For years, Mitsubishi set the superior technology standard for Canadian printers. Today, RM Machinery returns that innovation to Canada, but with an even higher standard: Ryobi Mitsubishi Graphic Technology (RMGT).

Serving the US market for nearly a decade, RM Machinery (RMM) proudly brings our expertise to Canada’s printing industry. We deliver the highest quality sheetfed o set, digital inkjet, and flexo printing presses by partnering with the finest manufacturers in the industry.

RMM is the premier distributor in Canada for Mitsubishi, RMGT, and Miyakoshi printing presses; Bottcher rollers, blankets, and chemistry; Standard Horizon finishing systems; and GEW UV curing systems.

We are stable, local, and o er the best-in-class technology. We maintain an ample supply of parts, and for as long as you own one of our supported presses, you are guaranteed ongoing service and support programs that are among the best in the industry.

RM Machinery Inc.

905-238-9797 • 1-855-RMGT-123 5250 Satellite Drive, Unit 9 Mississauga, ON l4W 5G5 www.rmmc.ca

Equipping North America to print.

An Adidas installation at the Toronto Eaton Centre early last year put dye sublimation on display 14

Strategies to mitigate the effects of long-term stress caused by the pandemic

After four decades in the industry, Jay Mandarino reflects on running a successful print business

GAMUT

5 News, Calendar, People, Installs

TECHNOLOGY REPORT

18 An overview of newly-released short-run finishing technologies

NEW PRODUCTS

19 Detailing new products from Mark Andy, Soda PDF, Konica Minolta Business Solutions (Canada) Ltd. and Scodix

SPOTLIGHT

22 Janis Akmentins, head of engineering at Printful

FROM THE EDITOR

4 Kavita Sabharwal-Chomiuk New beginnings

CHRONICLE

8 Nick Howard

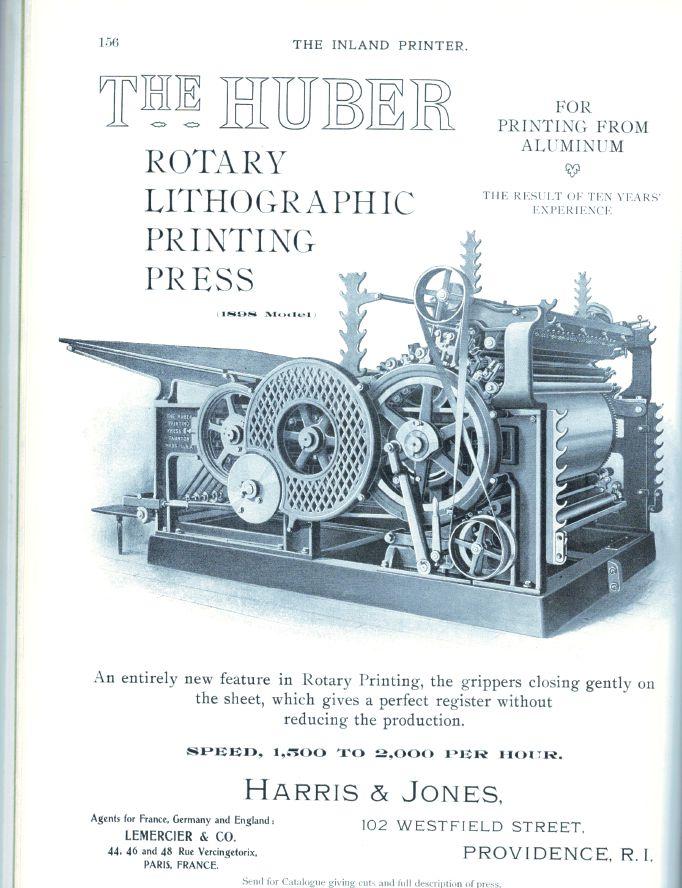

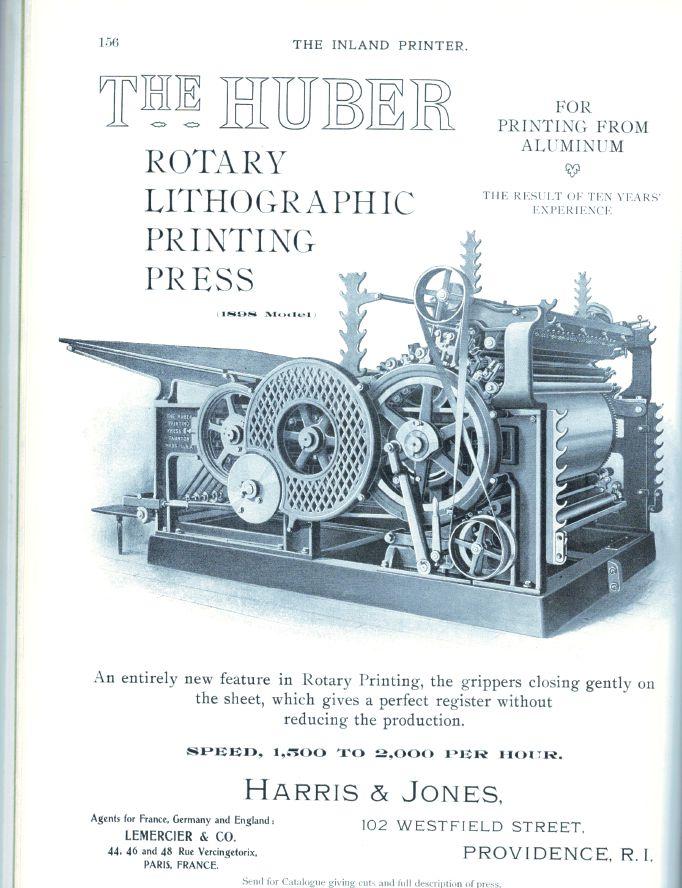

When the next big thing… isn’t: The long-forgotten zinco-aluminum press

INSIDER

13 Bob Dale

Marketing to marketers: Resources to help sell printed communications over digital

Welcome to the first 2021 issue of PrintAction! I’m delighted to kick off a new year with you, especially because we have something new in store to benefit our readers

We’ve enlisted the help of a number of industry experts to form an editorial advisory board for the magazine. The editorial advisory board will help us guide some of the content we cover in the magazine, as well as act as a sounding board when discussing issues in the industry.

The number of global survey respondents that indicated their company is planning to increase its spending on 3D printing.

Members include Chris Fraser of Moveable, Wayne Collins of the British Columbia Institute of Technology, Martin Habekost of Ryerson University, Bob Dale of Connecting for Results, Scott Gray of Mitchell Press, April Burke of Bellwyck, Jamie Barbieri of PDI Group, Jeff Ekstein of the Canadian Printing Industries Scholarship Trust Fund, Tracey Preston of the Ontario Printing & Imaging Association, and our cover interview this month, Jay Mandarino of CJ Graphics (p. 16).

This issue is also a special one, because it is the first of our 60th anniversary year! Yes, PrintAction has a storied six-decade heritage, and I’m so pleased to be able to start this special year with you.

are turning to advanced 3D printing to improve their businesses, including agility, modernizing supply chains, furthering innovation and enabling mass personalization. 3D printing can also reduce waste, lower carbon dioxide emissions and encourage a more circular economy, so this process appeals to companies that are aiming to limit their environmental impact.

