one of the most pressing health issues facing Canadians, which has been largely ignored for years, is the risk poised by the wireless transmission of concentrated data. The standard radio-wave emitting frequencies of smartphones and tablets should have been disturbing enough to raise flags, but the data-funneling engineering behind these devices, to pull in streams of wireless radiation, will become a major health issue over the next couple of decades.

Percentage of greater likelihood of developing brain cancer when you use a cell phone for a year when compared to someone who does not. This research from Sweden was published in 2013 in the peer-reviewed International Journal of Oncology. 70%

School boards and politicians have eagerly pushed aside old-fashioned print to trumpet their modernized learning environments; piping WiFi into classrooms with seemingly little concern for the potential negative effects that cancerous radiation might have on young, developing minds. Common sense was lost somewhere between the feeding of political coffers and the public marvel of astounding technology.

After years of perseverance by groups like Canadians For Safe Technology (C4ST.org), the blind eye of global health authorities is now being forced wide open. In early May, the Canadian Medical Association Journal (CMAJ), interviewed multiple international experts in radiation and cancer and published a scathing condemnation of Health Canada’s safety guidelines for cellphones and WiFi. The report warns that the microwave levels allowed in Canadian classrooms, residences and workplaces are “a disaster to public health.”

As outlined in a C4ST statement about the CMAJ report, Health Canada staff are either, “unwilling or not competent to make evaluations of the current literature.” C4ST also points to one oncologist, who was interviewed by the CMAJ, stating Canada’s safety guidelines for wireless radiation need to be urgently revised because of the obvious risk of cancer. The CMAJ report also notes there are more than 140 studies available showing wireless radiation emitted by cellphones and WiFi can cause harm.

“That Canada’s wireless safety code is out of date and mired in conflict of interest is no longer a question, it’s a fact,” said Frank Clegg, former CEO of Microsoft Canada and current CEO of C4ST, in an interview with Canadian Newswire “We’re hoping the Parliamentary Standing Committee will have strong recommendations to fix it.”

Health Canada is taking a new position on the risks by drafting changes to what is known as Safety Code 6 to reduce the allowable microwatts per square centimetre, a measure relating to the level of electromagnetic radiation produced by wireless devices. The draft ap-

pears to be a change of upwards of 50 percent (from 1000 uw/cm2 to 535 uw/ cm2). Despite this new stance, which a keen eye might also pick up in the fine print of newer health insurance contracts, many questions still remain about creating public awareness for the problem. Even though it cost many millions of dollars in the late-1990s to retool gravure printing presses, it is hard to argue against the effectiveness of forcing tobacco companies to print horrific 4-colour warnings directly onto their packaging sold in Canada.

On May 12, 2015, Berkeley, California, became the first city in North America to pass a Cell Phone Right to Know Ordinance, by a vote of 9-0, requiring health warnings to be handed out with the purchase of a cellphone. This law is scheduled to be enacted in July, but may face legal challenges. It requires all smartphone sellers to warn consumers of possible radiation risks when keeping devices close to their bodies.

The Berkeley ordinance requires the safety information to be displayed in public view and for a city-prepared notice to be given to smartphone buyers. This movement might one day mirror what happened with tobacco and take the form of a printing application applied directly to cellphone packaging. Hawaii, New Mexico, California, Oregon and Pennsylvania, according to CBC News, have also considered warnings to address cellphone radiation, while Maine’s state government is currently awaiting a floor vote.

International momentum behind cell phone label warnings is largely building from EMFscientist.org, which is a group of more than 200 scientists from 40-plus countries calling for the United Nations and the World Health Organization to produce impartial studies on the potential dangers of electromagnetic fields (EMF) and wireless technology.

In an open letter to these organizations, the group writes, “Numerous recent scientific publications have shown that EMF affects living organisms at levels well below most international and national guidelines… Effects include increased cancer risk, cellular stress, increase in harmful free radicals, genetic damages, structural and functional changes of the reproductive system, learning and memory deficits, neurological disorders, and negative impacts on general well-being in humans.”

Editor Jon Robinson jrobinson@annexweb.com 905-713-4302

Contributing writers

Zac Bolan, Peter Ebner, Chris Fraser, Victoria Gaitskell, Martin Habekost, Nick Howard, Andy McCourt, Nicole Rycroft, Abhay Sharma, Trish Witkowski

Publisher Paul Grossinger pgrossinger@annexweb.com 905-713-4387

Associate Publisher Stephen Longmire slongmire@annexweb.com 905-713-4300

Director of Soul/COO Sue Fredericks

National Advertising Manager Danielle Labrie dlabrie@annexweb.com 888-599-2228 ext 245

Media Designer Gerry Wiebe gwiebe@annexweb.com

Circulation Nicole Cuerrier ncuerrier@annexweb.com 866-790-6070

Subscription rates

For a 1 year monthly subscription (12 issues): Canada — $39.99 ($35.39 + $4.60 HST) United States — CN$69.99 Other foreign — CN$139.99

Mailing address

Annex Business Media 222 Edward Street Aurora, ON, L4G 1W6 printaction.com

Tel: 905-727-0077

Fax: 905-727-0017

Jon robinson, editor jrobinson@annexweb.com

CalenDar

The Kongsberg project team in 1980. Their drafting table designs would soon reach into the signage and packaging industries.

esko of Ghent, Belgium, is celebrating the 50th anniversary of Esko Kongsberg, a manufacturer of digital finishing systems with many thousands of installations around the globe. In the early years, Kongsberg manufactured the first drafting tables used to produce test-parts and verify cutting programs for ship building. The portfolio then expanded to include equipment to engrave print clichés for map printing and then full-size designs for cars and trucks.

In the 1980s, the traditional Kongsberg drafting tables were used in both the sign and packaging markets. The company then changed owners through a series of acquisitions: first Artios, followed by Barco, which transformed in what is today known as Esko. In 2011, Esko – including its Kongsberg operation – was acquired by Danaher. Today, Esko Kongsberg serves three primary markets: packaging, displays and signage.

aditya birla, the world’s largest supplier of viscose, used widely in clothes and textiles (made from wood pulp) worked with Vancouver-based Canopy on a commitment to eliminate any sourcing from the world’s ancient and endangered forests for all of its fibres. The company manufactures 20 percent of the world’s supply of viscose material. Its new commitment applies to wood and pulp sourcing for all its mills, including those in Canada, Indonesia and China.

tilia labs of Ottawa, Ontario, entered into an exclusive agreement with Fujifilm Global Graphic Systems to distribute its Phoenix

imposition and planning software in Japan. The technology, using JDF protocols, can be combined with Fujifilm’s XMF workflow. Phoenix is designed for a range of work, such as packaging, labels, tags, and wide-format, among other applications. Tilia Labs explains Phoenix’ set of ganging tools allow for generating accurate estimates in minutes, which can then be re-used for final touches in prepress. Phoenix also has what Tilia Labs describes as specific integration with XMF allowing for seamless pass off via JDF to Fujifilm’s workflow.

thomas o’Connor Jr., Chairman and CEO at Mohawk, unveiled a new strategic alliance whereby Mohawk and Arjowiggins Creative Papers are to share manufacturing facilities, sales and marketing resources. Mohawk is to have exclusive rights to manufacture Arjowiggins’ luxury packaging products, Delos and Butterfly, as well as rights to license and distribute these and other select Arjowiggins products to customers in North America. Likewise, Arjowiggins gets exclusive rights to manufacture and distribute Mohawk Superfine with iTone.

r.r. Donnelley & sons Company, led by CEO Thomas Quinlan III, reported first-quarter net sales of US$2.7 billion grew 2.7 percent from the first quarter of 2014. The Chicago-based company, with operations across Canada, stated the increase was largely due to the acquisitions of Consolidated Graphics and the North American operations of Esselte.

