Thirty of the most influential business developments from the past year that have shaped Canadian print

Print leaders share their best practices and tips for recruiting and hiring the next generation

GAMUT

5 News, People, Installs, Globe, Dots, Calendar

NEW PRODUCTS

21 Introducing new offerings from 3M, DuPont Advanced Printing, EFI, Fujifilm, GMG, HP, Mohawk Fine Papers, Roland DG, Rotoflex, SmartSoft and Tecnau

SPOTLIGHT

26 Derek McGeachie, CEO and Founder, Mi5 Print & Digital

FROM THE EDITOR

4 Alyssa Dalton

The holiday experience

CHRONICLE

10 Nick Howard

The outliers among us Industrial strength digital has arrived

SALES

12 Dave Fellman

Do you make it all about price? Build a successful sales strategy by leading with more than the cost

“Humans build culture – and, by extension, brands – primarily through telling stories. That’s how we make sense of the world and of ourselves: Storytelling. It’s innate. And since the dawn of capitalism, we’ve been telling stories to sell ourselves and our brands too,” said Peter Grossman of Quora in an August 2018 interview with Forbes

Indiana-based consulting firm

Walker Information predicts that by 2020, the customer experience will overtake price and product to become the key brand differentiator.

One of the most recognizable holiday symbols is the Starbucks holiday cup, first introduced in 1997. For many, the anticipated return of the ‘red cup’ signals the start of winter. The holiday designs, over the past two decades, have ranged from whimsical brushstrokes in bold colours to vintage flair. This year the company welcomed the festive season with four retro designs inspired by its own coffee roasts and logo.

“The emotional connection that our store partners [employees] have when they open that first box of the red cups and start using them that first day, and the emotional connection they see from their customers, that’s what we strive for,”

Terry Davenport, then-Senior Vice President, Global Brand and Creative Studios at Starbucks, said in a 2013 interview with Dieline

In past years, Starbucks has gone for a more interactive cup design. Last year the traditional red cups were white with colour-it-yourself doodles, while the 2016 cups featured 13 crowd-sourced designs submitted by customers through a worldwide Instagram contest.

As a physical form of communication, print helps to cultivate rich customer interactions that forge authentic, emotional relationships. Companies often take advantage of the festive season to experiment with their brand strategy.

For the 2015 holiday season, Oreo gave consumers the chance to get creative with the cookie wrappers through customizable illustrations, printed using an HP Indigo WS6600 digital press. Customers could choose to colour the package online or order a white-andblack pack for at-home colouring. The packaging also allowed customers to add a personal message.

Texas-based Karbach Brewing Co. takes beer fans down a nostalgic road with its seasonal brew, Yule shoot your eye out, inspired by the 1983 classic film, A Christmas Story. The can is decorated with the infamous ‘leg lamp’ – a lamp consisting of a stockinged woman’s leg wearing a highheeled shoe, topped with a black-fringed bell shade – one of the most distinguishable movie props of all time.

Heineken released its limited-edition 1.5-litre bottle last month, mirroring the festive look of a champagne bottle — an unusual size and shape for the Dutch pale lager beer well-known for its signature green bottle. “Beer is an essential purchase for holiday celebrations. More than any other season, consumers want the brands they serve during the holidays to reflect the spirit of the season,” says Bjorn Trowery, Director, External Communications at Heineken USA.

Lee Yohn continues, “Whether through product design, web design or retail design, great brands create extraordinary experiences – brand ‘worlds’ of sorts – that appeal to all the senses and use details and decor to help express their brand personalities.”

Breakfast sausage brand Jimmy Dean, from November 12 to December 23, is hosting a recipe gift exchange for free holiday swag. After sharing their favourite recipe that features a Jimmy Dean product, customers can choose from various gifts, such as sausage-scented gift wrap, a holiday apron or a glass sausage tree ornament, as a thank-you for their participation. The “smells like sausage, tastes like paper” gift wrap proved to be a hit and was out of stock several weeks into the promotion.

Last year Hemlock Printers released its own scented wrapping paper through Hemlock Holiday Wrap, a yearly staple in its project portfolio. With eight different compositions, the 2017 series was dedicated to the passing of founder Dick Kouwenhoven. One of the featured designs, the Hemlock Bake Sale sheet, recognizes the company’s annual fundraising bake sale and pictures a few of Kouwenhoven’s favourite baked delicacies. The sheet was printed with a UV CMYK ink sequence with a gingerbread-scented spot varnish.

“Because well-crafted design elicits emotional responses, great brands use packaging design to stand out in the crowd and make powerful first impressions. The best packaging designs are not only emotionally appealing to customers; they also convey the unique meaning and value of the brand. Packaging design alone can facilitate an emotional connection and bonds customers to brands,” writes brand leadership expert Denise Lee Yohn in the Forbes’ article, Let design do the talking for brands ALYSSA DALTON, editor adalton@annexbusinessmedia.com

“Every single encounter that people have with your brand will either enhance its value or diminish it. Creating a ‘brand world’ means carefully choosing and integrating every element,” Lee Yohn says.

Editor Alyssa Dalton adalton@annexbusinessmedia.com 416-510-5225

Contributing writers

Zac Bolan, Wayne Collins, David Fellman, Victoria Gaitskell, Martin Habekost, Nick Howard, Neva Murtha, Abhay Sharma

Associate Publisher Stephen Longmire slongmire@annexbusinessmedia.com 416-510-5246

Media Designer Lisa Zambri lzambri@annexbusinessmedia.com

Account Coordinator Alice Chen achen@annexbusinessmedia.com 416-510-5217

Circulation Manager Barbara Adelt badelt@annexbusinessmedia.com 416-442-5600 ext. 3546

Circulation apotal@annexbusinessmedia.com

Tel: 416-510-5113

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Group Publisher Diane Kleer dkleer@annexbusinessmedia.com

President & CEO

Mike Fredericks

Subscription rates

For a 1 year subscription (10 issues): Canada — $42.00 Canada 2 year— $69.00 United States — CN$74.00 Other foreign — CN$144.00

Mailing address

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

printaction.com

Tel: 416-442-5600

Fax: 416-442-2230

Annex Privacy Officer Privacy@annexbusinessmedia.com 800-668-2384

PrintAction is printed by Annex Printing on Creator Gloss 80lb text and Creator Silk 70lb text available from Spicers Canada.

