Dissecting digital and conventional printing systems at drupa 2016

Canon Canada Inc. has the industry's most comprehensive portfolio of professional printing solutions ranging from high quality cut sheet presses, to versatile flatbed solutions, to extremely productive digital web fed presses. Canon's innovative and award-winning technologies enable our customers to create highly profitable prints without compromising on quality, productivity, or speed. Every application is different and with our team of expert sales, support and application specialists, we can demonstrate how Canon solutions can drive your business forward.

► imagePRESS® C800

A light production toner press that provides exceptional output quality with a wide variety of inline finishing options allowing for a small, scalable footprint.

A production toner press that rivals offset output quality and provides vibrant, stable colour at print speeds of 100ppm on coated/uncoated media up to 350gsm.

► imagePRESS® C10000VP

A highly innovative, high volume colour inkjet sheetfed press that combines the proven inkjet advantages of high productivity with cut sheet versatility and media flexibility.

A highly flexible and versatile inkjet full colour web press for the efficient production of mail, publishing, and commercial applications with speeds from 246-417 feet/minute.

► Océ ColorStream® 3000Z

An all-rounder colour printer designed for wider graphic arts applications and offers high quality, instant dry and waterproof prints on uncoated, thick and custom media.

The highly productive Océ Arizona series of UV flatbed printers combine exceptional print quality with true application versatility.

The positive vibe and innovation displayed at drupa 2016 illustrates print is far from dead, even if how and when it will be produced is changing

By Martin Habekost

This year I had the privilege to attend the drupa tradeshow again. I was in good company with seven students from the Graphic Communications Management program at Ryerson University and six of my colleagues. We spent three days at drupa exploring the trade show.

First of all, I would like to say that the whole show carried a very positive and energetic vibe. It was like a fest, almost a party, compared to the sombre tone from 2012. The halls were bustling with people from more than 188 different countries. Many pieces of equipment carried a Sold to... sign. I see this as a positive trend towards the future of the printing industry. Companies are investing again to modernize their equipment and add new services.

Yes, the hype of the show was HP, which had hall 17 completely to itself, as well as Landa, Kodak and Highcon. There were many exhibits in regards to 3D printing, functional printing and so on, but the majority

of exhibitors were focused on supporting existing businesses and their needs from new inks to better knifes for a cutter. The paper manufacturers had a hall to themselves to show off many new products. What I also liked was the hustling and bustling in hall 1, occupied by Heidelberg.

Overall, 260,000 visitors visited the 1,837 exhibitors who themselves came from 54 different countries. These numbers are little bit less than statistics from drupa 2012, but, as I said before, the spirit was quite positive throughout the show. Messe Düsseldorf states 54 percent of the visitors came to drupa with concrete investment intentions and 29 percent placed orders and another 30 percent plan to place orders after drupa.

Although previous drupa trade shows have been labelled as the digital drupa, this 2016 version was for sure the digital drupa. Benny Landa’s famous saying “Anything than can be printed digital, will be printed digital” was

clearly on display at the show. The speed of digital presses using inkjet technology is continuing to increase and the print resolution is also getting better. Sometimes you really have to look closely (with a magnifying glass) to see the difference. Also more and more special inks are being developed for digital printing presses, which used to be available only in offset or flexo ink sets.

Kodak showed interesting new inkjet technology with the introduction of its Ultrastream platform, which was incorporated into its Prosper 6000C press.

Landa, meanwhile, stated it will finally ship machines after the show to a number of beta customers.

Automation is still a big topic by all accounts. Due to the increasing number of short run jobs, the changeover between print jobs has to be as quick as possible.

Expanded gamut printing is not only a trend for digital printing, it also for conventional printing. Expanded gamut

printing uses CMYK plus OGV (Orange, green and violet, sometimes also called blue), to cover up to 95 percent of the Pantone book. Using expanded gamut printing eliminates wash-up or ink changing between press run. Digital presses and conventional presses were shown at drupa that used this technology during live demonstrations and the changeover time was a few minutes for new plates or plate cylinders before the next print job started printing.

Pantone just released a book that shows the Pantone colours and how they can be achieved using expanded gamut printing. Just think of it as the Pantone Bridge book, but instead of four colours, seven colours are being used. I also saw quite a number of vendors showing MIS technology. One would think that this is somewhat of an old hat, but there still seems to be quite a need for it. Another important item seems to be Digital Asset Management (DAM) systems. Local and cloud-based solutions were shown. I found it interesting that each user can have different levels of access, from low resolution, for position only, up to full editing rights. The important DAM trend is that the original image does not get edited, it is always a copy that is being modified. The DAM systems can also be searched to see which image was used for which product or campaign.

A clear indication of the changing print industry was that HP had hall 17 completely to itself. In 2008 HP had a relatively small booth in a hall. In 2012, the company occupied half of a hall, and it was one of the busiest booths at that show. In 2016, HP was the largest exhibitor at drupa 2016 with its hall measuring 6,200 square metres. It would be possible to write a complete article on all of the things HP showed in hall 17, but I am focusing on just a few items that sparked my interest.

The first item is the HP T490 HD PageWide inkjet web press. It can run webs from 16 to 42 inches wide. The press can run in two modes, called performance and quality mode. In quality mode, the press runs at 500 feet per minute and at 1,000 feet per minute in performance mode. I asked a representative from HP what the amortization period for such a press would be and received the answer of 20 years. It was pointed out to me that the press is field upgradable in regards to the

inkjet heads and also in regards to the digital front end (DFE). I also asked about ink costs. Although the inks costs are twice as much as offset inks, there are no costs for plates, makeready or wash-up.

HP prides itself in the fact that the T-series machines are made from solid metal, even the small gears, and therefore built to last. HP is also experimenting with different kind of inks that used to be only available for conventional print processes. The company is experimenting with colour-shifting and glitter inks, fluorescents, spot gloss, adhesive, thermochromic ink, silver ink and also with digital lenticular ink. In order to show off the versatility of the inks, HP displayed a board with print samples produced on coated paper, compressed cardboard, synthetic paper, SBS, fluted PP, foam PVC, PE film, Acrylic and Polyester film.

HP’s 3D printer is set to mix-up the 3D print market. The difference to most current models is that it does not matter if one copy or 10 copies of the same item are made, as long as they fit on the table inside the device. HP leverages Jet Fusion technology that uses bonding and fusing agents that are applied separately after the material has been deposited. Another unique feature of the 3D system is its ability to print in colour.

Kodak, as mentioned, introduced its Prosper 6000C inkjet press with Ultrastream technology, which is based on a continuousfeed inkjet system to achieve high print speeds. This allows users to print at an equivalent resolution of 1,200 x 1,200 dpi. The web width on this machine can range from eight to 97 inches. The web speed can reach up to 500 feet per minute and is limited to 150 feet per minute for vinyls and plastics.

The inks are safe for indirect food contact. Due to the high printing speed of the Propser 6000C inkjet press, the roll unwind is handled by a MEGTEC roll stand and the in-line folding operation is done by a manroland websystems’ Foldline technology.

The new NexPress zx3900 has five printing units and can print white ink and MICR ink. The operator also has the option to change the fusion roller to achieve a different gloss on the printed material. This press can be equipped with a fusion roller for a glossy finish or a matte finish, without changing the toner.

