The 14th annual Canadian Printing Awards took place in Toronto with more than 110 awards handed out for print innovation and industry achievement

Details on the Best of Show and Gold, Silver and Bronze award winners

Seven steps print service providers should follow to gain a competitive advantage

GAMUT

5 News, Calendar, People, Installs

TECH REPORT

20 Elevate ordinary printed materials with eye-catching postpress techniques

NEW PRODUCTS

22 Detailing new product offerings from APP Canada, Bobst, Kernow, Markzware, Mimaki, Roland DGA, swissQprint and Xeikon

SPOTLIGHT

26 Renée Walsh, Vice President, Enterprise Sales, TI Group

FROM THE EDITOR

4 Alyssa Dalton

Retailers get creative with their toy catalogues as the holiday season approaches

CHRONICLE

8 Nick Howard

If we don’t learn from our mistakes, we are bound to repeat them

For many, seasonal catalogues, especially those filled with the latest must-have toys, gadgets and holiday magic, evoke a sense of nostalgia and childhood memories.

In 1933, Sears introduced the Wish Book, an annual gift guide that grew into an iconic holiday catalogue over the years — in 1968, the Wish Book totalled 605 pages. While Sears retired the catalogue in 2011 in an effort to focus on online sales, it brought the gift guide back in 2017 for the season due to overwhelming customer demand.

Last month Walmart announced its seasonal toy catalogue has been enhanced with Digimarc barcodes that let shoppers scan pages with their smartphones and order items online, marking the retailer’s first catalogue integration with mobile technology. Designed to be a simple ‘scan and shop’ experience, customers with Apple iOS and Google Android devices can now use their phones to shop by activating the barcode scanner in the Walmart app over the desired page. The app will then show a list of toys that can be added to a wish list or online shopping cart.

Scan & Shop powered by Digimarc is featured in 35 million print catalogues available in Walmart’s nearly 4,800 U.S. stores, with millions also mailed to U.S. homes and major omnichannel toy resellers, Digimarc explains.

“Creating convenience for Walmart’s customers was a key priority for this year’s toy catalogue. Through our partnership with Digimarc, we were able to enhance our catalogue with a Scan & Shop option for our customers,” Alvis Washington,Vice President of Marketing, Walmart, says. “This is an exciting new feature that I know will resonate with our customers.”

According to Adobe Analytics research, consumers will boost mobile spending by 20 percent to US$14 billion during this holiday season from a year earlier, making up 36 percent of all online sales. As consumers increasingly rely on their smartphone to purchase holiday gifts – for family, friends and themselves – savvy retailers are working to combine the nostalgia and excitement of flipping through a printed holiday catalogue with the ease of mobile shopping.

For the second consecutive year, Amazon.com Inc. mailed a toy catalogue ahead of the holiday season, instead of relying on all-digital advertising. Titled Play together, the eye-catching 94-page catalogue features hundreds of toys, but they aren’t marked with prices, just QR codes that draw consumers to the Amazon website. There is also a sticker sheet to flag items as well as a mad-libs page that invites children to write out their own holiday wish list.

“Once you turn this page, you’ll enter a world where holiday dreams are made. So stack the cookies high, keep the cocoa toasty, and cozy up together because you’ll definitely want to check this book twice,” reads page 2 of the scannable catalogue.

Tim Curtis, President of direct mail consultancy CohereOne, believes Amazon will soon customize its catalogue based on the recipient’s household if it isn’t already, as quoted in a November 2019 Forbes article by Kiri Masters. “Their roadmap will probably include custom content for each recipient. They know from the size of Halloween costumes we ordered, what are the ages of the children in our household,” he said, noting that the online retailer could even feature certain products based on the TV shows the family watches in their Prime Video account.

“Amazon will surely see positive responses from this. We know from neuroscience that [direct mail] is extremely effective at building an emotional connection with customers and driving demand. Even the stickers in the catalogue — it’s nostalgia. They are doing it right,” Curtis said.

The strategy represents a repeat effort from Amazon to incorporate traditional engagement tools used by brick-and-mortar stores, as analysts speculate the e-commerce giant pivoted to print catalogues last year in a move to capitalize on the July closure of Toys “R” Us stores in the U.S. Meanwhile north of the border, Toys “R” Us Canada is experimenting with augmented reality (AR) through a new partnership with Snapchat. The toy retailer recently published what it says is its most “interactive and creative” Holiday Toy Book, a 44-page booklet with characters and products that “literally pop out from the pages.” A printed version was mailed to more than five million households, while the digital counterpart is available on the Flipp flyer app. Snapchatters simply open the app, use the Snapcode in the Holiday Toy Book to add the lens, and a 3D Geoffrey the Giraffe will guide users through the portal. The retailer is the first in Canada to market the Snapchat Portal Lens, a unique lens designed to give consumers an immersive experience as they interact with the season’s top toys.

“AR is a powerful new technology and we are excited to use it to improve the customer experience,” explains Frank Juhasz, VP Marketing and Omni Channel Innovation at Toys “R” Us Canada. “Through this partnership, we’re able to bring our toys and products to life in new ways. Canadians expect this type of innovation from great retailers and we’re happy to be leading the charge.”

Despite these different innovations, it’s clear the coveted toy catalogue remains a vital part of the holiday shopping experience.

ALYSSA DALTON, editor

adalton@annexbusinessmedia.com

Editor Alyssa Dalton adalton@annexbusinessmedia.com 416-510-5225

Contributing writers

Zac Bolan, Wayne Collins, Victoria Gaitskell, Martin Habekost, Nick Howard, Neva Murtha, Abhay Sharma

Associate Publisher Stephen Longmire slongmire@annexbusinessmedia.com 416-510-5246

Media Designer - Team Lead

Lisa Zambri lzambri@annexbusinessmedia.com

Account Coordinator Alice Chen achen@annexbusinessmedia.com 416-510-5217

Circulation Manager

Beata Olechnowicz bolechnowicz@annexbusinessmedia.com 416-442-5600 ext. 3543

Circulation apotal@annexbusinessmedia.com

Tel: 416-510-5113

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Group Publisher

Diane Kleer dkleer@annexbusinessmedia.com

COO

Scott Jamieson sjamieson@annexbusinessmedia.com

Subscription rates

For a 1 year

subscription (10 issues): Canada — $43.00 +Tax Canada 2 year — $70.50 +Tax

United States — USD$75.50

Other foreign — USD$147.00

Mailing address

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 printaction.com

Tel: 416-442-5600

Fax: 416-442-2230

Annex Privacy Officer

Privacy@annexbusinessmedia.com 800-668-2384

PrintAction is printed by Annex Printing on Creator Gloss 80lb text and Creator Silk 70lb text available from Spicers Canada.

ISSN 1481 9287 Mail Agreement No. 40065710

Rod Froment, VP and COO, and Darrell Friesen, President and CEO, last year as they celebrate Jet Label’s 20th anniversary with uniquely labelled cans.

ProMach has acquired Jet Label & Packaging, a move that will expand its labelling and coding capabilities and provide customers across Canada with enhanced sales and support, it says. Founded in 1998 and headquartered in Edmonton, Alta., Jet Label manufactures labels and printed tape for a range of industries, including food and beverage, consumer packaged goods, pharmaceuticals, forestry, transportation, and mass-market retailers. Jet Label provides sales, service and support from seven offices throughout Western Canada, from Vancouver to Winnipeg. ProMach’s ID Technology product brand has six existing label converting facilities throughout North America, with locations in California, Texas, Wisconsin, Georgia, New Hampshire, and Ontario that provide flexographic labels, blank and shell labels, digital labels, synthetic labels, and more. ID Technology also provides various labelling and coding systems, offering customers ranging from small local startups to national retailers with a solution that includes both labels and machinery, supported by a network of more than 15 sales and service offices. The addition of Alberta-based Jet Label now adds a seventh flagship converting facility as well as additional sales and service offices so customer needs can be met by a local team of labelling and coding personnel. Darrell Friesen, President and CEO of Jet Label, along with Rod Froment, Vice President and COO of Jet Label, will continue leading the Jet Label team, spanning over 80 employees across its multiple locations. Also joining ProMach is

material handler designed to load and unload directly to and from a pallet without operator involvement. The Esko product portfolio will offer enhanced value to users of Konica Minolta’s AccurioWide 160 and 200 wide-format printers. The AccurioWide series of printers are hybrid devices that print on both flexible and rigid substrates, allowing for the production of traditional sign and display applications and more niche applications, including printing directly to metals, plastics, wood, and glass.

