Go beyond colour. Bring print to life with glittering golds, stunning silvers, vibrant fluorescents and versatile layers of white and clear. xerox.ca/beyondcmyk

59, No. 10 • printaction.com

The future of print looks bright 10 16 22 6

ISSN 1481 9287. PrintAction is published 10 times per year by Annex Business Media. Canada Post Publications Mail Agreement No. 40065710. Return undeliverable Canadian addresses to: Circulation Department, 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1. No part of the editorial content in this publication may be reprinted without the publisher’s written permission. © 2020 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada.

In a year plagued with change and uncertainty, these 30 significant moments made an impact on the Canadian print industry

How decorative embellishment can enhance perceived value

GAMUT

5 News, Calendar, People, Installs

TECH REPORT

18 A look at the latest releases in offset print technology

NEW PRODUCTS

19 Detailing new products from Brother Mobile Solutions, Scodix, Epson and Standard Finishing Systems

SPOTLIGHT

22 Irfan Rajabali, director of business development at E.B. Box

FROM THE EDITOR

4 Kavita Sabharwal-Chomiuk

The year in closing

CHRONICLE

8 Nick Howard

Cornering the market: Offset’s early attempt at mercantilism

INSIDER

14 Bob Dale

What a year it has been.

I think I can speak for many of us when I say I’m glad 2020 is finally drawing to a close. It has provided the world with more challenges than we expected and, in some cases, were able to handle.

Benefits Strategy & Benchmarking Survey revealed that moving forward, employers may look to implement more flexible total rewards strategies, policies and practices that can more easily align with trends in workforce interests and necessities.

Reader Service

Print and digital subscription inquires or changes, please contact Barbara Adelt, Audience Development Manager Tel: 416-510-5184

Fax: 416-510-6875

Email: badelt@annexbusinessmedia.com

The number of employers that modified their employee raise plans this year. 85%

The number of employers that expect to retain their work-athome policies following the pandemic.

It seems unlikely that even if we had known the pandemic were coming, we would have been able to prepare for a year that resulted in astounding loss of life, our economy grinding to a halt, and a sharp decline in employment. That doesn’t even include the changes we’ve had to make to the way we live our lives and do business – masking up anytime we’re in public; sanitizing every surface, including ourselves, several times a day; and keeping six feet away from others at all times. Seeing family and friends in person, travelling, even going to the grocery store has all been turned on its head.

Even our essential industry has faced some stumbling blocks. According to Alignable’s State of Small Business Report for November, small businesses in North America are, predictably, facing challenges. In fact, 43 per cent of the 8,092 small business owners surveyed are reporting that they’ve had fewer than 50 per cent of their pre-pandemic customers return, up from 35 per cent in Alignable’s previous report.

In order to balance the effects of the pandemic, nearly half of Canadian employers plan to modify salary increases next year due to continued economic uncertainty, according to a new study from Gallagher.

The 2020/2021 Salary Planning Survey – Canada Edition finds that 62 per cent of employers implemented pay raises before the pandemic. However, as the economic implications of the pandemic set in towards the end of Q1-2020, many organizations were forced to let employees go, implement hiring freezes and decrease salary-increase budgets. As a result, 38 per cent of employers indicated that not only did they modify their employee raise plans for this year, but that has carried over into 2021, as well.

As Canadian employers plan for 2021, the survey found that the economic impact of the pandemic is resulting in Canadian employers shifting their priorities to reducing expenses and focusing on financial stability.

Key findings from Gallagher’s

In many industries, full-time telecommuting reached 72 per cent by June 2020, and most employers (85 per cent) expect to retain their work-at-home policies following the pandemic for employees that prefer this arrangement. In addition, managers are now placing more importance on physical and emotional health, providing increased access to more flexible sick-day policies and personal-day allowances.

As businesses closed, the packaging industry experienced one of the few bright spots of business during the pandemic: increased demand as people were stuck at home, making purchases online. This extends to the flexible packaging and labelling industries, as they are part of the supply chain of basic necessities, according to a Memjet blog post on the impact of COVID-19 on the print industry.

Although many regions in Canada have now entered a second wave of the pandemic, we’re now more knowledgeable and better prepared to deal with what lies ahead. That resiliency is something special, and something we need to hold on to collectively. Looking forward to 2021, we’ll hopefully see the welcome news that this pandemic is finally beginning to wind down, or at least, governments and people will be better-equipped to handle whatever comes next. Come what may, we can count on the fact that we will adapt to the challenges ahead.

In that light, this issue, we reflect on the year 2020 and its impacts on the print industry, both positive and negative (p. 10). This issue also features an article on how decorative print embellishment can enhance the perceived value of a project (p. 16), and a Q&A with Irfan Rajabali, director of business development at E.B. Box, on what initially drew him to the print industry, and his suggestions on how to attract the next generation of talent (p. 22).

Until next time, stay well.

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor

Kavita Sabharwal-Chomiuk kchomiuk@annexbusinessmedia.com 437-220-3039

Contributing writers

Bob Dale, MGI/Konica Minolta, Nick Howard

Media Designer

Lisa Zambri lzambri@annexbusinessmedia.com

Account Coordinator Alice Chen achen@annexbusinessmedia.com 416-510-5217

Group Publisher Diane Kleer dkleer@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Subscription rates

For a 1 year

subscription (10 issues): Canada — $43.00 +Tax Canada 2 year — $70.50 +Tax United States —$98.00 Other foreign —$191.00 All prices in CAD funds

Mailing address

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 printaction.com Tel: 416-442-5600 Fax: 416-442-2230

Annex Privacy Officer Privacy@annexbusinessmedia.com 800-668-2384

PrintAction is printed by Annex Printing on Creator Gloss 80lb text and Creator Silk 70lb text available from Spicers Canada.

ISSN 1481 9287 Mail Agreement No. 40065710 KAVITA

Two Ryerson Graphic Communication Management (GCM) students, Dorotea Bajic and Laura Rendell-Dean, earned the top spot in the Paperboard Packaging Alliance (PPA)’s Student Design Challenge. This marks the first time Ryerson students have achieved a top-three result in the competition, and also the first time a Canadian project has won the challenge.

This year’s design challenge was to create an educational package for Trees Into Cartons, Cartons Into Trees (TICCIT), an outreach and educational program developed by the Packaging Paperboard Council. The program aims to educate school-aged children on the renewability and sustainability of paper and paperboard packaging by promoting it as sustainable packaging material and emphasizing the importance of recycling.

“Our idea started by taking the TICCIT logo and turning it into this three-dimensional hexagon box that would include many touchpoints to suit different types of students. The package was for children aged 8-10, so hands-on learning would be key for their engagement,” Dorotea and Laura explained on a Ryerson GCM Instagram post.

The final product, the Education Crate, is a ready-toship package containing education materials and interactive activities, a

sampling carton dieline from TICCIT and planting instructions. The final design was required to promote brand recognition and the TICCIT program, be commercially viable on standard machinery and highlight paperboard packaging as a preferred substrate.

This competition marks the second international packaging competition win for Ryerson GCM this year.