“We’re seeing significant interest in digital manufacturing technologies across regions and industries when it comes to economic growth, and it’s no surprise why: Manufacturing is the engine that supports entire economies and ecosystems,” said Ramon Pastor, head of 3D Printing Technology, Operations, and Metals at HP Inc. “Digital manufacturing will continue to be a transformative driver of growth across a variety of segments, including orthotics, footwear, tooling and beyond.”

One industry that is set to see the most advancement in 3D printing is health and wellness, with 55 per cent of survey respondents predicting that the medical industry will see the most innovation over the next five years.

January/February 2021 | Vol. 60, No. 1

Reader Service

Print and digital subscription inquires or changes, please contact Barbara Adelt, Audience Development Manager

Tel: 416-510-5184

Fax: 416-510-6875

Email: badelt@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor

Kavita Sabharwal-Chomiuk kchomiuk@annexbusinessmedia.com 437-220-3039

Contributing writers

Bob Dale, Treena Hein, Nick Howard

Media Sales Manager

Kim Barton kbarton@annexbusinessmedia.com 416-510-5246

Media Designer Lisa Zambri lzambri@annexbusinessmedia.com

Account Coordinator Alice Chen achen@annexbusinessmedia.com 416-510-5217

Group Publisher Diane Kleer dkleer@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Subscription rates

For a 1 year

The number of respondents that plan to invest in digital manufacturing technologies by mid-2021.

PrintAction’s 60th year follows one I’m sure will be difficult to forget. However, when faced with challenges, many often thrive. That’s why last year, we launched the first-ever Champions of Print Awards, celebrating companies and individuals that displayed innovation and made contributions to their communities or to the country during the pandemic. We also kicked off our first-ever podcast series to highlight the winners of the Champions of Print Awards, and a special digital edition featuring interviews with the winners. This is just the start of our podcast program – stay tuned to hear more from us this year!

One trend to look forward to seeing more of this year is 3D printing. The HP Digital Manufacturing Trends Report polled over 2,000 respondents in the 3D printing and digital manufacturing space from Europe, Asia, the U.S., Canada and Mexico. According to the survey, this technology is integral to creating a new manufacturing value chain, and respondents overwhelmingly agreed it would help spur economies around the world. Respondents

Meanwhile, 50 per cent of respondents expect the industrial sector to see a lot of advancement due to 3D printing, indicating how far-reaching this technology can go. Respondents believe manufacturers are relying on new and continued innovation to achieve new product breakthroughs in this sector, including 59 per cent that say improved tools is the most significant factor in their companies’ use of 3D printing.

For the first issue in our 60th anniversary year, we provide some suggestions to help mitigate the effects of stress due to COVID-19 (p. 14). This issue also features an article on how dye sublimation was used in a creative marketing installation on behalf of Adidas (p. 10), and a Q&A with Janis Akmentins, head of engineering at Printful, on the company’s implementation of AI solutions and how they help provide better service to customers (p. 22).

Until next time, stay well.

KAVITA SABHARWAL-CHOMIUK Editor kchomiuk@annexbusinessmedia.com

subscription (10 issues): Canada — $43.00 +Tax Canada 2 year — $70.50 +Tax United States —$98.00 Other foreign —$191.00 All prices in CAD funds

Mailing address

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 printaction.com Tel: 416-442-5600 Fax: 416-442-2230

Annex Privacy Officer Privacy@annexbusinessmedia.com 800-668-2384

PrintAction is printed by Annex Printing on Creator Gloss 80lb text and Creator Silk 70lb text available from Spicers Canada.

ISSN 1481 9287 Mail Agreement No. 40065710

Rotoflex is relocating to a new manufacturing building in Mississauga, Ont. to accommodate its growing team and increased manufacturing capacity. New product development, insourced manufacturing and customer demand has led to a successful year for the company, which has allowed it to increase production within a new, more efficient facility.

The company’s sales and aftermarket growth increased by approximately 30 per cent year-over-year due to strategic management decisions involving increased R&D investments to improve final product quality and speed up lead times, which also eliminated outsourced production and increased customer demand.

The Ontario government is investing $550,000 to help two local manufacturers retool their operations in order to increase the capacity of masks manufactured for both adults and children. Funding is being provided through the Ontario Together Fund. The two companies that will be receiving funding are:

Viva Healthcare Packaging, which will receive $450,000 to retool its operations and begin making three-ply, disposable surgical masks in both regular and children’s sizes at its Toronto facility. The funding will go towards modifying its facility to accommodate new

equipment and set up new mask production lines. Production will start at 7.5 million masks per month, and is expected to climb to 22.5 million masks per month by March 31, 2021. The medical-grade masks will be ASTM-rated level 1 or 2 and will be developed using locally-sourced materials.

Ckdpack Packaging, which will receive $100,000 to purchase cutting, fabric welding and sewing equipment for its Straffordville facility in southwestern Ontario to automate and expand its current production of surgical masks and disposable gowns. The funding will help the company significantly increase its capacity to make 300,000 certified surgical masks per month and 30,000 gowns per month.

Following consultation with exhibitors and partners, drupa 2021 has officially been cancelled due to the impact of the COVID-19 pandemic. The next drupa will take place as scheduled from May 28 to June 7, 2024, in Dusseldorf, Germany. In place of next year’s in-person event, drupa will be holding virtual.drupa, a four-day virtual event set to take place from April 20 to 23, 2021, during the time frame drupa was originally scheduled to occur.

The virtual event will allow companies to showcase themselves and their innova-

tions virtually, as well as network with current and new connections.

FESPA has postponed the 2021 Global Print Expo, as well as the co-located European Sign Expo, from March until October 2021. The event will remain at the same venue, the RAI exhibition centre in Amsterdam, the Netherlands.

The postponement follows confirmation that all international exhibitions set to take place at the RAI exhibition centre in Q1 have been rescheduled into Q2 or later. The move reflects ongoing uncertainty surrounding COVID-related travel restrictions and visitor quarantine requirements in the Netherlands, which may continue to affect exhibitors and visitors in early 2021. The FESPA events will now take place from October 12-15, 2021.

Avery Dennison has teamed up with Schreiner MediPharm and PragmatIC on extending the use of NFC technology to the unit-level for everyday pharmaceutical products.

The smart technology can provide important functions such as tamper evidence, secure authentication, end-to-end traceability and easy re-ordering. In the case of pharmaceutical products, it can also help the patient access instructions, video/audio guides, helplines, social media support groups, or even their doctor or clinician.

Traditionally, the costs of NFC technology and its inlays and integrated circuits have been prohibitive, but due to this new partnership, these options can be embedded in cost-sensitive, everyday healthcare and pharmaceutical products.

The technology features Avery Dennison’s NFC inlays, which include NFC ICs from the ConnectIC range of products by PragmatIC, a UK-based company that specializes in ultra-low-cost electronics. These ICs, called

FlexICs, are thinner than a human hair, making them suitable for small diameter objects such as small syringes or vials. Avery Dennison’s inlays with ConnectIC chips have been adopted by Schreiner MediPharm to extend its portfolio.

The low-cost NFC inlays and Schreiner MediPharm’s labelling technology are expected to be available in Q1-2021.