June 23

mutoh rip software Workshop series, onyx Phoenix, aZ

June 24

iapHC Golf tournament Wooden sticks, uxbridge, oN

July 10

mutoh rip software Workshop series, Flexi atlanta, ga

august 8

opia 2015 toronto Golf Classic angus glen, Markham, oN

United states postal service ended the second quarter of fiscal 2015 (January 1, 2015 to March 31, 2015) with an operating revenue increase of $223 million, or 1.3 percent, over the same period last year. The organization, however, also recorded a net loss of $1.5 billion for the quarter (all figures in US dollars). The increase in operating revenue was driven by a 14.4 percent growth in shipping and package volume. The net loss for the quarter was $1.5 billion compared to a net loss of $1.9 billion for the same period last year.

august 13

mutoh rip software Workshop series, Caldera Chicago, IL

august 31

Canadian printing awards entry Deadline Printaction.com/CPa

september 13-16

Graph expo 2015 Chicago, IL

september 16-19 sign China shanghai, China

september 25-26

Consac imagemakers International Centre, Mississauga, oN

Zarik megerdichian, CEO of 4over, one of North America’s largest trade-printing operations, announced the company’s entrance into 3D Printing, with plans to provide the service to other printers through its online platform. The 3D Printing initiative is being offered out of the company’s headquarters in Glendale, California. 4over employs a 3D manufacturing method called Fused Deposition Modeling, which is well suited for the creation of prototypes, samples for packaging development, and original items.

Quad/Graphics remains the primary printer for Hearst’s magazines division, signing a deal to manufacture 20 of Hearst’s 21 U.S.-based magazines, including brands like Cosmopolitan, ELLE, Esquire and Good Housekeeping

september 28-30 packexpo Las vegas, Nv

october 7

printaction education series, business of printing delta Markham, Markham, oN

october 8-10

aiGa Design Conference New orleans, La

November 4-6

sGia expo atlanta, ga

November 8-10

bmi annual Conference boca Raton, fL

November 12

Canadian printing award Gala The grand Luxe, Toronto, oN

May 31-June 10, 2016 drupa dusseldorf, germany

Wally richards, a former well-known leader within Canada’s printing industry, passed away on May 8 at age 76. Richards was diagnosed with cancer in June 2014 and given three to six months to live, but he fought for almost 11 months after his diagnosis. Richards worked with leading technology vendors like eastman kodak, graphic Litho and Treck Photographic before venturing out on his own with graffix distribution and then later purchased henning graphics. “I worked with him at graffix and henning and he was the most amazing boss ever,” says Lisa egri, Richards’ daughter.

paul smith, vP, Xerox Research Centre of Canada, becomes Chair of the board of directors for the Canadian Printable electronics Industry association (CPeIa). Peter kallai subsequently was named President and Ceo of CPeIa other board members include: Michael Tischler, CTo, Cooledge Lighting and Robin Jeffries, President, Tangio Printed electronics. CPeIa’s board of advisors include Thomas d ucellier, executive director, Pe flagship Program, National Research Council of Canada; andré dion, gM, Printability and graphic Communications Institute; and Mario Leclerc, Professor of Chemistry, université Laval.

paul barker joins drytac Canada in the newly created position of custom coatings account manager-outside sales. barker, who has more than 28 years of sales experience in the plastics, printing and packaging markets, has spent the past 10 years in the pressure sensitive label market.

a lex s tepanian becomes Regional sales director, a newly created position, for kba North a merica. stepanian, whose sales career spans more than 34 years in the printing industry, joins kba after serving as district sales manager with three other printing press manufacturers. he graduated from baruch College in New york with a bachelor’s degree in business specializing in marketing management.

marc olin becomes Cfo of efI. he joined efI in 2003 when the company acquired Nasdaq-listed PrintCafe, where he was Ceo olin previously served as gM of efI’s Productivity software business, and most recently as Coo and Interim Cfo

Dr. mark bohan of Printing Industries of america joins the board of directors for the Integration of Processes in Prepress, Press and Postpress o rganization (CIP4), as its Membership officer. With representatives from 27 countries, CIP4 consists of more than 1,600 individuals from approximately 200 member companies.

richard lloyd becomes vP of sales for gMC americas. he joined gMC as a Client executive in 2013. Lloyd began his career with IbM in the area of complex print and electronic output solutions and then moved to eastman kodak for five years.

prismtech Graphics of burnaby, bC, installed a 30-inch reconditioned PoLaR cutter, pictured with operator Renato Palalay, sold through Colter & Peterson of New Jersey. The new system joins PrismTech’s existing 57-inch PoLaR cutter.

berco labels of Quebec City is highlighting its growth after the 2012 installation of a Xeikon 3300 press, lead by Manon Leclerc, Ceo of group Magnitude, parent company of berco. The bulk of berco’s digital label production is for the food and beverage industries.

boehmer box of kitchener, ontario, is scheduled to install an 8-colour, 56-inch manroland R908 hiPrint press in the late-June, early-July time frame, as the company pushes deeper into high-end packaging applications.

ADAM NG GmbH of Bruchsal, Germany, recently finished a retrofit of its heatset Manroland Web LITHOMAN and ROTOMAN presses, by integrating new drive systems for the press lines. Located 20 km northeast of Karlsruhe in the state of Baden-Württemberg, Germany, ADAM is a family managed web offset printer with 75 employees. It is described as one of a few companies in Europe with special imprint units that enable a plate change while the press runs at full speed.

In 2014, ADAM invested more than €500,000 for retrofits and upgrades in prepress and for its printing technology. This was mostly meant for realizing more efficient printing of large runs. The company points to the production of a leaflet for an automobile manufacturer, as an example of its new press parameters, which included coverage of 16 million, 300 versions. “The digitalization also rapidly changes the printing industry. The individualized on-site trade marketing, ADAM is specialized in, will not work without traditional print products – also in the future,” said Paul Haas, Technical Director of ADAM.

Number of American and Canadian casinos served by the printing work of TPI, based in Des Moines, Iowa, one of North America’s largest variable data printers. TPI recently replaced one of its old 54-inch Polar cutters with a new 36-inch Prism cutter, sold by Colter & Peterson, to better fit the size work its does for the casinos. The Benskin family opened its commercial shop in 1973 and began printing for casinos in 2002.

In the course of a complete upgrade, the hardware and software of the control desks of the LITHOMAN and the ROTOMAN have been upgraded according to new press technology. With these drive systems, ADAM NG secures what Manroland Web describes as 100 percent protection against breakdowns of the control desks by using a redundant system technology. In case of a breakdown of one of the new control units, the second parallel working unit could take over in a seamless manner.

Edições de Angola, EAL, a third-generation family business, has purchased a second Highcon Euclid digital cutting and creasing machine. The company is based in Luanda, formerly named São Paulo da Assunção de Loanda, the capital city of Angola. EAL is spread over several sites and hosts a number of offset and digital presses.

EAL first saw the Euclid, with its patented Digital Adhesive Rule Technology, at drupa in May 2012 and installed the machine in their site at the end of 2013. Since then this 48-year-old commercial printer, with over 200 employees, has been serving its local and international customers with a wide range of digital finishing services, producing labels, books, boxes, greeting cards, and even using the laser etching for security jobs.

“We handle a lot of short run jobs and the Highcon Euclid has opened up the market for us,” said Carlos Santos, Manager of EAL, who is leading the company’s recent move into packaging. “ We are able to be far more responsive to our customers, offering rapid turnaround and highly differentiated designs.

Offsetdruckerei Schwarzach GmbH of Vorarlberger Rheintal in Austria has installed two ROLAND 700 Evolution presses with the intent of dedicating one for the production of packaging. Over its history, the printing company has ordered more than 90 ROLAND 700 printing units. Prior to its Evolution press order, Schwarzac most recently installed two ROLAND 707 LV HS presses. The new Evolution machine for packaging includes UV dryers, InlineColorPilot and the new InlineInspector 2.0 with PDF detection.

Schwarzach has 335 employees in its 52,000-square-metre facility, including Austria’s champion for print technology and winner of the EuroSkills (Apprentice European Championship) competition. The company produces around 25,000 tons of cardboard and paper per year for folding carton in food and beverage, consumables and luxury goods markets.

The company positions itself as an environmentally progressive company with ISO 50001 and ÖKO certification, running FSC and PEFC certified materials.

Height in metres (seven feet and two inches) of the first Magnum Compact press installed into the United States at Advance Publishing of Staten Island. The unique low-height design was crucial to project success. Web slots were cut into the ceiling to accommodate turner bars for delivering the web to a folder on the floor above. Extra web slots were also cut to feed an additional, future folder that has been allowed for in the configuration. The Staten Island Advance newspaper was established in 1886.

