Recruitment

Virtual

Spotlight

Andrew Wong, Manager of Market Development at Jones Healthcare Group P.22

Virtual

Spotlight

Andrew Wong, Manager of Market Development at Jones Healthcare Group P.22

For years, Mitsubishi set the superior technology standard for Canadian printers. Today, RM Machinery returns that innovation to Canada, but with an even higher standard: Ryobi Mitsubishi Graphic Technology (RMGT).

Serving the US market for nearly a decade, RM Machinery (RMM) proudly brings our expertise to Canada’s printing industry. We deliver the highest quality sheetfed o set, digital inkjet, and flexo printing presses by partnering with the finest manufacturers in the industry.

RMM is the premier distributor in Canada for Mitsubishi, RMGT, and Miyakoshi printing presses; Bottcher rollers, blankets, and chemistry; Standard Horizon finishing systems; and GEW UV curing systems.

We are stable, local, and o er the best-in-class technology. We maintain an ample supply of parts, and for as long as you own one of our supported presses, you are guaranteed ongoing service and support programs that are among the best in the industry.

RM Machinery Inc.

905-238-9797 • 1-855-RMGT-123

5250 Satellite Drive, Unit 9 Mississauga, ON l4W 5G5

12

HP Canada partners with the federal government to print and supply face shields to frontline workers

14 Printing and finishing the humble label

22 6 12

A closer look at the processes behind the array of labels seen today

16 How much will COVID-19 affect recruitment?

Virtual onboarding and training will become part of the new normal

GAMUT

5 News, Calendar, People, Installs

TECH REPORT

18 Highlighting new offerings in the labelling segment

NEW PRODUCTS

19 Detailing new products and solutions from Flint Group, Koenig & Bauer, Neenah, Vastex and Manroland Sheetfed

SPOTLIGHT

22 Andrew Wong, Manager of Market Development at Jones Healthcare Group

FROM THE EDITOR

4 Kavita Sabharwal-Chomiuk The post-COVID workplace

CHRONICLE

8 Nick Howard

Choosing the perfect equipment often comes down to personal preference

INSIDER

10 Bob Dale

Some pitfalls to avoid when competing for a job

As regions move into stages 2 and 3 of reopening post-pandemic, the future of the workplace remains foggy. According to research from the Adecco Group, the working world should expect sweeping workplace changes in the post-pandemic landscape.

The study, called Resetting Normal: Defining the New Era of Work , finds that the pandemic has resulted in major shifts in not only attitude, but expectations among both workers and leaders, as both call for permanent changes in how and where we work, workplace relationships and future skills.

The survey found a whopping 88 per cent of respondents said their employer met or exceeded expectations in adapting to the challenges of the pandemic.

The study examined the expected shortand long-term impacts of the pandemic on workplace norms. Research was conducted in May 2020, with responses from 8,000 global office-based individuals ranging from 18 to 60 years of age.

“The world of work will never return to the ‘normal’ we knew before the pandemic struck. The sudden and dramatic change in the workplace landscape has accelerated emerging trends such as flexible working, high-EQ leadership, and re-skilling, to the point where they are now fundamental to organisational success,” said Alain Dehaze, the Adecco Group’s CEO, in a press release.

“As many countries emerge from the acute crisis phase of the pandemic, employers have an opportunity to ‘hit reset’ on traditional workplace practices – many of which have remained largely unchanged since the industrial revolution,” Dehaze continued. “This research highlights that employee attitudes have shifted and gaps between workforce expectations and entrenched labour market processes have been exposed. As we step into the new era of work, now is the time to establish better norms that will enable a holistically healthy, productive and inclusive workforce into the future.”

The research found that many office workers are ready for a new ‘hybrid’ work model, as 74 per cent of respondents said a mix of office-based and remote working was the best way forward. The ‘universal ideal’ of spending half of their time in the office and half working remotely was seen across demographics of those surveyed. In addition, company executives agreed, as 77 per cent of C-suite respondents said businesses will benefit from increased flexibility.

The survey found that over two-thirds (69 per cent) of workers are in favour of what they call “results-driven work” rather than working on an hours-based contract or 40-hour work week. This would mean contracts are based on delivering a finished product, rather than working a set number

of hours. According to the study, 74 per cent of C-suite respondents agreed that the length of the work week should be reconsidered.

The pandemic has also resulted in a new set of leadership competencies born out of necessity. Because of this, the future view of a modern executive or manager is changing. Emotional intelligence has emerged as a defining trait of a successful manager, but the soft skills gap is evident. The survey found 28 per cent of those surveyed said their mental wellbeing had gotten worse due to the pandemic, with only 10 per cent of respondents saying their managers were skilled in supporting their emotional health.

The survey also analyzed how workers’ skills have changed during lockdown. According to the survey, 61 per cent of respondents said their technological skills have improved during quarantine, while a further 69 per cent are looking for additional improvements to their digital skill set in the post-pandemic future. A number of skills were identified as important by those surveyed, including managing staff remotely, soft skills and creative thinking.

The study also analyzed the importance of gaining and keeping trust in the future workplace. Some companies have done a wonderful job in supporting their employees during the COVID-19 pandemic, and as a result, trust in corporations has increased. The survey found a whopping 88 per cent of respondents said their employer met or exceeded expectations in adapting to the challenges of the pandemic.

However, with a higher degree of trust comes higher expectations, as 80 per cent of survey respondents believe their employer is responsible for ensuring a better working world post-pandemic. This is compared with 73 per cent who place the onus on the government to get things back on track, 72 per cent who believe it is an individual’s responsibility, and 63 per cent who say it is the responsibility of labour unions.

Speaking of the workplace, this issue, we discuss how recruiting new employees during the pandemic using virtual onboarding and training could become our new normal (p. 16).This issue also features an article on the processes behind the array of labels seen today (p. 14), and an interview with Jones Healthcare Group’s Andrew Wong on NFC technology in smart packaging (p. 22).

Until next time, stay well.

KAVITA SABHARWAL-CHOMIUK Editor kchomiuk@annexbusinessmedia.com

Editor Kavita Sabharwal-Chomiuk kchomiuk@annexbusinessmedia.com 416-510-5142

Contributing writers

Bob Dale, Meagan Gillmore, Nick Howard, Heather Roth

Associate Publisher Stephen Longmire slongmire@annexbusinessmedia.com 416-510-5246

Media Designer Lisa Zambri lzambri@annexbusinessmedia.com

Account Coordinator

Alice Chen

achen@annexbusinessmedia.com 416-510-5217

Circulation Manager

Beata Olechnowicz bolechnowicz@annexbusinessmedia.com 416-510-5182

Circulation bolechnowicz@annexbusinessmedia.com Tel: 416-510-5182

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Group Publisher Diane Kleer dkleer@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Subscription rates

For a 1 year

subscription (10 issues): Canada — $43.00 +Tax Canada 2 year — $70.50 +Tax United States —$98.00 Other foreign —$191.00

All prices in CAD funds

Mailing address

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 printaction.com Tel: 416-442-5600 Fax: 416-442-2230

Annex Privacy Officer Privacy@annexbusinessmedia.com 800-668-2384 PrintAction

Organizers of drupa 2021 have announced the duration of the trade fair will be shortened from 11 to nine days. drupa 2021 will now be held from April 20 to 28, 2021, at the fairgrounds in Dusseldorf, Germany.

This decision was made due to the wishes of partner association VDMA (Printing and Paper Technology Trade Association) and exhibitors. The move was also made in reaction to any continuing travel restrictions, and organizers assuming that due to restrictions, the fair would have fewer visitors from overseas.

Despite recent COVID-19-related cancellations, such as Heidelberg, Manroland Sheetfed and Komori, drupa organizers say it currently still has over 1,500 exhibitors set to participate, including Koenig & Bauer, as well as a net hall space of more than 140,000 square metres.

