FEATURES

Being a person of integrity and honour is key to excelling in print sales 18 14 30 6

Being a person of integrity and honour is key to excelling in print sales 18 14 30 6

Toronto conference addresses technology, innovation and print evolution

The vast possibilities of digital label printing continue to drive growth in the flourishing market segment

GAMUT

5 News, People, Installs, Calendar, Dots, Globe

TECHNOLOGY REPORT

22 New innovations in continuous inkjet printing strive to deliver versatility, flexibility and efficiency

NEW PRODUCTS

25 Detailing new technologies from Agfa Graphics, ARC, Epson, EyeC, Fujifilm, HP, Komori, Mimaki, Ricoh and X-Rite Pantone

SPOTLIGHT

30 Marc Raad, Executive VP, Significans Automation

COLUMNS

FROM THE EDITOR

4 Alyssa Dalton

Disruption in the data era

CHRONICLE

10 Nick Howard

Cutting to the chase

Exploring the fine craftsmanship of letterpress printing

SALES

12 Dave Fellman

More for your money

In today’s evolving manufacturing landscape, embracing digital disruption is a fact of business prosperity.

“The mantra at every board level needs to be ‘transform or be transformed,’” says Keven Peesker, President of Microsoft Canada, in an interview withYvon Audette, Partner and National Leader, IT Advisory at KPMG in Canada. “To remain competitive and to evolve with the customer, organizations need to be thinking about how they can use data as a strategic asset and optimize their operations in new and innovative ways to better engage their customers.”

improved decision-making,” writes Shreeshant Dabir, National Lead, Lighthouse KPMG in Canada, and Carl Barrelet, Lighthouse KPMG in Canada.

Editor Alyssa Dalton adalton@annexbusinessmedia.com 416-510-5225

Contributing writers

The percentage of survey respondents who view technological disruption as an opportunity, not a threat, according to a new KPMG outlook.

When it comes to business transformation, Big Data is one of the most significant disruptive advancements manufacturers can, and must, adopt. According to the International Data Corporation (IDC), more data has been created in the past two years than in the entire previous history of the world. It estimates by 2020, 1.7 megabytes of new information will be created every second for every human being on the planet, and by 2025, the world will produce 163 zettabytes of data a year.

“The data is out there and many organizations are already sitting on decades of operational and customer data to begin with,” Peesker says. “Now, they need to invest in the tools and capabilities to organize that data and pull insights from it that will help businesses understand customer attitudes and behaviours.”

Innovative service models and emerging mobile technologies, Peesker says, are critical in helping business be more customer-focused and optimize their operations. “AI, in particular, will be critical in driving innovation. Through it, technology will become more intuitive, more conversational, and more intelligent, and enable businesses to better know and serve their customers in previously unimaginable ways.”

Disruptive technologies will enable organizations to develop and support new business models, advanced product innovation and holistic customer servitization.

The time to embrace digital disruption is now, according to KPMG’s 2018 Canadian CEO Outlook . The Outlook , released in June, finds Canadian CEOs are “overwhelmingly optimistic” about change, noting 96 percent of survey respondents say they view technological disruption as more of an opportunity than a threat. Comparatively, in the same survey last year, only 74 percent of CEOs were as positive about this disruption.

“There is a reason CEOs want to talk to us about predictive analytics; it’s because they know it is the key to vastly

Describing it as a continuously evolving field, Dabir and Barrelet say analytics help organizations better understand their operations, clientele and market by identifying trends while interpreting the performance of products/services and market position. “Successful businesses are those that leverage and push the boundaries of analytics to attain reliable, predictive insights, unleashing opportunities for operational performance, risk management, and improved customer experience.”

They suggest several ways Canadian CEOs can enhance their data analytics capabilities and improve decision-making. First, organizations must understand what predictive analytics can do. Spend time talking to advisors, startups, incubators and service providers about what they see in the market, they advise, so businesses can assess how and where predictive analytics can improve the business value.

Developing a roadmap that is practical and strategic for digitization is key to embedding analytics into the company culture, Dabir and Barrelet note. In order to make analytics an essential tool, businesses must remove data siloes and scale up analytics successes. They recommend moving the predictive analytics team “down the hall from the executive suite” to provide immediate access to insights while encouraging employees to integrate analytics into their work processes.

As well, organizations should focus on “small yet reliable” data sets. “Instead of spending all your time and resources on gathering as much data as possible, start exploring what data could be telling you and then focus your efforts on finding and curating the right data to support deeper insights,” Dabir and Barrelet write. “The need for good data is much greater now than ever before and your organization needs to have a robust enterprise data strategy in order to deploy intelligent automation at scale.”

Technological advancements will continue to reshape today’s workplaces, allowing organizations to drive operating efficiency and create new, innovative solutions rather than pursue traditional ways of doing business. Dabir and Barrelet estimate within the next three years, all corporate decision-making will be influenced – in some way or another – by predictive analytics.

Zac Bolan, Wayne Collins, David Fellman, Victoria Gaitskell, Martin Habekost, Nick Howard, Neva Murtha, Abhay Sharma

Associate Publisher Stephen Longmire slongmire@annexbusinessmedia.com 416-510-5246

Media Designer Lisa Zambri lzambri@annexbusinessmedia.com

Account Coordinator Alice Chen achen@annexbusinessmedia.com 416-510-5217

Circulation Manager Barbara Adelt badelt@annexbusinessmedia.com 416-442-5600 ext. 3546

Circulation apotal@annexbusinessmedia.com Tel: 416-510-5113 Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Group Publisher Diane Kleer dkleer@annexbusinessmedia.com

President & CEO Mike Fredericks

Subscription rates

For a 1 year subscription (10 issues): Canada — $42.00 Canada 2 year— $69.00 United States — CN$74.00 Other foreign — CN$144.00

Mailing address

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 printaction.com Tel: 416-442-5600 Fax: 416-442-2230

Annex Privacy Officer Privacy@annexbusinessmedia.com 800-668-2384

PrintAction

International tradeshow Ipex has decided to close its doors, effective immediately, after consultations with the print industry.

Organizers of Ipex, an international print technology and equipment tradeshow, say they have decided to close the show after consulting with the print technology industry. The most recent edition, Ipex 2017, was held at the ExCel International Centre in London, U.K., from October 31 to November 3. Over 150 exhibitors from 20 countries showcased the latest solutions in print technology and equipment, drawing a crowd of more than 7,000 visitors, according to Ipex show owner Informa Exhibitions. “The changing market conditions and appetite for a large-scale event which focuses on ‘Print in Action’ continues to be challenging. Having engaged with a range of exhibitors and partners to evaluate the options for Ipex, we have concluded that the requirements of the industry no longer match our own in terms of the cycle, scale and what is required to help us further support and fully invest in the brand,” Rob Fisher, Ipex Event Director, says.

Glacier Media has announced it is shutting down the pressroom of the Victoria Times Colonist on September 30, leaving 18 press workers without jobs. Unifor says it is negotiating with Glacier Media to improve severance packages and secure positions for the members in other areas at the newspaper. “The press hall workers have a long history with our local and have helped trailblaze collective agreement rights enjoyed by other unionized employees at the paper,” says Brian Gibson, President of Unifor Local 2000. He says the average years of service for those

another move from the online retailer to incorporate traditional tools used by brick-and-mortar stores into its business model, and comes soon after the recent closure of ‘Toys “R” Us’ U.K. and U.S. operations earlier this year, reports Bloomberg.

laid off is 19 years. The Times Colonist is described as the oldest daily newspaper in Western Canada, created by the 1980 merger of the British Colonist, which started in 1858, and the Victoria Daily Times, which began publishing in 1884.

ICP Industrial – a division of Innovative Chemical Products Group (the ICP Group), and global manufacturer of specialty coatings for the packaging, labelling and graphic arts industry – has formed ICP Industrial Canada. With manufacturing operations already in the United States and Mexico, the additional footprint in Canada aims to help drive the company’s international growth strategy. In addition to this formation, ICP Industrial Canada has entered into a strategic partnership with manufacturing representative firm Divicor of Montreal, Que., to supply its pressroom consumables to the Canadian market.

Amazon.com is reportedly publishing a printed holiday toy catalogue to be mailed to U.S. households and handed out at various Whole Foods Market locations, the grocery chain Amazon bought last year. The strategy represents

Wayside, headquartered in Vernon, B.C., has acquired Lakeside Printing. The acquisition includes all three Lakeside locations in Vernon, Revelstoke and Salmon Arm. Established in 1921 as Wayside Printing, the company is described as the North Okanagan’s oldest printing and marketing firm. In 2011, the company changed its name to Wayside to better reflect its expanded offering of print services, direct mail campaigns, and marketing solutions. Lakeside Printing, founded in 1975, offers a range of products and services including rack cards, flyers, envelopes, labels, banners, booklets, calendars, business cards and more. Lakeside Printing will continue to operate under its existing name, as a Wayside company, reports the Vernon Morning Star

packaging business.