Polychrome GAN/GAP Plate System

Polychrome GAN negative-working plate system.

Polychrome’s electro-Clad anodizing treatment acts as an anti-halation barrier during exposure. by sharply reducing the angle of refracted light, the image (dot) is faithfully transferred from the film negative and halation is virtually eliminated. The grained anodized Negative processing is accomplished with a single water-based solution free of fumes or odours, sludge or fire hazards, and over development is practically impossible. by loosening the unwanted background coating during a 30 to 45 second dwell time on the plate, the developer does most of the work, eliminating the strenuous scrubbing so often associated with manual platemaking. Colour control is further enhanced by the fotomer coating, which eliminates dot sharpening during even the longest run.

The Personal Typesetting Workstation (PTW), a new software package for the IbM PC, is available from Itek Composition systems. PTW uses a codeless WysIWyg display with menus and prompts, which makes it easy to learn and eliminates guesswork.

The PTW is fully interactive. as an operator keyboards the job and it appears instantly on the screen, just like a word processor, so errors can be spotted during input and corrected immediately. all text and rules are displayed 14 percent larger than actual size for an optimum balance between legibility of small sizes and amount of copy on the screen.

kodak’s digital Camera 40 combines the ease of a point-and-shoot camera with the convenience of plug-and-play digital image capture. The company explains its new camera can take colour digital pictures (at a resolution as high as 756 x 504 pixels) as easily as people take conventional snapshots today. The camera saves the images in internal memory and when it is full the user connects the camera to a desktop or laptop computer for retrieval. There is 4Mb of onboard memory capable of storing 48 images. The dC 40 is available now for a suggested retail price of $1,345.

Kodak’s digital camera offering in 1995, with 4MB of memory, sold for $1,345.

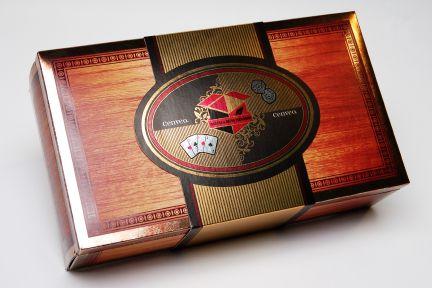

using its kba Rapida 106 press Cenveo’s packaging division created a unique and intricate multi-dimensional self promotional product for the tobacco and vapour industry. The 41-inch, 8-colour kba press includes two coating units, uv drying capabilities, and an inline cold foil system at its facility in Jacksonville, florida. The press also includes varidry blue infrared/hot air drying system, kba’s ergoTronic and QualiTronic systems, a kba board package and a raised platform.

a recent winner of the fsea g old Leaf awards

Competition for best use of specialty Coating, the promotional kit includes a box intertwined with gambling and spirits motifs with realistic wood grain texture and a die-cut gold band. When opened, the box contains several Cenveo branded items, such as beverage coasters, a deck of playing cards, a carton with five dice, and a shot glass.

Cenveo’s Labels division printed and produced the playing cards, while its strategic sourcing division supplied the additional products.

“originally we were going to use actual wood board, but it would have tripled the cost of the piece,” said emily allen, director of Marketing and XP sales for Cenveo’s packaging division. “In order to offer a cost competitive solution to our customers, we decided to simulate the look and feel of the wood grain texture. The combination of all the unique print and coating elements elevated the piece to a higher perceived value, which is exactly the message we’re promoting to our client base for their brand packaging.”

Consecutive years in which RyeTAGA of Ryerson’s GCM program has won the Helmut Kipphan Cup. The research journal, primarily written and produced by the students, was enclosed in an overlapping, wraparound case printed 4-colour UV at Mi5 using its Pro-Brite inks. The cover of the journal was printed with silver metallic ink on GCM’s 2-colour Heidelberg. All inside pages were then printed with toner systems. The title pages of each chapter were printed on an HP Indigo press at Colour Innovations using metallic substrates and Color-Logic software.

the 2015 Blueline report reveals that canadian printers are global environmental leaders

By Marcus Ginder

if Canadians are bad at anything it’s bragging. It’s just not in our cultural DNA to toot our own horn. Nonetheless, it is hard to ignore the achievements of select Canadian printers for their environmentally progressive leadership on a global scale. The strong position of these companies is easily seen in Canopy’s newly released report called The Blueline Report 2015, Trends of North American Printers in Sustainability, Transparency, Paper Sourcing & Forest Conservation, A Business-to-business Consumer Guide & Ranking. The report was unveiled at the industry-leading Sustainable Brands Conference in San Diego this month.

Several Canadian printers are clearly leading the charge on environmental sustainability and that leadership may help spur a North American sector shift to protect the world’s ancient and endangered forests.

Printers understand the role of the print medium is to positively reflect their customer’s message and image. As environmental concerns have continued to gain resonance in the marketplace, the messages crafted by print clients are reflected not only in words and images, but also by the paper they use and, ultimately, in the print budgets they allocate.

When the Canadian printer Friesens Corporation of Altona, Manitoba, responded to author Alice Munro and her publisher’s request to see her book printed on 100 percent recycled paper back in 2001, sourcing the paper was no easy task. Still, they literally stopped the presses while New Leaf Paper created the paper that meet Munro’s request. Born in 1931 in Wingham, Ontario, Munro received the Nobel Prize for Literature in 2013, becoming the first Canadian woman to receive the honour.

Following Munro’s and Friesens’ early commitment to environmental change in the book world, three Canadian editions of the popular Harry Potter series were printed on 100 percent recycled paper and over 20 international publishers followed suit. Nearly 200,000 trees were spared as a result, and almost 8,000 tonnes of CO2 emissions were avoided.

The Boreal Forest stretches across Northern Canada and contains seven of the 10 largest intact forests left on earth. It holds the largest unfrozen freshwater supply on the planet, and plays a vital role in stabilizing our climate. Canopy is currently engaging a collaborative effort to secure the protection of 3.2 million acres of critical habitat and Boreal forests in Quebec’s Broadback Valley.

The trend of environmental progress in the Canadian publishing and printing industries then continued in 2008 when Canadian Geographic magazine, with the manufacturing support of Ottawa’s Dollco Printing (now owned by The Lowe-Martin Group), partnered with Canopy to become the first magazine in North America to print on the “Wheat Sheet”, a 20 percent wheat straw coated paper designed specifically for their special environment issue of the magazine.

Innovation grew with Margaret Atwood’s 2011 edition of In Other Worlds, published by Random House and printed on Second Harvest paper with a wheat/ flax straw and recycled fibre mix. Most recently, rolls of wheat straw paper have been tested commercially in six North American printing plants.

The common thread running through these projects was that publishers and the printers worked together to develop world-leading paper sourcing policies designed to protect endangered forests. These policies then offered the business incentive needed to develop and pull eco-papers through the supply chain. Many of the printers involved in these projects are now North American leaders in transparent environmental reporting and forest conservation engagement, as evidenced in Canopy’s The Blueline Report 2015.

But while the contributions that leading Canadian printers have made to the sustainability of the North American print sector is undeniable; the gap between leaders and laggards is wide. Too

many printers, here in Canada and in the United States, have not yet developed progressive purchasing policies to protect ancient and endangered forests and continue to buy paper from controversial suppliers with track records of forest degradation, human rights abuses and lack of consent from First Nations. Some of these suppliers are embroiled in controversy and losing business as a result. There is little doubt that this trend will only continue in the future, as it is clear that the emerging generations of media buyers and corporate leadership expect accountability from their suppliers. This attitude is often reflected in the print-focused RFQs of major corporations.

From urban offices to industrial print facilities, a “leaf” of paper seems a long way from its forest of origin.Yet there is a strong rationale to vet the origin of the fibre. Procurement decisions have the potential to shape the future for the last strands of majestic Coastal Temperate Rainforest; the endangered woodland Caribou in the Boreal; the less than 6,000 orangutans left in Indonesia and the rights of many communities who are witnessing the impacts of industrial development on their traditional lands.

Canadian paper buyers, big and small, have been quietly wielding their market power in order to increase the sustainability of forest practices. They are demonstrating a preference for FSC certified products and advocating for increased protection of intact forest landscapes.