Xeikon is known for its toner-based digital print machines delivering a high print quality. At drupa 2012, the Trillium toner technology was introduced, but at this year’s drupa a working roll-to-roll press using this technology was shown. The interesting thing about Trillium toner technology is its use of a liquid toner. The liquid toner gets transported via an anilox roller and a doctor roller onto the photoconductor drum.

From the photoconductor drum, the image is then transferred onto an intermediate rubber-covered cylinder before the transfer to the substrate takes place. All this time, the toner is in a carrier oil. The Trillium technology is slated towards shortrun book printing, transactional direct mail and transpromo printing. Xeikon also showed machines geared toward the short-run label market. The printing machine can be equipped for heat transfer or in-mold labels.

Delphax, a Canadian player in the inkjet printing market, uses the Memjet print head technology in its Elan 500 press. Interestingly, this machine has a relatively

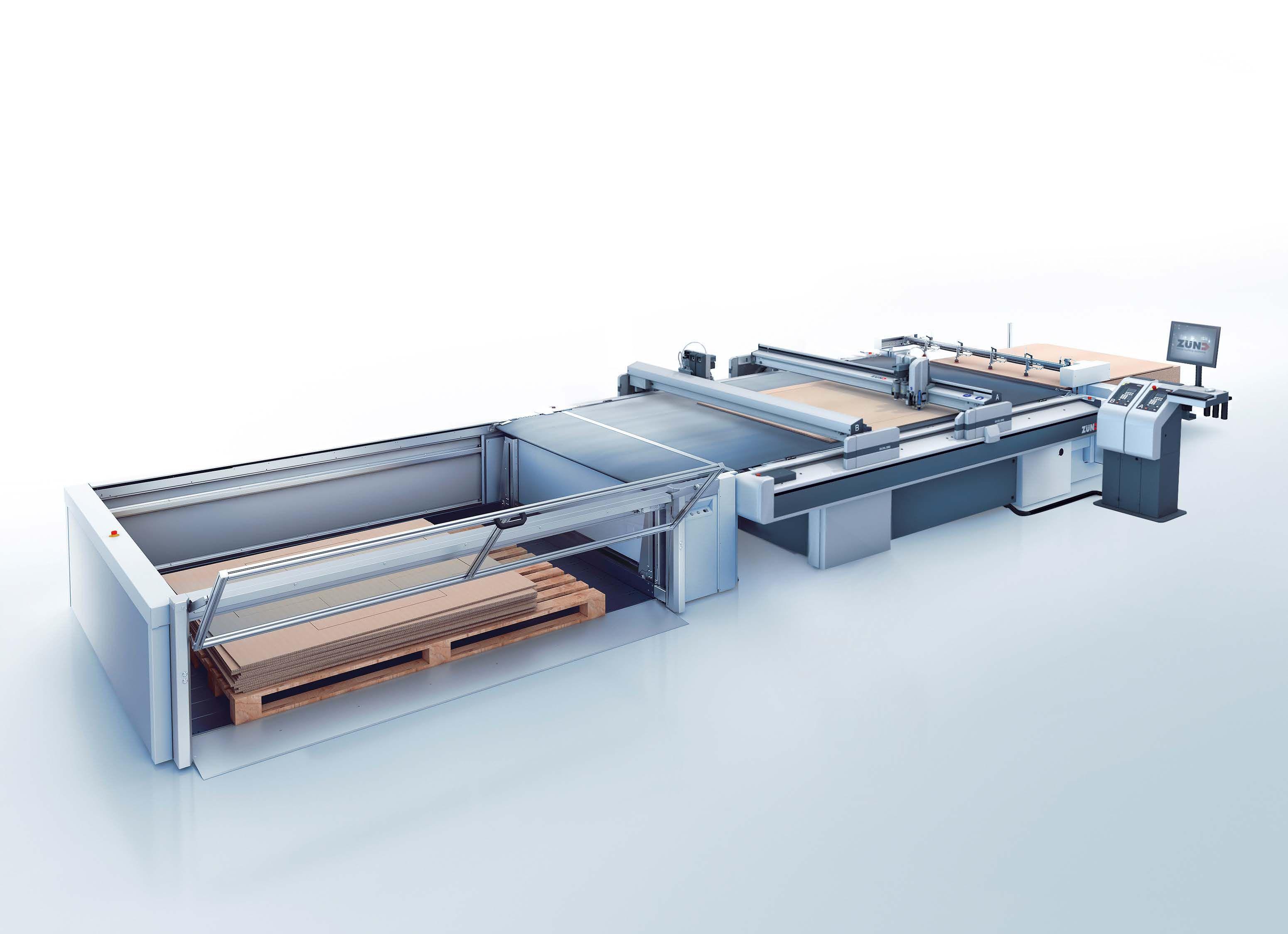

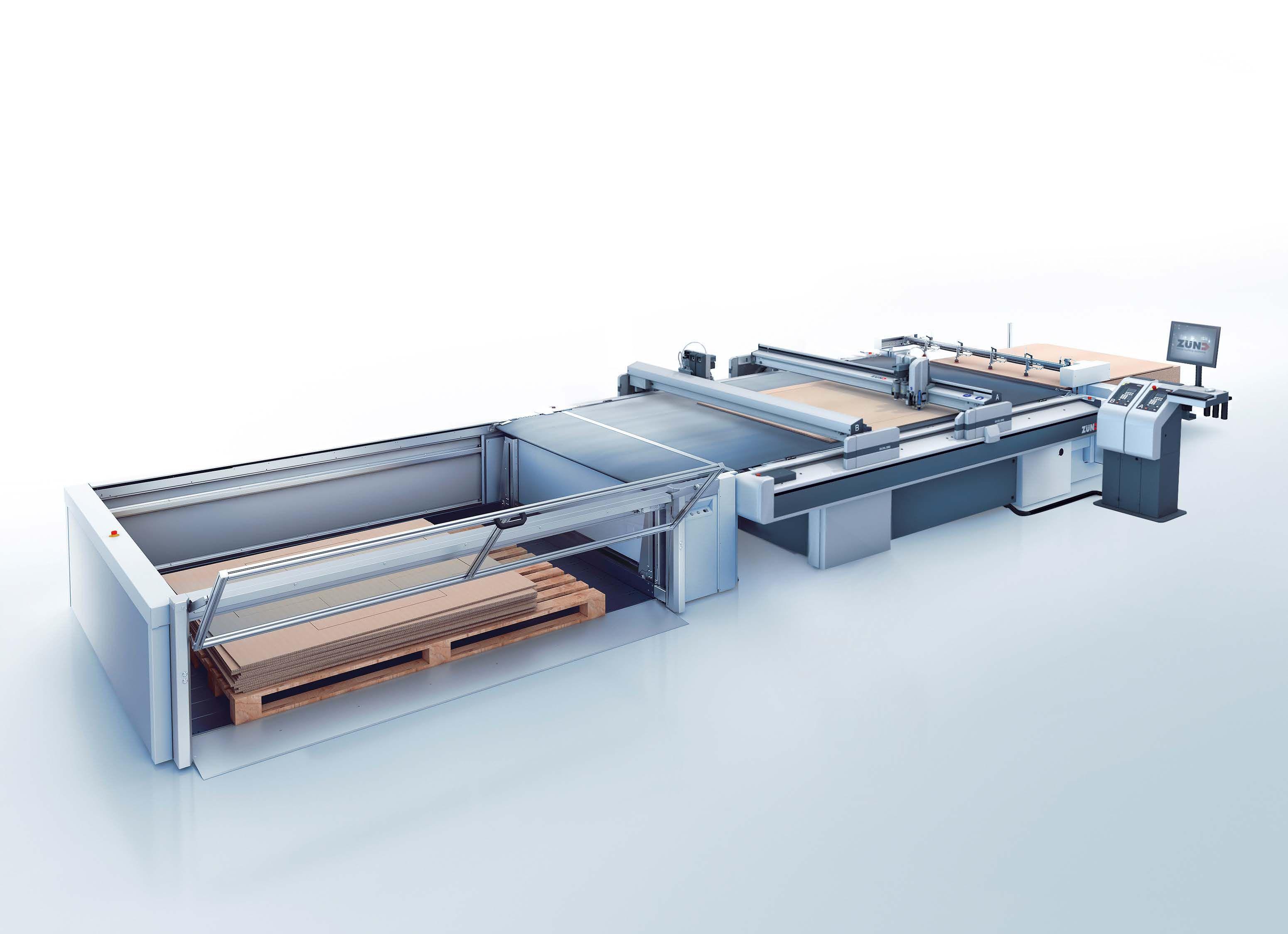

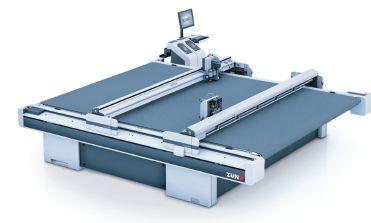

NEW dual-beam Zünd D3:

• Capable of doubling the throughput

• 3 different modules/tools on each beam

• Modular tooling, material handling automation

• Easy integration in existing production workflows

• Proven G3 technology, precision, reliability

Click here to preview the Zünd D3 showing at SGIA, Sep 14 - 16, Las Vegas

Why Zünd?

• State-of-the-art cutting solutions

• Widest range of tool & automation options

• Modular, upgradeable, easy to use

• Reliable non-stop cutting/finishing

• Unsurpassed ROI & longevity

high speed for cutsheet inkjet printing. The top speed hits 500 sheets per minute in A4/ letter size. The maximum print resolution can be 1,600 dpi and full duplex is possible in one pass. The maximum sheet size for the Elan 500 is 18 x 26 inches and the paper weight can range from 20 to 130 lb.

At drupa 2012, Benny Landa introduced the printing world to his Nanography branding. Nanography uses nano-sized pigment particles in a water-based inkjet ink. The difference to current inkjet technology is that the water gets removed from the inkjet ink before the printed image gets transferred to the substrate. In Nanography, the image is jetted onto a heated transfer belt, which removes all the water from the ink and turns the ink into a semi-plastic, before it gets transferred to the substrate. The design of the S10 sheetfed press has changed a lot from drupa 2012. The machine looks more like a conventional printing press with a cockpit at the end. The press also has coating capabilities if the customer so desires. Beta machines of the S10 presses will soon be delivered to selected beta-site customers. Quad-Graphics is one the selected customers for North America.

Landa positions its technology in terms of production between current digital print technology and offset print technology, at the run lengths between 1,000 and 10,000. This was shown during its theatre style presentation. It was also stressed that the quality of the printed dot on coated and uncoated paper is higher compared to current inkjet technologies. Images were on display that demonstrated this fact. Another

advantage for Landa is, that the CMYK gamut of its inks is wider than the conventional CMYK gamut, as is the case with most inkjet systems. Landa can also print with an expanded gamut set that covers almost all of the Pantone colours. Interestingly, the ink containers are made from cardboard and can be flattened and recycled once the plastic bag that contains the ink concentrate is empty. The plastic bag for the ink can be recycled in the current plastic recycling stream. Prints made with Nanographic inks are also recyclable according to the INGEDE test method.