Bosch says after considering all its strategic options, it is looking for a buyer for its packaging machinery business, more specifically the pharmaceuticals and food units of the Packaging Technology division. Citing a need to focus on the transformation ahead, Bosch says it has not identified any sufficiently relevant synergy effects in terms of business or technology that might offer the division prospects for the future within Bosch, noting that packaging technology is not part of the group’s core business. The company’s special-purpose machinery manufacturer Robert Bosch Manufacturing Solutions GmbH is a separate entity, and will remain part of the Bosch Group.

On April 6, 2018, the Humboldt Broncos junior hockey team was involved in a fatal bus crash in Saskatchewan. Carmen and Erick

Pins for Humboldt Broncos fundraising efforts.

Hofer, owners of Minuteman Press Ellerslie in Edmonton, Alta., helped contribute to the fundraising efforts by creating and selling t-shirts, pins, ribbons and car decals at the local university. “To be able to do our small part to help them meant a lot to us,” Carmen says. The Hofers say they raised over $4,000, with entire proceeds going to the families of the bus crash victims.

Mark Andy has acquired Brandtjen & Kluge, a manufacturer of print finishing equipment for foil stamping, diecutting, folding and gluing, and UV coating. Dedicated to small- and medium-sized formats, Wisconsin-based Kluge offers equipment suitable for commercial printers and finishers, direct mail manufacturers, as well as packaging converters. Headquartered in Chesterfield, Mo., Mark Andy develops technologies for the label and packaging industries. In March, Mark Andy purchased Presstek, a supplier of direct imaging offset plates and presses, and CTP solutions.

Canon Canada has announced partnerships with EM Plastic & Electric Products, Grimco and Mediatech to sell the Océ Colorado 1640 printer. These partnerships, it explains, will provide large-format graphic printers with UVgel print technology for the growing graphic arts industry.

Colour and specialty chemicals company Archroma has inaugurated its new Global Competence Center for Whiteness in Prat, Spain. The centre, which opened on July 5, strives to bring innovative whiteness and brightness solutions to the specialty paper and packaging markets. Together with the Global Competence Centers for Colorants in Reinach, Switzerland, and for Surface & Coating Technology in Bradford, U.K., the Global Competence Center for Whiteness forms a network of experts dedicated to developing product packages to support its customer production process with integrated system solutions.

Marc Giroux has been named Pazazz Group President, where he will assume leadership and operational duties with the senior management team reporting directly to him. He joins Pazazz with more than 18 years of experience working for a manufacturing company that saw “hyper-growth” and a complete reorganization of its business processes.

Drytac has appointed D’Arcy Lewis Technical Sales Manager for the company’s industrial division. In his new position, he will be responsible for increasing custom and contract adhesive coating business in the packaging, construction, medical, automotive, label and industrial markets throughout North America.

Jared Reck passed away peacefully at Oakville Trafalgar Memorial Hospital on June 29 at the age of 47. Born in Mississauga, Ont., he graduated from Humber College on the Dean’s Honour Role with a Certified Engineering Technologist Certification. He owned JR Technical Services Inc., and as Technical Advisor, travelled around the world troubleshooting and working on various printing presses.

Quebec-based Imprimerie FL Web has acquired a Goss Sunday 3000 48-page rotary press, explaining the $11-million investment purchase has allowed it to triple its production to over 4.3 million pages/hour. At full capacity, the press can print 10 truckloads of paper per day.

SA International (SAi) has named Bobby Fosson Channel Sales Manager for North America.The position will see Fosson – who brings over 20 years of sign industry experience –drive and develop relations with SAi’s dealer and OEM channel partners, focusing on the provision of commercial support and training to sales and technical staff.

After leading Canada Post Group for seven years, Deepak Chopra has stepped down as President and CEO and has joined Drone Delivery Canada (DDC) as Strategic Advisor – Commercialization. Under his leadership, Canada Post has reinvented itself from a mail-centric business to an e-commerce powerhouse. In his new role, Chopra will advise DDC on identifying commercial opportunities in the areas of remote healthcare, transportation and logistics, and time-sensitive package delivery.

Komori America has added Richard Freeley to its sales team as Inkjet Sales Manager. He joins Komori America from MBO America, where he served as Director of Sales. In this position, he worked closely with customers, providing solutions to help boost revenue and profits. Prior to his time at MBO America, he held the role of Sales Development Executive/Inkjet Specialist for Canon Solutions America.

Xerox has appointed John Visentin as CEO and Vice Chairman of the Board, joining newly elected Chairman of the board Keith Cozza. Additionally, Steve Bandrowczak has been named President and COO and a member of the company’s Executive Committee, where he will be responsible for developing and executing a global operations strategy in the company’s business support functions.

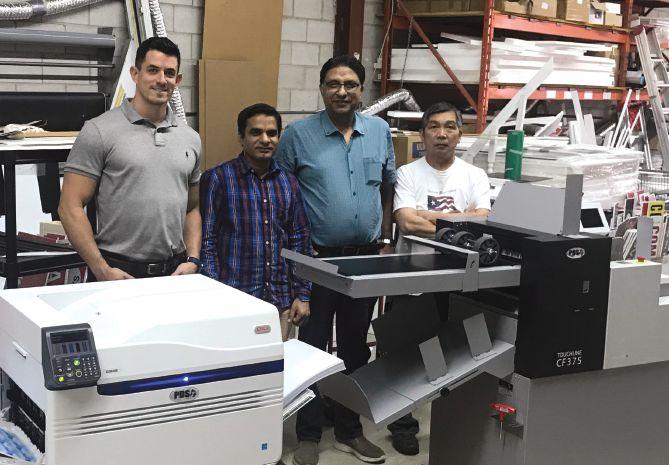

Signs2Go in Mississauga, Ont., has purchased an OKI 942 White Printer along with a Multigraf CF375 Creaser Folder from Print Digital Solutions (PDS). Pictured from left to right is Brett Kisiloski from PDS and Muhammad Yousuf, Anjum Alvi and Le Bao from Signs2Go.

Graphics and Printing, a trade printer located in Scarborough, Ont., has added a second Komori 40-inch press to its lineup of equipment, installed by Komcan. The 16,000 sheetsper-hour LS640C press comes loaded with plate changers and Komori’s productivity improvement software.

September 25-27, 2018

Labelexpo Americas

Donald E Stephens Convention Center, Chicago, Ill.

September 26-27, 2018

PAC to the Future II, Retail Reinvented Montreal, Que.

September 30-October 3, 2018

PRINT 18

McCormick Place South, Chicago, Ill.

October 18-20, 2018

SGIA Expo

Las Vegas, Nev.

October 24-28, 2018

All in Print China Shanghai, China

November 5-7, 2018

Digital Packaging Summit

Ponte Vedra Beach, Fla.

November 8, 2018

Canadian Printing Awards Palais Royale, Toronto, Ont.

November 12–16, 2018

IS&T Color and Imaging Conference Vancouver, B.C.

April 11-13, 2019

Graphics Canada

The International Centre, Mississauga, Ont.

April 24-25, 2019

AICC Canada Trade Show and Conference Toronto, Ont.

November 25-28, 2019

Shanghai World of Packaging Shanghai, China

June 16-26, 2020 drupa 2020 Dusseldorf, Germany

PNH Solutions of Montreal, Que., recently supplied the print portion of three multi-level, fully-custom viewing docks, measuring 30 x 13 x 12 feet, 32 x 13 x 20 feet and 48 x 13 x 20 feet (all measurements in WxHxD) for Hyundai at the 2018 Festival International de Jazz de Montréal.

The 39th edition of the festival, which ran June 28 to July 7, featured a program of 500 concerts, two-thirds of them free. The annual music extravaganza has been frequently ranked as the world’s largest jazz festival in the Guinness World Records.

With printed fabric banners and floor adhesives, PNH Solutions created a fully branded environment, where visitors were able to engage with Hyundai brand ambassadors and view the new vehicles on display: the Kona Electric Vehicle, Veloster N and Veloster Turbo, Kona, Tucson and the 2019 Santa Fe. Used outdoors in high-traffic areas near the Place des Spectacles, PNH Solutions worked to ensure the products would remain in-place for the duration of the event and adhere to all necessary safety requirements. PNH Solutions explains the fabric banners were made of a lightweight, perforated material, so air could flow through it, rather than against it thus reducing the sail-effect, and the floor adhesives used a special laminate designed to be slip-resistant. As well, all visuals had to be aligned perfectly with one another on the structure’s pillars, sides, floors and steps, without any spaces or gaps.

In addition to the custom viewing docks, PNH Solutions also supplied fabric banners and floor graphics (‘ShowFloor’) for the Hyundai stage and media walls (‘Fabgraphic Pop-Up Media Walls’) for its VIP section.