Canadian fashion designers can now access short-run, digital printing technology as a result of a new partnership between Epson and George Brown College

January 21-24, 2020

EFI Connect Users’ Conference Las Vegas, Nev.

March 24-27, 2020

FESPA Global Print Expo 2020 Madrid, Spain

June 16-26, 2020 drupa 2020

Düsseldorf, Germany

September 15-17, 2020

Labelexpo Americas 2020 Rosemont, Ill.

Jet Label’s sister company, Jet Marking Systems, a provider of label applicators, industrial printers, tracking and traceability solutions, as well as other ancillary equipment, led by General Manager Dan Stickney.

Simpson Print of Bloomingdale, Ont., has launched a new division, Sawmill Display, specializing in business décor, custom retail merchandising, exhibits and displays, tradeshow and module systems, and commercial display. Simpson Print President Carla Johanns says the new division is “our answer as to how you diversify,” and will address the evolving retail world and the growing trend of pop-up retail — temporary sales establishments that emerge for a few hours, days or weeks, creating a new touchpoint for brands to engage with customers. The opportunity allows businesses to experiment with short-term sales strategies without having to invest in a permanent location, she explains.

Konica Minolta Business Solutions (Canada) has announced its new distribution partnership with Esko. As part of the agreement, Konica Minolta will act as a Canadian distributor of Esko’s Kongsberg line of digital cutters and workflow automation hardware solutions. Headquartered in Gent, Belgium, Esko is a global supplier of flatbed wide-format cutters, workflow automation technology, and packaging solution applications. The company also offers a series of automation hardware options including an automatic board feeder and stacker, and a robotic

The Epson SureColor will be used to create customized patterns.

Described as the first of its kind in Canada, the college’s Fashion Exchange LIFT (Leading Innovation in Fashion Technology) Lab is a working short-run manufacturing facility that offers hands-on education, applied research, manufacturing services and mentorship in support of local brands, designers, researchers and entrepreneurs. The lab features a range of apparel design and production technologies, including an Epson SureColor dye-sublimation fabric printer. As Epson explains, the SureColor fabric printer will give Canadian designers and design students the ability to experiment and customize patterns, while efficiently creating and producing collections. At the launch event on October 29, experts from George Brown’s Fashion Exchange and Epson participated in a panel discussion on the future of the digital textile industry and its impact on design, sustainability and commerce.

Hemlock Printers last month announced an expansion to its Zero Carbon Neutral Printing Program. In partnership with Mohawk Fine Papers, the initiative aims to provide expanded opportunities to reduce and mitigate

CO2 emissions through the paper supply chain lifecycle, from forest to mill and transportation to recycling. Developed in 2009 in partnership with Offsetters, a Vancouver, B.C.-based provider of climate change solutions, Hemlock says its Zero program has enabled hundreds of customers to neutralize over 12 million kilograms of carbon emissions by investing in renewable energy and clean technology projects, including the Great Bear Rainforest Carbon Project in Haida Gwaii, B.C. Core to the program expansion is the addition of Mohawk Options 100% PC, a FSC- and Green-e certified 100-percent post-consumer paper, which is now automatically carbon neutral when specified by the customer. The direct emissions of manufacturing Mohawk Options 100% PC are offset exclusively for Hemlock through Mohawk’s contributions to the Darkwoods Forest Carbon Project, conserving the biodiversity and water stewardship of boreal forests in southeastern British Columbia. The new carbon-neutral sheet is available in various colours and finishes, including Options 100% PC Smooth, Vellum, Warm White, Cool White and Smooth Digital

The carbon-neutral sheet comes in many colours and finishes.

Eric Gowland in August joined Simpson Print as Vice President, where he leads the Bloomingdale, Ont., company’s operations. The company explains Gowland will manage the innovations in equipment and product development required in the evolving print industry.

Color Concepts has appointed Danielle King Sales Manager, where she will be responsible for sales in the North American region. Born and raised in Canada, King did her studies at Memorial University of Newfoundland. Later, she started as Key Account Manager at ND Graphics. “For the past 17 years, she gained a lot of experience in channel management and consultancy. Throughout these years, Danielle has become familiar in wide-format printing and digital printing. Furthermore, she developed skills in colour management, sales management, and marketing,” Color Concepts explains. With its global headquarters in The Netherlands and a North American branch in Salt Lake City, Utah, Color Concepts describes itself as the world’s largest, independent profiling and testing lab for the professional digital wide-format printing industry.

St. Jude Elementary School, part of the Riverside school board in Quebec, operates various academic programs ranging from pre-Kindergarten to Grade 6 and full daycare services. It recently replaced an old laminator with the GBC Ultima 65 EZload laminator, for laminating posters, flash cards and other learning tools.

Sabine Geldermann , Director of drupa and Global Head Print Technologies, is the recipient of this year’s Girls Who Print Girlie Award. She received the award from Deborah Corn, known as the Intergalactic Ambassador to The Printerverse at Print Media Centr, on International Print Day 2019 during Printing United 2019. The Girlie Award is presented annually to a woman who demonstrates outstanding leadership and strong commitment to serve the printing industry. “Sabine Geldermann travels around the globe advocating for print and addressing the challenges of an evolving industry, engaging with local associations and ensuring that drupa’s market research is representative of the industry on a global scale,” Messe Düsseldorf North America explains. “Sabine is the first female director of drupa, the world’s leading trade fair for printing technologies, a global ambassador for print and an unwavering visionary who keeps the industry moving forward. [She is] a truly incredible woman,” Corn adds.

Global Graphics PLC has appointed Mike Rottenborn (in photo) its new CEO following Gary Fry’s decision to step down from the post at the end of the year to pursue other avenues in the printing and publishing software industry. Rottenborn is the current President and CEO of Hybrid Software and will take on his new role on January 1, 2020. Serving as CEO since 2008, Fry has steered the company through a significant growth period and several strategic acquisitions, including Meteor Inkjet and Xitron LLC. Hybrid Software has subsequently announced the promotion of Mike Agness to Executive Vice President for the Americas, succeeding Rottenborn. Agness joined Hybrid Software in 2011 after a long career at Pitman Company and Agfa Corp. and is the current VP Sales for North America

Friesens of Altona, Man., is investing in two new HP Indigo 50000 digital presses as it shifts more capacity to digital production. Installation of the first unit was completed in early November. The B1 (30-inch) duplex, roll-toroll HP Indigo 50000 is the first in this digital productivity class to be installed in Canada.

Richmond Hill, Ont.-based Canpak has acquired a new folder gluer, die-cutting system supporting offset presses up to 40 inches and digital cutsheet sizes, along with its new Xerox Iridesse. Canpak specializes in packing and folding carton applications and other jobs with unique finishing requirements.

If we don’t learn from our mistakes, we are bound to repeat them

By Nick Howard

Recent world events have exposed lessons learned over the last one hundred years — if we don’t learn from our mistakes, we are bound to repeat them.

If there is one thing any business owner can agree on, it would be that instability is bad for business. Our current global situation provides plenty of uncertainty. Politics offered by unstable leaders threaten many Western democracies, with a new form of nationalism spreading like it’s 1933 again.

In the United States, both Congress and President are at loggerheads over everything from immigration to trade. The United Kingdom struggles with Brexit. Hungary and Poland, even the Philippines, have turned sharply to the right. The near east is mired in bloodshed with over a million displaced people. We are in a very uncertain time where misleading rhetoric, particularly with trade, has hurt the Western consumer and supporting industries, including printing.