ISSN 1481 9287 Mail Agreement No. 40065710

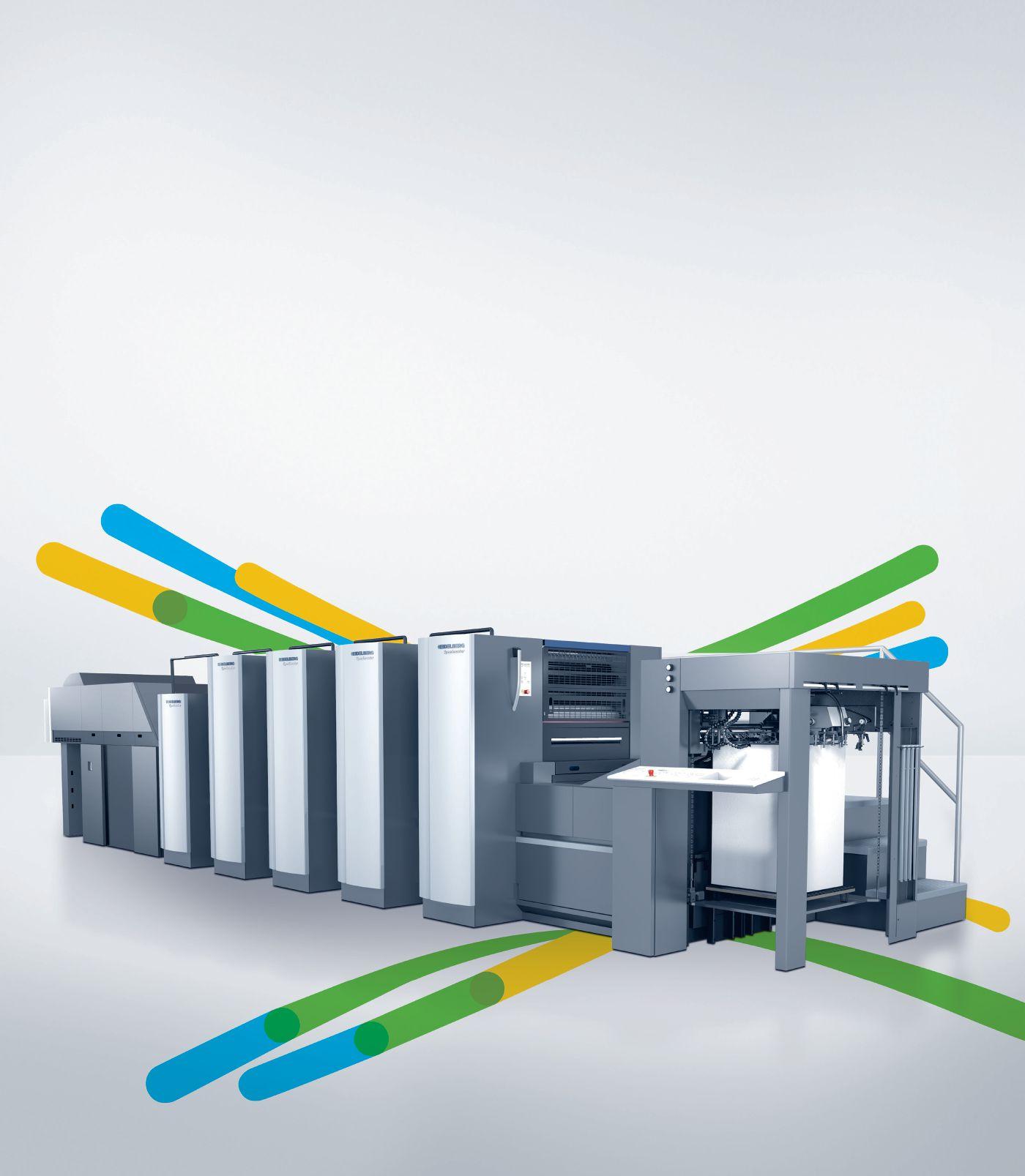

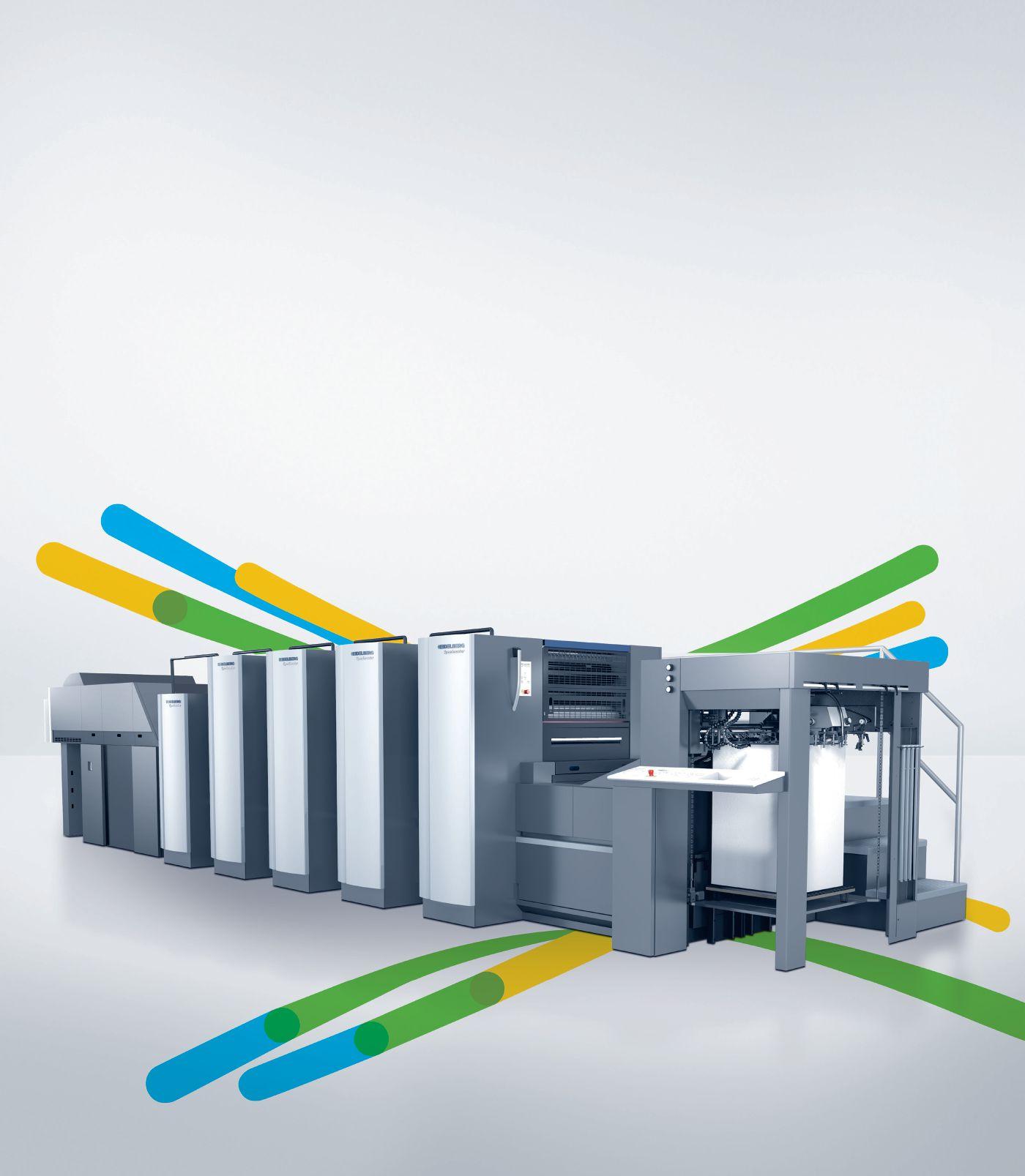

Through the subscription model, Heidelberg will provide Burke with new equipment, Prinect software, Saphira consumables, consulting and service.

The Burke Group of Edmonton, Alta., recently signed the first Heidelberg subscription contract in North America, which is expected to help Burke double its productivity and increase profit without the challenges that come with equipment ownership. Burke’s subscription contract includes a new Speedmaster XL 106 8-colour perfector with coater and LE UV curing, a Stahlfolder TH 82-P with the high-performance PFX pallet feeder, and a Polar N 137 cutting machine. Running 24 hours a day and 7 days a week, Burke says it plans to run twice as much work through its print shop as a result of the new equipment and partnership. Replacing a competitive press, the Speedmaster XL 106 will join Burke’s Speedmaster SM 52 and Speedmaster SX 52 in the press room.

In November Eastman Kodak Company entered into a definitive agreement to sell its Flexographic Packaging Division (FPD) to Montagu Private Equity LLP, a private equity firm. After closing, the business will operate as a new standalone company which will develop, manufacture and sell flexographic products, including the flagship Kodak Flexcel NX System, to the packaging print segment. Under its new ownership, the business will have the same organizational structure, management team and growth culture that has served Kodak’s FPD in recent years.

Canadian printing companies The Printing House and Mitchell Press are two of the three most forest-friendly printers in the 2018

Blueline Ranking, a comprehensive assessment of the environmental performance of North American printers published by Canopy, a global environmental not-for-profit. The interactive Blueline Ranking is designed to help paper and packaging customers choose printers that can help them meet their own climate and sustainability goals and access Ancient Forest Friendly papers. Printers at the top of the ranking were active in advocating for the conservation of Ancient and Endangered Forests, supporting the development of next-generation solutions, and bringing greater transparency to sustainability reporting, Canopy explains. The Printing House came in as the top-rated Dark Green Ink-drop winner, receiving 43.5 of a possible 45 points, the highest ranking in Blueline history, while Mitchell Press makes its entry in the Blueline Ranking as third top printer.

Sydney Stone has been named the exclusive distributor of Xanté Corporation products in Canada. Established in 1951, the Canadian distributor of print finishing equipment and supplies will sell Xanté products directly as well as through the existing network of local dealers. “Sydney Stone is very pleased to be adding the Xanté range to our fold of customer offerings. The new En/Press combines industry-leading 4800 dpi resolution with the lowest consumable cost in the market category. This is going to give our customers the chance to improve in-house productivity and, above all, profits,” says Michael Steele, President at Sydney Stone.

Advertising company Pattison Outdoor Advertising is expanding its product portfolio in Saskatchewan with the addition of Saskatoon Transit. The five-year contract will offer interior and exterior advertising space on 145 transit vehicles and 38 shelters (76 faces). “With the addition of Saskatoon Transit into the Pattison portfolio, we are thrilled to have the ability to offer our clients one-stop shopping for media products in Saskatchewan with coverage on outdoor, digital, airport and transit,” says Brian de Ruiter, Vice President and General Manager, Prairie Region at Pattison Outdoor Advertising. Pattison Outdoor now offers coverage in the province’s major markets utilizing advertising products across the Regina, Saskatoon and Moose Jaw transit systems. Established in 1908, the company is headquartered in Toronto, Ont., and includes more than 25 sales offices across the country.

Starting November 15, Flint Group Packaging Inks increased its prices for all Flint Group Packaging Inks products sold in Canada and the U.S. to alleviate raw material and freight cost increases. “The recent trade tariffs imposed by the U.S. government are soon to rise from 10 to 25 percent, a cost Flint Group cannot bear alone. Additionally, the market has seen significant cost increases in raw materials and freight across the North American region, which place further pressure on Flint Group’s cost base,” reads a statement from the company.

Mark Andy Print Products, the supplies and consumables division of Mark Andy, has been appointed the preferred distributor of RotoMetrics’ line of print cylinders including RotoGuard and RotoGuard, and the line of magnetic cylinders including AccuBase XT and AccuBase. Pairing the tooling from RotoMetrics with Mark Andy’s distribution network and a team of technical

experts, the deal aims to provide customers with “high-quality products and best-in-class service.”