PNH Solutions explains it produced all materials for the festival in a short timeframe with last-minute structural changes to the design of the viewing docks. The printing company also coordinated the installation and decommissioning of the printed pieces.

A recently purchased VUTEk 5r LED roll-to-roll printer from Electronics For Imaging is driving new business opportunities at Italian digital printing company New Decor System. The system – the company’s fourth 5-metre inkjet device – will be used to expand the printing company’s range of large format prints as it works to grow local and national demand.

New Decor System is a Rome-based supplier of digitally printed wide-format signage and graphics, including out-of-home advertising, backlit panels, banners, vehicle wraps and soft signage.

“Large-format work is on the rise and the demands of our customers exceed our current production capacity,” company CEO Angelo Modica says. New Decor System says it chose the VUTEk machine for its speed – printing at up to 460 ft²/hour – as well as for the printer’s ‘cool cure’ LED technology, designed to reduce operating costs with lower energy consumption and result in less consumable waste. New Decor System’s new VUTEk 5r printer has four colours and UltraDrop Technology with seven picolitre printheads.

“We were impressed to see that with a litre of ink it prints up to 170 square metres,” Modica says. “With this investment, we want to increase the production of canvas panels. It is a process that requires very high-definition printing and also requires a high-precision sewing process that few of our competitors can offer.”

Commercial and newspaper printing house ICP-Roto industrie graphique in Réunion, an island and region of France in the Indian Ocean, recently started up its new Cortina from Koenig & Bauer.

Koenig & Bauer describes the Cortina as featuring an automatic reelstand, a compact printing tower, an efficient hot-air dryer system, a flexible superstructure and two semi-commercial jaw folders. The press line incorporates a range of automation modules such as the Patras A reel-loading system, automatic plate and circumference change, CleanTronic washing systems and RollerTronic roller locks, as well as colour and cut-off register controls.

“The new Cortina is the centrepiece of our printing house. Our whole team is incredibly proud of the new press. Once again, Koenig & Bauer and our team worked together perfectly on its installation and commissioning,” says Managing Director and Owner Alfred Chane-Pane.

Koenig & Bauer explains the Cortina largely features the same technology as its conventional offset counterpart, the Commander CT, but with one key difference – it produces newspapers, magazines and ad supplements in coldset and/or heatset without water and ink keys. Its waterless, keyless inking unit technology is designed to reduce waste and is said to deliver dot-sharp images in 70lpc (175lpi) and FM screens.

“Environmental protection is a matter dear to our hearts. Given that it eliminates the need for dampening units and all the associated additives, Cortina technology is ideal for the eco-friendly production of many very sophisticated products,” says Chane-Pane.

Smurfit Kappa has installed a new industrial-scale HP PageWide C500 digital press for corrugated printing. Placed in its Interwell plant in Austria in April, the PageWide C500 Press is described as the first commercial HP single-pass press in Europe.

Japan Card Products in Soka, Japan, has installed a Jetstream XY bi-directional finishing system from Rollem International. With fully automated trimming, slitting, scoring and perforating functions, the system will be used for trading card applications. The Jetstream works independently offline or in-line, directly with presses, coaters and folders, explains Rollem. Established more than 70 years ago, Japan Card Products specializes in trading card production.

By Nick Howard

Tactile — representing exciting new processes brought by early pioneers Scodix and Konica-Minolta/MGI, showcase how we have moved from “essential print” to eye-catching communication. As more of this digital technology enters shop floors, one thing is clear: The hardware is pricey. Whether with thick specialized varnishes that pop off the page, or hot and cold foils that mimic more traditional techniques, these eye-candy effects dazzle without the same skills needed for relief printing (letterpress). Printers can now do more exciting projects in-house. But can they sell enough of these new effects?

We all get how the traditional print model has transformed in the last 15 years and a good portion have made substantial efforts to be part of the next digital wave. The winners have figured out why their clients will pay twice as much for a coffee. Sadly though, industry news is often dismal. Seems almost daily, word spreads of another shuttered plant or a reduction in print periodicals. The once dependable forms and stationary sector has been essentially wiped out by online paperless solutions. Just last week our HVAC tech was onsite for a service call. When completed he handed the office manager a tablet and asked for a signature. He wasn’t even out of our parking lot when into our inbox whizzed an email invoice.

Anyone successful today already bade farewell to all the loser segments. But there is a new group – for the first time in a long time – entering our industry.

On a recent afternoon, we had a visitor, excited and full of enthusiasm. With husband in tow, Sibylle was here to learn how to run her new Heidelberg platen. Wow, is Sibylle passionate about print! Just a few years ago, working out of the family garage, Sibylle started off with a 10 x 15 inch hand-fed platen. Soon her creativity in designing and printing all types of stationary and wedding invitations forced her to look for a better and faster press than the old Chandler & Price. Busier than ever and with more demanding designs requiring multiple press passes meant getting an

automatic letterpress was a necessity. I’ve never seen anyone learn the Heidelberg as fast as Sibylle. After two hours of instruction she was off to the races. Why? Sibylle and all the letterpress lovers who come to our museum simply fall in love with the letterpress process and want to learn. It may also help that just like Sibylle, most are university educated, have worked in disparate industries and are drawn – like a magnet – to the enjoyment of letterpress’s version 2018.

1752

The year letterpress printing was introduced in Canada by John Bushell in the newspaper format, according to the Canadian Science and Technology Museum.

Similar things happened with a couple in Miami who flew up to buy their windmill, a young lady in western Canada who had her heart set on a hand-fed platen, the card shop owner in Moscow who simply had to have a Gordon. Then there is the truffle maker who insisted on doing his own label diecutting and the boutique chocolatier who wanted to print and diecut his own boxes. Maybe the most enthusiastic was the gentleman who drove right across the country to load up an R.HOE hand iron press. Letterpress isn’t just localized either. Besides Russia we’ve sold presses and Columbians to universities and museums in Boston, Ann Arbor and New Zealand. These are just a few of the thriving folks entering the world of printing and loving it.

When we have visitors at the museum they often get very excited with the array of type and machines. Women especially bring a zeitgeist into the space our industry hasn’t seen for a long time. This male-dominated industry needs more women like Sibylle who break the taboos.

As depressing as world news can be, folks living in developed countries are generally doing better than ever. They seem to have more personal time and more money to enjoy the things they really want to do. Print, as well as other forms of ink on substrate communication, is still a creative process. Someone has to manipulate type and images to make a bespoke article that besides being exclusive is also made by hand. Take a look at fashion.Virtually all of it comes from mass production using machinery. But high fashion Couture clothing is handmade. Monster offset sheetfed sales are shrinking because they are very good at only one thing – analogue mass production. Unless this exists (packaging, labels etc.) the graph chart looks like the backside of a letter “M.” But as I can clearly see, now is the cool rebirth of print. Only this time from a long ago technology that was made redundant by the offset press: Letterpress.

For less than $15,000, you could easily equip a small print shop. Even if as most do, farm out their photopolymer printing plates, all you need is paper stock, ink, a manual platen press, small guillotine and a thirst to be the operator. No one even needs to use the original lead type anymore as photopolymer plates are excellent and eliminate all the “locking up the form” challenges.

If you succeed in doing reasonable quality then get a Shopify or Etsy platform and start soliciting business. The small cottage industry letterpress shops can market their products the same way large printers do with the Internet. The ability to showcase your designs and abilities, take orders and receive payments is a major ingredient to success.

What we call “Letterpress Printing” today would have got you fired back in the 1950s. The heavy embossing into paper is what clients look for. I quit telling our new friends why they aren’t respecting the original craft as they simply don’t care to know.

Here’s to Sibylle and the exuberant new generation of printers that have a real passion for the art of printing. All measured by the growing public that seeks to differentiate themselves when they too want to use print. Small perhaps but Sybille and her fellow artists are helping the rest of the industry promote itself. You have to really love what you do.

NICK HOWARD, a partner in Howard Graphic Equipment and Howard Iron Works, is a printing historian, consultant and Certified Appraiser of capital equipment.

nick@howardgraphicequipment.com

Being a person of integrity and honour is key to excelling in print sales

By David Fellman

I’m nowhere near fluent in French, but like many North Americans, I know a few words in a lot of languages. One of the French words I know is lagniappe. The strict definition of this Creole French term is “a small gift given to a customer by a merchant at the time of a purchase.”

So what does that have to do with printing sales? A more common definition of lagniappe, especially in Louisiana where my experience with the term comes from, is “a little something extra.” In marketing terms, we might express that as “more for your money.”

We might also express it as “exceptional value.” How do you calculate value? It’s really a pretty simple equation. When you feel like you got what you paid for, that’s value. When you feel you got more for your money, that’s exceptional value. If you feel you got less than you paid for, that’s the opposite of value.