Koenig & Bauer Durst has received UL Ecologo Certification for its water-based food safety inks.

Koenig & Bauer Durst’s water-based food safety printing inks have successfully achieved UL Ecologo Certification, demonstrating third-party validation of the products’ sustainability performance.

The Durst WT Food SP Ink and the Durst WT Food MP Ink product lines achieved the certification by meeting rigorous lifecycle-based environmental performance criteria as defined in UL’s stringent Ecologo Standard (2801 – 2012 Standard for Sustainability for Printing Inks). Black, cyan, light cyan, magenta, light magenta and yellow inks have all been assessed and include no hazardous components defined by the Ecologo Standard.

The inks were also evaluated based on multiple criteria throughout their lifecycles, including energy use, waste disposal and toxic reductions, among other areas.

Kim Barton has joined the PrintAction team as media sales manager. In this role, Kim will be assisting PrintAction clients with their marketing campaigns to Canada’s printing and imaging industry. Kim brings 17 years of sales experience in B2B media, along with event logistics and marketing, to the position.

“Kim’s extensive sales background, along with her enthusiastic personality, will be a valuable resource for PrintAction and its clients,” says Diane Kleer, VP production/group publisher, Annex Business Media.

Kim will be based out of the Gordon Baker office in Toronto. She can be reached at 416-4359229 or kbarton@annexbusinessmedia.com.

Koenig & Bauer (US/CA) has announced that Kilian Renschler, its current executive vice president of sales, has been named its new CEO and president. After 11 years leading Koenig & Bauer (US/CA), Mark Hischar has officially retired, effective Dec. 31, 2020.

In this role, Renschler will provide leadership to the company’s North American divisions, which includes sheetfed, web, digital, flexography, post-press and specialty printing. Renschler brings over 30 years of experience in the graphic arts industry to the role.

Industry veteran Howard Conway has joined Connecting for Results Inc. Howard has over four decades of experience and is an expert in the fields of change management and customer service. Howard has experience in implementing process improvement, cost realignment, quality methods and operational re-engineering in industries ranging from consumer goods through to printing and digital printing applications and services. Howard has held a number of senior management positions across a wide range of print communication organizations.

In September, Ellis Packaging completed the installation of a custom-made 12-station press from CPS Canadian Primoflex Systems at its Pickering facility. The press’ inline inspection system guarantees cartons are consistent, run-to-run. It can run up to 10 colours and add cold foil and holographic effects.

Richmond Hill, Ont.-based E.B. Box recently installed a new Heidelberg Speedmaster XL 106+6+L with Push to Stop technology and Prinect Production Manager, a move that the company says has helped it increase its packaging capacity by 50 to 60 per cent per shift.

Nicole Morrison has also joined the team in the newly created role of communications and marketing consultant.With over a decade of experience in public relations, Nicole has successfully helped her clients communicate effectively over both traditional and digital channels, and receive national recognition. In this new role, Nicole will provide promotional support across organisational and client initiatives, and will also coordinate CFR’s Corporate Social Responsibility programs.

Alberta-based Wide Open Throttle Graphics recently upgraded from wrapping snowmobiles with a Roland TrueVIS SG-540 to a TrueVIS VG2-540 to wrap not only snowmobiles, but also motocross bikes, personal cars and trucks, and fleet vehicles, allowing the start-up to grow into a full-service shop.

March 11, 2021

GCM Colloquium Online

April 15-17, 2021

Graphics Canada Mississauga, Ont.

April 20-23, 2021 virtual.drupa 2021 Online

June 8-10, 2021

Labelexpo Americas 2021 Chicago, Ill.

June 8-10, 2021

Brand Print Americas 2021 Chicago, Ill.

June 10, 2021

DIA Annual Golf Tournament Aurora, Ont.

August 12, 2021

OPIA Toronto Golf Classic Brampton, Ont.

October 12-15, 2021

FESPA Global Print Expo Amsterdam, The Netherlands

Editor’s note: Please note, we’ll be postponing the Canadian Printing Awards until further notice. However, we’ll still be accepting your submissions produced between 2019 and 2020 once nominations open. Please stay tuned for more information!

By Nick Howard

Whatever hap pened to beaver pelt hats and mink coats?

The former went out of style in the early 20th century, while the latter is perilously close to the same fate. If there is a “want,” then someone will source and cap italize on materials needed to satisfy it. Once a society has moved on, complete industries are often wiped out if they didn’t pay heed to the prevail ing winds of change.

In one notable case, when a rabbit pelt seller in France learned that his largest custom er, Haloid/Xerox, found a new man-made material to replace fur wipers for their 714 photocopiers, he committed suicide.

Perhaps the next behemoth to fall will be “Big Oil.” Radical new battery technologies will empower more fuel guzzlers to use the grid and thereby reduce the oil demand. The reduction of crude will slowly trickle down to petrochemical refineries and result in price increases for the host of oil-based by-products humans desperately need.

During the printing industry’s existence, there are many examples of technologies that were supposed to solve problems and failed. During the early 1800s, printers were increasingly on the lookout for a new process or machine that would increase print quality and raise production levels.

My good friend, Frank Her-

up and down, back and forth or around in circles,” he said.

Printers knew this to be true, as did anyone attempting to invent or improve a mechanical device, and printing presses were certainly clumsy devices that needed all the help they could get. A circular motion was key to increased speeds and when the first Gravure attempt was identified in 1852 England, progress on a new technology began.

Nicephore Niepce and Fox Talbot hand-engraved copper plates for a radically new process which even today is still in use. Gravure (or Tiefdruck in German) is an Intaglio process. The history of Intaglio dates back centuries before Talbot

and still commands a percentage of print today. One only needs to look at paper money or a stock certificate to see and feel the difference. In 1852, Talbot wasn’t attempting another “engraving,” but rather a new way to utilize the wondrous invention of photography.

With film developments beginning in 1839, Gravure printing could increase reproduction quality. It wasn’t until Mungo Ponton discovered a paper soaked in bichromate of potassium that he realized he had made the paper light-sensitive, thus leading to another compound, bichromated gelatine. This last bit would lead to Karl Klic, a Czech, to invent the Carbon Tissue Resist and usher in the real beginnings of applicable Photogravure in 1877. This process utilized the gelatine applied to the carbon sheet, which is impervious to the acids used to etch the image on a plate or later a roll

(Rotogravure). The results were mind-blowing. For the first time, images, such as a halftone, could be printed as if they were the original photograph. A long-plagued problem for printers was in replicating the wide tonal values in letterpress. Film improved tones and Gravure was now thought to be important and would be continually improved to exploit the opportunity.

Letterpress soon discovered a use for film in the discovery and development of “electros.” Electros are usually copper plates that would take the bichromated gelatine discovery for their gain and produce much finer reproductions than lead or hand-carved woodcuts. Although initially a hopeful new technology, Gravure faced the headwinds of Letterpress for decades to come. As hard as they tried, Letterpress Printers would never reach the quality of Gravure, and ironically, Gravure found new markets.