Over 100 people attended the annual MPIA awards evening.

On October 17, the Manitoba Print Industry Association (MPIA) held its sixth annual Name in Print awards, recognizing companies and individuals for their contributions to the print community.

Fibre-based materials provider Ahlstrom-Munksjö has partnered with five companies to develop a new flexible paper-based packaging solution. The objective of the project, dubbed Sherpack, is to develop a renewable, biodegradable and recyclable flexible paper-based packaging material by replacing current materials with more sustainable ones, leading to fewer plastic films. The four-year project, which kicked off in 2017, involves Ahlstrom-Munksjö, Cargill and Borregaard, as well as research centres CTP, ITENE and ISOF-CNR.

Ricoh Company in November reached an agreement to buy ColorGATE Digital Output Solutions GmbH, a colour management software provider in the printing industry. Founded in 1997, ColorGATE of Hannover, Germany, provides software for the wide-format and industrial printing sectors. The company explains it offers unique colour management technology to print and decorate a variety of materials used for packaging, floor and wall coverings as well as textiles and signage, noting it offers performance-optimized colour management and workflow software to standardize and automate growing digital print markets including decor and textiles. In February Ricoh announced Ricoh Ignite, its growth strategy plan which aims to reinforce its value offering by expanding its printing technology portfolio. The investment in ColorGATE is the latest part of this plan. Ricoh has announced Thomas Kirschner, Co-founder of ColorGATE, will continue to serve as CEO of the company.

Roger Gouveia is joining the Divicor team, where he will be leading business growth in Central and Western Canada. He brings over 20 years of experience in the chemical distribution industry with extensive knowledge of the graphic arts market, the company explains. Gouveia joins Divicor from Azelis Canada Inc. where he served as the Senior Account Manager, CASE Division for Ontario and Quebec. During his tenure with Azelis, he was responsible for the graphic arts, coatings (powder and industrial), rubber and specialty markets. Divicor is an independent salesforce representing a grouping of manufacturers to the Canadian marketplace with ICP Industrial Canada Inc. (coating, adhesive & silicone brand manufacturer of Nicoat and MinusNine Technology) and Technorol-Innovachon (a rollers manufacturer, a blanket converter, distributor of pressroom chemistries and pressroom supplies).

Flash Reproductions has added the DigiBook 450 Perfect Binder in its Mississauga, Ont., facility, calling it the “ideal piece of equipment” for its binding needs. “The 450 offers the widest range in book sizes in the category, it’s easy to use and reliable, plus the finished product looks fantastic,” says Rich Pauptit, President.

Jet Marking Systems (JMS), a provider of label application solutions and ancillary equipment, is welcoming Dan Stickney as General Manager where he will be responsible for overseeing all aspects of the company’s business operations, client relations and strategic direction. In addition to sales, JMS – a sister company of Jet Label & Packaging – offers maintenance programs designed to minimize machinery downtime while maximizing overall performance. Spanning Western Canada, JMS’ team of technicians and OEMs aim to automate and streamline processes to help customers optimize their labelling operations. Stickney earned an MBA from the University of Alberta and an undergraduate degree from the University of British Columbia, and currently resides in Edmonton.

Esko has appointed Mattias Byström President effective January 1, 2019, succeeding Udo Panenka who is leaving the company to pursue new opportunities, Esko explains. Byström brings over two decades of general management experience. Most recently he was CEO of FlexLink, a global $300-million factory automation solutions business with headquarters in Gothenburg, Sweden.

Family-owned Full Frame Signs in Toronto, Ont., has acquired Fujifilm’s Acuity Select 28 UV inkjet press for creative print applications. The Acuity Select 20 Series features up to eight colour channels, including options to run white, varnish and now light inks, showcasing Fujifilm’s Uvijet KN ink for a variety of output.

Contiweb has named Chuck Irons Vice President for the Americas, where he will oversee North and South American operations, including sales, customer support, customer service and parts supply. Irons brings a wealth of knowledge to his new role, with over 35 years of experience in the printing industry alone, approximately 20 of which with Contiweb.

MPS Systems, a Dutch-based manufacturer of flexo, offset, and hybrid printing presses, has named Atze Bosma its new CEO. Bosma will lead MPS alongside Willem Huijink, CFO, effective December 1.

Pronto Reproductions Ltd., based in Mississauga, Ont., recently added to its line-up of litho offset and digital printing presses with the installation of a new Xerox iGen 5 digital press for short-run capabilities, with 2,400 x 2,400dpi imaging, matte toner, white and clear ink, and extended colour gamut.

Dunapack Packaging, a maker of printed corrugated packaging in Poland, has invested in the EFI Escada Profile, a closed-loop process control system designed to enable consistent quality and overall efficiency.

Kingery Printing is marking its 50th anniversary with the operation of its new Koenig & Bauer Rapida 105 PRO 41-inch 10-colour five-over-five perfecting press with an inline tower coater.

It was December 2017 when the family-owned firm that specializes in print-driven products and services, such as catalogues, publications, marketing collateral and book production, took delivery at its headquarters facility in Effingham, Ill. Since then, the firm says it has experienced higher quality and accuracy, over 50-percent increase in net press speeds, “significant waste reduction and incredibly fast changeovers from job to job in under eight minutes.”

To maintain its growth, Kingery chose to invest in a new highly-automated press from Koenig & Bauer, which replaced three older presses. The Rapida 105 PRO produces jobs either straight or perfecting at 15,000 sph, 50 percent faster net speeds than was previously possible, the company explains.

On the front end of the new Rapida 105 PRO, two non-stop fully-automatic feeding options are in place that allow for either sheets or paper from rolls to be fed into the press with no operator intervention. Printing from rolls has enabled Kingery to realize paper savings of up to 30 percent. To the delight of press operators, the Rapida’s auto-plate loading system has also contributed to reducing makeready time. All of this top-flight automation has reduced waste significantly by as much as two-thirds, making this one of the greenest assets in the Kingery Printing arsenal, it says.

With Kingery’s array of customers, the firm was challenged to print on a range of substrates from lightweight paper to heavy board stock. It was necessary for its new Koenig & Bauer press to offer the flexibility and quality to tackle these demands. The Rapida 105 PRO is designed to print 40 lb book substrates up to 28 pt. board as well as on specialty substrates such as plastics, synthetic paper and label stock, which will allow Kingery to open new markets.

The firm says it will run the two Roland VersaEXPRESS RF-640 inkjet printers and Roland cutting systems 24 hours a day to produce made-to-measure wall graphics.

New England specialty printer Bradford & Bigelow has purchased a Lithoman 48-page four-colour press for its 50,000-square-foot pressroom addition at its Newburyport, Mass., location. The Lithoman press, one of several new machines planned for the updated facility in the future, includes a full portfolio of automated inline controls, including InlineRegistration Control, InlineCutoff Control Dynamic, and InlineDensity Control (IDCm).

The press also includes the DynaChange imprint function, which uses only the blanket cylinders of engaged printing units, allowing for increased production speed, and a fully automated printing plate changing device (APL). Remote diagnostics systems will allow technicians from manroland Goss to diagnose any variables to the printing process, helping to ensure maximum uptime, it adds.

Wallpaper Ink has installed a second Roland VersaEXPRESS RF-640 printer, running it around the clock to cater for the ever-increasing demand for bespoke wall murals. “The buzz around murals has been growing for over six years,” says Scott Evans, Managing Director of specialist wall mural manufacturer Wallpaper Ink. “There’s a kick-on effect; when people see one, they want one of their own. Wallpaper is back in fashion generally and that, combined with a demand for personalization, means a thriving market.”

Based in Wales but serving customers entirely online, Wallpaper Ink runs its two Roland VersaEXPRESS RF-640 inkjet printers and Roland cutting systems 24 hours a day to produce made-to-measure wall graphics. Customers – around 30 percent commercial and 70 percent private – can choose their mural image from over 40 million options on Wallpaper Ink’s website, plus their preferred material and dimensions.

The company explains it can turn around an order in hours, offering next-day shipping for orders placed before 3 p.m., noting that this has been reduced from 1 p.m. since the installation of the first Roland printer, which Evans says ticks all the boxes for his business.

Located in Central Jawa, Indonesia, PT Macanajaya Cemerlang is a multifaceted printing company with three printing plants, two in Central Jawa and one in South Sumatra.

In March, Tensor International was awarded a contract for a new book press consisting of two T-400 4-high printing towers and one H-50 folder. The 40,000 iph rated Tensor T400 printing units are equipped with remote inking and spray bar dampening. Tensor, along with its sister company DCOS Automation Sweden, designed into the configuration a unit shaftless drive system, integrated press console, and an automatic camera-based registration and cut-off control system. The shaftless heavy duty H-50 folder, it explains, is equipped with commercial grade quarter folder along with a complete signature perforation package.

The T-400 was added to its existing Solna press and will produce four-colour textbooks.

The equipment, the company explains, shipped in early September and installation was completed in November.

Various Tensor T-400BE installations for newspaper and semi-commercial applications in Turkey.

