusually extended supply chain for the self-adhesive label industry always makes the biennial FINAT Technical Seminar an interesting event in many ways. It brings together a diverse community – all of whom have a strong interest in technical advances that will impact labelling and packaging. This year’s event, held in Barcelona for the sixth time, was no exception. Over two days, March 7 to 9, the seminar combined networking and exploring and evaluating the “challenges in the label market.”

The seminar’s keynote speaker, Andy Hobsbawm, cofounder and CMO of leading Internet of Things smart products platform EVRYTHNG, set the tone for the event. He discussed the way in which the Internet of Things and its key advantage – data – have enabled smart products to transform brand relationships, customer interactions, product authentication and brand security, business management, and service experiences – a vast arena where labels on packaging can play a number of key roles.

More than 100 people from across Europe attended FINAT’s technical update on flexography trends, which this year focused on trends like peel-and-stick labels, UV and EB curing, foiling and the Internet of Things.

IoT is in its infancy, he explained, but growing fast – particularly in such areas as serialization and on-pack augmented reality devices. In fact, said Hobsbawm, “99 percent of things will become part of a connected network.” The benefit of on-pack ‘communicators’ for brand owners is, of course, the huge source of data received as a result. It can deliver end-to-end visibility across a product’s lifecycle, enhance business efficiency, and help to secure the supply chain. Hobsbawm adjured seminar participants to actively exploit these opportunities and “transform your products into smart digital assets.”

As if in answer to this plea, Günther Dieroff, Sales and Marketing Manager of Swedish label printers Beneli, which already has a reputation in smart labels, went on to discuss in detail the sheer scope of the customer engagement market, which is “everywhere from childhood to retirement,” particularly in partnership with mobile devices. Dieroff led the audience along the NFC digital corridors that can deliver successful business results for

brands and retailers, as well as successful purchasing and brand engagement for consumers. On-pack promotions and invitations to connect with a product are creating increased consumer engagement. However, he said, QR codes are not the route to follow. “Only 15 percent of smart device users know how to scan properly,” he said, and “they are ugly.” He showed that there are plenty of other creative communication solutions for NFC scanning.

Do things differently

The complex business of making ready the production process is today much simplified and quickened by the linking of frontend activities via digital workflows, as Xeikon’s Director, Product Management, Jeroen van Bauwel, showed. Particularly in light of today’s customer demands for shorter print runs and shorter lead times, “make-ready time becomes a major bottleneck.” Digitizing the production process can, he showed, not only reduce the costs of print job preparation, prepress, and manufacturing time (by over 20 percent), but it also creates additional production capacity, reduces on-press waste, and can improve all-round quality.

A no-paper workflow from order entry to invoicing is a prime benefit of digital production, coupled with optimized colour management; substrate standardization and order grouping based on substrate; plus the addition of separator labels for better integration with on-press finishing systems.

The principles of workflow automation were then addressed in depth, appropri-

ately, by Esko’s Director, Solutions Marketing, Geert de Proost, who described his paper as “automation myths debunked.” In a world where speed to market is the desire of product manufacturers and their customers alike, “great packaging” is also a key requirement. There is one way that the label converter can make this dream come true, said de Proost: “digitize, automate, connect.” He detailed the ways in which production can be streamlined, so that label converters can better meet the requirements of their brand owner customers.

“All of a sudden, your bottleneck is not the printing machine,” said Daragh Whelan, Process Manager at Bobst, who discussed digital automation for flexography. Bobst is a member of the REVO Partnership formed with other leading industry suppliers to provide full-circle digital flexo and he showed how, with digital UV flexo, the REVO solution delivers wide graphic flexibility in terms of extended colour gamut technology. It also offers significant improvements over conventional flexo in terms of both minimal process waste and make-ready time, which is reduced from a total of three hours for conventional flexo to 10 minutes with digital flexo.

Accept, create, invest

MPS Systems’ Global Marketing Manager, Marjolein Ekkelboom, was uncompromising in telling seminar participants to “accept, create, invest” in the benefits of connectivity. The hardware and software are ready, as prior speakers had shown, and can deliver multiple core business rewards in terms of a successful business future.

Indeed, she underlined that revenue generated from IoT and Big Data services is set to exceed €300 billion by 2020 – and

that is just the beginning.

The afternoon session consisted two parallel interactive troubleshooting workshops for delegates, based label converting scenarios. John Hammond, Sales Director of Nilpeter UK, led the workshop on selfadhesive multi-layer peel-and-read labels and their construction.

