ISSN 1481 9287. PrintAction is published 10 times per year by Annex Business Media. Canada Post Publications Mail Agreement No. 40065710. Return undeliverable Canadian addresses to: Circulation Department, 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1. No part of the editorial content in this publication may be reprinted without the publisher’s written permission. © 2020 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada.

11 Jason O. Harris Five ways to protect your workforce 16 8 30 6

Highlights from the NAPIM Fall Technical and the Ink World Printed Electronic/eInk conferences

Kick off the new year with a look at the 10 most-read stories of the past decade

A Quebec printer explains why you should keep your eye on the dye-sublimation market segment

The seven keys of effective customer communications management every print service provider should know

Experts weigh in on cutsheet production inkjet advancements and opportunities

17 proven direct marketing tactics designed to drive consumers in-store

GAMUT

5 News, People, Installs, Calendar

NEW PRODUCTS

24 Detailing new offerings from Bobst, Domino, Epson, Koenig & Bauer Flexotecnica, X-Rite and more

SPOTLIGHT

30 Deanne Sinclair, Owner and Vice President, Cambridge Label

COLUMNS

FROM THE EDITOR

4 Alyssa Dalton

Starting off the new year with a review of the past

CHRONICLE

8 Nick Howard

A stroke of genius, but… ink and water don’t mix!

STAFFING

The start of a new year brings new opportunities. It’s a time for reflection and analysis, goal setting and future planning — a chance to mull over what worked, what didn’t and the various opportunities your team can better capitalize on in the next 12 months. The first step to successfully plan for the future is to reflect on the past. What major projects and tasks did your business take on? How were they successful? What obstacles came up? Start by listing out the different achievements your business, department or team hit in 2019.

that matter, to be successful. You just need framework and a dream.”

Business Insider research finds that 72 percent of small businesses focus on increasing revenue as their top goal, followed by establishing new customer relationships (60 percent), and marketing and advertising (46 percent).

“You can’t connect the dots looking forward; you can only connect them looking backwards. So you have to trust that the dots will somehow connect in your future. You have to trust in something — your gut, destiny, life, karma, whatever. This approach has never let me down, and it has made all the difference in my life,” Steve Jobs, Apple CoFounder, once said.

At the end of every year, I like to look back and review the events of the past 12 months and reflect on how things have changed. Our December enewsletter highlights 25 of the most significant moments of 2019 that have driven Canada’s printing industry. From Friesens’ continued shift into digital production, to the passing of print trailblazer Mary Black, MET Fine Printers’ new Vancouver headquarters, and CJ Graphics’ monumental Benny wins, what a year it was. Visit http://ow.ly/5gw750y2Dvc to see our complete list.

To mark the new decade, we compiled a list of our most-read news stories from 2010 to 2019. Flip to page 14 and join us for a walk down memory lane as we recap these top PrintAction.com articles. It was certainly a period of consolidation and business turbulence, with the majority of the stories being company closures, acquisitions and bankruptcy filings. Here’s an interesting tidbit — two of our top-read articles of all time are also on this list: The 2017 passing of Hemlock Printers’ Dick Kouwenhoven, and the 2019 Canada Post stamp price increase. How do you intend to make your mark this year? Will 2020 be the year your business expands its services and capabilities? Or perhaps you and your team have decided to focus on operational efficiencies as you strive to minimize makeready times, costs and waste. The new year might also serve as the time to refocus your company brand and culture.

Consider this advice from Michael Dell, Founder, Chairman and CEO of Dell: “You don’t need to be a genius or a visionary, or even a college graduate for

Here at PrintAction, we have reinvigorated our portfolio to ensure we meet and exceed your needs. We are entering this new decade with a refreshed attitude and will continue to keep you informed with timely, accurate and insightful content across our print, digital and social media platforms. The thing I’m looking forward to most in 2020? Attending my first drupa tradeshow in June. PrintAction is delighted to bring you pre- and post-show coverage, as well as live updates throughout the enormous trade fair. Messe Düsseldorf is estimating that well over 250,000 visitors and 1,800+ exhibitors from 50 countries are expected to attend drupa 2020. If past drupas are any indication, the innovation on display this summer will undoubtedly reiterate that print remains a powerful tool, even if how it is produced and consumed continues to evolve.

“It has become very apparent in recent years that the appeal of print products is growing as the technology steadily advances,” says Sabine Geldermann, Director of drupa and Global Head of Print Technologies at Messe Düsseldorf. “Print is conquering new dimensions with haptic elements, innovative materials and finishing techniques that engage the senses in previously unknown ways for an entirely new experience.”

According to Smithers research, the worldwide print industry remains in a stage of transition. Total print volumes are forecast broadly and unchanged at 49.5 trillion A4 sheets between 2019 and 2024. During the same period, overall value will increase at 1.3 percent year-on-year in real terms, from US$818 billion in 2019 to US$874 billion in 2024, an indication that value-adding potential still exists.

“Global print is in good shape overall,” according to the 6th drupa Global Trends Report, released by Messe Düsseldorf in spring 2019. “Clearly there are some regions doing better than others. Equally there are stronger and weaker markets. The industry has found its collective confidence again after the twin shocks of the last decade — the global recession and the impact of digital media.”

We can’t wait to see what the new year brings. As always, thank you for your continued support throughout the past year. From all of us at PrintAction, we wish you a happy, safe and prosperous 2020.

ALYSSA DALTON, editor adalton@annexbusinessmedia.com

Editor Alyssa Dalton adalton@annexbusinessmedia.com 416-510-5225

Contributing writers

Zac Bolan, Wayne Collins, Victoria Gaitskell, Martin Habekost, Nick Howard, Neva Murtha, Abhay Sharma

Associate Publisher Stephen Longmire slongmire@annexbusinessmedia.com 416-510-5246

Media Designer

Lisa Zambri

lzambri@annexbusinessmedia.com

Account Coordinator

Alice Chen achen@annexbusinessmedia.com 416-510-5217

Circulation Manager

Beata Olechnowicz bolechnowicz@annexbusinessmedia.com 416-510-5182

Circulation bolechnowicz@annexbusinessmedia.com

Tel: 416-510-5182

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Group Publisher Diane Kleer dkleer@annexbusinessmedia.com

COO

Scott Jamieson sjamieson@annexbusinessmedia.com

Subscription rates

For a 1 year

subscription (10 issues): Canada — $43.00 +Tax Canada 2 year — $70.50 +Tax United States —$98.00

Other foreign —$191.00

All prices in CAD funds

Mailing address

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

printaction.com

Tel: 416-442-5600

Fax: 416-442-2230

Annex Privacy Officer Privacy@annexbusinessmedia.com 800-668-2384

PrintAction is printed by Annex Printing on Creator Gloss 80lb text and Creator Silk 70lb text available from Spicers Canada.

ISSN 1481 9287 Mail Agreement No. 40065710

Pantone has announced Pantone 19-4052, Classic Blue, as its Color of the Year for 2020 for its tranquil and calming quality.

Colour authority Pantone has announced Pantone 19-4052 Classic Blue as the Pantone Color of the Year for 2020 for its tranquil and calming quality. “Suggestive of the sky at dusk, the reassuring qualities of the thought-provoking Pantone 19-4052 Classic Blue highlight our desire for a dependable and stable foundation from which to build as we cross the threshold into a new era,” Pantone explains. “We are living in a time that requires trust and faith. It is this kind of constancy and confidence that is expressed by Pantone 19-4052 Classic Blue, a solid and dependable blue hue we can always rely on,” says Leatrice Eiseman, Executive Director of the Pantone Color Institute. “Imbued with a deep resonance, Pantone 19-4052 Classic Blue provides an anchoring foundation. A boundless blue evocative of the vast and infinite evening sky, Pantone 19-4052 Classic Blue encourages us to look beyond the obvious to expand our thinking; challenging us to think more deeply, increase our perspective and open the flow of communication.”

Brace Holdings, owner of SaltWire Network, has sold Nova Scotia’s Bounty Print Limited to New Brunswick-based Taylor Printing Group Inc. Terms of the transaction have not been announced.