We recently celebrated the 30th anniversary of the fall of the Berlin Wall and with it, the Soviet Union and Eastern Bloc. Few ever thought we’d see the day when the whole of Europe would be rid of the menace conveniently referred to as

communism. Except those countries were never really socialist at all, just state-controlled fascists that stunted the growth of a once progressive people.

The state owned everything, and the dictatorship of the proletariat mandated that society held power, except it wasn’t like that. The Soviets and their satellite economies were just state controlled, everyone had a job, there were no rights to speak of, and there was the secret police to keep the masses in line. All orders came from Moscow, and life was miserable. The ultimate source of this madness in Eastern Europe derived from the Third Reich.

Neither socialism in its purest form or

Bottom:

communism has ever worked, but there are plenty of examples of socialism working in western capitalist democracies, including the U.S. — medicare for one, old-age pensions for another. Our police and firefighters are part of this group too. In Canada and all of Western Europe, subsidized healthcare is a form of socialism. Governments cannot operate as if they are a business; they must oversee and set the rules, keep order, and supply a helping hand to those who require assistance. Democracies need a form of socialism, especially today.

Trade and commerce are the biggest elephants in the room at this moment. Getting this wrong has caused more chaos and wars than anything else. Even after a victor is anointed animosities percolate for decades after. In 1918, after the First World War, the Allies made Germany pay and pay they did. Besides financial reparations, chunks of Germany were lobbed off to settle years-old disputes with France. The impact on the German people was catastrophic and led to the rise of Adolf Hitler and his Nazi party in 1933. The Nazis seized on hyper-inflation and the weakness of the Weimar government then found scapegoats and went to work restoring Germanic pride lost in the war. The decisions made in the reparation agreement of 1919 would lead to another disastrous war in 1939.

World War Two was another bloodbath with millions of lives lost, and many industries ruined. For the printing industry,

the worst was yet to come. The Soviet Union managed to get to Berlin before the Allies and overnight, the German state was hacked up with, as Winston Churchill would later describe, the Iron Curtain dividing more than half of Europe. Imagine for a moment what it would be like if your business, possibly handed down from generation to generation, was on the wrong side of that line and nationalized overnight. You wouldn’t own it anymore. This reality was precisely the fate that awaited a significant portion of Germany’s industry. The area around Leipzig was “ground zero” for the massive German printing industry, and its only luck was the Allies weren’t a day or two late; otherwise, Koenig & Bauer and M.A.N. would today be footnotes in history.

Companies that had been in business for decades simply vanished, as an example, Agfa’s plant in Leipzig was dismantled and shipped off to Russia, while the intellectual property transferred to the American firm G.A.F. as reparations (Agfa was then part of the infamous German chemical company IG Farben). The few remaining were reorganized into state collectives called Volkseigener Betrieb or V.E.B. Karl Krause was a substantial company encompassing over one hundred acres of land near Leipzig. The Biagosch family, decedents of the founder, were only an identity card border check away from not escaping to Bielefeld in the allied controlled west. Had this not happened, the printing industry would have never heard of Wohlenberg paper cutters. For it was the newly incorporated Krause that partnered with machine-tool maker Wohlenberg to start manufacturing Krause guillotines again. All was lost back in Leipzig, and the former Krause plant was taken over by the state.

Related businesses – Victoria Werk,

Mansfeld, Druckma, Gutberlet, August Koebig, O. Hoppe & Co, Kohma, Vomag, Kama, Paul Glöckner and Gebrüder Brehmer – were rounded up and faced the future as V.E.B.s. Today almost all except Kama are just memories. Some more successful firms retained their names and would limp along under the weight of the D.D.R. Perfecta and Planeta brought in much needed hard currency. Planeta, in particular, was a thriving business before the war with exports to as far away as China. At the time of reunification in 1990, Planeta was the East German state’s most significant manufacturer employing over 5,500 people.

By 1990s, an agency was set up to dispose of East Germany’s V.E.B.s. Treuhandanstalt, “Trust Agency,” was handed the enormous task of restructuring or selling over 8,500 state-owned businesses that employed four million people. Massive closings soon resulted in 2.5 million employees losing their jobs within months. April 1, 1990, saw Detliev Rohwedder, Chairman of Treuhand, shot dead over civil unrest. Things were bad. What were once world-class printing equipment manufacturers before 1939 became inept and bloated state-run factories that no one wanted.

In 1990, Planeta was the jewel of former East Germany with sales of US$350 million, of which US$50 million came from the United States. Koenig & Bauer would end up winning the Planeta prize and would pay nothing for it, but assume the massive task of pumping millions into bringing Planeta up to western standards. First off, Koenig & Bauer had to offload a third of the 5,500 staff, then supplant West German management into a dilapidated factory to mend 45 years of socialist incompetence. At the time, Koenig & Bauer’s Klaus Schmidt pointed out that

In 1986, Koenig & Bauer launched the Rapida 104, a unit-type press designed for high flexibility and printing speeds up 15,000 sheets per hour.

they were not getting Planeta for “an apple and an egg” (next to nothing), but rightly so, were taking tremendous financial risks to save the legendary press builder.

Ultimately the sacrifices Koenig & Bauer made turned fruitful as the one weak spot in its product line was sheetfed. At the time the company had sputtered along with a small sheetfed division that produced unusually designed equipment that had a very small following. To help boost its fortunes, a new ground-up design (the Rapida 104) would enter the drupa 1986 trade fair, but with meek interest. The sheetfed program was almost exclusively built at Koenig & Bauer’s Mödling plant in Austria. With Planeta well entrenched in B1 to size 8 presses, virtually overnight Koenig & Bauer became a player in offset sheet presses too. In fact even in today’s latest model Rapida 106, you can see the transfer of technology from Planeta, especially in the gripper systems.

As we look ahead to 2020, Planeta may have saved the company as the majority of Koenig & Bauer’s products have shifted from newspaper and publication web to sheetfed. Koenig & Bauer’s takeover spared an icon of the printing world, which would probably have collapsed along with almost every other East German enterprise and all because of war. The tragedy of the Iron Curtain has its inception at the end of World War One. Disputes and quarrels most of us don’t even understand, caused by failed leadership, led to evil autocrats that had to be destroyed to save the rest of us. We see this problem again with recent trade disputes and far-right governments erupting everywhere. Where is our sense of history so we can avoid needless disasters of our own making? Planeta was lucky; it found an outstretched hand in Koenig & Bauer.

A photo of the Karl Krause abandoned factory in Leipzig, Germany, taken by Nick Howard in 2018.

Global harmony must be taken seriously; no man can be an island in today’s fast-changing world. Our leaders must do better. Business doesn’t like uncertainty. Investment stops when commerce is restricted by borders and trade disputes. Let’s not find ourselves on the wrong side of history again with all lost. Leipzig and Dresden were the epicentres of Europe’s printing industry before the last war and still have not recovered after unification. Who’s to say it can’t happen again?

NICK HOWARD, a partner in Howard Graphic Equipment and Howard Iron Works, is a printing historian, consultant and Certified Appraiser of capital equipment.

nick@howardgraphicequipment.com

More than 230 people from across the country attended the sold-out 14th annual Canadian Printing Awards in Toronto on November 7, organized by PrintAction and parent company Annex Business Media, in what has become the country’s largest national celebration of print.

A. Young Lifetime Achievement Award

David Friesen, former President, CEO and Chairman, Friesens Corp.

Friesen was born into the printing business his grandfather started in 1907, and at 22 years of age, formally entered the Altona, Man., business. After various roles, he was named President and CEO in 1986 and held the position until his retirement in 2007. He stayed on as Chairman until earlier this year. Friesen has been involved in many printing and print related organizations, serving as Chairman of the Canadian Book Manufacturers Association as well as serving on the board of the Canadian Printing Industries Association and the National Association for Printing Leadership, among others. His accolades include the Manitoba Manufacturers Hall of Fame (2006), the Cased-In Club by the Book Manufacturers Institute (2007), and the Order of Manitoba (2008).