Landa also unveiled a new technology brand called Metallography, which is set to replace foil stamping for any kind of metallic ink effect on any kind of printing. The Metallography application unit can be retrofitted onto an existing press. This concept was shown on a narrow-web flexographic press. Metallography uses nano-silver which is attracted to the printed material via a trigger image and a donour roll applies the metallic flake to the print. Metallography can save a lot of metallic foil material. It was said that one kg of this silver material replaces 3,000 kg of foil stamping material. Another advantage of this process is that prints with Metallography can be used in a microwave without causing any fires or damaging electric discharges.

Although most of the hype at drupa was around digital printing, current industry powers were not sitting on their hands and waiting for things to happen. Many inventions were shown in press technology for offset and flexography that drive the use of

automation and shorter time frames between printing jobs. True press and print automation can only be done if the press operator prints to the numbers. Some of the lifting that used to be done in the press room needs to take place in the pre-media portion of any job through profiling, but also the press has to be set for printing at optimal print conditions.

Heidelberg’s hall was quite full the day I visited. Many people were talking with representatives from Heidelberg and a flair of excitement was in the air.

Heidelberg showed its Speedmaster XL106-8-P with UV LED curing, which is technology I saw at other well-know press manufacturers. It seems that UV LED, although not new, is to become more mainstream. On the XL 106, Heidelberg introduced the concept of autonomous manufacturing, printing one job after another with the operator there to stop the press, not to start it. Heidelberg calls this principle Push to stop. During the short presentation of the XL 106, three small jobs were completed. The operator only needed to take the plates from job #1 out from the automatic plate changer and load the plates for job#3 into the plate loading system. The press starts automatically based on the lined-up jobs. Of course, the main attraction for me in the Heidelberg hall was the Primefire 106, a digital inkjet press built in co-operation with Fujifilm. Heidelberg contributed the paper handling and coating unit, while Fujifilm provided its inkjet print heads. The showcased press was configured for 7-colour printing with expanded gamut and the print resolution is 1,200 x 1,200 dpi. One feature I liked a lot on this press is the fact that the operator gets a pulled sheet by the touch of a button on the control table.

Gallus showcased its Labelfire 340 which is based on UV-inkjet technology with in-line finishing. The press prints at 1,200 x 1,200 dpi with up to eight colours. The eighth colour is white plus CMYK and OGV. Again, expanded gamut printing is used. The print speed of the Labelfire 340 ranges from 50 to 150 feet per minute.

I walked onto the KBA booth when a demonstration of the Flexotechnica XD LR started. The common impression cylinder flexographic printing press showed that it is possible to print with water-based inks on clear PET film. The press can also be configured to run EB-curable inks. Another development from KBA, in co-operation with Xerox, is the 40-inch VariJET 106 for the folding carton market. This press prints at 4,500 iph and is geared toward short-run applications of folding cartons. The press can be configured with coating, cold-foil, rotary die-cutting, creasing and perforating units.

or less just pushes a start or stop button. The machine features a fully automatic plate loading and ejecting system. The imager can be combined with the XPS Crystal 5080 for the exposure of the plates. The unique feature of the plate exposure unit is that front and back exposure are done in the same moment through an exposure bar that travels over the plate with UV LED exposure for the back exposure.