Following Pacific Bindery Services Ltd. (PBS) ceasing its operations in September 2020, Burnaby, BC-based Mitchell Press (Mitchell) acquired key equipment, experienced personnel, capabilities and trademark rights. Now, Mitchell is launching an independent trade-specific finishing division, called “Pacific Bindery, a division of Mitchell.”

According to Scott Gray, Mitchell’s VP of sales and marketing, this move provides Pacific Bindery with complete independence from the rest of the company’s commercial

operations.

“It is our intent to continue to provide British Columbia and Alberta print communicators the same level of service, confidence and quality finishing they have grown to expect,” he said. “Some of the services that will be provided include perfect binding (digital and offset), saddle stitching, coil and wire-o-binding, cutting, folding, glue-folding, tipping, shrink-wrapping, padding, drilling and neighborhood mail preparation for commercial print communicators.”

Gray went on to add that the company now has the benefit of complete manufacturing independence, which allows them to reduce their client’s carbon footprint, expand their options, and keep costs predictable and under control.

The Printing House Ltd. has launched its Give Love, Give Back Campaign, which donates 10 per cent of every holiday product purchased at its 70 company-owned stores Canada-wide to The Hospital for Sick Children (SickKids). The donations will go towards SickKids Foundation’s campaign to build a new hospital.

TPH’s holiday gift collection includes customized apparel, ornaments, puzzles, wall art and stocking stuffers. The company has also created custom-made CARE packages for corporate brands to help businesses show appreciation for remote workers and loyal customers.

Multipanel UK is partnering with a network of Canadian

distributors to carry its Alupanel and Steel composite panels. The panels, produced in the UK, offer one of the widest ranges of ACM colours and finishes available and have become a sought-after material in the sign, display and architectural industries.

The Multipanel range includes Alupanel, which has a 0.3 mm aluminium skin, can be easily fabricated, folded and formed, and is available in a wide range of colours including brushed and metallic finishes. Also available is the print panel A-Lite Digital and Multishield, a magnetically receptive steel composite that is available with dry wipe or digital print coatings.

IMAC, one of the first companies to exclusively sell and service wide format printing systems across Canada, has merged with DNA Fabric & Graphic Supplies Inc., a wide-format fabric and traditional print media provider, effective Sept. 1, 2020. The new name for the combined organization will be LUX – Wide Format Everything!

“This merger will allow IMAC to expand into the emerging custom fabric décor and soft signage markets,” said Al Whittaker, president at IMAC.

“This merger will make the two companies significantly stronger,” added Aki Singh, director of DNA Fabric & Graphic Supplies Inc. “We can offer current and new customers quicker response times, a wider range of products and a better overall customer service experience.”

The Printing House’s Give Love, Give Back Campaign will see 10 per cent of holiday product purchases donated to The Hospital for Sick Children.

Fujifilm Canada Inc. has named Martin Boucher as its new director of sales for the company’s Graphic Systems Division. Martin has over 25 years of experience in the printing and graphics industry, and has held roles at the Canadian Professional Sales Association and Ricoh Canada.

In this role, Martin will be responsible for leading sales strategies, ensuring customer satisfaction and driving the continued sales growth of graphics products throughout the country.

Zund America, Inc. has appointed Bill Richards to the position of sales director, responsible for the U.S., Canada and Caribbean. Bill has over 20 years of sales and sales management experience in manufacturing workflows, digital cutting, software design and enterprise solutions.

In this role, Bill will manage Zund America’s inside, outside and strategic account sales team with a focus on driving both direct and channel sales in the graphics and packaging segments.

Koenig & Bauer Flexotecnica has named Daniel Vilchez as its area sales director for North America and Latin America. In this role, Daniel will be responsible for sales and business development, providing his expertise to the firm’s range of flexography presses and its service support.

Prior to joining Koenig & Bauer, Daniel managed his own company that worked with some of the biggest suppliers in the flexo industry.

Domino has promoted Matt Condon to the role of business development manager, corrugated. A Domino employee for over 10 years, Matt has held roles as project manager, product manager and, most recently, OEM manager.

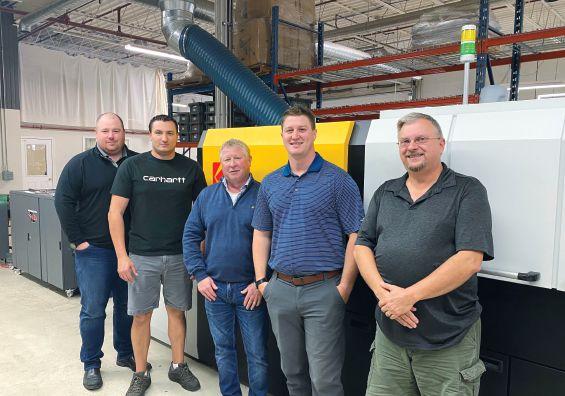

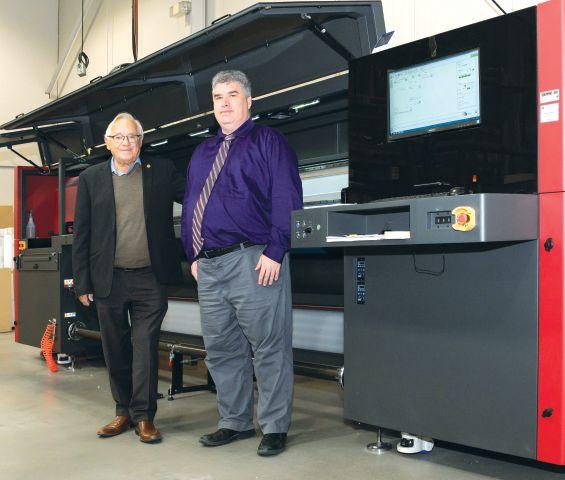

A Lowe-Martin branch in Mississauga, Ont. has upgraded its wide-format services with its recent installation of the Agfa Jeti Tauro H2500. The printer provides the branch with the latest UV flatbed printing technologies to deliver quality print on a variety of materials, ranging from rigid substrates to window clings.

Printing of St. Thomas, Ont. is the first Canadian printer to install a Kodak Nexfinity digital press. Within weeks of installation, the shop noted a 40 per cent increase in speed and improvements from the extended sheet size and other features.

Dale Rawhoof has been named Domino’s technical product manager, corrugated. Company veteran Dale has held various roles at Domino, including electrical technician, technical trainer & application specialist, project manager and product manager, for 31 years.

Winnipeg, Man.-based Intergraphics

Decal Ltd. is the first company in Canada to acquire an EFI Pro 32r Plus wide format printer. With this installation, Intergraphics says it expects to triple its current output capacity of large format materials.

March 9-12, 2021

FESPA Global Print Expo 2021

Amsterdam, The Netherlands

April 15-17, 2021

Graphics Canada Mississauga, Ont.

April 20-30, 2021

drupa 2021 Düsseldorf, Germany

June 8-10, 2021

Labelexpo Americas 2021 Chicago, Ill.

June 8-10, 2021

Brand Print Americas 2021 Chicago, Ill.

June 10, 2021

DIA Annual Golf Tournament Aurora, Ont.