In order to provide a safe environment, drupa is relying on a hygiene and infection protection concept that is is being updated regularly to reflect the latest protection regulations and official requirements.

Turbo Images has announced that it has acquired Lettrapub in a deal that brings together two Quebec-based leaders in fleet graphics. The acquisition also includes

Lettrapub’s U.S. operation, Team Coach Imaging

Turbo Images was founded in 1993 with a goal of becoming an expert in fleet graphics, while Lettrapub was established just a year later, in 1994, to become an expert in large-format printing and commercial signage. Its Team Coach Imaging operation specializes in fleet signage and digital printing for bus and recreational vehicles.

The acquisition became effective June 29, 2020. The financial terms of the agreement are confidential.

Image360, a franchise concept for the sign and graphics industry, is expanding throughout North America with two new locations set for Calgary, Alta.

The new Image360 centres will provide a comprehensive range of graphic solutions services to the local business community. Trained graphics specialists will work alongside clients to maximize the creativity and visual impact of environmental graphics, mobile graphics, way-finding solutions, trade show displays, retail signage and more.

Image360, which is a member of the Alliance Franchise Brands network, has locations in Canada and the United States.

Komcan Inc. and MBO America have reached an agreement naming Komcan as the sole authorized distributor of MBO equipment in Canada. The agreement is to include sale of equipment, parts supply and service of the MBO line of equipment.

Effective May 1, 2020, MBO became a wholly-owned subsidiary

of Komori Corp. under a new company name of MBO Postpress Solutions GmbH. Komcan is also the sole authorized dealer of Komori products in Canada.

The new agreement allows Komcan to offer both Komori offset and digital press lineups, as well as MBO finishing solutions.

Printing United recently announced its decision to move from an in-person event in Atlanta to a completely digital experience.

Printing United has now provided an update on its plans to present global programming and new product announcements with four weeks of content, running from October 5 to 26.

The digital experience will provide a new series each week, highlighting a different community focus, spanning from apparel, commercial, digital textile, graphics/ wide-format, in-plant, industrial, mailing/fulfillment and packaging.

The Mailworks has raised over $30,000 in sales of vinyl decals to support and stand with the Black Lives Matter movement. One hundred per cent of the proceeds of the decals will be donated in support of Black-owned organizations and enterprises.

Available on The Mailworks’ website, the 8.5” x 11” vinyl decals are available in four styles for $10 each. All proceeds from the sale of these decals will support a Blackowned organization or enterprise of the purchaser’s choice. Customers also have the opportunity to increase the amount of their donation.

Decals are printed on the Xerox iGen 5. This 2015 model printer offers a fifth colour option and multiple speed choices, and can produce up to 150 pages per minute.

The Mailworks’ vinyl decals are repositionable and removable. Items are shipped within one business day.

Sun Chemical and its parent company, DIC Corporation, have completed the purchase of 100 per cent of the shares of Sensient Imaging Technologies and certain other assets related to the production of inks.

The strategic investment in digital ink supplier Sensient Imaging Technologies will allow Sun Chemical and DIC to expand its inkjet ink capabilities and expertise using complementary technologies that further strengthen

the highest standards of services and solutions to its customers and distributor partners.

The acquisition also supports Sun Chemical’s ongoing commitment to sustainability by expanding its offering of inkjet inks for textile and dye sublimation printing –known for their improved sustainability profile. Inkjet is a strategic segment for Sun Chemical and DIC, and this new investment demonstrates its commitment to the digital segment.

Through this acquisition, Sun Chemical hopes to capitalize on the opportunities digital print has to offer for growth and expansion.

St. Johns Packaging Ltd., based in Quebec, recently announced that it has completed the acquisition of Amcor Flexibles UK Ltd.’s bakery packaging business in Ilkeston, Derbyshire. The centrally-located facility specializes in printing and wicket bag manufacturing for the UK bakery market.

Tetra Pak has announced it has set a target of net zero emissions across its value chain by 2050, along with an intermediate target of net zero emissions across its own operations by 2030.

Tetra Pak will focus on four key areas to achieve net zero GHG emissions across its own operations by 2030, and across its value chain by 2050: lowering energy-related emissions through energy conservation; improvements in energy efficiency; installing on-site solar photovoltaics; and purchasing renewable energy.

Since 2011, Tetra Pak has invested over EUR16 million in energy efficiency, preventing energy use from increasing by 23 per cent over that time period. To date, the company has installed about 8,000 solar panels, delivering low-carbon electricity while saving operational costs.

Tetra Pak has increased its renewable energy usage from 20 per cent in 2014 to 69 per cent in 2019, and is on track to reach its target of 80 per cent in 2020. It did this by installing solar panels across its operations and purchasing renewable certificates.

Fujifilm Canada Inc. has announced the promotion of Stephane Blais to the newly-created role of vice president, graphics systems and technical services divisions. In this role, Blais will be responsible for managing the expansion of Fujifilm’s graphics systems business in Canada by creating and implementing strategic business plans, financial planning and overseeing customer relationships, including national contract, direct and channel sales.

Company veteran Blais has been with Fujifilm for 30 years. Most recently, he served as national director of technical services at Fujifilm Canada Inc., and has also held a number of roles with increasing responsibility within the graphic systems, imaging and photofinishing divisions of the business. In this new role, Blais will report directly to Hideaki Tsuda, company president.

Light Visions has appointed Wes McCallum as its new vice president, transformation to help lead an overall organizational growth strategy. This recently-created role reflects the company’s recent deployment of disruptive technology to meet demand.

“I am delighted that Wes McCallum has accepted the invitation to join our organization as we’ve been designing this position over the past two years and have tailored the role for the changing, new world,” said Al Alexandruk, president, Prolific Group.

Landa Digital Printing (LDP) has announced the appointment of Arik Gordon as its new chief executive officer. Gordon joins the company after spending 18 years at Orbotech. In the past two years, he served as executive VP of strategy and growth at the company, and was responsible for defining and leading the company’s future technological growth strategy and its expansion into new markets. Most recently, he served as president of Orbotech’s Printed Circuit Board division.

Michelman has added two new associates to help continue growth in its digital printing, flexible packaging, paper converting and corrugated markets.

Pete Petrie joins Michelman as sales director for the company’s Printing & Packaging, Americas region. Most recently, Petrie spent 23 years with WS Packaging Group, leading multiple teams responsible for the Labels for Package Decoration market segment, strategy development and relationship management with major brands.

Dave Jeffers has been named Michelman’s territory sales manager for Digital Printing. Jeffers has spent over 17 years with Yupo Corporation America, managing technical service and new business development. Most recently, Jeffers served as territory sales manager at The Eastman Kodak Company.

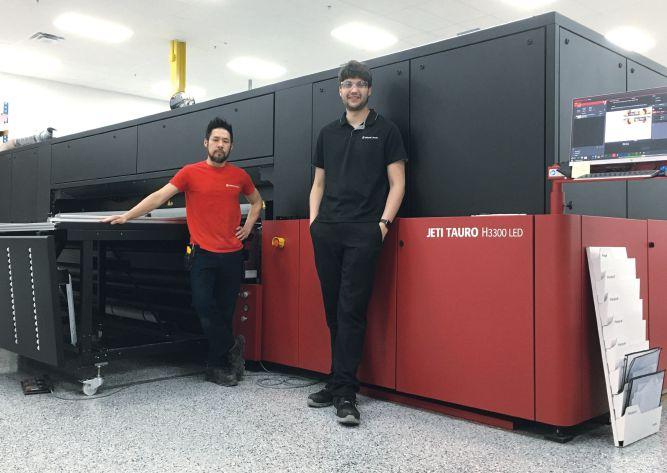

Mitchel Lincoln Packaging, based in Montreal, Que., has completed the installation of an Agfa Jeti Tauro H3300 UV LED wide-format inkjet press. The 10’ wide press offers increased productivity, high print quality and low ink consumption, which the company says will help improve its service offerings with faster turnaround times.