Esko also introduced a combination of a robotic loading and unloading with a Kongsberg table for cutting and scoring. The unique thing is that the cutting table and robotic loading arm “talk” to each other, so both machines know what the other one is doing and do not try to execute conflicting operations.

Esko shared a booth with other companies now belonging to Danaher, including X-Rite, Pantone and Enfocus. Together with seven GCM students and six colleagues we had an extended tour of the booth. For nine out of 10 major brands, Esko solutions are used to produce packaging. One interesting new Esko product is the CDI Crystal 5080 imager, which can be used for HD Flexo and Full HD flexo plates. Esko has simplified the operation of this imager with a touchscreen mounted to the left of the device. The operator more

The German company Bobst might be familiar to most people for its die-cutting machines, but it also builds flexo and gravure printing presses. Bobst showed its M6 flexographic printing press for food packaging. The demonstrated press ran in extended gamut configuration with UV-flexographic inks. The press has two unique features, including tracking the curing of the UV ink after each print unit and the ability to change plate cylinders on the fly. The press has one plate cylinder in use, while the other one is in a waiting position.

When the operator presses the button for a complete plate change, the press slows down to make-ready speed and a system lifts the current plate cylinder into a storage position, while the other one slides into printing position. The automatic register control system adjusts the register quickly and

the press can ramp up to production speed. Bobst claims that the press has an uptime of 95 percent. After the new plate cylinders are in use, the plate cylinders from the previous job can manually be removed from the press and fitted with plates for the next job. This is a highly productive printing press.

The surprise of the show was the exhibit from Highcon, an Israeli company that has specialized in manufacturing 3D objects with the help of laser-cutting. Its machines can cut up to two-mm thick material. Depending on the machine type, the 3D object can either be manually assembled or the machine can do it for you. On display was a wine-bottle stand that took roughly 30 minutes to cut and assemble out of cardboard. The displayed wine stand was at least one metre tall. Trying to create the same item with 3D printing would have taking quite a number of hours. Highcon first introduced its technology to the print world at drupa 2012, but its products in 2016 made quite an impact on the visitors at the show.

Although it is simply impossible to see everything at the drupa there is always an overall trend most visitors get out of the show. For me, the overall trends from this drupa are: Print is alive and coming back strong, the how and when has changed, and digital printing is making strong inroads into the offset print market with increased print speeds and high quality.

It was great to attend drupa again and see where the printing industry is headed. Its landscape will become quite diverse, but it will still be print.

Tech giants make relatively small but important gains in toner, inkjet and wide-format hardware to enable printing companies to produce a larger range of print products with a single investment

By Zac Bolan

Advances in automation and digital print technology are driving the innovations being showcased on the drupa 2016 exhibition floor. While conventional offset technology perseveres in most high-volume print environments, significant gains are being made in digital print, large-format inkjet and digital finishing technologies. giving printers the ability to produce a wider range of products for their customers.

Since acquiring Xeikon late in 2015, the Flint Group has put the company at the heart of its recently formed Digital Printing Solutions division to expand its corporate focus into this burgeoning market. With the acquisition,

Flint expands its portfolio of digital printing solutions through a combined offering of hardware, consumables and services across its global markets. In its first major show since the acquisition, Xeikon has a major presence at drupa 2016 showcasing its first digital printing press using unique liquid toner technology.

The Trillium liquid toner printing process, debuted by Xeikon at drupa 2012, has been integrated into the Trillium One digital fourcolour web press being demonstrated at this year’s show. The Trillium One is the product of a joint venture between Xeikon and Miyakoshi, a leading Japanese press manufacturer. The new press is capable of running at 60 metres per minute at a resolution of 1,200 dpi across a 500-mm web. All print can be fully variable, and is dry to the touch and ready for post-

press production as soon as it feeds onto the takeup spool.

Agfa’s Tauro engine can include a ¾ automation package with board feeder and unloading unit.

To achieve this, the Trillium One relies on Xeikon’s Tonnik, a liquid toner that combines the advantages of a dry toner (economical and efficient) with imaging qual- ity that, according to the company, compares favourably to conventional offset technologies. Tonnik consists of very small toner particles (less than two microns) suspended in a high-viscosity carrier liquid derived from bio-materials. The press mechanically recycles the liquid while the toner particle accurately transfers from roller to substrate at very high speeds.

Xeikon is positioning the Trillium One to compete with the economy of offset litho for longer runs while offering all the advantages of digital printing such as variable print. The first Trillium One presses will ship from Q2 2017.

The company is also showing Fusion at drupa 2016 – another potentially gamechanging digital imaging technology. First demonstrated at Labelexpo last September, Fusion is aimed at the high-end label and packaging market. Xeikon’s Fusion Technology will be implemented through a number of modules released over time that add digital embellishing capabilities

to a Xeikon press. Fusion Technology will combine four-colour printing with a number of digitally rendered effects potentially including: hot or cold foiling; matte or gloss, spot or flood varnishes; and digital Braille. The advantages of producing these effects digitally through integrated embellishing modules include a high degree of automation and content variability – something unheard of with conventional finishing. While Fusion is initially targeting the label and packaging industry, it could really shake things up in the commercial print world.

Esko proclaimed its ‘Packaging Simplified’ mantra at a pre-drupa press conference held in Bruges, Belgium this past March (PrintAction, May 2016) as the company rolled out its latest software solutions. Now Esko is following through with some significant updates to its digital finishing workflow as well as Kongsberg cutting, creasing and milling table portfolio. By introducing the latest version of its i-Cut software suite for artwork preparation along with enhancements to Automation Engine and ArtiosCAD, Esko promises users greater throughput with significantly less operator intervention and a 50 percent reduction in training time. Meanwhile, the Kongsberg table collection has been simplified into two lines – Kongsberg X and Kongsberg C. The Kongsberg X product family is aimed at the prototyping market, and users requiring a great deal of creative control over the products they cut. The X tables come in a variety of configurations and offer the user an ability to add a range of creasing, cutting and milling tools to meet the needs of a growing business.

While the Kongsberg C line of tables is well known to existing packaging shops, Esko has extended the family to include a smaller table sizes aimed serving short run packaging and signage production needs. Wisely, Esko has configured an entry-level table for each line with as an upgrade path to reduce the capex for new players in the hot packaging industry.

A big problem with elaborate prototyping and production tables is the extensive amount of time needed to setup for a job. To address this, the new Kongsberg tables feature an Auto Adjust Tool with

camera inspection that adjusts tools at the start of each project and memorizes the settings for individual substrates in a comprehensive materials database. When changing configurations, the Auto Adjust Tool recalls and automates the setting for the new substrate – saving operator time and reducing spoilage. And according to Esko, new operators benefit by getting expert ‘advice’ from the Kongsberg system on how to setup the job and which tools to use, enabling efficient setups and changeovers.

Agfa’s Jeti and Anapurna solutions are well known in the wide-format and very-largeformat world of industrial inkjet printing. However, automation has always been a challenge, especially when dealing with printing on rigid substrates such as gator board. At drupa 2016, Agfa introduces the latest iteration of the VLF production workhorse – The Jeti Tauro, a six-colour UV inkjet printer sporting an elaborate ¾ automation package including a board feeder and unloading unit.