As a result of increasingly strict regulatory requirements in terms of the provision of more in-depth product information in the field of pharmaceuticals and OTC medicines, as well as a general desire to place just “one label” on a product, peeland-read labels now represent a strong opportunity arena for label converters. Hammond said, “You just took away all the brand owners’ problems with a single solution.” He explained in depth both the single-web and dual-web production options, and concluded that one-pass production of peel-and-read labels would additionally give label converters “the opportunity to bring that advantage to the market.”

It makes sense

Nanette Thomas, CEO and founder of Synthogra, led a very lively and positive workshop about going into flexible packaging and sleeves on narrow-web presses, alongside traditional self-adhesive labels. She encouraged participants to look at the process of starting up such a process, including the practical production challenges and pitfalls, brand owners’ buying behaviour, and the implications of food safety regulations. She showed, for label converters today, flexible packaging and sleeve label production represent a genuine opportunity to gain additional market share with existing brand owner customers, as well as increased profitability.

As moderator Paul de Ruijter commented, “Flexible packaging is very important for the label industry in terms of increasing its role with the brand owners… and it can really raise the bar for the industry, taking it from secondary packaging print into the realms of primary packaging production.” FINAT’s role in enabling such industry evolution is of course key, he underlined.

Inks and surface decoration

Next morning, inks and decoration were the focus of the presentations. Opening the program, Bo Meyer of UEI Falcontec looked at non-ink-based label surface en-

hancement in the form of hot or cold foiling, embossing, or texturing. This is today a popular choice for adding on-shelf value to labels on consumer products like wines, he said, as well as for micro-embossing in product authentication applications. He laid out the technical parameters for hot foiling, including controlling heat dwell time, pressure, temperature, machine speed, and heat conduction in the foiling tool – and for cold foiling, primarily featuring metallized foils, which may be overprinted to achieve the required colour.

Then Dr Heinz Schweiger of Zeller+Gmelin talked about the way in which, in label converting, the issue of ink migration into foods from labels and packaging can be addressed. He showed how the company’s proprietary DirectCure (curing technology for special UV inks employing a reduced number of photoinitiators) can cost-effectively replace EB curing n such applications.

Sun Chemical’s Jonathan Sexton explored the characteristics of all the key ink drying methods in use today, with a particular focus on UV and EB curing. “Substrate isn’t really important,” he stated, but emphasized that the choice of a drying system must satisfy multiple criteria for both analogue and digital print, if optimal results in process optimization and final print quality are to be achieved.

It was time, then, to look at varnishes, which perform a variety of functions, from surface protection to the visual enhancement of print. Volker Michel, Pulse Roll Label Products, discussed their chemistry, manufacture and applications. He looked at overcoming common challenges, including the requirements of digital print; special finishes such as rough texture; print-to-cure dwell times; and possible contamination of the cationic systems used for peel-and-read labels. The key to a successful end result is, he said, collaboration between ink and varnish supplier, anilox supplier, repro company, and printer to identify the right formulation.

Closing the program and thanking all involved in creating the event, Chairman of the FINAT Technical Seminar Subcommitte, Alex Knott of Dow Silicones, summed up the event in one statement: “I think we’ve learnt a lot about significant changes in our industry” – a statement which drew enthusiastic agreement from the seminar participants.

When every impression counts, you can count on Ricoh.

Invigorate your print operations with Ricoh’s ultra-reliable production printing systems and market leading service & support. Our cutting edge technology delivers outstanding colour consistency, quality and speed so you can handle the big jobs and quick turnarounds with precision. And with a wide range of size, media as well as our market leading service and support team, Ricoh has the machine you need to meet your printing demands – and grow your business.

For more information, talk to a Ricoh printing systems representative today. Expand your production printing horizons.

Pro C5200 Series

High productivity and image quality

Versatile

Pro C9200 Series

Exceptional print quality and outstanding reliability

Best in Class Media Handling

Pro VC60000

High productivity, image quality and durability

Next-Gen Continuous Feed Inkjet

Pro C7200GA 5th Station Technology Series

High productivity and image quality

Expanded application support

Best in Class Media Handling

5th colour station for White, Clear, Neon Yellow, Neon Pink, & Invisible/Security Red Toners

Detailing new technologies from Bobst, Rollem, Tilia, Xaar and more

HellermannTyton TagPrint Pro 4.0

HellermannTyton says its new TagPrint Pro 4.0. Print automation label creation software gives users the ability to automate most of their print workflow, boosting efficiency while reducing waste. With the new software, single- and even multilabel jobs can be stored along with print data, such as printer names, print quantities and even variable data fields within individual label files, HellermannTyton explains. Scanning a single barcode on a work order (or entering a job number in the absence of a scanner) can send multiple labels to print on separate printers in predetermined quantities. As well, the technology enables every printer utilized to run simultaneously, it adds. “Shop owners and management agree that user error is the biggest threat to productivity and profitability where labeling is concerned,” said Marketing Manager – Identification Systems Todd Fries. “With print automation, one action can print an entire batch of labels. There is virtually no opportunity to waste labels or worse, send a mistake to a customer.”