They say beauty is in the eye of the beholder; they should also say value is in the eye of the buyer. I have noted there is often a value gap in printing sales, with sellers talking about the value they bring, but buyers not seeing or appreciating it. As an example, I was recently out on calls with a salesperson who confidently stated he brought value through exceptional customer service. His prospect said, “Prove it” and the salesperson said, “Just give me an order and I will.” The prospect said, “No, that’s not the way I work. You have to prove it to me before I’ll give you an order.” Lesson to learn: If you’re going to make bold statements, you’d better be able to back them up!

One of the biggest challenges printing salespeople face these days is to sell against lower-priced competition — and it shames me to tell you most printing companies in North America make it mostly about price. They say they don’t, but they do, and I’ll write more about that in a future column. For today, I’m hoping

to show you how you can use ‘reverse lagniappe’ to meet this challenge.

If lagniappe means “more for your money,” reverse lagniappe means “less for your money.” I’m not talking about less value, though. I’m talking about more value reflected as less pain and aggravation. I’m talking about selling the idea that you sometimes get what you pay for, but not what you need.

This all hinges on a single question: “Are you perfectly happy with what you got — or what you’re getting — from my lower-priced competitor?” If the answer is yes, that’s a problem. But if the answer is no, you have a real opportunity to defend your price.You can say, “I think what’s happening here is you got what you paid for, and it simply costs more to get what you really want or need.”

Here’s an observation. I think most people will pay what they have to pay to get what they really want or need. The complicating factor is they usually don’t know how much that is. What they do know is what one or more printers are willing to charge them, and the easiest decision is to buy at the lower price. I’m pretty sure they’ll continue to do that unless people like you have the courage to challenge them.

Suppose you ask the “perfectly happy” question and the answer is yes. As I said, that’s a problem, but it’s not insurmountable. Here’s what I think you could say if you find yourself in that situation. “I need to ask that question again, and I want to make sure I stress the ‘perfectly’ part. I’m

Percentage of companies with high-performing sales departments that do sales planning more than a year out, according to a 2016 McKinsey & Company survey.

not going to lower my price, because our prices support a whole structure of talented people and comprehensive quality control. I want to ask you to consider whether a company with lower prices is providing the same thing. Because if not, I’m concerned that at some point, you might get what you paid for, which would be a loss for both of us.”

Obviously, it takes courage to continue the conversation in this manner, and there’s one more thing that’s important to this strategy. Let me teach you another word, this one has its origin in Yiddish, a language my grandparents spoke. The word is mensch, and the strict translation is “a person of integrity and honour.” A more common definition is “a good guy” – with “guy” being used in its non-genderspecific tense. When you say something like this, be real, be down-to-earth, be a mensch — don’t be the stereotype of a salesperson. If you can convince people that you’re a person of integrity and honour, you’ll do very well in print sales.

DAVID FELLMAN is the president of David Fellman & Associates, a graphic arts industry consulting firm based in Raleigh, N.C. He is a popular speaker who has delivered keynotes and seminars at industry events across the United States, Canada, England, Ireland and Australia. He is the author of “Sell More Printing” and “Listen To The Dinosaur.” Visit his website at www.davefellman.com.

By Alyssa Dalton

More than 250 print professionals attended PrintForum 2018, held June 6 in Mississauga, Ont., presented by PrintAction . The conference program hit on a range of topics, including sheetfed offset, digital enhancement, wide-format inkjet, and production inkjet. Now in its third year, the 2018 edition was our largest show yet.

Greg Neath, General Manager, In-Store Marketing Products for TC Transcontinental Printing, kicked off the day with a dynamic keynote on the company’s shift into

flexible packaging. Neath detailed five lessons learned from TC Transcontinental’s transformation: Decide who you want to be; Implementation is key; Figure out what not to do; Change fast; and Culture is critical.

An hour-long panel discussion –featuring Carla Johanns, President, Simpson Print; Mike Meshkati, President, SinaLite; Rich Pauptit, President, Flash Reproductions; Warren Werbitt, Founder and CEO, Pazazz; and Deanne Sinclair, Coowner and General Manager, Cambridge Label – addressed the top opportunities and challenges facing today’s printing companies.

Sean Springett, CEO, Manroland Sheetfed North America; Walter Chmura, Vice President of Technical Sales, KBA North America; and Anthony Thirlby, Global SVP Commercial Segment & Head Of Subscription Sales, Heidelberger Druckmaschinen AG, noted the growing use of business intelligence to drive transparency into a printing plant’s overall operating efficiency.

Back-to-back technology presentations followed from CMD Insight and Canon Canada, focusing on the biggest trends in digital printing. Christian Knapp, President, CMD Insight, spoke about the profit effects of digital additive

Based on attendee feedback, the Profit-leading Printers panel was the highest ranked session of the day.

and subtractive print manufacturing, and Jim Stalford, Senior Director of Sales, Wide Format Printing Systems, Canon Canada, discussed diversifying commercial print with wide format.

The day concluded with a spirited in-depth market analysis on different production inkjet applications – commercial, newspaper, sign & display, packaging and industrial – from Brent Moncrief, VP Strategic Marketing and Brand Management, Fujifilm North America, Graphic Systems Division.

Visit www.printforum.ca for video highlights and presentation slides from the event.

By Emily Wong

The printing and packaging industry has entered an era with expectations for more customization and faster turnaround times without compromising quality. Clients are looking for ways to differentiate and enhance their printed products beyond just ink. To remain competitive, it has become instrumental for printers to invest in the right technology to help meet their business needs while exceeding their customers’ expectations.

With the introduction of AccurioJet KM-1 inkjet press and the MGI JETvarnish 3D series, Konica Minolta has propelled its position within the commercial and industrial print market. They support the early adopters in inkjet press and finishing, to create more value for their customers and deliver innovative solutions that help create differentiation.

On July 10th, the owners from three clients of Konica Minolta Canada came together in Markham, Ontario at ICON Print to share their ideas about the production of cover art for PrintAction’s July/August 2018 issue. For the first time in 56 years, Print Panther, ICON Print and Belmont Press collaborated on the production of PrintAction’s cover art to be versioned, and both printed and finished digitally.

It was monumental for Chris Dewart, President & CEO of Konica Minolta Canada, to have the opportunity to see three Canadian companies team up and collaborate in person to turn the cover art into a reality. By pairing each company’s years of experience and talent with the technology, the capabilities of Konica Minolta’s inkjet and decorative finishing was able to be highlighted to its fullest. “There is an emphasized need for cooperation in the printing industry in order to

develop leading edge innovation,” said Dewart. “And this cover really showcases that Konica Minolta can provide an end-to-end solution, from digital printing to full embellishments.”

With Print Panther’s experience and expertise in digital finishing, it was beneficial for the creative design to be in their hands. Being familiar with the various embellishments of the MGI JETvarnish 3D series, Print Panther was able to understand on a deep level the different ways the colours and textures on the cover art that can be highlighted using the variety of embellishments in digital finishing.

“We wanted to have a vibrant cover for this issue of PrintAction,” said Christine Yardley, President of Print Panther. “Using an image that really showcased the KM-1, with its amazing inkjet print head and image processing technologies. The image quality is close to offset, providing a perfect base for applying foils and varnish.”

From sourcing the image for the cover art to the creative input, Print Panther’s involvement stitched together the process, including the preparation of the print-ready files to ICON Print and set-up for the foil and varnish files to Belmont Press. Their involvement with each stage of the cover emphasizes the importance of communication and collaboration when working on projects across multiple printers and partners.

Digitally printed on the AccurioJet KM-1, ICON Print produced the cover image’s wide colour gamut with superior image quality. Rivalling the quality of offset, the array of colours on the cover are contrasted against various shades of

orange - one of the most challenging colours to reproduce in print.

The AccurioJet KM-1 has a large sheet size for its class at 23” x 29.5”, which allowed the cover to be printed 2-up and a more efficient press run. The cover was run on a 100lb Supreme Stock prior to digitally finishing.

For the cover’s finishing stage, Belmont Press had the opportunity to add the final touches to enhance the printed covers they received from ICON Print. Using the TIFF image file provided by Print Panther with the varying levels of greys for varnishing, Belmont Press was able to highlight the flexible capabilities of the MGI JETvarnish 3D Evolution. Prior to foiling and varnishing, Belmont Press applied a 1.2mm anti-scratch matte thermal film to ensure the printed cover art was scuff-proof. The cover art was then digitally enhanced in three versions, each of which was distributed to one of three regions in Canada: Eastern Canada, Ontario and Western Canada. Each version showcased different colours of foil (Rose Gold, Satin Gold and Silver) with embossing levels from 0-58 microns to enhance the textures of the cover image.

Using its drop-on-demand technology with ultra-precise piezoelectric print heads, the MGI JETvarnish 3D Evolution is able to create extremely thin lines (0.5mm) alongside wide uniform solid areas for finishing.