August 12, 2021

OPIA Toronto Golf Classic Brampton, Ont.

Sept. 9-11, 2021

Sign Expo Canada 2021 Mississauga, Ont.

Editor’s note: Please note, we’ll be postponing the Canadian Print Awards until further notice. However, we’ll still be accepting your submissions produced from August 31, 2019 to August 31, 2020 once nominations open. Please stay tuned for more information!

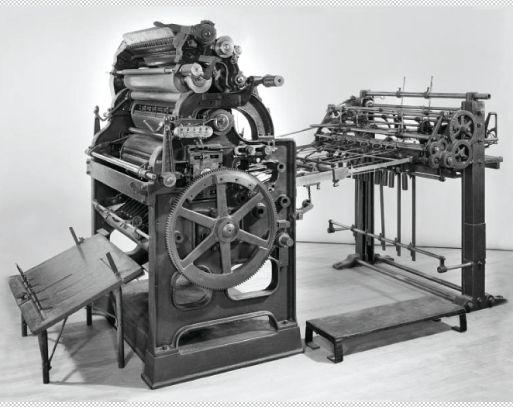

By Nick Howard

Ira Washington Rubel was a born salesman; he could spot a winner with just a glance. Having passed the bar in Chicago, Rubel ran his own print shop in Nutley, NJ. The business was booming, and Rubel ran several Direct Rotary Litho presses, which used zinc litho plates directly transferred to paper. Rubel also owned a small paper mill producing cheap sulfate paper used to gang-run bank deposit slips on large sheets, thereby destroying the competition. One day a sheet was miss-fed, and to everyone’s surprise, the wrong-reading image had transferred to the cylinder tympan with more superb quality than printing directly to paper. This would become the Eureka! moment that would change everything. Rubel studied the tympan in greater detail, and as if he was looking through the form, he realized something magical just happened. Rubel knew what he needed to do: design a new printing press using a new technique with three rotary cylinders. The year was 1904.

Only the Rubel discovery wasn’t so new. Since Austrian/ German Alois Senefelder’s accidental discovery of lithography in 1800, lithography using Bavarian limestone had been

discovered, yet developed very slowly. It wasn’t until 1821 when Barnett & Doolittle opened shop in the U.S. that the Americas even had a practical stone printer. The real Eureka! moment actually arrived in 1875, when Englishman Robert Barclay invented what would be true offset. Barclay was a metal decorator, and his new machine featured an extra cylinder with specially treated cardboard as the transfer medium. Nobody ever thought to attempt printing on paper other than tin printing (printing on steel sheets). At least, until the little mishap in New Jersey at Rubel’s Litho-Print Company 30 years later.

Rubel got busy. He hired an engineer who designed a single-colour 36” with three cylinders (plate, blanket and impression) of the same diameter. A suction pile feeder supplied by the E.C. Fuller Co. of NewYork was added. Word spread throughout the United States that a newfangled contraption had been invented that just might make letterpress redundant.

The Jenison C. Hall printing company of Providence, RI had expanded and opened up an office in San Francisco in 1887. But J.C. Hall, a big player in

producing bank stationery, farmed out all their lithographing to New York’s Schmolze & Hildenbrand printers. J.C. Hall’s west coast plant would soon be renamed the Union Litho Company. Luckily, the Spanish-American War proved a boon to Hall, since they were in a select group of seven contractors appointed in 1898 for imprinting stamps on checks. In 1905, Hall’s owner, Bert Hubbard, contacted Rubel and requested a visit to see the press as he heard whisperings about the Rubel machine.

Under a cloud of secrecy, Rubel agreed, and the two met in the confines of the Eastern Lithoprint Co shop in New York City. Until then, nobody from the east coast was allowed to see the new machine. Hall’s plant in San Francisco apparently wasn’t a problem, and at this meeting, Rubel agreed to sell J.C. Hall two offset presses for a sum of $11,000. ($325,000 today). Considering a typical flatbed letterpress cylinder was selling for $1,500, one can sense the excitement of owning a true offset press. One press was delivered just as the San Francisco earthquake of 1906 struck

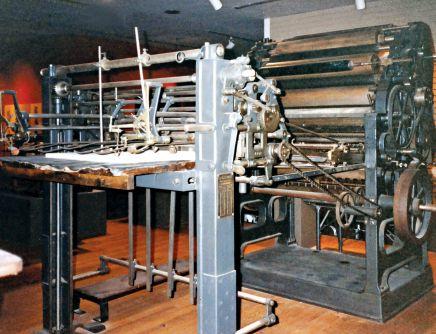

northern California, but luckily, the press was still sitting at an Oakland transport depot and was undamaged. Once installed, the press took months to get going, and Ira Rubel’s brother, a mechanic, was put in charge of the installation. This press is now at the Smithsonian Museum.

The same year, Ira Rubel announced that he was forming a joint venture with a Chicago printer, Ike Sherwood, and the new entity would be called the Sherbel Syndicate. Ike Sherwood had many reasons why he didn’t want any other printer in Chicago to get the offset advantage over him: mainly, Charles Goes of the highly-respected Goes Lithographing Co. As partners, Rubel and Sherwood laid a plan and announced they would grant only eleven printers the “opportunity” to purchase the Sherbel offset press.

Oddly, Rubel attempted to register a U.S. patent for his invention, but was stifled. The Patent Office ruled that “offset” was already an accepted art since the metal decorating industry (printing on metal) had been using the technology for at least 30 years.

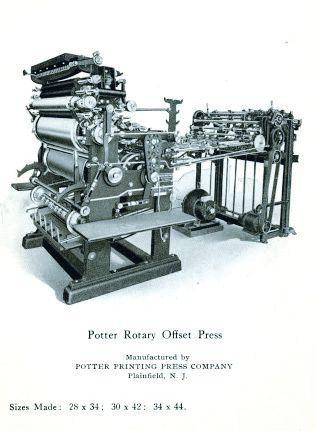

Initially, the two partners would be introduced to machine builder Andrew Kellogg. Kellogg manufactured his press in New Hampshire but soon left the partnership, leaving Rubel and Sherwood to fend for themselves. Money was tight and the iron casting foundry would not release any materials until paid in full. The syndicate was in serious trouble. Sherwood went to the Premier-Potter Ptg Press Co. of Plainfield, New Jersey, for assistance, and Potter agreed to build the Rubel press going forward. Sherwood’s partnership with Potter ended the syndicate, and in 1906, Rubel found himself in England. Although his

many stories have managed to live on, one trait stands out: Rubel, with his derby hat, was a born salesman and a hustler; he just couldn’t run a machinery enterprise.

Howard took this photo of the Rubel offset press at the Smithsonian’s American History Museum in 1988.

In England, Rubel contacted the well-respected printing machine builder Waite & Saville of Otley. The two worked a deal for the Rubel to be manufactured, but Rubel was still contacting other manufacturers.The George Mann Co. in Leeds came into possession of various sketches and print samples left at Rubel’s hotel and quickly decided they too would manufacture a press of their own design. Rubel would die virtually penniless of a stroke while still in England in 1908.

lesson for today, especially in world trade, where threats of duties and restrictions negatively impact all human beings.