To mark the 100th anniversary of the end of the First World War, Maclean’s printed 66,349 commemorative issues, each featuring the name of a Canadian who sacrificed their life in the conflict.

“Sixty-six thousand, three hundred and forty-nine names — and one ‘Unknown,’ representing all the soldiers, some 20,000 never accounted for; buried in forgotten graves, or sucked deep into the mud of Flanders, or obliterated by the destructive power of weaponry never before seen in battle,” Maclean’s writes in the article, In their honour, we publish their names

Since the issue’s publication in October, the magazine received a number of requests from readers seeking more information, either to connect with the living relatives of the service man or woman featured on their cover, or to find out where a particular cover ended up. In an attempt to facilitate connections, Maclean’s created a registry for those looking for more information or to order a customized edition that features the name of a family member or significant individual.

“[We] created this initiative to mark the sacrifice made by each of them,” the magazine explains on the registry homepage. “Moreover, we wanted to offer a glimpse of these servicemen and women as people — individuals with a family, a job, a church and a community. They were ordinary people called upon to make an extraordinary sacrifice.”

April 11-13, 2019

Graphics Canada

The International Centre, Mississauga, Ont.

April 24-25, 2019

AICC Canada Trade Show and Conference Toronto, Ont.

May 14-17, 2019

FESPA Global Print Expo 2019 Messe München, Germany

June 13, 2019

PrintForum 2019

The International Centre, Mississauga, Ont.

October 3-5, 2019

Print 19 Chicago, Ill.

October 23-25, 2019

Printing United 2019 Dallas, Texas

November 7, 2019

Canadian Printing Awards

Palais Royale, Toronto, Ont.

November 25-28, 2019

Shanghai World of Packaging Shanghai, China

June 16-26, 2020 drupa 2020 Dusseldorf, Germany

By Nick Howard

Malcolm Gladwell’s 2008 bestseller Outliers garnered worldwide attention, posing the argument that successful people needed more than brains, ambition, hustle and hard work to reach the top. Gladwell reasoned they also needed luck. Using various examples such as Bill Gates’ access to a university computer or the Beatles 10,000+ hours of practice, Gladwell postulated that luck combined with serendipity played a key role in one’s success.

All those interminable nightclub dates in Liverpool and Hamburg polished Lennon and McCartney’s music.

The same can also be said of Apple Inc.’s Steve Jobs. Xerox Corporation has a developmental lab in Palo Alto, Calif. Started in 1970, its purpose is to incumbent new technologies within the realm of graphic communications and to develop new tools for the exploitation of the Xerox business. Known as PARC, ground-breaking technologies such as the graphical user interface and the mouse came out of the research and development lab. Today Xerox is the recipient of about half of the technology generated. Giants such as Fujitsu, Dai Nippon Printing Co., Ltd. and Samsung are also current clients of PARC.

The graphical user interface (GUI) is something we take for granted today. GUI is used everywhere. Anyone who stills remembers DOS and its brain-freezing use of the ‘F’ buttons will certainly be appreciative of this watershed technology, perhaps no one more than Steve Jobs. An urban legend suggests that Jobs gained access to PARC and upon seeing the GUI and the mouse, used it to develop the Lisa computer. Perhaps that’s not all accurate but regardless, PARC indeed did invent the GUI and seemingly lost interest as the tie-in with Xerox toner-base printers was not evident or obvious. Jobs had been to PARC and that is one fact that is corroborated. Another fact is some members of the Apple development team had also worked previously at PARC.

Xerox PARC is also credited with inventing the personal computer. Our office bought one (a Star) around 1981. I recall it was really expensive; $16,000 comes to mind.That’s equivalent to $45,000 today! The PC was huge with a pack-to-pack dot matrix printer and monstrous 8-inch floppy discs. With minimal computing power in an era where simple word processing was prevalent, the Xerox PC quickly disappeared with the onslaught of both the Macintosh and IBM.

Xerox’s Rochester neighbour Kodak owned the technology for the world’s first digital camera in 1975 when Kodak engineer Steven Sasson invented it. Kodak shelved this breakthrough for similar reasons as Xerox’s GUI. Both either feared the death of their bread-and-butter businesses or simply could not fathom a need, not realizing that they would get it all so terribly wrong. How do we sell more photocopiers if offices printed less? How would the fabulous film business cope when no one needed to buy film?

In today’s print marketplace, radical technologies are coming fast and furious. History always repeats itself. Change of any type is the hardest human trait to break. When you shake an apple tree sometimes more than fruit falls out. It is the same when disruptors use methods outside of what we think is the norm in order to solve problems. It’s these same outliers who discover the next potentially radical idea. Inkjet technology is fast becoming that idea. For years the majority

of people running print communication businesses threw cold water on the concept that inkjet was going to be anything more than useful on an addressing machine.

But within the space of the last 24 months, machines have gotten better and faster. So much faster that our industry is spoiled for choice on what to buy. Recently Heidelberg unveiled two installations of its new Primefire 106 collaboration with Fujifilm; ColorDruck in Germany and Warneke Paper Box in the U.S. Not to be outdone, Landa Digital placed four of its S-10 40-inch presses in print shops of Germany, Switzerland and the United States. Océ’s ImageStream roll-fed as well as the Konica Minolta-Komori joint venture (KM-1 and Komori IS29) and Fujifilm’s latest J Press 750S are after years – if not decades – starting to find homes that were the exclusive enclave of offset. Inkjet in all its various manifestations has, in a relatively few short years, become an anchor of the printing process. Consider also the rapid developments with dry and liquid toner equipment from Kodak, HP, Xerox, Ricoh and Konica Minolta. Toner has a fair share of the offset market as well. After drupa 2016, I heard negative opinions by some printers about the various demos they saw. Many complained that images were weak and rub-off was poor. Some brought up other key weaknesses such as available colour gamut or difficulties in post-press. Few seemed to be preoccupied with slow speeds or over-the-top price tags. Since 2016 things have changed and improved

considerably and more to the point, printers seem to finally have connected the dots in how implementing digital as a replacement for offset makes profitable sense. Run lengths are still shrinking and quality is increasing – the perfect situation for slower platforms. Add in variable data and more SKUs and all of a sudden digital looks like a godsend.

With a few exceptions – Landa, Heidelberg and Koenig & Bauer (who use legacy offset platforms) – are the only ones to offer a tower coater. Few, if any others, have offered in-line coaters. This will no doubt be a welcomed addition in the near future. Fujifilm’s J Press 750S, released in November 2018, has already increased its output 33 percent compared to its first 720S model albeit still without a coater. We now talk months, not years, for rapid improvements in both speeds and flexibility.

As we approach 2019, it would seem that Gladwell’s Outliers has finally taken a stranglehold on our print industry. Perhaps up until now the majority of printers collectively refused to think outside the box for the next great thing.

Malcolm Gladwell’s Outliers debuted at number 1 on the bestseller lists for The New York Times and The Globe and Mail , holding the position on the former for 11 consecutive weeks.

In the next 10 short years when our history is again rewritten, will we ponder why we hung on to [offset] technology that was over 100 years old? Or will we celebrate just how easy it is to produce beautiful work in all guises with the help of a mouse, a screen and imaging devices the size of a fist? Or even perhaps surprisingly, the invention of the PC and GUI, discarded as irrelevant, would be embraced by folks that could dream differently?

I think Steve Jobs said it best when he addressed the graduating class of Stanford University in 2005:

“I decided to take a calligraphy class to learn how to do this. I learned about serif and sans serif typefaces, about varying the amount of space between different letter combinations, about what makes great typography great. It was beautiful, historical, artistically subtle in a way that science can’t capture, and I found it fascinating.

“None of this had even a hope of any practical application in my life. But 10 years later, when we were designing the

first Macintosh computer, it all came back to me. And we designed it all into the Mac. It was the first computer with beautiful typography. If I had never dropped in on that single course in college, the Mac would have never had multiple typefaces or proportionally spaced fonts. And since Windows just copied the Mac, it’s likely that no personal computer would have them. If I had never dropped out, I would have never dropped in on this calligraphy class, and personal computers might not have the wonderful typography that they do. Of course it was impossible to connect the dots looking forward when I was in college. But it was very, very clear looking backward 10 years later. Again, you can’t connect the dots looking forward; you can only connect them looking backward.”

NICK HOWARD, a partner in Howard Graphic Equipment and Howard Iron Works, is a printing historian, consultant and Certified Appraiser of capital equipment. nick@howardgraphicequipment.com

Way more than an envelope press.

The En/Press is, by far, the best machine for printing not only envelopes, but also for NCR business forms, stationery, posters, flyers, brochures, banners, newsletters, magnets, stickers, decals and much more.

a successful sales strategy by leading with more than the cost

By David M. Fellman

This is the fourth instalment in my series, The top 5 ways to talk yourself out of a sale Today’s topic is Making it all about price — which you hopefully don’t do. I hear many complaints from print salespeople that buyers who only care about price. Sadly, some of the blame lies with the salespeople and printing companies. One of my early sales trainers had a favourite expression, that he or she who mentions price first, loses. In my experience, too many printing salespeople are guilty of that selling sin.