Mactac paper and film craft beer labels

Officially announcing its entrance into the craft beer labeling market, Mactac Roll Label has launched a new line of all-temperature pressure-sensitive paper and film craft beer labels. Designed to meet the unique needs of craft beer brand owners, Mactac’s new craft beer labels are specially formulated with a variety of facestocks and finishes. With roughly 13 products available, Mactac offers semi-gloss, white and clear film options for bottle applications as well as chrome films for cans.

“With a goal to stand out as much as possible at the point of sale, brand owners are seeking labels with special effects that give the perception of quality – such as varnishes, textures, the ‘no label look’ and specialty inks, in addition to vibrant, colourful labeling solutions,” says Kim Hensley, Marketing Manager, Mactac Performance Adhesives. Mactac explains the new craft beer label solutions are all designed with either Mactac’s 640-AT acrylic adhesive or Chill At hot-melt rubber adhesive, both suitable for cold and damp environments as well as elevated temperatures. They also contain water resistance properties, helping to maintain adhesive integrity and aesthetic appeal if exposed to water or moisture, Mactac says.

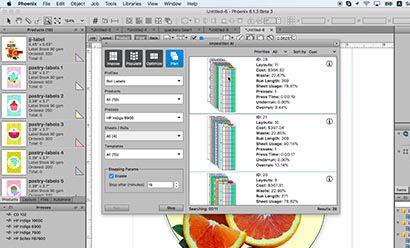

Tilia Phoenix 7.0

At Labelexpo Americas 2018 in Chicago, Tilia Labs unveiled its forthcoming Phoenix 7.0 software release for narrow web production. For the first time in North America,Tilia showcased the new features, described as optimizing substrate usage and boosting setup speed, flexibility and control for narrow-web label printers. Tilia Phoenix uses artificial intelligence (AI) in automating planning and imposition for all types of print and postpress applications. The system factors in parameters, such as job specifications (quantity, dimensions, colours and substrates), presses/print devices, postpress requirements, and delivery considerations, to deliver the layout options. When a final option has been selected, tilia Phoenix generates print-ready layouts and JDF or die instructions, for all devices in the production chain. Among the highlights previewed at Labelexpo are new developments in narrow-web planning, standing die support and marks

control, such as: Optimized lane-based planning – Phoenix 7.0 delivers combinations designed to help reduce substrate consumption, including combining items of differing sizes and shapes in the same lane; Custom grouping rules – Phoenix 7.0 adds custom properties and grouping rules to give users greater flexibility to set combination preferences for lanes and standing dies; and Lead-in and lead-outs – Specify required lead-in and lead-out for each label to be planned and apply dynamic marks such as barcodes and eye marks. Version 7.0 also boasts significant performance enhancements to the Imposition AI engine which forms the core of the Phoenix solution. According to the company, these enhancements push the speed boundary further for Phoenix in searching across millions of combinations to find the most cost-effective layouts within a matter of minutes. Major estimating and reporting enhancements also allow for better analysis, accountability and future planning, including press-time granularity, it adds.

Xaar 2001+ printhead for Océ LabelStream 4000

Xaar describes its 2001+ U printhead brings speed, quality and reliability to the Canon Océ LabelStream 4000 press for digital label printing. The roll-to-roll industrial-scale UV inkjet press provides CMYK+W printing and features the latest Xaar 2001+ U printheads. Targeted at label and flexible packaging converters, it can print on a range of standard label stocks including PP and PE plus selected special substrates. The Océ LabelStream 4000 was developed in collaboration with FFEI, incorporating Xaar’s 2001+ U printhead technology. Designed for flexibility, the Océ LabelStream 4000 uses different printhead variants from the Xaar 2001+ U family. Xaar says the small drop size of the Xaar 2001+ GS6U provides crisp details in CMYK, whereas the larger drop size of the Xaar 2001+ GS12U helps achieve high opacity with white ink. As a result, the Océ LabelStream 4000 is said to deliver an 80 percent opacity (“alpine white”) at speeds of 48m/min in its

Graphics mode, and a 67 percent opacity (“true white”) in a faster production mode at 68m/min. Available in a number of configurations to suit different needs in labels and flexible packaging, the Océ LabelStream 4000 will launch in two widths at 330 mm and 410 mm.