Back in the United States, Potter Ptg Press Co. was busy working the kinks out of the original Rubel press and stepped up production to become the first offset press manufacturer in the world. Ripples of interest turned into torrents when the Harris Automatic Press Co. modified a 30” rotary letterpress (the S4) and turned it into an offset (S4L). Several others, including the Andrew H. Kellogg Co., who was an early participant with Rubel, the Hall Printing Press Co., Walter Scott & Co., and the R. Hoe & Co. entered the fray with various models of their own. Hoe and Scott both pushed hand-feed presses, while the rest had aligned with some of the suction feeder firms such as Fuller and Dexter.

As we now know, Harris received the most significant life changing benefit of offset, but Potter was not far behind. In the United Kingdom, Potter held a premier position in offset presses for over 19 years, before finally being engulfed by Harris in 1927.

This short review of the dawn of the offset press has been repeated many times. However, what has not been discussed are the mistakes both Rubel and Sherwood made in attempting to “corner the market” on a blazing new technology. Provided that Rubel was able to finagle a U.S. patent, would he have been able to decide who he would sell to? The answer is absolutely not. Somehow any new technology will find its way to market: either through the inventor or by reverse-engineering. The Sherbel Syndicate fiasco is still a

In this year of remarkable events, current offset manufacturers have either learned from Sherbel or not. I think for various reasons, they have. Print technology’s future is not going to be offset, but imminently starting to look a lot like the hybrid offset/ digital processes are being intertwined. Koenig & Bauer is putting resources into new platforms. The Delta SPC 130 FlexLine Automatic is a joint venture with the Italian inkjet company Durst. Although specified for corrugated, the press combines tried and tested elements of K & B’s sheet handling and coating technology with Durst’s inkjet platform. The VariJet 106 is a further example, for paper and carton, using Fujifilm Dimatrix Samba inkjet heads. Komori decided years ago that ignoring the higher-tech digital manufacturers might be a mistake. Komori’s partnership with Konica Minolta for a smaller inkjet press, and more recent association with the Israeli firm Landa Digital, sends the same message. At one time, offset manufacturers turned up their noses at the smaller toner and inkjet suppliers, as if these digital guys were annoying, but never a threat. Today the tables are turned, and offset presses are starting to embrace digital.

Starting from scratch has a massive cost if anyone not already in the game wants to attempt a new inkjet alternative. The only ones that can do this are companies that have already spent the R & D money and have the resources, engineers and scientists already deployed.

The lessons of controlling production and deciding what a printer gets to buy are long gone. The printing industry has very little time to think long-term. The Sherbel disaster, had it played out differently, would have left more of us remembering Ira W. Rubel’s name.

NICK HOWARD, a partner in Howard Graphic Equipment and Howard Iron Works, is a printing historian, consultant and Certified Appraiser of capital equipment.

nick@howardgraphicequipment.com

In a year plagued with change and uncertainty, these 30 significant moments made an impact on the Canadian print industry

By Kavita Sabharwal -Chomiuk

020. What a year it has been!

2I’m sure many of us are glad to see the back of this year, and are full of hopeful wishes for a safer, less-stressful 2021. In this fluid year of ups and downs, we’ve compiled a list of 30 significant moments (in rough chronological order) that have made an impact, good or bad, on the state of the Canadian print industry.

In January, Mitchell Press acquired the assets of North West Book Operating Company of Bellingham, Wash., which closed in December 2018. The deal allowed Mitchell to bring perfect binding services inhouse, expanding its book-making and custom fabric-wrapped box

fabrication capabilities.

In January, Spicers Canada acquired the assets and business of All Graphic Supplies, expanding its position in the distribution of wide-format and digital equipment, supplies and ink. All Graphic Supplies is operating as an independent division of Spicers Canada.

This year, Roland DGA Corporation named Kelowna’s CanCADD Imaging Solutions as its newest Canadian authorized reseller. CanCADD is offering the complete line of Roland colour products to customers throughout British Columbia.

Cascades named one of the world’s most sustainable

Cascades was ranked 49th on a list of the top 100 most sustainable corporations globally from Toronto-based Corporate Knights. Cascades was the only entry in the Containers & Packaging category.

In February, Crawford Technologies acquired Composition Research Technologies Inc. (CRT), a developer and marketer of technologies that recognize, compose, transform and archive high-volume transactional documents. CRT is now operating as a wholly owned subsidiary of Crawford Technologies.

In March, most provinces ordered all non-essential businesses to shut down in an effort to help prevent the spread of COVID-19. As the months progressed, many businesses gradually reopened as regions went into Stages 2 and 3, however a second wave that started up in early fall has hampered reopening efforts in several regions. The print industry was deemed essential, but that did not stop business from slowing considerably, due to other industries that work with print being shuttered for the time being.

In an effort to prevent Canadians from experiencing loss of income as businesses closed, the federal government launched the Canada Emergency Response Benefit (CERB) for Canadians that lost their incomes due to COVID-19. It also launched the Canada Emergency Wage Subsidy to help companies avoid laying off employees during the pandemic, and provided rent relief for small business affected by COVID-19.

After 60 years in business, Canada’s flagship national Jewish newspaper, the Canadian Jewish News, closed, ceasing both its print and online editions. In an official statement published on its website on April 6, CJN cited COVID-19 as the cause for the shutdown.

At the start of the shutdown, Markham, Ont.-based PCL Graphics converted into a PPE safety supplier in an effort to help fight COVID-19. At the time, the company switched over its printing facilities to mass-produce wearable face shields, masks and large screens.

In May, Great Little Box Company (GLBC) announced that it had acquired Ideon Packaging, a custom packaging company.The acquisition brought together two independent, locally-owned businesses, after talks of uniting began in late 2019.

In May, RM Machinery was named North American distribution partner for Miyakoshi Digital Inkjet label and book presses, Bottcher America Corporation’s printing rollers, blankets and chemistry solutions, and Horizon Print Finishing Solutions’ folding, binding, stitching and rotary die cutting solutions.

Printful, an on-demand fulfillment company, announced plans in May to open a 2,900-square-metre facility in Mississauga, Ont., with production expected to start by the end of 2020. This is Printful’s first Canadian facility and seventh worldwide. The company is planning to grow its Canadian team to 50 people in its first three years of operation.

In an effort to help the print industry recover amid COVID-19, in June, SinaLite launched its Bounceback

Resource Center, a page on its website that houses a number of timely resources that are free to download and use. The resources include sell sheets, product images, webinar recordings, product guides, how-to guides and useful links.

4over announced the permanent closure of its Mississauga plant in June, as part of the company’s North American restructuring plan. The 36,000-square-foot plant housed about 55 employees. Staff had originally been temporarily laid off in March, but in June, the company made it official that the closure was permanent.

Komcan

sole

Komcan Inc. has been named the sole authorized distributor of MBO equipment in Canada. The agreement is to include sale of equipment, parts supply and service of the MBO line of equipment.

In May, 30-year industry veteran

Steve Klaric joined RM Machinery as Canadian regional sales manager. He will lead RM Machinery’s recently-opened first Canadian office in Mississauga, Ont.