The race to the bottom

Seth Godin has written 12 best-selling business books that have been translated into 33 languages. He has also posted thousands of blog entries and delivered hundreds of keynotes. I was privileged to be on the same program with him some years ago, and I got a front-row seat for his presentation. He talked about marketing and selling that day, and even about the printing industry specifically, even though this was not a print conference. I sat in embarrassment as he used us as an example of bad selling strategy.

“I buy a lot of printing,” he said, “and the printing industry seems determined to convince me that I should always buy their product from whoever offers me the lowest price.” He said that everyone who called on him had the same initial strategy and follow-up strategy. First, they asked for the opportunity to bid on his printing. Then, they called to see how their prices compared. He recalled always telling them that their price was competitive, but not the lowest he was being offered. And then they always, he said, asked for the opportunity to “sharpen their pencil” and re-submit their bid.

I am not sure I believe the “always” part, but I know this is a very common strategy. Godin calls it “the race to the bottom” and I have to ask you, what good does it do you to win that race?

Other variables

Here are two stories from my own print-buying experience. When I was

ready to print my Sell more printing book, I gave three local printers the specifications. The first one told me it would be cheaper to use a lighter paper than I had originally selected. He never asked me what look or feel I was going for, he just assumed a lower price would be better. He committed another selling sin by using the word cheaper. Think about the connotation of that word. When I hear cheap, I hear the opposite of quality. I think of corners being cut on craft and materials to come up with a lower price. If you mean to say less expensive or more cost-effective, either of those is a better term than cheap.

Some years ago, I asked another salesperson for a price on 800 postcard mailers. He told me I should buy at least 1,000 to get a better price and that each one would be even cheaper if I ordered 5,000. Now, the reason I asked for a price on 800 was that I had a mailing list of 765. What service was he doing me by telling me to order more? It would have been one thing if he asked about the quantity and learned I would probably be ordering similar quantities again. But instead, he simply made the assumption that price was the most important factor in my buying decision.

Another complaint I hear regularly from salespeople is about people hiding behind their voicemail. I completely reject the idea that they are hiding, they are simply taking advantage of technology to make

According to InsideSales.com, sales representatives can spend up to 40 percent of their time looking for somebody to call.

themselves more efficient. I use my own voicemail to screen calls and I return the ones I want to return.

Now ask yourself why you want to return some and not others. It mostly boils down to whether the caller gives me a compelling reason to call back. The reason I hear most often is, “I think I can save you some money on your…”

Obviously it is not just printing salespeople who are guilty of this selling sin, but I care less about all the rest than I do about you. I hope you can give me a better reason for me to call you back. For example: “I’d like to talk about every aspect of your use of print to see if I can help you to improve on it.”

Please understand I have nothing against saving money and if it turns out you can help me do that, I will certainly appreciate it. The point I’m trying to make is that I want you to lead with something else. Be the last to talk about price, not the first. Let someone else win the race to the bottom.

DAVE FELLMAN is the president of David Fellman & Associates, a graphic arts industry consulting firm based in Raleigh, N.C., USA. He is a popular speaker who has delivered keynotes and seminars at industry events across the United States, Canada, England, Ireland and Australia. He is the author of “Sell More Printing” and “Listen To The Dinosaur.” Visit his website at www.davefellman.com.

Thirty significant business developments from the past year that have driven Canada’s printing industry

By Alyssa Dalton

Marquis buys Webcom

Marquis Book Printing of Montmagny, Que., in October acquired Webcom, creating one of Canada’s largest printing companies with an annual production capacity of over 100 million books produced in three plants. As a result of the deal, the Marquis team grew from 400 to 600 employees.The purchase comes after a partnership agreement with EPAC in June, which involved a C$9-million investment to install three inkjet production lines in Montmagny.

The Xerox Board of Directors welcomed John Visentin (in photo) as CEO and Vice Chairman of the Board in May. Keith Cozza was also elected Chairman of the Board, while Steve Bandrowczak was

named President and COO and a member of the Executive Committee. The appointments are part of the agreement Xerox reached with stakeholders Carl Icahn and Darwin Deason to resolve a proxy contest and ongoing litigation related to the company’s proposed US$6.1-billion combination with Fuji Xerox Co. Ltd., a subsidiary of Fujifilm, which would allow Fujifilm to take the controlling interest in Xerox. Under the agreement, then-CEO Jeff Jacobson and six other Xerox board members resigned.

In May TC Transcontinental completed its purchase of Coveris Americas in a deal valued at C$1.72 billion, in its continuing

push to become a North American leader in flexible packaging. Since entering the market in 2014, this is TC Transcontinental’s seventh flexible packaging acquisition, including its March 2018 purchase of Multifilm Packaging Corp. Meanwhile the Montreal-based printing company continues to pivot away from magazine and newspaper ownership. In late April its media sector, TC Media, sold 30 publications, which includes 21 weeklies, to Transmet Logistics & Metropolitan Media, and in June, sold three local newspapers and the related web properties to Groupe Lexis Média inc.

4.

DATA Communications Management (DCM) of Brampton, Ont., acquired privately held Perennial Group of Companies for a purchase price of roughly C$12 million. The acquisition includes Perennial Inc., a design firm focused on creating and delivering design strategies

for retail brands, in addition to The Finished Line Studios Inc., an independent creative, execution and production art studio. A provider of business communication solutions, DCM’s range of core capabilities include direct marketing, print services, labels and asset tracking, event tickets and gift cards, logistics and fulfillment, content and workflow management, data management and analytics, and regulatory communications. The deal closed in May.

The Burke Group of Edmonton, Alta., has signed the first North American Heidelberg subscription contract, which it says will help Burke double its productivity and increase profit without the challenges that come with equipment ownership. Through the subscription model, Heidelberg will provide Burke with new equipment, Prinect software, Saphira consumables, parts, consulting and service for a monthly fee based on the number of printed sheets Burke produces each month. This move by Heidelberg fits its growing push toward creating new digital business models, particularly with the company’s new digital packaging (Primefire for carton) and label (Gallus) presses.

In October marketing solutions provider Quad/Graphics acquired LSC Communications, a provider of print and digital media solutions, in an all-stock deal valued at US$1.4 billion. The transaction is expected to help create a “highly efficient” print platform to fuel Quad’s 3.0 transformation. As of September 30, 2018, the combined company would have had annual revenue of approximately US$8 billion.

Long-time web offset printing manufacturers and service provid-

ers manroland web systems and Goss International completed the transaction to combine their businesses in August. Operating under the brand name manroland Goss web systems, the new company is led by Alexander Wassermann, CEO of manroland web systems, with global headquarters in Augsburg, Germany. The company’s North American headquarters will be in Durham, N.H.

The Canadian Printing Industries Association, known as CPIA, launched a newly restructured printing industry association this October. Proposed by its board of directors and ratified by its membership in March, the CPIA intends to operate under a new membership structure to help unify the industry. Six regional associations and one supplier association make up the membership, with one or two representatives from each association comprising the board. Richard Kouwenhoven, President and COO of Hemlock Printers, currently serves as Board Chair.

9. Jason Lisi named Ryerson GCM Chair

Jason Lisi (left) assumed his new role as Chair of Ryerson University’s School of Graphic Communications Management (GCM) on July 1. Ian Baitz, the outgoing Chair who began his tenure in 2009, continues as a fulltime professor in the GCM program. Under the past nine years of Baitz’ leadership, GCM has become the largest graphic communications school in North America with 640 full-time students and 30 full- and part-time faculty and staff.

More than 210 people from across the country attended the sold-out 13th annual Canadian Printing Awards in downtown Toronto on November 8, organized by PrintAction and parent company Annex Business Media. A record 114 gold, silver and bronze awards were presented to Canadian printers and technology suppliers in what has

become the country’s largest national celebration of print.

On November 27, mail service resumed across Canada after the Senate voted to pass back-towork legislation ending five weeks of rotating strikes by postal workers. Since October 22, the Canadian Union of Postal Workers (CUPW)’s rotating strikes have shut down Canada Post operations in more than 150 communities across the country, touching virtually every Canada Post facility and every Canadian address.

This fall Mi5 Print & Digital acquired the physical assets of Boss Logo Print & Graphics, a Markham, Ont., trade printer that went into receivership this September. Taking on about three-quarters of Boss Logo’s equipment, Mi5 will gain several systems including a Heidelberg 6-colour XL and a Scodix digital 3-dimensional coating and foil machine. The equipment acquisition comes nearly two years after Mi5 Print & Digital moved into a new 180,000-square-foot facility in Toronto.

Specializing in short- to mediumrun book printing, Hignell Book Printing of Winnipeg, Man., celebrates its 110-year anniversary in 2018. Founder Albert Hignell began the company as a small printing shop with the dream of it becoming a prosperous business based on quality and service. The dream was continued first by Hignell’s two sons, then onto his grandson and his great grandson. In the beginning, Hignell printed commercial needs for businesses. In 1989, the Hignell family sold the business to Unigraphics. Remaining true to Hignell’s dream, Hignell Printing/ Unigraphics continues to print

books for authors and publishers from all over the world.