Bobst digital label printing

At Labelexpo Americas 2018, Bobst highlighted the production of trending label specialties. “In an industry where specialties are fast becoming the norm in some label segments where standard products won’t work anymore, converters need to keep their finger on the pulse and rely on a knowledgeable partner that provides them with the technical capabilities to solve even the toughest challenges,” explains Matteo Cardinotti, Managing Director of Bobst Firenze and Head of Bobst Narrow & midweb multi-process Product Line. Bobst ran different machine demonstrations through the day on two production lines: The M6 inline Digital Flexo line spotlighted the advantages of the unique Digital Flexo and Digital Automation workflow technology, including the REVO 7-colour extended gamut printing; and the M1 inline flexo press in its latest IoT configuration, described as the first mechanical shaft connected label press in the industry. During the demonstrations, visitors were able to view, in real time on a large screen next to the press, the production data available on the presenter’s mobile phone. Mouvent – the digital printing competence centre of the Bobst Group –was also at the booth during the exhibition, displaying the technology behind its range of digital UV- and water-based label printers. Attendees had the opportunity to take a close-up look at the Mouvent Cluster, a new approach which uses lightweight clusters instead of fixed size print bars by colour, arranging them in a modular, scalable matrix. The result, it explains, is one system that can be adapted for all substrates, of all widths, for all markets.

UPM Raflatac Small Roll Service

UPM Raflatac has expanded its Small Roll Service to include standard and welded wine stocks as well as 13-inch digital rolls, suitable for durable and industrial chemical labelling, it says. The Small Roll Service is available to North America with the flexibility to purchase one roll or many rolls with each order, UPM Raflatac says, explaining this will enable printers and converters to economically meet the needs of their customers without over-ordering label materials to meet minimums. “This program is designed to support your short run labeling needs,” says Amy Jensen, Director, Specials, Americas, UPM Raflatac. “At UPM Raflatac, we are always looking for new opportunities to expand our service offering of the highest quality label materials on the market.”

Screen, OneVision Software team up for label printing workflow

A new collaboration between OneVision Software AG and Screen GP Americas aims to make day-to-day production for label printers significantly easier. OneVision’s automated label printing software solution DigiLabel integrates with Screen’s Equios Workflow, and is designed to streamline production time and help achieve cost and production savings. The announcement builds upon past partnerships between the two companies. The integration of the two software solutions with Screen’s Truepress Jet L350UV and L350UV+ inkjet label presses boasts smooth production workflows and maximum utilization of the presses’ capabilities. In addition to streamlining the prepress stage, DigiLabel is designed to optimize the process from order receipt through artwork preparation for printing, production planning and automated job transmission to printing and stamping presses. While the Equios Workflow focuses on ripping PDF files and providing printer queue management, high-end screening, colour matching and spot colour adjustments, DigiLabel supplies Equios with optimized PDF files including any required register marks, correct bleeds as well as any required white masks and varnish masks, the companies explain. As well, the preparation of the PDF files ahead of the printing process helps accelerate the

printing process. The continuous supply of optimized printing data further heightens the utilization of the Truepress Jet L350UV and provides increased throughput, explain the companies.

Rollem InsigniaX3 die-cutter

Rollem International presented its latest Insignia die-cutter model at Print 18. Designed to die-cut materials up to 30 pt. thickness, the system is suitable for ID cards, gift cards, school IDs and memberships. The ISX3, the company explains, is suitable for flexible sheet sizes of 24 x 24 inches, enabling the ability to feed sheets either portrait or landscape. Performing functions including die-cutting, kiss cutting, embossing, creasing and perforating in a single pass, Rollem says the Insignia delivers a speedy ROI coupled with quick set-ups and easy change-overs utilizing flexible dies. It is also suitable for digital printers offering customized products such as folded cartons for cosmetics, soaps, craft boxes, beverage labels, and retail hang tags, card carriers, industrial components, promotional products and much more. The InsigniaX3 is the newest model to join the IS5 (20 x 15 inches), the IS6 (20 x 20 inches) and the IS7 (30 x 24 inches) sizes.