Seeing the automated Jeti Tauro in action is like watching a mechanical chorus line. A single operator can feed multiple boards onto the 2.5-metre-wide table where they automatically align before going under the inking print heads and coming out dry on the other side. The unloading table is equipped with multiple suction arms that lift the finished boards and stack them neatly offline.

Besides automating VLF, Agfa is moving online with the announcement of PrintSphere, its take on a cloud solution. In addition to standardizing data exchange, PrintSphere is being positioned as an answer for users needing secure back-ups of production databases for their Asanti, Arkitex and Apogee workflows – a necessity in this cloudbased world we live in!

Agfa also introduced its ECO3 initiative at drupa, which stands for “Eco-friendly, Economic and Extremely convenient.” Agfa has gone to great lengths to expand and improve its chemistry-free printing-plate applications with some new clean-out units for its VCF plates, and brand new Azura TU VLF chem-free plates for very large offset presses. On the thermal CTP side of the fence, Agfa launched its new Energy Elite Eco no-bake positive thermal plates promising

extended run lengths for both sheetfed and heatset web use.

In late May (just in time for drupa), X-Rite announced the next-generation of its noncontact, automated colour measurement solution – the IntelliTrax2. This new device still meets the demands of the sheetfed printer, but also has added capabilities to appeal to folding carton converters. The IntelliTrax2 now supports M1 measurement illumination conditions – in plain speak that means it can accurately measure colour on substrates containing optical brighteners, or printed with fluorescent inks. The system includes an integrated look-ahead sensor that automatically adjusts the scanning head to locate colour bars as small as two millimetres. In a nod to the burgeoning packaging printing and converting industry, the IntelliTrax2 can scan much thicker materials than its predecessor – up to one millimetre – and supports all the latest measurement standards in case your shop runs to G7 or FOGRA standards. According to X-Rite, the IntelliTrax2 can automatically scan a typical colour bar in less than 15 seconds while effectively measuring Pantone colours, PantoneLIVE colours, paper colour and, of course, process colours.

The potential to leverage Xeikon’s Fusion technology and print variable data in foil or varnishes in a commercial print environment will be too good to pass up for many still married to offset. And with the high-level of automation and ease of training promised under Esko’s Packaging Simplified mandate, the knowledge barrier is being lowered for adventurous commercial printers wanting to test the waters of the lucrative label and packaging industry.

Although legacy sheetfed and web offset configurations continue to dominate the commercial printing world – especially in large-volume and high-quality print and finishing applications – economical digital print and custom digital finishing technologies are moving to the forefront of the label and packaging stage. It won’t be long before these technologies find their way into commercial print and start eroding offset’s dominance.

Unveiled at drupa, German press maker KBA is working with Xerox to develop a new B1 sheetfed press, called the KBA VariJET 106, aimed at folding-carton printing. There are currently two such presses being developed at KBA’s German facilities and the company describes the program’s progress as being in the final stages of development. VariJET 106 combines offset printing and finishing technologies with inkjet technologies, the latter developed by Xerox, in a highly modular system that can be tailored for customer requirements, including optimized inline processes.

The press presentation via video at drupa included post inkjet options, double coating and drying, rotary die-cutting, pre-treatment and drying, corona treatment, offset units, opaque white and cold foil application. KBA explains the press is suitable for industrial production and can run a range of substrates. Described as “digital sheetfed for folding carton,” KBA expects the system to be complete in a few months for 2017.

The VariJET 106 is currently being put through its pacees at KBA’s German plant before beta site installs begin in 2017.

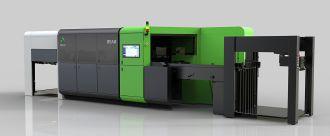

Unveiled at drupa, EFI’s new Nozomi C18000 can reach speeds of up to 75 linear metres (246 linear feet) per minute, producing up to 9,000 80 x 60-cm boards per hour using what EFI describes as a double-lane printing feature. EFI explains it prints up to seven colours, including white, at a 360 x 720-dpi

resolution, and can handle materials of up to 1.8 x 3 metres – and thicknesses up to triplewall board – at full rated speeds. Its LED, continues EFI, can image on just about any board substrate, including traditional Kemi, model, bleach and kraft materials. Packaging produced with the press, according to the company, is certified for repulpability and recyclability.

EFI’s new 1.8-metre-wide, single-pass Nozomi C18000 press for boxboard applications.

The new Xeikon 9600 press replaces the Xeikon 8600 as the company’s flagship production solution. The dedicated printer for a range of document printing and other applications delivers both standard and nonstandard formats combined with virtually unlimited print lengths. The one-pass duplex web-fed system is capable of speeds of up to 14.5 mpm (47.5 fpm) at a resolution of 1,200dpi with variable dot density. It integrates the variable-data capabilities of the Xeikon X-800 frontend and incorporates a 5th colour station for spot colour reproduction and security applications.

The Zünd D3 cutter is a new dual-beam system, largely based on the G3 series, aimed at high-volume, industrial applications. The company explains D3’s gains in productivity are primarily due to the series’ dualbeam construction: twin beams operating simultaneously in one production workflow, with each beam carrying up to three different

The Zünd D3 cutter features a unique dual-beam system, each handling three tools.

tool modules. The D3 systems are available in four different sizes ranging from the D3 L-3200 with a working area of 1,800 x 3,200 mm (71 x 126 inches) to the D3 3XL 3200 with a working area of 3,210 x 3,200 mm (126 x 126 inches). D3 cutters allow for the addition of new tools, modules or automated load/off-load devices. The system also leverages the Zünd Cut Center for production workflow.

HP’s concept PageWide C500 press is expected to reach beta in 2017.

HP unveiled the new PageWide C500 press, which is still under development, aimed at corrugated direct-to-board printing. The press will leverage 30 years of HP thermal inkjet technology and the company’s newer PageWide printing technology. HP explains the press will integrate into a standard production environment, from large integrated packaging converters with centralized or distributed printing, to small, independent sheet plants. HP plans to start testing the PageWide C500 Press at customer sites in 2017, and the press is expected to be commercially available in 2018. HP Corrugated Grip Technology allows customers to handle

a range of media from the lightest micro-flute to the heaviest double-wall board. Additionally, new water-based HP inks are designed for printing on the non-food contact surface of paperboard packaging and comply with global food safety regulations and industry guidelines necessary to produce foodcompliant packaging, thus allowing customers to capture more opportunities with leading food and packaging brands.

Xaar’s new 1003 family of print heads is aimed at industrial inkjet printing, which builds on the company’s preceding 1002 and 1001 products. Xaar explains the 1003 introduces an important new feature called the XaarGuard, which provides nozzle plate protection and, coupled with other design innovations, achieves what the company states to be the longest maintenance-free production runs in the industry. The Xaar 1003 was produced with the company’s new X-ACT Micro Electric Mechanical Systems (MEMS) manufacturing process, which was recently awarded Manufacturing Site of the Year by the National Microelectronics Institute.