“Purchasing Bounty Print enables Taylor Printing, already New Brunswick’s premier print service provider, to expand its operations into the largest commercial market in Atlantic Canada,” says Scott Williams, CEO of Taylor Printing Group. Taylor Printing has acquired all of Bounty Print’s business in Nova Scotia as well as

company specializing in the production of retail environments, point-of-purchase displays and large-format printing. The transaction, which follows the acquisition of Holland & Crosby Limited in October 2019, is aligned with TC Transcontinental’s strategy to continue growing its in-store marketing product printing vertical. Located in Markham, Ont., Artisan Complete employs 187 people and is one of North America’s most awarded in-store marketing companies, providing design, turnkey production and strategic deployment services to its clients. Edwin Lemieux, President of Artisan Complete, will continue in his role with the TC Transcontinental Printing team.

brought businesses, industry experts and students together for a day of learning and networking.

printer and social enterprise that prepares youth experiencing homelessness for employment in the print and graphics sector; the DFL-500 Dry Coat/Foil/Laminator; HP large-format printers; and Konica Minolta’s TrueBlue program for pre-owned models.

all 32 staff members throughout the province. Bounty Print’s book of business includes various printing options such as offset, digital, wide-format printing, finishing and direct mail services. SaltWire Network is described as Atlantic Canada’s largest publisher of daily newspapers, websites and mobile media apps, including The Chronicle Herald, The Guardian and Saltwire.com.

More than 1,600 guests attended CJ Graphics’ 33rd annual season’s greetings open house party and fundraiser on December 6, 2019, at its 240,000-square-foot facility in Mississauga, Ont., helping to raise over $28,000 for CJ’s Skatepark and The Mississauga Food Bank through live ($12,725) and silent ($13,209) auctions, as well as food and monetary donations. This year, the annual event raised roughly 1,430 pounds of food and $780 in funds, which was matched by CJ Graphics to total $1,560. Meanwhile, $1,143 was raised for the Skatepark Foundation. Dubbed the world’s largest not-for-profit air-conditioned indoor skatepark, CJ’s Skatepark serves children and youth of all abilities.

TC Transcontinental in January announced the acquisition of Artisan Complete Limited, a

Innovative Chemical Products Group (ICP Group) has acquired Hi-Tech Coatings, a developer and manufacturer of high-performance coatings for the packaging and commercial printing industries, from Heidelberger Druckmaschinen AG (Heidelberg). Hi-Tech Coatings develops and produces more than 1,000 environmentally compatible products and formulations, primarily water-based and UV-based coatings. Hi-Tech Coatings, whose offerings will become part of ICP Group’s Industrial Services Group (ISG), has provided professionals with coatings for nearly 30 years. The acquisition provides ICP ISG with two significant opportunities — it expands its product offerings within the water-based and ultraviolet-curable coatings, and it diversifies and expands its international customer base in Europe, the Middle East and Asia-Pacific regions. Hi-Tech Coatings will also expand ICP Group’s manufacturing footprint by adding new production facilities in the United Kingdom, the Netherlands and an additional facility in Michigan, U.S. Finally, it will expand ICP ISG’s exposure to global packaging end markets.

PrintAction was there in November at Konica Minolta Business Solutions (Canada) Ltd.’s ReThink Print Innovation Showcase. In addition to live demos, the event consisted of educational presentations on various topics, including: ReadyPrint/ReadyPrint Pro, full-function prepress solutions that integrate with RSA’s WebCRD and QDirect solutions; Eva’s Phoenix Print Shop, a Toronto-based commercial

Canadian short-run offset packaging specialist SoOPAK has bolstered its internal systems by earning the International Featured Standard (IFS) certification and Hazard Analysis Critical Control

SoOPAK says the certifications will benefit its pharmaceutical and food packaging clients.

Point (HACCP) certification, making its facility compliant with HACCP food safety regulations. With operations in Mississauga and Scarborough, Ont., SoOPAK is a manufacturer of short-run packaging, with jobs starting at 500 pieces. The two new certifications join SoOPAK’s existing ISO 9001:2015 certification, an advanced upgraded standard highlighting the firm’s commitment to quality management and customer satisfaction. International Featured Standard (IFS) Food certification is a GFSI-recognized standard for certifying the safety and quality of food products and production processes. HACCP certification recognizes that a food business has developed, documented and implemented systems and procedures in accordance with HACCP. It is granted by an external certification authority that has the necessary knowledge and skills to undertake an assessment of the HACCP system or HACCP plan.

The Digital Imaging Association (DIA) announced its new Officers and Directors for 2020 during its annual holiday lunch and AGM on December 4, 2019, which featured a keynote from Jeff Dowd on mega trends and their effect on the print industry. The officers and executive board for the upcoming year include: Past President, Larry Stewart, Emulate Global; President, Stephen Longmire, PrintAction; First Vice President, Paul Tarvydas,Tsus4; Second Vice President, Maria Aggelonits, Spicers Canada; Secretary/Treasurer, Mark Norlock, Canon Canada; and Directors: Jim Dickson, Xerox Canada; Ray Fagan, Heidelberg Canada; Danny Goulart, Marquis/Webcom; Jason Hamilton, Agfa Inc.; Paul McCarthy, HP Canada; Mike Millard, Ellis Packaging; Ed Rooney; Dino Sinnathurai; Randall Stevenson; and Bob Weller

Isabelle Marcoux, Chair of the Board of Directors of TC Transcontinental, has been appointed Member of the Order of Canada, making her the second generation of the family to be granted the prestigious Canadian honour. The Order of Canada is described as one of the country’s highest civilian honours. Created in 1967, it recognizes outstanding achievement, dedication to the community and service to the nation. Her father, Rémi Marcoux, Founder of TC Transcontinental and a Director on its board, was invested into the Order of Canada himself in 2007. Her career has been marked by many professional and philanthropic achievements over the years, particularly since she took over as TC Transcontinental Board Chair in 2012, including: Strategic transformation of the company into flexible packaging; advancement of women into leadership roles in the business community; and Co-Chair of the 2016 campaign of Centraide of Greater Montréal and, for the last two years, Chair of the Major Donors’ Circle.

Komcan Inc., Canada’s exclusive Komori dealer, has announced a new addition to the service team. George Webber joins the team as a Press Demonstrator – Service Technician. He has spent the last 12 years as a press operator running 40-inch presses in Toronto, Ont.

Imprimerie Héon & Nadeau of Victoriaville, Que., has purchased its second HP Indigo press. The addition of the HP Indigo 7R will help the Quebec printer gain increased “capacity and speed, and the best digital offset quality in the market,” Charles Héon, President, says.

Calgary, Alta.-based specialty printer Anvy Digital says it is experiencing increased revenue with the Inca SpyderX.

“The SpyderX allows more capacity,” says Bob Lush, Vice President of Sales, Anvy Digital. The press is distributed in North America by Fujifilm.

Koenig & Bauer has promoted Preston Neetzel to Director of Flexo Sales. In his new role, Neetzel will expand on his current direct sales responsibilities by providing his expertise to Koenig & Bauer’s CI flexo team in Canada and the United States. With more than 30 years in the flexible packaging industry, the company describes Neetzel as a “key component in the organization.”

Hybrid Software has promoted Mike Agness to Executive Vice President for the Americas, responsible for all sales and operations in North and South America. He will operationally replace Mike Rottenborn, who was recently named CEO of Global Graphics Software, based in Cambridge, U.K. In addition, Derek Hurst has been promoted to Customer Service Manager for Hybrid’s customers in Canada and the U.S.

Kelly Signs, a sign and display company based in Ottawa, Ont., has acquired an Agfa Jeti Tauro H2500 LED large-format UV inkjet press.

“This new investment will allow us to develop new business throughout Eastern Canada,” says Howard Greenberg, VP of Kelly Signs.

But… ink and water don’t mix!

By Nick Howard

Another decade has arrived, and with it, new optimism for a fledgling print industry. Digital inkjet continues to elbow its way into pressrooms around the world, redefining our industry and bringing new hope.

But there was a time when printers focused only on finding ways to produce more for less. Today it’s the opposite — produce less for more money. During the early periods of offset (1906 to 1960), printing press functions hardly changed. Makereadies and wash-ups were long and physically demanding, especially as VLF grew exponentially in the mid-1950s. Three- and sometimes four-man crews manually washed up and pulled dampeners out each night, only to reinstall them the next day.

The offset riddle is still a mystery to most pressmen. The idea that ink and water don’t mix was complex. Water dampening was always segregated and had one job to do — dampen the plate. Ever since the first offset press, dampening was carried out using an absorbent cloth-covered roller. It could hold and retain enough solution and was fed by a ductor roller connected to a roller sitting in a water tray. At the end of each day, these three-rolls-per-unit had to be lifted out of the press, washed (usually in a solution of Pine-Sol), and reinstalled. Not much fun, especially if it was a 77inch Harris or Miehle.