Print Resources Group has expanded its product offering with the recent addition of the Any-002 Digital Label Printer and AnyBlade Label Finisher. “Labels & packaging is a fast growing industry and with this latest install, PRG is able to increase revenue and capture some of the market share,” said the company.

Jones Healthcare Group has invested in a new Uhlmann blister packaging line. The automated line includes a two-lane B 1440 blister machine and C 2305 cartoner, with end-of-line stretch-wrapping and bundling. The line will be installed at Jones’ Brampton, Ont. facility, and is expected to be operational early next year.

October 5-26, 2020

Printing United Digital Experience Online

March 9-12, 2021

FESPA Global Print Expo 2021 Amsterdam, The Netherlands

March 23-25, 2021

Labelexpo Americas 2021 Chicago, Ill.

March 23-25, 2021

Brand Print Americas 2021 Chicago, Ill.

April 15-17, 2021

Graphics Canada Mississauga, Ont.

April 20-28, 2021

drupa 2021

Düsseldorf, Germany

June 10, 2021

DIA Annual Golf Tournament Aurora, Ont.

August 12, 2021

OPIA Toronto Golf Classic Brampton, Ont.

Sept. 9-11, 2021

Sign Expo Canada 2021 Mississauga, Ont.

Editor’s note:

Please note, we’ll be postponing the Canadian Print Awards until further notice. However, we’ll still be accepting your submissions produced from August 31, 2019 to August 31, 2020! Please stay tuned for more information.

The year brought new trends such as inker response times and getting up to colour in less time.

By Nick Howard

For well over 40 years, I have only used one brand of paint spray gun. Sure, I did drift once and tried a Binks, but I always returned to my DeVilbiss JGA. It so happens I still have that original gun. I love my DeVilbiss. Why, you may wonder? I don’t have an entirely rational reason other than during thick and thin, with some jobs being more than challenging, my JGA has never let me down. Today there are dozens of probably fantastic paint spray guns, which, when used correctly, can apply coatings from base primers to seal coats, but I have no plans to change. Everything from air dry oilbase enamels to lacquers and base primers has run through my JGA, and I take excellent care of it, carefully cleaning it after each use. This DeVilbiss is part of who I am.

ing politics, now entirely on display in the United States, is full of often ridiculous drum-beating for one party or another. Facts rarely play a role. Often gut instinct prejudices our ability to reason and access correctly.

Today’s printing machines are truly amazing. Nobody makes an awful press, digital or offset. Some are more user friendly, while others have features only they can offer. However, every press can produce a high-quality saleable print. Twentyfive years ago, offset press manufacturers started to take waste seriously. This period was well after a milestone of press innovations, including plate loading and preset functions, which appeared around 1992.

tial prospects were treated to an offthe-cuff remark from a competing salesman, and it had a negative effect, though the design issue was solved in a very short time.

manroland’s sleekest and most technologically advanced press in the mid-1990s.

Since 1820, a few years after American George Clymer had finally invented the first “all iron” printing press, without a “wine screw,” he found himself in a dog fight with Englishman Richard Cope and his all English “Albion” design. For the next 25 years, Clymer’s Columbian and Cope’s Albion would battle it out for a printer’s favor. So began the argument of who makes the best printing press.

As with my DeVilbiss JGA, I bonded with a tool that seemed never to let me down even though there are similar arguments amongst the trade favouring other brands. Humans act like this, bringing preferences and bias to play. We don’t have far to look for it, either. Polariz-

The year 1998 brought new trends such as inker response times and getting up to colour in less time. One particular manufacturer drastically reduced the number of rollers in their newly designed inker. Fewer rollers provided a faster reaction, except that’s not quite how it ended up. Severe ghosting was an unfortunate result. Back to the drawing board they went, to correct the flaw, but not before word spread throughout the industry. Someone once said that a lie gets halfway around the world before the truth can get its pants on. How true, and yet how unfortunate. Most likely spurred by competitive salesmen, design missteps such as this are the elixir of the competition in the hope customers will form negative opinions. Poten-

During the summer of 1995, a battle was in full swing to win a crucial order from a large packaging printer in North Carolina. As is often the case, the various press manufacturers were whittled down to only two. One of them was manroland. I knew the salesperson for the competing press quite well, and he had worked hard to win this order. Demonstrations and press trials all went well, and there seemed no potholes on the road to victory. Then he got the call to come in. He was ensconced in a chair in the company board room when the CEO gave the salesperson the bad news: manroland was winning the order.

Great news obviously for manroland, but utter dejection for the competing salesperson. When pushed, the CEO could not come up with one technical issue that moved the needle. All the CEO said was both presses performed well – there were no real differences noted. However, one thing swayed the decision: “That manroland sure looked damn good.”

In the mid-1990s, manroland certainly had the sleekest and most technologically advanced press in the 700. The press stood out just in appearance. Under the covers, the 700 was bursting with all sorts of futuristic technology as well. This

A Nebiolo press, circa 1978, which looked quite modern for its day and age.

CEO felt he was buying the future, which, in fact, he was. Looks alone will not drive sales, though. If it did, Nebiolo would still be in business. What Nebiolo could do with metal covers and the Italian flair for style was so amazing, someone should have written a book called One Hundred and One ThingsYou Can Do with Sheet Metal

A good friend told me a story about how he started his print shop. Looking to purchase some machines, he called a local rep of one of the most prestigious manufacturers. Describing the type of work he wanted to produce, the salesperson, looking disinterested, gave him some unsolicited advice: “you’ll never make it, give up now.” Angered, the printer did not “give up” and, to this day, has refused to buy a press from that manufacturer. That meeting and the salesperson’s stupidity proved costly, but not for the printer, who has gone on to great success. This manufacturer simply lost out by making wrong assumptions. How crazy to lose a potential order when the loss had absolutely nothing to do with the actual printing press or the company behind it.

In my 40-plus years spent in this industry, I worked hard to read a person’s bias and preferences. Our usual clients were small to medium-size firms, and often the owner started the business working like a dog to build and nurture it. As the company grew, employees were hired, and they brought along their own opinions and preferences. In those early days, if a printer purchased

a press that seemed never to let them down, they generally stuck with it. I especially loved dealing with those entrepreneurs because they were genuine. If they cut their teeth on a particular press, they stayed loyal.

Salespeople play essential roles in decision-making and, ultimately, which machine ends up as number one. The owners that have operated machines could see through any rep’s sales pitch and personality. If the salesperson had experience running a press (and this is quite rare), then they often spoke as peers. However, if that salesperson was fast and loose with facts, or offhandedly muttered untruths or repeated manipulated gossip, a void could quickly form. Today’s printer/manager who is the decision-maker rarely has the “on-press” experience and is much more likely to use a salesperson to arrive at a decision. That same manager is also less likely to be loyal to a brand.

Ultimately. coming to a determination and therefore rating a top choice can be quite simple when other variables are factored in. Is the current service support pleasant? Were the suppliers easy to deal with and willing to solve problems quickly, or was it always difficult to get parts and service in rapid time? How many technicians are in my area, and of those, how many are any good? If every time you need assistance and someone has to always fly in, this is both costly and slow. When you look at the entire industry, there is a wide disparity between the best and the worst manufacturers and dealers when it comes to the most crucial decision factor: service and customer care.

Whether your choice is German or Japanese, the best press doesn’t care what language the factories speak. Although both ecosystems try and do the same quality work, that doesn’t always mean they are equal. Consider how language could impact your choice. Is there confusion when you’re desperate for the right information? Are there difficulties having the press serviced or updated? Can a foreign language affect the speed of response?