BST solutions for narrow web market

BST North America presented its range of quality assurance products for label printing and the narrow web market at Labelexpo Americas 2018. At the joint booth, visitors were able to explore a portfolio of solutions designed to address the label industry’s technical and economic challenges that arise with the weboriented manufacture of labels. The inspection systems, the quality assurance systems in the iPQ family, as well as the web guiding systems aim to ensure and control quality in web-oriented processes. With the new QLink Workflow, the company has expanded its TubeScan product portfolio and has concentrated on syn-

DO MORE WITH YOUR CURRENT

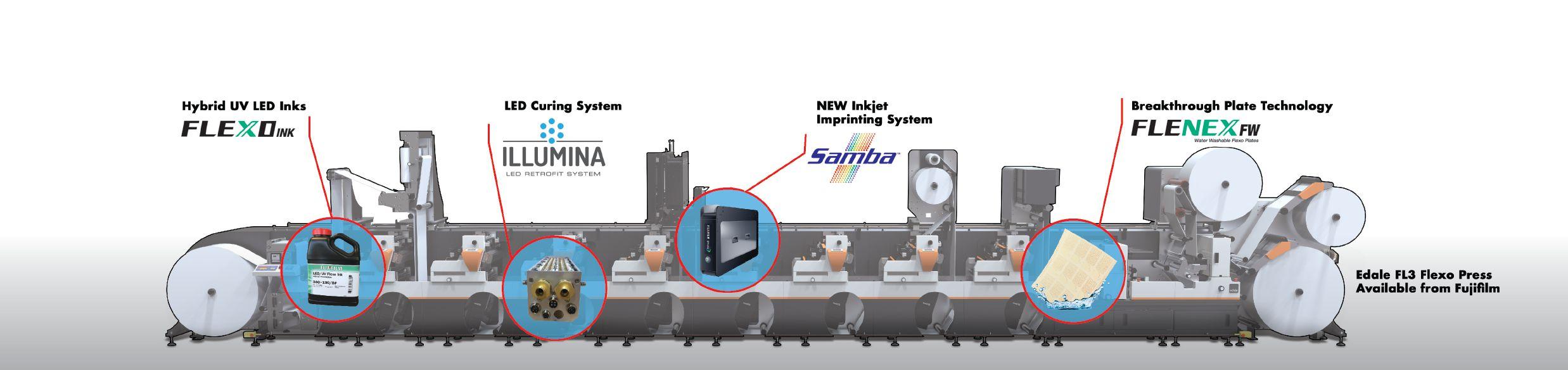

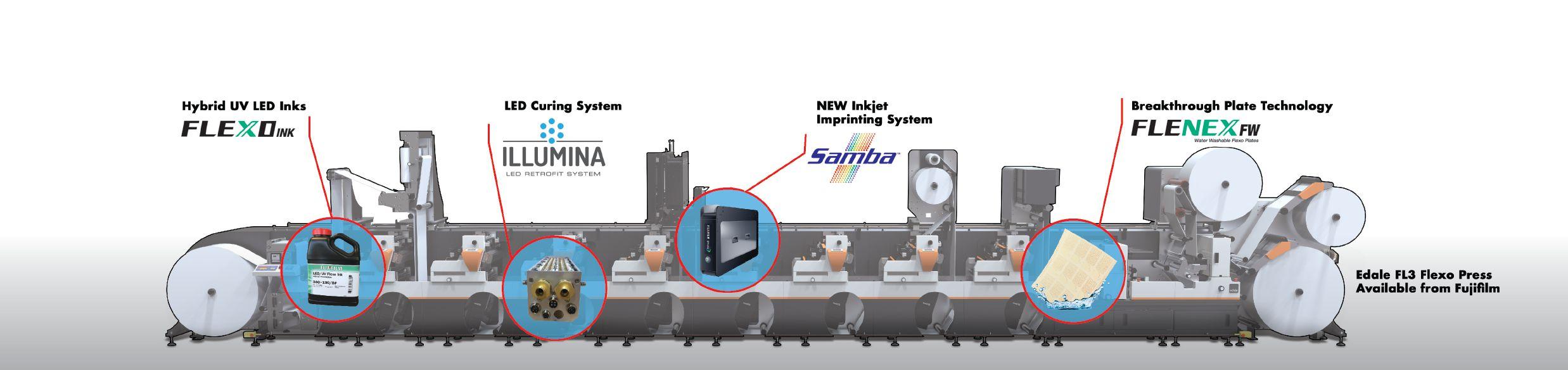

Im a gi ne ru n n in g f a ster press spee d s, pro d uci n g m ult i ple ve r si on an d p r in t i n g new s u bst r ates l i ke th i n fi lms a n d sh rin k sleeves – all

pr ess w i t h out a dd in g c h i ll d r u ms. W i t h F u j i fi l m F lenex plates, Ill u s y stems, a nd Sa m ba Printbar System, n o w y ou c an .