Woven coverings would have to be changed periodically, and that too was a chore. Still, the biggest flaw was the inability to control the amount of water on the plate precisely. Skill was a prerequisite for the pressman as they balanced the dampener, so a minimal amount of water would not affect the print quality and emulsify the ink. The constant variable in the offset process – going even further back to the very first attempts in 1875 – is the interplay between water and ink. The industry seemed so preoccupied with keeping up with production that few thought of finding a better way — that is, until a young man from Mobile, Ala., did just that.

In 1942, a 20-year-old of Swedish lineage had just signed up to join the U.S. Army. Having previously worked at the U.S. Engineer’s office in Reproduction, Harold Phillip Dahlgren (known as Hal to his friends) first set his eyes upon an offset printing press. While working on a Harris press, Hal searched for a better way. Armed with only three years of high school, he certainly didn’t possess the engineering abilities one would assume to be essential, but that didn’t hold him back. After serving out his military service in the print shop at Wright-Patterson Air Force Base in Dayton, Ohio, Hal learned enough about offset to get a job with the Harris Intertype Company as a press erector.

“I didn’t

know what the answer was,

but I

did know what it was not.”

By the early 1950s, Hal went freelance so he could put more thought into the problem of eliminating molletons. Science was required – skills he didn’t have – so he set about to simplify the problem. One night in 1954, while brushing his hair, he saw droplets of water on the mirror and in a moment he thought he had seized a solution: A brush roller! Hal moved to Dallas, Texas, built one to fit a web offset press and it worked. A large press manufacturer came calling and agreed to provide annual royalties. Hal was in heaven and

quickly took off for a Mexican vacation with thoughts of grandeur. By the time he returned, he realized the brush dampener wasn’t the answer.

Hal described the problem this way: “I didn’t know what the answer was, but I did know what it was not. So I kept thinking.” One day when driving from Dallas to Fort Worth, he recalled something he learned from an old pressman years before. The man ran his finger over an ink form roller to check the ink-water balance.

“But… ink and water don’t mix! That can’t be true!” Hal turned the car around and headed back to Dallas, and by the time he got home, he had figured out what he needed to do.The second attempt became known as the Sponge machine, because a sponge roller sat in a tray and supplied water to a newly developed hydrophilic chrome roller and then to the inker form. Although the idea worked and Hal sold quite a few, a sponge was not the answer. However, the concept directs Hal into a new territory that would eventually lead to a fantastic breakthrough — altering the speed of the chrome roller.

The Dahlgren Manufacturing Company was off and running, or was it? Not so fast. There was still a variable and it was related to press speeds. The faster the press ran, the fewer problems. But slower (and

at that time, any high-quality work was run at reduced speeds), and water streaks showed up on the plate. How could that be resolved?

This time, the answer came to Hal in a martini glass. “One evening, while racking my brain about those water streaks, I fixed a martini and sat down, and [was] rolling the glass in my hand. I was trying to think out a solution when I noticed the behaviour of the moisture right at the level of the martini. It was always working. Little things were running up and down. It occurred to me that alcohol mixes with water, and maybe that’s a good thing. Alcohol evaporates [and] leaves no residue.” Isopropyl alcohol (IPA) would solve a host of problems and also reduce the surface tension and amount of water needed. The old pressman’s catchphrase – “alcohol makes water wetter” – would live on until IPA was outlawed in the early 2000s. The addition of alcohol would also mark the start of refrigeration and recirculators.

“Thank God, the waitress did not take off the empty cans.”

Dahlgren had a workable dampener, one that was so simple to operate (only three rollers) and it provided instant ink-water balance and had virtually no mainten-

Top left: Fitted to each printing unit, these Dahlgren control stations allow the operator to engage the dampener and control the speed (amount of solution to the plate).

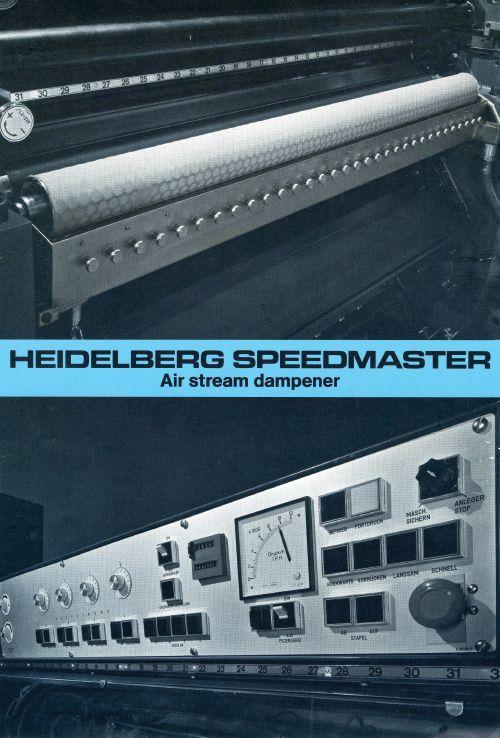

Below: Images of the Heidelberg Speedmaster Air Stream Dampener from approximately 1977.

ance. Foremost, there were no molleton covers to change and ink emulsification became a problem of the past. But a final hurdle soon appeared. It’s important to note that by 1960, the Dahlgren Company had virtually no assets, no manufacturing and only a few loyal employees. The debt was like a dark cloud hanging over Hal’s head. Only an offset printer would have seen the excitement building. For everyone else, it’s as if Dahlgren was discussing the merits of wall thicknesses on cast iron pipe — dull, to say the least.

The final hurdle was only unmasked after Dahlgren won a few orders to go on 60- and 77-inch presses. These large formats magnified the problem of rollers being too wet in the middle and too dry at the ends. Hal recalls the answer: “One afternoon in 1961 in a Mexican restaurant, I was drinking a can of beer, trying to figure out what would solve the problem. I finished the can and ordered another. I poured it into a glass. Thank God, the waitress did not take off the empty cans. I picked them up and rolled them together, twisting them a bit and then, bingo! There it was. The skew device — a metering roller adjustment that would let me positively control the moisture all across the plate.”

With a perfected dampener, it would seem that every printer would be knocking on Hal’s door, but few printers grasped the significance of the invention. The ones who did held it in secret, not wanting competitors to get the same edge. By 1962, the Dahlgren Company was at nearly US$250,000 (US$2 million today) in the red. Hal had to demand 50-percent cash upfront on new orders, and if a printer checked Dahlgren’s credit rating,

bugs in them. “Why don’t you take them off?” “They still work better than the conventional system,” they said. The investor made Hal a $1-million offer, and he thought about it before declining — he would go it alone. In January 1963, Dahlgren changed its sales pitch. Now Dahlgren offered to install its dampeners for nothing down and if the printer liked them excellent, if not, Dahlgren would take them off and reinstall the old molletons. “Once we put them in, the Dampeners sold themselves,” Hal said.

Soon after, Hal – who held patents on his designs, signed agreements for licencing with Harris and Miehle. In Miehle’s case, a licence-royalty agreement that allowed Miehle to adopt the technology into its Miehlematic dampener. Because Miehle also represented Roland (now manroland), Roland entered a similar royalty agreement when it designed the Rolandmatic dampener. Some companies refused. Heidelberg, steadfastly defiant, warned off buyers of new presses, citing a potential loss of warranties and the negative impact of a loss of the first ink form, an issue Dahlgren would fight for decades. When it became apparent to the Germans that Dahlgren’s continuous flow dampeners were far superior, Heidelberg tried a workaround designing the ill-fated Air Stream Dampener in the late 1970s. When that failed, Heidelberg set about to develop Alcolor, first in 1979 (which also failed), then finally in 1982 the highly successful Alcolor II. Heidelberg would design a crowned rubber metering roller to counter the Dahlgren

Hal didn’t have all these technological tools at hand. What he did have was an idea and a dogged determination to succeed.

it usually backed off assuming Dahlgren would be out of business in the next 72 hours. Plowing on a seemingly even steeper incline, Hal sought out an investor. This guy, who had made his money in trucking, hired the Arthur D. Little firm to survey the litho industry with an emphasis on plants using early Dahlgren models. The results were encouraging. Users of early dampeners said they had

skew feature. Every press – and I mean every press – today uses Dahlgren’s technology.

