Detailing

The Growth in Cutting Automation

Beatrice Drury of Zünd discusses commercial wide-format finishing

Detailing

The Growth in Cutting Automation

Beatrice Drury of Zünd discusses commercial wide-format finishing

Exhibitors describe what products attracted the most attention in Toronto and why

Exhibitors at Graphics Canada 2015, which took place from April 16 to 17 at The International Centre in Mississauga, were asked what one technology or service offering attracted the most attention at their booth. To better understand how technology will help pave the road ahead for Canadian printers, leaders from the exhibiting company also explain how this product is unique or impactful for the market.

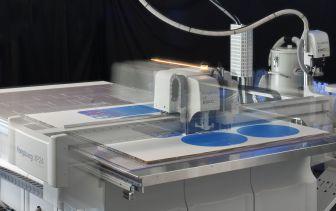

Product

Jeti Mira MG2716 S/HS

Market Impact

“PSPs need to be versatile while offering their customers fast, high-quality printing. The new Jeti Mira MG2716 S/HS from Agfa Graphics is a 6C+W UV inkjet printing system designed for industrial workloads. Its moving-gantry architecture offers a print-and-prepare mode allowing non-stop production. Six vacuum zones enable fast, accurate double-sided printing. The field upgradeable RTR option is designed to minimize waste on rolls up to 80-inches wide. Enter new markets with optional varnish or primer.”

– Ruben Silva, Managing Director, Agfa Graphics Canada

Editor

Jon Robinson - jrobinson@annexweb.com 905-713-4302

Publisher Paul Grossinger - pgrossinger@annexweb.com 905-713-4387

Associate Publisher Stephen Longmire - slongmire@annexweb.com 905-713-4300

National Advertising Manager

Danielle Labrie - dlabrie@annexweb.com 888-599-2228 ext 245

Media Designer

Graham Jeffrey - gjeffrey@annexweb.com

Director of Soul/COO Sue Fredericks

Annex Business Media

222 Edward Street Aurora, ON, L4G 1W6 printaction.com 905-727-0077

Product

Ricoh Pro C7110X

Market Impact

Ricoh explains the Pro C7110X attracted the most attention at Graphics Canada because it allows print-for-pay establishments to grow their business by leveraging oversize printing, such as full-size tri-fold brochures and posters, as well as new white and clear applications like back-lit displays, security patterns and metallic effects. “Commercial printers can do the same, as they shift short-run jobs from offset to more efficient digital systems. In addition, inplant/CRDs also can reduce costs – less outsourcing –while increasing job turnaround times and information security.”

Product

SureColor F2000

Market Impact

Epson explains the SureColor F2000 direct-to-garment printer is designed with some of the imaging company’s newest advancements like PrecisionCore TFP

print heads, along with its new garment ink technology called UltraChrome DG.

“The SureColor F2000 series is a new benchmark in high-performance garment imaging. For over three years, Epson dedicated a team of mechanical, chemical and software engineers to create a new imaging technology dedicated for printing directly to garments. This endeavor allowed us to rethink and design a garment printer the way it was meant to be.”

– Andrew Patrick, Manager of Professional Imaging, Epson Canada

Product

Avanti Slingshot, grand format functionality

Market Impact

Avanti explains the new grand format functionality of its Slingshot Management Information System attracted a lot of attention based on its uniqueness of focusing on grand-format applications, which is very different than wide format. The company explains several systems can handle wide format, but that shops have been struggling for years looking for a system designed for the nuances of grand format.

“Managing tiling can be a real issue for those in the grand-format business, both in estimating as well as production. Quoting alone can be a real challenge, as you also need to take into account various layouts to maximize sheet/role utilization. Avanti Slingshot can quickly estimate costs for different layouts. For example, ‘number up’ and ‘number along.’ Our demos of that functionality got a lot of traction.”

– Stephen McWilliam, Executive Vice President, Avanti

Product

EFI H1625 LED

Market Impact

Cansel, a national technology distributor focused on wide-format imaging, points to the EFI H1625 system, which runs at 50 square feet per hour and leverages LED technology.

“The EFI H1625 produces photographic image quality, saturated colours and smooth colour gradations using LED technology, which allows users to benefit from lower power consumption and costs. Whether you’re a sign shop owner or print service provider, the EFI H1625 boasts the ability to print quality pieces on a greater range of substrates, offering a solution for various applications. Simple operation makes this the perfect low-maintenance, entry-level wide format solution.”