Well into the 20th century, Gravure was (and still is) used for everything from long-run magazines to packaging. The trouble was, the process was incredibly costly. The agony of preparing a cylinder or plate required hours of tedious work by specialists. Complete chromium plating lines and spindle grinders were only but a few of the expensive pieces of auxiliary equipment needed. Then there were machine-room costs to prevent explosions and fires. The flammable solvents used in the ink were not only toxic, but easily ignitable. Large Rotogravure plants would require expensive fire-abatement systems including carbon dioxide, stored in bottles, and made to release in the event of a fire breaking out. If the bell rang and you were slow, chances were, you’d be carted out of the factory boots first.

Gravure would also harm Planography (Lithography) during the late 19 th century. Stone printing had been the best way to reproduce fine art and anything with shading or half-tones, and although agonizingly slow, drew clients who insisted on only the finest reproductions. Gravure had been gnawing away at Lithography because it excelled at everything Lithography was good at. With massive infrastructure costs,

Gravure printing was also the most expensive. What to do?

The old stone-men figured that if they could eliminate Solenhofen limestone in favor of a thin metal plate, they could alter the landscape tremendously. Zinc plates were first chosen as zinc could be rolled down to a thin sheet of say 0.024 inches and made sensitive with a series of processes similar to Gravure. This attempt grew legs and by the 1890s was being used sporadically in Europe and America.

Initially, a modified letterpress was chosen, but talk soon turned to devise a “special machine” that didn’t have a back-and-forth bed, but two rotary cylinders: a plate cylinder and an impression cylinder. If you took a modern offset press, removed the blanket cylinder, and placed the plate cylinder (with ink and dampener) in its place, you have a Direct-Lithographic, or Zinco press. The terms Zinco-Lithography and early in the 20th century, Aluminographic-Lithography (the first use of aluminum) would enter our vocabulary. Dozens of press manufacturers rushed Zinco presses to the market and clambered to take advantage of the faltering stone industry. These rotary presses didn’t suffer from the old ways of back-and-forth letterpress, plus the plates were cheaper than stone.

New technology was born and ready to take over the entire industry. Only, that’s not what happened: zinc and aluminum plate processing was fickle. Add the expense of large cameras, platemakers, graining machines, and skilled “touch-up” artists, and you can imagine the road to modernity was fraught with potholes. Direct-Lithography saw its peak between 1898 and 1904, when Ira Rubel re-discovered the long-forgotten Offset principle. Its time in the sun was over, not because of niggling plate problems, but because the print quality was not great. Manufacturers, who must have poured fortunes into machinery, found no buyers and even today, I have never seen a surviving Zinco or aluminum press. Just as quickly as it appeared, Direct-Lithography was gone to history.

Gravure, of course, didn’t disappear and went on to be dominant well into the 1990s, only losing much of its magazine work to the

Image is Gravure, produced in 1921.

Image is Gravure, produced in Germany in the early 1900s.

surging Web Offset market. Recently, the British press reported that OK! and Hello! magazines had changed printers and would no longer print Gravure. In the 1980s, Playboy and National Geographic were just some of the bigger names that heralded a massive switch to Web Offset. But Gravure held onto labels, packaging and various important elements of print. Technology advanced accordingly to reduce the costs of cylinder preparation, with sleeves often used. Gravure, through its spinoff Aniline (flexo) even gave Offset printers the technology to incorporate a doctor blade and screen-roller in their coating units. If you have a TRESU or Harris & Bruno coater, that’s Gravure in action.

History teaches us a great deal when we apply the lessons learned to our current lives. Few bother to take advantage of the numerous mistakes our forefathers made. If we did, we would see how history is often repeated. With today’s amazing progress of digital devices, we must determine what platform will ultimately prevail and use caution when assuming nothing can ever defeat the status quo. Meanwhile, if anyone has a Direct-Lithography press available, I want one for the museum!

NICK HOWARD, a partner in Howard Graphic Equipment and Howard Iron Works, is a printing historian, consultant and Certified Appraiser of capital equipment. nick@howardgraphicequipment.com

An Adidas installation at the Toronto Eaton Centre early last year put dye sublimation on display

By Kavita Sabharwal-Chomiuk

Product installations are meant to tell a story and drum up customer interest in a unique, interactive way. In the case of an installation completed on behalf of Adidas, Foot Locker and lifestyle marketing firm MKTG at the Toronto Eaton Centre early last year, the installation did just that, and more.

The installation was designed in a collaborative process between MKTG and PNH Solutions to celebrate the 50-year anniversary of Adidas’ Superstar shoe. The 15-footby-15-foot brand activation was installed at the shopping mall on Feb. 21, 2020, with the event held from

Feb. 22 to 23.The installation’s print, fabrication (welding, millwork, LED lighting), installation and decommission [of the project] was managed by PNH.

“PNH Solutions completed both the installation and decommission process with two people from its team,” says Katherine Hudon, marketing coordinator at PNH Solutions.

“While the installation took about five hours, the decommission took around three hours.”

Because Adidas was celebrating an important milestone, Hudon says MKTG wanted to highlight the value of the brand’s Superstar shoe

through its importance in culture and history. The aim was to create a powerful brand experience to increase foot traffic to the nearby Foot Locker store, create an online buzz on social media, and ultimately drive sales.

“Through a collaborative process, PNH Solutions, led by Carlos de la Rosa’s creative direction, and MKTG developed an activation with a bank vault and museum-inspired display cases to present the shoes as products worth protecting

Visitors were able to get their photo taken inside the installation’s “bank vault” by a professional photographer.

“PNH Solutions completed both the installation and decommission process with two people from its team.”

and preserving,” explains Hudon.

To further this point, PNH designed and built a photo booth to look like a bank vault and added lit-up podiums where it would display the Superstar shoes. The podiums were battery-operated, allowing the public to walk around them freely without the risk of tripping on wires.

PNH drew attention to the installation using an original concept with a lenticular wall featuring frontlit

graphics, visible from different levels of the mall. Hudon says the addition of the lenticular wall further encouraged passersby to double-take and walk around the display to identify both images.

Once the public was on the site of the installation, they were treated to a live DJ and were able to get their photo taken inside the main structure by a professional photographer; they were later able to share those photos on social media with different hashtags.

A live DJ was present as part of the installation.

The installation featured a double-sided silicone edge graphic (SEG) Fabric Lightbox on the ceiling, providing ambient lighting for the photographer on one side and advertisement on the other that was visible from higher stories in the mall. The SEG fabric frames will also allow Adidas to easily replace the graphics present for future campaigns, if desired.

To further entice customers to visit the nearby Foot Locker store and encourage sales, on-site brand ambassadors were promoting prizes with purchases.

PNH printed most of the graphics for the installation, from both the inside and outside walls on the main structure to the lenticular wall, on fabric. They did this using a dye-sublimation process on the Durst Rhotex 320. The remainder of the visuals featuring the campaign’s branding were printed on polymer flooring materials using the Durst Rho 900.

According to Hudon, the activation was well-received by the public, MKTG and Adidas. In fact, The Adidas Group was so impressed that it kept the products used in the installation to display within the main lobby of its Canadian headquarters.

“The feedback from our client and from consumers on the ground was exceptional.”

“Thank you for everyone on the team that had a hand in making this come to life! The feedback from our client and from consumers on the ground was exceptional,” says Jake Clements, manager – Live at MKTG. “We are thrilled with how we made the concept come to life from start to finish. Despite the tight timelines, we were able to work together to deliver on stakeholder expectations. We appreciated the effort, attention and, most importantly, the teamwork that led to the final product.”