The advantages of the MGI JETvarnish 3D Evolution include the elimination of makeready, plates and dies for hot foiling. This results in a huge reduction in time and labour in addition to the elimination of cleaning the system between jobs.

“The set-up of traditional foil stamping and UV coating is complicated and requires an experienced operator to produce excellent results,” said Jamie

Connecting three Canadian companies to collaborate on the production of PrintAction’s first versioned and digitally printed and finished cover art exemplifies the power of combining talent and innovative technology.

Outsourcing is part of the culture and workflow at ICON Print. ICON Print has established trust with their clients because their main objective is to always find a solution to a problem. “In this day and age, not all companies can do it all. The industry is shifting towards collaboration,” said Juan Lau, President & CEO of ICON Digital Productions Inc. “To be competitive, you need to be agile. By collaborating with different companies, ICON Print has established a reputation as being reliable and able to always deliver.”

“ This

is the future and it will begin to spread throughout the industry.”

- Chris Dewart, President & CEO of Konica Minolta Canada

In this new generation of print, companies need to work together in order to thrive. Konica Minolta’s commitment to support printers to collaborate and achieve success together will not only position them as leaders of technology within the Canadian printing industry, but help create opportunities so that everyone wins.

Schaeffer, Manager of Belmont Press. “The MGI is a press that is operated by a computer program. With the understanding of how UV coating works and a can-do attitude, any technologically adept individual can run the press.”

Additionally, the MGI JETvarnish 3D Evolution has an Artificial Intelligence SmartScanner (AIS) and an Automatic Registration Camera (ARC) system with two built-in cameras which allowed Belmont Press to register the coating with the press sheet without requiring any registration marks. A huge plus for Belmont Press has been the maximum sheet-size of 29” x 47” which allows them to be the perfect partner to enhance both offset and digital printed products.

Digital foil stamping is not restricted by the maximum size of a die, but rather the maximum sheet size. Additionally, they are able to produce variable data foiling (VDF), allowing them to enhance and personalize printed products with an array of colours in foil finishing. Although Belmont Press has not explored many projects using this enhancement, it is an untapped opportunity for companies to add foil finishing and embossing with precision that could not have been achieved using traditional methods.

Since Print Panther’s investment in the MGI JETvarnish 3DS and iFOIL S, revenue has grown over 30%, and the client base and repeat business has doubled. President Christine Yardley said, “The custom finishing we do in-house, truly sets us apart. When we combine these new technologies with client-centric focus, we have a winning combination.”

When asked why it was important for Belmont Press to invest in digital finishing, Paul Schaeffer responded, “We needed something new to offer the customers. The digital finishing machine just happened to be perfect for us. This opened us up to printers that focused on digital printing that we were not previously able to do business with, such as trade finishing for small digital shops.”

Following Drupa in 2016, Frank Romano noticed a growth of inkjet systems entering the market with the ability to print on almost any substrate. “The next generation is going to print on new kinds of substrates.” There has already been a growth within inkjet technology, expanding beyond just paper with signage, vehicle wraps, and even the digital fabrication for medical applications and electronic devices.

As the level of innovation and technology continues to advance for inkjet printing and embellishments, the industry will continue to benefit with more efficiencies and a streamlined production to help maximize profitability. With the shift from analog to digital finishing, it has moved towards shorter press runs and customization. Inkjet technology and finishing, such as VDF, and rapid prototyping are following a similar trajectory.

Founded in 1997, Print Panther has provided clients with artistic creative, innovative print and leading edge finishing. As the first company in Canada to invest in the MGI JETvarnish 3DS and iFOIL System, Print Panther has expanded their portfolio of digitally finished projects - from luxury packaging to magazine covers. In recognition for their high-quality print and design, Print Panther has recently been named the recipient of seven awards at the 2018 Premier Print Awards, led by Printing Industries of America (PIA).

A division of ICON Digital Productions Inc., ICON Print specializes in enhancing brand experiences through print. Being part of a multi-faceted visual communications media company, ICON Print is an instrumental pillar that supports the company’s mandate to be All Things Visual. Since the investment of the AccurioJet KM-1 Digital Color B2 + UV Inkjet Press, ICON Print has been able to run jobs at the largest sheet size of its class with superior registration and image quality with the capability for variable data printing on a wide range of substrates.

Belmont Press is a trade finisher that has been specializing in pre-bindery operations since 1952. The business has come a long way since its beginnings in a garage on Dupont Street that offered creasing, embossing and die-cutting. Since 2006, Paul Schaeffer, President and Owner of Belmont Press Ltd, has revitalized and diversified the business with the investment in digital finishing technology. As the first to install the MGI JETvarnish 3D Evolution in Canada, the investment allowed Belmont Press to become more efficient while breaking into new markets.

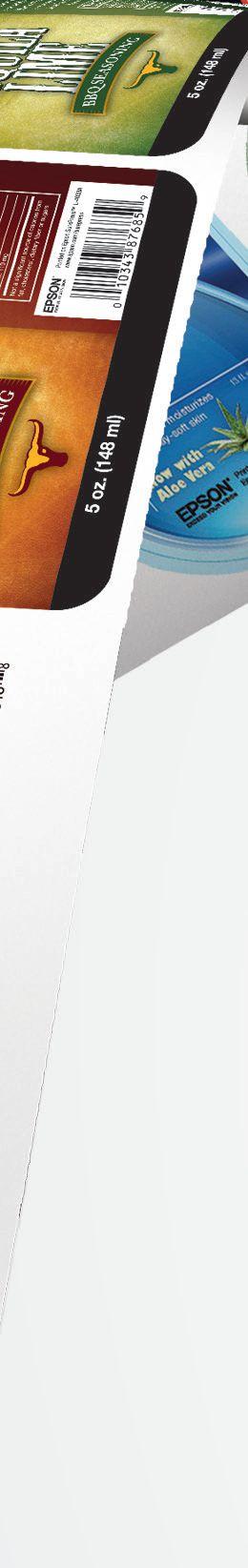

The vast possibilities of digital label printing continue to drive growth in the flourishing market segment

By Victoria Gaitskell

For a better understanding of the directions in which digital label printing is growing and evolving, PrintAction spoke to Griffin Schrack, HP’s Labels and Packaging Specialist for Canada and the Northeastern U.S. A recent report by Future Market Insights forecasts a significantly high growth rate for the digital label segment, estimating it will increase in revenues at 16.7 percent CAGR from over US$7.1 billion in 2016 to US$38.4 billion in 2026. The report further predicts that during the same 10year period, digital label production will grow its global market share of digital packaging printing from 64.1 percent to over 70 percent.

Schrack, who has worked at HP for 12 years, points out that digital label produc-

tion is a post-mature market for which his company has been supplying technology for two decades.

He clarifies that many of the same trends that prompted the rise of digital label printing in the first place still remain among its major driving forces. Factors such as the decline of print warehousing and demand for just-in-time manufacturing and personalization using variable data all continue to exert a formative influence on the digital label market – although these factors have now metamorphosized and intensified into the latest trends and applications outlined below.

Schrack says in the old days, a major brand owner would develop a new product, then create a few million labels for it, stockpile the labels in a warehouse, and

pull them out of storage as required for use on the packaging line. Back then, he says, the cost per label was the main thing everyone worried about. He recalls in 2008, digital label production grew almost 60 percent in six months because it was the only way to effectively avoid warehousing by producing labels fast and truly just in time.

He says the trend has since continued to escalate as companies become increasingly vigilant about reducing not only warehousing costs but also such other expenses as inventory management and especially the disposal of labels that have become waste through obsolescence (still the fate of 15 to 25 percent of printed labels).

“If you have a warehouse full of labels for 12-ounce jars of peanut butter, and when things get tight you decide to reduce

“You must be able to see no difference between two SKUs of the same product when both are placed side by side on the shelf...if one looks different, consumers won’t buy either one because they think one is counterfeit.”

the jar size by several ounces, what do you do with all that obsolete printing?” he asks. “Or if you make vitamins in the U.S. (where vitamins are not as regulated by the government as they are in Canada) and you strike a better deal to produce a new batch in China that changes the ingredient panel, your conventional printer has to make a completely new plate. But with digital printing all you have to do is send the printer revised digital artwork.”

“Across the board, the prices of substrates, both paper stocks and polyester film, are rising globally, especially in the last 90 days,” he says. “I’m hearing that prices are rising about 5 percent each time, and that two to three increases are expected in 2018.

“In digital printing there’s no makeready, but in conventional printing every four-colour job requires initial adjustments that produce trash. For this reason, the higher the cost of substrates, the more lucrative digital printing looks.”

Because stocks for digital printing need the application of a primer that promotes adhesion of ink to the substrate, Schrack notes HP Indigo and other manufacturers build in-line priming (ILP) units into their digital presses.