Communication and methodologies can be troublesome and not intentional, but one wonders if an Enigma decoder is needed to unscramble some manufacturers’ thinking processes. Difficulty dealing with a supplier is a crucial reason why printers choose the machines they do and alter their preferences and bias towards a specific manufacturer.

So, if we are going to rank equipment from first to worst, it’s the overall picture that counts more than a particular brand and machine model.Whenever we had customers at our plant for a press inspection, I took particular interest in getting to know all the entourage members, from the owner to his designated pressman. Understand-

ing how both think and what biases they hold helped me focus on what decisions they would ultimately make.

The best press is more than a salesperson’s chatter. It’s about harmonizing one’s instincts with positive experiences. Indeed, in today’s environment, with younger managers making critical choices, the price still gets top billing. But after price, there is that gut impression often based on previous experiences. If it were fair and easy to rate machinery based on simple criteria such as a manufacturer’s experience or the number of units in the field, decisions could be clear. For example, if you appreciated legacies, of those that have been manufacturing offset presses the longest, manroland wins that prize, with Komori and Koenig & Bauer not far behind. If it’s based on units sold, then Heidelberg takes the win. Innovation? Now that gets much more difficult.

Koenig & Bauer, the world’s oldest press builder, has launched a brand-new press: the Rapida 106 X. Not be dismissed, Komori, manroland, RMGT and Heidelberg have also recently upgraded their platforms. There is no clear ultimate number-one here, even though the Rapida is said to be able to run carton at an unfathomable 20,000 sheets per hour.

Every press manufacturer builds fantastic equipment that, given the right set of circumstances, would be a wise choice. Ranking these companies is misleading to anyone not coming in at the top spot. The best way to rank presses is to weigh other factors, including price, service response time and your own experience and bias. Just recently, a large high-end cosmetics printer bought a new press. This firm had been loyal to a supplier and had several of the manufacturer’s presses on the floor, going back to the 1970s. A new plant manager arrived about a year ago, and things changed quickly.This plant manager had a decades-long association with another press builder, knew most of the people, visited the factory a few times, and guess what? This printer just changed suppliers.

We all have particular tastes and prejudices that are instrumental in how we live our lives and make the decisions we do. I will never change my DeVilbiss JGA even though there are possibly better alternatives. My brand of vehicle hasn’t changed in almost twenty years. I choose what I like, but it may not be the best. The one that gets the winning order either has the cheapest press (especially a factor today) or has understood a buyer the best, and shown it exemplary service. That manufacturer gets the number-one slot.

NICK HOWARD, a partner in Howard Graphic Equipment and Howard Iron Works, is a printing historian, consultant and Certified Appraiser of capital equipment.

nick@howardgraphicequipment.com

By Bob Dale

With competitive bidding, everyone has heard horror stories of someone being awarded a job where the price charged is less than the cost of materials. We tell the customer that this is not possible, but the job is never awarded to us.

I was on the buyers’ side for the last 15 years and remember during a competitive bid for a tender, one supplier quoted almost 50 per cent of the current price. As a former printer, I advised our procurement team that this was not possible without any major technology, production or material changes, and actually had to convince the printer that this was not possible. I had the printer prepare an invoice for some specific orders and he realized his mistake and the quote was corrected.

There are not many buyers who would do this, but I needed to ensure my company would have a sustainable supply for this printed product, and I was interested in a long-term relationship, instead of short-term savings.

The impact of the COVID-19 pandemic has resulted in less work in some

Printers need to focus on value-added services instead of selling on price. This requires a consultative sales approach – understand full supply chain and product life cycle to explore opportunities to reduce costs to win the client!

segments, and some printers are getting desperate to get whatever work is available. Desperation pricing will not help; not only does it harm your bottom line, but it also harms your staff, suppliers and the industry! If you are operating a lean

organization, selling below cost and not costing the work properly will speed up your demise.

Customers who award the job to you only because you have the lowest price may abandon you when you quote work at true cost or, heaven forbid, try to recover previous losses, because your relationship is based on low cost only. Earn the respect of the client and bring more to the relationship than low prices.

Printers need to focus on value-added services instead of selling on price. This requires a consultative sales approach –understand full supply chain and product life cycle to explore opportunities to reduce costs to win the client! But that discussion is for another day.

For those printers that think that the temporary Canada Emergency Wage Subsidy (CEWS) program enables printers to lower their prices, that is a quick way to bankruptcy. To be eligible, your company has experienced a defined loss of revenue, which also means your utilization rate has declined. As your utilization rate decreases your true cost increases, since you now need more revenue to cover your fixed costs that are amortized in your Budgeted Hourly Rate (BHR). On paper, accounts would say that you need to increase your BHR, but in today’s competitive market that would be a challenge.

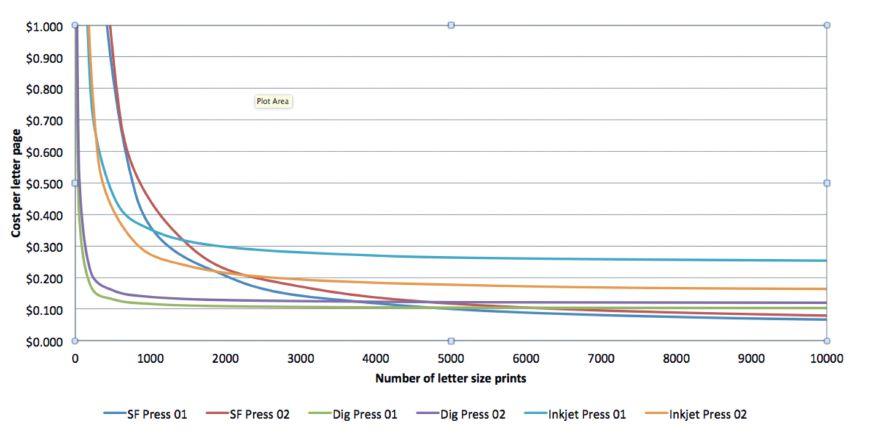

Understand your cost structure with budgeted hourly rates. There are great tools available through the CPIA/Printing United Alliance. They have several tools and services such as Print-AS Cost Calculator or Cost Rate Advisor subscription.

The impact of the COVID-19 pandemic has resulted in less work in some segments, and some printers are getting desperate to get whatever work is available.

With the BHR calculations, the final adjustments are for number of shifts the equipment is planned to operate and the estimated utilization rate. The difference between a press operating one shift with low utilization has a true cost rate that can be four times more than the same press operating three shifts with high utilization! Therefore, if your operation pre-COVID was charging $200 per hour based on a high utilization, multi-shift operation, and you now reduce your shifts and decrease your utilization, your true cost can now be $800 per hour for the same piece of equipment.

Measure your win/loss ratio. If you have three main competitors, a competitively priced printer should win one of three quotes submitted. If you’re winning more than that ratio, that indicates your prices are too low and you are leaving money on the table. If you are winning less than that ratio, then your prices may be high, or someone else has a more economical way to produce the work.

One final thought: pricing only matters if you are getting paid, so don’t forget credit checks! Reward paying customers with good pricing and service, and add a little for interest and recovery effort for the slow payers.

BOB DALE is Vice President of Connecting for Results Inc. Bob has many years of graphic communication management experience, including over 15 years offering management consulting services, transition execution and support, and has published many columns on effective cost management and management information systems for the graphic arts industry.

Discover the new Speedmaster 2020 generation with innovative solutions for Commercial, Label, and Packaging Printing. Experience unprecedented performance thanks to a new scalable user interface and intelligent assistance systems, which enable integrated automation and simplifed production processes.

Discover these innovations at heidelberg.com/nextgeneration

HP Canada partners with federal government to 3D print face shields for frontline workers

By Kavita Sabharwal-Chomiuk

s the coronavirus pandemic continues to impact lives around the globe, personal protective equipment (PPE) remains vital to guard frontline workers against the spread of COVID-19.