By Bob Dale

hile 2020 was a difficult year for most companies in the commercial print segment, the return to ‘business as usual’ in 2021 is not expected to materialize.

WMost commercial printers, direct mail firms and digital printers produce a significant amount of branded marketing material (70.2 per cent of commercial printers, according to SGIA research). Gartner Inc. is a leading research and advisory company that has conducted studies on corporate marketing practices and trends. We all know that marketing budgets were reduced in 2020, but one key finding is that now 80 per cent of marketing budgets will be spent on digital channels.

In order to help marketers make informed decisions, they need facts. While many digital channels have analytics and tools to demonstrate effectiveness, there are many studies about the effectiveness of printed communications that also can help sales reps overcome objections.

Here are some resources that should be shared with the sales team to prepare for customer challenges.

This initiative was sponsored by the PIA of Southern California in 2011. The PIA is now the Printing United Alliance, and the CPIA, OPIA and other Canadian affiliates are members. While some of the material has been updated, there are links to other online resources that are current. They include links, material and studies from Two Sides North America, Domtar, International Paper, USPS and others. http://chooseprint.org/

Print in the Mix is a clearinghouse of curated third-party research demonstrating the effectiveness of print, web, mobile, social media and other formats in the crossmedia communications value chain.

Two resources available from Canada Post on the benefits of direct mail.

According to Choose Print, Direct Mail is far more persuasive than digital media, resulting in a 20 per cent higher motivation response.

The mission is to advocate and educate for the value of print as a viable and effective return on investment in the marketing strategy media mix – alone and working synergistically with other media to drive results.

Print in the Mix was created in 2007 with a grant from The Print Council and is housed at the Rochester Institute of Technology and published by the School of Media Sciences Cross-Media Innovation Center. The Print Council ceased operations in fall 2012 and sponsorship of the Clearinghouse was transferred to RIT.

http://printinthemix.cad.rit.edu

We can’t forget that Canada Post has conducted a number of relevant and current studies that contain facts and case studies on the benefits of direct mail.

In addition to the information contained in the section Direct Mail in the Marketing Mix, you can also subscribe to Incite Magazine, which has excellent case studies that are great to share.

https://www.canadapost.ca/cpc/

en/business/marketing

Unlike some politicians these days, we need to be able to make a compelling argument using facts to help our clients make informed decisions to choose printed media. I trust you can use and share some of these tools to make a difference. Please share your experience. I’d love to hear from you, so we can share your success stories.

Bob Dale is Sr. Vice President of Connecting for Results Inc. Bob has many years of graphic communication management experience, including over 15 years offering management consulting services, transition execution and support. He was also a part-time faculty member at Ryerson University, and has published many columns on effective cost management and management information systems. Over the past 14 years, he was employed by RBC as a specialist to lead national and international efforts for the effective print category management. He can be reached at b.dale@cfrincorporated.com.

By Treena Hein

Many aspects are still unknown about the COVID-19 pandemic, but one thing is certain – it’s had a mostly negative effect on our mental health. Isolation, financial stress, worries about our health, the health and financial situations of loved ones, feelings of helplessness and lack of control, worry about the future – the list of stressors from this pandemic is long. There is good news, however,

in that there are many effective strategies available for protecting and nurturing our mental health. But first, let’s look at a few measurements. In its Mental Health Index for Canada published in December, HR company Morneau Shepell notes that for the last nine consecutive months, the mental health of Canadians has been “significantly lower” than prior to the pandemic. “The level of mental health in December continues to be a concern as it indi-

cates that the working population is currently as distressed as the most distressed one per cent of working Canadians, prior to 2020,” state the report authors. Respondents surveyed are 95 per cent employed, although some have experienced drops in pay due to the pandemic, and they also represent different racial groups and locations across Canada (see sidebar for more).

Another pandemic-era study by Mental Health Research Canada shows similar results. “Levels of anxiety and depression are still, respectively, four times and two times pre-pandemic levels,” and, “the proportion of Canadians reporting high depression doubled following the COVID outbreak and remains at this level.” Among other results Statistics Canada reported in October, the agency noted that “those reporting poor mental health are up to four times more likely to report increased substance use since the pandemic began.”

The first thing to understand about mental health and this pandemic is that the effects are serious. Manitoba-based Marriage and Family Therapist Elan Jury explains that, “COVID-19 is an uncertainty. We don’t know when it will end and what the outcome will be. This is a collective, prolonged trauma, and with that sort of situation, the naturally-wired human stress response of ‘fight, flight or freeze’ gets stuck in overdrive, because there’s no way to escape the stressor. At the same time, we need to realize we are grieving.We are grieving the loss of normal life, loss of connection, in some cases, loss of jobs and other aspects of our lives.”

Under chronic, traumatic stress, there are a few important strategies to consider. One is to use our innate ability for stress management to flexibly regulate our stress response throughout the day.

“We need to learn to tune into ourselves and how to listen to our nervous systems and bodies to determine what they need,” Jury explains. “Everyone is different, and your body will tell you. For instance, if you feel unsettled and jittery, perhaps you need to do an activity like walking or yoga to discharge the flight response. If you’re feeling lethargic and having trouble concentrating, perhaps you

need to unwind through deep breathing or having a nap.”

Of course, looking after the body that houses our nervous system is also critical. Watch your diet and explore the benefits of taking Omega-3 fatty acids, B vitamins and other supplements related to brain function, stress and mood. Get regular exercise and watch your sleep. Avoid drugs and alcohol. Explore deep breathing and other ways of calming your parasympathetic nervous system.

Reach out to a therapist as needed or desired. Understand that signs of stress are much broader than are generally realized, and can include changes to sleep patterns, inability to concentrate, worsening of existing health problems and much more. Use a crisis line if you need to.

The internet provides a wealth of mental health resources – countless articles, anonymous discussion boards, groups, and resources related to meditation, exercise, hobbies and activities, from virtual choirs to learning a new language.

However, at the same time, the internet also provides a steady stream of information on pandemic case numbers, economic indicators and so on. Jury notes that receiving a constant stream of updates isn’t the wisest course.

“It’s likely ok to receive updates less often,” she says. “Wean yourself to longer intervals without them. Get used to unplugging for periods of time, especially before bed. Also, take a close look at what information you currently receive that is actually useful or beneficial to you.”

We can also regulate our stress response to this pandemic through nurturing our connections with others. Jury advises us to start noticing how much we are actually connecting with the people who are important to us, to offer and receive support, laugh at life, celebrate achievements and brainstorm ideas to deal with challenges. Then, work to increase our level of actual connection.

“Even quick check-ins make a big difference,” she says. “You’ll begin to see that strengthened connections really do help reduce feelings of overwhelm and isolation.”

More results from the latest Morneau Shepell Mental Health Index report for Canada (December 2020)

In December (and for the nine previous months), women achieved a significantly lower mental health score compared to men.

Respondents identifying as Black, South Asian and Latino had lower scores, but those identifying as Other (aggregate of Pacific Islander and Mixed [Black and other racial groups]) had the highest score.

Those with at least one child score lower to those without children.

Those reporting reduced salary when compared to the prior month have the lowest mental health scores, and self-employed/sole proprietors have the highest.

Individuals without emergency savings continue to experience a lower score in mental health than the overall group.