In mid-August the Central Group acquired Packaging Technologies Inc., an Ontario designer and manufacturer of graphic corrugated packaging and point-of-purchase displays. The deal aims to expand the Central Group’s service and product offerings across all subsidiaries including Central Graphics and Container Group Ltd. and Independent Corrugator Inc. A privately held Platinum member of Canada’s Best Managed companies, the Central Group is a Mississauga, Ontario-based firm that combines in-store strategy, research, design and execution with analysis and reporting.

15. Canon welcomes Phil Hampson Canon Canada welcomed Phil Hampson to the role of Senior Director, Production Printing Systems, PPSG in July. With over 20 years in the graphics industry, Hampson most recently served as the National Sales Manager, Canada, for the Graphic Systems Division of Fujifilm North America Corporation.

Friesens of Altona, Man., this spring installed Canada’s first Manroland Sheetfed Evolution press –an Evolution R708P featuring LED technology – marking the company’s first foray into offset-UV technology. This is Friesens’ second major Manroland Sheetfed investment in the past three years, after installing what was the world’s largest perfecting press at 73-inches in mid-2015.

17. Greg Running joins HP

In March Greg Running joined the General Commercial Sales team of HP Canada, where he is responsible for the full HP Indigo press line in Western Canada, as well as the HP PageWide web press solutions.

Running brings more than 25 years of printing industry experience, having most recently worked with Kodak Canada for the past 11 years, including almost six years as Canadian Sales Director.

18. Customized covers for WWI centennial

To mark the 100th anniversary of the end of the First World War, Maclean’s printed 66,349 commemorative issues in an impactful tribute – each featuring the unique name of a Canadian service man or woman who sacrificed their life in the conflict, along with one ‘Unknown.’

19. Cansel launches Cobalt Graphics Distribution

Cansel in August introduced Cobalt Graphics Distribution, a new company that will operate as a national distributor of wide-format, flexographic and offset products to the print communications market in Canada. With the launch of Cobalt, the Cansel Geospatial division will continue to distribute wide-format products to its architecture, engineering and construction customers while the new, independently run Cobalt says it retained the employees, suppliers and relationships that are focused in the reprographics, wholesale distribution and printing markets.

20. Canada’s first vertical bank note

A new $10 bank note featuring social justice icon Viola Desmond went into circulation last month, marking the first vertically oriented bank note issued in Canada and the first time a Canadian woman is portrayed on a regularly circulating Bank of Canada note.

21. Sydney Stone named Xanté exclusive distributor

Starting November 1, Sydney Stone became the exclusive distributor of

Xanté Corporation products in Canada. A Canadian distributor of print finishing equipment and supplies, Sydney Stone will sell Xanté products directly as well as through the existing network of Canadian dealers.

ICP Industrial – a division of Innovative Chemical Products Group (the ICP Group), and global manufacturer of specialty coatings for the packaging, labelling and graphic arts industry – formed ICP Industrial Canada in July. With manufacturing operations already in the U.S. and Mexico, the additional footprint in Canada aims to help drive the company’s international growth strategy. In addition to its formation, ICP Industrial Canada entered into a strategic partnership with manufacturing representative firm Divicor of Montreal, Que., to supply its pressroom consumables to the Canadian market.

Postmedia announced in late June it would close six small-town newspapers and reduce print publication of three more, while cutting 10 percent of its workforce across the entire newspaper chain. The company said the changes are part of its plan to reduce salary expenses by 10 per cent by August 31, the end of its fiscal year. Some jobs were identified for elimination, while voluntary buyouts were offered to unionized employees and editorial staff, both unionized and non-unionized.

Wayside, headquartered in Vernon, B.C., in July announced it had acquired Lakeside Printing, taking on all three Lakeside locations in Vernon, Revelstoke and Salmon Arm. Established in 1921 as Wayside Printing, the company is described as North Okanagan’s oldest printing and marketing firm. Lakeside Printing continues to operate under its existing name, as a Wayside company, reports the Vernon Morning Star

25. Jeff Ekstein receives lifetime achievement award

On November 9 at the Ben Franklin Honor Society Award Dinner during the Printing Industries of America’s fall meeting, Jeff Ekstein, a third-generation owner of 65-yearold Willow Printing Group, received the 2018 Lewis Memorial Lifetime

Achievement Award. Established in 1950, the Lewis Award pays homage to business leaders who have made long-term contributions to the graphic arts industry. As President and CEO, Ekstein has led the Willow Printing Group through a number of strategic acquisitions and business model evolutions.

26. St. Joseph launches targeted flyer delivery program

St. Joseph Communications this spring launched what it described as a new flyer distribution model, under its media brand name Best Life, a weekly editorial lifestyle magazine, for Canadian retailers to reach consumers. The first Best Life package reached Canadian mailboxes for a controlled test in the London, Ont., market on April 27. St. Joseph explains this model presents a more cost-effective solution than other Canada Post flyer delivery programs, as well as what the company describes as a cluttered delivery environment. Best Life was deposited directly into the mailboxes of targeted houses, apartments and condos.

27. Whitehouse Graphics adds Komori GL640C Whitehouse Graphics based in Vaughan, Ont., purchased a Komori GL640C press which was installed in late April. The company’s new press, replacing an existing press, produces all of Whitehouse’s offset work and is equipped with fully automatic plate changers, PDC-SX closed-loop colour control, and Komori’s productivity improvement system, KHS-AI, which optimizes press presets by self-learning, it explains.

Last month Amazon published and mailed a holiday toy catalogue, A holiday of play, to a number of U.S. households. The printed catalogue was also handed out at various

Whole Foods Market locations, the grocery chain Amazon bought last year. This represents another move from the e-commerce giant to incorporate traditional tools used by brick-and-mortar stores into its business model, and follows the closure of Toys “R” Us U.K. and U.S. operations earlier this year.

Organizers of Ipex, an international print technology and equipment tradeshow, announced in late-June the decision to close the show after consulting with the print technology industry. “The changing market conditions and appetite for a largescale event which focuses on ‘Print in Action’ continues to be challenging. Having engaged with a range of exhibitors and partners to evaluate the options for Ipex, we have concluded that the requirements of the industry no longer match our own in terms of the cycle, scale and what is required to help us further support and fully invest in the brand,” Rob Fisher, Ipex Event Director, said. The most recent edition was held in London, U.K., from October 31 to November 3, 2017.

Eastman Kodak Company entered into a definitive agreement in November to sell its Flexographic Packaging Division to Montagu Private Equity LLP, a private equity firm. After closing, the business will operate as a new standalone company which will develop, manufacture and sell flexographic products, including the flagship Kodak Flexcel NX System, to the packaging print segment. Chris Payne, who has served as President of the Flexographic Packaging Division for the last three years, will lead the new company as CEO. Under its new ownership, the business will have the same organizational structure, management team and growth culture that has served Kodak’s Flexographic Packaging Division in recent years.

Print leaders share their strategies for recruiting and hiring the next generation

By Victoria Gaitskell

Geography has made Friesens, one of North America’s leading book, yearbook and packaging manufacturers, especially creative at recruiting new candidates for the printing workforce. The company is situated in the town of Altona, Man., (population 4,212), 100 km south of the provincial capital of Winnipeg and 10 km north of the U.S. border. Although this location helps foster the company’s cross-border trade (about 50 percent of its book and 20 percent of its yearbook production enters the U.S. market), it also creates challenges for finding staff in the town and surrounding rural municipality of Rhineland, an area largely devoted to farming and agriculture-based business.

Coordinator, says the company’s local staff totals about 500, not including the 100 sales representatives scattered across North America. “Because of where we’re located we struggle with getting skilled workers, so we train up a lot of our own workers who start in entry-level positions. Right now, if the right individuals walked through the door, we would probably hire 15 to 20 more people,” she says.

One way Friesens cultivates potential new hires is by providing openings for the local high school’s Career Internship Program. This program helps Grade 11 and 12 students gain both academic credit and employability by spending 75 hours in the workforce in a field of their choice. Bergman explains these high school internships are unpaid and at

We o er solutions ranging from coated and uncoated text and cover papers; custom boards for standard and specialty printing; product packaging for a variety of applications, including food and pharmaceuticals; to high quality bonds and digital paper products for commercial and personal printing jobs.

APP sources its fiber from plantations and not from high conservation or high carbon stock areas, ensuring a sustainably sourced product. Further, the Company o ers a full complement of PEFC certified papers.

APP has strategically located national presence – Toronto, Montreal, Vancouver, Calgary, Winnipeg, Edmonton, Saskatchewan and the Maritimes – with the ability to meet your “just-in-time” needs from our large warehouse inventories.

For more information, please contact your local

First image: A group shot of the Humber College students who visited Mi5. The tour included a walk-through of the litho, web, digital, large-format and in-house bindery departments and a look at file preparation and prepress planning and proofing. Second image: Winnipeg’s Westwood Collegiate tours TC Transcontinental Printing.