– Joe Rothwell, Wide Format Segment Manager, Cansel

Mimaki CJV300, cut and print capability

Mimaki points to the cut and print capabilities of its Mimaki CJV300 wideformat-inkjet system, available in 54- and 64-inch widths. Dye-sublimation inks are also available for textile, apparel and soft signage production.

“Mimaki CJV300 Series cut-and-print devices can deliver an amazing array of applications. Eco-solvent inks – including silver, white, light black and orange – and advanced printing technologies offer the ability to create anything from fine-art reproductions

to outdoor signage. With precision cutting capability on board, complete campaigns –including labels, decals and T-shirt transfers – can be produced.”

– Ken VanHorn, Director, Marketing and Business Development, Mimaki USA

Digital Labels

Market Impact

Cambridge Label, which provides label trade services, points to the printing of labels on its high-end digital label press, which produces improved print quality, short runs and quicker turnarounds for brokers.

“Our digital press has the ability to print seven colours: cyan, magenta, yellow, black, orange, violet (CMYKOV) and white. Printing a 6-colour blend of CMYKOV allows us to accurately match Pantone colours at a substantially reduced cost to flexo printing. Furthermore, our ability to print white digitally allows us to print short-run window decals on clear stock very inexpensively… We used to take seven days to turnaround a fullcolour label job, now we manufacture in two to three days.”

– Deanne Sinclair, Marketing Manager and Product Development, Cambridge Label

Roland LEJ-640FT

Market Impact

“The LEJ-640FT flatbed UV printer is the latest, greatest addition to the award-winning VersaUV series from Roland DGA. Delivering unparalleled 1,440 dpi printing capabilities and superior compatibility, the LEJ-640FT offers the widest range of substrates, including heavy, rigid materials up to six inches thick and weighing up to 220 pounds.

With the addition of white and clear coat ECO-UV inks for dimensional effects, the LEJ-640FT can produce graphics that are anything but flat.”

– Christopher Cicero, Regional Sales Manager, Canada, Roland DGA

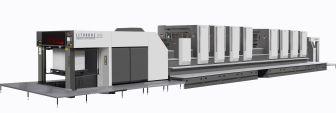

KOMCAN Product

Komori GL series, featuring UV options

Market Impact

KOMCAN, the exclusive distributor of Komori presses in Ontario and Western Canada, points to the recently introduced Komori GL line of presses, coupled with UV integration.

“Komori is the industry leader in our low energy UV drying systems including our own H-UV drying. The newest place where people are utilizing this technology is on perfecting machines. The printer can now print at speed with no worry of marking while perfecting, as well as no issue from slow down wheels due to the sheet being dry when delivered. In addition, the printer no longer has to concern themselves with costly transfer jackets on the press being damaged or constantly cleaned.”

– Steve Ranson, President, KOMCAN

Sydney Stone Product

Morgana System AF500

Market Impact

“Digital printers require equipment to process a wide range of work with operator ease. The Morgana System AF500 high-capacity sheet

feeder and booklet maker offers a completely automated booklet-making solution capable of processing booklets up to 200 pages thick. Launched at Graphics Canada 2015, with a first ever showing in North America, this system was an eye catcher both for its easy and automatic setup, as well as the ability to process booklets with art-quality papers well above the capacity of the comparable booklet makers in the market.”

– Dylan Westgate, Managing Partner, Sydney Stone

for the North American market. It is a totally clear front print window graphics media with a water-activated adhesive.

Esko

Product

Kongsberg XP24

Market Impact

“Many companies are trying to determine what to do with the graphics they print on digital inkjet printers. The Kongsberg XP24 finishing table handles corrugated board and other rigid or roll materials used in POP products and displays. It helps turn short-run POP/POS display work into profitable, value added jobs, offering on-demand production, 24/7, with just-in-time delivery. An optional conveyor extension works with rolls or sheets/boards with an auto-feeder with scissor-lift and transfer cart system.”