Younger respondents are experiencing a greater increase in mental stress when compared to older respondents.

The greatest increase in stress month over month is being experienced by those living in Alberta, followed by Saskatchewan, Manitoba, and B.C.

“We are grieving the loss of normal life, loss of connection, in some cases, loss of jobs and other aspects of our lives.”

However, tailor your connection as much as you can. “You may be being asked to participate in many Zoom calls with family and friends and that can be difficult for some people if it’s too often,” Jury notes. “Perhaps individual phone calls are what work for you or getting together for a physically-distant walk where possible.Your needs might not be the same as others, so you need to respect that but also respectfully communicate your own needs. It’s also important to recognize that your body will tell you when connection with others is too much. Sometimes you need to say ‘no’ if you do not have the capacity to be with others.”

As this pandemic continues, Jury’s parting advice is to be gentle with ourselves. “If you’re having a hard time coping or getting motivated, don’t beat yourself up,” she says. “Give yourself permission to take things day by day and be kind to yourself. Nourish yourself. It’s hard to think about the future, so try and pay more attention to the things that are in your present moment that bring you joy. Zero-in on the meaningful things and moments we don’t normally pay much attention to.This will help us feel anchored and not be as focussed on what may happen in the future.”

Treena Hein is an award-winning Canadian science, technology and industry business trends writer.

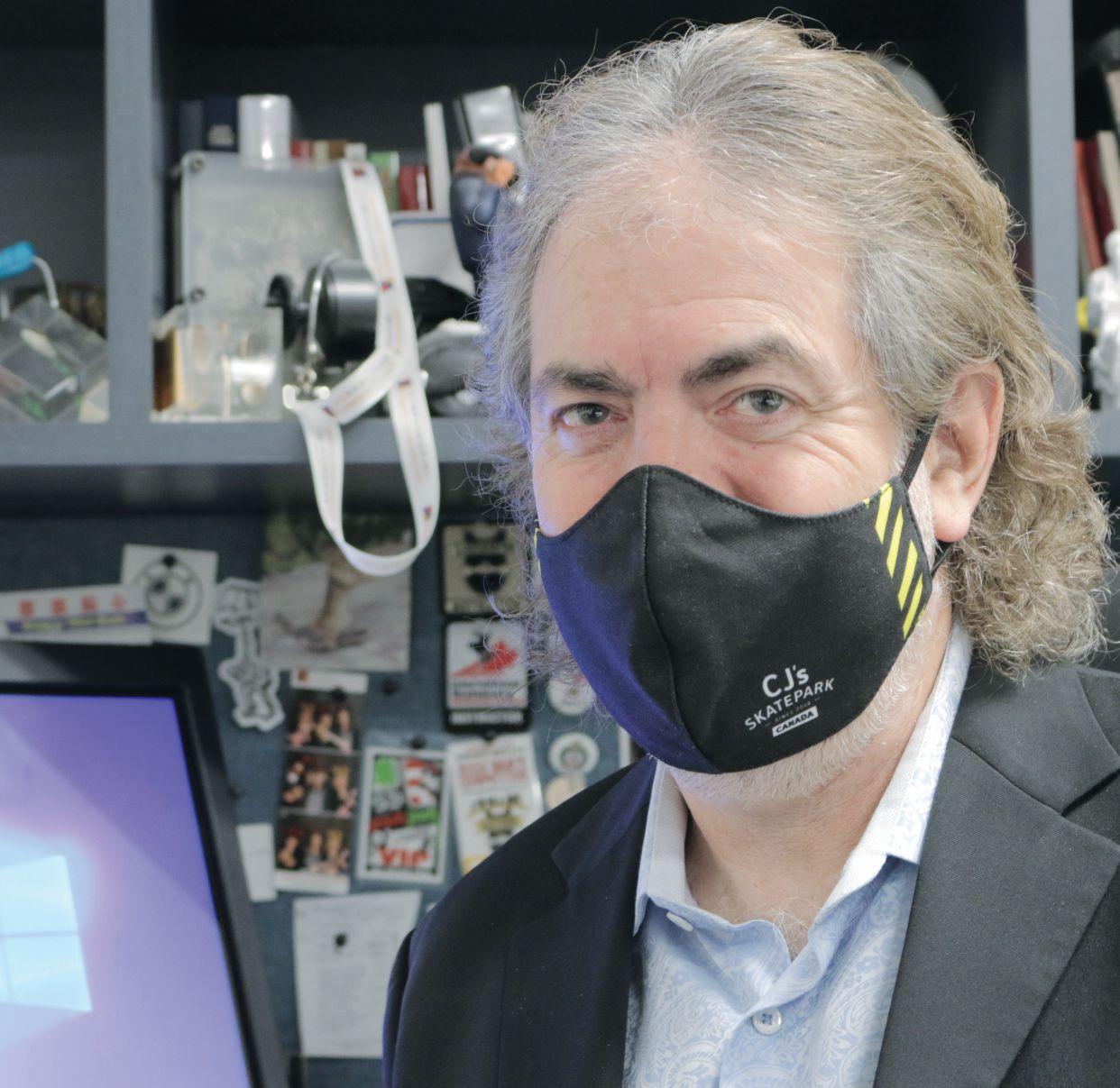

Mandarino

After four decades in the industry, Jay Mandarino reflects on running his print business

By Kavita Sabharwal-Chomiuk

Jay Mandarino is president and CEO of the CJ Group of Companies. In this role, he oversees the daily operations of several ventures, including CJ Graphics Inc. and CJ’s Skatepark.

Founded in 1980, CJ Graphics Inc. is housed in a 240,000 sq. ft. facility in Mississauga, Ont. Recognized as the most-awarded printing company in the world, CJ Graphics has been the recipient of over 6,500 awards since its inception, including several Benny Awards, handed out by the Printing United Alliance. Mandarino himself has also been the recipient of several of PrintAction’s Canadian Printing Awards, including Canada’s Printing Leader of the Year, Community Leader of the Year and a Lifetime Achievement Award.

Mandarino notes that the company didn’t set out to win awards, but the awards have opened doors that may not have otherwise been available to them.

“[The awards we’ve won] became a marketing tool, and it certainly got us into places that we wouldn’t have necessarily gotten into before. It let us get a lot of right refusals and jobs, so even if we charged a higher price, people would say, ‘we want you to do it,’” says Mandarino. “People are buying a brand when they’re buying a CJ product. We stand behind our work and [clients] know they’re going to get it on time.”

As the company celebrated its 40th year in business in 2020, Mandarino says it’s humbling to have been able to withstand the test of

time, especially during a global pandemic.

“In 1990, I received one of my first big awards. I looked around the room and I was in awe of these amazing printers. A few months ago, I realized that most of those companies have closed, have been sold or went bankrupt,” he says. “Only one [other] company is still around, which is kind of scary. It makes you realize, wow, we have staying power.”

According to Mandarino, the company has seen this level of success because it has always prioritized investing in new technology, including beta testing, and adhering to best practices, including information sharing, even with competitors.

One annual tradition that Mandarino enjoys carrying out is an awards ceremony honouring his employees, to whom he attributes a large portion of the company’s success.