John A. Young Lifetime Achievement Award

Jay Mandarino, President and CEO, CJ Graphics Inc.

As President and CEO of The CJ Group of Companies, Mandarino oversees the daily operations of 35 companies in a 240,000-square-foot facility in Mississauga, Ont. He launched his founding company, now known as CJ Graphics, in 1980 as a print

brokerage firm to help finance his schooling at York University. Today CJ Graphics is one of the world’s most award-winning printing and communication solutions companies, receiving over 6,500 awards to date. This year, CJ Graphics was the first in the world to win 22 Benny awards in a single year. Serving on the boards of numerous associations and committees, Mandarino’s entrepreneurial spirit and philanthropic work has been recognized through many accolades, including the Queen Elizabeth II Diamond Jubilee Medal, the Ontario Medal for Good Citizenship from the Lieutenant Governor of Ontario, and the Order of International Ambassadors Medal. In 2008, Mandarino established CJ’s Skatepark, one of the world’s largest not-for-profit indoor skate parks, which supports children of all ages and abilities, including at-risk youth and those with special needs.

Marc Boyer, General Manager, Strategic Sourcing and Customer Solutions, Spicers Canada

Boyer has spent more than 40 years in the industry and has worked for paper distributors, envelope manufacturers and paper manufacturers over his career. This summer, Boyer and his cycling partner Yvon Jackson participated in MS Bike, cycling across the country from Vancouver to Halifax to raise funds for Multiple Sclerosis Society of Canada. The pair cycled about 7,000 kilometres over the course of 10 weeks, cycling about 7 to 8 hours a day, and have raised over $161,000 and counting. Boyer says he is privileged to have a wonderful family. He has been married to his wife Lucie for more than 35 years, and has four children and four grandchildren who he cherishes.

Brad Ranson, Business Development and Regional Sales Manager (Western Canada), Komcan Inc.

Ranson started his print career at the age of 15, working on a saddle stitcher for a printer in the Greater Toronto Area, Ont. After two summers, he started with Komcan of Georgetown, Ont., assisting with installations and removals. After graduating high school, he was in charge of running the Parts department and in January 2018, began his current role of Business Development and Western Canadian sales. Ranson is the third generation of his family to be in the printing industry, and says he was attracted to the industry by his father, who held a similar position for most of his career. He studied Economics at the University of Guelph.

Cathie Ellis, President, Ellis Packaging Ltd.

Founded by Bill Ellis in 1983, Ellis Packaging started as a small company in Scarborough, Ont., and has grown into a thriving business consisting of three manufacturing facilities that produce folding cartons. The Ellis Group currently owns six Komori Litho Presses and a 10-colour Primographic Press by CPS with a second press arriving next spring. Cathie has worked for the family business dating back to the 1980s. Over the past 30 years, she performed many jobs throughout the operation and rose through the company, officially taking the reins from her father in 2010 as President.

A 12-person judging panel, working from a blind scoring system, poured through more than 310 submissions to determine Gold, Silver and Bronze recipients across 28 Print Design and Printing categories, as well as a Best of Show winner. Winners of the Environmental and Technology categories were determined by PrintAction and third-party industry experts based on more extensive submissions.

Chosen from among all Print Design and Printing category entries, the Best of Show Award went to Hemlock Printers of Burnaby, B.C., for CP Connects. The cover was printed Black plus 1 PMS with a matte varnish, high-build gloss on the text and grit coating on the image on 95 lb TopKote Gloss cover. The text pages were printed UV 4-colour process + 1 PMS plus strike-through throughout on 100 lb TopKote Gloss text, and the back cover was die-cut with business card slots.

PRINT DESIGN EXCELLENCE

Gold: Eye on Design Magazine, Issue 5, Hemlock Printers

Silver: Honest Ed’s Memories, Moveable

Bronze: IdeaCity Program Book, Moveable

Gold: Johnnie Walker Blue Label

Carton, CJ Graphics

Gold: Undercrown, Gravure Choquet

Silver: Revolution 81 Carton, CJ Graphics

Bronze: J.P. Wiser’s Gift Pack Carton, CJ Graphics

Gold: Print Against The Grain, PBI – Printing By Innovation

Silver: All Is Calm Christmas Card, Aylmer Express Graphics Group

Silver: CP Connects, Hemlock Printers

Bronze: CAMH Sean Hill Box, CJ Graphics

Bronze: Aragon/Shift Brochure, Hemlock Printers

Miscellaneous

Gold: CJ Look Book, Special Effects, CJ Graphics

Silver: Cirque du Soleil – Alegria, PDI Group

Silver: PDI Large Format Solutions

Building Wrap, PDI Group

Bronze: World’s Largest Sticker Store Interior, StickerYou

PRINTING EXCELLENCE

Self Promotion, printing company

Gold: 2019 Annual Dayplanner, Simpson

Silver: Print Against The Grain, PBI – Printing By Innovation

Bronze: CJ Look Book, Special Effects, CJ Graphics

Self Promotion, printing industry supplier

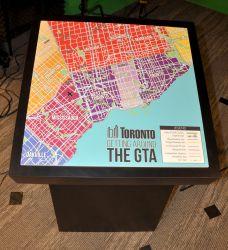

Gold: Dimensional Toronto Map, Canon Canada Inc.

Silver: Customized Activity Tables, Canon Canada Inc.

Bronze: Imagery – 3 versions, Mitchell Press

Brochures & Booklets, offset

Gold: Nobel, Gravure Choquet

Silver: Emily Carr Graduate Studies

2019/20 Brochure, Hemlock Printers

Bronze: Georgetown A-Kit, Hemlock Printers

Bronze: Vancouver House Book, Creative Version, MET Fine Printers

Brochures & Booklets, digital

Gold: CJ Look Book, Special Effects, CJ Graphics

Silver: Ryerson University – FCAD The Creative Innovation Hub, CJ Graphics

Bronze: Epochs History Books, MET Fine Printers

BY

“This year’s Canadian Print Awards proved that print is thriving and more exciting than ever. Canon Canada wants to thank our customers and the Canadian print community for the continuous support and inspiration.”

Nobuhiko Kitajima President and CEO, Canon Canada

GOLD WINNERS

Most Environmentally Progressive Technology Company

Océ Colorado 1650 – Most Progressive Printing Process, Wide-Format Roll Inkjet

Canon imagePRESS C910 – Most Progressive Printing Process

Océ Arizona Xpert – Most Progressive Printing Process, Software or IT

Dimensional Toronto Map – Self Promotion, Printing Industry Supplier

SILVER WINNERS

Océ ProStream 1000 – Most Progressive Printing Process, Production Inkjet

Océ Arizona 1300 Series – Most Progressive Printing Process, Wide-Format Flatbed Inkjet