– Marc Raad, Esko Account Manager, Canada

Sihl

Product

Clearsol 3550

Market Impact

Sihl points to Clearsol 3550 as a new product

“Clearsol 3550 creates a new class of its own for window graphics as it doesn’t have a backing liner and therefore reduces waste. Clearsol is essentially an enhanced cling film. The water-activated adhesive creates the enhanced feature that allows for months of display potential without leaving a residue on the window. Typically, if a static cling is used, it is susceptible to humidity and can fall off a window in a short period of time. This is the main function improvement of Clearsol. Clearsol 3550 was designed for the application by retail franchises’ or small shops’ own employees without needing special installers to place the window graphics.”

– Bruce Walker, Client Solutions & Apps Technician, Sihl

eCardBuilder, Web-to-print storefront

“Web-to-print is the fastest growing sector of the print industry, automating orders, design, proofing, and billing. Over 30 percent of customers have indicated that they want to personalize their jobs online and over $20 billion of print orders are already being transacted online. Amazing Print Tech’s online designer has the largest variety of templates and images in its award winning Web-to-print technology that comes ready with storefront creation, online designer and a shopping cart.”

– Slava Apel, CEO, Amazing Print Tech

GTI Graphic Technology Product

VPI Vertical Print Inspector

Market Impact

“To help ensure accurate colour matches and to maintain brand integrity, output from large-format devices should be viewed in controlled lighting conditions. The VPI provides an ISO 3664:2009 compliant viewing area that makes it easy to visually inspect large-format prints. The VPI is available in three sizes with viewing areas ranging from 40 × 45 inches to 64 × 45 inches. Options include digital dimming, a lower luminaire, height adjustable artwork holder, and side walls.”

– Brian Wolfenden, Field Marketing Manager, GTI Graphic Technology

Canon Canada Product

Océ ColorWave 700/900

Market Impact

“Canon showcased a new generation of products that redefine productivity, while offering consistent high quality and media versatility. The Océ ColorWave 700 provides

flexibility to print on a range of media, from uncoated papers to self-adhesive wall paper and textiles, while the Océ ColorWave 900 prints up to 12 per second.”

– Antonina Catalfamo, Sr. Manager, Marketing & Operations, PPSG, Canon Canada

Product

DigiMaxx, super-wide magnetic media

DigiMaxx is the first and only super-wide magnetic media manufactured in North America. DigiMaxx is a printable, flexible

magnetic material designed for wide-format systems. It is available in 25- and 50-foot long rolls and widths of 40 and 48 inches. Custom materials can be made to order.

“Being manufactured entirely in North America allows DigiMaxx to be supported by excellent lead times, outstanding product quality, and unparalleled customer service.”

– Jim Cirigliano, Marketing Manager, Magnum Magnetics

Product

PackJet coding system

Highlighting the newest technology on its booth, Insource describes PackJet as a cartridge-based case coding/packaging printing solution for use on many different substrates, such as corrugated, UV and AG coated paper, plastic, glass, metal and poly.

“PackJet can be configured in any print format with unlimited options of vertical and horizontal print dimensions. Unique to PackJet is the lifetime replacement warranty, without exception. PackJet also has a direct connection to a camera system for immediate print verification, reporting and tracking.”

– Tim Wakefield, President, Insource

OPEN YOUR E YES TO A WORLD OF NEW OPPORTUNITIES.

Insource IQ Vision System improves the automated processing of unique identifiers / personalization while ensuring the integrity of the contents with proof of completion and quality control. Errors are costly to both you and your customers. How you ensure delivery of the highest quality output and service is critical to your company and the added value you can bring to your clients. Our Vision system, MatchMate, is completely customizable and will provide you with an easy way to control and customize your printing, output processing, verification and inspection processes.

• VERIFICATION

• READ & PRINT

• MATCHING

• ASSOCIATION

• INTELLIGENT FEEDER CONTROL

• DUPLEX PRINTING

• PATTERN RECOGNITION

• SELECTIVE INSERTING

• PLANT PRODUCTION CONTROL

• QUALITY/QUANTITY CONTROL

• REPRINT QUEUE

Improve quality and accuracy by ensuring integrity throughout the production process. Increase productivity and lower costs by reducing errors. MatchMate is so flexible it can be used with virtually any machine. Its customizable software allows you to configure your machine to enable it to track products throughout the production process. MatchMate’s power comes from each of the software modules that make up the intelligence it brings to the printing, packaging and mailing process, allowing users to selectively purchase modules based on their individual needs.