“I’m sure people hear this all the time and hopefully they believe it, but the strongest asset you have is your people,” says Mandarino. “We do some pretty unique projects that

are really out of the box. A lot of people are not set up to do those. We have some really creative people in house – structural engineers – and we’ve been able to come up with some really clever ways of doing things, and clients love it.”

One such out-of-the-box project are the modular beds that CJ Graphics assembled to help address hospital overflow during COVID-19, which is just one of the innovative projects that earned the company a Champions of Print Award from PrintAction (editor’s note: for more on the 2020 Champions of Print Awards, please visit PrintAction. com).

Mandarino makes the effort to stay on top of industry information-sharing events, including conventions, virtual events and podcasts. His suggestion is to, “get around, meet people and learn new things. It’s about taking that all in and thinking of what the next big thing is, and then trying to get ahead of the curve

“Don’t pigeonhole yourself or your business and think of yourself as just one thing. You are your own limit.”

on that.”

He adds that he had some amazing mentors himself that shared advice, thoughts and opinions with him, but at the end of the day, he followed his own gut instincts to get where he is today. “Too often, we don’t listen to our gut instinct, but it’s generally right, and we talk ourselves out of it,” he muses.

Looking forward, one of Mandarino’s main future goals for CJ Graphics is forming a succession plan. “To me, it’s not as important what I get for the company, but I just [want to maintain] the same craftsmanship, respect of staff and people,” he says.

Mandarino believes the industry will change drastically in the coming years. In order to deal with too much competition with not enough people buying, which is one of the major challenges faced by companies in the industry, Mandarino suggests the idea of merging in order to stay afloat during the pandemic.

“I think you’re going to see 30 per cent of [print] businesses gone,” he

says. “I think some companies will become stronger; some will merge and become bigger,” Mandarino adds. “We really have to think about what we’re going to do, because we need small businesses. All these huge businesses, you can’t compete against them.”

Mandarino’s advice on becoming worthy competition: “Don’t pigeonhole yourself or your business and think of yourself as just one thing. You are your own limit,” he says.

After 40 years in the industry, Mandarino’s recipe for success is to never give up. “There’s no secret to being successful. It’s hard work and being at the right place at the right time and how they collide,” he says.

“Be positive, but you have to work hard. If you truly believe it, if you wish for it, then it will happen.” PrintAction is having a birthday!

We’re working on launching the Canadian Printing Awards in 2021 in a virtual format. Please stay tuned for more information!

are celebrating 60 years as Canada’s resource for the printing and imaging industries. As we prepare for the anniversary issue in September, we are looking back over the past 60 years.

Italy-based Tecnau has introduced its new StreamFolder 5152 cut and stack line for high-speed, web-fed colour inkjet finishing.

The system is said to efficiently produce short-run digital book printing jobs of varying run lengths including ‘books of one.’ Available with a tack-gluing option, the StreamFolder 5152 operates, in-line or near-line, at speeds up to 750 fpm/230 mpm to take full advantage of the emerging generation of highspeed inkjet presses.

“StreamFolder 5152 plow-folds the web once or twice along the travel direction, enabling efficient use of a web-fed press at its maximum print width,”Tecnau said in an April 27 statement. “This folded web is very strong as the paper is up to three times thicker for system reliability (especially for lighter weight papers) feeding through the cutter and stacker.”

In addition, all modules operate in taut web to generate the smooth paper flow required for high-speed operations. “Curl is cancelled out as the web is folded back onto itself, for reliably flat books,” Tecnau said. “The StreamFolder 5152 also features ‘north/south job offsetting’, offsetting sets/book-blocks back and forth in the direction of travel to maintain full speed even for multiple consecutive small sets.”

The StreamFolder 5152 is a member of Tecnau’s Revolution 50 series, a family of products featuring IoT compatibility and media flexibility.

Sydney Stone, Canada’s exclusive dealer of Morgana technology, has announced the North American release of the AutoCreaser Pro XL.

The new feeder system features Adaptive Process Control that monitors sheet feeding in a closed-loop process, allowing for a wide variety of media handling and the ability to adjust on the fly by monitoring the

Tecnau’s Streamfolder 5152 is said to efficiently produce short-run digital jobs of varying lengths, including books of one.

paper float zone.

The AutoCreaser Pro XL can run at a maximum of 8,500 A4 sheets per hour, with no loss of accuracy. It accepts sheets sized at 385mm x 1300mm with the table extension, which comes as standard with this new machine.

The machine can be linked to the AutoFold Pro, an automatic folding system for the professional printer, to provide a more complete finishing solution. The AutoFold Pro was designed for folding digital stocks and uses the patented “Flying Knife” technology developed to prevent scuffing and marking on digital stocks.

The AutoCreaser Pro range includes rotary perforation as standard, with a wide variety of wheels available. An optional cross-perforating unit can be added for more complex jobs, including multiple perforation layouts.

Morgana’s AutoCreaser Pro XL monitors sheet feeding in a closed-loop process.

short-run digital print production. The Conveyance software “helps to create opportunities to streamline operations, distribute prints faster, and develop new revenue streams for book manufacturers, publishers, and commercial printers.”

The software’s features include file transfer and job information exchange via a standardized, comprehensive XML-based file format. Conveyance’s workflow also allows complete automation of order submission, CIP4 impositions, job grouping, splitting and routing, while tracking the integrity of each order. Conveyance provides a single workflow platform to efficiently produce books, magazines and booklike products. Additional benefits include:

• CIP4 compliance using a common language to support the production process and product life cycles.

• Features designed to quickly react to changes in the market and produce digital short runs to accommodate unexpected demand while eliminating warehousing costs.

• Reduced manual intervention, limiting paper changes, streamlining workflows, and reduced cost of short-run digital production.

• Reduced operator intervention by minimizing paper changes with intelligent job grouping and sending feedback from devices to controlling software for real-time order tracking.

Canon Solutions America Inc. has launched Conveyance, a JDF-enabled automated workflow tool developed to boost high-volume, Canon’s Conveyance workflow tool was developed to boost high-volume, short-run digital print production.

• Increased flexibility through dynamic bindery to impose signature layouts during runtime without returning to prepress.

• Flexibility to manage inline and nearline finishing, covers to text block authentication, and reprints from the main production through a central system control panel.

Evolution Series E3 is the second iteration of Mark Andy’s Evolution Series flexo press

Mark Andy is set to launch the second iteration of its Evolution Series flexo press. The new press, Evolution Series E3, will help fill a gap in the market for a servo powered machine that is both easy to use and reduces operating costs.

The original Evolution Series flagship press is being rebranded as Evolution Series E5, and provides converters with a scalable production solution for current and future needs.

Evolution Series E3 is available in 13 and 17-inch (330 and 430 mm) web widths with production speeds up to 500 fpm (150 mpm). The E5 maintains its technical specifications and is available in 13 and 17-inch web widths with speeds of up to 750 fpm (230 mpm).

With the launch of the E3, the company is also introducing Mark Andy ProUV, which will come standard on all E3 presses. Using Phidastien’s proven UV curing technology, ProUV enables reliable results backed by Mark

Andy’s global service network. In addition, ProUV is a fully integrated curing system, with power and air located on-press and within a single cabinet to help converters maintain a smaller pressroom footprint.