Friesens occur mostly in production areas in the pressroom or bindery. “We work with the school to assess the students’ interest and mechanical skills and whether they are a good fit for our environment...and some we have been able to give on-the-job technical training and employment after graduation. One IT student who went on to full-time employment here is now one of our intermediate software developers.”

Friesens annually hires two to five students on mandatory unpaid eightweek practicums from the Manitoba Institute of Trades and Technology (MITT)’s Graphic and Print Technician Program in Winnipeg, Man.

Kevin Gregg, Internship Coordinator for Ryerson University’s Graphic Communications Management (GCM) in Toronto, Ont., oversees about 130 fourmonth internships a year. The support both Ryerson and MITT students receive to find a job for their internship includes a job fair where students attend a series of 10-minute ‘get acquainted’ interviews with a variety of prospective employers in a process akin to speed dating. Gregg says the job fair often leads to internships and part-time jobs while in about 40 percent of cases, students complete their remaining studies and take on full-time jobs.

Gregg continues: “Although larger printing companies may take three or four interns at a time, we place no size requirements for companies that provide internships. One student from Gravenhurst [Ontario], whose hometown printer wasn’t hiring, successfully convinced the owner to give him an internship and the situation worked out really well on both

sides. If a smaller printer has difficulty providing the prerequisite full job description for the intern, I have no problem phoning the employer to clarify things.”

Based in Toronto, Ont., Eva’s Phoenix Print Shop – operated by Eva’s Initiatives For Homeless Youth – is a commercial printer and social enterprise that trains young people experiencing and at risk of homelessness. Through a seven/eightweek training program, the students are introduced to the pillars of the industry and learn digital printing, bindery, large-format printing, prepress and design fundamentals using Adobe Creative Suite, as well as job readiness training such as workplace expectations and effective communication skills.

To further the program, Eva’s Phoenix Print Shop has announced that starting next February, its eligible cohort of eight graduates will be ready to fill work placements and potential employers who take on the job-ready candidates will be able to receive up to 11 weeks of paid subsidized work placement – equating to potentially $5,000 in wage subsidies – from Eva’s Print Training Program.

Friesens provides post-secondary education scholarships to children of staff members as well as post-secondary students who have returned to the company after working at least one summer there. Also in the works is a new plan for tuition reimbursement to support post-secondary learning for students in positions for which they have a high need, including estimating, customer project management, and press and bindery operators. “We’re looking to engage with Grade 12 students before they graduate by saying, ‘If you are interested in any of these fields, we will support your education, build in paid periods of work between school years and enter into a post-graduation contract with you,’” Bergman says. “Sponsoring students while they work here helps us attract and retain local talent.”

“Without printing there would be no food, no soap, no shampoo, no toilet paper — there’s nothing sold,” Warren Werbitt, Founder of Pazazz in Montreal, Que., says. “Everybody in the world needs us yet nobody likes us. The bottom line is the industry is not a sexy business, so how are we supposed to get young people in?”

Barry Miller is Executive Director of the Manitoba Print Industry Association (MPIA), an 85-percent provincially funded non-profit organization focused on attracting and retaining individuals in the industry. He recounts: “Historically Winnipeg’s geographic location in the centre of Canada has been favourable for print and is home to companies like Pollard Banknote, Duha and Color Ad Packaging. Yet if I’m at a career fair and I ask students

to name one local company that prints, most of them can’t even come up with the Winnipeg Free Press

“Often times employers can’t find a bindery worker or press operator in Winnipeg because any who exist are already working or retired. Especially with retirement and people moving up in their companies, who will fill those entry-level jobs? We are trying to help people realize the opportunities that are available.”

Besides public education, MPIA’s other services include training opportunities, professional awards, and a scholarship program for printing and/or graphic design students. Elisa Solomon, the association’s second staff person, serves as Career and Human Resource Consultant, primarily for small companies without a human resources capacity, providing such assistance as consultations, screening resumes, hiring interviews, policies, records and performance management.

Throughout the year, Friesens engages youth and the public by hosting tours for MITT and other organizations, including schools that print their yearbooks with Friesens. As well, high school electrical technology and robotics classes from a neighbouring town have also visited Friesens to learn how their subjects apply to the print industry.

For 25 years, Friesens has also held a week-long summer day camp free of charge for 9-to-11-year-old children of staff members where the variety of activities offered to campers includes participating in the content creation, design and production of a book.

Werbitt, who created Printing’s Alive and other popular YouTube videos in which he enthuses about print, says a first-year Ryerson GCM student emailed him in October to ask if she could visit his plant. He invited her to come any time, and when she arrived for a tour, he spent an hour and a half showing her around. She later told Werbitt he was the only one out of five printers who responded to her request. “Oh my God, how wrong is that? How do we not encourage the young people?”

He continues: “In 2016 I was speaking at an Idealliance conference, and when I was up at the podium, I looked around and said, ‘Where are all the young people? Why are all you old people here? Most of you aren’t happy with the business.You’re going to go back, and you’re not going to bring any value. You can’t tell me you can’t afford to bring some young people to these shows. Enlighten them, empower them, make them feel special. When they get back, they’ll spread the word about what they’ve heard.’”

Learn more about the Eva’s Phoenix Print Shop placement program in our January/February 2019 issue. Stay tuned!

Mohawk Fine Papers in October released A maker’s field guide to digital materials and digital processes, the latest in a series of printed guides designed to bring inspiration and education to clients, designers and printers on the importance of choosing the right materials and process for print. Created by Hybrid Design of San Francisco, the guide is printed by Flash Reproductions, Toronto, Ont.; Sandy Alexander, Clifton, N.J.; Dupli, Syracuse, N.Y.; and finished and bound by Fey Printing, Wisconsin Rapids, Wisc. The 71-page book, including the cover and dust jacket, demonstrates 22 different digitally printed materials and is organized into three sections: Introduction / Make Good Great, Printed Samples / Materials with Purpose, and Resources / Become the Digital Print Expert.

SmartSoft highlighted the latest tools and features that have been added to PressWise, its all-in-one web-to-print, MIS and workflow automation platform at Print 18.

PressWise is designed to provide a complete Cloud-based print shop management system that aims to eliminate manual touches from the print workflow to help companies grow their business. It includes unlimited web-to-print storefronts, print estimating, order management, production automation, shipping and fulfillment, mail processing and integration into accounting systems. Some of the latest tools and enhancements include a new embedded analytics and reporting platform for real-time information on sales and production, unique accounting codes for inplant print shops that allow for the designation of different categories, accounts receivable/multi-invoice payment, and enhanced prepress tools, such as checks to ensure artwork is in a print-ready PDF/X format, and new finishing task calculations.

Fujifilm North America in November announced the third generation J Press 750S, available in North America by the end of the year, generating 3,600 B2 sheets per

The new flagship J Press 750S delivers double the sellable output over the previous version, Fujifilm explains.

hour, for both static and variable jobs, with a maximum sheet size of 23 x 29.5 inches. Taking the core technologies of the 720S, the J Press 750S features Fujifilm Dimatix Samba printheads and aqueous pigment Vividia ink along with a 6-up letter size imposition and increased speed, delivering double the sellable output over the previous version, the company says. The J Press 750S comes standard from the factory as a commercial printing platform and can be field configured to print up to 24 pt. board stock. Fujifilm says the press reduces energy consumption by 23 percent. Like the 720S, the 750S incorporates an inline scanning procedure of each sheet for quality assurance throughout the print run. To further enhance this capability, it is offering an optional full sheet scanning function to help ensure each printed sheet matches a pre-approved image quality standard.

Ontario-based Rotoflex has debuted the Rotoflex DF3, a configurable offline digital finishing and con-

verting solution designed to complement digital, non-hybrid label presses without inline converting functionality. As well, the DF3 intends to eliminate the need for single-application embellishment units. The rail enables lamination, foil decoration, rotary screen (both conventional or UV digital alternatives), waste removal features and turnbars. Suitable for businesses that operate roll-to-roll digital label presses, the DF3 boasts the capabilities of both full and semi-rotary die-cutting and can accommodate a range of repeat sizes and existing investments in tooling. Die changeovers can be achieved in 30 seconds or less, Rotoflex says. Additionally, the DF3 boasts a converting and finishing speed of 1,000 fpm.

In October colour management specialist GMG released version 2.2, extending the functionality to its GMG OpenColor profiling solution which incorporates automatic, spectral data-based optimization of measurement data. GMG OpenColor explains the user measures

The Rotoflex DF3 is available for demonstrations at the company’s Mississauga, Ont., headquarters.

GMG explains version 2.2 of its GMG OpenColor profiling solution incorporates automatic, spectral data-based optimization of measurement data.

test charts or colour patches in order to obtain data needed for characterization. This data is subsequently combined with other parameters from the printing process to create a dynamic profile. Naturally, the data obtained from the calibration process has to be optimized. Erroneous test charts, poor substrate textures and dust can all cause an excessive degree of distortion. Deviations can also arise from the measuring device itself. Previously, users were reliant on third-party software to optimize the measurement data or had to subsequently correct profiles themselves in a manual process. With version 2.2, users can create a colour-accurate profile in a few steps, the company explains. Another new feature includes CxF/X-4 support according to ISO 17972-4, meaning that now, spectral values along with dot gain steps can be communicated to other parties involved in a print production.