In an effort to help ease the PPE shortage, in May, HP Canada announced it had formed a partnership with the federal government to supply 540,000 3D printed face shields to frontline healthcare workers. According to HP Canada, “this part-

nership marks the largest coordinated effort to establish a domestic supply chain for critical PPE at this scale”.

In order to fulfill the order, HP Canada enlisted nine members of its digital manufacturing partner network that specialize in 3D printing technology to mobilize their teams, technology, experience and production capacity to manufacture face shields for Canada’s frontline workers. The nine partner businesses are spread across Ontario, British Columbia, Manitoba, Quebec and Alberta, and include Leo Lab, EXO-S and Proto3000. The shields began shipping out soon after the

HP Canada has formed a partnership with the federal government to supply 540,000 3D printed face shields to be distributed to frontline healthcare workers.

The ear-saver technology on HP Canada’s 3D printed face shields help make them more comfortable for all-day wear.

partnership was announced in May.

According to Mary Ann Yule, president and CEO at HP Canada, HP decided early in the pandemic to enlist its 3D printing team and digital manufacturing community with designing, validating and producing essential parts for medical responders and hospitals. In March, HP also announced that it was making 3D design files available for free to accelerate production of critical parts, including PPE.

“We knew we could step in with a 3D printed solution manufactured in Canada to help fulfill the urgent need for PPE, but couldn’t do it alone,” saysYule. “Thanks to the strength of our digital manufacturing community, we leaned on small and medium sized businesses across the country to quickly pivot their supply chain and outputs to focus on PPE.”

Reuben Menezes is marketing manager at Proto3000, a member of HP’s digital

PPE due to the printer’s speed, throughput and ability to 3D print with biocompatible materials.

“It is a binder jetting style of 3D printing that layers powdered PA 12 Nylon material, combines it with fusion agents and heats it to produce a very strong part,” says Menezes.

Menezes says a single printer can produce approximately 275 shields over an 11-to-16-hour period, however he notes that Proto3000 has multiple systems. At full capacity, Proto3000 can manufacture 1,500 to 2,000 face shields per day.

He adds that Proto3000 doubled its 3D printers to make sure the company would be able to produce the face shields as quickly as possible. The shields are being delivered to the Government of Canada, which is handling the logistics of where to distribute the critical PPE.

The shields have been approved for use by frontline workers by Health Canada. The process to get the shields approved was not a lengthy one, as the necessity for PPE was strong enough that the request was rushed by the federal government.

“HP Canada brought together industry experts and our digital manufacturing community to form a council which allowed us to respond quickly to the urgent need for PPE,” says Yule. “The Canadian federal government then expedited the process by moving to ensure COVID applications for licensing were processed quickly. I like to say we went from a dream and powder to face shields protecting Canadians in less than one month.”

According toYule, the pandemic has led to a watershed moment for the 3D printing industry, as its benefits – speed, flexibility, sustainability and design capabilities –have allowed manufacturers to shift gears quickly amid the pandemic.

manufacturing partner network. According to him, as one of Canada’s largest 3D printing companies, Proto3000 knew that it would be going to work to help supply critical PPE amid the shortage experienced when the pandemic hit.

“We worked on getting our Health Canada approval to manufacture class 1 medical devices, and in tandem, the HP team quickly validated different designs and applications that could be 3D printed and once a final design was settled on for the face shield, as an HP production partner, we got to work on making them,” says Menezes.

The HP MultiJet Fusion 3D printing technology is used to create the headpiece of the face shield. Proto3000 has been using its HP MultiJet Fusion 3D printing technology in its ISO 9001:2015 service bureau for nearly two years, so it was a natural next step to start quickly creating

“Now, companies are developing new supply chain strategies for risk mitigation to address future pandemics and guard against volatile global economic trade cycles. Advanced 3D printing solutions can help organizations accelerate these strategies and will continue to shape the manufacturing landscape in Canada,” she says. “Increasingly, more companies are looking to transform their manufacturing capabilities, not only to remain competitive but to strengthen their response to demand for products made in Canada. It is fantastic to see local businesses joining forces to reinvent manufacturing in Canada. We are extremely proud to be able to support the healthcare industry during these unprecedented times.”

Menezes adds that the team at Proto3000 is happy to play its part in supporting the country amid the pandemic.

“We see all that our healthcare workers and essential staff are doing to keep us safe and keep the country moving, and we are honoured to be able to support them in any way we can,” he says.

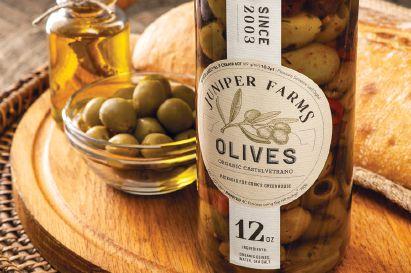

A closer look at the processes behind the array of labels seen today

By Heather Roth

When buying a product, do you often make your choice based on the label? If your answer is yes, you’re not alone.

As consumers decide within seconds which product to buy, labels and packaging are key factors for product to be competitive on the shelf. It’s not just the visual appeal of a label or package that makes the sale, but also its tactile allure with embellishments such as gloss or embossing.

Since the mid-2000s, digital label printing and finishing has evolved as a popular process for printers. What’s produced in the printing industry and the technologies behind it is heavily influenced by consumer purchasing behaviour.

Here’s a closer look at the processes behind the array of labels you see on

shelves today.

Why go digital?

The need to produce great looking labels that consumers love is the same today as it was years ago. However today, more challenges are involved.

When label printers combine their customers’ needs with their own business revenue and profit initiatives, it’s obvious that the process for completing jobs quickly and efficiently is changing fast.

Label printers look to invest in presses that provide added potential for greater sales growth and increased profitability, while reducing production cost and complexity.

Inkjet technology is non-contact, with few moving parts, no printing plates, no drums and no blankets. Quite simply, it provides consistent print results.

The inks are designed to deliver a wide gamut while also delivering key mechanic-

With digital label finishing, printers can produce complex labels on a wide range of substrates for maximum flexibility and future-proofed production capabilities.

al features and benefits of inkjet digital printing technologies. They provide superior adhesion with unparalleled resistance to heat and cold, sunlight, chemicals and abrasion to maintain the highest quality through the life of the final product.

Unique digital textured effects deliver increased shelf appeal that can open up new applications for the press owner.

There are digital label presses in the market capable of achieving in excess of 92 per cent of the Pantone® colour range without the need to make plates or the complexity of mixing spot colours.

These presses can also accommodate customer demand for shorter production runs, reduce lead-time with multiple SKUs or versions (i.e. flavours, colours or varieties), and combine the productivity of flexo printing. The flexibility offered by rapid job changes in digital technology are just a few of the many benefits of inkjet printing.

To keep the inkjet label press churning, it’s common to move the printed rolls to a separate machine to complete the finishing process.This helps reduce production cost and complexity.

Finishing machines for digitally printed labels can range from basic inspection, slitting and rewinding to more elaborate die-cutting and embellishing. Short set-up times, low waste generation, simple handling and a modular design for later expansion possibilities are key benefits of offline label finishing machines.

This is also where special finishing effects come into play that make labels and packaging pop, such as hot foil stamping, gloss or matte varnish, laminating foil gloss or matte, UV-blocker laminate, multilayer labels, screen printing and cold foil.

The result is a digitally printed label on a finished roll that is slit, embellished and ready to be applied to a bottle, container or package.

Hybrid label printing and finishing systems provide both processes in a modular, single in-line solution and are especially advantageous when producing highly-refined labels. Many suppliers in the narrow web industry have aligned their expertise in close partnerships to offer these hybrid solutions to a growing number of label printers.