Schrack says today’s manufacturers are trying to make their brands as personal to the end-consumer as possible, and one way they try to achieve this is to produce more pack sizes and varieties of a single brand, each with a different SKU (or inventory identification code).

For example, for a dishwashing liquid, these multiple SKUs might include different colours and fragrances, an extra-strength version for superior cleaning, a milder detergent for sensitive skin, and so on. Skippy Peanut Butter now comes in Creamy, Super Chunk, Roasted Honey Nut, Reduced Fat, Natural and Natural With Honey varieties. Pringles Potato Chips come in 37 different flavours and formats. Schrack expects digital label volumes will continue to rise as the trend toward SKU proliferation becomes more pronounced in consumer packaged goods.

“Digital printing makes it faster and more economical than flexography to get 20 SKUs of 5,000 or 50,000 each on the shelf immediately, while also ensuring the labels appear identical to the ones on the brand’s standard packaging,” he says. “You must be able to see no difference between two SKUs of the same product when both are placed side by side on the shelf. They must look identical because, if

one looks different, consumers won’t buy either one because they think one is counterfeit. For hitting brand colours, automatic digital colour calibration and matching processes can provide extreme accuracy and consistency.”

He continues: “Once the brand owner finds out which SKUs are really popular, they can print them more economically on a conventional flexographic press, but the others that didn’t take off and have a much shorter product lifecycle are only printed using short-run digital.”

“When I was younger, major brands would tell advertising trade publications they would never change their brand colours or look so that consumers could always find their products in supermarkets,” recalls Schrack. “But now the major brands tend to think they have to change their look relatively often because people get bored. Research by industry associations suggests the current length of a package’s shelf appeal is around 120 days, whereas before it used to be three or four years.”

He says cause marketing, such as promoting breast cancer awareness, has become a popular way for brands to change the look of their product label just a little.

Other approaches include regionalization in which, for example, brand owners will decorate their labels with references to winning teams in major national or international sports tournaments immediately after their victories. Schrack says in many cases, an item will appear on the news –such as a study showing a particular supplement is effective in reducing flu symptoms – and vitamin producers will want to reference the news item on their labels before the end of day tomorrow. He recounts after the Boston Marathon bombing in April 2013, all his customers in the local area were inundated with orders for labels to add the phrase “Boston Strong” to the product packaging. He says the quick turnaround required for these types of applications is something that only digital printing can accomplish.

In recent years major brand owners have been experimenting with ways to forge deeper, more personal connections with consumers, often millennials, by offering unexpected, customized and sharable brand experiences that make them feel special by catering to their desire for individuality.

An early, much-publicized example was Coca-Cola’s international ‘Share A Coke’ campaign, reportedly the largest print job of colour digital consumer labels ever produced. Launched in 2011 and extended over several years across 32 countries, the campaign used HP Indigo presses to print individually customized labels, each bearing a popular name found in each respective market.

Coke credited the campaign with gains of 2.5 percent in sales – following a decade-long decline – and 1.14 billion hits on social media.

In 2015, Bud Light became the first brand in the United States to use HP SmartStream Mosaic software for mass customization, producing 200,000 unique, limited-edition beer cans for distribution at Mad Decent Block Party music festival events in cities across Canada and the U.S. HP SmartStream Mosaic creates huge numbers of one-of-a-kind graphics by automatically generating millions of unique designs based on core patterns.

Diet Coke’s 2016 ‘It’s Mine’ campaign used the same software to generate 900,000 one-of-a-kind sleeves for its bottles and cans. “Consumers thought ‘Nobody in the world has that container but me.’ And if they really liked the pattern, they could order a shirt with the same design on the Diet Coke website.The only way to produce this type of print run of one is digitally,” says Schrack.

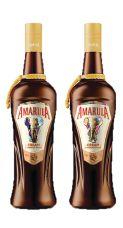

Another campaign called ‘Name Them, Save Them’ by Amarula Cream Liqueur raised awareness of the African elephant as an endangered species by letting consumers visit a virtual African savannah where they could design and name a oneof-a-kind African elephant. In turn, these consumer-produced designs were used to decorate individualized labels on 400,000 Amarula bottles — one bottle for every African elephant still surviving in the wild. “Brands don’t mind investing large amounts of money on a label when the label does most of the selling,” Schrack explains.

“All these trends are never going away,” says Schrack. “They are going to accelerate. Ten years ago, when we were marketing our products, services and presses, some printers rejected digital processes because it was too expensive. But now they know if they’re going to be a full-service label and packaging provider, they must have a digital asset on the floor.

“In fact, in the last two or three years we find people printing digitally, even when it’s not the most economical choice,” he continues. “We see runs of 20,000 or 50,000 that might be done less expensively with flexography, but they’re being done digitally because the process lets them know how fast the printing time will be to the second and exactly how much the job will cost.”

Shrack says declining availability of conventional press operators is also a factor in promoting digital printing.

“We see that as a real problem in the graphic arts industry. Everywhere I go, from Montreal to New York City, people are buying digital presses because it’s easier to find and train someone to run a digital asset than a conventional press.”

Western Canada’s Jet Label & Packaging Ltd. recently celebrated its 20-year anniversary with uniquely labelled refreshments, showcasing two decades of labelling evolution. The feat was accomplished with HP SmartStream Mosaic printing, creating unique-to-unit labels from a finite number of original designs.

Jet Label explains Mosaic printing has a two-fold function of “uniquifying” products to make consumers feel special and differentiating a brand’s product from competitors, while staying true to overall brand consistency.

16%

Smithers Pira reports digital printing accounted for 16.2 percent of the global print market value and 2.9 percent of the volume in 2017, noting that growth is accelerating to 3.9 percent of volume by 2022.

“The Mosaic beverages represent our commitment to prioritizing innovation and customer satisfaction along parallel lines,” says Darrell Friesen, President and CEO. “Forward-thinking capabilities like Mosaic are what differentiate Jet as a company, and have allowed us to be a leader in the industry for 20 years –and hopefully many more to come.”

Beginning as a single-press, single-client startup in 1998, in a space so small that the owner/ operator’s office was literally a closet, the company has grown into a label manufacturer with over 80 employees, manufacturing facilities in Edmonton, Alta., and Vancouver, B.C., and $25 million in annual revenue.

Today, Jet Label produces labels and printed tape for a range of customers, including grocery stores, international forest product companies, consumer product companies, and industrial application companies. It also supplies parking and boarding passes and baggage tags to the Toronto, Calgary, and Edmonton International Airports. It says digital printing, precision colour-matching capabilities and a commitment to total platform redundancy have all been key factors to gain and retain customers.

Jet Label’s growth has been largely investment-driven through the years. Last year, it acquired United Label Company of Coquitlam, B.C. – a move that secured additional space and production capacity by means of a second facility.

New innovations in continuous inkjet strive to deliver versatility, flexibility and efficiency

The Ricoh Pro VC40000 next-generation continuous feed inkjet platform, aimed at transactional and direct mail clients, features what Ricoh describes as a combination of speed, resolution and ease of use. At the heart of this solution lies the Ricoh TotalFlow Print Server R600A digital front end (DFE) that has been optimized to deliver workflow management for the production of complex, data-driven direct mail and transactional output. It operates at speeds up to 120 metres per minute, making it capable of producing more than 100,000 A4 images per hour. With paper support from 40 to 250 gsm, application possibilities range from lightweight books to high coverage postcards.

HP announced two new six-colour PageWide ultra high-volume inkjet web presses for pre-print corrugated packaging, the HP PageWide T1190 and HP PageWide T1170. The company says the flagship PageWide T1190 Press offers 67 percent more throughput productivity compared with the current PageWide T1100S, delivering up to 1,000 linear feet per minute at full press speed. The addition of six-colour printing (CMYKOV) also expands the colour gamut for matching colours, allowing for “new digital possibilities for brands, including short-runs, faster turnaround time, and versioning,” HP says. Additionally, the 110-inch thermal inkjet technology web presses use HP A30 true water-based inks, which HP says contains no UV-reactive chemistries and does not require additional barriers for food packaging applications.

The PageWide T1170 Press prints 600 linear feet per minute in six colours, compared with four-colour printing at the same speed on the PageWide T1100S. Both the T1170 and T1190 presses are

suitable for both coated and uncoated media, from 80 gsm to 350 gsm. Additionally, HP Multi-lane Print Architecture (MLPA) can boost plant productivity by splitting the web into multiple print lanes, so different jobs, with different box sizes and run lengths, can be printed in the individual lanes, HP says, adding that multiple ultra-short or short runs can be queued and printed together while a long run is printed in another lane.