Customized Activity Tables – Self Promotion, Printing Industry Supplier

Gold: Utah Jazz Year Book, MET Fine Printers

Silver: Uncommon Grit, Friesens

Silver: Sergio Castiglia Designer Book, English Version, MET Fine Printers

Bronze: A History of Sid Lee, PDI Group

Gold: Dairy Farmers of Ontario Milk 2017/18 Annual Report, CJ Graphics

Silver: Teck Resources 2018 Annual Report, Hemlock Printers

Bronze: Morguard Corporation 2018 Annual Report, CJ Graphics

Gold: Gravure Choquet 2019 Calendar, Gravure Choquet

Silver: 2019 Lynden Calendar, Hemlock Printers

Bronze: 2020 Ultimate Sailing Calendar, Friesens

Gold: Jim Beam Barbecue - Cooking Wood Pellets, Energex, Farnell Packaging

Gold: 40th Annual ACE Awards Book, Burke Group

Silver: Rocvale 2019, PDI Group

Bronze: Invest In The Future Of Wellness – Copper, MET Fine Printers

Gold: Kita Swiss Bound Book, English Version, MET Fine Printers

Silver: CJ Look Book, Special Effects, CJ Graphics

Bronze: Photographers Without Borders Magazine, Issue 11, CJ Graphics

Gold: Pereira, Multi-Color Corporation

Montreal Canada

Silver: Dote Magazine, The Bridal Issue, Mitchell Press

Bronze: Mountain Life, Mitchell Press

Gold: The Macallan – The Power of Two 12s, CJ Graphics

Silver: Hendrick’s Gin Neck Tag Mask, CJ Graphics

Bronze: Mitchell Design Icon Series, Mitchell Press

Gold: Kallima, Gravure Choquet

Silver: Rocvale 2019, PDI Group

Bronze: Stormtech, Mitchell Press

Gold: Bell Media Advent Calendar, CJ Graphics

Silver: Martell Blue Swift Gift Carton, CJ Graphics

Bronze: Crown Royal Vanilla Gift Box, CJ Graphics

Bronze: Waterworks Food Hall Leasing Brochures, CJ Graphics

Gold: Henderson’s O-Pee-Chee Lager, Lorpon Labels

Silver: CJ Look Book, Special Effects, CJ Graphics

Bronze: Railway City Brewing ArtsCrawl, Lorpon Labels

Gold: Rise from the Ashes Amber Ale (Dog Island Brewing), Jet Label & Packaging

Silver: Prairie Fire Rauchbier (Town Square Brewing), Jet Label & Packaging

Bronze: Organic Jasmine Pearl White

Tea (Tea Leaves), Jet Label & Packaging

Gold: Lemay & Escobar Business Card, Gravure Choquet

Silver: Eat Print Love Business Card, Print Panther

Bronze: El Mocambo Business Card, CJ Graphics

Gold: Eye on Design Magazine, Issue 5, Hemlock Printers

Silver: Applied Arts Magazine, 2019

Design Annual, Mi5 Print and Digital

Bronze: 000 Magazine, Issue 010, Hemlock Printers

Labels, flexography/gravure

Gold: Henderson’s Ides of September 2018 – Lanny 2018 West Coast IPA, Lorpon Labels

Silver: Evazione Chardonnay, Multi-Color Corporation Montreal Canada

Bronze: Diabolica, Multi-Color Corporation Montreal Canada

Gold: CJ Graphics Open House Invitation, CJ Graphics

Silver: Menu Clifford, Graphiscan

Bronze: Mercedes-AMG Motorsport Night Invitation, CJ Graphics

Quick Makereadies, Fast run speeds, and the lowest cost of ownership in the Industry. There is a reason Komori has become the choice for both Commercial and Packaging Printers in Canada, and worldwide. To find out more, and discuss your plans for growth, contact us today. KOMCAN Inc. (905) 873-7070 info@komcan.com www.komcan.com

any of us have heard the old adage “a stitch in time saves nine”. But despite knowing this, all too often, deadlines, commitments, and ultimately the demands of customers (you know, the people and companies that pay for our services, and who without, we would not be in business?), get in the way of us actually following through on taking care to ensure our equipment is in top-notch condition.

We also all know that “bad stuff” happens at the worst possible time. This double edged sword finds a way gets us, in the worst possible way. And to make matters worse, Printing Presses somehow have a way of knowing when the worst possible time is!!!

For that reason, proper preventative maintenance is crucial. But beyond the cleaning, greasing, and checking of roller settings, there is a whole myriad of other maintenance activities that get taken for granted, forgotten, missed, or worst of all, ignored.

There are also a number of activities that are best left to the professionals. Perhaps you don’t have the equipment, or maybe the expertise to perform such activities. Those are still not reasons to let a breakdown “bite you in the @ss”.

Some common activities might include; Soda Blasting your anilox roller, performing the regular oil changes, or even better an overall health check of your machine, from feeder to delivery, can greatly reduce the risk of downtime, increase efficiencies while up, and prolong the life of your press.

Komcan has a strong team of professionals, that can perform health checks, make recommendations, and also perform the routine maintenance activities that you may be

missing, and ultimately save you time in the long run.

For a complete list of preventative maintenance activities, or to discuss your specific needs, contact Komcan Inc., and somebody will be happy to assist you in making sure your “bread and butter” (regardless of manufacturer) is running with optimal up time, operating at it’s most efficient, and performing as reliably as is possible.

Finishing

Gold: Coromandel P, Chopsticks box, Pacific Bindery Services

Silver: CAMH Sean Hill Box, CJ Graphics

Bronze: CJ Look Book, Special Effects, CJ Graphics

Specialty Project

Gold: Wilmar Book, MET Fine Printers

Silver: Medcan “M” Care Onboarding

Package, Wellington Printworks

Bronze: Kurz Foil Selector, Gravure Choquet

Most Environmentally Progressive Printing Project

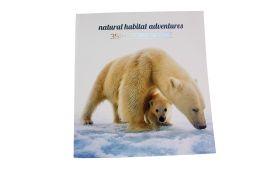

Gold: Natural Habitat Adventures Catalogue, Hemlock Printers

Most Environmentally Progressive Packaging Project

Gold: Houseplant Packaging – Sativa, Hybrid and Indica, Harbour Printing and Distribution

Silver: CAMH Sean Hill Box, CJ Graphics

TECHNOLOGY INNOVATION

Most Progressive Printing Process, Digital (Toner)

Gold: imagePRESS C910 Series, Canon Canada Inc.

Most Progressive Printing Process, Production Inkjet

Gold: Xerox Baltoro HF Inkjet Press, Xerox Corporation

Silver: Océ ProStream 1000, Canon Canada Inc.

Bronze: Fujifilm J Press 750S, Fujifilm Canada Inc.

Most Progressive Printing Process, Wide-Format Flatbed Inkjet

Gold: OnsetX3 HS from Fujifilm and Inca Digital, Fujifilm Canada Inc.

Silver: Océ Arizona 1300 Series, Canon Canada Inc.

Most Progressive Printing Process, Wide-Format Roll Inkjet

Gold: Océ Colorado 1650 UVgel Printer, Canon Canada Inc.

Most Progressive Printing Process, Software or IT

Gold: Océ Arizona Xpert, Canon Canada Inc.

Silver: Quotifly Lift Package, Quotifly

Bronze: Crops, www.Printer.CA

Specialty Effects

Gold: Designer’s Guide, Print Panther

Silver: Print Against The Grain, PBI – Printing By Innovation

Bronze: CJ Look Book, Special Effects, CJ Graphics

Wide-Format

Gold: PDI Large Format Solutions

Building Wrap, PDI Group

Silver: Worn M2 Competition, C17media

Bronze: Cirque du Soleil – Alegria, PDI Group

Most Environmentally Progressive Technology Company

Gold: Canon Canada Inc.

Most Environmentally Progressive Printing Company

Gold: Hemlock Printers

Gold: The Lowe-Martin Company Inc.

Silver: MET Fine Printers

Bronze: Symcor Inc.

Brian Bako, Canon Canada

Martin Habekost, Ryerson University

Nick Howard, Howard Graphic Equipment

Al Kershaw, The Print Wizard

Aleks Lajtman, Koenig & Bauer

Jason Lisi, Ryerson University

Paul McCarthy, HP Canada

Grant Robinson, Delphax Solutions

Brett Rogers, Komcan

Kareem Sesook, Insource

Sean Springett, Manroland Sheetfed North America

Emily Wong, CPA Canada

This year 113 Gold, Silver and Bronze Awards were presented in five program sections: Industry Achievement, Print Design, Printing, Technology and Environmental.

For more information about the awards program, how to apply, as well as coverage of previous winning projects and industry leaders, please visit PrintAction.com/CPA

By Brad Wolff

Doesn’t it seem that business is more competitive than it used to be? Take company ABC as an example — it previously dominated its marketplace but had suffered staggering losses in its previous fiscal year. It became apparent that what had worked in the past was no longer effective. It was time to use proven techniques for achieving a competitive advantage.

ABC engaged a firm that identified the root causes of its problems. After two years, sales and profits dramatically increased. The results came from a seven-step process based on sound principles that put a focus on leveraging internal talent. If you find your business falling behind, try putting these seven steps into practice.