In this end-to-end solution, a configuration could involve up to

seven colours including opaque white, 600 dpi native print resolution and operating speeds accelerating to 70 m/min(230 ft/min), an unwind/ rewind unit and waste rewind, multiple die cutting (die stations capable of running full or semi-rotary mode with simple changeover) and printing stations (rotary flexo and flatbed screen printing).

Embellishments also possible with a hybrid solution include lamination, cold foiling, hot stamping, label inspection, small roll programmable auto turret winding and 100 per cent servo control and compliance for food packaging.

User friendliness is a very high priority in the design, functionality and maintenance of both printing and finishing machines, with handson initial training and subsequent support traditionally provided by the suppliers.

An open architecture design provides easy operator access to the web and integrated modules, for increased efficiencies in operation/web handling and movement during production.

Applications for digital label printing and finishing are vast, including food and beverage, pharmaceutical, industrial, health and safety, consumer goods and personal care.

Vital for industrial applications, adhesion and abrasion are important for all printing applications to ensure the finished goods survive the journey to the shelf in prime condition, with the longest possible shelf life.

It’s important to use tested and proven ink sets using industry standards to maintain full adhesion on the widest range of substrates and remain highly abrasion resistant to maximize shelf appeal.

With virtually unlimited printing and converting options available in digital label finishing, printers can produce complex labels on a wide range of materials and substrates for maximum flexibility and future-proofed production capabilities.

Going digital helps label printers react to ever-changing customer demands, to ensure their labels remain a step ahead on the highly competitive shelf.

Heather Roth has been in the label printing industry for over 10 years as Marketing Communications Manager with Rotocontrol. Rotocontrol and Domino recently partnered to offer a hybrid solution in digital label printing and finishing.

The recruitment process has gone completely virtual during the pandemic, with many companies opting for video interviews with candidates.

will become part of the new normal

By Meagan Gillmore

Workplaces have fundamentally shifted during the COVID-19 pandemic.

As jurisdictions across Canada reopen their economies, employers need to consider how they will attract and retain top talent in this new work environment.

Virtual interactions have not just altered the process of recruitment, they’ve become the only available method for everything from initial recruitment of perspective employees to onboarding and training of new hires.

“People are being hired without the in-person meeting happening,” says Rowan O’Grady, president of Hays Canada. “And then, there’s the completely

unheard of concept that they’ve never been to the office even after they start working. It’s just completely different.”

In the future, many workers may consider in-person recruitment and onboarding methods just as baffling. Reports indicate that a majority of workers are content to work from home, and may prefer to continue doing so even after the pandemic restrictions are lifted.

In May, a Conference Board of Canada survey indicated that just four per cent of businesses will require employees who have been working remotely during the pandemic to return to the office full-time while the pandemic is active.

Also in May, RBC released a report that said 75 per cent of employees interviewed would prefer to continue working from

home — for at least some of the time — after the pandemic ends.

Some companies are already opting to move in the direction of virtual-first, or virtual-only workplaces. While those predictions became public, Shopify announced it would permanently move to a work-from-home model.

Techniques that may have seemed only beneficial in the pandemic may become mandatory skills for business progress and recruiting.

“I don’t think recruitment is going to be entirely virtual, like in some cases it is now,” says Evangeline Berube, a branch manager at Robert Half in Edmonton.

“I do see organizations hiring more remote workers moving forward, and some of those workers may not be in the same province or even country, so I think the skills that we learn right now around doing some of this is just going to help us be a little nimbler and more flexible, moving forward.”

The recruitment process has become completely virtual through COVID-19, with many companies opting for video interviews with candidates.

But these platforms, while helpful, can’t replicate the information gleaned through interpreting body language during an in-person conversation, says Berube.

“It probably takes a little more time to really feel comfortable when you meet someone for the first time online — to get a sense of their cultural fit,” she says.

Interviewers need to be even more prepared for virtual interviews, Berube adds. Conversations may not flow as naturally in this setting, so it’s best to have a more structured approach ready to use.

All participants need to know how to use the technology required for the interview, and how to contact each other if there are technical difficulties. It also means having a clear plan for what questions will be asked in the interview, and what structure it will take if more than one person is asking the questions.

Candidates should be informed beforehand if more than one person will be

Percentage of employees interviewed that would prefer to continue working from home — at least some of the time — after the pandemic ends.

interviewing them, says Berube. This will prevent any confusion or panic when they log onto the call and see several faces looking at them.

“It’s good to have them feel as comfortable as possible and have as little unknowns as possible going into the meeting.”

Candidates also need to know they have their interviewers’ undivided attention.

“There’s a potential to be flippant, or a potential to be not prepared, or not give the interview the respect that it probably needs,” says O’Grady.

An in-person interview is a “formal event,” where the employer has to physically remove themselves from their other duties and focus on the potential hire, he says.

With a virtual interview, it’s possible to review an unfinished report or pending email with just a click of a button while the candidate delivers a thorough answer to the question.

The “cardinal sin” would be to answer an email during the call, says O’Grady.

Employers need to be able to address concerns about COVID-19 in the interview. This includes knowing what the company plans to do to keep workers safe if they do have to work from the office eventually or travel for their work.

“People are highly aware right now of the social distancing and what’s being required (to take precautions with COVID-19),” says Berube. “That’s going to be a bigger part of the hiring process now in terms of their questions and comfort level about joining your company.”

At the same time, employers will need to assess if potential hires will be able to stay motivated and productive while working remotely. They want to determine whether or not individuals can remain focused and produce quality work when there is little direct supervision.

“References are very key when you’re recruiting to helping you understand people’s past performance as it relates to some of those characteristics,” says Berube.

COVID-19 has simultaneously restricted the amount of time employers and employees spend together and expanded the pool of eligible candidates.

As workplaces become increasingly virtual, limiting recruitment efforts to individuals who are able to physically work from a central location is unnecessary, says Shahid Wazed, founder of the Top Talent Summit and an Edmonton-based talent coach and consultant.

Companies need to “go with a virtual-first mindset. That opens up a whole lot of a talent pool,” he says. “Those artificial limitations were there until COVID-19 hit us.”

A virtual-first mindset does more than just open up qualified candidates who live further away from a company’s building, says Wazed.

It also could make it easier to attract top talent who are more experienced or established in their careers.

“It’s always been a challenge to make someone move in their mid-career. It doesn’t matter what you offer,” he says, noting that by the time someone reaches the middle of their career, they often have greater family responsibilities.

Employers should consider allowing more flexibility in work schedules, according to Wazed.

Employees should not be required to work a standard 40-hour workweek if they’re performing well and generating revenue for the organization.

The key is to “not be rigid,” he says. More flexible schedules can make it easier for candidates who may need more time to care for children or aging parents.

The pandemic has forced workplaces to recognize the need for employees to respond to unexpected and urgent situations, says Wazed.

The most challenging part of recruiting during a pandemic is successfully onboarding new hires, according to these experts.

“It’s an unsettling experience to join a team when you have physically never met them, you have probably never been in the office of the company,” says Berube. Introductory materials are often delivered virtually.

“That’s completely normal,” says O’Grady. “The bit that gets lost (when doing onboarding from home) is the feeling that you’re actually working for a company that other people are working in, that there’s people and personalities and relationships.”

“The people that you work with are a huge influence on whether you’re happy at work or not,” he says.

Employers need to intentionally schedule social videoconferences so new staff get to see the rest of their team and begin to develop relationships with them. When staff do return to the office, virtual meetings can be a way to keep all employees connected.

“I think that (employers) will have to figure out how to make people feel included and not feel left out when people go back to work,” says O’Grady. “Now, potentially, this is actually one of the challenges of inclusivity — how to include people who just aren’t there.”