Contact us for a no obligation consultation. Our team will review your current applications and provide value-added solutions to improve your efficiency, your performance and maximize your revenue.

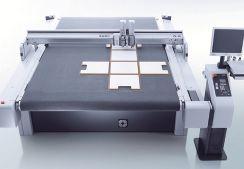

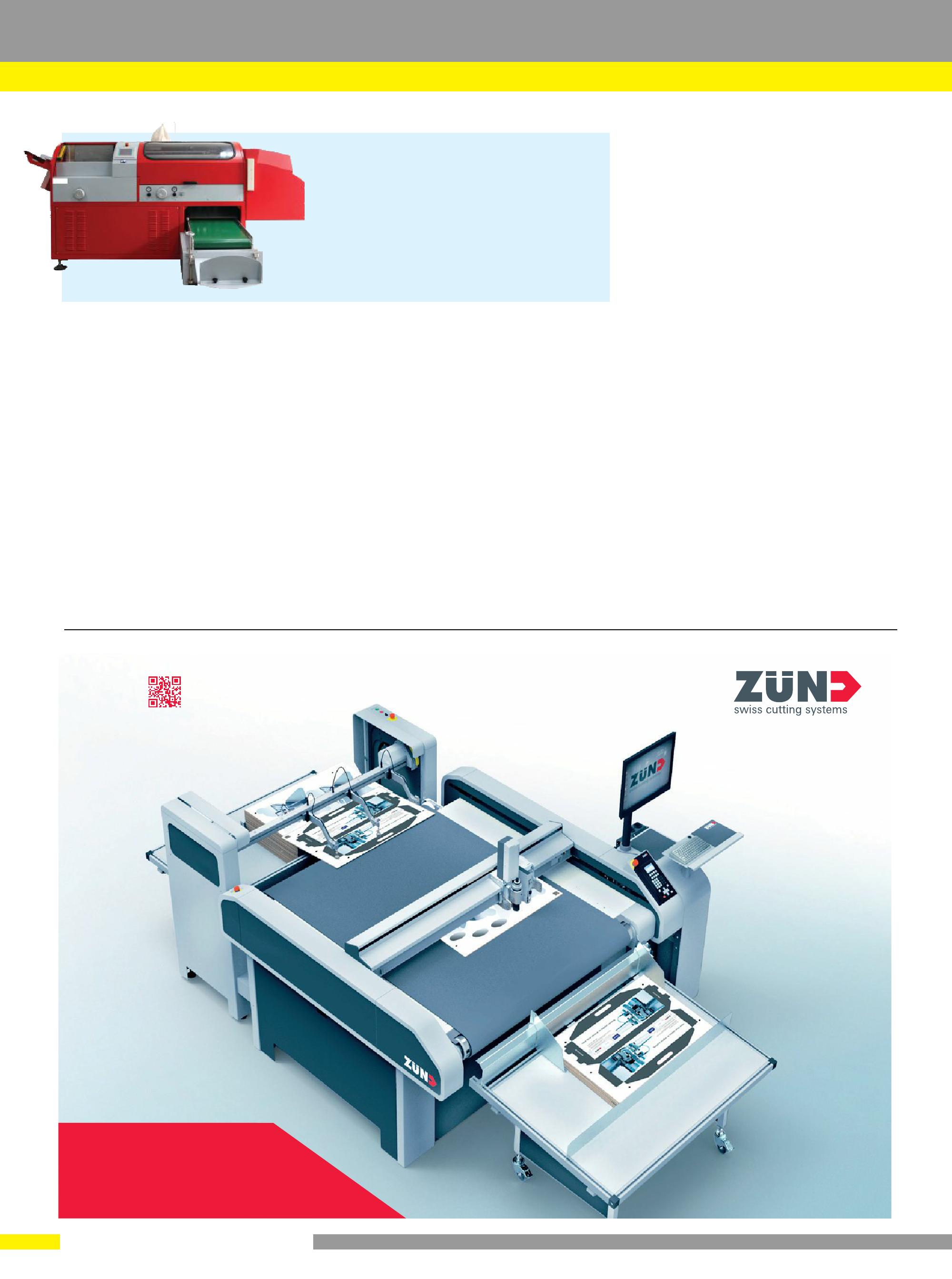

PrintAction spoke with Beatrice Drury, Director of Marketing & Communications, Zünd America, about new efficiency initiatives like Total QR Code Automation and tandem production, as well as the company’s renewed push into the Canadian market.