Senior corporate leadership is directly supporting and facilitating the establishment of meaningful protected areas. Purchasing heft, supply chain relationships, leading paper procurement policies and a willingness to engage with political leaders is helping create a legacy that will last generations. The results are evident with government announcements of conservation solutions in British Columbia’s Great Bear Rainforest and Quebec’s Broadback Forest expected soon.

Today, Canopy is working collaboratively with printers across North America, but we never forget our Canadian roots. The release of The Blueline Report 2015 acknowledges that history, as well as the printers and their customers who are currently driving the forest sustainability agenda. The report reveals who the leaders are, what they have done to achieve that status and how they stack up against each other.

marCUs GinDer is the Corporate boreal Conservation Campaigner for Canopy of vancouver, british Columbia. marcus@canopyplanet.org

driven by industry engagement, Bcit is once again stamping its position in canadian printing

By Wayne Collins

Every day of the week I put on my recruitment hat for a few minutes to promote our Graphic Communications Technology Management program at the British Columbia Institute of Technology in Vancouver. I am consistently confronted with someone chanting, “Print is dead,” and I have subconsciously crafted a standard response that keeps me lighthearted and optimistic.

Some of you might be old enough to remember the Dead Parrot skit in Monty Python’s Flying Circus, with John Cleese thumping a stuffed parrot on the counter insisting, “He’s not dead, he’s just sleeping!” In the case of the print industry, my verbal response is always, “It’s not dead – it’s just changing, really fast, and all the time!”

That is one of the attributes that I have loved about this industry since I began my own apprenticeship over 40 years ago. Print was dead then too, because hot metal engraving was quickly being replaced by photo lithography. I needed to simultaneously absorb a broad history of rich traditions and quickly embrace new technologies and production techniques. After completing a traditional 5-year journeyman certification in the Graphics Union, while attending the University of Regina for my Bachelor’s degree in English, I continued on in the printing industry in various management positions with companies like Zenith Graphics, Creo and Hemlock Printers. I spent 25 years working in Vancouver’s Graphic Communications industry, before starting the industry program at British Columbia Institute of Technology (BCIT) in 2006. I have enjoyed building it through the changes in our industry.

The young people I teach at BCIT face many of the same challenges today, but on a grander scale. Their world of technological change is so much more fastpaced. Their access to information is broader, so their ability to research, assess and adapt, is much keener. It is those problem-solving skills that are transferable to every technology change in our industry. These are also the skills that make those who are passionate about this

In late-May, the Graphic Communications Technology Management program at the British Columbia Institute of Technology officially opened its new Centre for Large Format Imaging at the campus in Burnaby.

industry keep a keen eye on the future. Our focus in the Graphic Communications Technology Management (GTEC) program is to build those skills by having students apply them to the wide range of imaging technologies that are the future of this industry.

The GTEC program at BCIT is unique in that it was founded by a group of business owners collaborating through our province’s professional association, British Columbia Printing & Imaging Association (BCPIA). They helped develop a 2-year diploma program that articulates into our Bachelor of Business degree at BCIT. The program is in the Digital Arts Department, which is part of BCIT’s School of Business. Our program delivers training on three fronts: Core business skills, computer graphics education, and hands-on training on a wide range of imaging technologies. The students learn a variety of real-world skills to take on roles like entry-level press operators, preflight operators, print estimators or bindery operators, as well as more mid-level press and prepress positions in addition to positions as operational or account managers. The first focus for GTEC curriculum was in computer-to-plate lithography, which represented a significant technological evolution in printing when the program began in the mid-2000s. GTEC has since expanded and adapted to encompass three modern and vital imaging technologies, including: electrophotography (toner or digital printing), flexography and large format inkjet.

These three printing processes represent some of the most interesting growth sectors of the graphic communications industry. Businesses that are thriving in today’s market place are diversifying to include at least two of these three core imaging processes. Most successful printing business models have a mass production technology like lithography, married with another form of personalized print technology, such as inkjet or electrophotography, to offer a more complete service to their customer base. Those customers are increasingly demanding marketing materials that integrate crossmedia campaigns and communicate personalized calls to action. Print media is expanding to meet those needs. Our training at BCIT is expanding to deliver trained professionals to the workplace, with the skills to adapt, integrate and constantly change.

On May 20, 2015, the program was to hold our official ribbon-cutting ceremony for our new Center for Large Format Imaging at BCIT. The large format imaging sector in British Columbia has seen tremendous growth over the past decade; growth that is not projected to slow down any time soon. Through detailed surveys with the companies where BCIT grads work, it was determined that the Graphics Communications Technology program needed to grow in four key areas to keep ahead of the rapid technological changes in the industry: Customer relations management; variable data and Web-toprint programming, colour management, and large format imaging. Delivering quality, hands-on experience in large format imaging is the most costly part of that mandate, but with help from industry, BCIT will be able to successfully complete this expansion initiative.

To date, the community has contributed enough software and imaging equipment to launch the Centre for Large Format Imaging at BCIT’s Burnaby campus. The institute has invested close to half a million dollars in renovations to accommodate the growth of this program. Business owners are getting involved to more than match the institute’s investment. Many of these leaders, along with equipment and consumables suppliers, educators, graduates and students were on hand to celebrate the opening of the Center for Large Format Imaging, as well as the fact that print is not dead, it’s just changing.

WaYne Collins is the program head of bCIT’s graphic Communications Technology program and has more than 25 years of industry experience. wayne_collins@bcit.ca

Now you have the ability to improve your bottom line with proven ecologically friendly inks and coatings. That’s because Sun Chemical uses a data-driven approach that provides more transparency through continuous monitoring and reporting. See how better data can help you grow a greener bottom line with our 2014 Sustainability Report.

Request your copy of the 2014 Sustainability Report at www.sunchemical.com/sustainability or call 1-708-236-3798.

For three days in march, some of the brightest technological minds in print gathered in new mexico to discuss rFid, ultra Violet, omni-marketing and colour management

By Martin Habekost

the Technical Association of the Graphic Arts held its annual conference in Albuquerque, New Mexico, in late March. As is tradition, the conference, focusing on the newest technological developments in printing systems kicked off with four high-profile keynote speakers.

The first keynote came from Chris Travis of KBA North America. He talked about many advances still being made in press technology, with more sales of complex machines, combining different printing features and more automation. Presses are being ordered with double coaters for spot UV, spot matte and special effect coatings. Sometimes the coating units are before the printing units for laying white down first, to print on foils and for the application of sizing. The goal of all these various press configurations is to get everything done in one pass.

Travis also points out that the decision to print a job digitally or offset starts at a relatively low good-copy count. He says any job with more than 191 good print copies is more cost effective when the job

is printed offset. UV technology is also changing, as the light tubes change from the standard mercury vapour to irondoped mercury vapour light tubes. This little change results in higher gloss levels for UV coatings. The coating manufacturers have to adjust the phot0-initiator mix so it will work with the iron-doped UV light tubes and UV LED technology is gaining more of a foothold in the print industry. Travis also points out that flexographic printing is growing and holds the most potential in the print industry. The industry overall is finally growing again even as a lot of mergers and acquisitions take place.

The second keynote was given by Patrick Younk from Los Alamos National Lab, introducing conference attendees to some of their incredible work. Many fundamental research projects are carried out by this research institute. Younk talked about the High Altitude Water Cherenkov observatory for the detection of gamma rays originating from the sun. He also talked about an ultra-fast optical ranging measurement system. It is a non-contact position measurement system that works with a 1-micron accuracy

0.4 to 99.6

Percentage of halftone tints that can be created with new DigiCapNX technology.

and it could be used to measure ink film thickness or colour registration.

Michael Van Haren from Quad/ Graphics presented the third keynote on omni-channel marketing. He began by describing the differences between multi-channel and omni-channel marketing. Omni-channel marketing is the same message on all media. Print of course is still the main driver of this. Why – because it works. It delivers the right message in the right place at the right time.

With the emergence of high-speed inkjet printing it is possible to personalize the message and with full colour inkjet the message to the consumer becomes very personalized. A highly targeted variable data print uses personalized URLs or PURLs. Through QR codes and image recognition apps, the printed piece has some augmented reality to it. For all this technology to work well, data is needed to drive the campaign. The contact strategy needs to be build with print being in sync with digital channels. Any digital tools that interact with the customer need to be tested over and over again to make sure they all work as intended.