Meagan Gillmore is a freelance journalist in Toronto. This article originally appeared in PrintAction’s sister publication, Talent Canada.

Ottawa-based Tilia Labs, a developer of planning and imposition solutions for the printing and graphic arts industry, is now offering its AI-driven software technology to improve productivity for HP Indigo digital presses.

As part of this collaboration, Tilia Phoenix uses AI technology to lower costs and optimize production in all print segments, including packaging, labels, commercial and wide-format. Its AI-generated layouts eliminate the need for template-based imposition, and instead focus on manufacturing requirements and constraints.

Tilia Phoenix’s imposition AI is able to keep up with the fastest presses on the market, according to the company. For HP Indigo users, the partnership opens up opportunities in a number of market segments, including labels and flexible packaging, folding carton, commercial sheetfed and commercial webfed.

Tilia Phoenix can also integrate with any workflow or MIS system to help with job estimation, planning, maximizing press time and reducing postpress complexity. Tilia Labs also adds HP-supported JDF output to streamline job submission to the HP Digital front end.

colours.

Konica Minolta says the AccurioJet KM-1e boasts high image durability without lamination, the ability to print on water-resistant media and compatibility with the MGI JetVarnish.

Konica Minolta has set its sights on cut-sheet label applications for the first time with the release of its AccurioJet KM-1e sheetfed inkjet press.

Featuring UV inkjet technology, the KM-1e prints, without pre-coating, on a wide range of media, including plastic substrates, foiled and embossed paper, metallic media and synthetic substrates. It will accept paper stocks in a thickness range between 0.06mm and 0.6mm and a width of up to 750 x 585 mm.

The press prints at a resolution of 1200 x 1200 dpi at 3,000 B2+ (585 x 750mm) sheets/hour, with automatic duplex printing at 1,500 sheets/hour.

The KM-1e features a new online interface allowing direct connection to third-party post processing lines. Konica Minolta is working with partner MGI on integrating its JetVarnish digital embellishment equipment with the KM-1e, including digital varnishing, digital cold foil and laser cutting. A tape inserter further provides efficiency in post-processing.

The printer prints in four colours in a single pass. The imaging system uses the company’s patented Dot Freeze technology (DFT) to “selffreeze” ink drops immediately upon contact with the substrate. This results in a rapid change in temperature, which turns high-viscosity inks coming from the printhead nozzle into low-viscosity, immobile ink droplets when they touch the material. Konica Minolta says this eliminates mottling and allows printing on porous materials while extending the CMYK colour gamut, reducing the need for special

Roland DGA Corporation has announced the launch of its new TrueVIS VF2-640, a 64-inch eco-solvent wide-format printer designed to provide unparalleled colour gamut expansion and print quality. The VF2-640 offers advanced colour control and vibrancy, making it easy to produce colour-accurate signs, vehicle graphics, labels, decals and heat transfer apparel.

Roland DG’s first “print-only” model within its TrueVIS series, the VF2-640 includes a number of features from the TrueVIS VG2 series of printer/cutters, and can also produce previously unattainable colours. With VF2 comes a new TR2 green ink which, when combined with TR2 orange ink in process colours, allows for a significantly wider colour gamut. This specially formulated TR2 green ink is now available for use with the TrueVIS VG2 series.

The VF2-640 features a new True Rich Color 2 Preset, which allows users to combine vibrant colours with neutral greys, smooth gradations and natural skin tones to produce vivid, photorealistic output. The expansion of green colours in True Rich Color 2 provides additional process colours, while a Green Roland DG Color System Library with 142 newly available spot colours allows for enhanced colour matching and reproduction.

The VF2 incorporates four FlexFire print heads, which provide colour vibrancy and detail, even in high-speed modes. It also includes a new, even more stable TU4 media take-up with two modes for versatility, a newly-designed pinch roller system for simple media loading and improved tracking accuracy, and smart new media clamps that

increase ease of use and streamline workflow. The VF2 is also equipped with Roland DG Mobile 2, a feature that allows test printing, cleaning and troubleshooting from a tablet or smartphone.

The VF2 can be paired with Roland DG’s GR-640 large-format cutter, or a Roland DG Pro series cutter, for the cutting of decals, labels, heat transfers and other print-and-cut applications. Print/ cut data can be automatically processed by the included VersaWorks 6 RIP software, for maximum production efficiency.

The VF2-640 comes with a twoyear warranty and Roland’s customer service and support.

Mactac has launched a new line of pressure-sensitive papers and films for the cannabis sector.

The new cannabis labelling materials can adhere to small mandrel containers and vials. They are also proven to withstand a range of environmental and other conditions, including moisture, heat and humidity.

Available in paper and film constructions, the labels are designed to meet the needs for all forms of cannabis, ranging from solid and

semi-solid to viscous and liquid. The labels can be used in a number of applications, including glass, pop-top and reversible cap vials, cartons, stock glasses, bags and pouches.

The line was developed to meet the strict needs of the medical cannabis market, ensuring label legibility with secure, long-lasting performance.

Superior

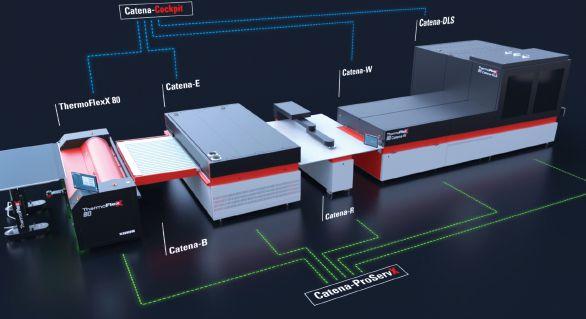

Flint Group recently announced its Catena+ fully automated plate processing line, featuring equipment modules Catena-E (UV LED exposure), Catena-W (solvent plate processor) and Catena-DLS (dryer, light finisher and plate stacker combination with robotized plate transport). The modular system can join together for various levels of automation with minimum operator intervention.

A Catena-DLS module can be connected to a Catena-W for automatic plate processing. The Catena-DLS has 10 drying units, 7 stacking positions and a light finisher. Robotic movements ensure plates are fully finished with no operator intervention after loading into the washer.

Once the operator has removed the cover sheet, the plate is automatically loaded into the imager, and is completely processed and fully finished with no further operator interventions required, eliminating any possible damage from manual plate handling.

Designed as an open system, Catena+ allows easy loading of plates from other imagers into the Catena-E LED exposure unit. Plates from other exposure frames can also be loaded.

With Catena ProServX software, the machine health status of all modules is constantly monitored, mini-

mizing the need for physical service interventions.

Koenig & Bauer Rapida 106 X

Koenig & Bauer’s Rapida 106 X is a new high-performance sheetfed offset press for the medium format 740 x 1060mm.The press, which features glass side panels, a new touchscreen operating concept and an expressive design language demonstrate the modernity of the automated printing system.The new Rapida 106 X series aims to provide more than performance due to its features.

The Rapida 106 X incorporates simultaneous plate changes in under a minute with unbent and process-free plates and can also balance parallel makeready processes. It can also manage the autonomous printing of a whole sequence of jobs with automatic activation of the goodsheet counter.

Koenig & Bauer says the Rapida 106 X reaches production speeds of up to 20,000 sheets per hour in perfecting mode. Optimizing job sequences is made easier with a new tool, the Job Optimizer, which links the MIS and PPS and optimizes the order of the jobs preset in the MIS scheduling module in accordance with technological or press-related considerations.

The Rapida features a single camera system (and two cameras on perfector presses) to cover three functions: inline colour control, sheet inspection with continuous

The Rapida 106 X is a new sheetfed offset press for the

ONE-STOP SHOP — Die Cutting, Bindery, Data & Lettershop.