The 1003 combines Xaar’s TF Technology and Hybrid Side Shooter architecture so that ink is recirculated directly past the back of the nozzle during drop ejection at high flow rates. This helps the print head operate reliably in the harsh environments. Ink is in constant circulation, preventing sedimentation and blocking of the nozzles when jetting. The 1003 will be available in three variants. The Xaar 1003 GS12 (rich colours or higher speeds) for ceramics applications is first to be launched, closely followed by the Xaar 1003 GS6 (for fine detail) and the Xaar 1003 GS40 (for special effects). The other variants for UV applications will also be available later this year.

HP unveiled its Indigo Combination Press, which is still under development, for unique label production. The press concept will incorporate HP Indigo print and digital

embellishments in one system, creating a single-pass solution for high-value labels and packaging production. As part of a dedicated line with an HP Indigo WS6800 press, this new digital combination concept, developed in alliance with JetFX, will enable the production of digital spot and tactile varnishes, digital foils, as well as embellishments of virtually unlimited designs made possible using HP SmartStream Mosaic.

Heidelberger Druckmaschinen is extended its digital printing portfolio at drupa 2016 with its new B1-format, inkjet-based system called Primefire 106. The inkjet technology was built leveraging Heidelberg’s offset technology and the inkjet developments of Fujifilm.

Heidelberg explains its core competencies of technologies like non-contacting paper sheet guide, feeder and delivery are incorporated into the system. Primefire 106 is aimed at short to medium production runs.

Prior to drupa, Xerox unveiled two new inkjet presses, including the Xerox Brenva HD Production Inkjet Press, which was made commercially available at drupa 2016, and the Xerox Trivor 2400 Inkjet Press, which is scheduled for a September 2016 release. Targeting a production gap between highend toner and low-end inkjet presses, the Xerox Brenva is a cut-sheet inkjet press that Xerox initially expects to disrupt light direct mail, transactional and book markets. The Brenva is to incorporate many of the paperpath components of the Xerox iGen press line, as well as an inline spectrophotometer to assist with calibration and profiling; object-oriented colour management to distinguish text, graphics and images; and a K-only mode to run as a cost-effective monochrome press.

The Xerox Trivor 2400 is a scalable continuous inkjet press initially targeting speeds of up to 551 feet (168 metres) per minute in colour and 656 feet (200 metres) per minute in monochrome. The smallfootprint press will initially be targeted at catalogues, magazines and colour books. A new print server developed in partnership with EFI, the Xerox IJ Print Server, will handle multiple data streams. Availability of the Trivor 2400 with the IJ Print Server will be revealed later this year. The Brenva HD will be available in North America in September 2016 as first shipments begin June 2016.

As of drupa 2016, Heidelberg is branding its entire digital printing portfolio under a standardized product line called Fire. As a result, the Heidelberg digital printing portfolio will have the following structure as of drupa 2016: Primefire 106; Versafire CP/ CV is the new name for the existing Linoprint CP/CV digital printing systems (launched in cooperation with Ricoh in 2011); Gallus Labelfire 340 is the new product name for the former Gallus DCS 340 for label printing; and Omnifire 250/1000 is the new name for Heidelberg’s 4D printing systems, replacing the former name Heidelberg Jetmaster Dimension 250/1000.

PrimeFire leverages offset-inspired innovations like non-contacting paper sheet guide, feeder and delivery.

CRON added two new plates to its portfolio at drupa, which are the result of two new production lines that were opened in 2015. The new plates are sold under the Blackwood brand, including the Blackwood Emerald UV plate designed to minimize the consumption of chemicals and water for UV exposed plates. With a ‘wash out’ bath, CRON states the plates are press ready in seconds and exhibit dot reproduction from 1-98% for either stochastic screening (20 micron) or conventional screening up to 200 dpi. Run length is up to 50,000 impressions without baking (20,000 for UV ink).

At drupa, Air Motion Systems introduced the new 100 percent LED UV Drip-Off, (Strike-Through) coating effect developed in conjunction with partners and recently proven for high-speed production printing on a KBA Rapida 106 6-Color plus Coater LED sheetfed press. The new process allows offset-based printers to achieve inline effects and contrast between gloss and matte images simply via the use of a litho plate and a coater. AMS explains gloss points of 90 and higher are achievable with a single LED lamp in a “wet-on-wet” process sequence, with a high-powered AMS XP9 Series LED UV lamp located in the delivery. AMS explains the new process runs counter to the idea that LED UV cannot be used for inline coating and finishing effects.

RISO’s new FW series is 33 percent slimmer than previous generations.

RISO’s new ComColor FW Series of inkjet printers is the fifth generation of cutsheet, colour inkjet printer. The FW series is 33 percent slimmer than previous models due to an integrated face-down tray, and it has a newly redesigned colour touch panel that is adjustable and customizable. The output of the FW series is 120 pages per minute in full colour. The scanner has likewise been improved for office use, and can scan both sides of a duplex document simultaneously, at a rate of 100 pages per minute.

Pulse is a B2, 29-inch cutting and creasing machine that holds a small footprint aimed at print service providers and converters with existing 29-inch-sheet workflows. Highcon explains its digital cutting and creasing technology provides an in-house controlled digital system that delivers improved

responsiveness, design flexibility and entry into a wide range of applications in numerous markets. Pulse supports substrate sizes from 320 x 457 mm (12.5 x 18 inches) up to 530 x 750 mm (21x 40 inches). It runs at speeds of up to 2,000 sheets per hour.

The Highcon Beam digital cutting and creasing solution, explains the company, extends digital finishing to mainstream production. With a speed of up to 5,000 sheets per hour, this variable data cutting machine was developed for folding carton converters and print service providers. It is meant to replace the expensive and slow conventional die-making and setup process. The B1 40-inch format system handles a substrate range from 120 µ / 5 point up to E-flute corrugated 2 mm 78 pt. It allows for a 3D Modeling Package (optional) and Highcon Axis Web-to-Pack Package (optional).

Highcon Beam features a speed of up to 5,000 sheets per hour.

In late-February, Fujifilm introduced its next generation 54-cm-wide LED-UV inkjet press, built around the company’s new EUCON technology, for flexible packaging. Fujifilm explains EUCON (Enhanced Under Coating and Nitrogen purging technology) is ideally suited for printing on the underside of flexible packaging. The proprietary EUCON technology in the new press is composed of three core components: a newly developed, high performance UV ink; a unique undercoating technology used to prevent ink bleed; and a Nitrogen purge technology, which is used to significantly reduce the characteristic odour of UV ink.

At drupa 2016, Canon highlighted its new continuous feed inkjet press called the ColorStream 6000 Chroma, aimed at commercial printing, which features the company’s new Chromera ink set for stronger

colour fidelity, wider gamut and higher optical densities. The high pigment load of the Chromera inks, explains Canon, extends the application range of the press to lighter weight media with reduced ink show-through, and allows for printing higher quality documents on uncoated or inkjet treated papers. The ColorStream 6000 Chroma offers running speeds from 48 metres per minutes to 127 metres per minute in full colour mode. while monochrome hits 150 metres per minute

Canon’s continuous feed ColorStream 6000 Chroma, aimed at commercial printing, features the company’s new Chromera ink set.