The fourth keynote was given by Bruce Khan from Clemson University and his topic was printed electronics. He said that print is and will be the manufacturing method of choice in this area, because it is fast and produces the electronic components at a relatively low cost. Khan also says that false hopes had been given by nanotechnology and RFID technology. The most successful printed electronic component is the glucose sensor strip for diabetics. Many obstacles still need to be overcome to successfully print something like flexible hybrid electronics.

On the second day of the TAGA conference, the series of presentations started with a diverse range of topics. John Anderson from Kodak talked about the

Flexcel NX flexographic printing plate that allows the manufacturing of plates with flat top dots. The Flexcel NX plate is coupled with DigiCapNX technology to achieve higher solid ink densities than with conventional plate technology. This technology allows for creating halftones from a 0.4 to a 99.6 percent tint. Through Hyperflex NX technology, the floor of the flexographic printing plate gets extended to support low tint value halftone dots. This presentation was an example of the advances that are currently made in flexography that allow the printing of finer details and more vibrant solids.

Print is and will be the manufacturing method of choice for electronic components because it is fast with quite a low cost.

Don Schroeder from Fujifilm was one of the first speakers to talk about the influence of optical brighteners in papers and that proofing papers have no or very little optical brighteners in them. This discrepancy causes colour differences between press sheet and proof, especially if the paper has a very blueish white colour. The new measurement conditions M1 as outlined in ISO 13655 requires a light source with UV component, so the optical brighteners in the paper get excited and influence the measurement of the printed colours. The standard datasets that many colour management solutions are built upon were created in 2006 and they have been measured under the M0 measurement conditions, which are without a UV component in the light source. The new dataset created in 2013 use measurements taken under the M1 conditions.

Many other presenters talked about the new M1 measurement conditions and how they will influence the printing industry, but there is a drawback to this new measurement condition. An extreme example is that two M1 compliant light sources can have 50 and 150 percent of UV component in them and this results in a b* difference of 7. This can be quite significant for the overall colour difference and can result in a pass or fail of a colour. In conjunction with ISO 13655, for the measurement conditions of light

booths, ISO 3664 has also been updated, so that the light source in the viewing booths also has a UV component in them. The compliance of a viewing booth with this updated ISO standard can be verified with a measurement device from GL Optics. Overall there were six presentations about the new M1 measurement condition and how it influences measured colours, the proofing stage and also the colour management part of any print job.

Although the DE2000 colour difference equation is not (yet) part of an ISO standard, work is being done to develop a colour space that is based on DE2000. John Seymour from QuadTech presented his advances in this project. His goal is to create a colour space with modified L*a*b*-axis that allow for the use the DeltaLab colour difference formula.

A presentation was given on the strategies of managing spot colours using traditional metrics and how to predict the colour outcome using simulated colours on screen. Research is also being done regarding working with expanded gamut printing using 7 colours (CMYK plus orange, green and violet). The use GCR and optimized colour sequence (KOVCGMY) are instrumental to more stable and predictable print results.

Raia Slivniak-Zorin from HP in Israel talked about the work she and her team did with regard to digitally printed flexible packaging. The work was done on an HP Indigo and the prints were also laminated. One of her main findings is that a primer needs to applied to the flexible substrate first, so the ElectroInk will adhere properly. Also an adhesive has to be applied first, before the printed material can be laminated. A corona treatment of the substrate greatly enhances the bonding of primer and ink.

The 2015 TAGA conference was a very high profile conference with many cutting-edge research presentations that will have an influence on the print industry in the coming years. The fact that the M1 measurement condition received so much attention during the conference shows that the new ISO standard requires more investigation.

martin Habekost received his Ph.d. in analytical Chemistry from universität hannover. he is associate Chair for Ryerson university’s school of graphic Communications Management. mhabekos@ryerson.ca

a 30,000-mile journey to rediscover the vagabond days of union-card-carrying printers and the allure of modern letterpress

By Jon Robinson

in early 2015, artist Chris Fritton, after leaving his 6-year position as Studio Director of the Western New York Book Arts Center, set out on the first leg of an ambitious journey to visit letterpress shops in all 48 American states, in addition to a handful of Canadian locations like Montreal’s Popolo Press. He intends to turn The Itinerant Printer project into a global adventure by 2016. Fritton estimates he will travel 30,000 miles this year alone and produce more than 30,000 prints, many of which will be mailed to project supporters as postcards.

Fritton raised more than $22,000 for his current excursion, primarily through an Indiegogo crowd funding campaign. He received additional support from the likes of Mailchimp, Van Son Holland Inks, Virgin Wood Type, Block Club and Pistachio Press.

PrintAction contacted Fritton when he returned home in April to run the 2-day Buffalo Small Press Book Fair, which he co-founded in 2007 and now attracts more than 150 vendors and 5,000 participants from across the U.S. and Canada. He was also preparing to embark on the southwest leg of his journey, having already travelled more than 10,000 miles by land and air, printing in 19 of the 26 letterpress shops he has visited so far, and produced more than 6,000 prints and 18,000 impressions.

WHAT INSPIRED yOUR TRIP?

Chris Fritton: The Itinerant Printer project is based on a long tradition of itinerant, or tramp printers. These tramp

10,000

Number of miles

Fritton has travelled so far visiting unique letterpress shops across the United States and Canada, with much more to come.

18,000

Number of impressions printed by Fritton on the first leg of his journeyman letterpress trip

printers were apprentices or journeymen who had an International Typographical Union Card that guaranteed them a job at any ITU print shop. Travelers, as they were called, could work in one city for a few weeks, quit a job, and pick up a job in another city immediately. Travelers would work their way around the country – they were nomadic, but earning their keep everywhere they went. Since there’s no longer an ITU and letterpress printing isn’t commercially viable in a way that I could expect a wage from places I visit, I had to re-envision what a modern version of tramp printing would look like; since letterpress has evolved from something commercial to something artisan, I decided it would be best to visit small-scale, artisanal shops, collectives, non-profit community spaces, and schools and universities.

I’m first and foremost a writer; I turned to letterpress printing as a way to improve my own books. I was writing and self-publishing work but I was always unhappy with the quality of production, so I began to letterpress print covers for my books while doing the guts digital, then I eventually moved on to printing and hand-binding entire editions. I was lucky to have a great mentor in Hal Leader, a local Buffalo printer. Hal had taken his company, Leader Printing, all the way from the time letterpress was viable up through the digital age – but all that time, he kept a small space in the middle of the company called Paradise Press. He was generous enough to allow artists and people interested in letterpress into Paradise, while sagely delivering advice in small doses.

After that time, my friend Richard Kegler started the Western New York Book Arts Center, and because of my natural predilections toward organization, I ran the letterpress studio there for five years. During that time I was able to branch out into large scale design work, doing gig posters, event posters, and even letterpress architecture prints; at the shop we had a fantastic collection of wood and metal type, so all the work we did was handset. What keeps me in letterpress? The problem solving. I love that every design presents a unique challenge, and every day you’re faced with new and different obstacles.

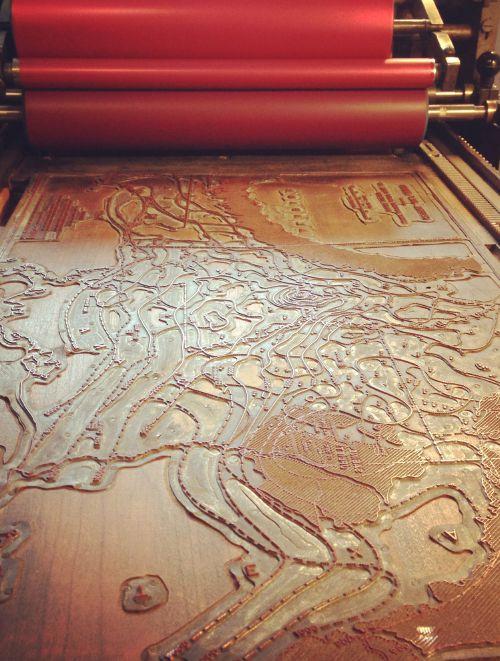

Chandler and Price platen presses at Atlanta Printmakers Studio (clockwise from top); A 13 x 22-inch magnesium cut of shale isopachs in the Gulf Coast region laid out on a Vandercook SP15 at Blackbird Letterpress in Baton Rouge; Fritton printing for an art tour on a Vandercook SP 15 at Nocturnal Press in Ft. Lauderdale (Photo by Lara Stephenson); and a haunting letterpress shop on Blind River near Baton Rouge.