What did Zünd highlight on its booth?

Drury: Essentially workflow automation –what we call Total Automation. It involves Zünd Cut Center, which is the software that drives our system. It now offers automatic QR Code sensing... you can have two different sheets set up on one machine. In the first step, the camera moves over to the QR Code, reads it [and] pulls up the correct file for that particular sheet. It also knows what tooling to use… It is touch-less file retrieval. It doesn’t matter in what sequence the sheets are on the machine. It doesn’t matter how each one is nested and the operator doesn’t have to spend any time making sure it is the correct file for the sheet at hand.

What other key automation features are available from Zünd?

Drury: On larger machines we can offer what is called tandem operation. You can have, depending on the size, one or two sheets set up on the front of the machine. As it goes around and cuts, [the operator is] laying down more material on the backside. Once the front is done cutting the beam will go to the back and the operator can remove the cut pieces and waste from the front, lay down new material, and the machine keeps flipping, essentially back and forth, which is a way to keep it in operation 100 percent of the time. It is really by far the most productive workflow.

Is tandem operation more cost effective than using robotics?

Drury: We do have robotics, too… but by the time you add a sheet feeder and robot you are looking at upwards of $50,000. Depending on the size of the machine, it can be $50,000 to $100,000 plus, in terms of full automation upgrades, versus a tandem workflow that really doesn’t add more than probably $10,000 or $20,000 maximum. It also becomes a space issue... if you have a 10 by 10-foot machine plus you add a sheet

feeder and maybe a board-handling system on the offload side, that becomes a 30-foot machine. [The tandem system] has definitely been a very popular configuration.

Can a system be upgraded for tandem operation in the field?

Drury: No – you have to get the machine that way from the start, because it requires a differently configured table/vacuum plate.

Is Zünd seeing more commercial printers getting into wide-format finishing?

Drury: That is happening, plus a lot more packaging companies are getting into digital printing as well, and, of course, digital cutting goes hand in hand.

Are your cutters primarily being used for packaging prototyping?

Drury: Traditionally it has been a lot of prototyping, but now, because of some of these automation features, it is moving more toward shorter-run production. Also, unlike with traditional die cutting, you obviously have a lot more leeway in terms of customization.

What is the best route for commercial printers to invest in wide-format finishing?

Drury: That is one of the benefits of the Zünd cutter – it is very modular. The last thing you want to do is [start] with a small-size system, because it is the one thing you cannot change later on. You can add tooling. Let’s say you are not particularly interested in adding a router at this point. That is something you can easily add later on, so you can focus on knife cutting… there are all kinds of materials that can be done short of going to a router. [You can] also minimize the complexity of the automatic material handling.

How is Zünd now approaching Canada?

Drury: Jim Patterson has been the Zünd representative, in recent years, pretty much exclusively… We would like to get a little more coverage throughout the country, instead of just in the Toronto area, so we are looking to expand and potentially adding more sales staff. We just added Jay [Lalonde]. Jim Patterson will continue as an independent reseller and Jay will be part of Zünd America, but based in Canada. We also have service technicians in Canada.

Fujifilm ran demos of the Acuity LED 1600 and the Acuity Advance Select HS wideformat-inkjet systems. The Acuity Select HS flatbed has up to six channels offering extended colour, white and clear ink options. The Acuity LED 1600, with lowenergy curing, is designed for companies new to wide-format-inkjet printing.

Fujifilm also setting up offset printing workflow stations running XMF workflow tools, including ColorPath, as well as ColorGATE software for wide-format. The booth will also include printed samples from Fujifilm’s Uvistar Pro-8 series and the Inca Onset UV.

KBR Graphics exhibited, for the first time at a Canadian trade show, the new Standard Horizon RD-4055 die cutter, which can die-cut, kiss-cut, crease, perforate, slit, hole punch, and round corner on a range of substrates in one process for both digital and offset prints. It accepts sheet sizes up to 15.74 x 21.65 inches. A repeat register function allows multiple-up applications from a single die pattern – up to five repeats in a single pass. The system is suited for applications like cards (greeting, note and playing cards), door hangers, labels, coasters, coupons and tickets, pocket folders and unique mailers.