Gallus, a member of the Heidelberg Group, introduced Labelfire 340, a rollto-roll digital label press now with extended digital and screen inline finishing functions. Upstream, the hybrid printing machine, the company explains, is equipped with a fully integrated screen printing unit, which enables an opaque white on transparent substrates that can be digitally printed over. Positioned downstream is the Digital Embellishment Unit (DEU), which can carry out inline coating digitally and apply matte, gloss and tactile spot coating effects to the substrate web in various thicknesses as haptic relief effects. What is new is that by using metallic foils, this relief effect can be executed in metallic looks, which Gallus says was previously not possible on any digital printing machine.

The Xerox Trivor 2400 High Fusion Inkjet Press is designed to allow print providers to expand their inkjet media range to produce cost-effective, higher-value personalized jobs such as direct mail, catalogues, magazines and colour books. The scalable continuous inkjet press initially targets speeds of up to 551 feet (168 metres) per minute in colour and 656 feet (200 metres) per minute in monochrome. The High Fusion Ink, Xerox explains, is specially formulated to help optimize printing and drying on offset coated media including matte, silk and glass stock from 60 to 250 gsm, up to

The Prosper 6000S press leverages Kodak’s nano-particulate pigment ink and intelligent inter-station drying.

250 feet per minute, producing high-quality results direct to paper, removing the need for intermediate coating processes, primers or added hardware.

Powered by Kodak Stream Inkjet Technology, the Kodak Prosper 6000S press is available in standalone or hybrid configurations for a print width of 620 mm to 203 mm. The hybrid configuration seeks to streamline production by offering a simplex digital press that integrates into existing printing or finishing lines to create a hybrid production process. When printing the standard resolution of 600 x 600 dpi, Prosper 6000S can run at a speed of 300 mpm or at 200 mpm when printing at 600 x 900 dpi resolution. Leveraging Kodak’s nano-particulate pigment ink and intelligent inter-station drying, the system prints on uncoated and coated papers, including lightweight coated and traditional newsprint, as well as a range of label and packaging materials.

The Océ ProStream prints uncoated, inkjet-optimized, gloss and matte-coated papers at a rate of 80 metres per minute.

The Canon Océ ProStream series prints uncoated, inkjet-optimized, gloss and matte-coated papers up to 1,144 letter size or 35 million pages per month in 2-up duplex production speed at a speed of 262 feet/min. The latest piezo drop-ondemand inkjet printhead generation, Canon explains, is leveraged with Océ Multilevel technology for sharper details, smoother half tones and economized ink usage. An Océ-developed set of ColorGrip and polymer pigment inks creates strong colours on uncoated, inkjet-optimized and gloss and matte-coated offset papers. The series uses a sensitive floatation air dryer in which the printed paper is not touched until the print images are fully robust — there are no scratches or changes to gloss levels and minimal paper stress for maximum quality, explains Canon.

September 30 - October 2, 2018

Emerging technology. Business strategy. The connections to grow your business. Experience it all firsthand at the event for revenue-generating innovations and solutions-focused education. You will get exclusive access to everything you need to Grow YOUR Business.

• NEW! Keynote, Marketing and Publishing Guru Seth Godin

• NEW! Hot Technology Guide to the Exhibit Floor

• NEW! Virtual Reality Experience

• NEW! Learning Experience Topics Focused on Business Growth Bigger and better things await you, your business and your profit margins at PRINT 18. Join us to drive the entire industry on the path to success.

In 2017, more than 22,000 visitors came together in Chicago—making it one of the top 25 fastest-growing shows in attendance by Trade Show News Network.

Available in a range of thicknesses, ARC’s new digital printing films are described as featuring excellent lay flat properties.

ARC digital printing films

American Renolit Corp. (ARC) is introducing what it describes as more environmentally friendly non-phthalate versions to its range of digital printing films, suitable for indoor and outdoor printing applications. ARC says the digital printing films are suitable for a variety of printing methods and ink types, noting both the matte and very high gloss versions can be custom embossed. Available in a range of thicknesses and flexibilities, from soft to rigid, the films boast low shrinkage.

Mimaki has announced the availability of the UCJV300-75, UCJV300-107 and UCJV300-130 printers, described as featuring a

smaller footprint with the same operational features of the larger UCJV300-160 model. The new UCJV300 printers deliver different applications with four-layer printing in addition to five-layer printing capabilities. Their integrated cut functionality enables volume production of labels, decals, window clings, vehicle markings and more in each unit. The printers utilize flexible UV inks that cure instantly, allowing customers to quickly print and immediately move to the finished product without waiting for drying, Mimaki explains. With the capability of multilayer printing, each printer can deliver backlit graphics that are transformed with different light sources. The company explains UV-curable inks offer greater opacity with less ink con -

all the possibilities if you had

The affordable OKI 900 series printers allow you to produce premium output on demand without relying on expensive equipment or outsourcing. The combination of white toner and variable data printing lets you do what most can't - broaden printed offerings, offer new services, and grow your business and profits. Produce fully customizable white-on-color printing on dark media..

(416) 297-7996 (800) 608-4506

sumption than other ink formulations, noting its high-opacity white ink enables block out printing with a single layer for specialized applications. Each machine includes the newest version of RasterLink6 Plus software, featuring a four-layer print preview and an ID Cut function that generates registration marks and barcodes.

1x Mitsubishi 40” 10 Colour Tandem with AQ

1x Mitsubishi 40” 8 Colour Tandem with AQ

1x Mitsubishi 40” 8 Colour Perfector with AQ

3x Mitsubishi 40” 6 Colour with AQ

2x Heidelberg Printmasters

3x Saddle Stitchers / 1 Perfect Binder / 10+ MBO Folders

Over 75,000 sq ft plant housing state-of-the-art nishing and bindery

Personalized account management and complete control over production

24/7 Production with fully automated and barcode controlled plant

FSC / PEFC / SFI certi ed

Ricoh in July 2018 presented the Pro C7200 series, featuring its Graphic Arts Edition and fifth colour station models (C7210X and C7210SX). The sheetfed presses print at 2400 x 4800 dpi VCSEL image quality. Inline sensors and calibration deliver better front-toback registration and colour consistency, Ricoh explains, without the need for lengthy, specialized training. The series offers 85- and 95ppm models, each with auto-duplex capabilities. Each have the option to print on paper lengths up to 49.6 inches simplex or 27.5 inches duplex. As well, the platform can print white and CMYK inks in a single pass. Invisible Red toner is the latest addition to the suite of toners available for the Ricoh five-colour presses, described as invisible under regular circumstances but under ultraviolet light, it shows as a clear, distinguishable red.

The Epson SureColor S80600 64inch roll-to-roll solvent printer has been certified by GMG Americas, a subsidiary of GMG Color, for use with software GMG ColorProof

5.10 and

2.1.5. GMG Americas says it selected the Epson SureColor S80600 as the final output component of its packaging solution due to its high-performance white ink printing capabilities, advanced printhead technology, and ultra-wide colour gamut with light black, red and orange inks. Meanwhile GMG OpenColor and ColorProof work together to deliver a complete printing press simulator designed to enable accurate proof simulation of the overprinting effects of spot colours using special multicolour profiles. Leveraging Epson UltraChrome GS3 nine-colour ink featuring red and orange ink and optional white or metallic silver, the SureColor S80600 boasts the highest Pantone coverage in its class.

In July 2018, HP Inc. expanded its hybrid Latex R printer series with the R1000 printer, offering a single set of inks for a range of flexible and rigid media including applications for retail, outdoor signage, window graphics, events and exhibitions, and decorations. The new printer comes with three litre-ink cartridges, compared to the larger model with five litres, and is designed to accommodate materials up to 1.64 metres wide and up to 5 centimetres thick while the R2000 prints up to 2.5 metres wide and up to 5 centimetres thick.

The R1000 printer features HP Thermal Inkjet Printheads and redesigned HP Latex Inks for a “vibrant” colour gamut on rigid while preserving media gloss and feel with

no smell, HP says, adding the Latex White Ink delivers the glossiest white on transparent and coloured media and achieves no waste between white print jobs. Meanwhile the belt workflow, HP explains, enables customers to meet short deadlines with up to 57 squaremetres/hour with up to 60-kg/150-lb rolls for flexible printing.

Komori is introducing an eight-colour Lithrone G37P perfector capable of one-pass double-sided printing, designed with a compact body size. The system, Komori says, can be equipped with a range of options, including H-UV or H-UV L (LED) curing systems. As well, the optional PQA-S Print Quality Assessment System can be added to inspect each sheet for defects and adjust ink keys designed to maintain consistent colour throughout the run, all at maximum speed. The PQA-S works in conjunction with the PDC-SX Spectral Print Density Control by combining automatic register functions with analysis of print characteristics, such as grey balance, dot gains and Delta E, the company notes. The perfecting mechanism of the 37-inch Komori press does not require any gripper change as the sheet is flipped; instead, the entire mechanism rotates after taking the tail of the sheet from the vacuum cylinder, explains the company.