I had the idea to do a traveling letterpress project for at least three years, and finally decided to take the plunge. I understood that it would be a big shift in lifestyle, but I thought it was necessary to develop my skills further as well. The New Craftsperson in America (and beyond) doesn’t have the advantage of the infrastructure that gave rise to mastery. We no longer have access to a system in letterpress where one undergoes a formal apprenticeship, then experiences a journeyman time, then settles in to work toward being a Master Printer. This is true of many vocations and many crafts now, and it’s had a deleterious effect on the quality of the work that’s being produced. I wanted to understand more about that aporia in my knowledge, accept it, and work toward filling in the gaps.

I wanted to involve the print community and public in all aspects of the trip, and I thought that crowd funding would be a great way to share the work that I’m making with people, while ensuring the success of the journey. Early in my career, I spent a lot of time making mail art and creating

correspondence art, so I think things have come full circle, in that this project is primarily about letterpress, but the way that I share that with my supporters, and the general public, is via mail art.

I was definitely humbled by the generosity of individuals, and there was a groundswell of support from printers, designers, typographers, and commercial sponsors. It’s been fantastic to hear from people who really believe in the project and think it’s an exciting opportunity for the letterpress print community to rally around. The crowd funding campaign is an ongoing part of the project now, so that helps keep things solvent while I’m on the road.

Absolutely – but no more than I normally do. Every time I step in front of a press, I want to do my best work. The only difference when I’m on the road is: I don’t always have as much time as I’d like. When I was working out of the studio at WNYBAC, if a print took five weeks, it took five weeks. Some of the stops on the tour are only two days, so I have to make design and layout decisions quickly, as well as select elements to print that I believe are going to be interesting. Decisiveness has become key to saving time, but it does lend to failure.

I joke all the time on the road that this trip is about analog printing, but I spend 80 percent of my time doing digital work: Correspondence, scheduling, social media outlets, mapping, you name it, I’m doing it on the computer. The analogue design aspects and printing probably take up less than a quarter of my time. I think of it as a necessary part of what I’m doing; if social media didn’t exist to spread the word about what I’m doing, the chances of each event, as well as the overall journey, being a success would be very slim.

The public goal is to bring the members of the larger letterpress community together. I believe there’s a nationwide, even a global-wide family of printers that are bound by technique. Even if we speak different languages, we share the grammar and rules of printing, and those are the ties that bind. I want printers to know what other printers are doing, and often we assume that everyone knows everything – social media makes information ubiquitous – but this simply isn’t true.

Every one is so unique. I always say there’s something very Americana about this trip, because it’s about the little guy. It’s populist in nature, just like printing is – I’m out to visit the people who have shops in their garage, or tiny places no one has ever heard of, because I believe that’s the heart of letterpress printing. One individual toiling away in obscurity may seem romantic, or have historical precedent, but I think printmaking is communal by nature. So, I wanted to make sure people were connected. I also wanted to see for myself how people worked. Their workflows. Their quirks. Their genius. All of it’s there if you watch closely, and everywhere I go I learn something, but I hope that I teach something as well. I selected about 50 percent of the venues on the trip, and the other 50 percent reached out to me... every single person involved loves printing.

When I first had the idea, people kept asking me, “Are you even going to be able to find 100 places?” And I thought, “Definitely.” That’s only two in each state in the U.S. What I soon realized is that there are hundreds and hundreds of functional shops. My dance card is so full in certain areas of the country that I’ve had to say no to many shops, or just visit a number of them, but only print at one or two.

I timed this trip, I believe, perfectly with the crest of the resurgence of letterpress. And that’s a huge part of this story, because in five years, some of these shops won’t be around. Some of the people will bow out. Letterpress has exploded recently because of trends in the design and typography world, as well as the wedding industry. But long after those trends are gone, printers will continue printing, and I’m sure letterpress will see a trough in the cycle, and it will lie in wait for another renaissance.

demystifying the technology and investment rationale driving the growth in uV, optimized uV and now Led uV in sheetfed commercial printing

By Jon Robinson

the use of Ultra Violet curing is certainly not new to the printing industry. It is a sound process backed by a huge range of ink sets, coatings, blankets and a myriad of press configurations. What has changed in the past few years, however, is the widespread use of the technology in commercial sheetfed printing. Almost every 40-inch press leaving the world’s major press-building factories today are at the very least prepped for UV and the vast majority of new presses sold, 70 to 80 percent, are equipped to run UV when they hit the pressroom floor.

There have also been recent changes in the availability of different forms of UV curing, which ultimately boil down to a matter of electrostatic frequency based on energy source. The wide swath of

A KBA LED UV stick with 98 light-emitting diodes across the maximum sheet size on a KBA Rapida 106 press will turn on or off based on the sheet size.

traditional UV in the market place, which has been around for decades in the form of mercury vapour bulbs, is now shifting to tighter and more powerful frequencies with optimized UV and the intriguing arrival of Light Emitting Diodes (LED). The optimized UV curing process (designated as H-UV by Komori, LE-UV by Heidelberg, LEC-UV by Manroland and HR-UV by KBA) continues to rely on mercury vapour bulbs, but they are infused with dopants, which amounts to adding metals (primarily iron) to the mercury inside of a curing bulb to increase intensities in some parts of the UV spectrum. “All of these systems are all UV,” says Steve Ranson, President of KOMCAN, which distributes Komori presses in Canada and recently signed an exclusive domestic distribution agreement with UV-giant Air Motion Systems. “LED is also UV. It is just a different

Estimated percentage of available LED UV inks and coatings relative to traditional UV.

frequency of UV, which I think a lot of people do not realize.”

All three of these processes – traditional UV, optimized UV and LED UV – are being used in the market place. Which frequency you invest in will ultimately be determined by the position of your printing company, because each process holds advantages and disadvantages. There is little doubt, however, that LED UV, which is already making a major impact on perfecting presses, will eventually dominate the energy-curing process in sheetfed printing.

Light Emitting Diodes, which are the same form of energy common to so many industrial and household applications, operate in their own UV frequency band. It is a narrow and powerful band. The electrostatic nature of LED produces little heat from its energy, which is a major reason why it holds so much potential for curing printed substrates.

“The cost of the LEDs was just too high in comparison to the traditional mercury vapour bulbs,” says Chris Travis, Technical Director of KBA North America, explaining why LED took so long to impact the sheetfed world. “It was not really until the last three or four years when it become affordable for the printing manufacturers to get into.” Travis is one of the continent’s leading experts on the application of UV. KBA, which is the only press manufacturer currently making its own UV drying systems, has been at the forefront of UV energy curing for decades based on its early push into packaging, where most every press sold now has some UV capability.

“LED is the future of energy curing. It is simple as that. Now when is this future, that is up for debate,” says Travis. “We are selling LED presses now but a lot of it will depend on the configuration and the market space that the customer is getting into… but in the foreseeable future LED will be the mainstay of energy curing options over traditional UV.”