2. SUPERIOR TECHNOLOGY — Die crease without a die, then fold and even glue all on the same machine, up to 30 pt.

3. INTEGRATED MODULAR UNITS — Combined in-line finishing: crease, fold, glue, tipping, envelope inserting, ink jetting (Duplex), clip seal (3 sides), mail prep.

4. SAVE ON POSTAGE COSTS

—As a Certified Canada Post Direct Marketing Specialist, we get contract pricing reductions.

5. RETURN MAIL PRODUCTS — Customized “Return Mailers” created in-line with “U” or “BOX-shape” remoistenable glue, time perfed applications and envelope formation.

6. MINI-BOOKLETS — Saddle-stitch and trim 2-up booklets in-line to the size of a business card. No need to trim off-line, or do 2 passes.

7. HIGH SPEED EQUIPMENT — High speed Tipping, Folding, Saddle-stitching and soft folding ensuring on time delivery.

production monitoring and comparison of the printed sheets with the pre-press PDF.

The press features PressCall, which optimizes maintenance processes. The feature improves communication with the remote maintenance service and optimizes communication by eliminating language barriers. PressSupport increases the scope of services that can be provided by remote maintenance by enabling direct insight into the press using the operator’s smartphone.

The press also features digitization to detect faults in the press before they result in downtime. As soon as abnormalities are detected, bots automatically generate a service ticket.

The Rapida 106 X can also include a number of optional additions, including the PlateTronic plate logistics system and the use of Rapida LiveApps.

The seventh volume in the Neenah series features samples of sustainable branding ideas for small, local retail businesses.

Printed digitally using the HP Indigo 7900, the projects showcase the new HP Indigo ElectroInk Silver metallic ink and a multitude of specialty printing techniques including holographic foil, a realistic foilstamped and embossed rivet handwritten variable data.

Neenah offers designers and printers downloadable dielines for every printed sample included in Explore 7 and the previous six volumes.

Vastex International has introduced a new Face Mask Pallet with a quick-

Neenah’s Explore 7 features samples of sustainable branding ideas for small, local retailers.

stretch design for rapid screen printing on a wide variety of face mask types and styles. The pallet can be secured with two lock knobs to any Vastex press, or other presses with compatible rotor arms.

Rubber strips of the quickstretch frame stretch single- or multi-layer masks over the diamond-shaped rubber-covered pallets, which flattens pleats and contours in the imprint area with no shifting or need for pallet adhesive, according to the company.

The never-warp pallet is constructed of high-strength steel and includes a holder for the template frame during re-loading of masks.

The company also offers shirt pallets in numerous stock and custom sizes, and over 5o specialized pallets for screen printing on various textiles and hard goods. Square and trapezoidal pallets in a variety of sizes allows printing on sizes from infant to adult XXL, as well as all-over printing.

Manroland Sheetfed has launched the Roland 900 Evolution. The Roland 900 Evolution’s features include Autoprint, providing uninterrupted productivity from prepress to post-press at the touch of a button, and InLine ColorPilot 3.0, the most efficient and accurate colour measurement technology available, according to Manroland Sheetfed, measuring densitometrical and colorimetrical values in a single pass.

New Triple Flow inking technology provides three separate inker running modes, while the AC Drive promises annual savings of up to 10,000 kWh, or eight years over the lifetime of the press.

Vastex International’s Face Mask Pallet with quick-stretch design allows for rapid screen printing on a variety of face mask types and styles.

Heidelberg: K-Line/S-Line/Speedmaster/GTO/MO/KORD64

Komori: 1, 2, 4 or 5 colours & any size

Adast: 714/715/724/725

Mitsubishi: Any model

Ryobi: 2800CD/3200CD-MCD/640K

Itek: 960/975/985

Hamada: 600/700/800/E47/RS34

Shinohara/Fuji: 66/65 1,2 or 4 colours

Sakurai: 1, 2 or 4 colours and any size (newer model)

Polar: any size/older or newer models (66/72/76/78/82/90/92/107/115)

Horizon-BQ: 220/240/260/440/460

Andrew Wong is the manager of market development, Innovation Solutions Group at Jones Healthcare Group, a developer of packaging solutions for highly regulated industries such as healthcare and cannabis. We spoke with Andrew about why a company would choose near field communication (NFC) packaging technology and how it helps engage customers.

Why implement NFC technology?

AW: For Jones Healthcare Group, implementing new technology or innovation is always geared toward solving problems in response to market and consumer needs. We view NFC in the same lens – NFC on product packaging or labels is particularly useful for anyone looking to encourage a desired behaviour outcome; know consumers’ or patients’ wants, requirements and behaviour; and fully understand a product’s lifecycle.

How does NFC technology work in medication packaging? What are some other applications that it can be used for?

AW: NFC can help address common business problems for medication packaging such as anti-counterfeiting, dosage/ usage instructions and adherence. What’s exciting about NFC is one single tag on a package or product can execute all these applications.

NFC works through a tap interaction, such as tapping a smartphone to a package. When an NFC reader is placed near an NFC tag, it can trigger a smartphone to launch a webpage or app, make a phone call, or record information into a database or digital ledger, for example.

Consider a pack of multi-vitamins with an embedded NFC tag. With a quick tap of a smartphone, a consumer can be served a digital experience with the following:

1. A message saying the pack is authentic. NFC provides a secure level of authentication unmatched by traditional tamper labels or holograms. Thanks to backend server authentication, even if an NFC is duplicated, only the original tag will display the “authentic” message.

2. Additional product information and brand messaging, including usage instructions, promotional videos about the benefits of the product and more.

3. A dosage tracking application, which allows consumers to tap onto the pack every time they take a vitamin. Adherence metrics could even be displayed to the consumer with aspects of gamification to encourage consistent use.

Now consider every time a consumer taps onto that pack of vitamins, the brand receives data corresponding to that interaction. This may include time and location of interaction, length of interaction,

“The upside of the NFC medication adherence solution is we can integrate this into almost any medication dispensing format.”

what occurs during that interaction, the specific device interacting with the product, as well as the unique identifier encoded into each NFC.

This means brands and manufacturers can uncover where/when interactions occur, who is interacting, what that interaction was, as well as which exact product (not just SKU, but exact serialized product) with which the person interacted.

As the march toward regulated serialization expands around the globe, each NFC tag can also act as a serialized code thanks to its unique ID. This means brands can serialize products without adding printed codes, plus they can amortize the cost of serialization with an NFC tag that can also improve consumer safety, engage consumers and provide valuable item-level interaction data.

How does transmitting printed electronics work?

AW: Through a proprietary printing process developed with support from the National Research Council of Canada, we can use traditional printing methods to print conductive inks onto common packaging materials like paperboard as part of our CpaX™ connected packaging offering.

At the moment, we are using this printing technique on our Electronic Medication Adherence solution. We print circuit patterns across the top of each blister cavity of a disposable medication package, and connect that disposable blister card to

a reusable monitoring device. It sends electronic pulses through the printed circuit and can detect in real time whether medication has been removed from a blister cavity. We can add printed electronics to disposable packaging at price points conducive for mass deployment. We have even developed an NFC version of our medication adherence solution. The difference is that instead of persistent monitoring through printed electronic circuits, the NFC version involves a user tap interaction to confirm dosage. This is a great way to facilitate behavioural change. The upside of the NFC medication adherence solution is we can integrate this into almost any medication dispensing format, such as inhalers, syringes, standard pharmacy vials, etc. It also comes at a price point more conducive for mass deployment.

How does connected packaging help engage customers?

AW: At Jones, we’ve been developing and refining our NFC packaging integration capabilities for the past several years through our CpaX™ connected packaging offering. We believe our ability to facilitate high-speed integration of NFC and other electronic tags into packaging formats will play an integral part in the future connected packaging ecosystem.

Andrew’s responses were edited for length. For more Q&A Spotlight interviews, please visit www.printaction.com/profiles.