Dahlgrens appeared everywhere in North America, but was very slow to catch on in Europe. Often the Swedish name Dahlgren was mashed to read Dahlgreen . Japan embraced the Dahlgren concept, and Komori soon had its version – Komorimatic on Lithrones and Sprints

February 26-27, 2020

Packaging Innovations Birmingham, United Kingdom

March 24-27, 2020

FESPA Global Print Expo Madrid, Spain

June 16-26, 2020

drupa

Düsseldorf, Germany

September 15-17, 2020

Brand Print Chicago, Ill.

September 15-17, 2020

Labelexpo Americas Chicago, Ill.

September 18-19, 2020

Sign Expo Canada Mississauga, Ont.

October 21–23, 2020

Printing United Atlanta, Ga.

November 12, 2020

Canadian Printing Awards

Palais Royale, Toronto, Ont.

– but again with a necessary workaround reverse-nip to shield Komori from patent violations.

Having to give up the first ink form roller continued as an irritant for Hal. In 1977, his brother Harvey left the company to begin manufacturing his own version of the dampener, this time leaving the first ink form alone. Epic Products continues to this day. Epic also offered another revolutionary design, thought up by a California printer, then sold to Baldwin: The Delta [effect] dampener. Now commonplace, the altering of the form roller speed (7 percent slower than the ink and plate) reduced hickies and ghosting.

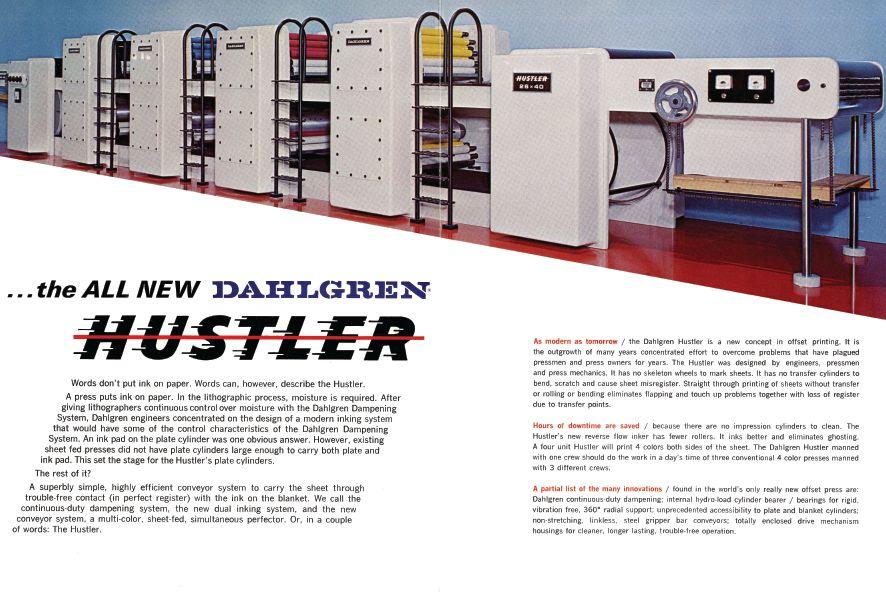

Ill-fated gambles, along with an ever-shrinking customer base, would prove to be insurmountable for Hal. First, an anti-ghosting inker retrofit, then owning an ink company, and a new radically designed Hustler offset press couldn’t return the magic that made Hal a household name. The concept Hustler did have some revolutionary features. It was a tandem perfector and printed four-over-four without turning the sheet. This design would be emulated by Akiyama then Komori 20 years into the future. However, Dahlgren tried to use only a chain with grippers to take the sheet from feeder to delivery, and that failed utterly. If you’ve ever seen a Bobst Autovariable, it worked the same way. Besides, Harvey’s Epic Products and most press manufacturers’ versions were nibbling away at a shrinking retrofit

dampener business.

Eventually, Hal left the business, and ownership changed hands several times before disappearing from view. Montrealer Paul Belair purchased the business in the 1990s, rebranding under the name MMT. MMT now does business in Georgia under a new umbrella name, MMT Sales & Design, but the Dahlgren dampener ran its course.

For anyone running a press in the 1970s and 1980s, you already know what a revelation Hal created. For those young enough to start running presses in the last 20 years, you probably have no idea. Rapid inventions such as closed-loop colour control, automatic plate loading, in-press density and presetting features all came about by a natural inclination to use exciting new technologies, devices or software. But what Dahlgren did was more profound than that. Hal didn’t have all these technological tools at hand; he didn’t even have an education. What he did have was an idea and a dogged determination to succeed.

Improvements to the offset process mostly came about as technology improved — think electronics. Hal had to borrow a press to continuously refine his invention. He didn’t have a lab full of equipment and an army of engineers at his fingertips. There was nothing ‘natural’ about the Dahlgren theory as just about every rule of common sense was broken. As long as there is an offset press, his genius is at work. Makereadies and paper waste plunged with Dahlgrens. In 1985,

Hal died at the age of 63, but what he left our industry lives and prospers to this day, and for however long, the offset press remains an integral part of print. I believe the Dahlgren dampener was the most profound improvement ever to be applied to offset.

HOWARD, a partner in Howard Graphic Equipment and Howard Iron Works, is a printing historian, consultant and Certified Appraiser of capital equipment. nick@howardgraphicequipment.com

Five keys to protect your company’s most valuable asset

By Jason O. Harris

Your company’s most precious cargo is its people.

Each day that you walk into your office, establishment and organization, you are responsible for cultivating the culture. You are responsible for fostering a workplace culture that is based on commitment and trust. As you nurture and grow the culture of your workplace, it is imperative you realize that your most valuable resource – your most precious cargo, as they say in the aviation business – are your people.

As you look to understand what you can do each and every day to impact your company culture, you need to look at the ways you can best take care of your teams. The foundation of taking care of your people is to create and cultivate a culture of trust. It is only when you cultivate cultures of trust and commitment that you can truly begin to support your company’s most valuable resource: The people within it.

A simple way you can create the professional environment you want is to implement a model, the C.A.R.G.O. model, designed to create and nurture a workplace ecosystem that thrives on commitment and trust.

As you look to take care of your people, it is essential that opportunities are provided that allow for creativity. This creativity is useful for many things, primarily in addressing the many challenges that present themselves in the workplace. When you trust and empower your people to harness their creativity to address and solve problems, it does many things across the levels of your organization. Freedom to be creative instills a sense of intrinsic trust and helps to reinforce an employee’s innate abilities and talents. Creativity to address challenges strengthens the case as to why you hired them to work in your organization in the first place.

A: Access to tools and resources

When the right tools and resources are

The foundation of taking care of your people is to create and cultivate a culture of trust.

provided, people know they have all that they need to succeed. Too often there is an expectation of the people in an organization that cannot be fulfilled due to a lack of resources or support. Effective leaders must be prepared to properly equip their teams with the right people in addition to the right tools and resources to set them up for success. Access to the appropriate tools and assets is imperative to creating and building a company culture that is rooted in trust.

It is essential that team members are empowered to own their unique responsibilities in an organization. When team members truly own their piece of the daily duties, tasks and projects, it reinforces the reality that their work really matters. When your team is aware of their value to the entire operation and that others are counting on them, like a combat aircrew, they will step up and perform to their best abilities. Empowerment of staff, ensuring that the training and processes clearly define and delineate their responsibilities, will lead to an empowered organization. This empowered organization will be full of team members who know what they are responsible for

and are ready to tackle the tasks at hand.

Goals and objectives of your team(s) and organization have to be plain, clear and articulated in a way that the team members can understand and appreciate. The best leaders must share the goals and objectives with the team. Your team needs to know that its leaders are fully invested. In turn, it’s necessary for members of your team to share their individual goals and objectives with each other and the leadership. This ensures that everyone holds each other accountable. Beyond holding one another accountable, knowing the goals and objectives of each other allows you to know that everyone is committed in some shape, form and fashion to the greater good of the organization and each other.

As a leader, you must provide the opportunities for your people to succeed. These successes exist as large and small opportunities. When provided with incremental chances to succeed and win, team members will stay engaged and continue to be committed to the organization and the team. Consider opportunities for team members to succeed in the simplest ways, which will lead to team wins, and consequently lead to organizational wins. Everyone loves to win. Everyone loves to be on a winning team!

The most precious resource in your organization, the most precious cargo in your aircraft, is your people. As you conduct business each and every day, are you and the leadership team equipping your people to sustain themselves and your organization through the inevitable turbulence they will encounter en route to accomplish their mission? When you provide your people with the right C.A.R.G.O., you will create, promote and cultivate a workplace culture of trust that is bound for success!