When assigning duties performed by em-

ployees that don’t fit their characteristics or core nature, they won’t perform well, like making people with poor detail orientation do work that requires high detail. Training and development, management encouragement and other well-intended efforts will not fix these issues. As management consultant and author Peter Drucker says, “A manager’s task is to make the strengths of people effective and their weaknesses irrelevant.”

Personal growth results in professional growth, creating a greater capacity to handle life challenges, accomplish longterm goals and work well with others. Personal growth and development includes an increased awareness of self and others, the ability to manage one’s ego and emotions, and develop innate talents to maximize productivity and effectiveness.

3. Align employees with your company’s mission and vision

Human beings have an innate need to have meaning and purpose in what they do. For example, take assembly line workers that produce incubators for premature babies. In one scenario, the workers were only told to mechanically perform the prescribed duties. In the other scenario, they were crystal clear about the importance of their work on the survival of infants. Which workers do you think are more motivated? Engagement and performance are directly affected by people’s connection to the outcomes of their work.

4. Align employees with your company’s culture and values

People need to feel like they fit in with their social groups. Employees who are out of sync with an organization’s culture and values will never contribute their best. Being aligned is the point, since diversity of thought and behaviour allow a culture to adapt and thrive. It’s important for leaders to consider whether they should change their culture, like when it’s become toxic or when there is a decreasing number of workers that fit the current culture. Without the ability to attract and retain the needed talent, organizations will fail.

Align

In today’s environment, organizational goals and strategies must change and adapt. Often times, roles and supporting job duties don’t adequately change to align with these shifts.Think of a company that changes its strategy to shift most customer communications from telephone to email, yet the employees’ duties and training still focus on telephone communications.

6. Assess your weaknesses, starting from the top

It’s impossible to have a strength without its vulnerable side. Our ego’s impulse to protect our self-image is normal but also counterproductive. When leaders openly acknowledge challenge areas, this sets an example for employees and demonstrates transparency.

Studies on human potential and positive change demonstrate that self-awareness is the first step, but it’s not the last. Committing to take baby steps generates positive habits that create lasting positive change. Changes intended to meet the needs of your environment create a flexible, adapt-

ive organization poised to thrive despite unpredictable or unwanted change. Your willingness to acknowledge change that you don’t like, openly discuss it and consistently take the actions required to adapt will strengthen you. At the end of the day, leaders simply making choices that define the present and future of themselves and their organizations. There’s nothing magical about the most effective leaders — they’re just making more effective choices. Equally important choices include their willingness to objectively look at themselves and take actions to grow in areas. They choose to become a more effective version of themselves. Leaders know that what they demonstrate – not what they say – is what has the greatest impact on the entire organization.

Brad Wolff specializes in workforce and personal optimization. He is a speaker and author of People Problems? How to Create People Solutions for a Competitive Advantage. As managing partner for Atlanta-based PeopleMax, Wolff specializes in helping companies maximize the potential and results of their people to make more money with less stress. His passion is empowering people to create the business success they desire, in a deep and lasting way. For more information, please visit www.PeopleMaximizers.com.

According to market research firm IDC, businesses lose between 20 to 30 percent in revenue every year due to inefficiencies. 20%

Experience innovations as well as fascinating technologies of the future. Be inspired by top speakers and the drupa highlight topics. Be part of the digital transformation and take advantage of opportunities for your business. Experience the future at the world’s leading trade

technologies.

the future

Elevate ordinary printed materials with eye-catching postpress techniques

Esko has extended its Kongsberg digital cutting table range with the Kongsberg X Edge, a fully upgradeable table design that delivers speeds of 30 m/min with acceleration of 0.3G for handling display, signage and packaging materials, from kiss cutting vinyl to heavy duty milling. The Kongsberg X Edge is suitable for short-run production, sample making and other packaging-related jobs, as well as signage and display production. “The extra fast tool loading, auto recognition and calibration features are ideal for short run jobs, with the added flexibility of an optional conveyor system available to support automated board and roll feeding when required,” says Russell Weller, Product Manager at Esko. Delivering a variety of milling options to match throughput requirements, the Kongsberg X Edge also boasts “perfect print-to-cut registration,” even in cases of heavy distortion and jobs longer than the table. The engineering of the rack and pinion drive, the construction of the tabletop and the quality of the motors and traverse are all designed to ensure that the table provides accurate and consistent cutting.

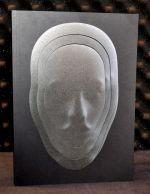

Printing United 2019 in Dallas, Texas, was the exclusive venue for the international debut of the new JETvarnish 3D One digital embellishment press from MGI and Konica Minolta. Designed for digital special effects for commercial printing, finishing and packaging applications, this new press offers a spectrum of 2D/3D spot coating and dimensional textures for commercial and in-plant printers. The price point and automatic inkjet head cleaning technology – along with the onboard Image Editor and Job Cost Calculator software programs –boast a simple path for developing new digital finishing applications and diverse new application-based revenue streams. Featuring key components of the JETvarnish 3D Press Series, including the intelligent and adaptive AIS SmartScanner registration system, the system is designed to provide full production and prototyping print embellishment capabilities

without screens, dies or plates. The all-purpose varnish formula allows both flat 2D Spot UV highlighting and sculptured 3D raised special effects on a range of substrates and media, such as paper, synthetics and plastics. Sheet sizes range up to 14 x 29 inches and the 2D/3D effects reach 116 microns in a single pass. Special MGI substrate management processes deliver tactile sensory print treatments on stocks from 135 to 600gsm – on various printed materials, from offset and digital inks to lamination films and aqueous coatings. The system is suitable for different commercial and in-plant applications, such as booklets, brochures, business cards, mail pieces, book covers, sheetfed labels, small folding cartons, retail display signs and posters.

The MGI JETvarnish 3D One offers a spectrum of 2D/3D spot coating and dimensional textures for commercial and in-plant printers.

Sakurai introduced the LQM 105 inline hot foil stamper to the North American market at Printing United 2019, where it also conducted live demonstrations of a Maestro MS-102AX cylinder screen press equipped with a Natgraph UV dryer, stacker and the LQM 105. The ScreenFoil LQM 105 aims to bring a “new level of flexibility, quality and performance” when combined with any size or vintage Sakurai screen press, the company explains, and is designed for folders, leaflets, business cards, loyalty cards, magazines, book covers, packaging, promotional items, labels, roll-to-roll, greeting card, automotive, appliance and plastic card applications. The featured Sakurai Maestro MS-102AX is a suitable screen press for a myriad of specialty finishing applications, such as specialty effects foil, glitter, soft touch, flood, soft spot coating and more, the company adds. The 29 5/8 x 41 1/2-inch MS-102AX operates at speeds up to 4,000 IPH and accepts stock from .003 to .032 inch thick. The Maestro is capable of printing on plastic film for electronic applications, membrane switches, display panels, touchscreens as well as paper, board and foil.

The Kongsberg X Edge is suitable for short-run production, sample making and other packaging-related jobs, in addition to signage and display production.

With the ability to perform up to six slits, 30 cuts and 20 creases in a single pass, the Duplo DC-618 can produce business cards, postcards, brochures, book covers and more with a full-bleed finish.

Duplo USA Corporation at Print 19 showcased the DC-618 slitter/cutter/ creaser, the newest addition to its signature line of fully automated finishers. Offering “significant” enhancements over its predecessor DC-616 Pro, the DC-618 is said to deliver output at a faster speed and on heavier stock. Duplo explains it also gave the PC Controller software and LCD control panel interfaces a facelift to make them more intuitive and user-friendly for in-plants and commercial printers looking to automate their shortrun finishing. With the ability to perform up to six slits, 30 cuts and 20 creases in a single pass, the DC-618 produces applications such as business cards, postcards, brochures and book covers with a fullbleed finish. Processing speed has been boosted from 10 to 23 sheets per minute and paper weight specifications have increased from 350 to 400 gsm. It comes loaded with standard features including an automatic barcode and registration mark scanner, ultrasonic double-feed detection and long paper tray. The workflow integration between EFI’s Fiery Impose and the slitter/cutter/creaser has been carried over as well to streamline the

job preparation process in Fiery Driven print environments by applying imposition, barcodes and registration marks for accurate finishing.