The Graphic Systems Division of Fujifilm North America in July 2018 released the first product in its

Samba Printbar System line, the Samba PS4300, for the commercial and packaging printing segments. Described as a compact printbar system, the Samba PS4300 is designed to be easily integrated into most existing print equipment or manufacturing process to add variable inkjet imprinting capabilities, including offset presses, flexo presses, mailing tables, and more. The new printbar system adds an inline digital printing option for a range of personalized or data printing applications including text, logos, QR and barcodes and graphics, Fujifilm explains. The system integrates Samba Printhead technology paired with fit-for-purpose inks developed by the company. The Samba PS4300 has a print width of 1.6 inches, with printheads delivering a native 1,200 dpi and speeds up to 1,000 feet per minute, explains Fujifilm. The Samba PS4300 is available with up to four discrete printbars, depending on the customer and application requirements.

X-Rite and Pantone in May 2018 introduced six new libraries for PantoneLIVE, a Cloud-based digital colour standard ecosystem. Developed with the PantoneLIVE Preferred Partner for ink supply, Sun Chemical, the six new dependent standard libraries allow UVcured flexography printers and converters to match Pantone colours in label and carton applications. The parties say the new libraries will help users better define, create, visualize and communicate colour palettes for clear film pack-

SUPERIOR TECHNOLOGY — Die crease without a die, then fold and even glue all on the same machine, up to 30 pt.

3. INTEGRATED MODULAR UNITS — Combined in-line finishing: crease, fold, glue, tipping, envelope inserting, ink jetting (Duplex), clip seal (3 sides), mail prep.

4. SAVE ON POSTAGE COSTS

—As a Certified Canada Post Direct Marketing Specialist, we get contract pricing reductions.

5. RETURN MAIL PRODUCTS — Customized “Return Mailers” created in-line with “U” or “BOX-shape” remoistenable glue, time perfed applications and envelope formation.

6. MINI-BOOKLETS — Saddle-stitch and trim 2-up booklets in-line to the size of a business card. No need to trim off-line, or do 2 passes.

7. HIGH SPEED EQUIPMENT — High speed Tipping, Folding, Saddle-stitching and soft folding ensuring on time delivery.

aging, aluminum labels and recycled cartons produced with UV-cured flexographic printing technology. The new libraries include: Metalized Paper Label with White Ink –UV Flexo; Clear Film with Varnish – UV Flexo; Clear Film with Base White Varnish – UV Flexo; Clear Film on Clear Plastic Bag – UV Flexo; Clear Film on White Base –UV Flexo; and Recycled Carton Board with Varnish – UV Flexo.

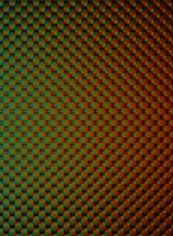

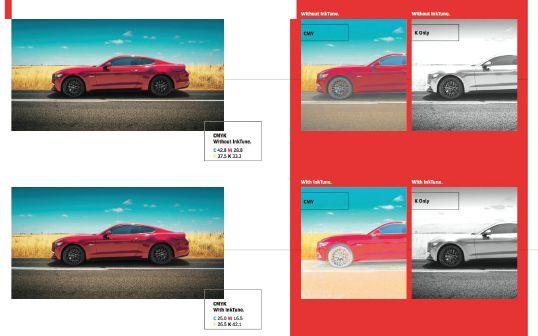

quality levels increase as rosette structures disappear and colour deviations become less visible, Agfa notes.

2018-06-22 11:38 AM

Agfa Graphics in June 2018 announced InkTune and PressTune, calling them tools that will enable “ultimate control” over printing resources and standards, while optimizing performance and lowering total cost-of-ownership. Part of the ECO³ offering, Agfa explains the new offerings will allow users to control all printing elements, from ink use to compliance with ISO, G7 and client-specific standards through real-time data insights, independent of printing technology and press manufacturer. Building on grey component replacement (GCR) technology, InkTune substitutes CMY inks with black ink. Integrating into the prepress workflow, InkTune uses Agfa technology such as Dynamic Ink Limit Control and Dynamic Device Link Generation to reduce ink consumption by up to 30 percent, the company says, while maintaining colour fidelity, resulting in reduced drying time. Furthermore,

The PressTune print standardization tool is designed to drive consistency, productivity and the ability to print to exacting standards, Agfa explains. Through intelligent analytics capabilities applied to print and colour data obtained from the press, PressTune reports in real time across printing technologies to each stakeholder. As a result, the solution enables issue identification and promotes press maintenance scheduling for brand owners in packaging and commercial print. Agfa says print houses can expect to see a reduction of up to 40 percent as a result of PressTune’s dynamic ink density adjustment.

With the new version of its ProofBook, EyeC says printers and customers can inspect multi-page documents with greater speed and precision. The new EyeC ProofBook scans and examines up to 20 pages a minute at 300 dpi and compares the front and back of each page against the approved PDF template and shows the operator the suspicious pages for more precise examination of the deviations. Featuring a duplex scanner with an automatic feeder, the system scans and inspects size A6 to A3 documents at up to 600 dpi and can pull in paper from 35 to 128 g/m².

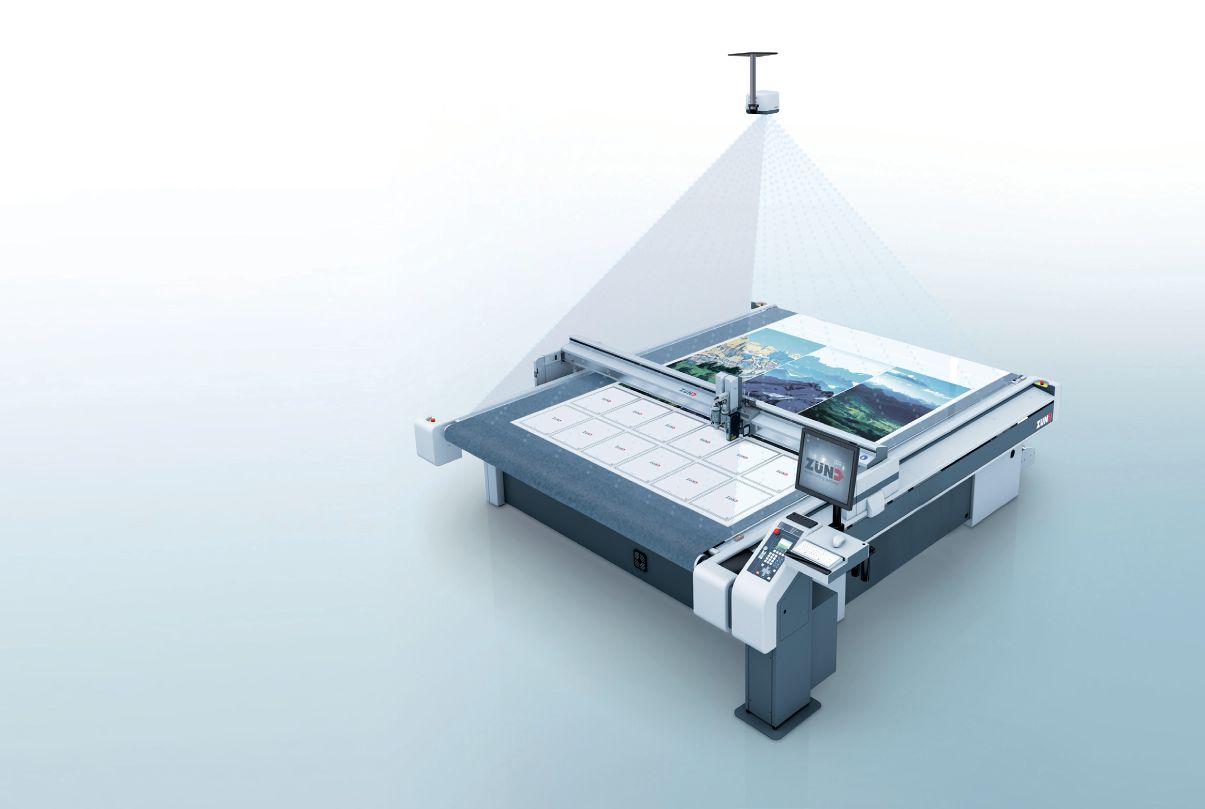

Toronto, Ontario-based Significans Automation Inc., a newly formed global professional services company that formerly operated as Myrpress Consulting Inc., has launched its prepress custom workflow automation solutions. Established this year by a team of graphic arts experts who share more than 100 years of experience between them, Significans Automation creates colour-managed, custom automated workflows that are built on existing foundational systems. Led by Marc Raad and Mircea Petrescu, the company says its customers can expect an “entirely integrated” operation that automates labour-intensive jobs, eliminates barriers to enhanced productivity, and facilitates robotics and robotic workflows in the future. Raad describes how increased automation will help drive print efficiency and development.