JASON O. HARRIS is a leadership and trust speaker, consultant and certified character coach. As a decorated combat veteran, Harris brings unique perspectives gained from his battlefield experience to your organization. His No Fail Trust™ methodology was crafted from his own harrowing, life-altering experiences, and conveys the importance of cross-generational communication and mutual trust. He enjoys working with organizations and leaders that are no longer willing to settle for cultures of compliance and are ready to build and cultivate cultures of commitment. For more information, visit www.jasonOharris.com.

By Martin Habekost

From October 15 to 18, 2019, three students from Ryerson University’s School of Graphic Communications Management (GCM) and I attended the National Association of Printing Ink Manufacturers’ Fall Technical Conference for the first time. NAPIM was founded in 1916 and its mission is to “promote the general development and improvement of member companies by fostering greater understanding and knowledge of the printing ink industry as well as representing the industry as a whole on a national basis.”

It’s an interesting story how this connection came together. During the TAGA Annual Technical Conference, Juanita Parris from Sun Chemical, who is also the President of the National Printing Ink Research Institute (NPIRI), asked if I could give her one of my business cards because NAPIM and NPIRI would like to get more involved with universities and students. Later, I was contacted by George Fuchs from NAPIM and arrangements

were made so that Ryerson GCM students and I could attend the conference. The NAPIM conference was held outside of Chicago in Oak Brook, Ill.

The keynote presentation for the NAPIM conference was on how paper stimulates all our senses when we read. Delivered by David Sullivan from Sappi Paper, the presentation noted that we have increased information retention when we read something that is printed. Not only do we retain information better, it also has a calming influence on us. When we read something on a screen, we switch to a skimming mode, where we just try to look for the important parts. Sullivan’s main point was that reading information on paper helps us comprehend and retain information better.

The next presentation was about sustainability from a printer’s perspective. Laura Rowell from Sonoco predicted that by 2025, we will have 100-percent reusable, recyclable or compostable plastic packaging. Many major brands are already on board and are working towards this goal. She also stated that printing inks should not contaminate the recycling process.

Lee Marcoe from Lake County Press gave a very informative talk about “hot topics” their clients are asking for. Until 2009, their clients were demanding sustainable substrates and insisted that the energy used to print their jobs came from wind energy. Prior to 2010, customers demanded soy-based inks, vegetable inks, low VOC or VOC-free inks. All these requests are not top of mind anymore, but there has been an uptake in litho printing and direct mailings, Marcoe said. Direct mailings are now more targeted than before, resulting in more customized campaigns.

After these presentations, it was my turn to introduce Ryerson University and the Graphic Communications Management program to the audience. Not many attendees were familiar with us. The audience was also introduced to the two Material Science courses that are part of the curriculum. At the end of my presentation, I shared the project that students Layla Abdi, Catherine Di Luca and Pauline Reyes – who attended the conference – did in their Advanced Material Science course. The students prepared posters about their projects that were displayed during the tabletop presentations at the end of the first day.

Above: Ryerson GCM students (left to right) Layla Abdi, Catherine Di Luca and Pauline Reyes at the NAPIM conference.

John Jilek from Ink Solutions and Bill Giczkowski from INX International gave a presentation on the state of the industry. They noted that overall, the ink industry has an optimistic outlook for the future. Their main concerns are raw material costs and the availability of raw materials. As well, healthcare costs and transportation costs are also issues on their radar. Ink companies are committed to consistent product quality, competitive prices and tech support. The number of ink companies went down from 397 in 2014 to 192 in 2016. Also the number of print companies is down, but there is a slight upwards trend in ink sales.

The next day’s presentations were more on the technical side. Darren Gapen from WestRock introduced the company to the attendees. Did you know that WestRock has more than 320 manufacturing sites worldwide? Gapen demonstrated the many raw materials the company uses

everyday and the other products, mainly solid bleached sulfate (SBS), that it manufactures. The numbers are mind-boggling. One surprising fact is that WestRock produces 18,000 t of air filter paper for furnaces every year.

Up next was a presentation by Sanjay Monie from Orion Engineered Carbons, formerly known as Degussa. His presentation gave an overview on how different types of carbon black are made and what their applications are. Carbon black can be surface-treated to make the material more polar, so it is easier to incorporate into different materials. Carbon black is also used for non-impact printing applications and Orion also manufactures a food packaging-compliant carbon black. It was interesting to learn how certain types of carbon black are surface-treated so they can be incorporated into waterborne inkjet inks.

Rachel Schwen from the Sherwin-Williams Performance Coatings Group spoke about colour measurement in the industry. First she spoke about colour, how humans perceive colour, how colour is measured, and how modern light sources, like LEDs, influence the way colour is seen and measured, since LED illuminants find their way into measurement devices. Her presentation also highlighted small and relatively inexpensive colour measurement devices, such as ColorMuse, Nix and Capsure. She said these devices are great to get a general idea about a colour, but are not a replacement for colour measurement devices from manufacturers like X-Rite, Techkon or Konica Minolta.

Jennifer Heathcote from Eminence UV gave a very detailed presentation about UV-LED curing. UV-LEDs were not able to produce UV-C light until recently, but these LEDs are not as powerful yet, as they need to be. She predicted that 275 nm UV-C LED curing will coming to the market in the near future. UV-LEDs are usually placed 15 mm above the web surface and sometimes at a distance of 25 mm to 100 mm. This is a lot closer than conventional mercury vapour lamps. If UVLED is used for curing UV ink on 3D printed parts, the distance to the surface is

John Copeland, NAPIM Executive Director (bottom left), and Jim Leitch, NAPIM President and President of Braden Sutphin Ink (bottom right), take the podium at the NAPIM awards dinner. According to MarketsandMarkets research, the printed electronics market is projected to be worth US$19.8 billion by 2024.

When we read something on a screen, we switch to a skimming mode, where we just try to look for the important parts.

usually 50 mm to 100 mm. An upcoming trend is also the inline measurement of UV intensity of the curing systems. Different systems are available that allow the inline control of the UV light intensity and energy density.

The remainder of the second day of the conference covered supply chain issues, smart manufacturing (also known as Industry 4.0) and inks for food contact. Inks for food contact are a very complex matter and as such, this presentation was given by a lawyer from a law firm that specializes in this area.

The NAPIM conference concluded with a reception and an awards dinner.

The following day and a half were dedicated to the Ink World Printed Electronic/eInk Conference. The keynote was given by Erika Rebrosova from Sun Chemical. She gave a very detailed and informative overview of printed electronics and eInks. There is a trend to use flexible circuit boards with screen printed silver-based inks. There is also the possibility of using materials called silver flex and copper flex to print electronic circuits. At the moment, it is not possible to make high power, high frequency, high density electronic circuits with silver-based inks. As I mentioned before, screen printing is the print process of choice for printed electronics, although some are done with inkjet or flexo technology. Conductive inks are made of conductive particles, resins and solvents. The conductive particles are silver, silver chloride, carbon black/graphite, conductive polymers, copper, silver-coated copper, graphene, carbon nano tubes and nickel. What is not possible at the moment is a UV-curable silver conductive ink. This is considered the Holy Grail of the printed electronics ink market.

Then, Robert Waldrop of DuPont Advanced Materials walked us through DuPont’s printed electronics history. It started in 1961 with screen-printed resistors and moved onto photovoltaic metallization in 1984, printed blood glucose sensors in 1985, printed electroluminescence in 1998 and printed heating elements in 1998. DuPont has also developed polyimide inks that can withstand temperatures of up to 320ºC, but cure at a low temperature of 60ºC to 100ºC. DuPont also has solutions for smart clothing.The challenge for smart clothing with electronic circuits is that the circuits need to be able to withstand stretching and washer and dryer cycles without breaking, which would render them unusable.

Casey Grenier from Tekscan presented the printed force sensor technology. The force sensors are also screen-printed.

They are force-sensitive resistors that can be used in robotic surgical systems, wearable pump manufacturers, an impact-sensitive organ transplant container or force-sensitive theft detection.

Chris Booher from ChemCubed talked about jettable solutions for printed electronics. He spoke about 3D jettable solutions for rigid and flexible substrates using nano-particle free silver conductive ink. The ink needs to get sintered at 80ºC, meaning that only after the sintering process will the printed circuit function. The company also has a so-called NanoJet aerosol spray printing technology which allows them to print resistors and capacitors with low production variances, almost like conventional manufacturing of these electronic components.They are currently working on flexible, extensible inks that allow for a stretch of 130 percent.