Scodix in February 2019 announced the commercial launch of the Scodix Ultra 101 and the Scodix Ultra 202 digital enhancement presses. The Scodix family of presses was designed to meet the increased demand for business-generating digital enhancement and allow print service providers to target new revenue opportunities. Boasting seamless integration, the Scodix Ultra 101 is described as being fully compatible with offset and HP Indigo presses. It offers six Scodix enhancements including Scodix Sense, Scodix Foil, Scodix Metallic, Scodix VDE, Scodix Glitter and Scodix Cast&Cure, plus combinations of all of

Scodix describes the Ultra 101 model as a “stepping stone” into the world of digital enhancement.

the above. The Scodix Ultra 101 solution made its worldwide debut at the HP Indigo Global VIP customer event on February 12. The full capabilities of the Scodix Ultra 101 was demonstrated with HP Indigo 12000 HD digital press. The Scodix Ultra 202 digital enhancement press aims to provide customers with the largest array of enhancement capabilities in the industry today. The press boasts “unmatched quality” – users can choose to print enhancements on paper, lamination, a variety of water-based coatings, PVC and carton. All nine of the Scodix applications run on the Scodix Ultra 202 press, replacing the need for separate systems on the production floor and preserving a small footprint, the company explains. By incorporating digital enhancement, print providers can expand their service offering with “attention-grabbing applications,” including business/greeting cards, folders, book covers, brochures, labels and packaging.

Xanté has announced two new configurations for its En/Press Multimedia Digital Press. Customers can choose extended paper handling with either two additional adjustable input trays or a single additional high-capacity letter/A4 tray. Both con-

figurations can be used along with the Enterprise High Speed Feed System. Customers that choose the additional two adjustable trays get the convenience of five total input source choices, including the Enterprise High Speed Feed System, on the En/Press. Three of the four input trays are adjustable up to 12.6 x 18 inches, bringing its total cutsheet capacity to 2,200 sheets. Having multiple trays, each with a capacity of up to 550 sheets, means fewer interruptions to change paper stocks or sizes, Xanté says. Choosing the single large-capacity input tray configuration gives customers an additional 2,000 sheets of letter/A4 media capacity in addition to the standard 550-sheet letter/ A4 tray and the 550-sheet adjustable tray included with the En/Press.

Rollem in September 2018 launched its latest Insignia die-cutter model, designed to die-cut materials up to 30 pt. thickness. Suitable for ID cards, gift cards, school IDs and memberships, the ISX3 is designed for flexible sheet sizes of 24 x 24 inches, enabling the ability to feed sheets either portrait or landscape. It performs various functions such as die-cutting, kiss-cutting, embossing, creasing and perforating in a single pass.

Today’s shorter and shorter runs, variable formats and sizes, plus customized content often complicate the production process. Enter Muller Martini’s Finishing 4.0 portfolio. Our game-changing solutions feature zero makeready, touchless workflow, and variable thickness, size, and content adaptability, so your organization can achieve amazing productivity despite today’s highly complex workflows. To learn more, contact your Regional Sales Manager.

APP Canada will expand its Paperline portfolio of products with Paperline Gold, a premium grade paper with 98 percent brightness, in early 2020. “APP has been a growing supplier of various uncoated offset and office paper to the Canadian market for the past 20 years,” says David Chin-Bing, President of APP Canada. “We remain fully committed to delivering the innovative and sustainable products the marketplace is demanding.” One of APP’s premium grade papers, Paperline Gold is designed for colour printing and high-end business communications for “sharp, clear copy and excellent print results with acid-free content.” The Paperline brand offers a full selection of bright white and various shades of colour paper. Paperline conforms to quality management systems of ISO

9001-2000, ISO 14001, and sources fibres from PEFC-certified sources.

Bobst in October 2019 launched the Bobst Vision CI flexo press for various production lengths on a wide range of substrates. Available as an initially eight-colour press, the Bobst Vision CI flexo press is said to be fast to setup and change over, and boasts consistent and repeatable printing quality with solvent-based and water-based ink printing. “With the Vision CI, Bobst has truly delivered on its vision for the future of CI flexo press printing,” said Mark McInulty, Managing Director CI Flexo Printing. Developed with sustainable benefits in mind, the press contains smartHEAT technology, which enables the machine to use its own heat as an internal energy source,

while its smartCLEAN technology is designed to save on ink and solvents. Furthermore, smartKEY and smartSET are designed to help maximize machine productivity by minimizing job setup time and material waste.

Roland DGA has introduced the IU-1000F, a UV-LED flatbed printer engineered for high-volume production. Designed for efficient printing on a range of substrates, including 4 x 8-foot rigid boards weighing up to 99 pounds,

the IU-1000F features 12 printheads in a staggered three-row arrangement and a four-inch carriage clearance. As Roland explains, the IU-1000F is ideal for printing vibrant, detailed graphics directly onto PETG, PVC board, foam board, wood, corrugated board, aluminum plate and more. The IU1000F prints edge-to-edge on thin or thick boards and offers multiple speed and performance options, including a maximum speed of 1,248.6 sqft/hr in a four-colour draft mode. Printing speed for a typical 4 x 8-foot (1,220 x 2,440-mm) size

The En/Press is, by far, the best machine for printing not only envelopes, but also for NCR business forms, stationery, posters, flyers, brochures, banners, newsletters, magnets, stickers, decals and much more.

rigid board averages about 35 boards per hour in draft mode (1,248.6 sqft/hr) or about 15 boards per hour in standard print mode (516 sqft/hr). In quality mode (174 sqft/hr), the IU-1000F averages about 10 boards per hour. A total of 1,280 nozzles per printhead, along with banding and mottling prevention features, allow for high-resolution image results of up to 635 x 1,800 dpi. Exclusively developed, high-density Greenguard Gold certified UV inks in CMYK, gloss and white cure “instantly and deliver stunning graphic results,” Roland explains, adding that a primer ink option allows for even greater adhesion, making it easy to prep and print on challenging materials, such as acrylic, glass and ceramic. Users can incorporate gloss and white specialty inks to enhance their prints with textural and dimensional effects. Meanwhile, variable dot technology allows for the simultaneous firing of droplets in three sizes to create high-definition images, smooth gradations and solid colour output. For easy media handling and print stability, the IU-1000F is equipped with a variable zone vacuum that can be applied to four different sections of the flatbed to maximize air cushion in specific areas. Other IU-1000F features include a media ionizer for increased ink-firing accuracy on materials that generate a lot of static; a Roland Print Control Center to manage the machine’s movements, speed, voltage and head cleaning; one-touch, automated daily printhead cleaning; and the ability to print on one or multiple boards at the same time.

Kernow North America describes its latest product, the KernowJet

MetaliK Window Perf, as a unique decoration film that enhances the visibility of communications on glass. The self-adhesive metallic material is a perforated, PVC-free film with a metallic effect on both sides. Specially designed for glass displays, the chosen perforation of 30-percent open area boasts “excellent shine and visibility of designs,” according to Kernow, adding that the film does not have a black rearside giving a see-through effect. The film is 2.2-mil thick and can be cut and weeded to create a negative image. Suitable for solvent, latex and UV-ink printing, KernowJet MetaliK Window Perf comes in gold, silver and rose gold, and is colour-matched on both sides.

Mimaki USA in October announced the next-generation TX300P-1800 MkII printer with dual-media and dual-ink support.TheTX300P-1800 MkII offers the ability to switch between transfer paper for dye-sublimation printing or direct-to-textile printing on one unit, and also offers additional dual-ink possibilities. When printing in direct-to-textile mode, excess ink that penetrates through the fabric is drained through a platen with an ink-receiving trough. To switch to transfer dye-sublimation mode, the user attaches a vacuum platen to support transfer paper. It can accept textile media up to 75.6 inches wide or transfer paper up to 76.7 inches wide. As Mimaki explains, the dual-ink capability of theTX300P-1800 MkII helps broaden the range of applications and markets served. It can be configured with three different ink combinations including textile pigment/direct sublimation, textile pigment/sublimation trans-

ONE-STOP SHOP — Die Cutting, Bindery, Data & Lettershop.