Image360, a franchise concept for the sign and graphics industry, is expanding throughout North Amer-

ica with two new locations in Calgary, Alta. The new Image360 centres provide a comprehensive range of graphic solutions services to the local business community.

In July, Fujifilm Canada Inc. promoted Stephane Blais to the newly-created role of vice president, graphics systems and technical services divisions. In this role, Stephane drives greater efficiency and teamwork across both divisions.

In July, Bellwyck Packaging Solutions announced it had installed two first-in-Canada presses: the longest Heidelberg Speedmaster CX 102 press in Canada, as well as the first Mark Andy Digital Series HD Hybrid Press.

Before COVID-19, the idea of a virtual event was practically unheard of, especially as far as large-scale trade shows went. Now, they’re standard, with events from Heidelberg, Koenig & Bauer and other OEMs taking place to showcase new innovations, along with trade shows and conferences like Printing United, all in a virtual format.

Rootree Inc., a company specializing in sustainable digital flexible packaging, has opened a second location in Montreal, Que., and has moved its company head office from Hamilton, Ont. to a 50,000-square-foot space in Burlington, Ont.

Canon Canada Inc. has appointed Naoki “Mike” Sannomiya as senior

vice-president and general manager for the company’s Business Information Communications Group. In this role, Naoki is responsible for the Business Information Communications Group’s various channels, sales groups and product lines.

Hemlock Printers and PDI Group formed a partnership to acquire Burnaby, B.C.-based PrismTech Graphics, a wide format and specialty printing company. The PrismTech team and brand will be retained under the new ownership.

As virtual events gained steam, several major OEMs decided that they would not be participating in the upcoming drupa show, which is set to take place in April 2021 in Dusseldorf, Germany. OEMs that have withdrawn their participation include Heidelberg, Manroland Sheetfed, Komori, Screen GA, Kodak, EFI, Ricoh, Canon, Konica Minolta and Dupont Image Solutions.

Canadian book manufacturer Marquis has announced two significant investments at its Toronto plant. Marquis has invested in a reconditioned Timson press, its ninth offset rotary press in operation. It has also upgraded servers and colour controls for its HP T300 and HP T360 rotary inkjet presses.

Hemlock Printers has teamed with Rolland, a Quebec-based mill to further expand its ZERO Carbon Neutral Printing Program with the addition of Rolland Enviro 100% PC, an FSC and Ancient Forest Friendly certified 100 per cent post-consumer waste paper.

TC Transcontinental Printing has invested over $10 million this year into its book printing platform in Québec, mainly at its Transcontinental Interglobe plant in the Beauce region. Most of the investments were used to purchase robotic equipment installed in the binding and bagging departments.

Neschen Coating has announced the launch of its new U.S.-based segment, Neschen Inc. As part of the company’s entrance into the North American market, Neschen Inc. has appointed Treck Hall Wide Format as its Canadian dealer.

This year cancelled our plans for us, so we fought back with the introduction of fully virtual events.

Emmerson Packaging invested $10 million this year in new equipment for its Amherst and Belleville facilities, in addition to the hiring of over 80 new employees.

CCL Industries has signed the New Plastics Economy Global Commitment led by the Ellen MacArthur Foundation. The foundation is dedicated to accelerating the transition to a circular economy by designing out waste and pollution, keeping products and materials in use, and regenerating natural systems.

Transcontinental Inc. has announced that it is closing its last printing plant in Winnipeg, Man., which currently employs 93 workers. The plant, which prints magazines and flyers, is scheduled to shut down by 2021, although workers will be let go as the work load lessens.The workers at the plant are members of Unifor Local 191.

This fall, PrintAction launched the Champions of Print Awards, designed to recognize individuals or companies in the Canadian print industry that have made a significant contribution to their community or been innovative to meet community or Canadian needs during these unprecedented times.

We are thrilled to present the winners of the 2020 Champions of Print Awards. Please join us in congratulating:

Produced 100,000 face shields, donating 4,000 to local hospitals. Remainder for public and private sector requests. Produced 300 sneeze guards. Retooled Esko cutting table to create this PPE.

Retooled various machines to start producing PPE, social distancing guards, office dividers, hospital beds and more. Developed a hand sanitizing line.

Retooled machines and started producing shields using donations from a GoFundMe they launched, distributed shields to hospitals and long-term care homes. SinaLite

Launched ‘Bounceback Resource Centre’ featuring information on webinars, cold-call strategies, industry product guides to help printers bounce back.

Each winner will be sharing their stories in a new PrintAction podcast series. This series will begin on December 14. To receive a notification for each of the podcasts, subscribe to the PrintAction e-Newsletter at PrintAction.com – Click on the Subscribe button.

SPONSORED BY

With programs and initiatives to recruit young workers to the print industry, it has a bright future

By Bob Dale

ith everything that’s in the news today, it’s natural to have concern for the future. Pre-pandemic, one major concern for the industry was recruiting new talent, but as work in the industry returned to normal levels, this issue has not changed.

While overall industry employment has declined in the past 15 years, it is projected that:

• The rate of decline is expected to flatten for the next 10 years.

• Skilled trade workers are retiring faster than they are being replaced.

• The packaging industry will experience significant annual growth.

• There will be an increased need for higher skilled workers with new technology.

• There will be a greater need for knowledge workers as communication channels become more integrated.

• The majority of graduates from post-secondary programs that provide industry-specific training will continue to receive multiple job offers and higher compensation rates. While government programs have not continued to assist in recruiting more skilled and talented workers, other organizations are doing something positive to help the industry.

Canadian Print Scholarships

Under the direction of Chair Jeff Ekstein and the board of trustees, the Canadian Print Scholarships initiative, run by the Canadian Printing Industries Scholarship Trust Fund, works hard to help students attending post-secondary institutions across Canada. Currently it supports nine institutions across the country.

The total value of the scholarships issued is regularly between $75,000 - $100,000 per year. It is funded by industry sources and donations. There are many success stories from students who have received financial support through this great program.

Another initiative that provides print industry skills training is Eva’s Print Shop, run by Eva’s Initiatives in Toronto. This program was started in partnership with Eva’s Initiatives and Rotary Club member Doug Dempsey, founder of Delta Web, in the 1990s and has continued with industry, corporate and charitable support.

Eva’s Phoenix is an emergency facility that provides homeless youths with shelter, transitional housing and programming to help young people build brighter futures free of homelessness. It provides the tools to transition out of homelessness permanently and collaborate and innovate to end youth home-

lessness.

The Phoenix Print Shop offers a Graphic Communication and Print Training Program, designed to provide homeless and at-risk youth with career preparation support and skills training to help overcome barriers to employment and access entry-level jobs in the print industry, which will allow them to secure housing and transition to independent living.

The Phoenix Print Shop seeks commercial work to help prepare youth experiencing homelessness for employment in the graphics and print sector. The organization reinvests every dollar of profit into shelter, food, caring support and basic needs for homeless youth.

While we can’t underestimate the challenges faced by the industry due to the economic impact of the pandemic, we also can’t forget that there is a bright future for the graphic communications industry and we need young, talented people to join us in this rewarding and exciting industry. There is sure to be bright future.