I mentioned the sintering process before. It’s an important step to have printed electronic circuits conduct electricity. The sintering can be done either through temperature, basically “baking” the conductive particles together or through photonic sintering. This process delivers a very intense light pulse onto the printed circuit, fusing the particles together. Lou Panico from Xenon Corporation presented the technology his company can manufacture for the photonic sintering process. Panico gave the comparison of delivering 100 Joules of light energy. You can do this by shining a 10W light for 10 seconds or 1 megawatt for 1 µs. The latter is used in photonic sintering. Photonic sintering reduces the curing (sintering) time from up to 30 minutes to less than 10 seconds, an important timegain for the mass production of printed electronics.

A few presentations focused on wearable printed electronics. There are a few takeaways from these sessions. Fashion and electronics engineers are starting to collaborate on designing wearable printed electronics. Wearable electronics will be part of the Internet of Things (IoT). They can also be used to monitor the health of the person wearing the clothing with circuits and sensors in the fabric. Besides manufacturing fabrics and printing circuits on them, thin lightweight and renewable power sources also need to be made. As of now, wearables do not have the consumer market pull yet.

Overall both conferences were very interesting and opened my mind to new topics that relate to printing. It was worth attending these conferences and I thank NAPIM and Ink World Magazine for making it possible for the students and I to attend.

We’re celebrating the start of 2020 with a wayback throwback. Take a stroll down memory lane and revisit the 10 most-read PrintAction stories from 2010 to 2019.

Remembering Dick Kouwenhoven

Dick Kouwenhoven, an icon of Canadian printing for more than four decades, passed away on April 25. He was the Founder, Chairman and CEO of Hemlock Printers, based in Burnaby, B.C., a highly revered commercial printing operation known for its industry leadership.

Canada Post stamp rates increase

Canada Post in early January announced it will increase its postage rates for 2019. The postage rate for domestic lettermail items weighing 30 grams or less when purchased in a booklet, coil or pane went up to $0.90, while the price of a single domestic stamp increased to $1.05.

Datamark shuts its doors

Datamark Systems headquartered in Laval, Que., shut its doors in March, leaving some 400 people out of work across all of its facilities. In a letter to employees obtained by Le LaSalle Messenger, Datamark states the closure is a result of “a combination of erosion markets and reduced margins due to the price of the commodity for many of our products and service.”

Peel Graphics enters bankruptcy

Peel Graphics filed for bankruptcy in August with total liabilities of approximately $6.6 million. Headquartered in Brampton, Ont., Peel Graphics’ roots trace back to 1933 and its production of a Brampton community newspaper. Advertek of Vaughan, Ont., consequently acquired the assets of Peel Graphics.

BMW turns car into printing press

To promote its new M6 sports car, BMW in November turned a M6 car into a printing press and used it to create its own promotion materials. In a collaboration between Toyo Ink, Sappi Paper and Chicago-based premedia house Classic Color, BMW used the M6 to lay down a tire track on sheets of paper positioned on a race track. From special tanks in the trunk of the car, ink was pumped onto the tread before being transferred onto the paper.

4over cuts ribbon on new Mississauga plant 4over Inc. in April officially opened its new 50,000-square-foot plant in Mississauga, Ont. The location began producing work in December 2011 under the leadership of printing veteran Tom Hogan.

Cober acquires Kempenfelt

Cober Evolving Solutions (Cober) announced in February its acquisition of Kempenfelt Group and Kempenfelt Wideformat. “Over the past 40 years, the Kempenfelt team has built a great company and a great reputation, and we are very proud to have them join the Cober team,” said Peter Cober, President.

Joseph Budarkiewicz Michaels, known across Canada’s printing community for his expertise as a press technician for manroland Canada, passed away on January 8 in a tragic vehicle accident at the age of 54. He was one of the first employees who helped establish manroland Canada and had spent the past 25 years with the organization as one of its premier press mechanics.

Acuity closes its doors

Richmond Hill, Ontario’s Acuity Solutions Group closed its doors in June, placing upwards of 80 employees out of work. The company was one of few 10-micron stochastic capable printers in Canada and offered end-to-end solutions, from digital asset management to point-of-purchase graphics.

Allprint Ainsworth enters bankruptcy protection

Allprint Ainsworth Associates, a commercial printer in Kitchener, Ont., filed for bankruptcy protection in February as then-company owner, Klaus Ertle, simultaneously announced his retirement.

Considering an expansion into dye-sublimation? PNH Solutions explains why printing companies should keep their eye on this growing market segment

By Katherine Hudon

Market intelligence and advisory firm Mordor Intelligence predicts the global dye-sublimation printing market will grow at a CAGR of 16.8 percent from 2020 to 2025. While the apparel and home textile segments will contribute to that growth, the increasing demand for soft signage for advertising purposes is expected to drive this market. With new and improved inks and print media, dye-sublimation printing – a digital printing process that uses heat to transfer dye to materials – is becoming the printing method of choice for brand owners.

flexibility

Although screen printing offers similar print quality, it usually requires large minimum order quantities and tooling costs. With dye-sublimation, print service

providers have greater flexibility to digitally produce one-offs at a fraction of the cost. As a result, brands can get on-demand, high-quality signage for time-sensitive promotions without having to commit to larger orders. Examples of soft signage using dye-sublimation include:

• Backlit banners, Silicone Edge Graphic (SEG) frames and lightboxes;

• Barricade and fencing covers;

• Construction hoarding;

• Fabric banners;

• Sampling counters and table covers;

• Tents and domes;

• Tension fabric displays;

• Umbrellas; and

• Window displays.

Dye-sublimated fabric can also be used to make custom products, such as pop-

products for an extended period of time. This is an especially attractive feature for brand managers looking for durable marketing products to refresh retail environments or to use as part of a long-term campaign that has multiple setups and teardowns.

Left: PNH Solutions printed dye-sublimated fabric banners on a Durst Rhotex for the MLB Play Ball Park, an exhibit dedicated to the league’s history, for the 2019 All-Star Game in Cleveland, Ohio.

Top right: PNH Solutions designed, built and installed a 10 x 20-foot tradeshow booth for Tin Shack using backlit graphics (standing SEG fabric lightboxes) printed on a Durst Rhotex.

up retail displays or tradeshow exhibits, as the material can bend and stretch to fit any frame or structure.

Instead of an inkjet printer’s individual dots and pixels, a dye-sublimation printer offers a continuous flow of colour, which produces clearer and brighter visuals.

As the heat-sensitive inks transfer to the surface of the media, they become part of the material. Without dot or pixel patterns, the final product is more durable, as the ink doesn’t fade and the prints don’t damage easily, even after repeated uses and washes.

As a more durable product, dye-sublimation printing offers new opportunities for advertisers that want to use their

Mordor Intelligence research finds the global dye-sublimation printing market will grow at a CAGR of 16.8 percent from 2020 to 2025.

With water-repellent print media and fade-resistant inks, dye-sublimated fabric can also be used to make promotional shelters (pop-up tents and domes), flags, umbrellas and outdoor media walls.

As the ink is embedded into the fabric rather than on the surface, dye-sublimated prints can be manipulated without the image fading or cracking.

Dye-sublimated fabric is easy to use, as it can be folded or rolled.While some print media options may need to be ironed or steamed after shipping, others – like fabric mesh – don’t crease and can be used as soon as they arrive onsite.

As practical and effective marketing products, Silicone Edge Graphic (SEG) fabric frames and lightboxes have been especially popular for retail displays and tradeshow exhibits. Due to the silicone beading, the dye-sublimated fabric print can be installed into the aluminum frame’s recessed groove easily and quickly without professional help. Claude Castonguay, Director of Research & Development at PNH Solutions, estimates that exhibitors can deduct about 25 percent from their total installation and decommission time when they use SEG fabric frames and lightboxes in their tradeshow booth compared to other finishing options, such as grommets, Velcro or pole pockets. Castonguay adds that silicone-edge beading also ensures the fabric banner remains taut, resulting in a cleaner, more professional finish.

As a compact and lightweight material, dye-sublimated fabric is cost-effective, as it can be shipped in smaller packages, which helps organizations reduce their shipping, drayage and warehousing costs.