Soda PDF, a PDF editing software by Avanquest, has launched Soda12, a new, revamped version of its software. Soda12 offers PDF editing functionality on desktop and online, and can be accessed from anywhere. It also offers

2. SUPERIOR TECHNOLOGY — Die crease without a die, then fold and even glue all on the same machine, up to 30 pt.

3. INTEGRATED MODULAR UNITS — Combined in-line finishing: crease, fold, glue, tipping, envelope inserting, ink jetting (Duplex), clip seal (3 sides), mail prep.

4. SAVE ON POSTAGE COSTS —As a Certified Canada Post Direct Marketing Specialist, we get contract pricing reductions.

5. RETURN MAIL PRODUCTS — Customized “Return Mailers” created in-line with “U” or “BOX-shape” remoistenable glue, time perfed applications and envelope formation.

6. MINI-BOOKLETS — Saddle-stitch and trim 2-up booklets in-line to the size of a business card. No need to trim off-line, or do 2 passes.

7. HIGH SPEED EQUIPMENT — High speed Tipping, Folding, Saddle-stitching and soft folding ensuring on time delivery.

Konica Minolta’s AccurioPress C4080 Series is a high-speed digital press that offers an easy transition into digital printing.

desktop or online plans to its tools and services, as well as a new 360 product for users in need of both options.

The new software includes hundreds of improvements to the look and feel of the product, including the user interface, e-sign functionality and PDF to Office converter.

The company says it has improved its E-Sign in Soda 12 to create better workflows.

The Soda12 desktop application can be downloaded for free from Soda PDF’s website.

Konica Minolta Business Solutions (Canada) Ltd. has introduced a new line of digital production presses, the AccurioPress C4080 Series. This high-speed digital press offers user-friendly production with advanced operation and ease of use for various applications.

According to Dino Pagliarello, senior vice president, Product Management and Planning, the C4080 Series provides an easy transition into digital printing with inline finishing options, allowing prints to be boxed and shipped right off the press.

The C4080 Series, which includes the AccurioPress C4070 and AccurioPrint C4065, provides automation with the TU-510 Inline Trimmer Unit, which produces fullyfinished output with inline slitting and trimming, and additional options for inline creasing (valley and mountain crease), business cards, postcard cutting and perforation (vertical and horizontal). It also has the option to deliver fully trimmed and creased long sheets of up to 51” to the output tray. The presses can also work with the IM-101 external media detection sensor, an optional

external sensor to measure and identify media.

The press provides image quality of 3,600 x 2,400 dpi resolution and prints duplex sheets up to 34”. Envelopes can be printed with the standard fuser at half speed or full speed with an optional dedicated envelope fuser. The press features media versatility up to 360 gsm for a wide portfolio of paper choices and print applications.

The C4080 Series replaces the C3080 Series, an entrylevel, light production press that was launched in March 2018.

Scodix has launched PolySense 550, a new polymer for digital enhancement for the food packaging industry. The polymer is compatible with the entire Scodix Ultra portfolio of machines.

“Scodix enhancements create great visual impact for the brands who use them, and food packaging is no exception,” said Guy Alon, VP of R&D at Scodix. “The value of adding digital enhancements to food packaging with the assurance that the printing procedure is safe for consumers according to food packaging standards is a big step forward for Scodix Ultra users.”

Scodix PolySense 550 food packaging compliance refers to indirect contact for low migration.

PolySense 550 is a new polymer for digital enhancement designed for the food packaging industry.

Heidelberg: K-Line/S-Line/Speedmaster/GTO/MO/KORD64

Komori: 1, 2, 4 or 5 colours & any size

Adast: 714/715/724/725

Mitsubishi: Any model

Ryobi: 2800CD/3200CD-MCD/640K

Itek: 960/975/985

Hamada: 600/700/800/E47/RS34

Shinohara/Fuji: 66/65 1,2 or 4 colours

Sakurai: 1, 2 or 4 colours and any size (newer model)

Polar: any size/older or newer models (66/72/76/78/82/90/92/107/115)

Horizon-BQ: 220/240/260/440/460

Printful is a global company that specializes in print-ondemand. We spoke with Janis Akmentins, head of engineering at the company, to discuss how implementing artificial intelligence (AI) and machine learning (ML) in print-on-demand provides customers with better images.

What is Printful trying to achieve by implementing AI solutions?

JA: Nowadays, AI can be used to solve problems in all kinds of areas. We use it for ensuring quality prints and detecting copyright violations. We put a lot of effort into making sure that the products we offer and the designs we print match all the quality standards that we’ve set for ourselves. However, while we have complete control over the quality of the physical products we provide, print quality is harder to ensure due to the design variety.

Our customers are very creative— every day they create numerous designs to put on their products. To keep the print quality in check, design files have to meet certain guidelines. This is where AI steps in.

AI solutions help us inform customers about cases where their designs don’t match print requirements. That way, customers can adjust their designs to get a quality end product.

Additionally, by implementing the Background Removal Tool, we allow our customers to make complex image adjustments straight from the website—they don’t have to use heavy image editing software. This saves our customers time and possibly money as well—if the software they would otherwise use is costly.

Another way we use AI is to detect copyright violations in designs. Our Quality Assurance team has an eye out for possible copyright violations so these designs don’t continue in the manufacturing flow.

Both copyright violation detection and design guideline matching are internal processes where we have now implemented an AI solution. Before we used AI solutions, all this work had to be done manually, and that affected the fulfillment time. Since we automated these internal processes, we’ve been able to get the orders out faster.

We see great potential for adding more AI solutions in the future.

How does AI work to correct a less-than-perfect printed image?

We put a lot of effort into making sure that the products we offer and the designs we print match all the quality standards that we’ve set for ourselves.

JA: First, we used image transparency detection. To train the neural network, we first had to create a dataset by manually classifying our customer designs with transparent areas. Based on our knowledge about the printing process, we manually categorized several images on a scale from one to nine, depending on how much impact it would have on the physical print. After creating the dataset, we trained the neural network to automatically categorize the designs.

Next, we tackled image upscaling. In this case, we also had to start with training the neural network. We manually entered two versions of the same image. The first was a low-resolution image and the second one was the same image in higher resolution.

During this process, the neural network was able to learn how the pixels differ in these images and what rules had to be applied to reconstruct the image from low to high resolution. Hence, when a customer uploads a low-resolution image, we can upscale it by adding better resolution.

What are some of the biggest opportunities you see in the print industry today?

JA: There are a lot of people whose work is affected by the restrictions set by their governments, and many start looking for additional income sources. The print-on-demand model is a good opportunity because they can experiment with launching their own business with no upfront costs.

Printful is helping our customers do their business. We open new fulfillment centers to be physically closer to end customers and provide quicker shipping.

Our IT team is continuously building tools and coming up with solutions to improve customer experience and make business management more pleasant. I believe that the changes we see now will have a long-lasting impact on e-commerce. I believe we’ll see these trends in the coming years: faster delivery times (with decentralized supply chains), richer user experience (with the help of AI), and an increasing amount of mobile app usage.

Janis’ responses were edited for length. For more Spotlight Q&As, visit www.printaction.com/profiles.

The Acuity family of printers is built to win.

The Acuity platform is popular for a reason: you won’t find better image quality, versatility and ease of use anywhere else. Choose from a plethora of machines and configurations to perfectly suit what you need.