Bob Dale is Vice President of Connecting for Results Inc. Bob has many years of graphic communication management experience, including over 15 years offering management consulting services, transition execution and support.

By

As human beings, the physical, biological vehicle of our bodies helps ground the sensory perception that fuels our minds. From a consumer marketing perspective, the rise of new digital “haptic printing” techniques are creating exciting and powerful methods of promoting brand messages and building customer relationships.

The word “haptics” describes the stimulation of the senses, primarily by the perception of physical characteristics. In our increasingly data-driven world and electronic era, we are all confronted daily by the continual and constant communications displayed on computer screens and mobile phones. This visual barrage of data can create a weariness of information fatigue. However, our thoughts and feelings will always be most dramatically impacted by the power of touch. This is the reason why the physical aspect of “haptic printing” offers

such an inspirational and hopeful future for consumer marketing professionals.

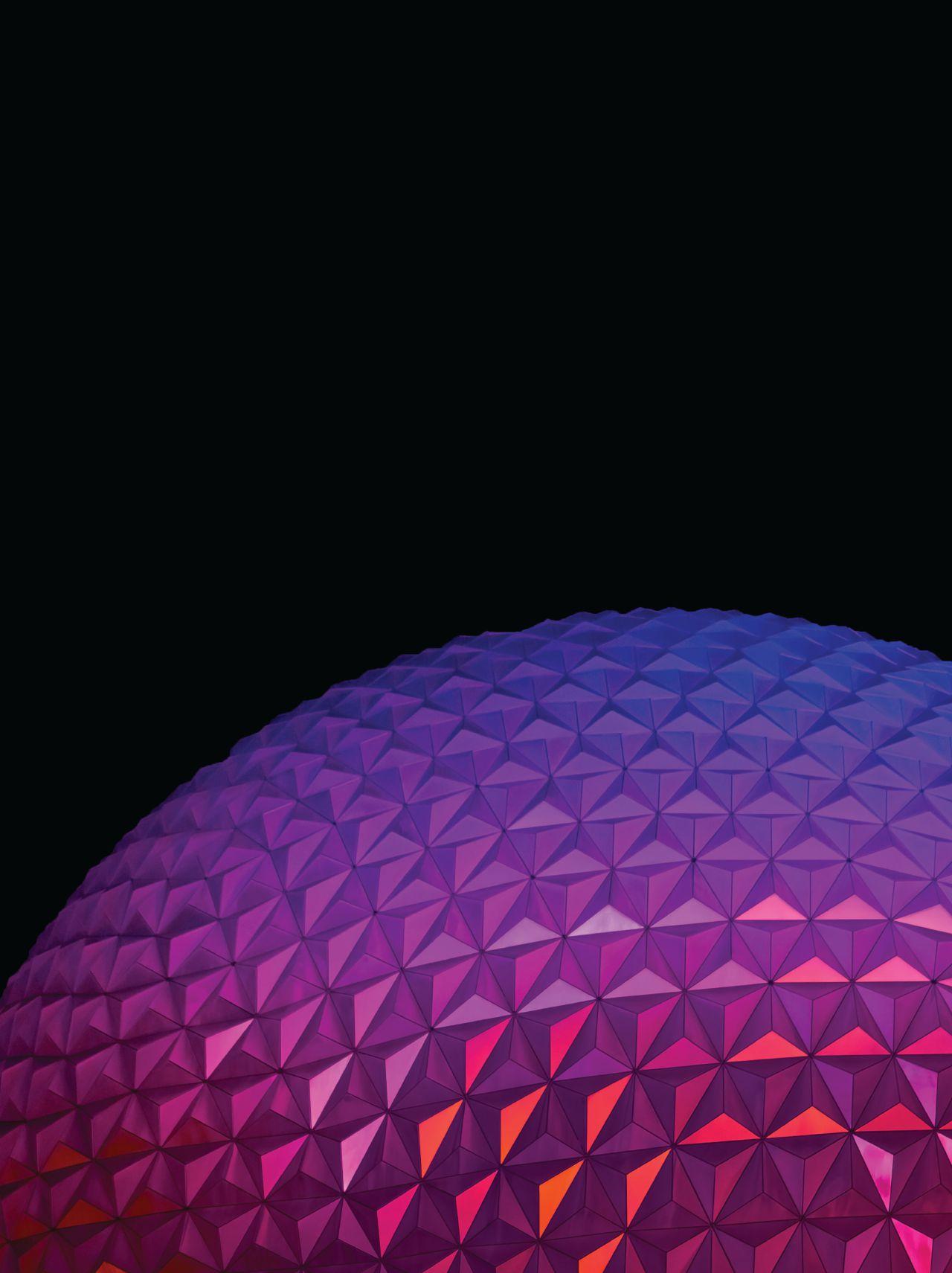

Haptic printing involves the elevation of traditional flat, two-dimensional ink and paper to three-dimensional textures, patterns and sculptured special effects. These decorative embellishments are often accompanied by additional eye-catching, sensory enhancements such as metallic foils, chemical coatings and lamination films. Haptic printing generates a stronger, deeper and more meaningful engagement with the printed piece because it increases the physical nature of the printed communication format.

The impact of haptic physical print experiences is far greater than traditional flat 2D impressions. This is because the human eye perceives the layers of special effects and it resonates deeper into the consciousness. A finger that runs over the embellishments generates more

Haptics describes the stimulation of the senses, primarily by the perception of physical characteristics.

neurological activity than mere optical awareness.The skin encounters a sensation of awareness that transmits information to the brain and embeds itself as a more memorable encounter than is possible with regular printed communications.

As a result, haptic prints get more attention and get held longer in the hand. This opens up new possibilities of successful impact for consumer marketing strategies and brand management tactics.

Haptic printing creates true physical touchpoints and “impact moments”. In contemporary marketing, every micro-second counts. Digital printed special effects create a more interactive brand experience. Dimensional messaging creates memories that linger longer in the mind and fuel consumer decision-making processes by creating greater “perceived value” to products with a higher sense of quality.

Improved “perceived value” trans-

lates into more “perceived ownership” for consumer purchasing processes. This strengthens and accelerates the inclination to associate value with a particular brand and is the core print project goal of every consumer marketing campaign. Ultimately, a more significant and interactive print experience will be interpreted as an aspect of quality for the product and attribute of the brand itself.

Over time, this type of haptic printing can help secure customer relationships and produce far greater sales revenue than average flat colour printing. The greater optical and physical encounters of sensory special effects become magnets of attraction for buyers and brands.

Sensory-based dimensional printing creates a competitive differential in the marketplace. The higher value of the printed communication piece equates to the product to

Haptic printing involves the elevation of traditional flat, two-dimensional ink and paper to three-dimensional textures, patterns and sculptured special effects.

which it refers. Truly successful brands compete on value and, thus, can command premium pricing that offers higher profit margins. Commodity products compete on price and, therefore, can only survive on supply chain models of mass-market distribution and are always vulnerable to erosions of market share by disruptive forces.