Beyond printing company names, logos and images, brand owners can

mimic the look of heavier materials, such as wood or stone, using dye-sublimated fabric for their pop-up activations and tradeshow booths.

Wholesale shoe distributor Tin Shack used dye-sublimated fabric with wood panelling instead of real wood for a recent tradeshow booth campaign to reduce its shipping, drayage and warehousing costs. With a modular frame and compact materials, Tin Shack was able to fit the 10 x 20-foot tradeshow booth into two shipping crates, which helped to save on various costs throughout the job.

Unlike screen printing, where large amounts of water is needed to dye the fabric, dye-sublimation doesn’t require water for dying, as the process involves turning colour into gas. As a result, dye-sublimation printing is considered the most environmentally-friendly, sustainable printing process for fabric that doesn’t contribute to waste water pollution and ground contamination.

Combined with water-based inks that are odourless and free of VOCs, dye-sublimation printing can use biodegradable polyesters as print substrates that are free of harmful substances, like heavy metals, toxic dyes, crop protection substances and carcinogenic substances, such as formaldehyde.

As a viable alternative to other forms of printing processes, it’s no surprise that dye-sublimation printing is growing in popularity. In addition to increased flexibility, dye-sublimated printing produces high-quality, durable and cost-effective marketing materials that are easy to manage and more sustainable to manufacture.

KATHERINE HUDON is Marketing Coordinator at PNH Solutions, a fully-integrated large-format print service provider and custom hardware supplier that specializes in turnkey marketing products for events, retail environments and tradeshows. Based in Montreal, Que., and Toronto, Ont., PNH completes projects all over the world.

The seven keys of effective customer communications management every print service provider should know

By Gina Ferrara

As more and more enterprises make the decision to outsource the physical manufacturing of customer communications (print and mail) to print service providers, companies are seeing the value in outsourcing the logical generation of their documents. For print service providers, expanding beyond print to offer a broader scope of customer communications management is an excellent source of additional revenue.

Many enterprises are burdened with legacy systems and a disjointed customer communications management (CCM) technology infrastructure that prevents

them from achieving strategic communications goals. Multiple document composition software solutions and content repositories make simple document change requests time-consuming and complicated. Thanks to advancing technology, consumer expectations for personalized and consistent experiences across any delivery channel have many organizations struggling to keep up. While internal IT resources are focused on timely delivery of communications and staying compliant with changing regulations, lines of business are becoming more frustrated by long lead times for document changes. To be competitive, organizations have made customer experience a top strategic priority to offer better value to customers, maintain their

loyalty, and ultimately increase revenue. Unfortunately, for some organizations, their current technology environment has caused them to lag behind their competitors. All of this presents the perfect opportunity for print service providers to offer CCM as a service, helping enterprises to focus less on the day-to-day activities associated with their customer communications and more on customer experience.

Print service providers that wish to offer CCM as a service should consider designing a solution that incorporates all seven components of CCM. These components include data, content and preference management, document composition, omnichannel delivery, archive and dashboard/reporting.

Although each component is critical to managing the end-to-end communication lifecycle, data is the most critical. Data comes from multiple sources and can be structured or unstructured. Many enterprises struggle with collection, aggregation and normalization into a standard data model. This is where service providers can add a lot of value for their clients. Data is used in the document composition process, execution of business rules that drive variable content, personalization of communications with targeted marketing messages, and for analytics and business intelligence.

Content includes all components necessary for the document composition process, such as document templates, business rules, digital images and regulatory text. Content should be stored in a centralized repository with version control to ensure that out of date content is not used. In addition, workflow and approval processes are necessary for when new content is loaded to the repository or when existing content is modified.

Preference management is another input for the composition process and is the collection of customer profile information and delivery preferences. Delivery preference data is used to optimize the composition process to generate the output according to the customer’s preferred channel of choice.

To create the communication, the document composition process combines data and variable content with document templates according to predetermined business rules. It is during this process that communications are optimized for the delivery channel.

In addition, an archive copy of the communication should also be generated for storage, future retrieval and re-delivery if needed.

Once the communications have been generated, the final step is delivery. In the CCM industry, the terms multi-channel and omnichannel delivery are often

used interchangeably, but there is a notable difference. With both multi-channel and omnichannel delivery, all channels are available to the consumer; however with omnichannel, all channels are integrated together. This is an important distinction as it helps to ensure the customer experience is consistent across all channels.

Despite declining volumes, printed communications are still valuable because print is a trusted channel and consumers still open and read their mail. Although many consumers are “digital first,” they are not “digital only” and still value eye-catching, colourful printed communications that are personalized

For print service providers, expanding beyond print to offer a broader scope of customer communications management is proving to be an excellent source of additional revenue.

and contain content that is relevant. This is also a great opportunity for print service providers to offer guidance to their clients on the benefits of colour and how redesigning communications to incorporate more colour can improve the customer experience.

The last component of a CCM offering includes a dashboard that has reporting capabilities. A dashboard provides full visibility into the entire production workflow and can be made available to client end-users through a browser-based user interface. Job-level and piece-level tracking provide additional monitoring capabilities and the opportunity to pull and reroute, destroy and redeliver documents as needed. Through the dashboard, standard and custom reports can be generated and made available to end-users.

Print service providers that offer CCM as a service will have their share of challenges to navigate when prospecting enterprise clients. For example, who within the organization has responsibility for CCM and its ownership across the business? Many of the enterprise clients we engage with do not have a single owner of CCM, but rather it is shared among

the individual lines of business, IT and in some cases, marketing. In situations where there are multiple owners of a particular function, there will be some who do not favour outsourcing CCM. In addition, the concept of outsourcing might give enterprises the feeling that they no longer have control over their customer communications. This perception can be mitigated by providing a user interface that gives business users access to manage content, control messaging and create business rules as needed.

The success of most projects can be likened to painting a room. The more time spent in the preparation phase, the better the outcome. This too applies to outsourcing CCM to a service provider. The transition process should begin with business requirements and specification gathering, followed by a complete inventory of all document applications, templates, content and business rules. The inventory process provides the opportunity to rationalize and consolidate all document templates and variable content to eliminate duplicates and out-of-date content and load to a single repository.

By providing CCM as a service, print service providers are able to expand their value proposition and deepen relationships with both existing and prospective clients. When selling this offering, it is important to highlight the fact that outsourcing to a service provider eliminates the need for enterprises to continuously make capital investments in technology and transfers the risks associated with purchasing and installing software to the provider. This allows the enterprise to obtain the full benefits of a CCM as a solution while focusing on other strategic initiatives, such as digital transformation and customer experience. CCM as a service also allows enterprises to benefit from an end-to-end technology solution that meets their communication requirements and offers efficient change control and workflow.

By outsourcing CCM, enterprises can realize a return on investment by shifting from a capital expenditure model (CapEx) to an operational expense model (OpEx) and the resulting customer experience.

GINA FERRARA is Senior Analyst at Madison Advisors. Connect with Madison Advisors at www.madison-advisors.com, on LinkedIn at www.linkedin.com/company/ madison-advisors or on Twitter @madison_advisor.

Experts share their perspectives on cutsheet production inkjet press advancements, challenges and the reasons to adopt it

Komori describes the Impremia NS40 as “the inkjet game-changer,” saying it combines the best of offset and inkjet with the use of Landa technology, Nanography and Nanoink.

Rob Ens, National Manager, Production Print, Professional Services and Solutions, Konica

Adoption of digital technology is an absolute necessity for any printer today. Right now, the market is served by both inkjet and toner solutions, depending on the volume and type of work. The popularity of inkjet printing has increased exponentially over the past decade, as new inkjet technology improvements increase the quality of print while reducing the cost per page. While 100-percent uptime is unrealistic with any equipment, the automation of time-consuming and cost-

ly tasks has led to great improvements in efficiency and ease of use.

The AccurioJet KM-1 inkjet press from Konica Minolta is one of the most efficient and accurate B2+ digital inkjet presses on the market today, capable of reaching upwards of 90-percent uptime. It is the ideal solution for commercial printers, and printers that run variable data personalization jobs. The KM-1 offers digital colour precision and ink density in its finished jobs that are indistinguishable from offset quality. With such advancements in technology, it’s no wonder more print shops are making the switch to digital.

Announced late 2018, Fujifilm’s third generation J Press 750S generates 3,600 B2 sheets per hour for both static and variable jobs.