Insource provides technology, service and consultation primarily in the industrial segments of paper/card handling, packaging/ fulfillment and mailing. The company showcased its Insource IQ camera system, designed with verification, read and print, matching, association, intelligent feeder control, duplex printing, pattern recognition, selective inserting, and reprint queue. Insource also highlighted Kirk-Rudy PackJet coding systems, its newest technology for the Canadian market. The 1/2-inch PackJet X1 model is comprised of a 7-inch screen and attached print head, along with SQL database integration.

The Craftsmen’s Club used its booth for the RyeTAGA initiative led by students of Ryerson’s Graphic Communications Management program. Students were on

hand to raise funds, discuss corporate sponsorship opportunities, and to provide details about their annual research journal production for the Helmut Kipphan Cup competition, which the group won again at the 67th Annual TAGA Conference in Albuquerque.

Ricoh demonstrated its Pro C7100 and Pro C5100 Series presses on its booth. Released in September 2014, the Pro C7100 Series features print speeds of up to 90 ppm and supports media up to 360 gsm. Image quality up to 1,200 x 4,800 dpi is achieved with Ricoh’s enhanced Vertical Cavity Surface Emitting Laser (VCSEL) technology. It supports a range of media, including new textured technology, as well as varying applications like light packaging, demo packaging, direct mail, books, brochures and business cards. The Pro C7100 Series features a fifth colour station allowing for clear gloss or white applications. While not on the booth, Ricoh also highlighted its Pro VC60000 and Pro C9100 systems.

RISO demonstrated a standalone ComColor X1 9150 inkjet printer and the RISO Print To Mail Solution. RISO describes the ComColor X1 9150 as the fastest printer of its kind, printing 1,000 full-colour single-sided pages in approximately 6.5 minutes. The company also explains its startup takes no more than five seconds. The Print To Mail system takes electronic files and outputs completed, ready-to-mail direct mail pieces, fully printed, addressed, folded, stuffed, sealed, and ready to go – all inline. RISO explains the unique system as a full direct mail house in a box.

SmartSoft demonstrated its PressWise workflow software for Web-to-Print, MIS and process automation. The newest version includes enhancements to PressWise’s Job Scheduling functionality and the addition of new customized reporting tools, allowing staff and management to gather insight important to their roles and responsibilities.

Southwest Bindings demonstrated its ALM 3222 automatic laminator as a portable system handling 13x19, 12x18, 11x17, 8.5x11inch sheet sizes. It features warm up of less than five minutes, automatic flush or sealededge trim, and 115 Volt, 15-amp service on economy mode. The ALM 3222 automatically feeds up to 200 sheets and laminates papers as heavy as 130-lb cover stock.

Zünd highlighted its Total QR-Code Automation system, which is driven through the Zünd Cut Center (ZCC). In a static-bed, tandem vacuum setup or fully automated, with automatic sheet-/roll-feed

CMD Insight, the exclusive distributor of LasX Industries, focused on the STS250 250W CO2 entry model with single laser (future expansion possible), as well as the LasX STS400 CO2 model with one or two lasers. The STS product handles sheets on the infeed section and the finished sheet on the output. Each model has the option of scaling from one to two lasers depending on needs of the user.

and integrated robotic off-load, Zünd cutters using QR-Code Automation have the ability to run without interruption. This is possible, according to Zünd, regardless of whether the graphics are nested, or of what sequence single or multiple stacks of printed sheets are fed onto the cutting table. ZCC automatically captures the embedded QR-codes, retrieves the corresponding cut files and keeps cutting.

Epson highlighted its SureColor F7170, SureColor F2000 and SureColor T5270 printing systems. The F7170 roll-to-roll dye-

Hans Shinohara Canada highlighted three primary systems, including a 5-colour Shinohara S75VHP offset press, as well as its new PUR perfect binder called Explore and the Hans Gronhi MQ 330 laser die-cutting system.

sublimation transfer printer is for polyesterbased textile manufacturing or soft-signage applications. It features a 64-inch-wide media feed and take-up system and new Epson PrecisionCore TFP print heads for use with UltraChrome DS inks. The SureColor F2000 Series marks Epson’s entrance into the direct-to-garment market with two inkjet printers. The SureColor T5270 is a largeformat colour imaging system designed for producing technical drawings, graphic posters, and retail signage at high speeds.