In business, time is money and every brand marketing campaign is designed to attract and keep attention for as long as possible. The target audience of consumers and shoppers is, conversely, racing against the clock in a very busy world and inclined to try and make purchase decisions as quickly as possible.

However, this dynamic of time and money is precisely why haptic printing is such a compelling solution for consumer marketing professionals at brands and agencies. It creates a more engaging, optical,

sensory and interactive print experience that encourages long-term product affinity. It also stimulates impulse purchases in the store, a longer mail moment in the mind and even a sense of unboxing excitement for e-commerce packages when they arrive.

In conclusion, new technologies of dimensional design and sensory communications are actively creating future possibilities of “feeling print” and not just viewing or reading it. This can greatly help energize consumer marketing messages and animate brand images via a greater perception of physical reality – with the power of touch in the hand and the sparkle of light in the eye.

This article was originally published on the Konica Minolta blog. Please visit https://kmbs.konicaminolta.us/ kmbs/technology/production-print/ industrial-printing/sensory for more information.

The future of finishing is at work in today’s smart factories worldwide. Experience the power of Muller Martini’s highly automated print finishing systems. Contact your Regional Sales Manager for more information, or to schedule a demo.

Manroland Sheetfed has launched the Roland 900 Evolution, its newest large-format offset press and latest addition to the Evolution series.

The Roland 900 Evolution offers a wealth of automation technology to deliver cost and energy savings for printers, along with faster makeready times. Its features include Autoprint, providing uninterrupted productivity from prepress to postpress at the touch of a button, and InLine ColorPilot 3.0, the most efficient and accurate colour measurement technology available, according to Manroland Sheetfed, measuring densitometrical and colorimetrical values in a single pass.

New Triple Flow inking technology provides three separate inker running modes, while the AC Drive promises annual savings of up to 10,000 kWh, or eight years over the lifetime of the press.

Agfa has launched Energy Verve, a negative-working, pre-heat, photopolymer offset printing plate aimed for heat-set web, cold-set web, as well as packaging & commercial sheet-fed printers that typically deal with demanding print conditions with oxidative and UV inks.

Due to its high chemical and mechanical resistance, Energy Verve

can achieve run lengths up to one million copies. In addition, its high sensitivity and non-ablative photopolymer layer maximize plate throughput of the platesetter.

The plate replaces the post-bake oven with a pre-heat module requiring a lower temperature, which brings down energy consumption by up to 50 per cent, and service costs by up to 65 per cent. In addition, plate waviness or cracking issues will disappear. Also, the pre-heating module is smaller than a post-bake oven.

One of the key cost drivers for heatset printers are paper web breaks, which can often occur with lightweight paper or multiple format changes. The plate’s specific design helps eliminate web breaks.

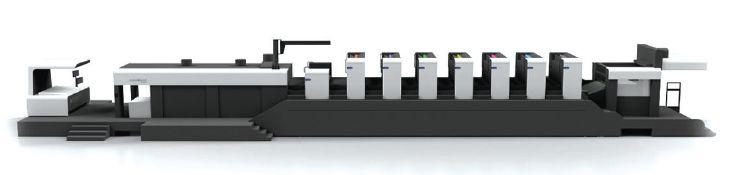

Komori Corporation has developed the Lithrone GX/G advance series, advanced Lithrone sheetfed offset presses designed to meet demands for small lots, high added value products and short turnaround times.

This launch provides improvements in the high-speed stability of the feeder and delivery, which provide the basic performance of a press. It is suitable for high-speed, long-run printing, while the performance of Komorimatic remains unchanged. The series also offers a reduction of touchpoints through a self-learning function and new

Komori’s Lithrone GX/G advance series was designed to meet demands for small lots and short turnaround times.

control platform for linkage of highlevel printing systems.

In addition, Komori provides increased collaboration with KP-Connect solution cloud, which enables the smart factory, including MIS, prepress and postpress, and was developed based on the company’s Connected Automation concept. This improves collaboration and optimization between processes, as well as high-level automation with presets based on information from high-end systems, resulting in productivity improvements throughout the entire printing process.

The Roland 900 Evolution is Manroland Sheetfed’s newest large-format offset press.

The presses provide improved feeder and delivery performance; stable high-speed printing and high productivity with minimum losses; tasks dependent on operator skill minimized by easy operation; maintained dot sharpness and stability with improved suitability for high speed/long run printing; new operating screen and platform with reduced touchpoints; linked with various mechatronics devices to maintain quality; fast feedback control to the press; and connection with KP-Connect Pro solution cloud, allowing job data to be sent to the press by direct presets.

Mobile Solutions’ Titan Industrial Printers are high-volume four-inch industrial barcode label

Brother Mobile Solutions has introduced the Brother Titan Industrial Printer series of high-volume four-inch industrial barcode label printers for warehouse, e-commerce, T&L supply chain, retail and manufacturing operations.

The Brother Titan Industrial Printer is a high-volume tabletop printer series that delivers crisp barcode labels up to 10 ips and scaling up to 300 dpi at high speeds. In addition to quick drop-in integration, the printer offers a complete set of software connectivity choices at affordable pricing and subscription options.

All models of the printer come standard with Ethernet/ LAN, USB 2.0, Host-USB and RS232C Serial. It also features a 3.5-inch, full-colour HVGA touch panel display.

Scodix has launched the next generation of its Ultra Digital Enhancement Press Series of six presses, each targeted to a specific market segment. The series includes:

Web-2-Print – The Scodix Ultra 3000 and Ultra 4000 incorporate Scodix Studio W2P software. The Ultra 3000 focuses on Web2Print, while the Ultra 4000, which allows larger format substrates and pallet feeders and stackers, is aimed at Web2Pack printers.

Commercial & Specialty – The Scodix Ultra 1000 and 2000 offer the same print areas and range of substrates. The Ultra 1000 delivers accessible digital enhancement, while the Ultra 2000 offers all Scodix applications on one platform.

Packaging – The Scodix Ultra 5000 and 6000 both allow thicker substrates used in packaging applications, up to 2 mm.

3. INTEGRATED MODULAR UNITS — Combined in-line finishing: crease, fold, glue, tipping, envelope inserting, ink jetting (Duplex), clip seal (3 sides), mail prep.

4. SAVE ON POSTAGE COSTS —As a Certified Canada Post Direct Marketing Specialist, we get contract pricing reductions.

5. RETURN MAIL PRODUCTS — Customized “Return Mailers” created in-line with “U” or “BOX-shape” remoistenable glue, time perfed applications and envelope formation.

6. MINI-BOOKLETS — Saddle-stitch and trim 2-up booklets in-line to the size of a business card. No need to trim off-line, or do 2 passes.

7. HIGH SPEED EQUIPMENT — High speed Tipping, Folding, Saddle-stitching and soft folding ensuring on time delivery.

Standard’s Horizon BQ-500 Perfect Binder was designed for increased book-of-one productivity.

They also incorporate industrial pallet feeders and stackers. The Ultra 6000 offers a larger format, and comes with a simplified range of enhancements.