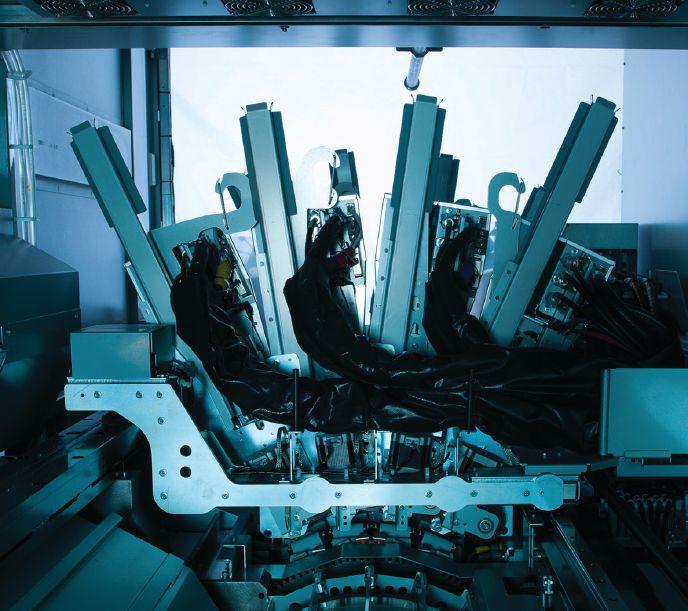

The development of newer optimized UV and LED UV systems present enormous opportunities for running long perfectors. What was once a finicky form of printing, handled by only some of the most technically sound companies, is opening up to the entire market because of these new UV frequencies, particularly LED. “It hasn’t become a trend here yet, but I can tell you Komori in the U.S. now doesn’t sell perfectors unless they have some kind of H-UV or LED curing. That is amazing when you think about it, 100 percent,” says Ranson. “It has gone from zero, never, to always in the last year and a half.”

Marcus Wengerd, owner of Carlisle Printing in Ohio, in late-2014 became one of the first North American printers

to retrofit an existing conventional sheetfed press with two Air Motion System XP7 Series LED UV lamps. They were applied to a 9-year-old, 40-inch 5 over 5 Manroland long perfector.

After more than six months of operation, Wengerd points to several LED UV curing advantages over conventional UV printing, including far fewer blanket washes. “The ink will not dry because it is LED UV, provided your pressroom does not have LED lights emitting in the same wavelength,” explains Sean Springett, Marketing Manager for manroland Sheetfed North America. This also translates as having a much cleaner pressroom.

Wengerd continues to explain, in terms of perfecting, the LED curing process, not only eliminates differing dot gain on long perfectors, with no hickeys or hickey delta effect to cause dot gain, it also means ceramic perfecting jackets can be trashed or replaced with steel jackets. Springett explains Carlisle Printing also

LED UV curing also eliminates the need for ceramic jackets in perfecting, which might cost $6,000 to $8,000 each. “If you smash one, you are out $8000,” says Ranson. “If you smash eight, you are out $64,000.” These jackets would also have to be changed from time to time as a consumable. “No jackets is a massive benefit... And no gutters, so you are saving paper,” says Travis. “The ink is glossy with LED as opposed to traditional UV, so the visual look is the same as conventional and I am getting no marking. LED is a no-brainer for commercial printers with perfecting presses.”

One of the disadvantages of LED UV curing can include the need for baked plates on runs greater than 100,000, explains Carlisle Printing’s Wengerd. Also, the ink water window is much more narrow than with conventional (again allowing for stochastic).

Marking goes from being a daily issue to being a non-issue

turned to 20 micron stochastic when it switched to LED UV because of the associated use of less water. The company was also able to move its chiller away from the press.

The application of LED UV arguably presents the most significant change to perfector printing in decades. “One of the problems that you always had were with gutters and slowdown wheels,” says Ranson. “You needed gutters for your slowdown wheels to avoid marking.” Ranson continues to explain most perfecting printers turned to smaller slowdown or star wheels and belts at the end of the press, in order to print with smaller gutters and, therefore, save paper. The smaller the belts, however, the less ability a press has to slow down the sheet. As a result, printers would need to slow their press down. The application of optimized UV and LED on a perfecting press, however, means a solid-coverage sheet is completely dry on the backside before turning toward the delivery. These newer forms of curing, which also provide a more glossy print than traditional UV perfecting, allows printers to use bigger wheels and eliminate gutters. “Marking goes from being a daily issue to being a non-issue,” says Ranson “And you can actually run at full speed production now because you do not have to worry about any marking anywhere. You do not have to worry about delivering the sheets – it is huge.”

Without investing in shadow-less press grippers, Wengerd found some of his sheets showed a shadow from the lamp that is curing coating on the blanket. This tends to happen on run lengths of 30,000 to 40,000 when applying ink train coatings. “The biggest problem with LED UV is coating,” says Springett. “There are not a lot of options available yet, so most guys run an ink train varnish.” This can lead to yellowing of the product. “Ink suppliers are working on it, but there isn’t a cornucopia of coatings right now.”

Ranson estimates that if you consider traditional UV to have 100 percent access to inks and coatings, then optimized UV sits at about 85 percent and LED UV sits at about 65 to 70 percent. He points out this potential limitation, however, can be overridden by the cost savings of LED. “With the old type of UV printing on a 6-colour press you would have three interdecks, plus two end-of-press lamps, so you have five,” he says. “On a new H-UV press you can run six colours and coating with one lamp. You can do the same thing with LED.”

The ultimate benefits of apply of UV, of course, remain the same for a commercial printer. “I think the environment for fast turnaround of jobs is the single largest benefit of UV,” says Springett. “The job no longer has to sit on the shop floor. It can go right into a postpress function.”

When we asked offset printers in 2007 to describe the perfect short run press solution, they didn’t mince words. The print quality needs to be as good as offset litho. Use standard coated and uncoated stocks, and load-up and off-load of sheets shouldn’t require an owners manual to figure out. The prints should be smooth, without any pile-height issues, and look and feel like an offset sheet. Prints need to be durable too, especially when using finishing equipment. And please…no more click charges.

Fujifilm’s J Press 720S technology delivers these benefits and J Press installations have produced millions of brand on demand impressions where it counts most – in the field. So why wait on the promises of new technology, when proven Fujifilm innovation can help you dominate the high-quality, short-run market today.

Seeing is believing. Visit fujifilminkjet.com today.

some of the world’s leading colour management experts gather in toronto to outline key developments in their field, as part of the printaction education series.

By Martin Habekost and Jon Robinson

On May 5, PrintAction and sponsor X-Rite hosted around 30 printing technicians and operational managers, at a daylong event – five sessions –focused on colour management, as part of the PrintAction Education Series.

The morning keynote was presented by one of world’s leading colour technologists, William Li, Color Technology Manager for Eastman Kodak, based out of Vancouver, BC. Li was at the forefront of software development during the meteoric rise of Creo. He joined the company in 1997 and helped develop Prinergy workflow, focusing on screening and calibration software. Li has led Kodak’s colour technology group since it acquired Creo in 2005 for approximately $1 billion.

Li is very active in international standards work, serving as ICC chair since 2006, and convener of ISO/TC 130 JWG7 on colour. He is also active on the TAGA advisory board, US CGATS, IDEAlliance PPC, the Fogra digital print working group, CIP4, and Ghent Workgroup. Colour improves brand recognition by up to 80 percent, explains Li, who also noted colour makes an impression that is 40 percent more memorable. Colour control can improve your bottom line, but also your top line by printing more volume, and it can also make your customers more profitable.

There are currently 11 ISO and other standards that help with increasing job consistency. Print quality has to be and should be interchangeable. One of the most recent changes and most impacting changes to our industry was done to ISO 13655. This ISO procedure describes the

Looking good on paper matters. ColorLok® Technology gives paper more vivid colors, bolder blacks, and faster drying times.* Learn more at colorlok.com

COLORS BOLDER BLACKS FASTER DRYING

© 2014 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice. * Independent testing by SpencerLab Digital Color Laboratory, commissioned by HP. The full October 2009 report, “Print Quality Analyses – ColorLok Media Evaluation: AiO Printers: Brother MFC-5490CN, Canon PIXMA MX860 & MX7600, Epson WorkForce 600, HP Officejet 6500 and Officejet Pro 8500,” is available for download at spencerlab.com

Domtar EarthChoice® Office Paper is a great-looking, everyday paper that represents your commitment to environmental responsibility. Featuring ColorLok ® Technology, it is designed to provide optimal printing results. To learn more visit www.egpaper.com or domtar.com.

measurement modes for colour measurement devices.The most important change is in regards to measuring colour with a defined amount of UV lighting. The UV component will excite the optical brightening agents (OBA) in the paper, which in turn will influence the printed colour. There are now four measurement modes for your spectro:

M0 legacy mode for instruments like an X-Rite 400/500

M1 D50 with a defined amount of UV lighting

M2 UV-excluded or UV-cut

M3 polarized measurement

It is now important to specify which measurement condition was used when you take a colour measurement. In tandem with ISO 13655, the ISO standard for viewing booths, ISO 3664, was updated as well to have the same amount of UV light present in the light tubes used in viewing booths. According to GTI and JUST Normlicht, 70 to 80 percent of all lightbooths already have the new light tubes installed. If you have replaced the light tubes in your viewing booths recently, the new light tubes are compliant with the new ISO standard.