2. SUPERIOR TECHNOLOGY — Die crease without a die, then fold and even glue all on the same machine, up to 30 pt.

3. INTEGRATED MODULAR UNITS — Combined in-line finishing: crease, fold, glue, tipping, envelope inserting, ink jetting (Duplex), clip seal (3 sides), mail prep.

4. SAVE ON POSTAGE COSTS

—As a Certified Canada Post Direct Marketing Specialist, we get contract pricing reductions.

5. RETURN MAIL PRODUCTS — Customized “Return Mailers” created in-line with “U” or “BOX-shape” remoistenable glue, time perfed applications and envelope formation.

6. MINI-BOOKLETS — Saddle-stitch and trim 2-up booklets in-line to the size of a business card. No need to trim off-line, or do 2 passes.

7. HIGH SPEED EQUIPMENT — High speed Tipping, Folding, Saddle-stitching and soft folding ensuring on time delivery.

fer, or direct sublimation/sublimation transfer. TX300P-1800 MkII users can also install a single type of ink, and can choose from direct sublimation, textile pigment, disperse dye, reactive dye and acid dye, depending on the application. All inks are available in two-litre ink packs, and are installed in the Mimaki Bulk Ink System 3 (MBIS3).

swissQprint’s current range of UV inkjet inks are now Greenguard and Greenguard Gold certified, making its printed products safe for use in critical environments such as schools and hospitals. The company explains this is a potential competitive advantage for digital print providers, in addition to added versatility of the Swiss precision printers. Greenguard certification aims to ensure that products for indoor use comply with strict upper limits to chemical emissions for a healthier room atmosphere. Greenguard Gold sets even stricter certification criteria with added emphasis on the safety of at-risk groups, such as children and the elderly.

Printing United 2019, held in Dallas, Texas, marked the North American debut of the Xeikon CX500 and its Wall Deco Discovery solution. The company describes the CX500 as a dry toner, roll-to-roll, five-colour digital label press driven by Xeikon’s digital X-800 front end. It has a web width of up to 20 inches and a full rotary printing speed of 98 feet per minute at 1200 dpi.

“This show breathes new life into trade events for our industry,” says Donna Covannon, Xeikon America’s Director of Marketing. “Most

visitors to our exhibit were on the lookout for new revenue-generating applications and a number of them were commercial printers looking to expand into label, packaging and industrial applications. They were impressed by the power and versatility of our web-fed dry toner presses.” The Xeikon CX500’s range of applications include direct mail marketing to wall coverings, POP/POS posters, paper cups, flexible stand-up pouches, large signage and a variety of roll-to-roll heat transfer and in-mold labels.

Markzware, a software developer for the printing, publishing and graphic design industries, in November launched IDMarkz, an application that acts as a hub for Adobe InDesign files. IDMarkz is designed to display InDesign file previews, export InDesign files to IDML and image file types, plus convert or open InDesign files in other DTP applications. It is available as a full-featured perpetual licence, as a paid subscription licence, and as a limited freebie (which displays InDesign file previews). IDMarkz app features include: Opening InDesign files CC 2020 in earlier InDesign versions, and in QuarkXPress, Affinity Publisher, Acrobat, or Illustrator; previewing any Adobe InDesign file and viewing basic file info, zooming previews and dragging thumbnails from the preview area, to create a PDF of the page; exporting InDesign files as IDML, PDF, TIFF, PNG, JPEG, or GIF; and creating PDFs with editable text from older InDesign files, annotating in Acrobat DC, then opening in InDesign CC 2020. System requirements include macOS 10.12 or newer, 4 GB of RAM, 1024×768 display, and an Internet connection.

Heidelberg: K-Line/S-Line/Speedmaster/GTO/MO/KORD64

Komori: 1, 2, 4 or 5 colours & any size

Adast: 714/715/724/725

Mitsubishi: Any model

Ryobi: 2800CD/3200CD-MCD/640K

Itek: 960/975/985

Hamada: 600/700/800/E47/RS34

Shinohara/Fuji: 66/65 1,2 or 4 colours

Sakurai: 1, 2 or 4 colours and any size

(newer model)

Polar: any size/older or newer models

(66/72/76/78/82/90/92/107/115)

Horizon-BQ: 220/240/260/440/460

Renée Walsh is Vice President, Enterprise Sales, at TI Group, where she works with clients to help strengthen their brand identity, grow their business, and gain market share. In this Q&A, Walsh shares her thoughts on opportunities in the industry and how print service providers can stay competitive.

PA: How does TI Group continue to innovate after 40 years of business?

RW: We have to listen to our customers. We have to really and truly understand our client’s business. Understanding their needs drives our innovation areas and where to make investments. To that end, we are very focused on ensuring proper inputs to the print production process. We have custom-built solutions for our clients to organize their data and streamline workflows. Whether the data is a store profile, a print specification or a complex distribution, we have to expertly manage this content. In addition –and most importantly – the talent at TI Group is outstanding, such a great group of hardworking people! It is our team that keeps TI Group successful.

PA: What do brand owners ask for?

RW: Brand owners are constantly looking for ways to lift sales and raise brand awareness. This translates to innovations in retail and unique brand activations/shopper experiences. TI Group is constantly presenting big ideas to our clients. Of course, in addition to exceptional print quality and brand consistency, marketers and visual merchandisers today rely on trusted print service providers for speed to market and full service solutions. This is the value that TI Group delivers, being able to produce across several platforms from ideation through to fulfilment.

PA: In this competitive landscape, how can printing companies win more sales?

RW: I strongly believe that people buy from people and therefore at TI Group, we strive to showcase the best client experience. We pride ourselves in our loyal and long standing relationships. We translate these successes into organic growth and new business partnerships. It is imperative that we understand our client’s needs and objectives so that we can bring more solutions. TI Group has grown through referrals and recommendations. There is no silver bullet for winning new business but it is very important that we do good work and deliver on time, on brand and on budget.

PA: How is the state of the print industry?

RW: Our industry is complex and rapidly changing. As a whole, the industry is regularly introducing new products and setting the bar higher and higher for

value-adding services. The challenge for print service providers is to adapt quickly to new market needs. Print used to be strictly a mass-media tactic, yet this has changed with customization capabilities. Although the industry is evolving and refining, print will continue to be relevant and thrive!

PA: What are some of the biggest opportunities you see?

A brand engagement study by Gensler finds 94 percent of respondents say they are very likely to recommend a brand they are emotionally engaged with. 94%

RW: Digital technologies and variable data printing present the opportunity for personalization. This is not new in the direct mail world, but we are seeing this in retail where messaging is localized at the store level — creating intimacy with the butcher or baker with a story about their background and curated recipes, for example. We are also seeing this with short-run digital packaging, which has been a growth area for us at TI Group. Customers are willing to pay more for a personalized product and are more willing to share personal information in exchange for an individualized experience.

PA: How did you get started in the industry? What attracted you to it?

RW: When I was in high school, I worked on the yearbook committee and learned about layout, graphic reproduction and print

production. My guidance counsellor introduced me to Ryerson University’s GCM program. Once I got hands on design software and film, I was hooked! As an intern in the program, I worked on both packaging and print advertising projects. There is nothing more gratifying than seeing the results of your work in the marketplace, knowing that you played a significant role in its execution.

PA: Why do you think print continues to be relevant in a digital future?

RW: As exciting as our digital future may be, print will always be relevant! Savvy marketers know how to integrate multiple platforms, media and touchpoints for the best results. There will always be mail, packaging, corporate interiors, wayfinding and other POP-printed signage or displays. Print complements digital in a tactile and memorable way.

PA: What is most exciting about print today?

RW: I get excited about executing outstanding creative and helping clients get a return on investment/experience. We all win when we can help brands with engagement, adoption, retention or sales success.