Epson has expanded its presence in the signage market with the SureColor R5070 and SureColor R5070L, 64-inch roll-to-roll resin signage printers that use six-colour resin ink on a variety of substrates.

promote even drying with pre, platen and post heating. A 4.3inch touchscreen control panel provides easy access to print functions. The replaceable fabric wiper system cleans the printhead and removes dust prior to printing, resulting in manual maintenance only being needed monthly.

1x Mitsubishi 40” 10 Colour Tandem with AQ

1x Mitsubishi 40” 8 Colour Tandem with AQ

1x Mitsubishi 40” 8 Colour Perfector with AQ

3x Mitsubishi 40” 6 Colour with AQ

2x Heidelberg Printmasters

3x Saddle Stitchers / 1 Perfect Binder / 10+ MBO Folders

Over 75,000 sq ft plant housing state-of-the-art nishing and bindery

Personalized account management and complete control over production

24/7 Production with fully automated and barcode controlled plant

FSC / PEFC / SFI certi ed

The printers deliver output ready for immediate lamination at true production speeds up to 290 square feet per hour. Both models feature 1.5L ink packs, and the R5070L includes 3L per colour with hot swap technology for uninterrupted printing.

The printers are the first of their kind to feature multi-purpose resin ink technology to be used on wallpapers, fabrics, uncoated papers and traditional signage.

Featuring a new 2.6-inch user-replaceable PrecisionCore Micro TFP print head, the printers are able to ensure projects with multiple panels have consistent, repeatable colour. The printers incorporate a three-heater system to

Standard Finishing Systems has launched the Standard Horizon BQ-500 Perfect Binder. The system is designed for increased book-of-one productivity, automation, and quality control over a wider range of substrates compared to competitive models.

The system features a 12.1” touchscreen and an enhanced delivery system for thin books. In a variable range of +/- 5mm, the BQ-500 can reach production speeds of up to 800 books per hour.

The Horizon BQ-500 features interchangeable EVA and PUR glue tanks with a new and improved tank removal process. The BQ-500 can be run in-line with Standard’s HT-300 ThreeSide Trimmer for seamless book production.

Heidelberg: K-Line/S-Line/Speedmaster/GTO/MO/KORD64

Komori: 1, 2, 4 or 5 colours & any size

Adast: 714/715/724/725

Mitsubishi: Any model

Ryobi: 2800CD/3200CD-MCD/640K

Itek: 960/975/985

Hamada: 600/700/800/E47/RS34

Shinohara/Fuji: 66/65 1,2 or 4 colours

Sakurai: 1, 2 or 4 colours and any size (newer model)

Polar: any size/older or newer models (66/72/76/78/82/90/92/107/115)

Horizon-BQ: 220/240/260/440/460

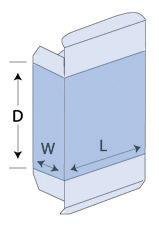

Irfan Rajabali joined E.B. Box Company 13 years ago. As director of business development, Irfan heads up the sales and strategy departments to manage client relationships, as well as lead the sales teams, managing them to help them grow their base, and work on new product innovation for the 48-year-old company.

What attracted you to the print industry?

IR: It was one of the industries that I saw growth as we start to look down the retail store shelf. In our business, a lot of the up-and-coming companies are really focused on branding, Instagram appeal and retail store shelf appeal. You could see that this was going to be a bigger part of the retail experience.

How do you think the industry can attract more of the next generation?

IR: It’s probably the single biggest challenge that we face. I think there’s a lot of other industries that are maybe a little more, on the face of it, appealing. As kids in this day and age are starting to leave university, they’re trying to get into some of these other industries, be it tech, banking or telco, but we have a hard time finding people who want to really focus on print and graphics management.

Unfortunately, with the school programs, it’s harder to attract people because it’s somewhat more of a trade school program than a traditional university route, and a lot of people who take the post-secondary route don’t necessarily come to a print shop as their first choice of work after. It’s not a traditionally appealing industry that people are targeting to join as they pursue higher education.

At some point, there’s going to have to be some collaboration with post-secondary programs and regional job boards and organizations that supply labour to really outline the fact that in a growing industry, like we have today, the actual wage rates inside the industry are very competitive with what people can make in a different sector. I don’t think that’s communicated well by our industry.

What are some strategies for a company to win more sales?

1972

The year E.B. Box Company was established.

IR: What we are seeing in the market is a lot of pressure on lead times. You’re starting to see the traditional folding carton shops, where lead times might be six to eight weeks, and traditional commercial print shops, [where] turnaround might be five to seven days, converge. Their business models are very different, but they’re starting to put a lot of downward pressure on lead times. It’s been a big focus of ours that we start to invest in the technology, people and processes required for us to bring our own lead times down.

What are some of the biggest opportunities you see in the industry?

IR: I think one of the biggest ones that may have been somewhat accelerated by COVID-19 has been in the food space. E.B. Box is about 80 per cent committed to food, so we’ve seen a lot of great opportunities because everybody needs to eat. People are accessing meals through the grocery channels, or through takeout food from restaurants, and that’s really driven up the requirements for packaging. If you look at the space that exists right now,

especially in the world that we’re in, food and pharmaceutical are the two fastest-growing segments of the folding carton packaging space.

What is one project you are particularly proud of working on?

IR: One of the things we’ve been working on as the world moves towards more eco-friendly packaging is replacing plastic coatings in boxes with an environmentally-friendly waterbased solution. We came up with a coating that we successfully pitched to a national grocery chain, allowing them to switch out all of their plastic packaging with paperboard boxes with an environmentally-friendly coating. We believe that you can get a box in a lot of places, but for us, we view ourselves as a partner to [our clients’] business, and being able to be flexible and meet the ever-changing needs in the food space has been the recipe for our success.

Irfan’s responses were edited for length. For more Spotlight Q&As, visit www.printaction.com/profiles.

RM Machinery has partnered with Standard and Horizon— the world leader in finishing solutions including folding, binding, stitching and cutting—to provide fully integrated finishing solutions that take your print products from the pressroom to the marketplace. Get ahead of the fold by contacting RM Machinery at 855-RMGT-123 or visiting us online: www.rmmc.ca.

The Standard Horizon BQ-500 Perfect Binder features the quickest set-up and changeover for variable book production in its class, especially for book-of-one.

• PUR-friendly design with gentle delivery system for 5mm drop and low temperature setting

• Easy glue changeover, between PUR and EVA

• Automated controls for adjusting roller height, nipping height, and amount of side glue

Equipping Canada to cut, fold, stitch and print.

RM Machinery Inc.

905-238-9797 • 1-855-RMGT-123

5250 Satellite Drive, Unit 9 Mississauga, ON L4W 5G5 www.rmmc.ca

With dual magnetic cylinders, the RD-4055DMC Rotary Die Cutter is designed to simultaneously die-cut and crease/score short-run product from both sides of the sheet. It can also perforate, slit, hole punch, and round corners in one process for digital and o set printed sheets.

• Crack-free creasing and clean, sharp creases

• Multiple-up applications from single-up die

• Handles complex creasing patterns and light packaging applications

The Acuity family of printers is built to win.

The Acuity platform is popular for a reason: you won’t find better image quality, versatility and ease of use anywhere else. Choose from a plethora of machines and configurations to perfectly suit what you need.