Li also spoke about print aims and globalization. Currently the world is divided into G7 for the Americas and PSO (Process Standard Offset) spearheaded by FOGRA in Germany. Li said that hopefully this will soon be resolved and that there is only one set of print aims for the entire printing world. He also discussed the critical need for Canada to become active in the ISO/ TC 130 program to have input in the direction of global standards relating to colour management.

Li also touched on extended gamut printing, which he prefers to call extended process printing. Extended process means that besides CMYK there is also Orange, Green and Violet used in the print process and it requires a 7-colour press. This print process allows you to generate most spot colours with seven colours (about 90 percent of the Pantone colours).

Li spoke also about the new efforts behind GRACoL Plus, which uses FM screening technology and allows you to print with higher CMYK densities to achieve a wider gamut. For this project you need to use colour management and G7.

The last item Li touched on was the new iccMAX initiative. Existing icc v4 profiles are limited to D50 lighting, cannot handle OBAs and lack resistance to metamerism, while iccMAX profiles use the new D50 lighting with UV component, can use spot colours and allow spectral handling.

In Session 2, Angus Pady of Toronto-based ColourManagement. ca, described some of the modern tools printers should embrace for colour management. He emphasized how printers should be doing what they can to take advantage of – and gather – all available colour data.

A tool like PressSign 6 can help with this. It connects to almost any spectrophotometer and helps with printing to press standards. The software not only describes if you are achieving print standards, but the beauty of this software is that its use is not limited to offset. It can be used for digital, flexo and gravure.

Pady also touched on G7, emphasizing it is a methodology and not a replacement for print standards. It works on top of current print standards. Paper plays an important role in the G7 process and if the paper is too blue, for example, Curve3 software is probably compensating by adding more magenta to the output curves, making the neutral grey look a bit too red. The G7 method does not work well with stochastic printing. It was stressed that grey balance is the essence of colour correction and colour control.

Pady also stressed the need to use colour servers, which can help change images to the same standard like GRACoL or SWOP. These colour servers are made by many companies, such as GMG, Kodak and Alwan, and they will cost between $7,000 to $15,000. Colour servers harmonize all incoming files to print conditions like GRACoL. This tool will help increase prepress and press efficiency.

Abhay Sharma, a world-leading expert in colour manage-

ment with Ryerson’s Graphic Communications Management program in Toronto, then teamed up with David Brenner of X-Rite to delve deeper into the new M measurement modes for printing. They focused on how the new M1 mode now accounts for the use of UV light, which has been traditionally cut out of calculations because it could not be properly measured.

While the UV-cut measurement is accounted for in M2, the M1 standard is able to account for the growing use of Optical Brightening Agents in papers. Brenner described how the M standards are to be accounted for in new measurement systems like X-Rite’s eXact, the iSis Pro 2 and i1iO Pro 2 systems.

Session 4 sparked a lot of discussion among attendees as speaker Peter Hedgecock, Business Improvement Consultant with Leapover Consulting, described

wrapped up the day with a session called Profit and Success with Colour Management. Aston provided attendees with hard data points to describe the importance of optimizing processes between prepress and press to realize effective colour management. With data tracked from dozens of printing companies, he related how such optimization can lead to enormous reductions in waste and increases in productivity. Aston also used a handful of case studies to describe how specific printing companies achieve enormous spikes in productivity.

Aston focused on how effective colour measurement can eliminate the idea that colour is a problem in the pressroom. Fast make-readies, low waste and high profitability can be achieved with the help of colour management. How colour management is essential to achieve these savings. Companies should standardize their processes, understand how they got there and eliminate waste. Waste is not only make-

Companies should measure, define, control, improve, analyze and measure again

some of the potential pitfalls of G7, based on his own experiences during a recent implementation of G7 Certification. Leveraging his experience in continuous improvement and as Canada’s first liaison for the SWOP working group, Hedgecock focused on why achieving grey balance is far from a proper definition of quality printing in offset printing, primarily relating to the adjustment of CTP curves.

One of his Hedgecock’s main questions was why a photographic concept was applied to a manufacturing process. He says all that G7 does is apply curves in the CTP system but it does not address any aspects of cylinder packing, blankets, roller setting, ink rheology, ink trapping, ink film thickness ink/water-balance and the control of dot gain. Also, according to Hedgecock, the G7 correction curves are often over aggressive and take the printing inks out of the print density sweet spot which leads to ink trapping issues, picking, piling and emulsification issues.

He also said that G7 is dismissive of the print fundamentals. After his presentation a more intense discussion took place in which some attendees pointed out that G7 is not there to replace well defined and standardized print conditions, but is meant to be used on top of those standard print conditions. Also the press has to be set up properly, so it can meet those standard print conditions, otherwise G7 will not work.

Peter Aston of Heidelberg Canada

ready sheets, but also all non-value things that are done in a pressroom. Companies should go through the cycle of measure, define, control, improve, analyze and measure again to close the loop, explained Aston. A print shop should also investigate if the use of make-ready books is really helping with reducing costs or if it is costing you more than buying extra sheets of virgin stock. If the make-ready causes frequent press stops because of a misfeed and blankets need to be washed once or twice, before the virgin stock of the job goes on press, then it is most likely that the make-ready books costs you more time and money than buying extra sheets of smoother running virgin stock.

Another important aspect of optimizing the operations of a print company is not only making sure everything and everybody works smoothly together, but top management has to buy into the whole process as well. If management does not buy into this, the whole process of optimizing all operations from prepress to finishing is a waste of time, money and effort. One should also keep in mind that these improvements do not happen overnight. They take some time to grab a foothold. On a lighter note, Peter Aston ended the intense technical day by describing a few iPhone apps in regards to DeltaE calculations and ink troubleshooting, as well as the interesting Cube tool developed by SwatchMate of Australia, which captures colour with a single tap.

delivering the industry’s most important consumables

technology companies were asked to submit recently introduced – or soon to be released – inks and toners, as well as coatings, for the printing market. Some of the companies also submitted recently introduced ink sets applied to existing printing machines or systems used to deliver these vital printing consumables.

Saphira Ink Elite Star 610 from Heidelberg is described as a universal high-end printing ink for offset presses that dries by means of absorption and oxidation. Key benefits of Elite Star 610 include, according to the company, strong press stability, very high gloss levels, good rub resistance, and low misting, even at high speeds.

The ink, which fulfills all the requirements of ISO 2846-1 and is suitable for printing to ISO 112647-2, is well suited for work-and-turn applications. Heidelberg also explains the ink is suitable for use with gloss, matte, and uncoated paper, as well as with coated and uncoated board. Saphira Ink Elite Star 610 is not suitable for food packaging without a functional barrier.

The new HP PageWide XL 8000 printer, introduced in April 2015, is to ultimately include new PageWide Pigment Inks that will be available beginning in September 2015. Other devices in the HP PageWide XL portfolio will be made incrementally available between November 2015 and January 2016 in select countries worldwide. HP explains the PageWide XL Pigment Ink, specially engineered for single-pass PageWide XL printers, is designed to increase print quality with crisp lines, fine detail and smooth grayscales.

HP also explains PageWide XL Pig-

ment Ink provides dark blacks, vivid colours, and moisture and fade resistance on uncoated bond paper at high speeds. The company states the ink produces durable prints, including GIS maps and point-of-sale posters, while supporting the print speeds of up to 30 D/A1 pages per minute in monochrome and colour.

Fujifilm’s Supernova White ink is designed for non-shrink flexo applications. Fujifilm describes the opacity of Supernova White as a standout product in flexo printing, aimed to reduce the reliance on slower rotary screen printing processes. It is said to provide smooth laydown with no pin-holing, broad adhesion range, fast curing, and very fine detail capability.

The company explains Supernova White provides both the extreme opacity and smooth laydown of a rotary screen white. At the same time it is running at flexographic-press speeds. Fujifilm also explains Supernova White prints strong detail when used with fine line anilox volumes. To this end, the company refers to it as one ink for all flexo applications.