NEW PRODUCTS

chronization, data handling and error editing. This solution was developed for customers who use the TubeScan system on print and cutting machines in parallel. With QLink, TubeScan systems can be used for the automatic control of cutting machines and stand-alone 100-percent inspection systems. Labelexpo attendees also saw both the Shark 4000 Lex and the TubeScan in action on a rewinder in the BST North America booth. In the field of web guiding, BST North America showed a CLS Pro 600 digital line and contrast sensor and a CompactGuide with a Wide Array sensor. A special booth highlight was the new AccuNET controller from AccuWeb. Promising faster response and a higher-resolution graphical display, the touchscreen of the new controller boasts maximum operating convenience. The new system provides support in all the areas where it makes sense to use a touchscreen – during setup or for direct data input, for example. The AccuNET controller was part of a moving web demo in the booth at Labelexpo Americas, where visitors could see real-time demonstrations of web oscillation, guide point adjustment, web width monitoring, and DualEdge technology for centerline guiding with a single WideArray edge detector.

Xeikon X-800 6.0 DFE

Xeikon has announced the newest version of its X-800 digital front-end (DFE), saying it is upgradable to all press-models from the Panther UV inkjet presses: the PX3000 and PX2000 to the Xeikon 3000

series to the Cheetah series for labels and the Xeikon 8000 and 9000 series for the graphic arts markets. The solution, according to Xeikon, enables print service providers to reduce job preparation time, automate converting and serve a new business which can only be enabled through digital print, such as variable data. “From label and packaging converters to operations with high-volume data throughput requirements, the latest version will help them streamline their workflow, reduce job preparation time for even the most complex work and become more responsive and efficient,” says Filip Weymans, Vice President Marketing at Xeikon. “X-800 6.0 strongly focuses on enhancing operational capabilities, one of which is automated impositioning. Streamlining this process can easily help operations save hundreds of prepress and job preparation hours per year. This alone delivers a clear and measurable value.”

Epson SurePress L-6534VW

Epson in September presented the Epson SurePress L-6534VW digital label press at Labelexpo Americas 2018, designed particularly for label converters investing in a digital label press for the first time or looking to expand production facilities. Joining the SurePress L-6034VW in the UV digital label press line, the SurePress L-6534VW will offer three print speed modes from 49 feet per minute to 162 feet per minute (fpm). The company explains the SurePress L-6534W digital LED UV inkjet press integrates all of the functions required for label production, including a Corona Treater, White ink, digital varnish, and an additional UV curing unit. The

printheads, inks, LED pinning and curing lamp units, media feeding, and control system are all developed and manufactured by Epson. Additional features include: PrecisionCore Linehead for singlepass printing while a digital monitoring system uses Nozzle Verification Technology to automatically manage inkjet nozzles; digital varnish – gloss or matte finish can be selected for partial accents or the overall label; Substrate Feed – a centre drum system, which feeds the substrate, is designed to achieve high accuracy colour registration and reduce the heat expansion or shrinkage of the substrate; and variable web width, which supports rolls from 3.15 to 13 inches wide up to 0.013 inches (0.32 mm) thick. The SurePress L-6534VW, and a conversion kit for the existing SurePress L-6034VW, are expected to be available next summer.

Neenah Kimdura Universal HC Synthetic Label Facestock

Neenah has launched Kimdura Universal HC Synthetic Label Facestock, the newest addition to the Kimdura Synthetic Paper portfolio for labels, designed to enable users to print highly durable labels, using compact printing technologies, without any additional lamination or overcoat. Kimdura Universal HC Synthetic Label Facestock, the company explains, is suitable for full-colour print-on-demand applications with demanding durability requirements, such as Laboratory, Anesthesia (OR), Pharmacy, Compounding, or Office/ Admission settings. Labels produced with Kimdura Universal HC, using dye-based and pigment-based aqueous inkjet printers or with dry toner/laser printers, are designed to withstand harsh exposures to chemicals, water, outdoor environment and extreme temperatures.