KBA’s RotaJET L digital press is described as a roll-fed inkjet press for the publishing and commercial printing markets. It has been expanded to print wider web widths and on a greater variety of substrates. The RotaJET series starts at a 30-inch web width and can be supplied by KBA in widths of up to 81 inches. The new KBA RotaJET L and RotaJET VL inkjet presses are both aimed at industrial application markets, while the latter is more conducive for unique applications like floor laminates. The modular RotaJET L platform is available in five different web widths from 35.2-inches to 51.1-inches and can be upgraded in the field. The RotaJET VL inkjet press is available with a printing width of over 5.2-ft or over 6.6 feet. Additionally, KBA explains it can be configured to suit all fundamental application areas in the highvolume digital printing segment. Retrofitting future generations of printing heads is also possible for colour content. KBA explains this allows users to react quickly and economically to changing demands without a need to invest in an entirely new machine.

MGI at drupa debuted a new system within its JETvarnish 3D digital enhancement product portfolio, called the JETvarnish 3D Evolution. The JETvarnish 3D Evolution is described as the world’s first B1 scalable sheetfed Digital Enhancement Press and features a modular

and field upgradeable architecture, digital foiling and an upgradeable inkjet expansion system with three available substrate size options ranging from 52 x 120 cm (20 x 47 inches), 64 x 120 cm (25 x 47 inches), as well as 75 x 120 cm (29 x 47 inches).

The B1+ size (29 x 47 inches) format option is designed to give printers and converters the ability to run fully personalized short, medium and long runs in a cost-efficient and “die-less” manner for packaging applications. Every piece finished on all of MGI’s JETvarnish 3D systems can be a unique blend of digitallyembellished images, text, data and brand designs using spot varnish, 3D raised varnish and digitally embossed foil in one pass. The JETvarnish 3D Evolution is described as a high-production system that incorporates pallet stacking, automated inkjet head cleaning, new automatic feeding, as well as a new artificial intelligence-based sheet registration system, all of which were launched at drupa 2016.

After its introduction four years ago in Germany, drupa 2016 marked the start of general availability of the Impremia IS29, Komori’s inkjet UV printing system. The Impremia IS29 is capable of printing on a range of stocks. By taking advantage of UV inkjet characteristics, Komori explains the system is suited for not only commercial print applications, but also package printing. Also being demonstrated on the Komori drupa stand is the new B1-size Impremia NS40 printing system that uses the branded Nanotechnology under license from Landa Corporation. Komori explains this new product will perform high-speed printing at 6,500 sheets per hour and is B1-size inkjet printing system.

On the offset side, Komori featured its new Lithrone GX40 with coater on its drupa stand, exhibited with optional accessories that include its PDF Comparator System,

Sheet Numbering System and automatic mask creation software for improved inspection efficiency in packaging applications. All offset presses on Komori’s show were equipped with proprietary H-UV curing system and demonstrated using K-Supply H-UV ink. Making its debut in Düsseldorf was the new Lithrone G29 29-inch offset printing press and the new Lithrone G37 for producing a 25 x 37-inch maximum sheet size.

Engineered for the packaging and converting industries, the single-sided B1 (41 inch/1,050 mm) format Landa S10 Nanographic Printing Press is designed for the production of folding carton, POP/POS and corrugated boxes. Landa states its S10 press prints 13,000 sheets per hour with off-the-shelf substrates.

With a crossover point of around 30,000 boxes and higher when ganging jobs or adding variable barcodes, Landa states the S10 provides a digital solution for more than 50 percent of all packaging jobs. Landa explains the press generates up to five times the throughput of other digital printing presses, provides plate-free printing for folding carton and boxes. The press also supports coated and uncoated off-the-shelf substrates, and delivers scalable printing from single copies to versioned jobs.

Landa explains its branded Nanographic Printing Process offers lithographic quality printing with the efficiency and versatility of plate-free digital printing. High-resolution ink ejectors deliver 1,200-dpi resolution in high coverage, multiple grey levels, and strong colour definition. Landa states images appear vivid, sharp, and uniform –similar to anything produced by an offset press. The Landa S10 press features an inline coating unit to enhance printed output using flood or selective coating of aqueous or UV materials.

Xeikon launched Trillium One at drupa with a liquid toner printing process first presented at drupa 2012. A joint development project between Xeikon and Miyakoshi, Trillium One is an LED-based system capable of running at 60 metres (200 feet) per minute at 1,200 dpi, with a print width of 500 mm (19.7 inches). Xeikon explains it combines cost-effectiveness, high quality and speed in a unique printing press poised to change the digital printing market. Direct marketing materials and catalogues have been identified by Xeikon as potential high-quality markets for Trillium One, with more targeted markets and applications expected to be added over time. Trillium’s level of quality is due its imaging heads (1,200 dpi) and the small toner particle size of less than two microns used in the Xeikon-crafted high viscosity liquid toner.

At drupa, Xeikon also launched its newly developed Flatbed Die-cut Unit, the Xeikon FDU, for end-to-end printing and converting of folding cartons. The Flatbed Die-cut Unit is designed for nearline finishing of digital work, but can also accommodate offset litho runs. This 2000-sheet-per-hour FDU system handles sheet sizes from 400 x 400 mm (15.7 x 15.7 inches) up to 530 x 1,000 mm (20.9 x 39.4 inches) and a maximum die cut size of 490 x 700 mm (19.2 x 27.6 inches). Substrate thickness can range from 160 to 890 micron for paper and carton board and also microflute corrugated board can be finished, making it suitable for completing both offset and digital runs.

Kodak at drupa debuted a range of new technologies, including its next generation inkjet platform called Ultrastream, a new NexPress ZX3900 press, cloud-based software packages, and new Sonora offset printing plates, among other technologies. Ultrastream, built on Kodak’s continuous inkjet Stream technology, is aimed at moving production inkjet into the mainstream of commercial and packaging printing. It will be showcased for the first time at drupa in an 8-inch configuration for label production, and feature what Kodak describes as a smaller drop size and precise placement accuracy for higher

resolution, clean lines and additional detailed definition. Ultrastream technology will co-exist in the market along with Stream technology to offer different platform options. Ultrastream’s writing system includes a modular print head that can be implemented in widths ranging from eight inches to 97 inches for different applications. Kodak explains it produces 600 x 1,800-dpi resolution at speeds of up to 150 metres per minute on a variety of paper and plastic substrates.

The new NexPress ZX3900 tonerbased press, which was running at drupa, has a delivery date aimed for early 2017. It supports thicker paper and the use of synthetic substrates, which can be leveraged for short-run packaging applications like labels, tags and small folding cartons, as well as differentiated commercial and publishing products. In conjunction with the NexPress ZX3900, Kodak also plans to preview a new NexPress platform that has not yet been unveiled. There will also be a new Opaque White Dry Ink for NexPress systems for the Fifth Imaging Unit.

Agfa Graphics introduced a new cloud-based data exchange service called PrintSphere as a standardized way to send and receive files within an existing Agfa workflow. This Software as a Service also provides Customer Service Reps with a dashboard to manage their customers and offers an overview of active jobs. When integrated with Apogee Prepress or Asanti, prepress operators can assign users to specific jobs. An automated

messaging system invites these assigned parties to deliver files for a particular job.