3M in October introduced two new digital tools to help shop owners grow their businesses: The 3M Graphics Install Wizard and the 3M Graphics Hub. The Graphics Install Wizard is described as a new software application that helps both shop owners and installers. 3M explains shop owners can access a database of installers based on location and capabilities, as well as list job opportunities, accept bids and book jobs. It aims to help shops manage a consistent workflow and stay organized, serving as a platform to share job details, documents and completion photos. The Graphics Install Wizard is linked to the new Graphics Hub, a free online resource centre that offers educational resources, news on different 3M

training programs, and information on new trends. There is no cost to sign up for and review the Graphics Install Wizard, and it is a free service for graphics manufacturers who use it to locate and manage external installers. There is a monthly subscription fee for managing internal installers, and a per-job fee for installers who accept and complete jobs through the software.

DuPont Advanced Printing has received Eco Passport by OEKOTEX certification from the Hohenstein Institute in Germany across the DuPont Artistri textiles digital inks and pretreatments portfolio for both roll-to-roll and direct-to-garment textiles printing applications and specifically apply to pre-treatments, acid, reactive, disperse, pigment and dye sublimation inks. Eco Passport by OEKO-TEX is an independent testing and certification system for textile chemical suppliers to demonstrate their products are safe and can be used in a sustainable textile production.

At Print 18, Tecnau introduced the new Revolution 50 series for highspeed colour inkjet printers, a family of products featuring top speeds up to 656 fpm/200 mpm, Internet-of-Things compatibility and media flexibility as required in digital print environments. The first member of the Revolution 50 family, the new Stack 5250 system for cutting and stacking continuous inkjet-printed output features the double-cutting Cutter c52 and is designed to accommodate assorted papers and heavy ink coverages. The Stack 5250, Tecnau explains, never lets go of the web, and is designed to

2. SUPERIOR TECHNOLOGY — Die crease without a die, then fold and even glue all on the same machine, up to 30 pt.

3. INTEGRATED MODULAR UNITS — Combined in-line finishing: crease, fold, glue, tipping, envelope inserting, ink jetting (Duplex), clip seal (3 sides), mail prep.

4. SAVE ON POSTAGE COSTS As a Certified Canada Post Direct Marketing Specialist, we get contract pricing reductions.

5. RETURN MAIL PRODUCTS — Customized “Return Mailers” created in-line with “U” or “BOX-shape” remoistenable glue, time perfed applications and envelope formation.

6. MINI-BOOKLETS — Saddle-stitch and trim 2-up booklets in-line to the size of a business card. No need to trim off-line, or do 2 passes.

7. HIGH SPEED EQUIPMENT — High speed Tipping, Folding, Saddle-stitching and soft folding ensuring on time delivery.

minimize friction on the printed surface, it says. Stack 5250’s Stacker s50 module produces 1-up, 2-up, 2-up merged or 3-up stacks, featuring a patented gripper technology for damage-free handling of highvalue print, it adds. The system includes natural-language error reporting on the user screen and onboard diagnostics to help keep the system up and running. IoT options are being introduced for remote monitoring and diagnostics, automatic software updates and preventive maintenance aids.

The next-generation, single-pass EFI Reggiani BOLT textile digital printer from Electronics For Imaging made its debut in mid-November during an open house at the EFI Reggiani facility in Bergamo, Italy. Described as having the potential to “revolutionize the textile printing market,” the printer aims to provide users with “high uptime and reliability, outstanding performance, superior printing uniformity and accuracy, long printhead life and minimal maintenance needs,” the company explains. The BOLT boasts a low-maintenance, fast-startup recirculation printhead designed to deliver more uniform printing. EFI explains the BOLT has throughput speeds of up to 295 feet per minute at a 600 x 600 dpi resolution. Paired with an EFI Fiery digital front end (DFE) print server, it also features high-end greyscale imaging in drop sizes from 5 to 30 picolitres, and provides 600 x 4,800 maximum-dpi resolution printing.

Roland DG has launched the Roland VersaEXPRESS RF-640 8 Colour eco-solvent printer, calling it a “game-changing device that offers the widest colour gamut” in its class for outdoor graphics. Powered by ErgoSoft Roland Edition 2 Special Plus RIP, the RF-640 8 Colour features CMYK plus light black, red, green and orange ink for “high

quality prints and super-accurate colour matching capabilities.” Up to 99 percent of Pantone+ Solid Coated is within gamut, the company says, adding that the RF-640 8 Colour is designed to colour match and reproduce colours normally difficult to achieve. Red, green and orange ink extend the range of achievable colours across the colour spectrum, and with light black, deliver “eye-popping colour, exceptional skin tones and smooth gradients.” Roland DG explains the RF-640 8 Colour is ideal for interior decor applications, fine art and image reproduction, whether supplying to hotel chains, museums, galleries, entertainment spaces or offices.

In November HP announced new hardware and solutions – for large format printing, HP PageWide XL printing technology, HP DesignJet Z9+ PostScript Printer Series printing Z by HP posters and the HP DesignJet T830 24-in Multifunction Printer – to help change the way architectural, engineering and construction industries design and print. Promising to be 25 percent faster, the upgraded HP PageWide XL 4000 series is the most cost-effective solution in the PageWide XL portfolio to achieve easy printing with a consolidated printing workflow, HP says. The HP PageWide XL 4600 Printer and MFP and HP PageWide XL 4100 Printer and MFP join the printer portfolio, offering speeds up to 15D/A1-size or 10D/A1-size prints per minute. The company explains the HP PageWide XL printers do the job of two printers in a single device, providing both monochrome and colour prints at breakthrough speeds: The Power of One. The new print solutions include: HP Click, a oneclick desktop printing software; HP Smart App to print, scan and share content from the Cloud; and HP Poster App, an online design tool to create and print professional looking posters.

Roland DG says the RF-640 8 Colour is designed to colour match and reproduce difficult colours, adding that 99+ percent of Pantone+ Solid Coated is within gamut.

HEIDELBERG QM46 PRESS OPERATOR

QM46 Press Operator. Must have minimum of 2 years’ experience and be able to work unsupervised in a busy shop. Standard days – Monday to Friday. Please email resume to: careerpath@printer.ca www.printer.ca

OPPORTUNITY FOR ADVANCEMENT.

A continually expanding company involved in selling Printing and Digital equipment, with over 35 years in business is seeking an individual to take on a variety of responsibilities and tasks including Customer Service/Order Desk, Inventory control and Shipping and Receiving. Must speak fluent English, have good people skills, and be a team player. The best in this role will be:

· Confident – you’re excited to talk classifieds@printaction.com

Place your own ad and view the latest postings: printaction.com/Marketplace

to a wide variety of people every day and offer great information and advice to our clients.

· Comfortable with multi-tasking –you know how to prioritize, so fastpaced environments don’t stress you out (they excite you!)

· You’re a team player - your teammates can count on you to support the team and pitch in wherever you can. When you need a hand, you have no problem asking for help.

· Meticulous – you’re great with details and provide top-notch services to our customers.

· Organized – you’re great at balancing multiple and competing priorities, and achieving your results are your number one priority

This is a full time position from 8:30 to 5:00, Monday to Friday. Our Company is located in Scarborough. Please apply in confidence to sales@ printdigitalsolutions.com

Slava Apel is the CEO of Amazing Print Tech and a pioneer in online marketing and web-to-print technology.

Dave Fellman is the author of 3 other books and more than 300 articles on print sales strategy and technique.

Both have been frequent speakers at industry trade shows and events for more than 20 years!

Heidelberg: K-Line/S-Line/Speedmaster/GTO/MO/KORD64

Komori: 1, 2, 4 or 5 colours & any size

Adast: 714/715/724/725

Mitsubishi: Any model

Ryobi: 2800CD/3200CD-MCD/640K Itek: 960/975/985

Hamada: 600/700/800/E47/RS34

Shinohara/Fuji: 66/65 1,2 or 4 colours

Sakurai: 1, 2 or 4 colours and any size (newer model)

Polar: any size/older or newer models (66/72/76/78/82/90/92/107/115)

Horizon-BQ: 220/240/260/440/460

Now in its 15th year of operation, Mi5 Print & Digital has grown into one of Canada’s largest privately owned commercial printing operations and has been recognized as one of Canada’s fastest growing companies nine years in a row on the Profit 500. Two years ago the company moved into an 180,000-square-foot facility in the Toronto area, encompassing its litho, web, digital printing and wide-format departments, as well as its finishing, fulfillment and packing operations. Following a decade of strong organic and M&A growth and technological investment, Mi5 continues to strengthen its print power in 2018, most recently with its purchase of Markham, Ontario-based trade printer Boss Logo Print & Graphics, which went into receivership this fall. PrintAction spoke with Derek McGeachie, CEO and Founder of Mi5 Print & Digital, to learn more about the deal and the everchanging nature of the print industry.

Can you tell us more about the Boss Logo purchase?