Sydney Stone exhibited, for the first time in North America, the new Morgana 350 and 500 booklet-making systems. As either a handfed offline unit or a near-line fully auto-feed system, the Morgana BM 350/500 will staple and fold up to 35/50 sheets with optional face trimming and spine squaring inline. It is designed to produce booklets on all types of coated and art-quality paper.

Multiple Pakfold Business Forms focused on its MP Short Run and MP Label products. The company, founded in 1952, provides simple short run jobs to complicated long run projects for printers and print brokers, focusing on a range of forms, labels and cheque products.

Trade printer 4over highlighted new packaging and promotional product capabilities, such as signage, 80-lb gloss flyers and booklets, as well as a new Every

Mutoh showcased its 64-inch ValueJet 1624 ecosolvent printer and the ValueJet 426UF. The company refers to the ValueJet 1624 as “The Wrapper’s Choice” printer. The ValueJet 426UF is tabletop UV-LED printer. It carries a 19 x 13-inch format for printing on virtually any item up to 2.75-inches thick. Mutoh explains the 426UF is designed to produce customized promotional items like pens, phone cases, golf balls and hockey pucks.

Door Direct Mail (EDDM) solution available through 4over.com. The company’s growing packaging focus includes a Custom Box quoting tool for most any dimensional box. Con4rm is a drag-and-drop online tool developed by 4over to inspect artwork files. 4over also announced its entrance into 3D Printing as an online trade service. Run out of its headquarters in Glendale, California, 4over employs a 3D manufacturing method called Fused Deposition Modeling, which is suited for the creation of prototypes, samples for packaging development, and original items.

Konica Minolta demonstrated its bizhub PRESS C1100 and bizhub PRESS C1060/ C1070 production systems on its booth. The bizhub PRESS C1060/C1070 features up to 70-ppm output speeds, PC-like operation with handheld mouse, and image density and colour density control sensors. The system has a 7,500-sheet paper capacity and auto duplexing of up to 300 gsm. It can handle 100-sheet stapling, 200-page booklets and 600page bound books. The bizhub PRESS C1100 features 100-ppm speed, in both colour and monochrome, Enhanced Simitri HDE toner, and 1,200 x 1,200 dpi resolution with 8-bit processing. The C1100 has a 13,890-sheet capacity, handling weights from 55 to 350 gsm.

Sihl, which primarily develops unique medias and coatings for wide-format production, highlighted its 3275 TexBanner Xtrem white 145. This 100 percent synthetic, non-woven banner features a water-fast inkjet coating, developed as an alternative to Tyvek. Sihl also showcased its 3550 ClearSol Wet Cling film 125: This cling film – using an ink receptive layer with a water-activated composition – was designed for window advertising but can also be used as a normal clear film.

Treckhall exhibited its new XMR 2.0 Magnetic Receptive Media, described as an environmentally progressive product available as 8-mil and 13-mil 100 percent opaque, 2-sided synthetic (non PVC) material. The company also highlighted its Umbra Display Materials, InView line of Nano Grip non-adhesive white and clear products, Ritrama adhesive vinyls, window films and lamination/mounting products. Treckhall also showcased Magic Inks for HP Latex, Canon, Epson, Roland and Mimaki printers.

Roland showcased its new VersaUV LEJ640FT flatbed UV printer, designed to handle a range of substrates, including heavy, rigid materials up to six inches thick and weighing as much as 220 pounds. The VersaUV LEJ640FT uses Roland’s CMYK, white and clear coat ECO-UV inks to produce POP displays, interior design, art, promotional products and 2-sided signs incorporating unique dimensional effects. Other LEJ-640FT features include a zoned vacuum system for holding difficult materials flat, a low-heat UV-LED curing system, and a handheld control unit.

Rollem highlighted its new line of Delta die cutters at Graphics Canada. The rotary sheetfed flexo-magnetic systems feature what the company describes as a small footprint, quick changeover and economical price point aimed at the digital print market. Delta can produce work like shaped cards, decals and labels, presentation folders, door hangers, bottle-neckers, and folded cartons. Handling sheet sizes from 20 x 15 up to 24 x 30 inches, it can include provide complete box production with an optional inline folder/ gluer unit. The models can also handle 20-lb paper up to .022-inch board.