PrintSphere can also be used to create archives of previous jobs, available to select customers. PrintSphere is accessible through its Website Printsphere.com or via client applications for Windows, Mac and mobile. Uploaded data synchronizes with local folders, making files available on-site as well.

DALIM refers to the new ES 5 tool as its most-significant upgrade to date. ES (Enterprise Solution) is an integrated media production platform for the management of media services, regardless of final output –print, packaging, large-format, web, e-book, video, and more. As part its collaborative brand management capabilities, DALIM ES now offers the concept of Desktops, a fully customizable, branded Web portal. A new set of triggers and actions are available in DALIM ES including watermarking, to protect assets through a pattern overlay.

Plug-ins for integration into Adobe Creative Cloud add to enhancements such as digital rights management and a check in/ check out file sharing concept. A new DALIM ES 3D media viewer interface mirrors that of the DALIM DIALOGUE Engine.

Scodix introduced its new E106 enhancement press for the folding carton producers and converters at drupa. Offered in a B1 (1,060 x

760 mm) format and enabling production of up to 4,000 sph, the press is aimed at medium to short run lengths. The Scodix E106 press delivers effects including Scodix Sense, Scodix Spot, Scodix Braille, Scodix Digital Embossing, Scodix Variable Data finishes and Scodix Foil, all in a single press. The E106 foil system was developed for Scodix by Compact Foilers Ltd.

Printgraph and PCO introduced a new range of Finito products, underpacking for offset presses. Finito No Stop is a new blanket designed to reduce down time. Finito No Stick is a full range of versatile and ready-to-use coating plates. Finito Gold is a special blanket to give more brightness and precision to hot stamping units. Finito Dress is a self-adhesive transparent film to dress and protect printing machines – offset, digital, and flexo – from ink or glue stain.

Sibress of Germany introduced its enhanced FC3D system, which is a 3D measuring instrument for flexo plates. The MD3Dqc (white light interferometer), for measuring anilox or gravure cylinders and gravure plates, has also been enhanced with new software. Sibress is the producer of SibScope, a microscope with 2D and 3D measurement functions for examining objects such as anilox or gravure cylinders and gravure plates and analyzing flexo plates. Sibress also unveiled its compact PIT II inspection tool with measurement software to check print.

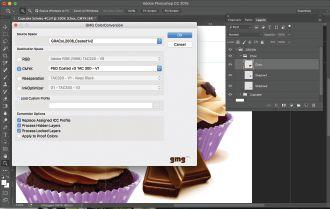

In May 2016, GMG released version 2.0.4 of its multichannel profiling software called OpenColor. The highlight of GMG OpenColor 2.0.4 is the ability to create separation profiles which can be exported to other applications. GMG OpenColor 2.0.5 will offer dot proof profiles for GMG proofing solutions. The variety of printing technologies, spot colours, substrates and inks provide challenges for proofing, GMG explains, especially with overprinting behaviour and the interplay of inks. To make proofing simpler, OpenColor calculates high-precision profiles and then transfers them to GMG ColorProof for printing.

Until this newest version arrived, the only way OpenColor profiles could be used was by creating proofs in GMG ColorProof. However, GMG now offers separation profiles from OpenColor 2.0.4 that can be used in a number of places: within GMG ColorServer, Adobe Photoshop, and within packaging software. For example, users of GMG ColorServer will be able to use more sophisticated profiles to convert RGB or CMYK images to CMYK with OpenColor separation profiles. GMG has concurrently introduced a plug-in that allows GMG separation profiles to be imported directly into Adobe Photoshop: GMG. With it, users can utilize GMG’s MX4 colour separation technology, including re-separation and ink optimization profiles, on the desktop rather than in a server based environment.

Roland DG launched what the company describes as its most advanced printer/cutter ever in the TrueVIS VG-640 and VG-540. These printer/cutters are equipped with four newly developed Roland DG FlexFire print heads to deliver droplet placement in three sizes and a 25 percent wider print swath compared to previous models. The combination of the new FlexFire head and new TrueVIS INK provides print speeds of up to 34.8 m2 per hour on banner in dual CMYK ink configuration. Available in 64-inch

and 54-inch models, TrueVIS VG Series ink comes in 500-cc pouches that fit into reusable cartridges, sliding into a hidden ink bay for clean operation with less waste. In dual CMYK configuration, up to one litre of ink can be loaded for each colour for high-volume, unattended production. A new, Bluetoothenabled Roland DG Mobile Panel allows users to remotely perform control panel functions with smartphones or tablets with iOS or Android operating systems. This innovative new feature provides a rich interface either directly on, or remotely in range of the VG.

HYBRID Software introduced its new PACKZ RoundTrip, which is based on the company’s native PDF editing software. PACKZ has more than 400 licenses sold during the first two years after its introduction. The new feature of PACKZ RoundTrip creates a two-way link between native Adobe Illustrator files and the industry-standard native PDF format. Using PACKZ RoundTrip, HYBRID explains even Illustrator files that are not saved with PDF compatibility can be opened and edited in PACKZ, then returned to the brand owner as a native Illustrator file containing all of the production features added using PACKZ, such as trapping, extended gamut colour mapping, step & repeat, barcodes, live or vectorized text, etc.

W+D launched a new envelope converting and finishing machine for commercial printers and mailers to convert short-run offset or digitally printed rectangular sheets into finished directmail envelopes. The 410 Easy Enveloper can produce 30,000 finished #10 envelopes with a window per hour (max. 500 epm). It can be driven with one operator, according to W+D, with no previous special envelope converting skills. Users can make a size change on jobs in 30 minutes or less. It features a compact layout (approx. 23 feet in length) with all machine utilities internally integrated, as well as inline finishing capabilities. It allows for automatically inserting RFID tags into the inside of an envelope as part of the inline converting workflow and to produce special shape envelopes with front and back windows or foil enhancements, all in line with no

secondary finishing processes. Easy Enveloper is the first product in over 10 years from W+D that addresses this issue, as well as the complexity of traditional envelope making.

The 410 Easy Enveloper can produce 30,000 finished #10 envelopes per hour.

Atlas Converting Equipment released its new Titan SR800 Series slitting & rewinding technology. The Titan SR800 Series is described as having both higher productivity and more flexibility for slitting and rewinding. In the development of the SR800, Atlas focused its product development on achieving significant reductions in machine downtime, including reduced set change time, lower operator intervention and also reduction of costly waste materials. The new system’s design is also focused on improvements in the quality of the final slit.

The Titan range includes the ER610, the SR9-DS and SR9-DT. The ER610 is a compact slitter rewinder with no hydraulics, meaning lower power consumption and risk of contamination.

Editor

Jon Robinson - jrobinson@annexweb.com 905-713-4302

Publisher Paul Grossinger - pgrossinger@annexweb.com 905-713-4387

Associate Publisher Stephen Longmire - slongmire@annexweb.com 905-713-4300

Media Designer

Graham Jeffrey - gjeffrey@annexweb.com

Director of Soul/COO

Sue Fredericks

Annex Business Media 222 Edward Street Aurora, ON, L4G 1W6 printaction.com 905-727-0077