Offset may have been pushed aside but the need for ink remains. Inkjet offers the best of both worlds, an ink-based device but on a digital platform that is easy to use. Inkjet makes the print shop more versatile, addresses jobs that requires ink and creates an avenue to new revenue streams. Inkjet uses “no heat” — unlike toner, it does not fuse the image to its substrate. The elimination of heat brings about less wear and tear on parts, increases uptime and as a result, opens the door to endless amounts of “burst printing.” If you’re printing a majority of your monthly volume in just a few days, inkjet is the way to go.

Inkjet makes it easy to put ink on paper. But equally as important are the B/W toner jobs being converted to inkjet colour. For all those people who have been trained to believe that colour was too expensive, inkjet is a lifesaver. It allows for the transition of monochrome to colour with minimal impact to the print budget. While end-users have embraced inkjet’s low-cost colour output, many industry resellers struggle with the look of the output and the economics of the technology.

The Riso GD9630, which prints cutsheet inkjet at 9600 impressions per hour in colour, is our best inkjet press for commercial printers.

This is the first instalment in a two-part series on cutsheet production inkjet. Catch part two in the next issue of PrintAction.

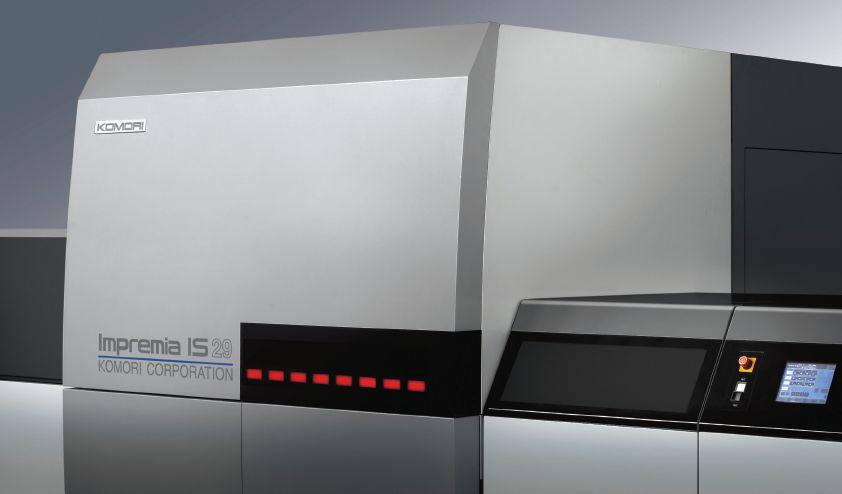

The Komori Impremia IS29 features a UV inkjet architecture to print on a range of stocks, making it suitable for commercial printing and packaging applications.

There has been, and continues to be, a shift in the market from being a volume-driven market to one that is value-driven with continuously decreasing run lengths. Each printed piece needs to provide more value and return. And, as run lengths decrease, the expectation of delivering high-quality printed output hasn’t gone down in a linear pattern with run lengths. Toner has continually improved and it still has a place, but it cannot achieve the quality levels of production inkjet technology.

Today’s inkjet technology, specifically the J Press 750S from Fujifilm, exceeds the quality of offset while answering the value proposition by delivering a cost-effective method to print short-run jobs, multiple versions as well as personalized applications. With the J Press 750S, there are no consumables that wear out and result in diminishing quality or require operator replacement. Daily maintenance is minimized to just a short cleaning of the primer roller at the end of the day – there is nothing else for the operator to maintain on their own on a daily basis. As the press is built on a very robust offset transport chassis, it is reported to experi-

ence uptimes of over 95 percent by actual customers, with most of the downtime attributed to automated head-cleaning cycles.

Featuring a larger sheet size of 23 x 29.5 inches, the 750S leads the category in hourly output at 3,600 sheets per hour for both static and variable data jobs. It also runs standard offset stocks, eliminating the need to purchase treated stocks which add unnecessary cost. Configuration flexibility is also important, as commercial printers look to use their assets for a variety of applications. The J Press can be configured to run both general commercial stocks and folding carton applications requiring stocks up to 24 pt.

Inkjet offers the best possible combination of incredible uptime, minimal makeready time and waste, print quality, substrate freedom, and durability. These can all lead to increased margins on existing work (running litho or other digital methods), and in many cases, expanding the markets printers currently serve. In some cases, given the higher crossover point with inkjet, jobs requiring larger sheet sizes and/or litho quality can easily make the switch to inkjet, saving time and money. Adoption of cutting-edge technology is always slow at the outset, but as the pool of users continues to grow, comfort levels will increase, making inkjet the de facto method for printing anything in the short- to medium-run and variable market. The Komori Impremia IS29 is our current flagship press for inkjet production. Komori stands behind the three main goals of our offering: Quality, productivity/reliability, and substrate freedom. All of these are easily achievable with the IS29, which is capable of perfecting a 23 x 29-inch sheet. Uptime specific to the IS29 is often reported in excess of 85 percent, and that only increases the more you run. Look to drupa when the NS40 will be commercially available, offering faster print speeds (6,500 sheets per hour) in the 29.5 x 41inch format.

Responses have been edited and condensed for length.

By Kevin Nuernberger

The key drivers for growing a successful, strong brand have stayed the same over the years. Your buyers still want the same three things: An irresistible product deal, a connection with you (the brand), and convenience. So, how do you deliver what customers expect? In today’s omnichannel environment, a strategic direct marketing approach is essential for engaging customers and winning their loyalty. Here are 17 direct marketing tactics that will help drive consumers into your store.

Personalize your brand. While the deal may be the driver, a personalized experience closes the deal. Present images of store managers, techs, owners and floor personnel in your messaging. Online and offline, consumers still count on a human touch.

Customize your copy. It’s not enough to sprinkle a consumer’s name on a website

or form. That feels generic in today’s world. Pull in geographic detail, locational key words, calendar events, and local and provincial imagery so recipients know the message was truly meant for them.

Show you can relate. Your buyer responds to visual cues as well as text, so leverage what you know to control the offer and how it is laid out. A message with vivid, relevant product imagery in a familiar context with accurate store mapping is portable across all digital media and mail.

Curate your solution. You learn about a customer’s priorities based on their web searches, clicks, inquiries, redemptions, purchases and past responses. So, present collections that quickly attract their eyes and forget the stuff they won’t bother to view.

Deliver value. Content marketing is the currency of the blogosphere, but long before that, direct mail, catalogues and newsletters shared editorial to engage read-

ers. People still crave information, so deliver content that has value. Empower your customer with knowledge.

Add meaning. Inspire your buyer with a greater purpose. Your message should answer these questions: How does this product/brand work? How will it make me better? How can it solve my problems? How will it make my life easier, better, more interesting, more convenient, etc.?

Make it a game. Most consumers will play a game if there is a reward. Quizzes, contests, games, puzzles and trivia spark interaction. Games educate (whether online or offline) and can be a tool for gathering additional data.

Cash in with coupons. The traditional static coupon litters every grocery bulletin board and tells a marketer little upon redemption. But customized variable-coded, feature-rich coupons drive consumers to websites and into stores. PURLs and codes help track buyer activity online and offline.

Capture attention with QR codes. Eliminate the distracting leap smartphone users make from mail piece to laptop. QR codes on handhelds are tickets for admission to brick-and-mortar events.

Loyalty programs unlock information. These are really trading platforms where consumers receive value in exchange for personal information. If you don’t have one

yet, get started. Cards and mobile apps are a vehicle for entry.

Pixel tracking works. Retarget buyers who abandon carts and browsers who don’t authenticate. Combining a visitor’s IP address with GPS technology, you can invite a prospect to your local store and follow up with direct mail.

Manage trigger programs. Manage your messaging to acknowledge, thank, review and upsell purchases. Remember birthdays. But beyond that, be careful how often and why you reach out to customers. Your goal is to optimize store visits without fatiguing the reader.

Integrate mail and email to build traffic. Intelligent mail barcoding can alert you about the peak time to send complementary email and post-display ads. Informed delivery enables URL activation of physical mail offers before they hit the mailbox.

Invest in targeting analytics. In addition to traditional RFMs, employ multivariate response modeling to identify high-propensity buyers and prospects.

Promote your “click and collect” capability. Use digital mapping, handheld tickets and parking passes for order pickup.

Deliver the best creative. Website designers, display ad artists, direct mail and email writers all have category-exclusive

Businesses that adopt omnichannel strategies achieve 91 percent greater year-over-year customer retention rates compared to businesses that don’t, according to an Aspect Software survey. 91%