Primera highlighted its CX 1200 label press and FX1200 finishing system, LX900 label printer and AP362 label applicator. The CX1200 delivers full-colour label printing, utilizing what the company describes as one of the fastest and highest-resolution colour laser engines available. It can be integrated

GTI discussed its Soft View SOFV-1xiQ, EVS Executive Viewing Stations, PDV Professional Desktop Viewers, Color Rendition Demonstrator, and Vertical Wall Viewing Systems. Soft View SOFV-1xiQ is a desktop soft proofing system that provides colour comparisons between hardcopy prints and computer monitors. The SOFV-1xiQ includes a viewing station and the wireless iQ sensor. The system enables lighting uniformity with a small desktop footprint that meets ISO 3664:2009 D50 light quality for strong colour rendition. The EVS D50 viewing stations combine electronic ballasts with Graphiclite T8 fluorescent lamps to produce light evenness and illumination.

with the FX1200 finishing system to provide an all-in-one offline solution to cut, label, rewind and laminate.

Announcement Converters exhibited a range of its unique substrates for marketing materials, including Gmund Urban (four colours in three finishes), Corkskin (actual cork veneer laminated to paper that is printable), Wood (actual Birch and Cherry wood veneer that is laminated to paper and is printable), AVEO (tree-free paper made from the waste of sugarcane with some waste products from linen and hemp), Crane’s Crest envelopes, Gmund Cotton Max White paper and envelopes, Savoy Grey paper and envelopes, MirriSparkle, Colorplan 260# cover, and Enclosure/Escort cards, folders and envelopes.

Racad Tech is a Canadian developer of modular Web-to-print technology. This includes its Web to Print Shop product highlighted at Graphics Canada. Web to Print Shop provides individual modules for printers to use with their existing solutions or a full suite of corporate portals and retail Websites using a browser-based template builder called uDraw. It can create products like

Drytac showcased its WipeOut substrate, released April 2014. It is described as a premium, dry erase, hard coat laminate with a chemical and scratch-resistant gloss surface. It can be paired with graphics printed on ReTac Wall, released December 2013, as an adhesive matte PVC film to create removable wall graphics with most solvent, UV and latex printers. Drytac also highlighted its Interlam Pro laminating films and various adhesive-coated products manufactured in Canada.

business cards, invitations, signs/banners, T-shirts, flyers and other miscellaneous items. Racad also recently launched Online Sign Studio, which offers Web-to-print tools for wide-format printing.

Afinia Label highlighted its L801 Memjetpowered desktop label printer, as well as the DLP-2000 Memjet-powered label press and the DLF-1000 label finisher.

Xerox exhibited its new Xerox Versant 80 press in addition to the existing Versant 2100 model, as well as the Xerox Color 1000i press and Color C60/C70 systems. The 1000i press is to be configured with 2-tray oversized high-capacity feeder, GBC AdvancedPunch and Booklet Maker Finisher with the Xerox SquareFold Trimmer Module, and EFI EX Print Server. The Versant 2100 was shown with 2-tray oversized high-capacity feeder, Standard Finisher Plus with Plockmatic Pro 50/35 booklet maker (with Rotate Crease and Bleed Trimmer), and EFI EX Print Server. Offline systems at the booth are to include the CP Bourg BSFEx and Duplo DC-646. Software highlights include FreeFlow Core, FreeFlow Digital Publisher, XMPie StoreFlow, and Prisme PrintSys Web-to-print software.

BCT Mississauga, the largest BCT franchise in Canada, a part of a network of more than

35 locations in North America, highlighted its specialization in short- to medium-run printing of stationery products in spot colour (flat or raised thermography ink) or fourcolour process, either offset or digital. BCT is also introducing its new line of laminated products like business cards and menus.

Esko showcased its Suite 14 software, with a focus on ArtiosCAD, as well as i-cut Suite, Automation Engine for signage production, and the Kongsberg XP24. With a maximum working area of 70 x 141 inches and a top speed of 66 inches per second, the Kongsberg XP24 can convert a range of board, sheet and roll materials. An optional conveyor extension is available that can work with rolls or sheets/boards with an AutoFeeder with scissor-lift and transfer cart system, expanding the quantity of print runs that can be pre-stacked.